clutch disc SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 21 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 0- i

0

Section 0

CONTENTS

General Information

General Information ................................ 0A-1

General Description ............................................. 0A-1

Abbreviations ...................................................... 0A-1

Symbols .............................................................. 0A-2

Wire Color Symbols ............................................ 0A-2

Fasteners Information ......................................... 0A-3

Vehicle Lifting Points ........................................... 0A-5

Engine Supporting Points ................................... 0A-7

Vehicle Identification Number ............................. 0A-7

Engine Identification Number .............................. 0A-7

Transmission Identification Number .................... 0A-7

Component Locatio n ........................................... 0A-8

Warning, Caution and Information Labels Location ............................................................ 0A-8

Maintenance and Lubricat ion ................. 0B-1

Precautions........................................................... 0B-1

Precautions for Maintenance and Lubrication ..... 0B-1

Scheduled Maintenance ...................................... 0B-1 Maintenance Schedule under Normal Driving Conditions ......................................................... 0B-1

Maintenance Recommended under Severe Driving Conditions ............................................. 0B-2

Repair Instructions .............................................. 0B-3 Accessory Drive Belt Inspection.......................... 0B-3

Accessory Drive Belt Repl acement ..................... 0B-4

Valve Lash (Clearance) Inspection ..................... 0B-4

Engine Oil and Filter Change .............................. 0B-4

Engine Coolant Change ...... ................................ 0B-5

Exhaust System Inspection ................................. 0B-6

Spark Plug Replacement .................................... 0B-6

Air Cleaner Filter Inspection ................................ 0B-6

Air Cleaner Filter Replac ement ........................... 0B-6 Fuel Lines and Connections Inspection .............. 0B-6

Fuel Filter Replacement ...................................... 0B-7

Fuel Tank Inspection ........................................... 0B-7

PCV Valve Inspection ......................................... 0B-7

Fuel Evaporative Emission Control System

Inspection .......................................................... 0B-7

Brake Discs and Pads Inspection ....................... 0B-7

Brake Hoses and Pipes Inspection ..................... 0B-7

Brake Fluid Inspection......................................... 0B-8

Brake Fluid Replacement .................................... 0B-8

Brake Lever and Cable Inspection ...................... 0B-8

Clutch Fluid Inspection ........................................ 0B-8

Tires Inspection ................................................... 0B-9

Wheel Discs Inspection ....................................... 0B-9

Wheel Bearing Inspection ................................... 0B-9

Suspension System Inspection ........................... 0B-9

Steering System Inspection .............................. 0B-10

Drive Shaft (Axle) Boots Inspection .................. 0B-10

Manual Transaxle Oil Inspection ....................... 0B-10

Manual Transaxle Oil Replacement .................. 0B-10

Automatic Transaxle Fluid Level Inspection...... 0B-11

Automatic Transaxle Fluid Replacement .......... 0B-11

Automatic Transaxle Fluid Cooler Hose Inspection ........................................................ 0B-11

All Latches, Hinges and Locks Inspection......... 0B-11

HVAC Air Filter (If Equipped) Inspection ........... 0B-12

HVAC Air Filter (If Equipped) Replacement ...... 0B-12

Final Inspection for Maint enance Service ......... 0B-12

Specifications .................... .................................0B-13

Tightening Torque Specifications ...................... 0B-13

Special Tools and Equipmen t ...........................0B-13

Recommended Fluids and Lubricants............... 0B-13

Special Tool ...................................................... 0B-14

Page 31 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-1

General Information

Maintenance and Lubrication

Precautions

Precautions for Maintenance and LubricationS7RS0B0200001

Air Bag Warning

Refer to “Air Bag Warning in Section 00”.

Scheduled Maintenance

Maintenance Schedule under Normal Driving ConditionsS7RS0B0205001

NOTE

• This interval should be judged by odometer reading or months, whichever comes first.

• This table includes service as scheduled up to 90,000 km (54,000 miles) mileage. Beyond 90,000 km

(54,000 miles), carry out the same services at the same intervals respectively.

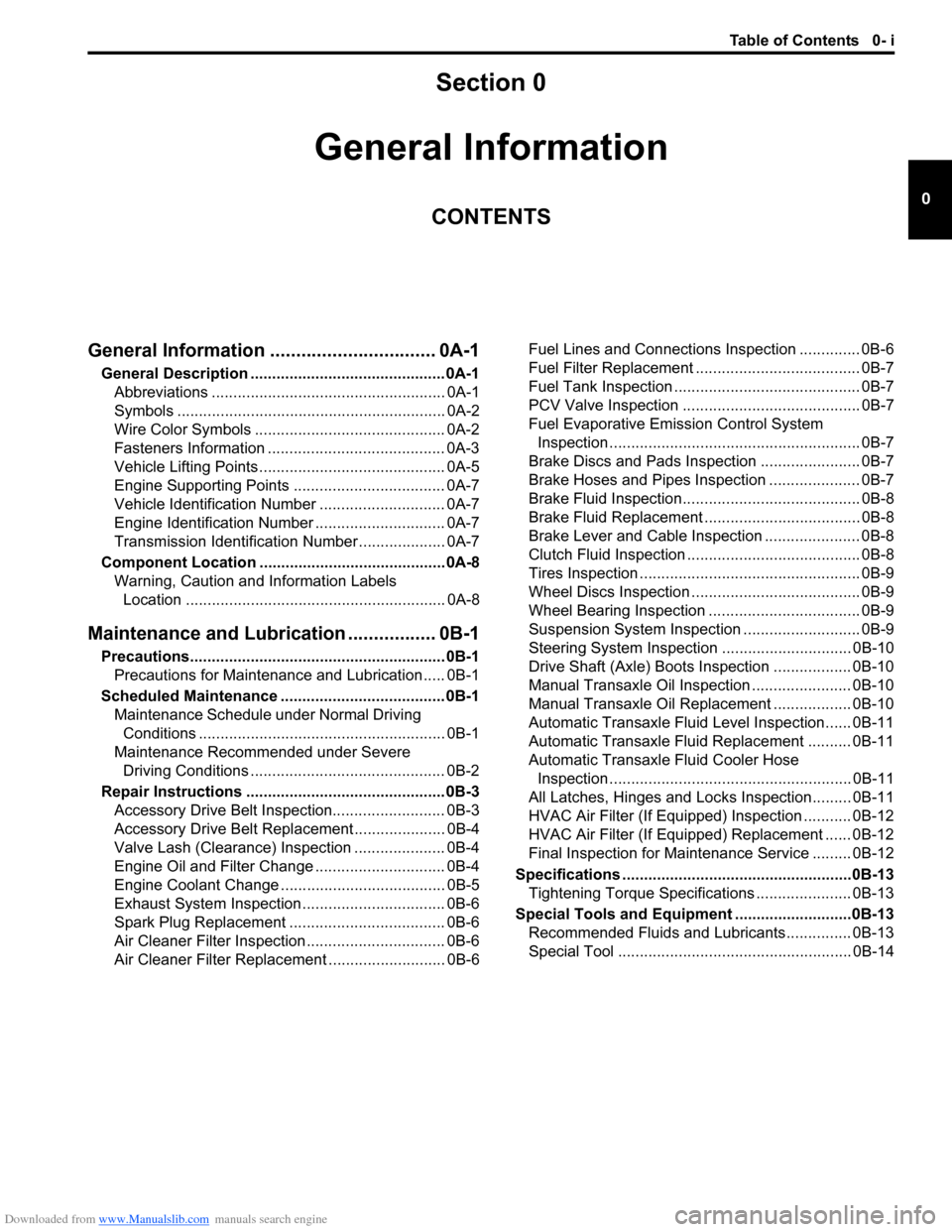

Interval Km (x 1,000) 15 30 45 60 75 90

Miles (x 1,000) 9 18 27 36 45 54

Months 12 24 36 48 60 72

Engine

Accessory drive belt (I: �), R: �))——I——R

Valve lash (clearance) (I: �)) —I—I—I

Engine oil and oil filter (R: �)) RRRRRR

Engine coolant (R: �))— —R— — R

Exhaust system (I: �)) —I—I—I

Ignition system

Spark plugs (R: �) )When unleaded fuel is used Iridium Plug

Replace every 60,000 km (36,000

miles) or 48 months

When leaded fuel is used, refer to “Maintenance Recommended under Severe Driving

Conditions”.

Fuel system

Air cleaner filter (R: �), I: �)) Paved-road

I I R I I R

Dusty conditions Refer to “Maintenance Recommended

under Severe Driv

ing Conditions”.

Fuel lines and connections (I: �)) —I—I—I

Fuel filter (R: �)) (See NOTE below) Replace every 105,000 km (63,000

miles)

Fuel tank (I: �))— —I— — I

Emission control system

PCV valve (I: �)) ————— I

Fuel evaporative emission control system (I: �)) ————— I

Brake

Brake discs and pads (thickness, wear, damage) (I: �)) IIIIII

Brake hoses and pipes (leakage, damage, clamp) (I: �)) —I—I—I

Brake fluid (R: �)) —R—R—R

Brake lever and cable (damage, stroke, operation) (I: �)) Inspect at first 15,000 km (9,000 miles

only)

Chassis and body

Clutch (fluid leakage, level) (I: �)) —I—I—I

Tires (wear, damage, rotation) / wheels (damage) (I: �) / �) ) IIIIII

Suspension system (tightness, damage, rattle, breakage) (I: �)) —I—I—I

Steering system (tightness, damage, breakage, rattle) (I: �)) —I—I—I

Drive shaft (axle) boots (I: �))— —I— — I

Manual transaxle oil (leakage, level) (I: �) 1st 15,000 km only) (R: �))I—R——R

Page 95 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-45

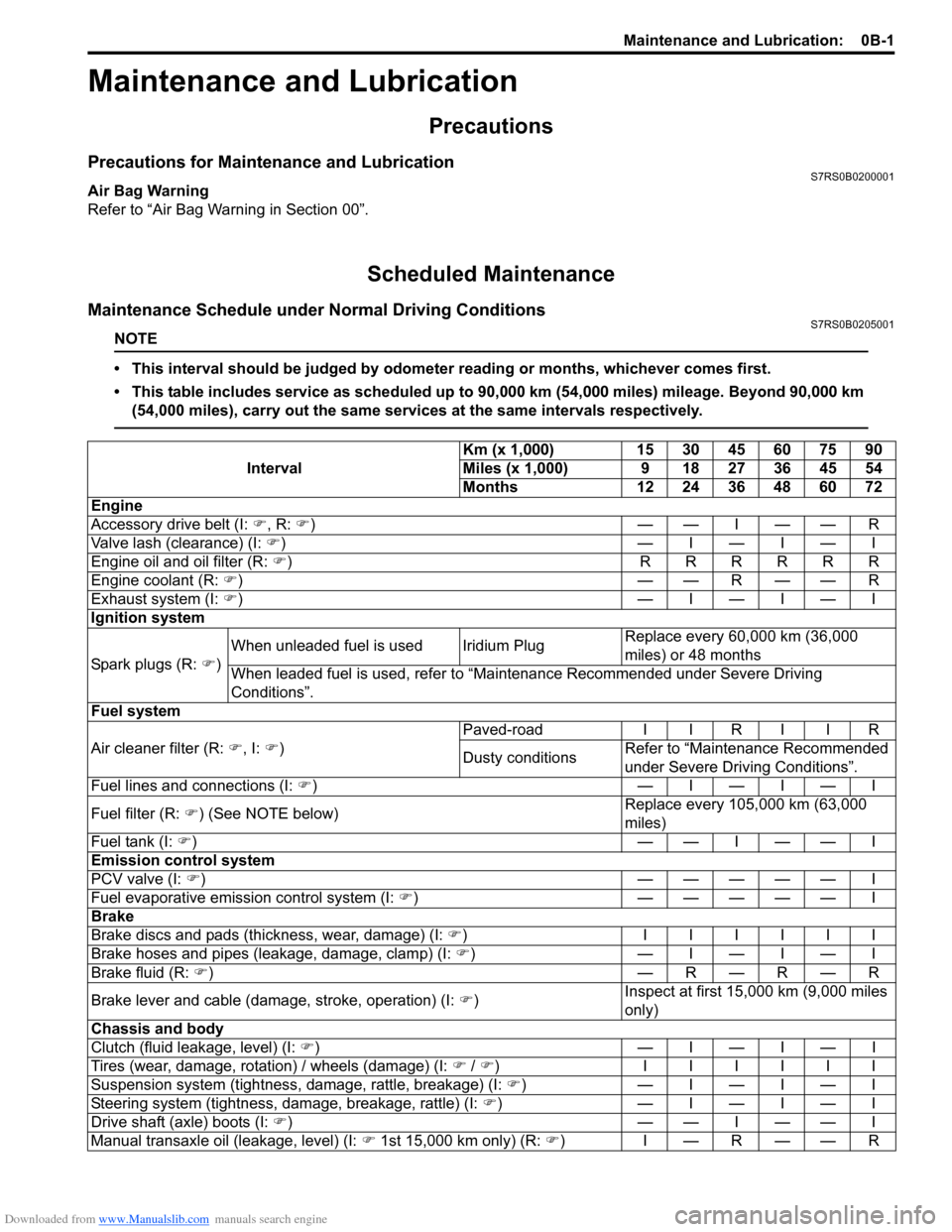

Engine has no powerFaulty spark plug “Spark Plug Inspection in Section 1H”

Faulty ignition coil with ignitor “Ignition Coil Assembly (Including ignitor)

Inspection in Section 1H”

Leaks, loose connection or

disconnection of high-tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Faulty knock sensor “DTC P0327 / P0328: Knock Sensor 1 Circuit

Low / High”

Clogged fuel hose or pipe “Fuel Pressure Check”

Malfunctioning fuel pump “Fuel Pump and Its Circuit Check”

Air drawn in through intake manifold

gasket or throttle body gasket

Engine overheating Condition “Engine overheating”

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Poor performance of ECT sensor or

MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty fuel injector(s) “Fuel Injector Circuit Check”

Faulty ECM

Dragging brakes Condition “Dragging brakes” in “Brakes

Symptom Diagnosis in Section 4A”

Slipping clutch Condition “Slipping clutch” in “Clutch System

Symptom Diagnosis in Section 5C”

Low compression “Compression Check in Section 1D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Improper engine idling or

engine fails to idle Faulty spark plug

“Spark Plug Inspection in Section 1H”

Leaky or disconnected high-tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Faulty ignition coil with ignitor “Ignition Coil Assembly (Including ignitor)

Inspection in Section 1H”

Fuel pressure out of specification “Fuel Pressure Check”

Leaky manifold, throttle body, or cylinder

head gasket

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Faulty evaporative emission control

system “EVAP Canister Purge Inspection in Section

1B”

Faulty EGR system “EGR System Inspection in Section 1B”

Faulty fuel injector(s) “Fuel Injector Circuit Check”

Poor performance of ECT sensor or

MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty ECM

Loose connection or disconnection of

vacuum hoses

Malfunctioning PCV valve “PCV Valve Inspection in Section 1B”

Engine overheating Condition “Engine overheating”

Low compression “Compression Check in Section 1D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Condition Possible cause Correction / Reference Item

Page 290 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-5 Engine Mechanical:

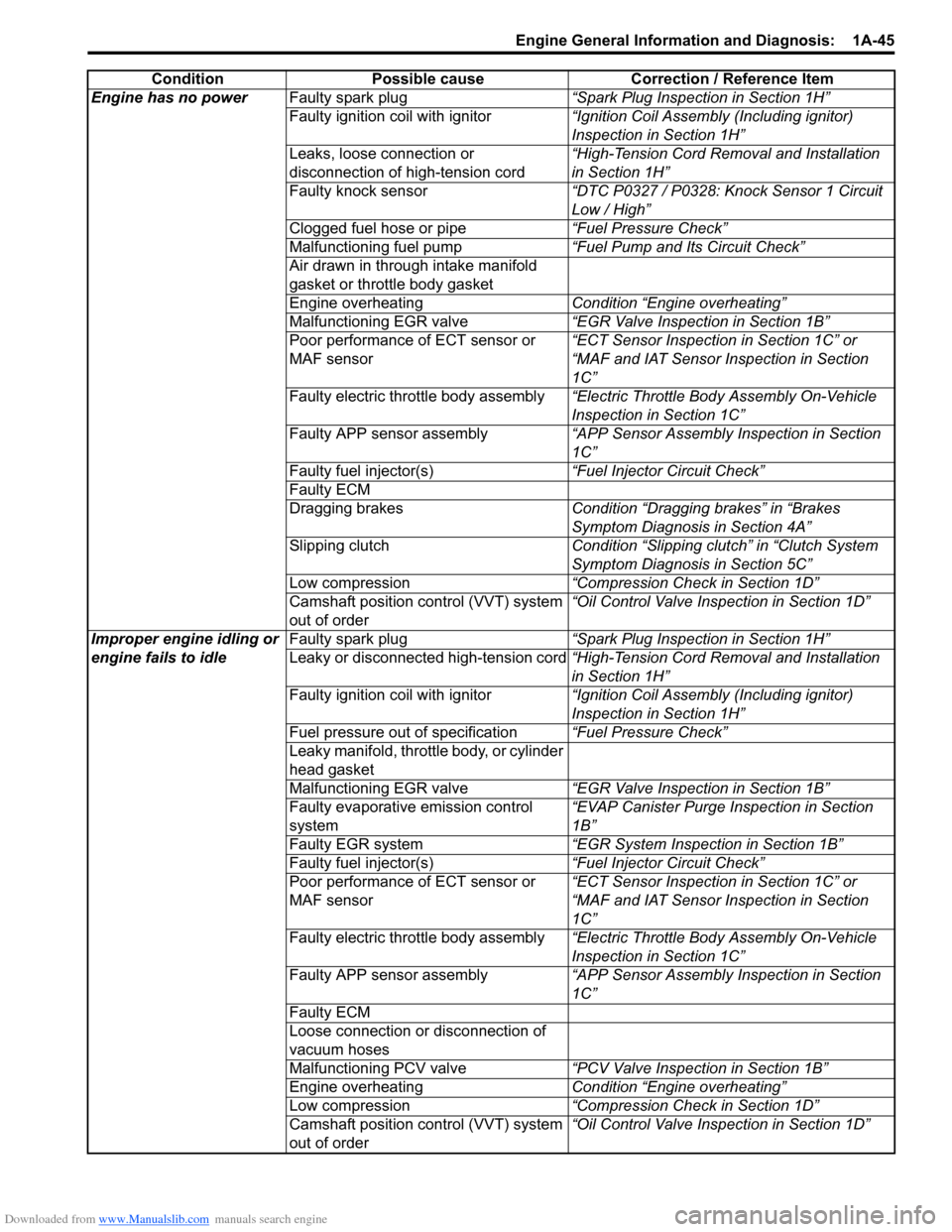

11) Connect negative cable at battery.

12) Install special tools (Compression gauge) into spark plug hole.

Special tool

(A): 09915–64512

(B): 09915–64530

(C): 09915–67010

13) Disengage clutch (1) (to lighten starting load on engine) for M/T vehicle, and depress accelerator

pedal (2) all the way to make throttle fully open.

14) Crank engine with fully charged battery, and read the highest pressure on compression gauge.

NOTE

• For measuring compression pressure, crank engine at least 250 r/min. by using

fully charged battery.

• If measured compression pressure is lower than limit value, check installation

condition of special tool. If it is properly

installed, possibility is compression

pressure leakage from where piston ring

and valve contact.

Compression pressure

Standard: 1400 kPa (14.0 kg/cm2, 199.0 psi)

Limit: 1100 kPa (11.0 kg/cm2, 156.0 psi)

Max. difference between any two cylinders: 100

kPa (1.0 kg/cm

2, 14.2 psi) 15) Carry out Steps 12) through 14) on each cylinder to

obtain 4 readings.

16) Disconnect negative cable at battery.

17) After checking, install spark plugs and ignition coil assemblies (2) with high-tension cord (3).

18) Connect ignition coil couplers (1).

19) Connect fuel injector wires (4) at the coupler.

20) Install cylinder head upper cover.

21) Install air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

22) Install engine cover.

23) Connect negative cable at battery.

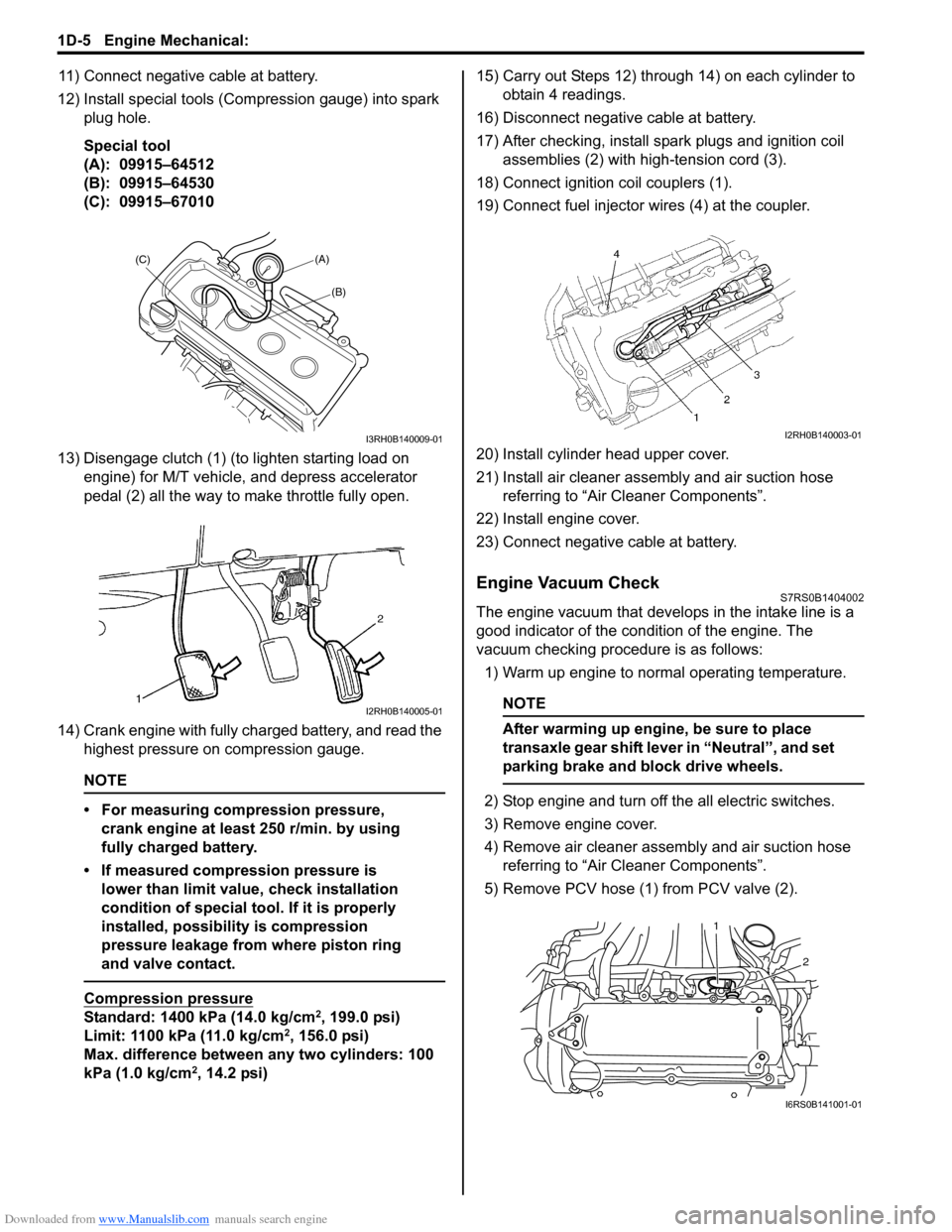

Engine Vacuum CheckS7RS0B1404002

The engine vacuum that develops in the intake line is a

good indicator of the condition of the engine. The

vacuum checking procedure is as follows:

1) Warm up engine to normal operating temperature.

NOTE

After warming up engine, be sure to place

transaxle gear shift lever in “Neutral”, and set

parking brake and block drive wheels.

2) Stop engine and turn off the all electric switches.

3) Remove engine cover.

4) Remove air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

5) Remove PCV hose (1) from PCV valve (2).

(A)

(C)

(B)

I3RH0B140009-01

I2RH0B140005-01

I2RH0B140003-01

2

1

I6RS0B141001-01

Page 302 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-17 Engine Mechanical:

Engine Assembly Removal and InstallationS7RS0B1406011

NOTE

After replacing electric throttle body

assembly, perform calibration of throttle

valve referring to “Electric Throttle Body

System Calibration in Section 1C”.

Removal1) Relieve fuel pressure according to “Fuel Pressure Relief Procedure in Section 1G”.

2) Disconnect negative and pos itive cable at battery.

3) Remove battery and tray.

4) Remove engine hood after disconnecting windshield washer hose.

5) Remove right and left side engine under covers.

6) Remove A/C compressor belt by referring to “Compressor Drive Belt Remo val and Installation in

Section 7B” or “Compressor Drive Belt Removal and

Installation in Section 7B”.

7) Drain engine oil, transaxle oil and coolant.

8) Remove cowl top plate referring to “Cowl Top Components in Section 9K”.

9) Remove air cleaner assembly referring to “Air Cleaner Components”.

10) With hose connected, detach A/C compressor from its bracket (A/C model) referring to “Compressor

Assembly Removal and Installation in Section 7B” or

“Compressor Assembly Removal and Installation in

Section 7B”.

CAUTION!

Suspend removed A/C compressor at a place

where no damage will be caused during

removal and installation of engine assembly.

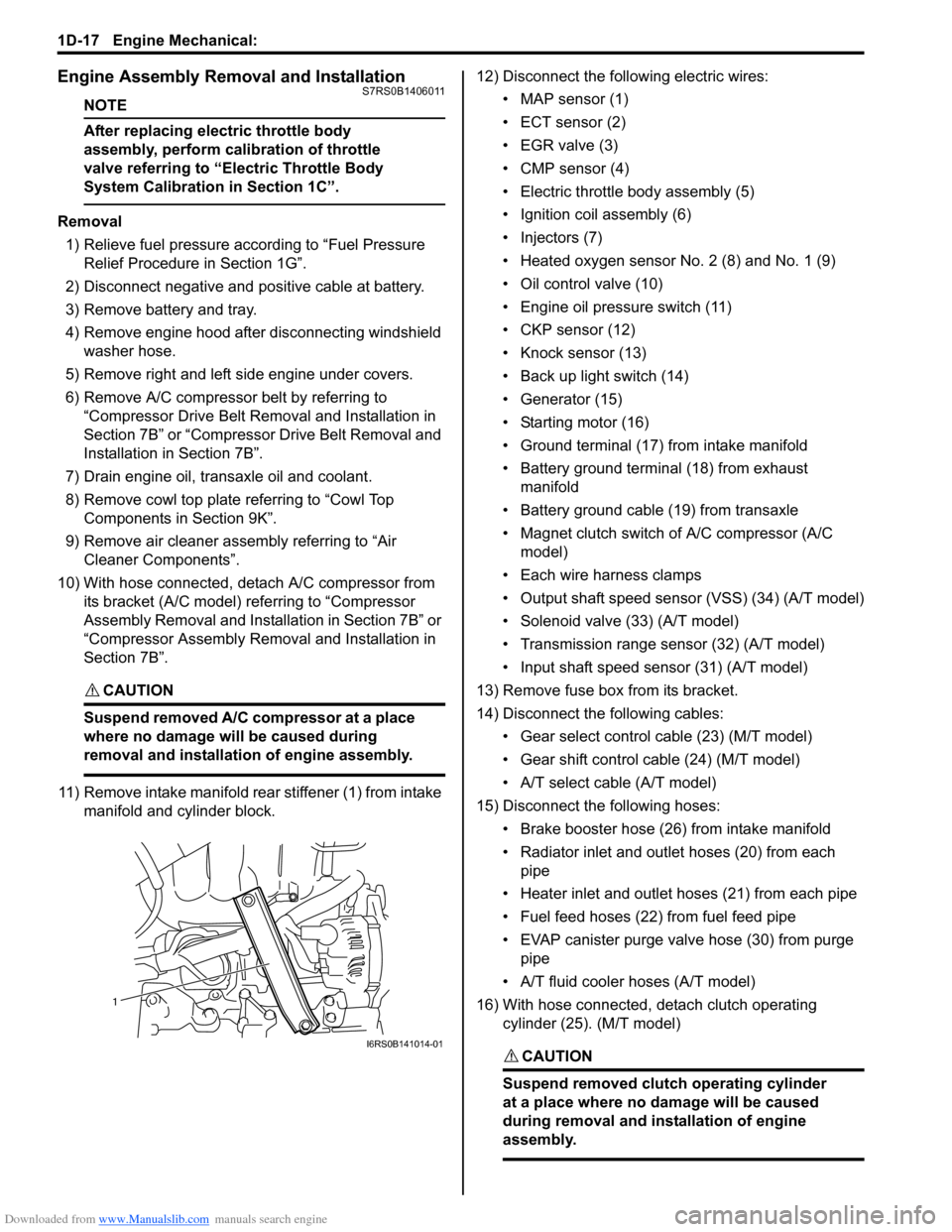

11) Remove intake manifold rear stiffener (1) from intake manifold and cylinder block. 12) Disconnect the following electric wires:

• MAP sensor (1)

• ECT sensor (2)

•EGR valve (3)

• CMP sensor (4)

• Electric throttle body assembly (5)

• Ignition coil assembly (6)

• Injectors (7)

• Heated oxygen sensor No. 2 (8) and No. 1 (9)

• Oil control valve (10)

• Engine oil pressure switch (11)

• CKP sensor (12)

• Knock sensor (13)

• Back up light switch (14)

• Generator (15)

• Starting motor (16)

• Ground terminal (17) from intake manifold

• Battery ground terminal (18) from exhaust manifold

• Battery ground cable (19) from transaxle

• Magnet clutch switch of A/C compressor (A/C model)

• Each wire harness clamps

• Output shaft speed sensor (VSS) (34) (A/T model)

• Solenoid valve (33) (A/T model)

• Transmission range sensor (32) (A/T model)

• Input shaft speed sensor (31) (A/T model)

13) Remove fuse box from its bracket.

14) Disconnect the following cables: • Gear select control cable (23) (M/T model)

• Gear shift control cable (24) (M/T model)

• A/T select cable (A/T model)

15) Disconnect the following hoses: • Brake booster hose (26) from intake manifold

• Radiator inlet and outlet hoses (20) from each pipe

• Heater inlet and outlet hoses (21) from each pipe

• Fuel feed hoses (22) from fuel feed pipe

• EVAP canister purge valve hose (30) from purge pipe

• A/T fluid cooler hoses (A/T model)

16) With hose connected, detach clutch operating cylinder (25). (M/T model)

CAUTION!

Suspend removed clutch operating cylinder

at a place where no damage will be caused

during removal and installation of engine

assembly.

1

I6RS0B141014-01

Page 304 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-19 Engine Mechanical:

24) Before removing engine with transaxle from engine compartment, recheck to make sure all hoses,

electric wires and cables are disconnected from

engine and transaxle.

25) Lower engine with transaxle from engine compartment.

CAUTION!

Before lowering engine, to avoid damage to

A/C compressor and clutch operating

cylinder, make clearance by rising them. Be

sure not to damage suspended A/C

compressor and clutch operating cylinder.

26) Disconnect transaxle from engine, referring to “Manual Transaxle Unit Dismounting and

Remounting in Section 5B” or “Automatic Transaxle

Unit Dismounting and Re mounting in Section 5A”.

27) For M/T model, remove clutch cover and clutch disk referring to “Clutch Cover, Clutch Disc and Flywheel

Removal and Installa tion in Section 5C”.

Installation 1) For M/T model, install clutch cover and clutch disk referring to “Clutch Cover, Clutch Disc and Flywheel

Removal and Installa tion in Section 5C”.

2) Connect transaxle to engine referring to “Manual Transaxle Unit Dismounting and Remounting in

Section 5B” or “Automatic Transaxle Unit

Dismounting and Remounting in Section 5A”.

3) Lift engine and transaxle into engine compartment with jack.

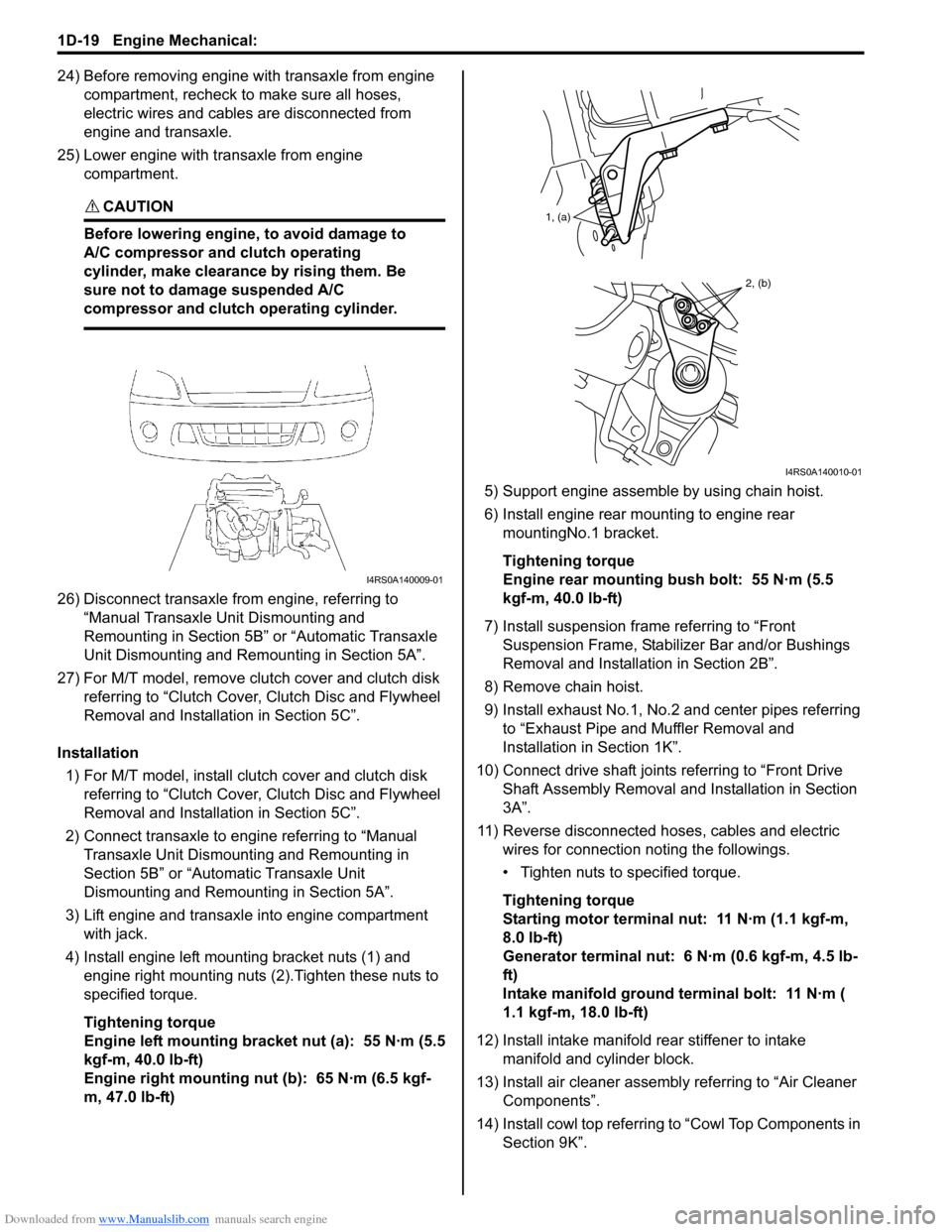

4) Install engine left mounting bracket nuts (1) and engine right mounting nuts (2).Tighten these nuts to

specified torque.

Tightening torque

Engine left mounting bracket nut (a): 55 N·m (5.5

kgf-m, 40.0 lb-ft)

Engine right mounting nut (b): 65 N·m (6.5 kgf-

m, 47.0 lb-ft) 5) Support engine assemble by using chain hoist.

6) Install engine rear mounting to engine rear

mountingNo.1 bracket.

Tightening torque

Engine rear mounting bush bolt: 55 N·m (5.5

kgf-m, 40.0 lb-ft)

7) Install suspension frame referring to “Front Suspension Frame, Stabiliz er Bar and/or Bushings

Removal and Installati on in Section 2B”.

8) Remove chain hoist.

9) Install exhaust No.1, No.2 and center pipes referring to “Exhaust Pipe and Muffler Removal and

Installation in Section 1K”.

10) Connect drive shaft joints referring to “Front Drive Shaft Assembly Removal and Installation in Section

3A”.

11) Reverse disconnected hoses, cables and electric wires for connection noting the followings.

• Tighten nuts to specified torque.

Tightening torque

Starting motor terminal nut: 11 N·m (1.1 kgf-m,

8.0 lb-ft)

Generator terminal nut: 6 N·m (0.6 kgf-m, 4.5 lb-

ft)

Intake manifold ground terminal bolt: 11 N·m (

1.1 kgf-m, 18.0 lb-ft)

12) Install intake manifold rear stiffener to intake

manifold and cylinder block.

13) Install air cleaner assembly referring to “Air Cleaner Components”.

14) Install cowl top referring to “Cowl Top Components in

Section 9K”.

I4RS0A140009-01

1, (a)

2, (b)

I4RS0A140010-01

Page 339 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-54

Main Bearings, Crankshaft and Cylinder Block

Removal and Installation

S7RS0B1406036

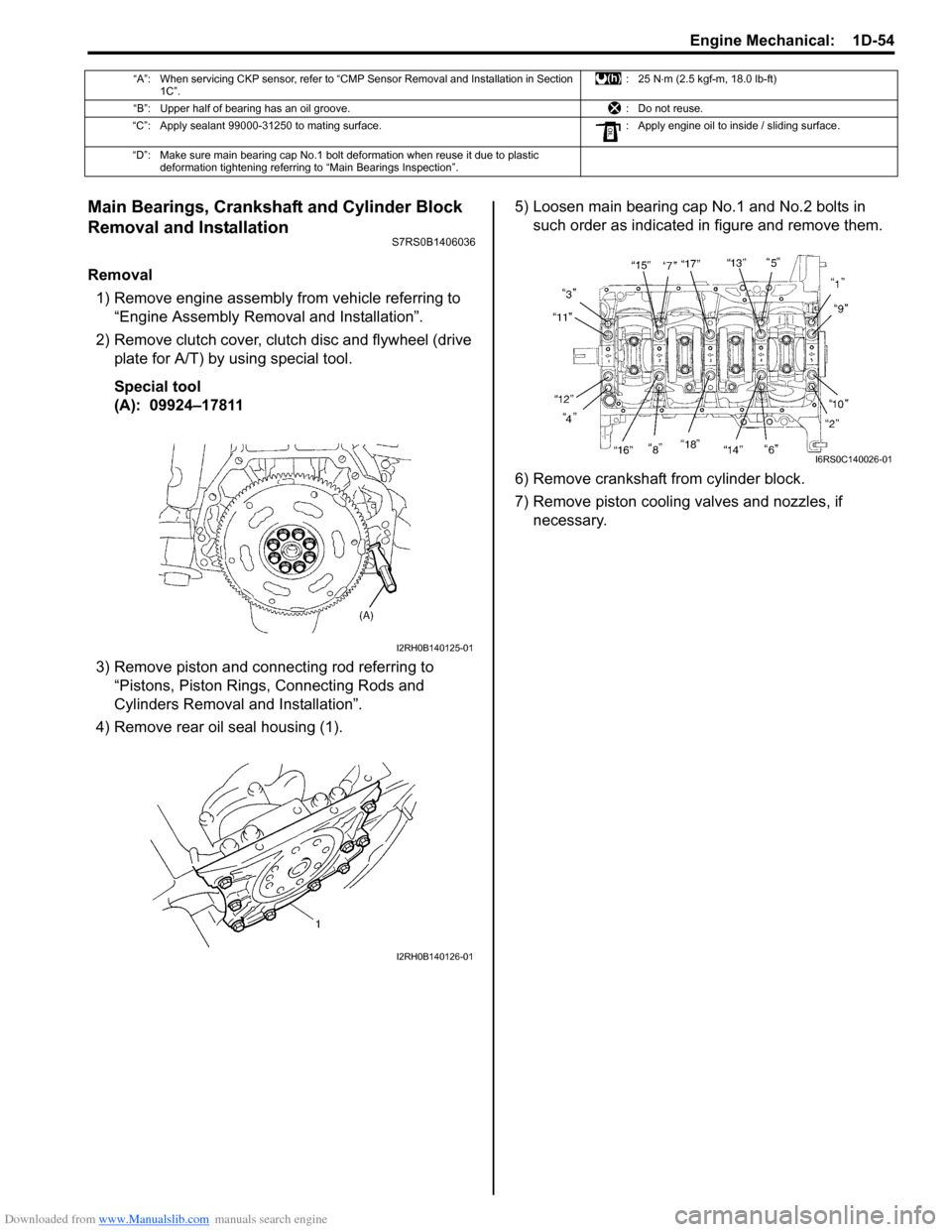

Removal1) Remove engine assembly from vehicle referring to “Engine Assembly Removal and Installation”.

2) Remove clutch cover, clut ch disc and flywheel (drive

plate for A/T) by using special tool.

Special tool

(A): 09924–17811

3) Remove piston and connecting rod referring to “Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation”.

4) Remove rear oil seal housing (1). 5) Loosen main bearing cap No.1 and No.2 bolts in

such order as indicated in figure and remove them.

6) Remove crankshaft from cylinder block.

7) Remove piston cooling valves and nozzles, if necessary.

“A”: When servicing CKP sensor, refer to “CMP Sensor Removal and Installation in Section 1C”. :25 N

⋅m (2.5 kgf-m, 18.0 lb-ft)

“B”: Upper half of bearing has an oil groove. : Do not reuse.

“C”: Apply sealant 99000-31250 to mating surface. : Apply engine oil to inside / sliding surface.

“D”: Make sure main bearing cap No.1 bolt deformation when reuse it due to plastic deformation tightening referring to “Main Bearings Inspection”.

I2RH0B140125-01

I2RH0B140126-01

I6RS0C140026-01

Page 402 of 1496

Downloaded from www.Manualslib.com manuals search engine 1I-1 Starting System:

Engine

Starting System

Schematic and Routing Diagram

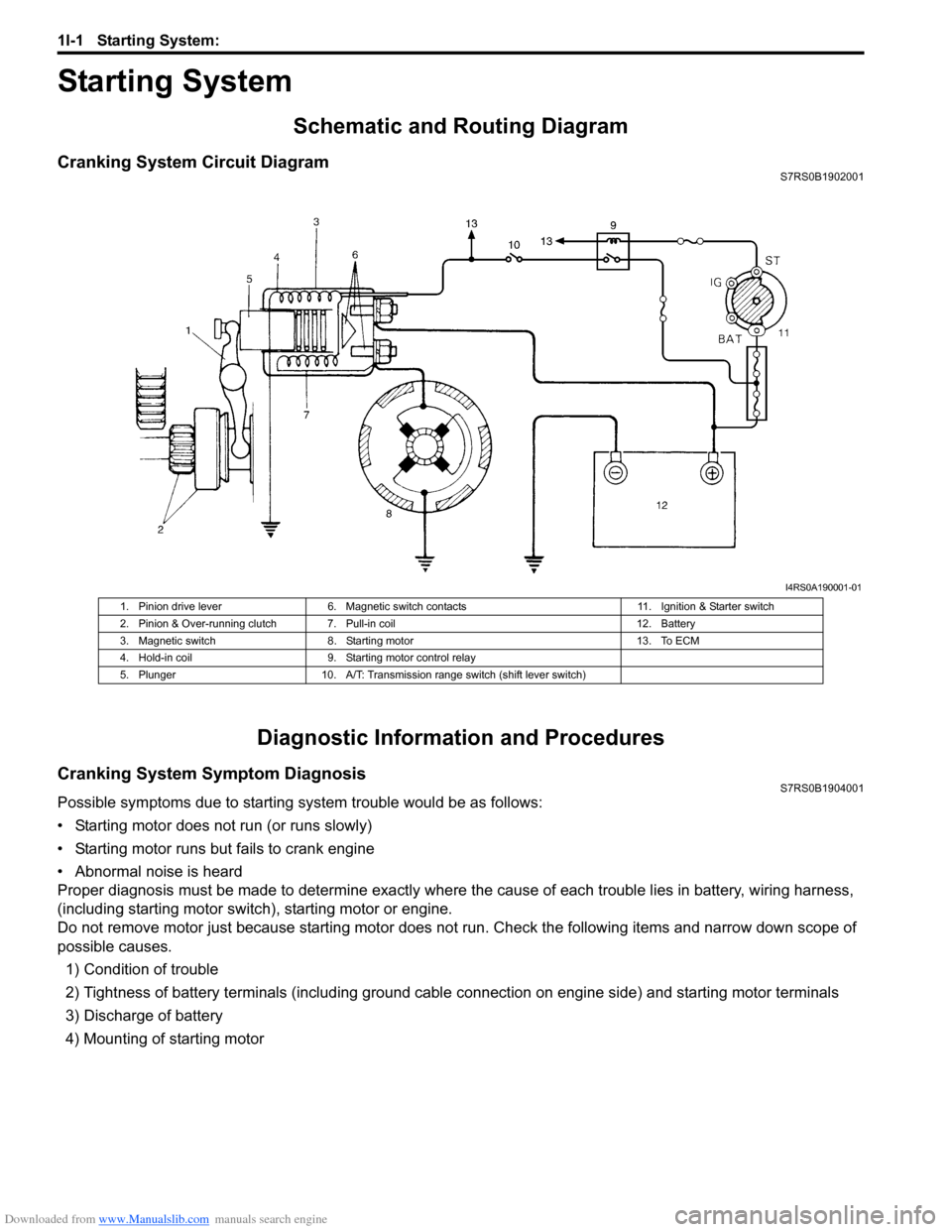

Cranking System Circuit DiagramS7RS0B1902001

Diagnostic Information and Procedures

Cranking System Symptom DiagnosisS7RS0B1904001

Possible symptoms due to starting system trouble would be as follows:

• Starting motor does not run (or runs slowly)

• Starting motor runs but fails to crank engine

• Abnormal noise is heard

Proper diagnosis must be made to determine exactly where the cause of each trouble lies in battery, wiring harness,

(including starting motor switch), starting motor or engine.

Do not remove motor just because starting motor does not run. Check the following items and narrow down scope of

possible causes.

1) Condition of trouble

2) Tightness of battery terminals (including ground cable connection on engine side) and starting motor terminals

3) Discharge of battery

4) Mounting of starting motor

I4RS0A190001-01

1. Pinion drive lever 6. Magnetic switch contacts 11. Ignition & Starter switch

2. Pinion & Over-running clutch 7. Pull-in coil 12. Battery

3. Magnetic switch 8. Starting motor 13. To ECM

4. Hold-in coil 9. Starting motor control relay

5. Plunger 10. A/T: Transmission range switch (shift lever switch)

Page 403 of 1496

Downloaded from www.Manualslib.com manuals search engine Starting System: 1I-2

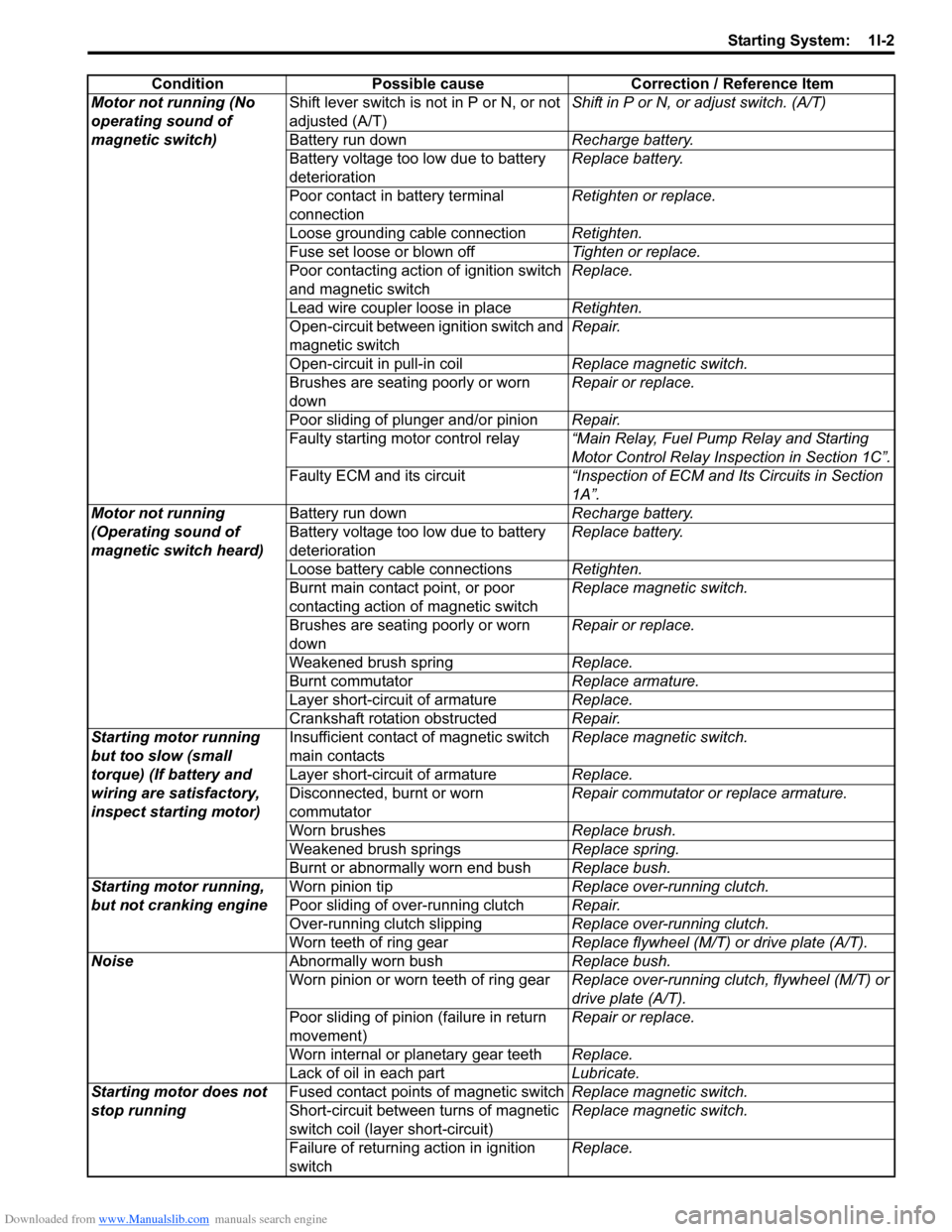

ConditionPossible cause Correction / Reference Item

Motor not running (No

operating sound of

magnetic switch) Shift lever switch is not in P or N, or not

adjusted (A/T)

Shift in P or N, or

adjust switch. (A/T)

Battery run down Recharge battery.

Battery voltage too low due to battery

deterioration Replace battery.

Poor contact in battery terminal

connection Retighten or replace.

Loose grounding cable connection Retighten.

Fuse set loose or blown off Tighten or replace.

Poor contacting action of ignition switch

and magnetic switch Replace.

Lead wire coupler loose in place Retighten.

Open-circuit between ignition switch and

magnetic switch Repair.

Open-circuit in pull-in coil Replace magnetic switch.

Brushes are seating poorly or worn

down Repair or replace.

Poor sliding of plunger and/or pinion Repair.

Faulty starting motor control relay “Main Relay, Fuel Pump Relay and Starting

Motor Control Relay Inspection in Section 1C”.

Faulty ECM and its circuit “Inspection of ECM and Its Circuits in Section

1A”.

Motor not running

(Operating sound of

magnetic switch heard) Battery run down

Recharge battery.

Battery voltage too low due to battery

deterioration Replace battery.

Loose battery cable connections Retighten.

Burnt main contact point, or poor

contacting action of magnetic switch Replace magnetic switch.

Brushes are seating poorly or worn

down Repair or replace.

Weakened brush spring Replace.

Burnt commutator Replace armature.

Layer short-circuit of armature Replace.

Crankshaft rotation obstructed Repair.

Starting motor running

but too slow (small

torque) (If battery and

wiring are satisfactory,

inspect starting motor) Insufficient contact

of magnetic switch

main contacts Replace magnetic switch.

Layer short-circuit of armature Replace.

Disconnected, burnt or worn

commutator Repair commutator or replace armature.

Worn brushes Replace brush.

Weakened brush springs Replace spring.

Burnt or abnormally worn end bush Replace bush.

Starting motor running,

but not cranking engine Worn pinion tip

Replace over-running clutch.

Poor sliding of over-running clutch Repair.

Over-running clutch slipping Replace over-running clutch.

Worn teeth of ring gear Replace flywheel (M/T) or drive plate (A/T).

Noise Abnormally worn bush Replace bush.

Worn pinion or worn teeth of ring gear Replace over-running clutch, flywheel (M/T) or

drive plate (A/T).

Poor sliding of pinion (failure in return

movement) Repair or replace.

Worn internal or planetary gear teeth Replace.

Lack of oil in each part Lubricate.

Starting motor does not

stop running Fused contact points of magnetic switch

Replace magnetic switch.

Short-circuit between turns of magnetic

switch coil (layer short-circuit) Replace magnetic switch.

Failure of returning action in ignition

switch Replace.

Page 510 of 1496

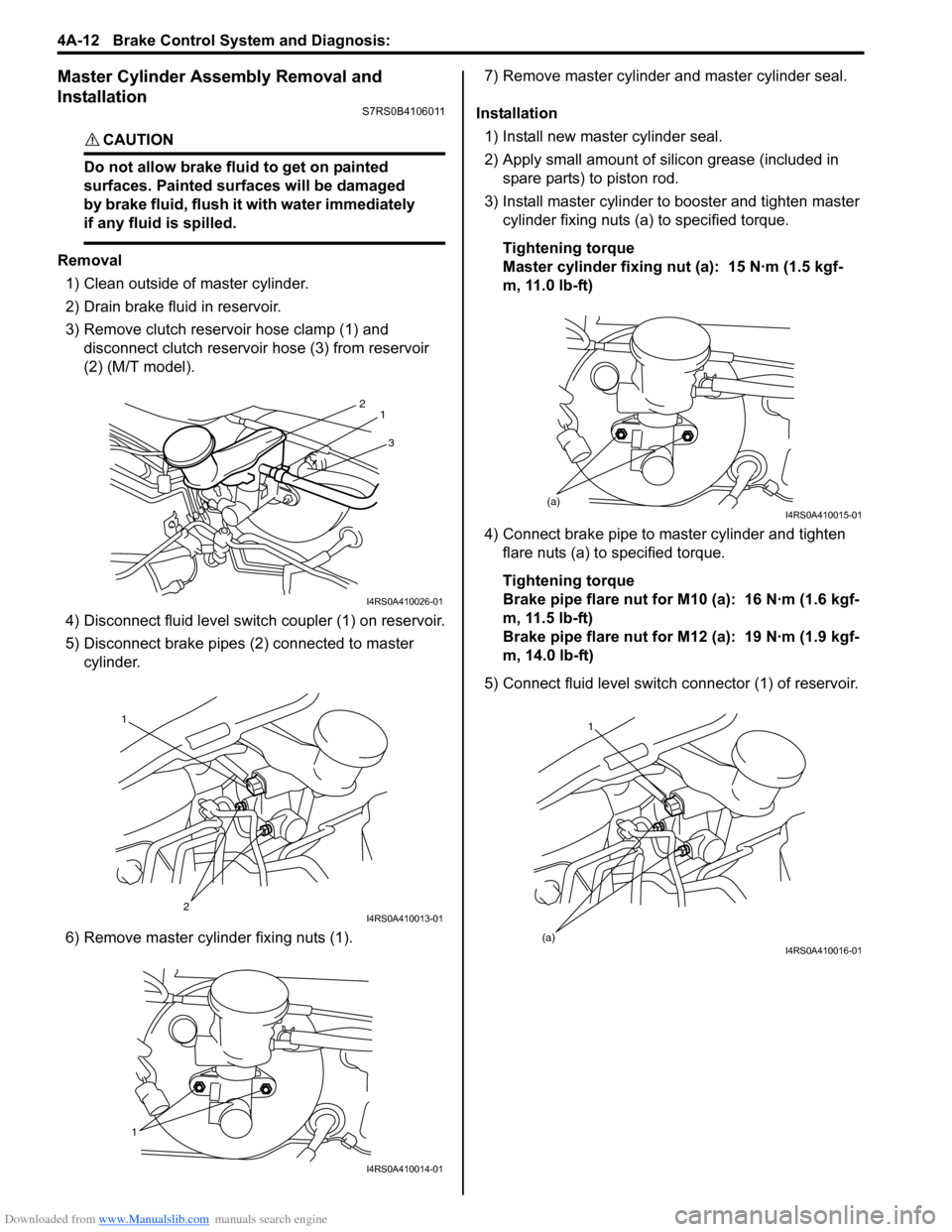

Downloaded from www.Manualslib.com manuals search engine 4A-12 Brake Control System and Diagnosis:

Master Cylinder Assembly Removal and

Installation

S7RS0B4106011

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Clean outside of master cylinder.

2) Drain brake fluid in reservoir.

3) Remove clutch reservoir hose clamp (1) and disconnect clutch reservoir hose (3) from reservoir

(2) (M/T model).

4) Disconnect fluid level switch coupler (1) on reservoir.

5) Disconnect brake pipes (2) connected to master cylinder.

6) Remove master cylinder fixing nuts (1). 7) Remove master cylinder and master cylinder seal.

Installation 1) Install new master cylinder seal.

2) Apply small amount of silic on grease (included in

spare parts) to piston rod.

3) Install master cylinder to booster and tighten master cylinder fixing nuts (a) to specified torque.

Tightening torque

Master cylinder fixing nut (a): 15 N·m (1.5 kgf-

m, 11.0 lb-ft)

4) Connect brake pipe to master cylinder and tighten flare nuts (a) to specified torque.

Tightening torque

Brake pipe flare nut for M10 (a): 16 N·m (1.6 kgf-

m, 11.5 lb-ft)

Brake pipe flare nut for M12 (a): 19 N·m (1.9 kgf-

m, 14.0 lb-ft)

5) Connect fluid level switch connector (1) of reservoir.

3

2

1

I4RS0A410026-01

1

2

I4RS0A410013-01

1

I4RS0A410014-01

(a)I4RS0A410015-01

1

(a)

I4RS0A410016-01