Lock SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 899 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-17

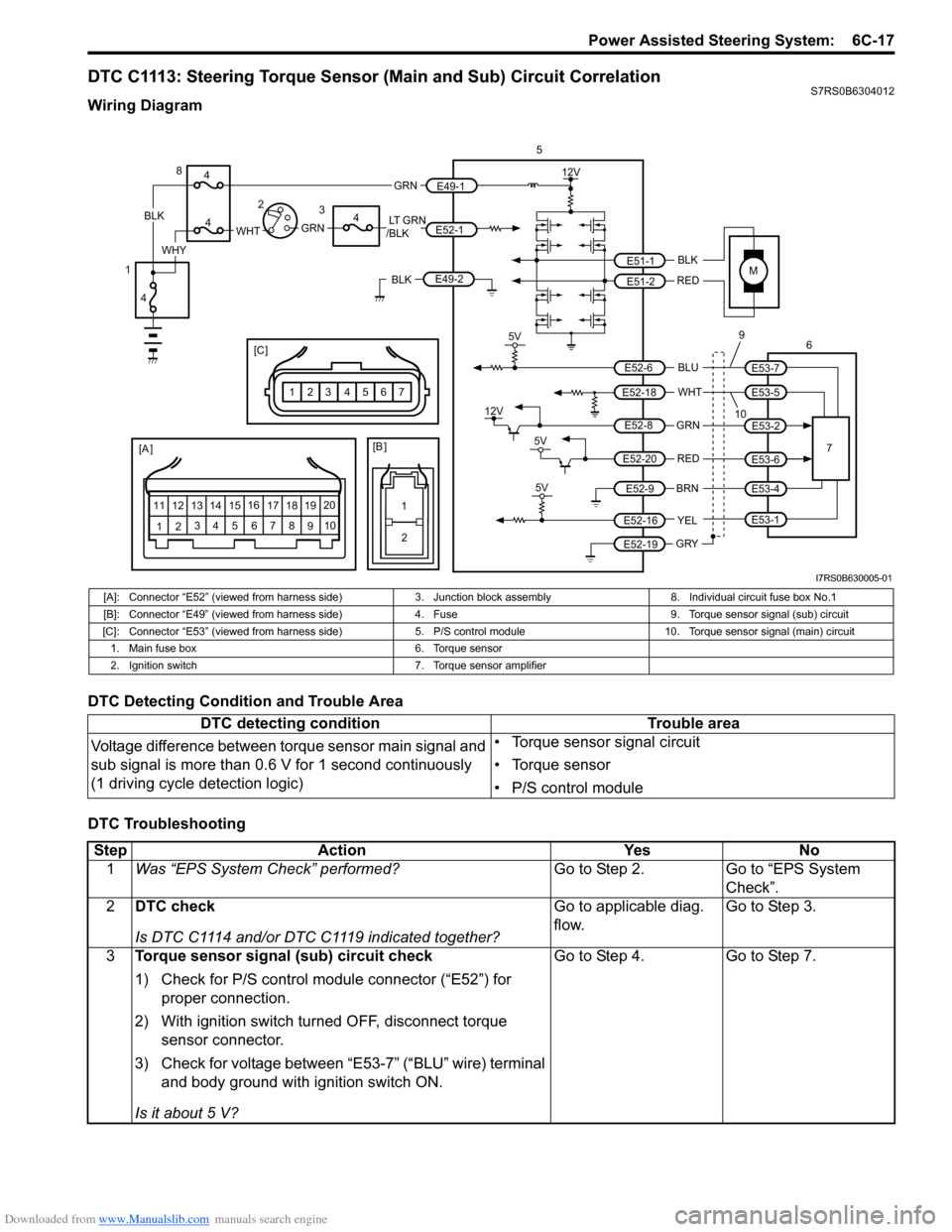

DTC C1113: Steering Torque Sensor (Main and Sub) Circuit CorrelationS7RS0B6304012

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

M

5V

BLK

RED

WHT BLU

GRN

BRN YEL

E51-1

E51-2

E52-18

E53-5

E53-7

E52-6

E52-8

E53-2

E52-9

E52-16

E52-19

GRY

[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

5

67

12V

5V

5V

12V

REDE52-20E53-6

E53-4

E53-1

109

1

2

[B ]

[C ]

7654321

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

8

3

4

4

4

4

1 2

E49-2BLK

I7RS0B630005-01

[A]: Connector “E52” (viewed from harness side)

3. Junction block assembly 8. Individual circuit fuse box No.1

[B]: Connector “E49” (viewed from harness side )4. Fuse 9. Torque sensor signal (sub) circuit

[C]: Connector “E53” (viewed from harness side) 5. P/S control module 10. Torque sensor signal (main) circuit

1. Main fuse box 6. Torque sensor

2. Ignition switch 7. Torque sensor amplifier

DTC detecting condition Trouble area

Voltage difference between torque sensor main signal and

sub signal is more than 0.6 V for 1 second continuously

(1 driving cycle detection logic) • Torque sensor signal circuit

• Torque sensor

• P/S control module

Step

Action YesNo

1 Was “EPS System Check” performed? Go to Step 2.Go to “EPS System

Check”.

2 DTC check

Is DTC C1114 and/or DTC C1119 indicated together? Go to applicable diag.

flow.

Go to Step 3.

3 Torque sensor signal (sub) circuit check

1) Check for P/S control module connector (“E52”) for

proper connection.

2) With ignition switch turned OFF, disconnect torque sensor connector.

3) Check for voltage between “E53-7” (“BLU” wire) terminal and body ground with ignition switch ON.

Is it about 5 V? Go to Step 4.

Go to Step 7.

Page 901 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-19

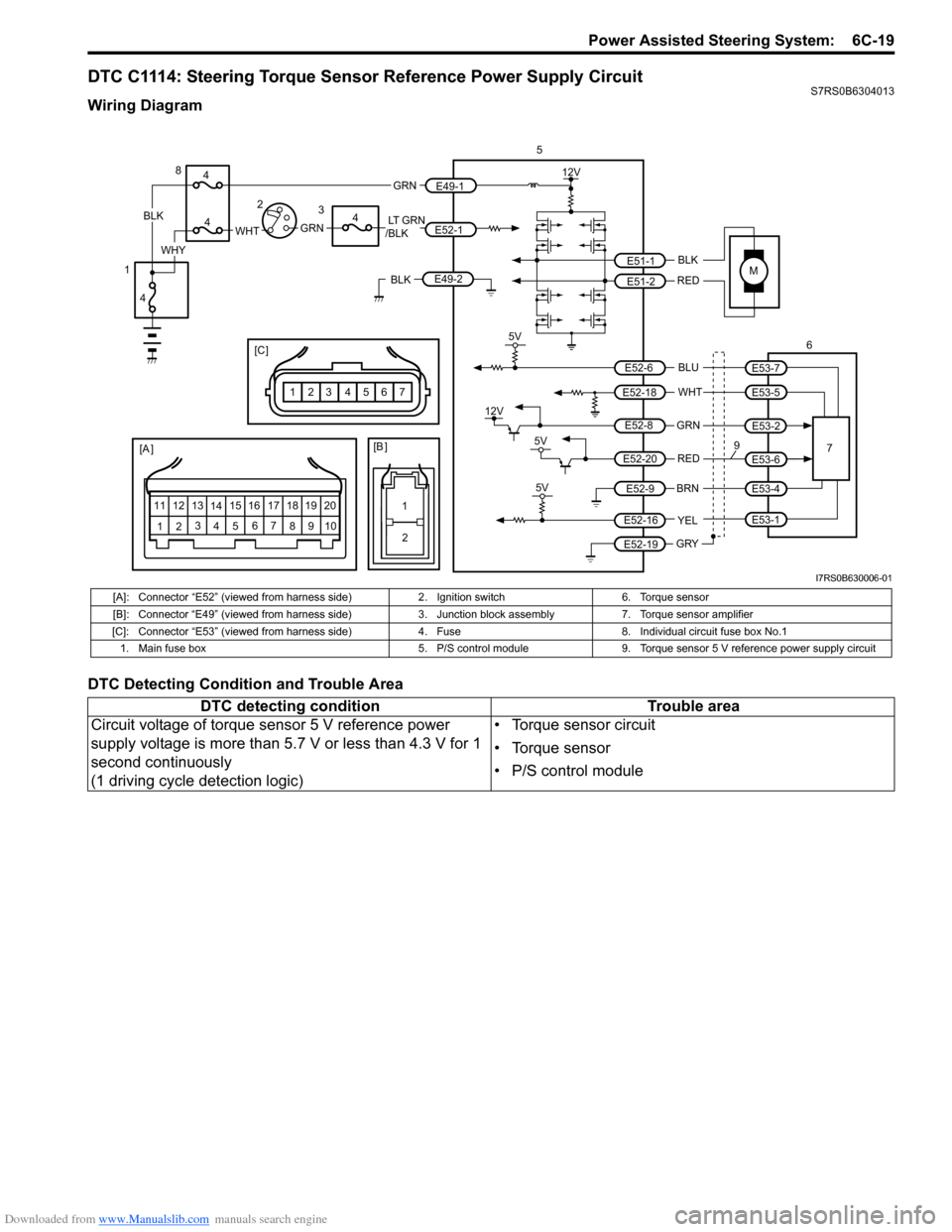

DTC C1114: Steering Torque Sensor Reference Power Supply CircuitS7RS0B6304013

Wiring Diagram

DTC Detecting Condition and Trouble Area

M

5V

BLK

RED

WHT BLU

GRN

BRN YEL

E51-1

E51-2

E52-18

E53-5

E53-7

E52-6

E52-8

E53-2

E52-9

E52-16

E52-19

GRY

5

67

12V

5V

5V

12V

REDE52-20E53-6

E53-4

E53-1

9[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

1

2

[B ]

[C ]

7654321

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

8

3

4

4

4

4

1 2

E49-2BLK

I7RS0B630006-01

[A]: Connector “E52” (viewed from harness side)

2. Ignition switch6. Torque sensor

[B]: Connector “E49” (viewed from harness side) 3. Junction block assembly 7. Torque sensor amplifier

[C]: Connector “E53” (viewed from harness si de)4. Fuse 8. Individual circuit fuse box No.1

1. Main fuse box 5. P/S control module9. Torque sensor 5 V reference power supply circuit

DTC detecting condition Trouble area

Circuit voltage of torque sensor 5 V reference power

supply voltage is more than 5.7 V or less than 4.3 V for 1

second continuously

(1 driving cycle detection logic) • Torque sensor circuit

• Torque sensor

• P/S control module

Page 903 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-21

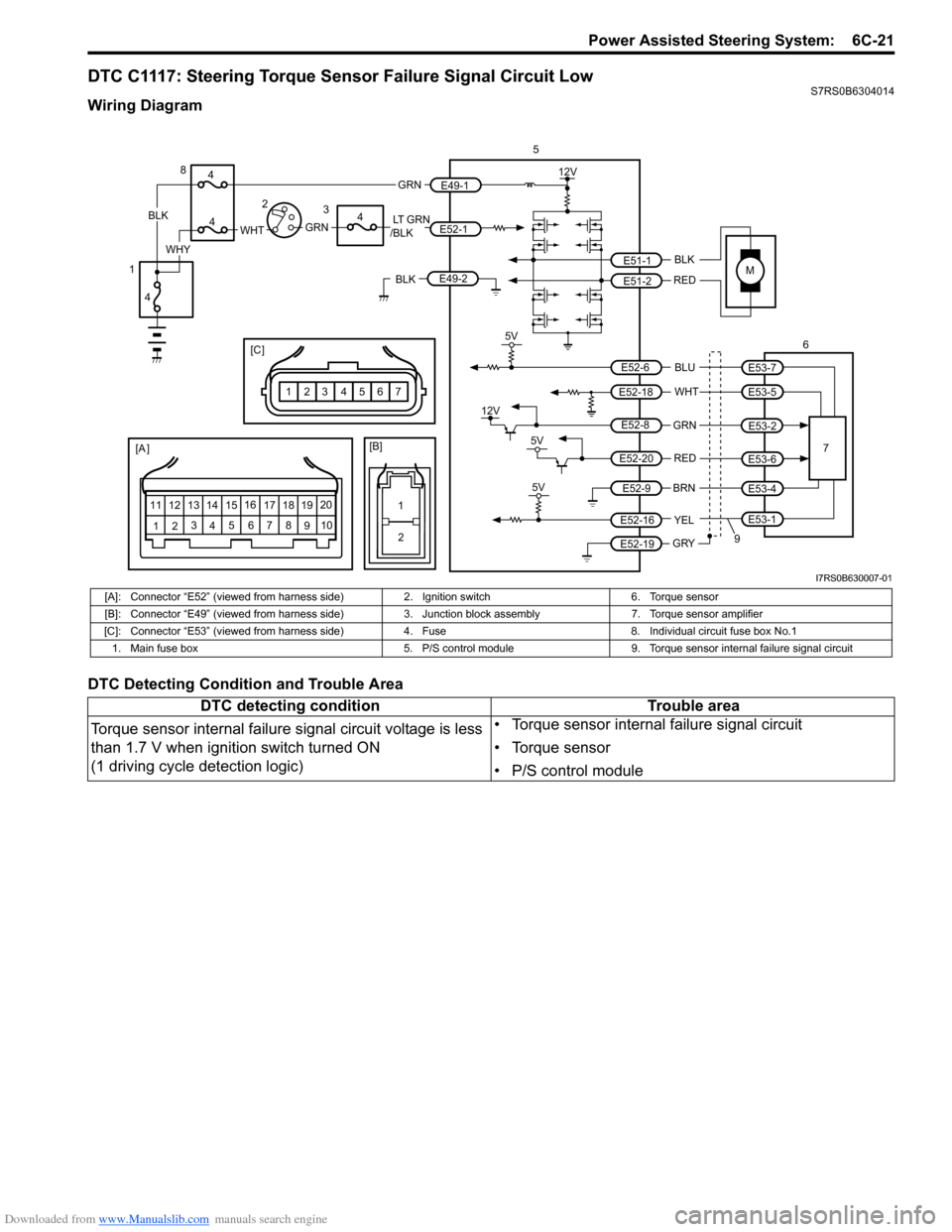

DTC C1117: Steering Torque Sensor Failure Signal Circuit LowS7RS0B6304014

Wiring Diagram

DTC Detecting Condition and Trouble Area

M

5V

BLK

RED

WHT BLU

GRN

BRN YEL

E51-1

E51-2

E52-18

E53-5

E53-7

E52-6

E52-8

E53-2

E52-9

E52-16

E52-19

GRY

[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

5

67

12V

5V

5V

12V

REDE52-20E53-6

E53-4

E53-1

9

12

[B]

[C ]

7654321

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

8

3

4

4

4

4

1 2

E49-2BLK

I7RS0B630007-01

[A]: Connector “E52” (viewed from harness side)

2. Ignition switch6. Torque sensor

[B]: Connector “E49” (viewed from harness side) 3. Junction block assembly7. Torque sensor amplifier

[C]: Connector “E53” (viewed from harness side) 4. Fuse8. Individual circuit fuse box No.1

1. Main fuse box 5. P/S control module9. Torque sensor internal failure signal circuit

DTC detecting condition Trouble area

Torque sensor internal failure signal circuit voltage is less

than 1.7 V when ignition switch turned ON

(1 driving cycle detection logic) • Torque sensor internal failure signal circuit

• Torque sensor

• P/S control module

Page 906 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-24 Power Assisted Steering System:

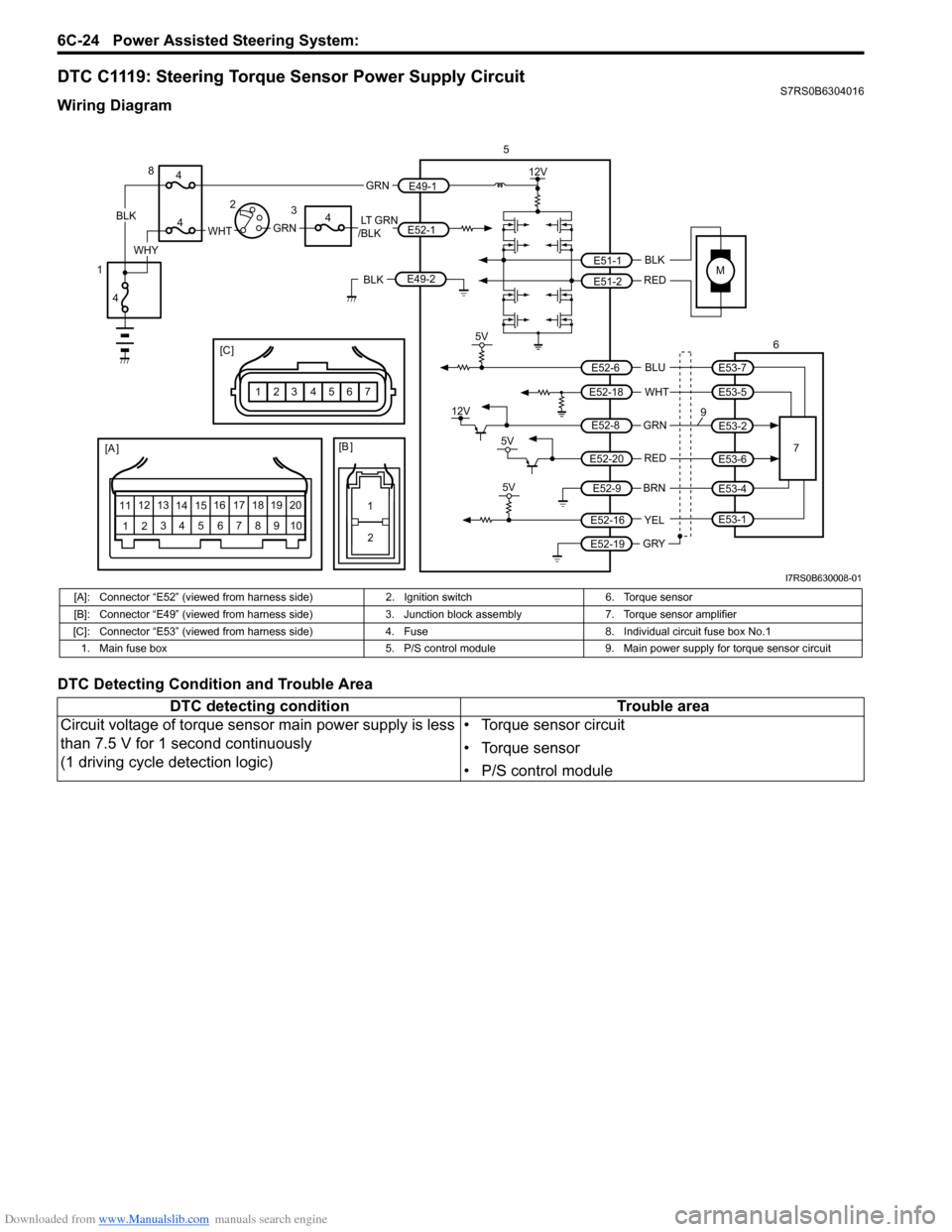

DTC C1119: Steering Torque Sensor Power Supply CircuitS7RS0B6304016

Wiring Diagram

DTC Detecting Condition and Trouble Area

M

5V

BLK

RED

WHT BLU

GRN

BRN YEL

E51-1

E51-2

E52-18

E53-5

E53-7

E52-6

E52-8

E53-2

E52-9

E52-16

E52-19

GRY

5

67

12V

5V

5V

12V

REDE52-20E53-6

E53-4

E53-1

9

[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

1

2

[B ]

[C ]

7654321

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

8

3

4

4

4

4

1 2

E49-2BLK

I7RS0B630008-01

[A]: Connector “E52” (viewed from harness side)

2. Ignition switch6. Torque sensor

[B]: Connector “E49” (viewed from harness side) 3. Junction block assembly7. Torque sensor amplifier

[C]: Connector “E53” (viewed from harness si de)4. Fuse 8. Individual circuit fuse box No.1

1. Main fuse box 5. P/S control module9. Main power supply for torque sensor circuit

DTC detecting condition Trouble area

Circuit voltage of torque sensor main power supply is less

than 7.5 V for 1 second continuously

(1 driving cycle detection logic) • Torque sensor circuit

• Torque sensor

• P/S control module

Page 908 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-26 Power Assisted Steering System:

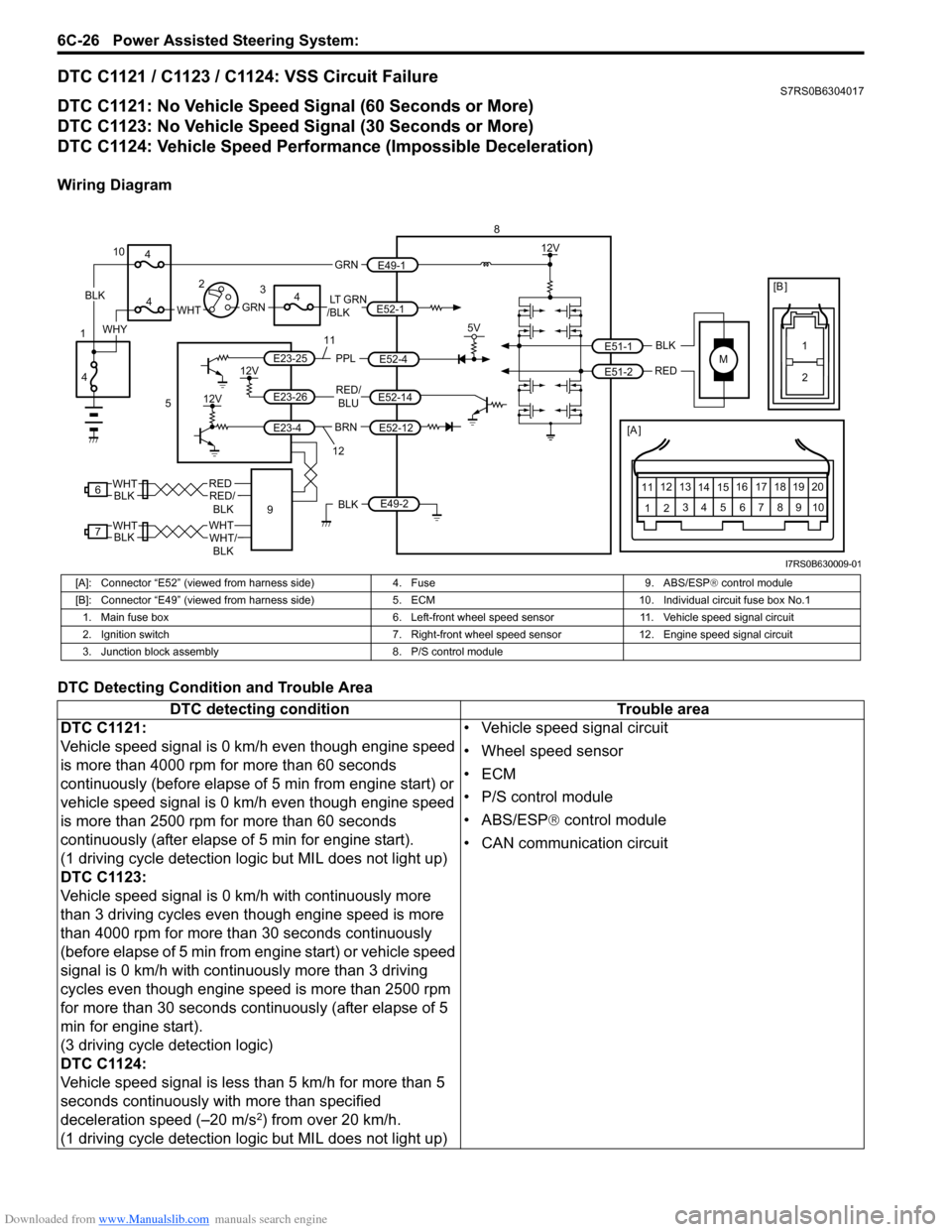

DTC C1121 / C1123 / C1124: VSS Circuit FailureS7RS0B6304017

DTC C1121: No Vehicle Speed Signal (60 Seconds or More)

DTC C1123: No Vehicle Speed Signal (30 Seconds or More)

DTC C1124: Vehicle Speed Performance (Impossible Deceleration)

Wiring Diagram

DTC Detecting Condition and Trouble Area

M

BRNRED/

BLU

BLK

RED

E52-14

E52-12

E23-4

E23-26

E23-25 E51-1

E51-2

[A ]

12

3

4 5 67

89

11

10

12 13

141516

17 18 19 20

5V

PPL

E52-4

8

5

12V

E49-2BLK

12V

12V

6REDRED/ BLKWHT

7WHTWHT/BLKWHTBLK BLK

111

2

[B ]

9

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

10

3

4

4

4

4

1 2

12

I7RS0B630009-01

[A]: Connector “E52” (viewed from harness side)

4. Fuse9. ABS/ESP® control module

[B]: Connector “E49” (viewed from harness si de)5. ECM 10. Individual circuit fuse box No.1

1. Main fuse box 6. Left-front wheel speed sensor11. Vehicle speed signal circuit

2. Ignition switch 7. Right-front wheel speed sensor 12. Engine speed signal circuit

3. Junction block assembly 8. P/S control module

DTC detecting condition Trouble area

DTC C1121:

Vehicle speed signal is 0 km/h even though engine speed

is more than 4000 rpm for more than 60 seconds

continuously (before elapse of 5 min from engine start) or

vehicle speed signal is 0 km/h even though engine speed

is more than 2500 rpm for more than 60 seconds

continuously (after elapse of 5 min for engine start).

(1 driving cycle detection logic but MIL does not light up)

DTC C1123:

Vehicle speed signal is 0 km/h with continuously more

than 3 driving cycles even though engine speed is more

than 4000 rpm for more than 30 seconds continuously

(before elapse of 5 min from engine start) or vehicle speed

signal is 0 km/h with continuously more than 3 driving

cycles even though engine speed is more than 2500 rpm

for more than 30 seconds continuously (after elapse of 5

min for engine start).

(3 driving cycle detection logic)

DTC C1124:

Vehicle speed signal is less than 5 km/h for more than 5

seconds continuously with more than specified

deceleration speed (–20 m/s

2) from over 20 km/h.

(1 driving cycle detection logic but MIL does not light up) • Vehicle speed signal circuit

• Wheel speed sensor

•ECM

• P/S control module

• ABS/ESP®

control module

• CAN communication circuit

Page 912 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-30 Power Assisted Steering System:

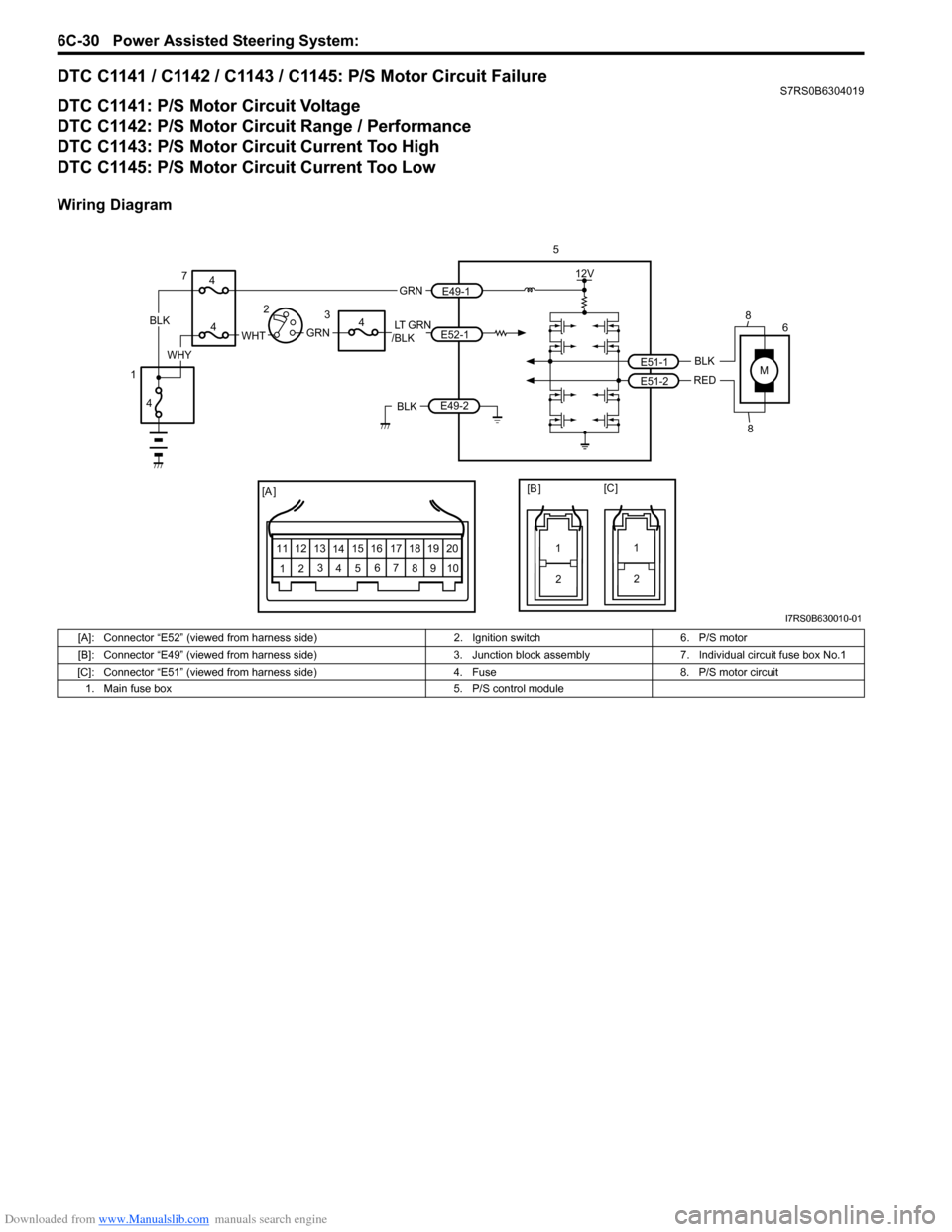

DTC C1141 / C1142 / C1143 / C1145: P/S Motor Circuit FailureS7RS0B6304019

DTC C1141: P/S Motor Circuit Voltage

DTC C1142: P/S Motor Circuit Range / Performance

DTC C1143: P/S Motor Circuit Current Too High

DTC C1145: P/S Motor Circuit Current Too Low

Wiring Diagram

MBLK

REDE51-1

E51-2

6

12V

5

[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20 8

8

12

[B ][C ]

12

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

7

3

4

4

4

4

1 2

E49-2BLK

I7RS0B630010-01

[A]: Connector “E52” (viewed from harness side)

2. Ignition switch6. P/S motor

[B]: Connector “E49” (viewed from harness side) 3. Junction block assembly 7. Individual circuit fuse box No.1

[C]: Connector “E51” (viewed from harness side) 4. Fuse8. P/S motor circuit

1. Main fuse box 5. P/S control module

Page 914 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-32 Power Assisted Steering System:

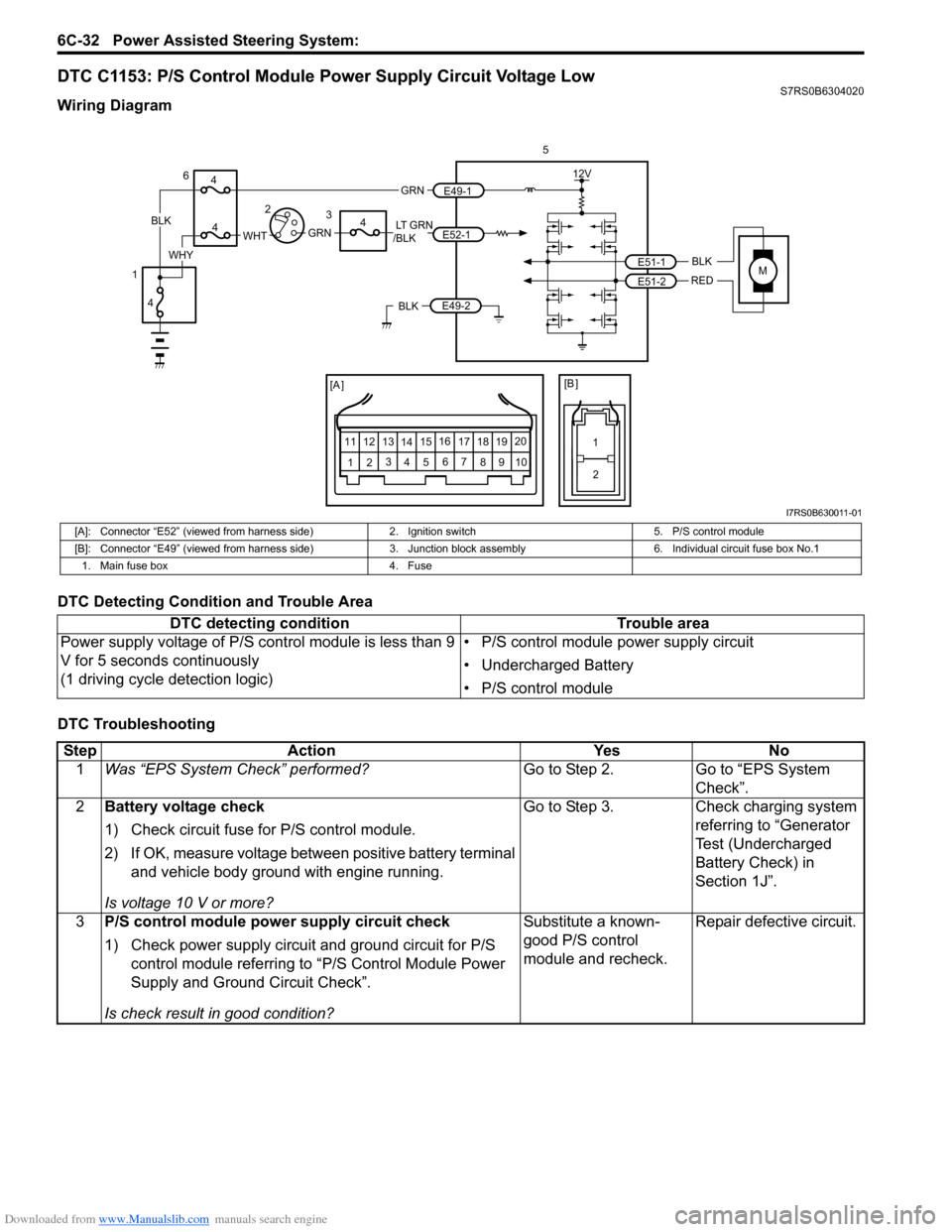

DTC C1153: P/S Control Module Power Supply Circuit Voltage LowS7RS0B6304020

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

MBLK

REDE51-1

E51-2

12V

5

[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

[B ]

1

2

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

6

3

4

4

4

4

1 2

E49-2BLK

I7RS0B630011-01

[A]: Connector “E52” (viewed from harness side)

2. Ignition switch5. P/S control module

[B]: Connector “E49” (viewed from harness side) 3. Junction block assembly 6. Individual circuit fuse box No.1

1. Main fuse box 4. Fuse

DTC detecting condition Trouble area

Power supply voltage of P/S control module is less than 9

V for 5 seconds continuously

(1 driving cycle detection logic) • P/S control module power supply circuit

• Undercharged Battery

• P/S control module

Step

Action YesNo

1 Was “EPS System Check” performed? Go to Step 2.Go to “EPS System

Check”.

2 Battery voltage check

1) Check circuit fuse for P/S control module.

2) If OK, measure voltage between positive battery terminal

and vehicle body ground with engine running.

Is voltage 10 V or more? Go to Step 3.

Check charging system

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J”.

3 P/S control module power supply circuit check

1) Check power supply circuit and ground circuit for P/S

control module referring to “P/S Control Module Power

Supply and Ground Circuit Check”.

Is check result in good condition? Substitute a known-

good P/S control

module and recheck.

Repair defective circuit.

Page 916 of 1496

![SUZUKI SWIFT 2007 2.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 6C-34 Power Assisted Steering System:

P/S Control Module Power Supply and Ground Circuit CheckS7RS0B6304022

Wiring Diagram

1

[A ]

123

4 5 67

8 SUZUKI SWIFT 2007 2.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 6C-34 Power Assisted Steering System:

P/S Control Module Power Supply and Ground Circuit CheckS7RS0B6304022

Wiring Diagram

1

[A ]

123

4 5 67

8](/img/20/7607/w960_7607-915.png)

Downloaded from www.Manualslib.com manuals search engine 6C-34 Power Assisted Steering System:

P/S Control Module Power Supply and Ground Circuit CheckS7RS0B6304022

Wiring Diagram

1

[A ]

123

4 5 67

89

11

10

12 13

141516

17 18 19 20

[B ]

7

1

2

MBLK

REDE51-1

E51-2

12V

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

3

3

5

6

1 2

E49-2BLK

I7RS0B630012-01

[A]: Connector “E52” (viewed from harness side)

2. Ignition switch5. “EPS” fuse

[B]: Connector “E49” (viewed from harness side) 3. Individual circuit fuse box No.1 6. “IG1 SIG” fuse

1. Main fuse box 4. Junction block assembly7. P/S control module

StepAction YesNo

1 Circuit fuse check

1) Disconnect P/S control modu le connector with ignition

switch turned OFF.

2) Check for proper connection to P/S control module connector at “E49-1”, “E49-2” and “E52-1” terminals.

3) If OK, check “P/S” fuse and “IG1 SIG” fuse for blowing.

Are “P/S” fuse and “IG1 SIG” fuse in good condition? Go to Step 2.

Replace fuse(s) and

check for short in

circuits connected to

fuse(s).

2 Power supply circuit check

1) Measure voltage between “E49-1” terminal of P/S

control module connector and body ground.

Is voltage 10 - 14 V? Go to Step 3.

“GRN” or “BLK” wire is

open circuit.

3 Ignition signal check

1) Turn ignition switch to ON position.

2) Measure voltage between “E52-1” terminal of P/S

control module connector and body ground.

Is voltage 10 - 14 V? Go to Step 4.

“LT GRN/BLK” or “GRN”

wire is open circuit.

4 P/S control module ground circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors from P/S control module.

3) Measure resistance between “E49-2” terminals of P/S

control module connector and body ground.

Is resistance 1

Ω or less? Go to Step 5. “BLK” wire is open or

high resistance circuit.

Page 918 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-36 Power Assisted Steering System:

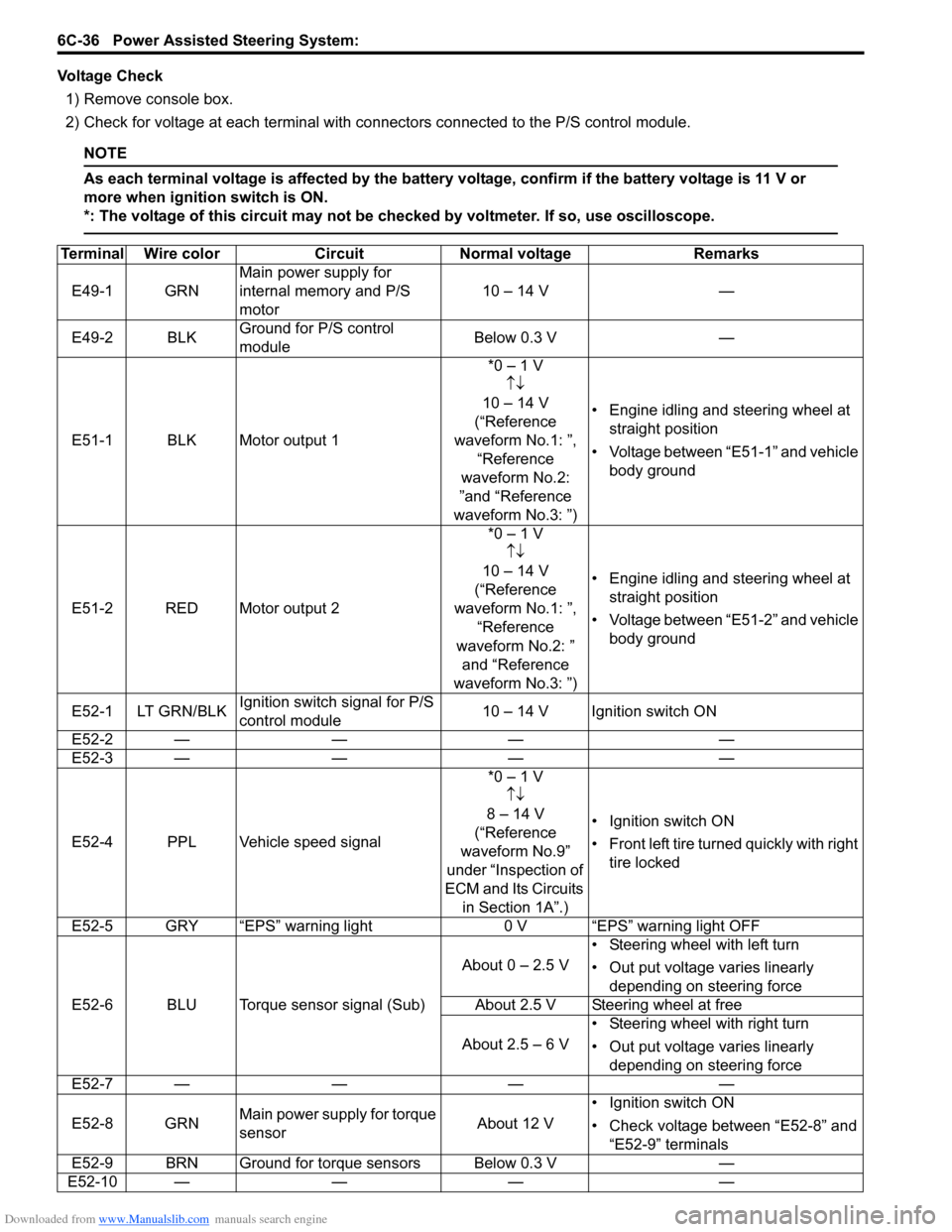

Voltage Check1) Remove console box.

2) Check for voltage at each terminal with co nnectors connected to the P/S control module.

NOTE

As each terminal voltage is affected by the battery voltage, confirm if the battery voltage is 11 V or

more when ignition switch is ON.

*: The voltage of this circuit may not be checked by voltmeter. If so, use oscilloscope.

Terminal Wire colorCircuit Normal voltage Remarks

E49-1 GRN Main power supply for

internal memory and P/S

motor 10 – 14 V

—

E49-2 BLK Ground for P/S control

module Below 0.3 V

—

E51-1 BLK Motor output 1 *0 – 1 V

↑↓

10 – 14 V

(“Reference

waveform No.1: ”, “Reference

waveform No.2:

”and “Reference

waveform No.3: ”) • Engine idling and steering wheel at

straight position

• Voltage between “E51-1” and vehicle body ground

E51-2 RED Motor output 2 *0 – 1 V

↑↓

10 – 14 V

(“Reference

waveform No.1: ”, “Reference

waveform No.2: ” and “Reference

waveform No.3: ”) • Engine idling and steering wheel at

straight position

• Voltage between “E51-2” and vehicle body ground

E52-1 LT GRN/BLK Ignition switch signal for P/S

control module 10 – 14 V Ignition switch ON

E52-2 — —— —

E52-3 — —— —

E52-4 PPL Vehicle speed signal *0 – 1 V

↑↓

8 – 14 V

(“Reference

waveform No.9”

under “Inspection of

ECM and Its Circuits in Section 1A”.) • Ignition switch ON

•Front left tire tu

rned quickly with right

tire locked

E52-5 GRY “EPS” warning light 0 V “EPS” warning light OFF

E52-6 BLU Torque sensor signal (Sub) About 0 – 2.5 V

• Steering wheel with left turn

• Out put voltage varies linearly

depending on steering force

About 2.5 V Steering wheel at free

About 2.5 – 6 V • Steering wheel with right turn

• Out put voltage varies linearly

depending on steering force

E52-7 — —— —

E52-8 GRN Main power supply for torque

sensor About 12 V• Ignition switch ON

• Check voltage between “E52-8” and

“E52-9” terminals

E52-9 BRN Ground for torque sensors Below 0.3 V —

E52-10 — —— —

Page 922 of 1496

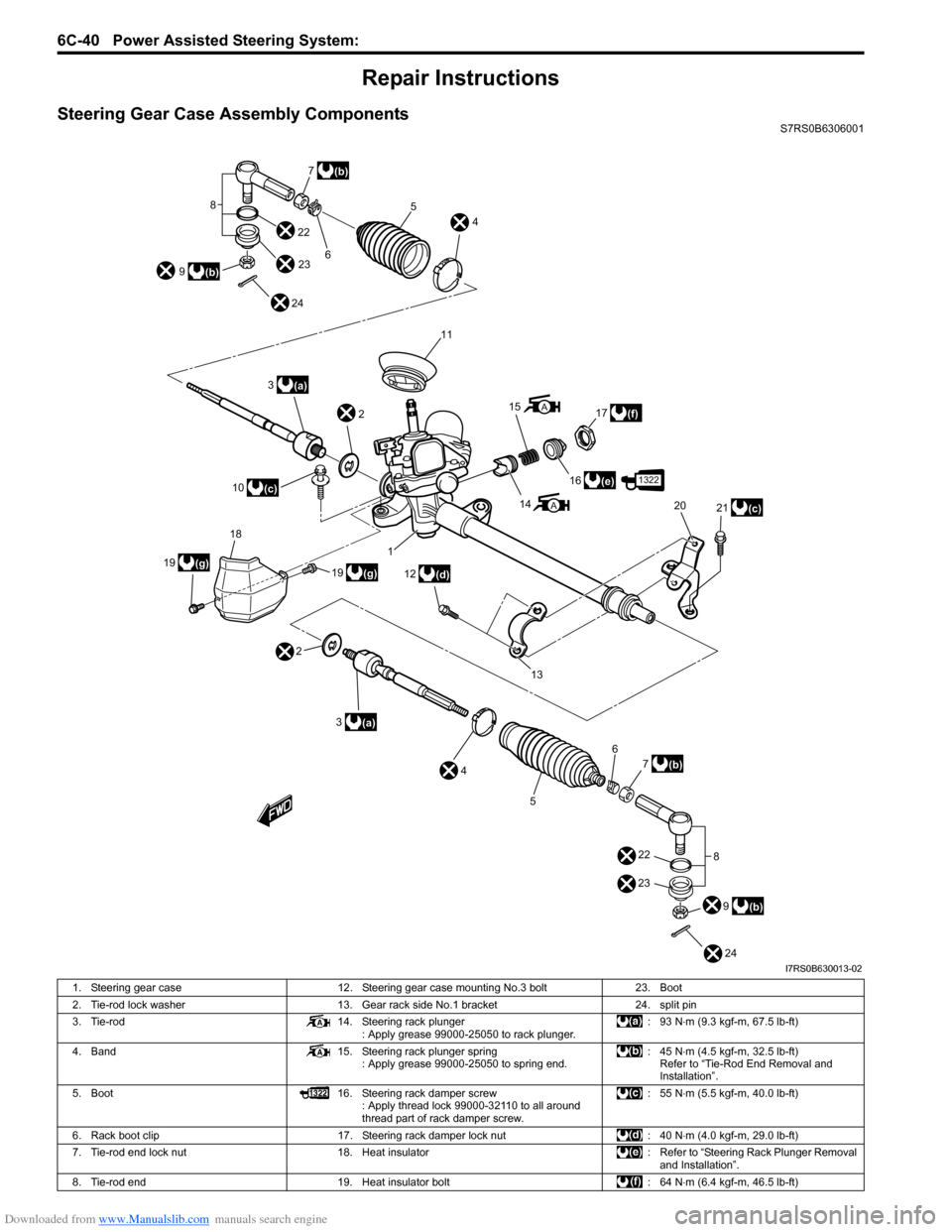

Downloaded from www.Manualslib.com manuals search engine 6C-40 Power Assisted Steering System:

Repair Instructions

Steering Gear Case Assembly ComponentsS7RS0B6306001

3(a)

10

(c) 2

3

(a)

2 1

19

(g)

19 18(g) 6

11

8

9

(b) 7

(b)

22 23

24 4

5

14

15

16

(e)

17

(f)

12

(d) 21

(c)

20

4 6

5 7

(b)

9

(b)

8

13

22

23

24

A

A

1322

I7RS0B630013-02

1. Steering gear case 12. Steering gear case mounting No.3 bolt 23. Boot

2. Tie-rod lock washer 13. Gear rack side No.1 bracket 24. split pin

3. Tie-rod 14. Steering rack plunger

: Apply grease 99000-25050 to rack plunger. : 93 N

⋅m (9.3 kgf-m, 67.5 lb-ft)

4. Band 15. Steering rack plunger spring

: Apply grease 99000-25050 to spring end. : 45 N

⋅m (4.5 kgf-m, 32.5 lb-ft)

Refer to “Tie-Rod End Removal and

Installation”.

5. Boot 16. Steering rack damper screw

: Apply thread lock 99000-32110 to all around

thread part of rack damper screw. : 55 N

⋅m (5.5 kgf-m, 40.0 lb-ft)

6. Rack boot clip 17. Steering rack damper lock nut : 40 N⋅m (4.0 kgf-m, 29.0 lb-ft)

7. Tie-rod end lock nut 18. Heat insulator : Refer to “Steering Rack Plunger Removal

and Installation”.

8. Tie-rod end 19. Heat insulator bolt : 64 N⋅m (6.4 kgf-m, 46.5 lb-ft)