Lock SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 1025 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-77

HVAC Control Module Removal and InstallationS7RS0B7226013

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Rear Speaker Removal and Installation

in Section 9C”.

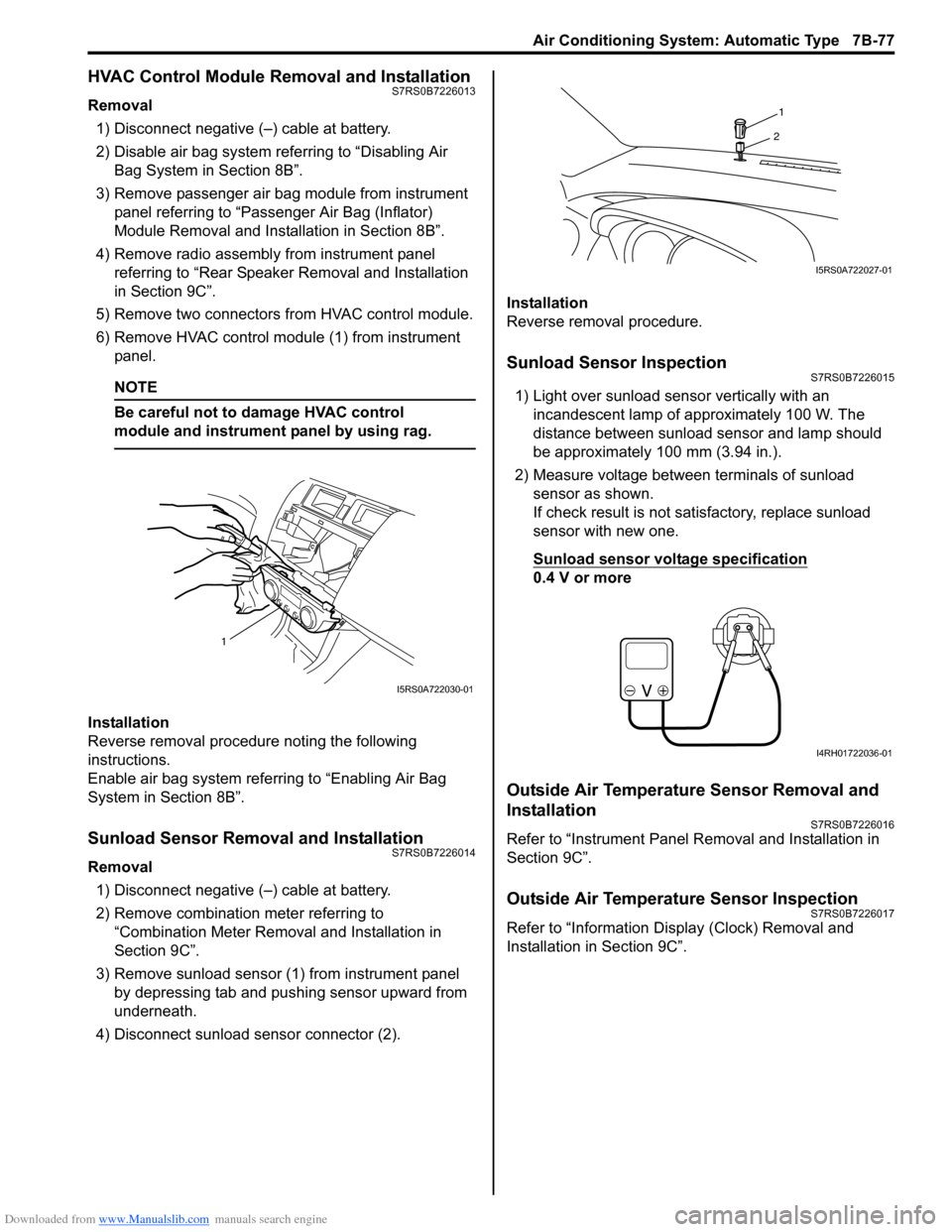

5) Remove two connectors fr om HVAC control module.

6) Remove HVAC control modu le (1) from instrument

panel.

NOTE

Be careful not to damage HVAC control

module and instrument panel by using rag.

Installation

Reverse removal procedure noting the following

instructions.

Enable air bag system referring to “Enabling Air Bag

System in Section 8B”.

Sunload Sensor Removal and InstallationS7RS0B7226014

Removal

1) Disconnect negative (–) cable at battery.

2) Remove combination meter referring to “Combination Meter Removal and Installation in

Section 9C”.

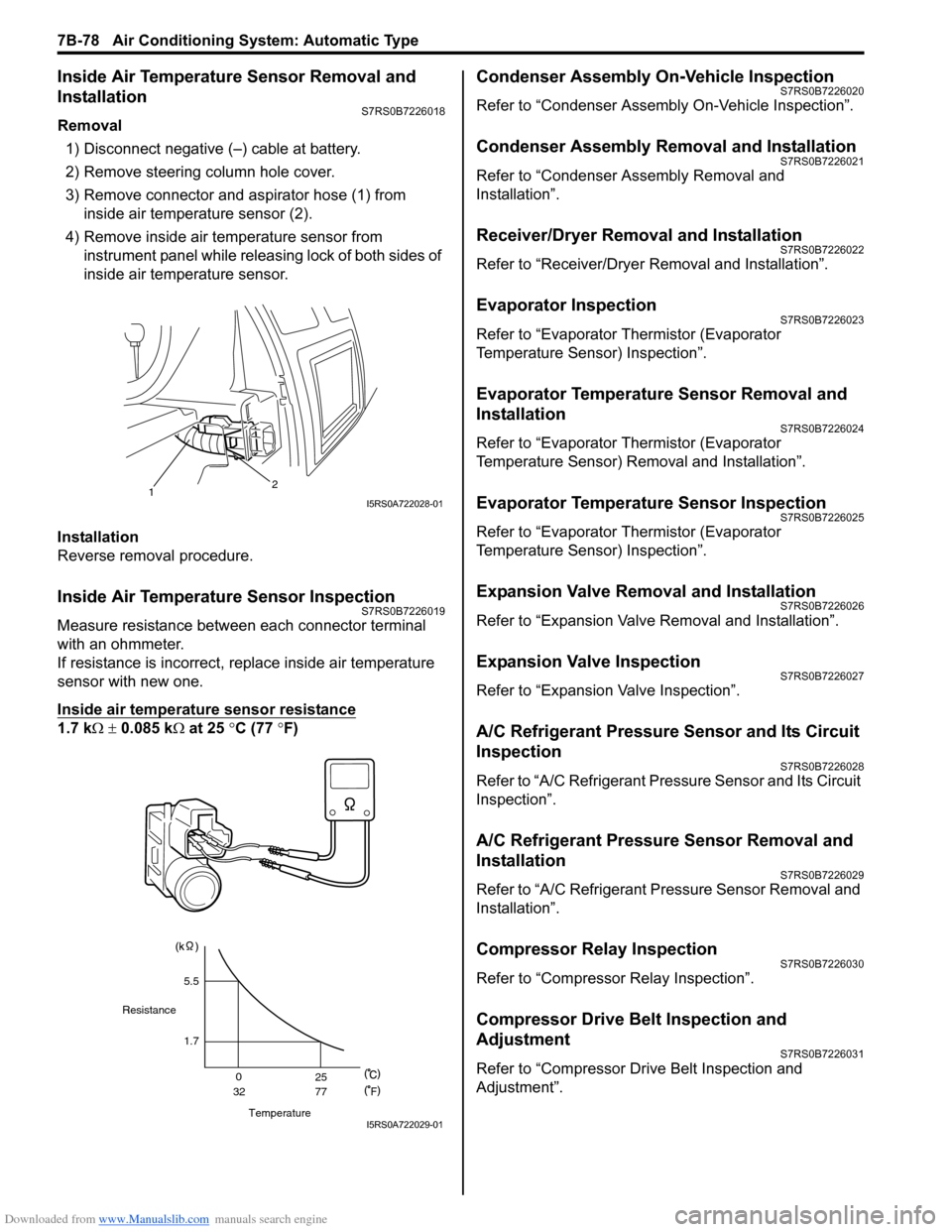

3) Remove sunload sensor (1) from instrument panel by depressing tab and pushing sensor upward from

underneath.

4) Disconnect sunload sensor connector (2). Installation

Reverse removal procedure.

Sunload Sensor InspectionS7RS0B7226015

1) Light over sunload sensor vertically with an

incandescent lamp of approximately 100 W. The

distance between sunload sensor and lamp should

be approximately 100 mm (3.94 in.).

2) Measure voltage between terminals of sunload sensor as shown.

If check result is not satisfactory, replace sunload

sensor with new one.

Sunload sensor voltage specification

0.4 V or more

Outside Air Temperature Sensor Removal and

Installation

S7RS0B7226016

Refer to “Instrument Panel Re moval and Installation in

Section 9C”.

Outside Air Temperature Sensor InspectionS7RS0B7226017

Refer to “Information Display (Clock) Removal and

Installation in Section 9C”.

1

I5RS0A722030-01

1

2

I5RS0A722027-01

I4RH01722036-01

Page 1026 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-78 Air Conditioning System: Automatic Type

Inside Air Temperature Sensor Removal and

Installation

S7RS0B7226018

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hole cover.

3) Remove connector and aspirator hose (1) from inside air temperature sensor (2).

4) Remove inside air temperature sensor from instrument panel while releas ing lock of both sides of

inside air temperature sensor.

Installation

Reverse removal procedure.

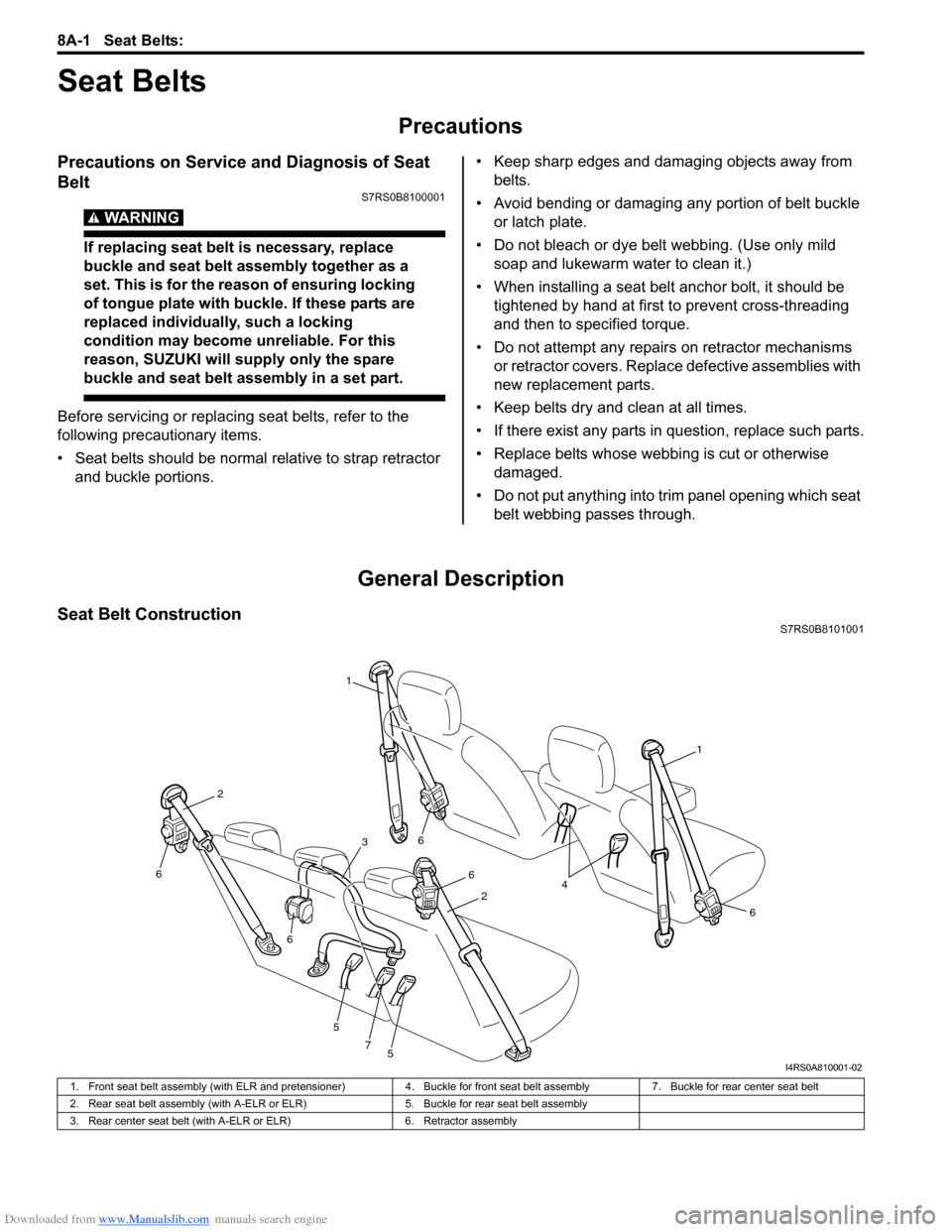

Inside Air Temperature Sensor InspectionS7RS0B7226019

Measure resistance between each connector terminal

with an ohmmeter.

If resistance is incorrect, replace inside air temperature

sensor with new one.

Inside air temperature sensor resistance

1.7 k Ω ± 0.085 k Ω at 25 °C (77 ° F)

Condenser Assembly On-Vehicle InspectionS7RS0B7226020

Refer to “Condenser Assembly On-Vehicle Inspection”.

Condenser Assembly Removal and InstallationS7RS0B7226021

Refer to “Condenser Assembly Removal and

Installation”.

Receiver/Dryer Removal and InstallationS7RS0B7226022

Refer to “Receiver/Dryer Removal and Installation”.

Evaporator InspectionS7RS0B7226023

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Evaporator Temperature Sensor Removal and

Installation

S7RS0B7226024

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Removal and Installation”.

Evaporator Temperature Sensor InspectionS7RS0B7226025

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Expansion Valve Removal and InstallationS7RS0B7226026

Refer to “Expansion Valve Removal and Installation”.

Expansion Valve InspectionS7RS0B7226027

Refer to “Expansion Valve Inspection”.

A/C Refrigerant Pressure Sensor and Its Circuit

Inspection

S7RS0B7226028

Refer to “A/C Refrigerant Pressure Sensor and Its Circuit

Inspection”.

A/C Refrigerant Pressure Sensor Removal and

Installation

S7RS0B7226029

Refer to “A/C Refrigerant Pressure Sensor Removal and

Installation”.

Compressor Relay InspectionS7RS0B7226030

Refer to “Compressor Relay Inspection”.

Compressor Drive Belt Inspection and

Adjustment

S7RS0B7226031

Refer to “Compressor Drive Belt Inspection and

Adjustment”.

12I5RS0A722028-01

Temperature

Resistance

1.7

0

32 25

77

F

5.5

I5RS0A722029-01

Page 1032 of 1496

Downloaded from www.Manualslib.com manuals search engine 8A-1 Seat Belts:

Restraint

Seat Belts

Precautions

Precautions on Service and Diagnosis of Seat

Belt

S7RS0B8100001

WARNING!

If replacing seat belt is necessary, replace

buckle and seat belt assembly together as a

set. This is for the reason of ensuring locking

of tongue plate with buckle. If these parts are

replaced individually, such a locking

condition may become unreliable. For this

reason, SUZUKI will supply only the spare

buckle and seat belt assembly in a set part.

Before servicing or replacing seat belts, refer to the

following precautionary items.

• Seat belts should be normal relative to strap retractor and buckle portions. • Keep sharp edges and damaging objects away from

belts.

• Avoid bending or damaging any portion of belt buckle or latch plate.

• Do not bleach or dye belt webbing. (Use only mild soap and lukewarm water to clean it.)

• When installing a seat belt anchor bolt, it should be tightened by hand at first to prevent cross-threading

and then to specified torque.

• Do not attempt any repair s on retractor mechanisms

or retractor covers. Replace defective assemblies with

new replacement parts.

• Keep belts dry and clean at all times.

• If there exist any parts in question, replace such parts.

• Replace belts whose webbing is cut or otherwise damaged.

• Do not put anything into trim panel opening which seat belt webbing passes through.

General Description

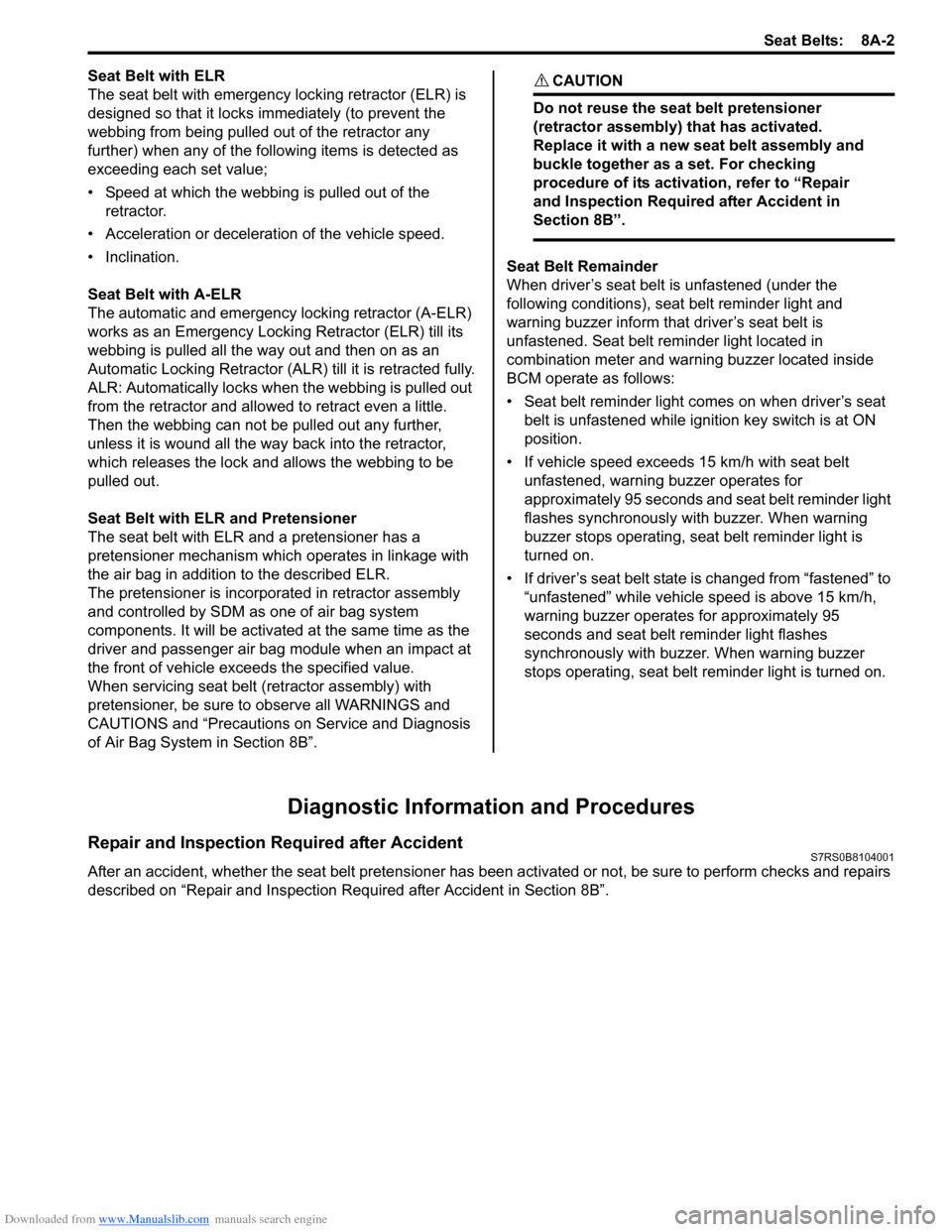

Seat Belt ConstructionS7RS0B8101001

1

1

6

6

6

5

5

7

6

6

2

2

3

4

I4RS0A810001-02

1. Front seat belt assembly (with ELR and pretensioner) 4. Buckle for front seat belt assembly7. Buckle for rear center seat belt

2. Rear seat belt assembly (with A-ELR or ELR) 5. Buckle for rear seat belt assembly

3. Rear center seat belt (with A-ELR or ELR) 6. Retractor assembly

Page 1033 of 1496

Downloaded from www.Manualslib.com manuals search engine Seat Belts: 8A-2

Seat Belt with ELR

The seat belt with emergency locking retractor (ELR) is

designed so that it locks immediately (to prevent the

webbing from being pulled out of the retractor any

further) when any of the following items is detected as

exceeding each set value;

• Speed at which the webbing is pulled out of the retractor.

• Acceleration or deceleration of the vehicle speed.

• Inclination.

Seat Belt with A-ELR

The automatic and emergency locking retractor (A-ELR)

works as an Emergency Locking Retractor (ELR) till its

webbing is pulled all the way out and then on as an

Automatic Locking Retractor (ALR ) till it is retracted fully.

ALR: Automatically locks when the webbing is pulled out

from the retractor and allowed to retract even a little.

Then the webbing can not be pulled out any further,

unless it is wound all the way back into the retractor,

which releases the lock and allows the webbing to be

pulled out.

Seat Belt with ELR and Pretensioner

The seat belt with ELR and a pretensioner has a

pretensioner mechanism whic h operates in linkage with

the air bag in addition to the described ELR.

The pretensioner is incorporated in retractor assembly

and controlled by SDM as one of air bag system

components. It will be activated at the same time as the

driver and passenger air bag module when an impact at

the front of vehicle exceeds the specified value.

When servicing seat belt (retractor assembly) with

pretensioner, be sure to observe all WARNINGS and

CAUTIONS and “Precautions on Service and Diagnosis

of Air Bag System in Section 8B”. CAUTION!

Do not reuse the seat belt pretensioner

(retractor assembly) that has activated.

Replace it with a new seat belt assembly and

buckle together as a set. For checking

procedure of its activation, refer to “Repair

and Inspection Required after Accident in

Section 8B”.

Seat Belt Remainder

When driver’s seat belt is unfastened (under the

following conditions), seat belt reminder light and

warning buzzer inform that driver’s seat belt is

unfastened. Seat belt reminder light located in

combination meter and warning buzzer located inside

BCM operate as follows:

• Seat belt reminder light comes on when driver’s seat belt is unfastened while igni tion key switch is at ON

position.

• If vehicle speed exceeds 15 km/h with seat belt unfastened, warning buzzer operates for

approximately 95 seconds and seat belt reminder light

flashes synchronously with buzzer. When warning

buzzer stops operating, seat belt reminder light is

turned on.

• If driver’s seat belt state is changed from “fastened” to “unfastened” while vehicle speed is above 15 km/h,

warning buzzer operates for approximately 95

seconds and seat belt reminder light flashes

synchronously with buzzer. When warning buzzer

stops operating, seat belt reminder light is turned on.

Diagnostic Information and Procedures

Repair and Inspection Required after AccidentS7RS0B8104001

After an accident, whether the seat belt pretensioner has been activated or not, be sure to perform checks and repairs

described on “Repair and Inspection Required after Accident in Section 8B”.

Page 1035 of 1496

Downloaded from www.Manualslib.com manuals search engine Seat Belts: 8A-4

Front Seat Belt Removal and InstallationS7RS0B8106002

WARNING!

• Never attempt to disassemble or repair the seat belt pretensioner (retractor

assembly). If any abnormality is found, be

sure to replace it with new one as an

assembly.

• Be sure to read “Precautions on Service and Diagnosis of Seat Belt” before starting

to work and observe every precaution

during work. Ne glecting them may result in

personal injury or una ctivation of the seat

belt pretensioner when necessary.

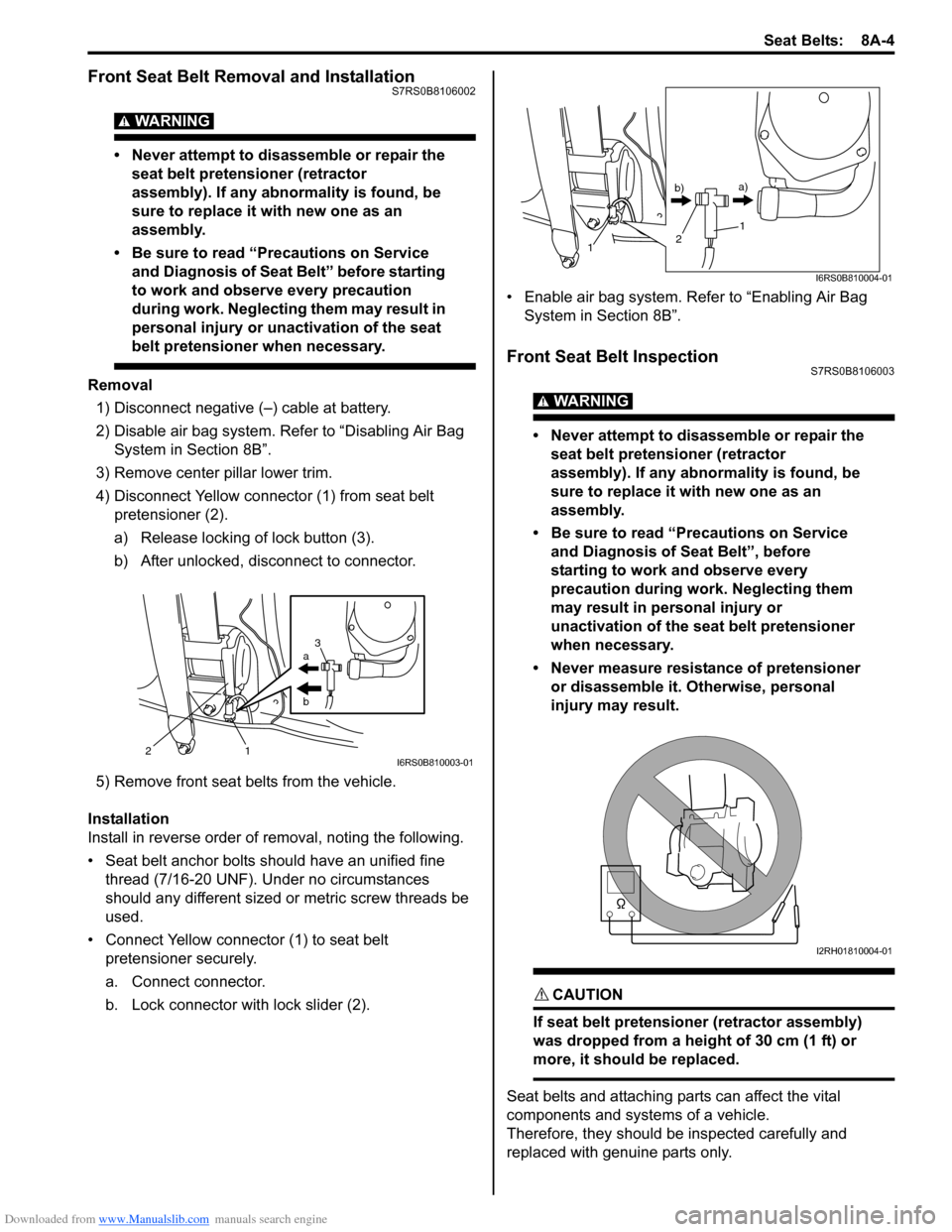

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Refer to “Disabling Air Bag System in Section 8B”.

3) Remove center pillar lower trim.

4) Disconnect Yellow connector (1) from seat belt pretensioner (2).

a) Release locking of lock button (3).

b) After unlocked, disconnect to connector.

5) Remove front seat belts from the vehicle.

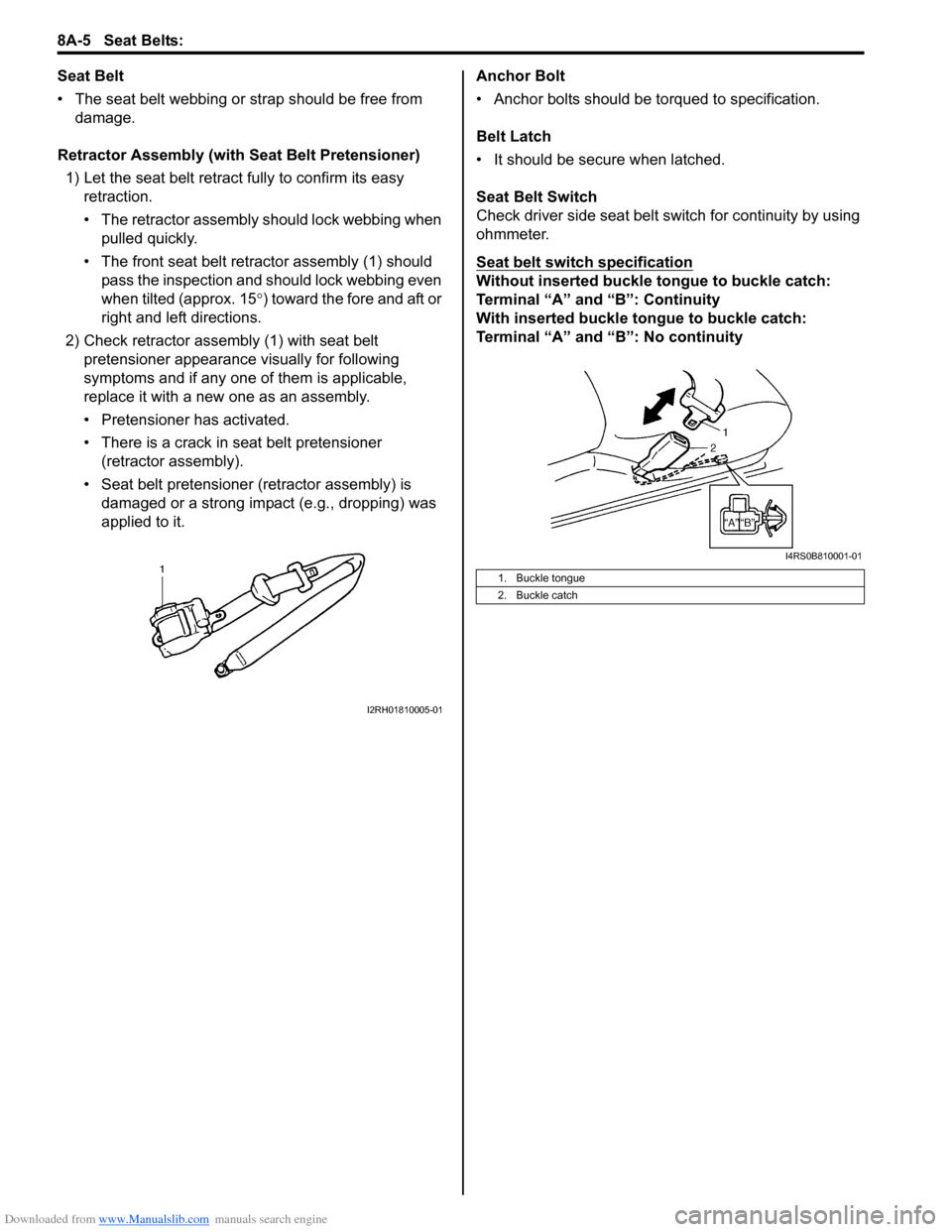

Installation

Install in reverse order of removal, noting the following.

• Seat belt anchor bolts should have an unified fine thread (7/16-20 UNF). Under no circumstances

should any different sized or metric screw threads be

used.

• Connect Yellow connector (1) to seat belt pretensioner securely.

a. Connect connector.

b. Lock connector with lock slider (2). • Enable air bag system. Refer to “Enabling Air Bag

System in Section 8B”.

Front Seat Belt InspectionS7RS0B8106003

WARNING!

• Never attempt to disassemble or repair the seat belt pretensioner (retractor

assembly). If any abnormality is found, be

sure to replace it with new one as an

assembly.

• Be sure to read “Precautions on Service and Diagnosis of Seat Belt”, before

starting to work and observe every

precaution during work. Neglecting them

may result in personal injury or

unactivation of the seat belt pretensioner

when necessary.

• Never measure resistance of pretensioner or disassemble it. Otherwise, personal

injury may result.

CAUTION!

If seat belt pretensioner (retractor assembly)

was dropped from a height of 30 cm (1 ft) or

more, it should be replaced.

Seat belts and attaching parts can affect the vital

components and systems of a vehicle.

Therefore, they should be inspected carefully and

replaced with genuine parts only.

a

b

21 3I6RS0B810003-01

1

1

2

b)

a)

I6RS0B810004-01

I2RH01810004-01

Page 1036 of 1496

Downloaded from www.Manualslib.com manuals search engine 8A-5 Seat Belts:

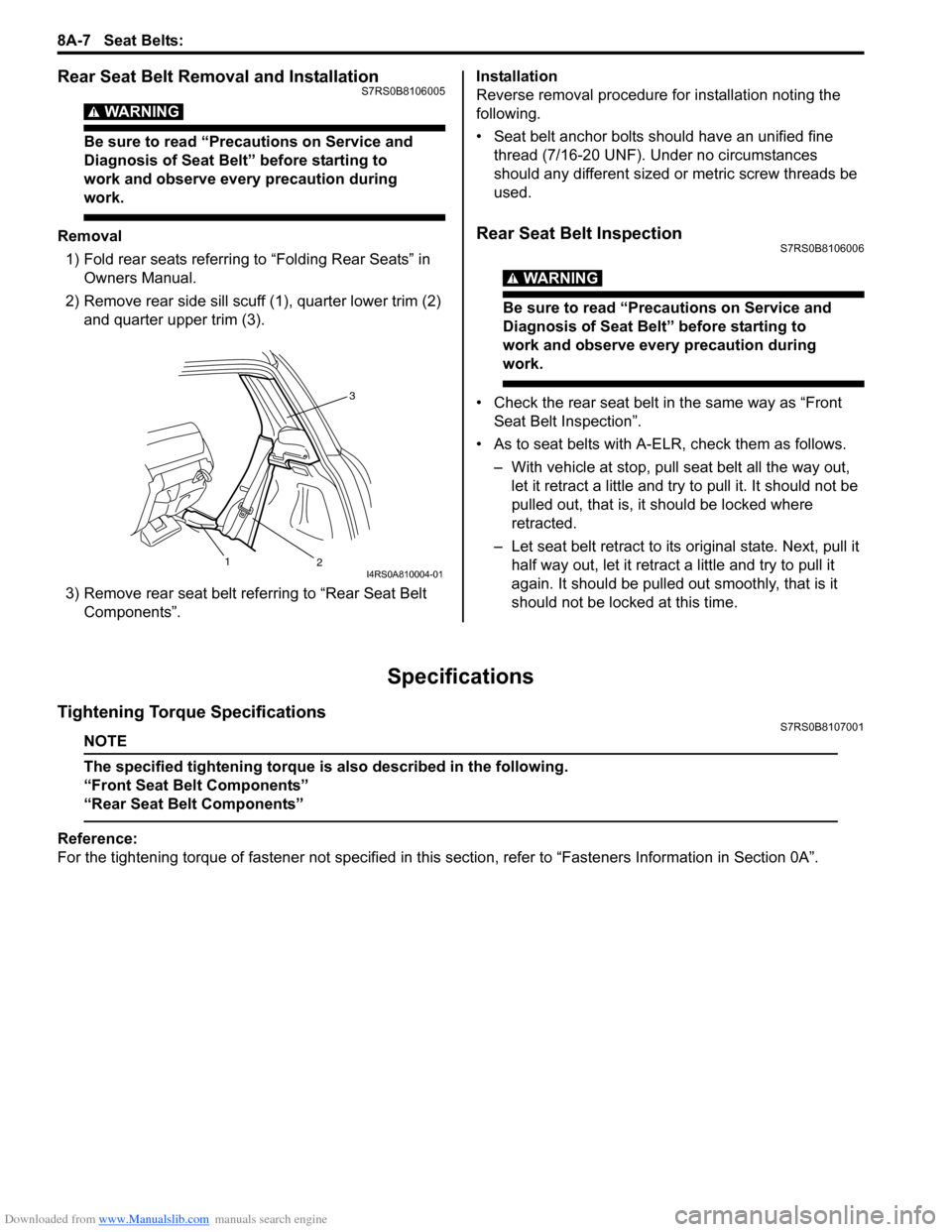

Seat Belt

• The seat belt webbing or strap should be free from damage.

Retractor Assembly (with Seat Belt Pretensioner) 1) Let the seat belt retract fully to confirm its easy retraction.

• The retractor assembly should lock webbing when

pulled quickly.

• The front seat belt retractor assembly (1) should pass the inspection and should lock webbing even

when tilted (approx. 15 °) toward the fore and aft or

right and left directions.

2) Check retractor assembly (1) with seat belt pretensioner appearance visually for following

symptoms and if any one of them is applicable,

replace it with a new one as an assembly.

• Pretensioner has activated.

• There is a crack in seat belt pretensioner (retractor assembly).

• Seat belt pretensioner (retractor assembly) is damaged or a strong impact (e.g., dropping) was

applied to it. Anchor Bolt

• Anchor bolts should be torqued to specification.

Belt Latch

• It should be secure when latched.

Seat Belt Switch

Check driver side seat belt s

witch for continuity by using

ohmmeter.

Seat belt switch specification

Without inserted buckle tongue to buckle catch:

Terminal “A” and “B”: Continuity

With inserted buckle tongue to buckle catch:

Terminal “A” and “B”: No continuity

I2RH01810005-01

1. Buckle tongue

2. Buckle catch

I4RS0B810001-01

Page 1038 of 1496

Downloaded from www.Manualslib.com manuals search engine 8A-7 Seat Belts:

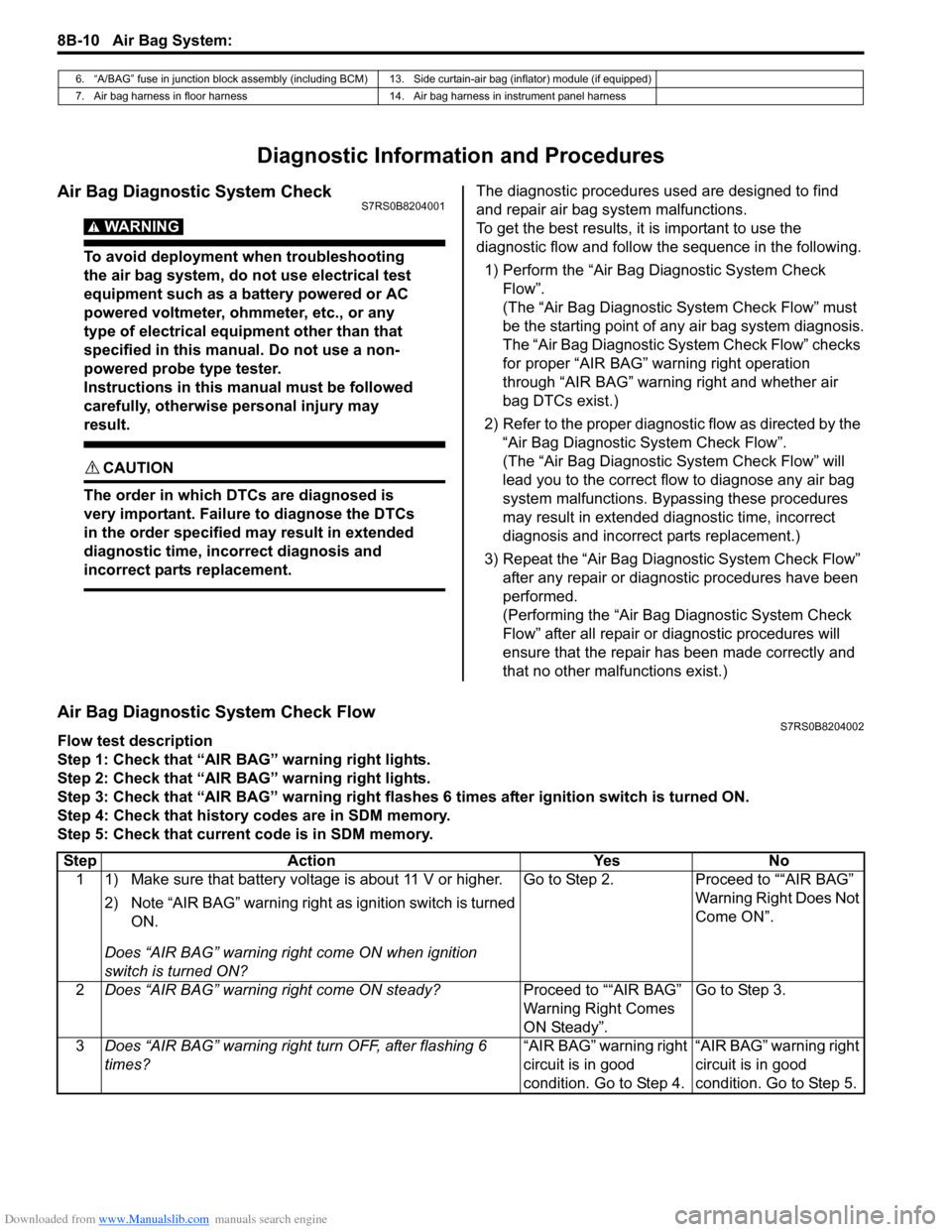

Rear Seat Belt Removal and InstallationS7RS0B8106005

WARNING!

Be sure to read “Precautions on Service and

Diagnosis of Seat Belt” before starting to

work and observe every precaution during

work.

Removal1) Fold rear seats referring to “Folding Rear Seats” in Owners Manual.

2) Remove rear side sill scuff (1), quarter lower trim (2)

and quarter upper trim (3).

3) Remove rear seat belt referring to “Rear Seat Belt Components”. Installation

Reverse removal procedure for installation noting the

following.

• Seat belt anchor bolts should have an unified fine

thread (7/16-20 UNF). Under no circumstances

should any different sized or metric screw threads be

used.Rear Seat Belt InspectionS7RS0B8106006

WARNING!

Be sure to read “Precautions on Service and

Diagnosis of Seat Belt” before starting to

work and observe every precaution during

work.

• Check the rear seat belt in the same way as “Front Seat Belt Inspection”.

• As to seat belts with A-ELR, check them as follows. – With vehicle at stop, pull seat belt all the way out, let it retract a little and try to pull it. It should not be

pulled out, that is, it should be locked where

retracted.

– Let seat belt retract to its original state. Next, pull it

half way out, let it retrac t a little and try to pull it

again. It should be pulled out smoothly, that is it

should not be locked at this time.

Specifications

Tightening Torque SpecificationsS7RS0B8107001

NOTE

The specified tightening torque is also described in the following.

“Front Seat Belt Components”

“Rear Seat Belt Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

3

2

1

I4RS0A810004-01

Page 1045 of 1496

![SUZUKI SWIFT 2007 2.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-7

Schematic and Routing Diagram

Air Bag System Wiring Circuit DiagramS7RS0B8202001

[A]

[B]“E13” “E44”, “G04� SUZUKI SWIFT 2007 2.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-7

Schematic and Routing Diagram

Air Bag System Wiring Circuit DiagramS7RS0B8202001

[A]

[B]“E13” “E44”, “G04�](/img/20/7607/w960_7607-1044.png)

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-7

Schematic and Routing Diagram

Air Bag System Wiring Circuit DiagramS7RS0B8202001

[A]

[B]“E13” “E44”, “G04” “G35” and "L03" \

"L41"

1

2 GRN/RED

GRN GRN/RED

GRN

BLU/RED YEL/RED BLU/RED

YEL/RED

GRN/ORN GRN/YEL

RED

13

PPL/WHT

9 7

8

5

6

10 “L10”

“L11”

“L04”

“G35” “G34”

“G33”

“G28”

“G32”

“L35”

L29-2

L29-27

L29-32 L29-5

L29-6 L29-4

L29-3

L29-8

L29-7

IG

ST

YEL L29-37ADS

WHT/RED

LT GRN/BLK L29-46

L29-47 SD+

SD-

11

WHT/GRN LT GRN

BLK L29-45

L29-44 WL

L29-28

E1 DP-

DP+ P- P+ D- D+

“G10”

“G04”“L29”

18

BLU/ORN

BLU/YEL “L36”

L29-9

L29-10

PP-

PP+

19 17

GRY/RED

GRY

L29-12

L29-11

DS- DS+ “L25”

20

BRN/WHT

BRN

L29-13

L29-14

PS- PS+ “L30”

21

YEL/GRN

YEL/BLU

L29-20

L29-19

DC- DC+ “L18”

22

BLK/YEL

BRN/YEL

L29-21

L29-22

PC- PC+ “L41”

2316

15

14

“L29”

SP+

SP-

“G26”“L32”

“L03”“E44”“E13”

12

ORN

PNK/BLK

GRY/RED

GRY L29-50

L29-51 FD+

FD-

3 4

YEL/BLK

YEL/BLK

GRN RED/BLK

I7RS0A820002-03

[A]: Shorting bar

8. BCM 17. Passenger air bag (inflator) module

[B]: Connector 9. To data link connector (DLC)18. Driver seat belt pretensioner

1. To battery 10. Driver side-sensor (if equipped)19. Passenger seat belt pretensioner

2. Ignition switch 11. Passenger side-sensor (if equipped) 20. Driver side-air bag (inflator) module (if equipped)

3. “AIR BAG” warning light 12. Forward-sensor 21. Passenger side-air bag (inflator) module (if equipped)

4. Light driver 13. Ground for air bag system 22. Driver side curtain-air bag (inflator) module (if equipped)

5. “METER” fuse 14. SDM 23. Passenger side curtain-air bag (inflator) module (if equipped)

6. “A/BAG” fuse 15. Contact coil

7. Junction block assembly 16. Driver air bag (inflator) module

Page 1048 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-10 Air Bag System:

Diagnostic Information and Procedures

Air Bag Diagnostic System CheckS7RS0B8204001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified in this manual. Do not use a non-

powered probe type tester.

Instructions in this manual must be followed

carefully, otherwise personal injury may

result.

CAUTION!

The order in which DTCs are diagnosed is

very important. Failure to diagnose the DTCs

in the order specified may result in extended

diagnostic time, incorrect diagnosis and

incorrect parts replacement.

The diagnostic procedures used are designed to find

and repair air bag system malfunctions.

To get the best results, it is important to use the

diagnostic flow and follow the sequence in the following.1) Perform the “Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” must

be the starting point of any air bag system diagnosis.

The “Air Bag Diagnostic System Check Flow” checks

for proper “AIR BAG” warning right operation

through “AIR BAG” warning right and whether air

bag DTCs exist.)

2) Refer to the proper diagnost ic flow as directed by the

“Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” will

lead you to the correct flow to diagnose any air bag

system malfunctions. Bypassing these procedures

may result in extended diagnostic time, incorrect

diagnosis and incorrect parts replacement.)

3) Repeat the “Air Bag Diagnostic System Check Flow” after any repair or diagnostic procedures have been

performed.

(Performing the “Air Bag Diagnostic System Check

Flow” after all repair or diagnostic procedures will

ensure that the repair has been made correctly and

that no other malfunctions exist.)

Air Bag Diagnostic System Check FlowS7RS0B8204002

Flow test description

Step 1: Check that “AIR BAG” warning right lights.

Step 2: Check that “AIR BAG” warning right lights.

Step 3: Check that “AIR BAG” warning right flas hes 6 times after ignition switch is turned ON.

Step 4: Check that history codes are in SDM memory.

Step 5: Check that current code is in SDM memory.

6. “A/BAG” fuse in junction block assembly (including BCM) 13. Side curtain-air bag (inflator) module (if equipped)

7. Air bag harness in floor harness 14. Air bag harness in instrument panel harness

Step Action YesNo

1 1) Make sure that battery voltage is about 11 V or higher.

2) Note “AIR BAG” warning right as ignition switch is turned

ON.

Does “AIR BAG” warning ri ght come ON when ignition

switch is turned ON? Go to Step 2.

Proceed to ““AIR BAG”

Warning Right Does Not

Come ON”.

2 Does “AIR BAG” warning right come ON steady? Proceed to ““AIR BAG”

Warning Right Comes

ON Steady”.Go to Step 3.

3 Does “AIR BAG” warning right turn OFF, after flashing 6

times? “AIR BAG” warning right

circuit is in good

condition. Go to Step 4.“AIR BAG” warning right

circuit is in good

condition. Go to Step 5.

Page 1051 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-13

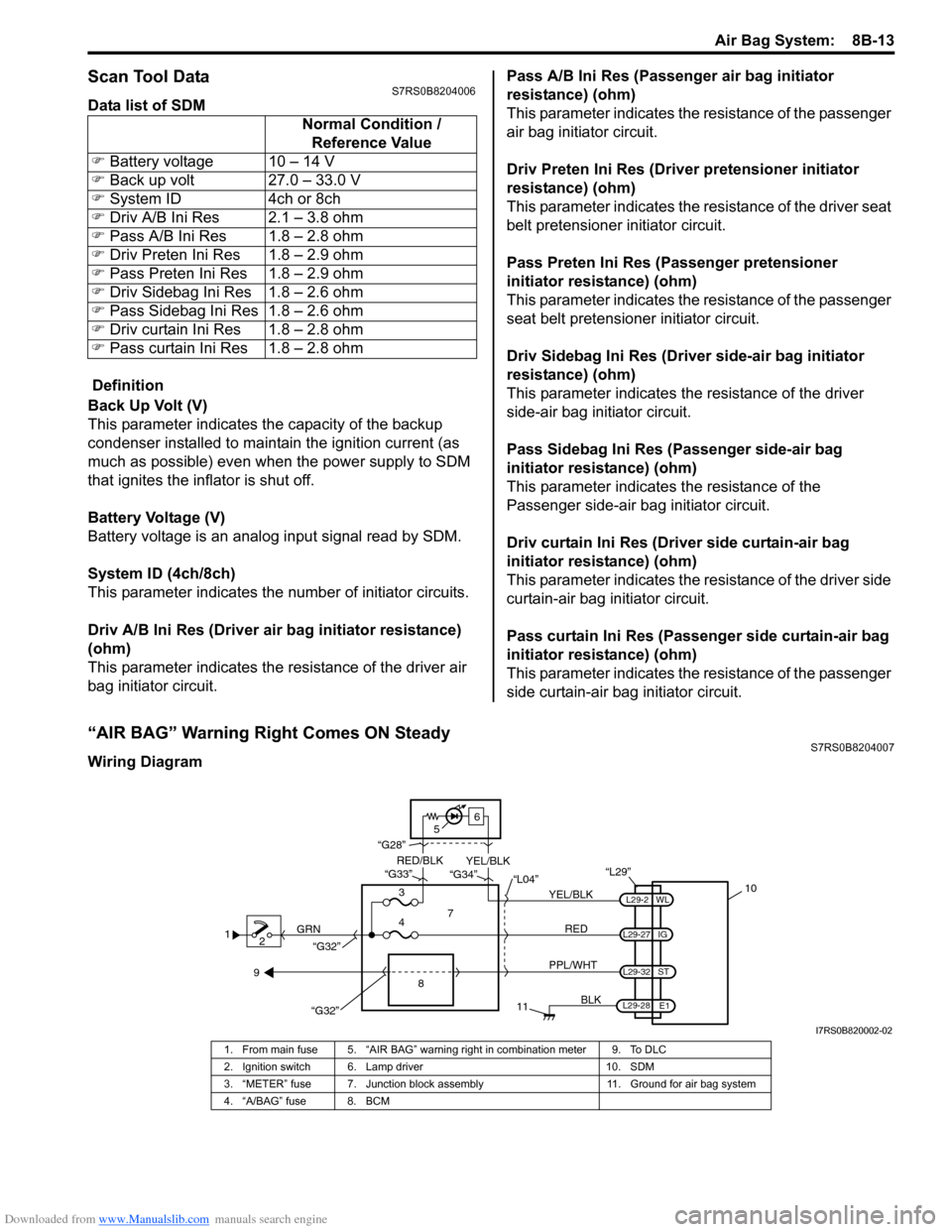

Scan Tool DataS7RS0B8204006

Data list of SDM

Definition

Back Up Volt (V)

This parameter indicates the capacity of the backup

condenser installed to maintain the ignition current (as

much as possible) even when the power supply to SDM

that ignites the inflator is shut off.

Battery Voltage (V)

Battery voltage is an analog input signal read by SDM.

System ID (4ch/8ch)

This parameter indicates the number of initiator circuits.

Driv A/B Ini Res (Driver air bag initiator resistance)

(ohm)

This parameter indicates the resistance of the driver air

bag initiator circuit. Pass A/B Ini Res (Passenger air bag initiator

resistance) (ohm)

This parameter indicates the

resistance of the passenger

air bag initiator circuit.

Driv Preten Ini Res (Dri ver pretensioner initiator

resistance) (ohm)

This parameter indicates the resistance of the driver seat

belt pretensioner initiator circuit.

Pass Preten Ini Res (Passenger pretensioner

initiator resistance) (ohm)

This parameter indicates the resistance of the passenger

seat belt pretensioner initiator circuit.

Driv Sidebag Ini Res (Driver side-air bag initiator

resistance) (ohm)

This parameter indicates the resistance of the driver

side-air bag initiator circuit.

Pass Sidebag Ini Res (Passenger side-air bag

initiator resistance) (ohm)

This parameter indicates the resistance of the

Passenger side-air bag initiator circuit.

Driv curtain Ini Res (Driver side curtain-air bag

initiator resistance) (ohm)

This parameter indicates the re sistance of the driver side

curtain-air bag initiator circuit.

Pass curtain Ini Res (Passenger side curtain-air bag

initiator resistance) (ohm)

This parameter indicates the resistance of the passenger

side curtain-air bag initiator circuit.

“AIR BAG” Warning Right Comes ON SteadyS7RS0B8204007

Wiring Diagram Normal Condition /

Reference Value

�) Battery voltage 10 – 14 V

�) Back up volt 27.0 – 33.0 V

�) System ID 4ch or 8ch

�) Driv A/B Ini Res 2.1 – 3.8 ohm

�) Pass A/B Ini Res 1.8 – 2.8 ohm

�) Driv Preten Ini Res 1.8 – 2.9 ohm

�) Pass Preten Ini Res 1.8 – 2.9 ohm

�) Driv Sidebag Ini Res 1.8 – 2.6 ohm

�) Pass Sidebag Ini Res 1.8 – 2.6 ohm

�) Driv curtain Ini Res 1.8 – 2.8 ohm

�) Pass curtain Ini Res 1.8 – 2.8 ohm

1

2 GRN

11

BLK

L29-27

L29-2

L29-28 WL

E1

IG

L29-32

ST

10

8

“L29”

RED

PPL/WHT

7

3

4 “L04”

“G34”

“G33”

“G28”

“G32”

5 6

“G32”

YEL/BLK

YEL/BLK

RED/BLK

9

I7RS0B820002-02

1. From main fuse 5. “AIR BAG” warning right in combination meter 9. To DLC

2. Ignition switch 6. Lamp driver 10. SDM

3. “METER” fuse 7. Junction block assembly 11. Ground for air bag system

4. “A/BAG” fuse 8. BCM