clutch disc SUZUKI SWIFT 2008 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 511 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-13

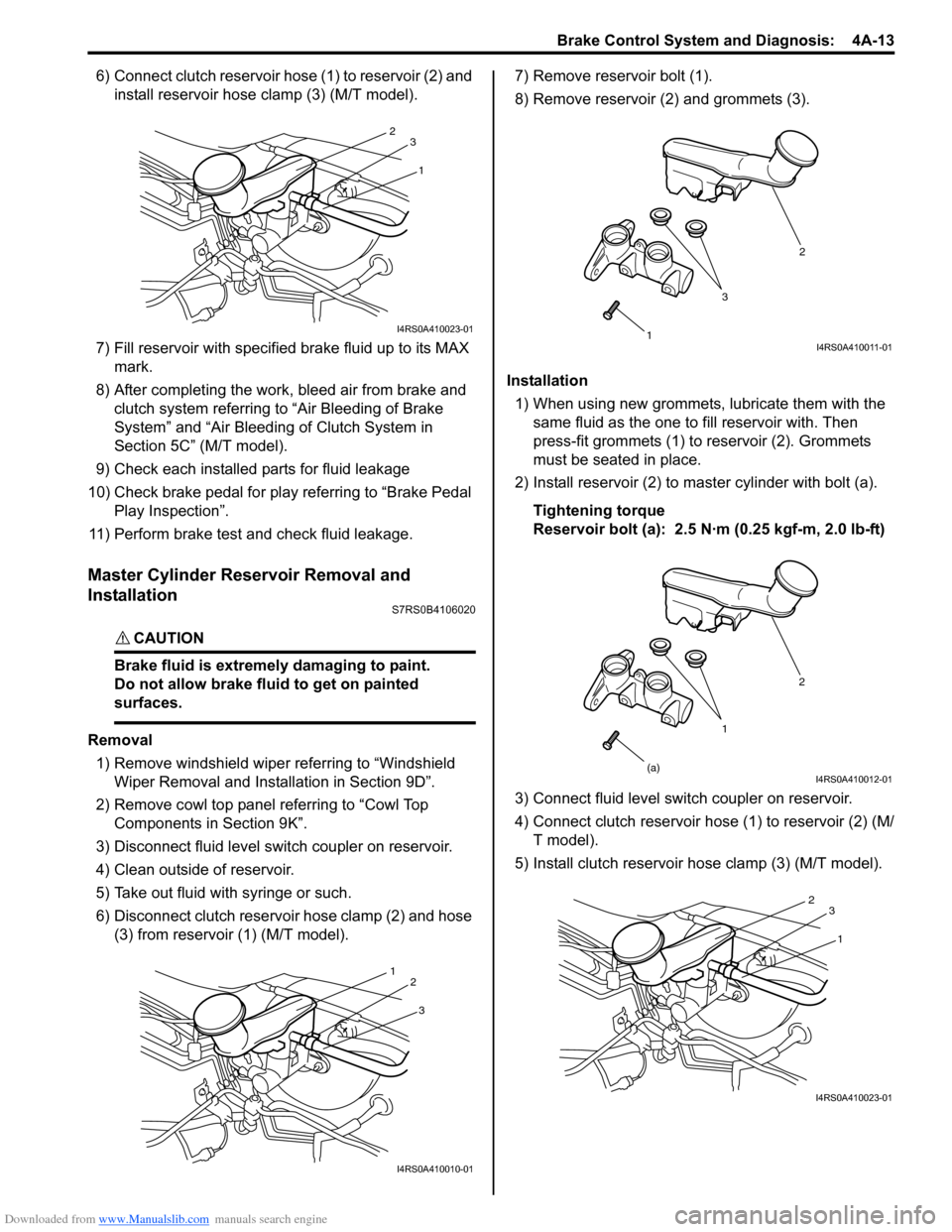

6) Connect clutch reservoir hose (1) to reservoir (2) and install reservoir hose clamp (3) (M/T model).

7) Fill reservoir with specified brake fluid up to its MAX

mark.

8) After completing the work, bleed air from brake and clutch system referring to “Air Bleeding of Brake

System” and “Air Bleeding of Clutch System in

Section 5C” (M/T model).

9) Check each installed parts for fluid leakage

10) Check brake pedal for play referring to “Brake Pedal Play Inspection”.

11) Perform brake test and check fluid leakage.

Master Cylinder Reservoir Removal and

Installation

S7RS0B4106020

CAUTION!

Brake fluid is extremely damaging to paint.

Do not allow brake fluid to get on painted

surfaces.

Removal 1) Remove windshield wiper referring to “Windshield Wiper Removal and Insta llation in Section 9D”.

2) Remove cowl top panel referring to “Cowl Top Components in Section 9K”.

3) Disconnect fluid level s witch coupler on reservoir.

4) Clean outside of reservoir.

5) Take out fluid with syringe or such.

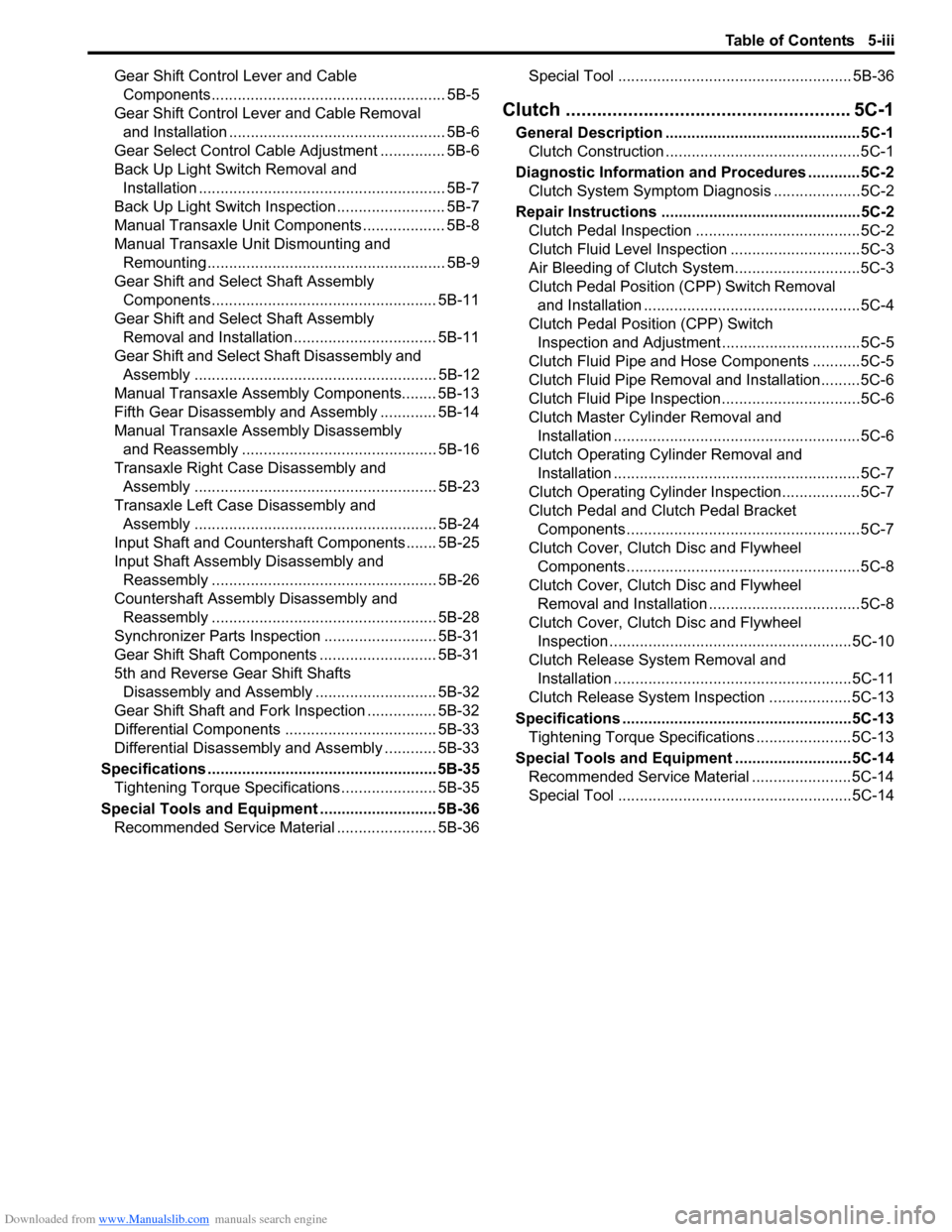

6) Disconnect clutch reservoir hose clamp (2) and hose (3) from reservoir (1) (M/T model). 7) Remove reservoir bolt (1).

8) Remove reservoir (2) and grommets (3).

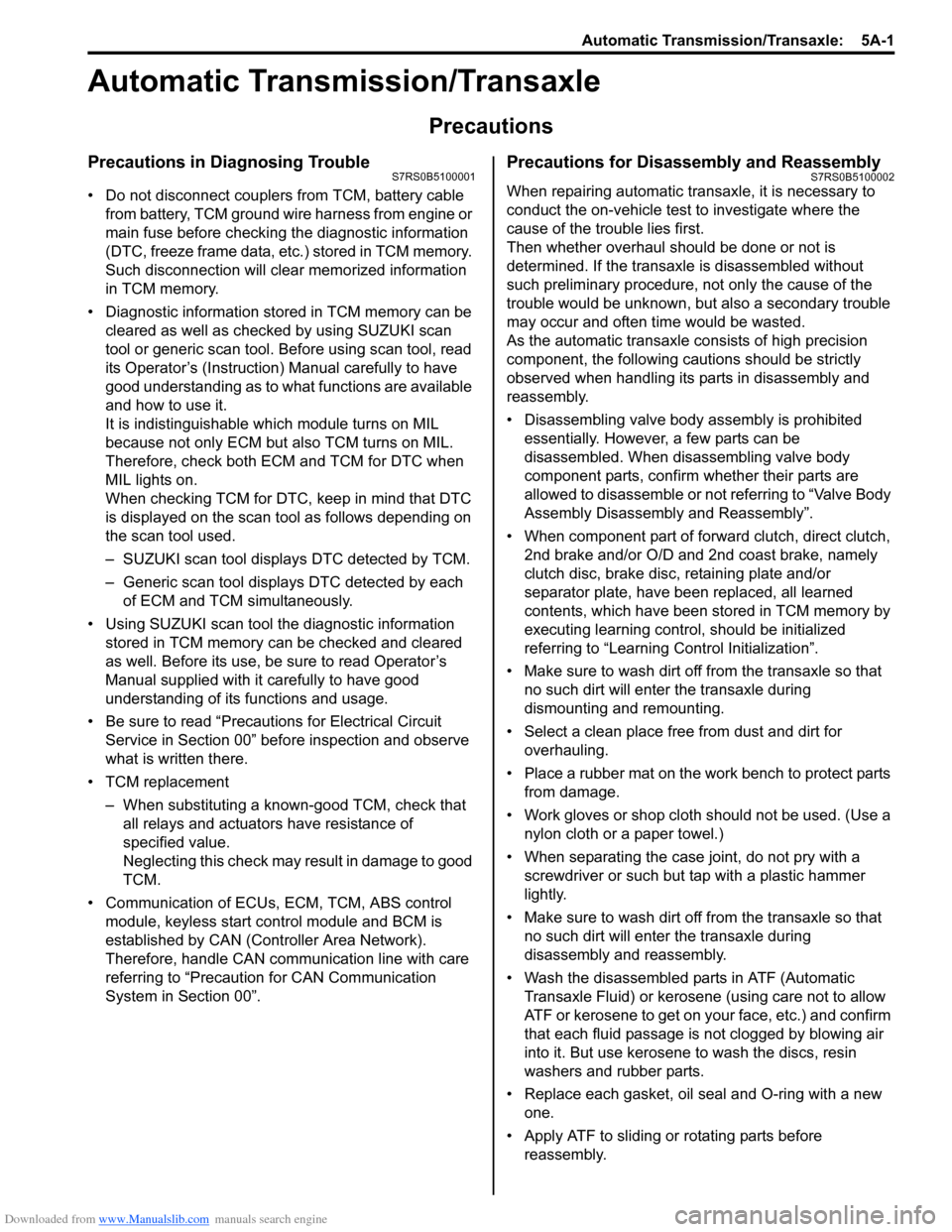

Installation 1) When using new grommets, lubricate them with the same fluid as the one to fill reservoir with. Then

press-fit grommets (1) to reservoir (2). Grommets

must be seated in place.

2) Install reservoir (2) to master cylinder with bolt (a).

Tightening torque

Reservoir bolt (a): 2.5 N·m (0.25 kgf-m, 2.0 lb-ft)

3) Connect fluid level switch coupler on reservoir.

4) Connect clutch reservoir hose (1) to reservoir (2) (M/ T model).

5) Install clutch reservoir hose clamp (3) (M/T model).

1

2

3

I4RS0A410023-01

3

1

2

I4RS0A410010-01

1 2

3I4RS0A410011-01

1 2

(a)

I4RS0A410012-01

1

2

3

I4RS0A410023-01

Page 643 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 5-iii

Gear Shift Control Lever and Cable Components...................................................... 5B-5

Gear Shift Control Le ver and Cable Removal

and Installation .................................................. 5B-6

Gear Select Control Cable Adjustment ............... 5B-6

Back Up Light Switch Removal and Installation ......................................................... 5B-7

Back Up Light Switch Inspection ......................... 5B-7

Manual Transaxle Unit Components ................... 5B-8

Manual Transaxle Unit Dismounting and Remounting....................................................... 5B-9

Gear Shift and Sele ct Shaft Assembly

Components.................................................... 5B-11

Gear Shift and Sele ct Shaft Assembly

Removal and Installation................................. 5B-11

Gear Shift and Select Shaft Disassembly and Assembly ........................................................ 5B-12

Manual Transaxle Assembly Components........ 5B-13

Fifth Gear Disassembly and Assembly ............. 5B-14

Manual Transaxle Assembly Disassembly and Reassembly ............................................. 5B-16

Transaxle Right Case Disassembly and Assembly ........................................................ 5B-23

Transaxle Left Case Disassembly and Assembly ........................................................ 5B-24

Input Shaft and Countershaft Components....... 5B-25

Input Shaft Assembly Disassembly and Reassembly .................................................... 5B-26

Countershaft Assembly Disassembly and Reassembly .................................................... 5B-28

Synchronizer Parts Inspec tion .......................... 5B-31

Gear Shift Shaft Components ........................... 5B-31

5th and Reverse Gear Shift Shafts Disassembly and Assembly ............................ 5B-32

Gear Shift Shaft and Fork Inspection ................ 5B-32

Differential Components ................................... 5B-33

Differential Disassembly and Assembly ............ 5B-33

Specifications ..................................................... 5B-35

Tightening Torque Specifications ...................... 5B-35

Special Tools and Equipmen t ........................... 5B-36

Recommended Service Material ....................... 5B-36 Special Tool ...................................................... 5B-36

Clutch ................

.............................. ......... 5C-1

General Description .............................................5C-1

Clutch Construction .............................................5C-1

Diagnostic Information and Procedures ............5C-2 Clutch System Symptom Diagnosis ....................5C-2

Repair Instructions ........... ...................................5C-2

Clutch Pedal Inspection ......................................5C-2

Clutch Fluid Level Inspection ..............................5C-3

Air Bleeding of Clutch System.............................5C-3

Clutch Pedal Position (CPP) Switch Removal and Installation ..................................................5C-4

Clutch Pedal Position (CPP) Switch Inspection and Adjustment ................................5C-5

Clutch Fluid Pipe and Hose Components ...........5C-5

Clutch Fluid Pipe Removal and Installation.........5C-6

Clutch Fluid Pipe Inspection................................5C-6

Clutch Master Cylinder Removal and Installation .........................................................5C-6

Clutch Operating Cylinder Removal and Installation .........................................................5C-7

Clutch Operating Cylinder Inspection..................5C-7

Clutch Pedal and Clutch Pedal Bracket Components ......................................................5C-7

Clutch Cover, Clutch Disc and Flywheel Components ......................................................5C-8

Clutch Cover, Clutch Disc and Flywheel Removal and Installation ...................................5C-8

Clutch Cover, Clutch Disc and Flywheel Inspection ........................................................5C-10

Clutch Release Syst em Removal and

Installation .......................................................5C-11

Clutch Release System Inspection ...................5C-13

Specifications .................... .................................5C-13

Tightening Torque Specifications ......................5C-13

Special Tools and Equipmen t ...........................5C-14

Recommended Service Material .......................5C-14

Special Tool ......................................................5C-14

Page 645 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-1

Transmission / Transaxle

Automatic Transmission/Transaxle

Precautions

Precautions in Diagnosing TroubleS7RS0B5100001

• Do not disconnect couplers from TCM, battery cable from battery, TCM ground wire harness from engine or

main fuse before checking the diagnostic information

(DTC, freeze frame data, etc.) stored in TCM memory.

Such disconnection will clea r memorized information

in TCM memory.

• Diagnostic information stored in TCM memory can be cleared as well as checked by using SUZUKI scan

tool or generic scan tool. Before using scan tool, read

its Operator’s (Instruction) Manual carefully to have

good understanding as to what functions are available

and how to use it.

It is indistinguishable wh ich module turns on MIL

because not only ECM but also TCM turns on MIL.

Therefore, check both ECM and TCM for DTC when

MIL lights on.

When checking TCM for DTC, keep in mind that DTC

is displayed on the scan tool as follows depending on

the scan tool used.

– SUZUKI scan tool displays DTC detected by TCM.

– Generic scan tool displays DTC detected by each of ECM and TCM simultaneously.

• Using SUZUKI scan tool the diagnostic information stored in TCM memory can be checked and cleared

as well. Before its use, be sure to read Operator’s

Manual supplied with it carefully to have good

understanding of its functions and usage.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• TCM replacement

– When substituting a known-good TCM, check that all relays and actuators have resistance of

specified value.

Neglecting this check may result in damage to good

TCM.

• Communication of ECUs , ECM, TCM, ABS control

module, keyless start control module and BCM is

established by CAN (Controller Area Network).

Therefore, handle CAN communication line with care

referring to “Precaution for CAN Communication

System in Section 00”.

Precautions for Disassembly and ReassemblyS7RS0B5100002

When repairing automatic transaxle, it is necessary to

conduct the on-vehicle test to investigate where the

cause of the trouble lies first.

Then whether overhaul should be done or not is

determined. If the transaxle is disassembled without

such preliminary procedure, not only the cause of the

trouble would be unknown, but also a secondary trouble

may occur and often time would be wasted.

As the automatic transaxle consists of high precision

component, the following cautions should be strictly

observed when handling its parts in disassembly and

reassembly.

• Disassembling valve body assembly is prohibited

essentially. However, a few parts can be

disassembled. When disassembling valve body

component parts, confirm whether their parts are

allowed to disassemble or not referring to “Valve Body

Assembly Disassembly and Reassembly”.

• When component part of forward clutch, direct clutch, 2nd brake and/or O/D and 2nd coast brake, namely

clutch disc, brake disc, retaining plate and/or

separator plate, have been replaced, all learned

contents, which have been stored in TCM memory by

executing learning control, should be initialized

referring to “Learning Control Initialization”.

• Make sure to wash dirt off from the transaxle so that no such dirt will enter the transaxle during

dismounting and remounting.

• Select a clean place free from dust and dirt for overhauling.

• Place a rubber mat on the work bench to protect parts from damage.

• Work gloves or shop cloth should not be used. (Use a nylon cloth or a paper towel.)

• When separating the case joint, do not pry with a screwdriver or such but tap with a plastic hammer

lightly.

• Make sure to wash dirt off from the transaxle so that no such dirt will enter the transaxle during

disassembly and reassembly.

• Wash the disassembled parts in ATF (Automatic Transaxle Fluid) or kerosene (using care not to allow

ATF or kerosene to get on your face, etc.) and confirm

that each fluid passage is not clogged by blowing air

into it. But use kerosene to wash the discs, resin

washers and rubber parts.

• Replace each gasket, oil seal and O-ring with a new one.

• Apply ATF to sliding or rotating parts before

reassembly.

Page 646 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-2 Automatic Transmission/Transaxle:

CAUTION!

• Keep component parts in group for each subassembly and avoid mixing them up.

• Clean all parts with cleaning solvent thoroughly and air dry them.

• Use kerosene or automatic transaxle fluid as cleaning solvent.

• Do not use wiping cloths or rags to clean or dry parts.

• All oil passages should be blown out and checked to make sure that they are not

obstructed.

• Keep face and eyes away from solvent spray while air blowing parts.

• Check mating surface for irregularities and remove them, if any, and clean it again.

• Soak new clutch discs and brake discs in transaxle fluid for at least 2 hours before

assembly.

• Replace all gaskets and O-ring with new ones.

• Apply automatic transaxle fluid to all O- rings.

• When installing seal ring, be careful so that it is not expanded excessively, extruded or

caught.

• Replace oil seals that are removed and apply grease to their lips.

• Before installing, be sure to apply automatic transaxle fluid to sliding, rolling

and thrusting surface of all component

part. Also after installation, make sure to

check each part for proper operation.

• Always use torque wrench when tightening bolts.

• A new discs should be soaked in ATF at least 2 hours before use.

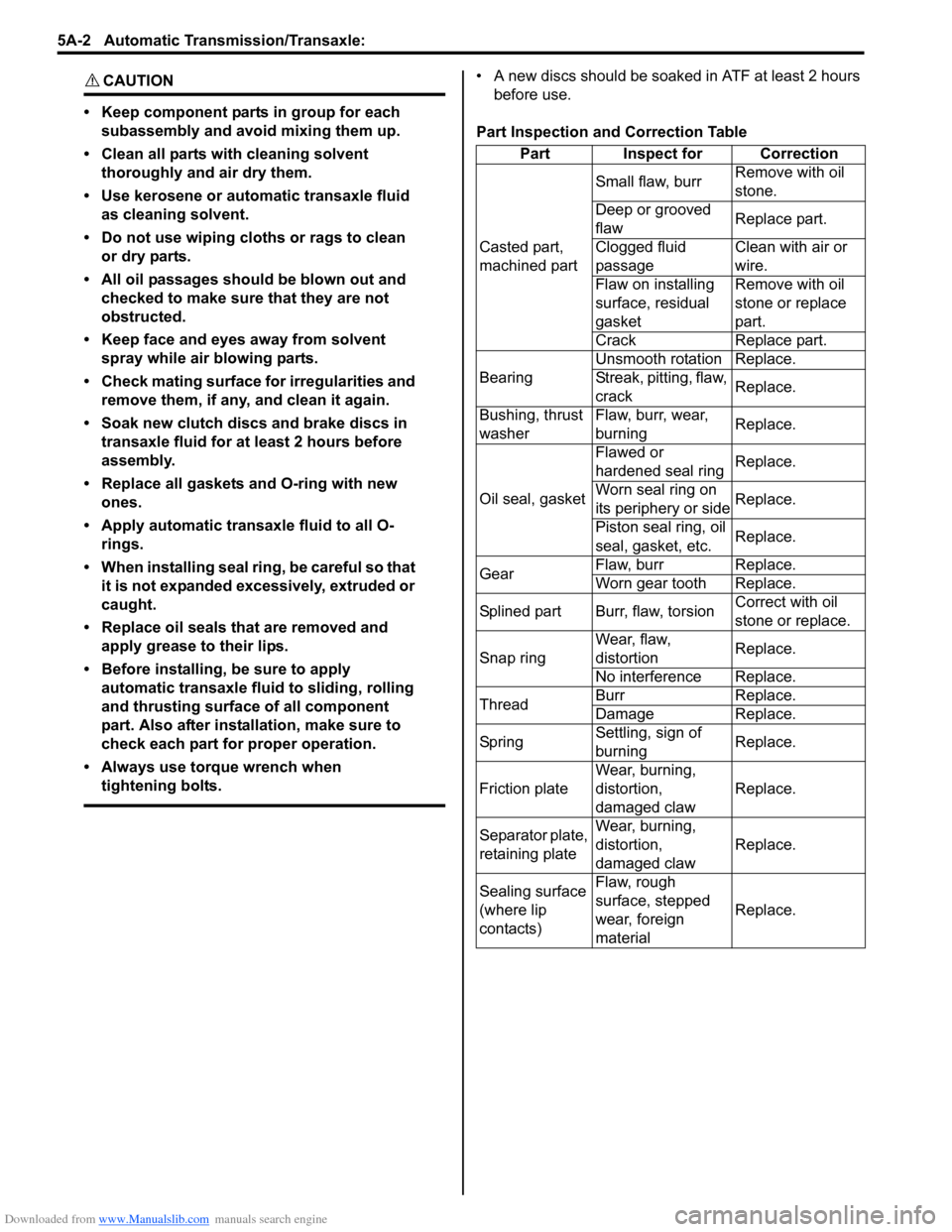

Part Inspection and Correction Table Part Inspect for Correction

Casted part,

machined part Small flaw, burr

Remove with oil

stone.

Deep or grooved

flaw Replace part.

Clogged fluid

passage Clean with air or

wire.

Flaw on installing

surface, residual

gasket Remove with oil

stone or replace

part.

Crack Replace part.

Bearing Unsmooth rotation Replace.

Streak, pitting, flaw,

crack

Replace.

Bushing, thrust

washer Flaw, burr, wear,

burning

Replace.

Oil seal, gasket Flawed or

hardened seal ring

Replace.

Worn seal ring on

its periphery or side Replace.

Piston seal ring, oil

seal, gasket, etc. Replace.

Gear Flaw, burr Replace.

Worn gear tooth Replace.

Splined part Burr, flaw, torsion Correct with oil

stone or replace.

Snap ring Wear, flaw,

distortion

Replace.

No interference Replace.

Thread Burr Replace.

Damage Replace.

Sp rin g Settling, sign of

burning Replace.

Friction plate Wear, burning,

distortion,

damaged claw Replace.

Separator plate,

retaining plate Wear, burning,

distortion,

damaged claw

Replace.

Sealing surface

(where lip

contacts) Flaw, rough

surface, stepped

wear, foreign

material

Replace.

Page 647 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-3

General Description

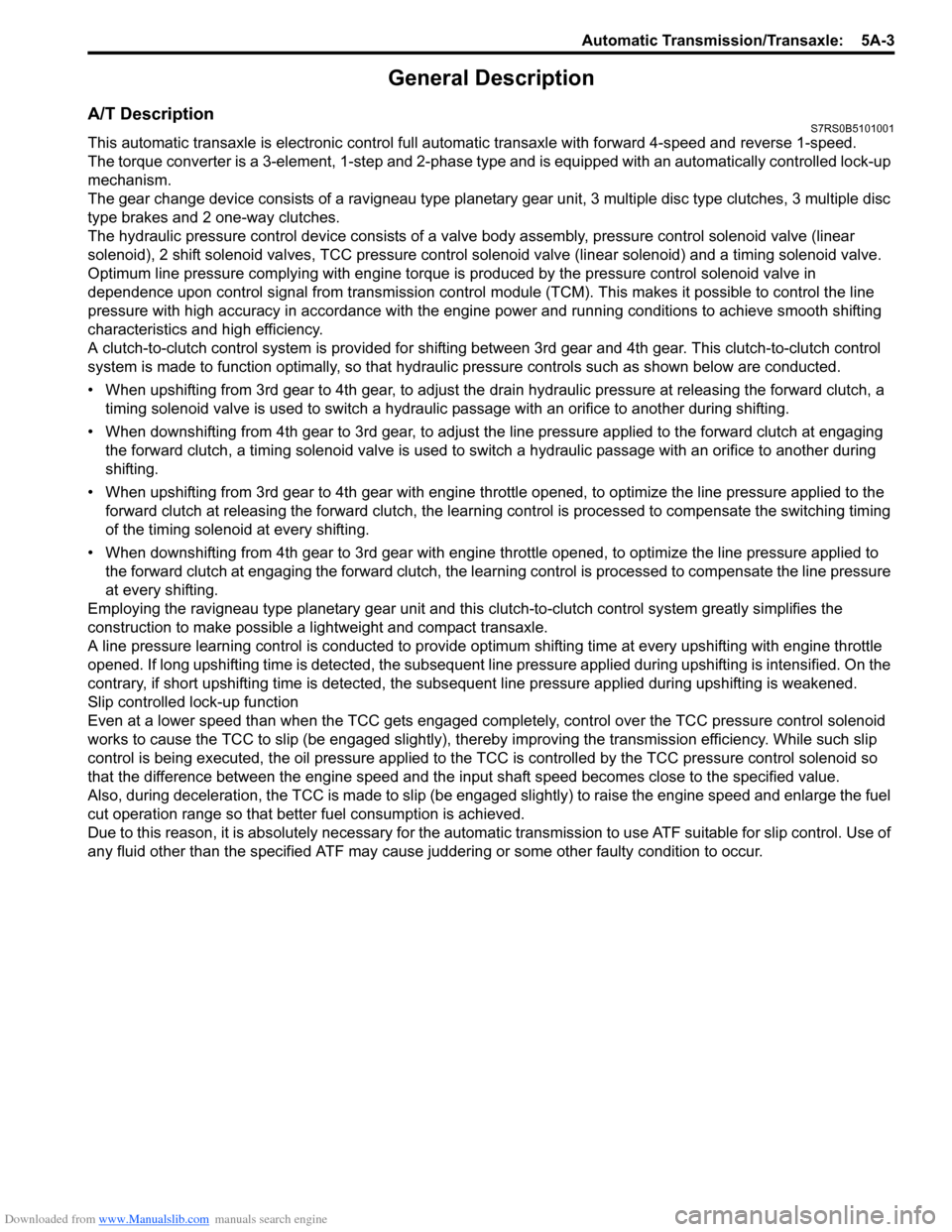

A/T DescriptionS7RS0B5101001

This automatic transaxle is electronic control full automatic transaxle with forward 4-speed and reverse 1-speed.

The torque converter is a 3-element, 1-step and 2-phase type and is equipped with an automatically controlled lock-up

mechanism.

The gear change device consists of a ravigneau type planet ary gear unit, 3 multiple disc type clutches, 3 multiple disc

type brakes and 2 one-way clutches.

The hydraulic pressure control device consists of a valve body assembly, pressure control solenoid valve (linear

solenoid), 2 shift solenoid va lves, TCC pressure control solenoid valve (lin ear solenoid) and a timing solenoid valve.

Optimum line pressure complying with engine torque is produced by the pressure control solenoid valve in

dependence upon control signal from transmission control module (TCM). This makes it possible to control the line

pressure with high accuracy in accordance with the engine power and running conditions to achieve smooth shifting

characteristics and high efficiency.

A clutch-to-clutch control system is prov ided for shifting between 3rd gear and 4th gear. This clutch-to-clutch control

system is made to function optimally , so that hydraulic pressure controls such as shown below are conducted.

• When upshifting from 3rd gear to 4th gear, to adjust the drain hydraulic pressure at releasing the forward clutch, a

timing solenoid valve is used to switch a hydraulic passage with an orifice to another during shifting.

• When downshifting from 4th gear to 3rd gear, to adjust the line pressure applied to the forward clutch at engaging the forward clutch, a timing solenoid valve is used to s witch a hydraulic passage with an orifice to another during

shifting.

• When upshifting from 3rd gear to 4th gear with engine throttle opened, to optimize the line pressure applied to the forward clutch at releasing the forward clutch, the learning control is processed to compensate the switching timing

of the timing solenoid at every shifting.

• When downshifting from 4th gear to 3rd gear with engine throttle opened, to optimize the line pressure applied to

the forward clutch at engaging the forw ard clutch, the learning control is processed to compensate the line pressure

at every shifting.

Employing the ravigneau type planetary gear unit and this clutch-to-clutch control system greatly simplifies the

construction to make possible a lightweight and compact transaxle.

A line pressure learning control is conducted to provide opti mum shifting time at every upshifting with engine throttle

opened. If long upshifting time is detected, the subsequent line pressure applied during upshifting is intensified. On the

contrary, if short upshifting time is detected, the subs equent line pressure applied during upshifting is weakened.

Slip controlled lock-up function

Even at a lower speed than when the TCC gets engaged completely, control over the TCC pressure control solenoid

works to cause the TCC to slip (be engaged slightly), ther eby improving the transmission efficiency. While such slip

control is being executed, the oil pressure applied to the TCC is controlled by the TCC pressure control solenoid so

that the difference between the engine speed and the input shaft speed becomes close to the specified value.

Also, during deceleration, the TCC is made to slip (be enga ged slightly) to raise the engine speed and enlarge the fuel

cut operation range so that better fuel consumption is achieved.

Due to this reason, it is absolutely necessary for the automati c transmission to use ATF suitable for slip control. Use of

any fluid other than the specified ATF may cause j uddering or some other faulty condition to occur.

Page 649 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-5

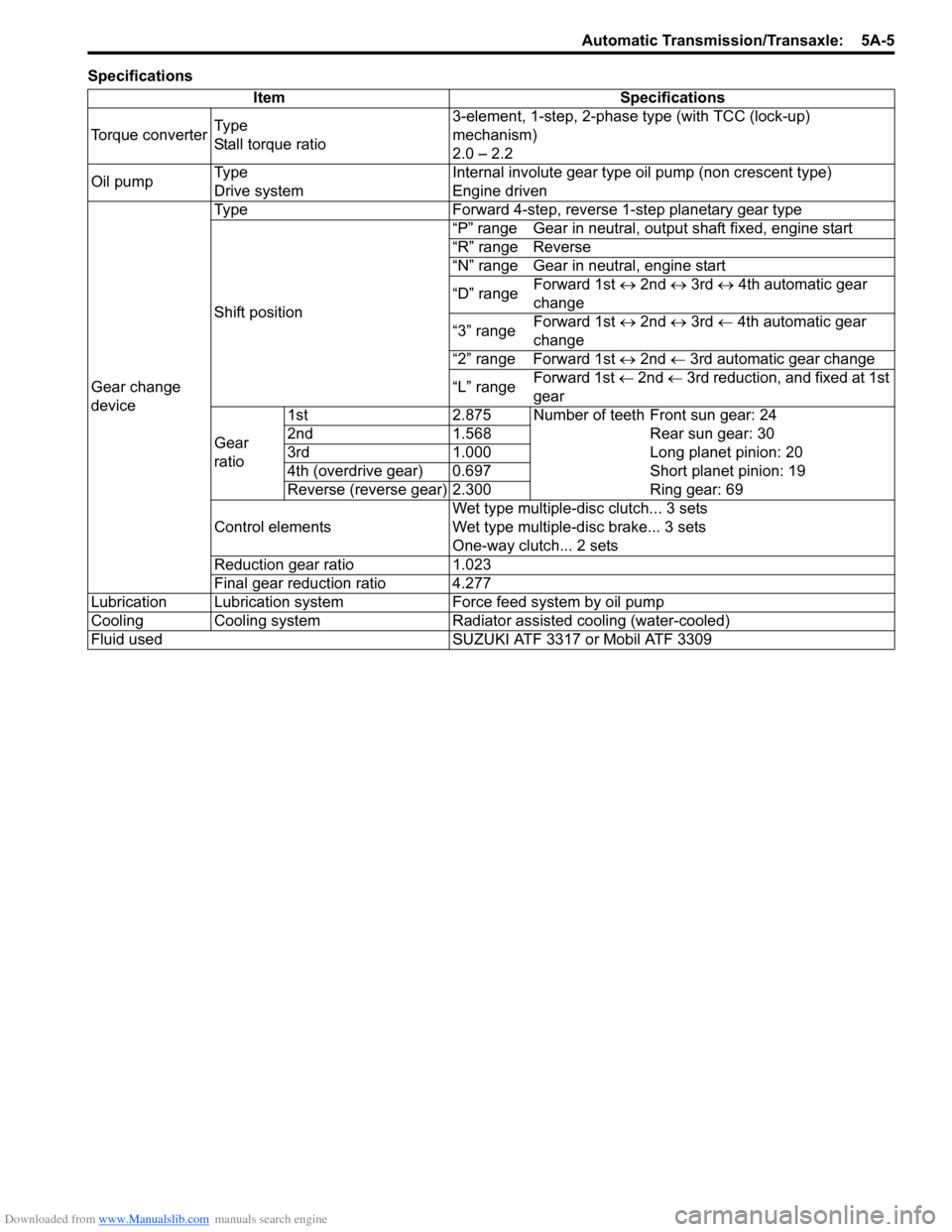

SpecificationsItem Specifications

Torque converter Ty p e

Stall torque ratio 3-element, 1-step, 2-phase type (with TCC (lock-up)

mechanism)

2.0 – 2.2

Oil pump Ty p e

Drive system Internal involute gear type oil pump (non crescent type)

Engine driven

Gear change

device Type Forward 4-step, reverse 1-step planetary gear type

Shift position

“P” range Gear in neutral, output shaft fixed, engine start

“R” range Reverse

“N” range Gear in neutral, engine start

“D” range

Forward 1st

↔ 2nd ↔ 3rd ↔ 4th automatic gear

change

“3” range Forward 1st

↔ 2nd ↔ 3rd ← 4th automatic gear

change

“2” range Forward 1st ↔ 2nd ← 3rd automatic gear change

“L” range Forward 1st

← 2nd ← 3rd reduction, and fixed at 1st

gear

Gear

ratio 1st 2.875 Number of teeth Front sun gear: 24

2nd 1.568 Rear sun gear: 30

3rd 1.000 Long planet pinion: 20

4th (overdrive gear) 0.697 Short planet pinion: 19

Reverse (reverse gear) 2.300 Ring gear: 69

Control elements Wet type multiple-disc clutch... 3 sets

Wet type multiple-d

isc brake... 3 sets

One-way clutch... 2 sets

Reduction gear ratio 1.023

Final gear reduction ratio 4.277

Lubrication Lubrication system Force feed system by oil pump

Cooling Cooling system Radiator assisted cooling (water-cooled)

Fluid used SUZUKI ATF 3317 or Mobil ATF 3309

Page 664 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-20 Automatic Transmission/Transaxle:

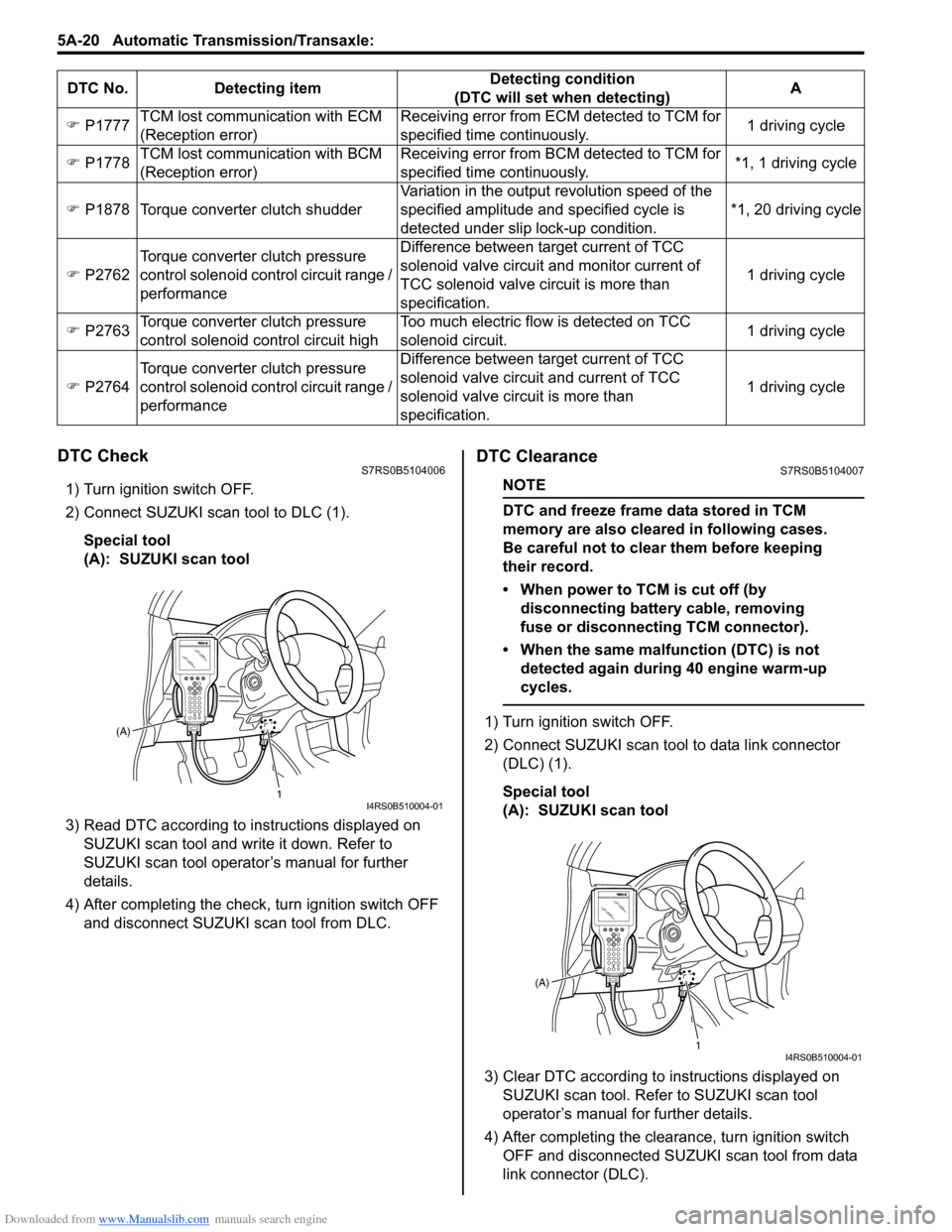

DTC CheckS7RS0B5104006

1) Turn ignition switch OFF.

2) Connect SUZUKI scan tool to DLC (1).

Special tool

(A): SUZUKI scan tool

3) Read DTC according to instructions displayed on SUZUKI scan tool and wr ite it down. Refer to

SUZUKI scan tool operator’s manual for further

details.

4) After completing the check, turn ignition switch OFF

and disconnect SUZUKI scan tool from DLC.

DTC ClearanceS7RS0B5104007

NOTE

DTC and freeze frame data stored in TCM

memory are also cleared in following cases.

Be careful not to clear them before keeping

their record.

• When power to TCM is cut off (by disconnecting battery cable, removing

fuse or disconnecting TCM connector).

• When the same malfunction (DTC) is not detected again during 40 engine warm-up

cycles.

1) Turn ignition switch OFF.

2) Connect SUZUKI scan tool to data link connector (DLC) (1).

Special tool

(A): SUZUKI scan tool

3) Clear DTC according to instructions displayed on SUZUKI scan tool. Refer to SUZUKI scan tool

operator’s manual for further details.

4) After completing the clearance, turn ignition switch OFF and disconnected SUZUKI scan tool from data

link connector (DLC).

�)

P1777 TCM lost communication with ECM

(Reception error) Receiving error from ECM detected to TCM for

specified time continuously.

1 driving cycle

�) P1778 TCM lost communication with BCM

(Reception error) Receiving error from BCM detected to TCM for

specified time continuously.

*1, 1 driving cycle

�) P1878 Torque converter clutch shudder Variation in the output revolution speed of the

specified amplitude and specified cycle is

detected under slip lock-up condition. *1, 20 driving cycle

�) P2762 Torque converter clutch pressure

control solenoid control circuit range /

performance Difference between target current of TCC

solenoid valve circuit and monitor current of

TCC solenoid valve ci

rcuit is more than

specification. 1 driving cycle

�) P2763 Torque converter clutch pressure

control solenoid control circuit high Too much electric flow is detected on TCC

solenoid circuit.

1 driving cycle

�) P2764 Torque converter clutch pressure

control solenoid control circuit range /

performance Difference between target current of TCC

solenoid valve circuit and current of TCC

solenoid valve circuit is more than

specification.

1 driving cycle

DTC No. Detecting item

Detecting condition

(DTC will set when detecting) A

1

(A)I4RS0B510004-01

1

(A)I4RS0B510004-01

Page 695 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-51

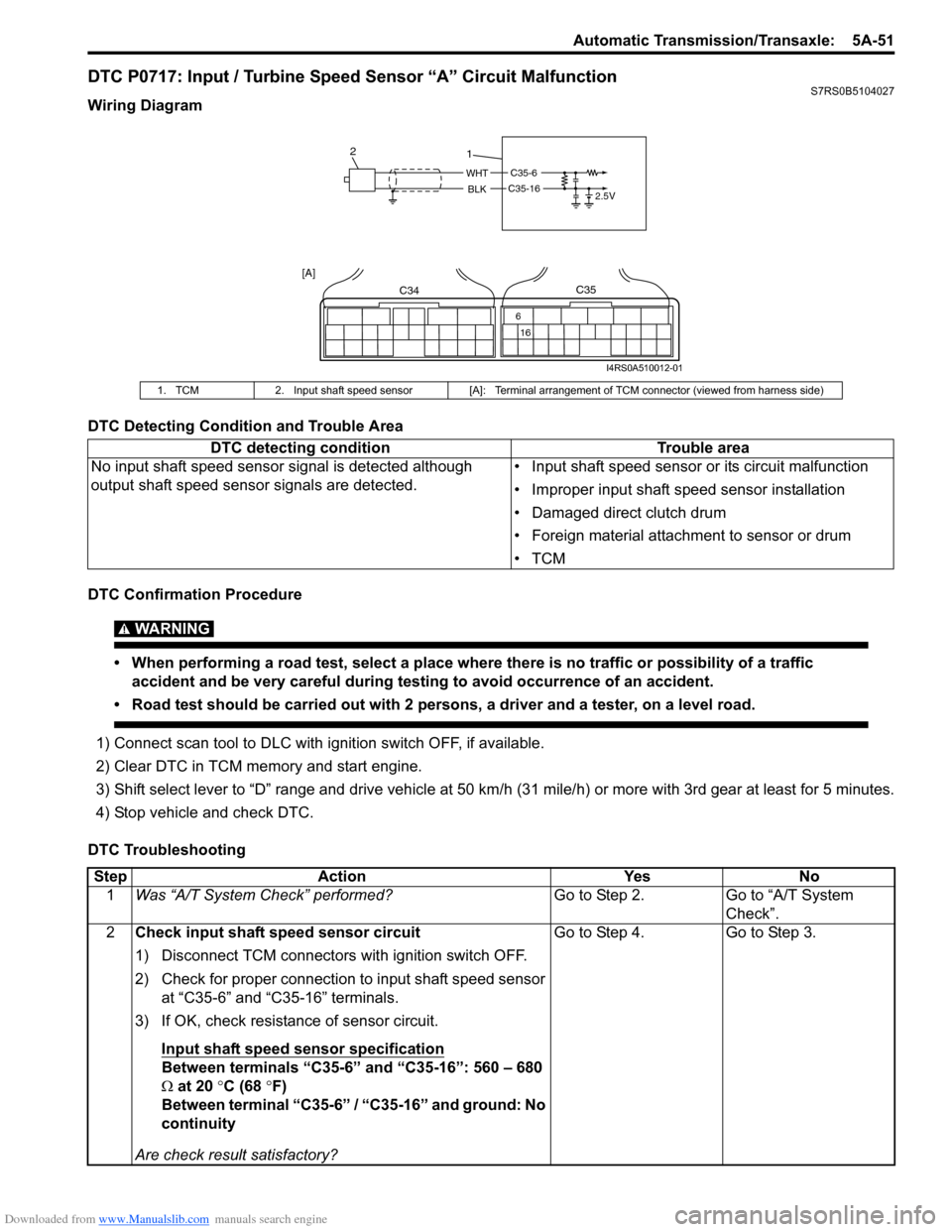

DTC P0717: Input / Turbine Speed Sensor “A” Circuit MalfunctionS7RS0B5104027

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory and start engine.

3) Shift select lever to “D” range and drive vehicle at 50 km /h (31 mile/h) or more with 3rd gear at least for 5 minutes.

4) Stop vehicle and check DTC.

DTC Troubleshooting

1. TCM 2. Input shaft speed sensor [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

No input shaft speed sensor signal is detected although

output shaft speed sens or signals are detected. • Input shaft speed sensor or its circuit malfunction

• Improper input shaft speed sensor installation

• Damaged direct clutch drum

• Foreign material attachment to sensor or drum

•TCM

C35-6

2.5VWHT

BLKC35-16

1

2

C34

16

6

C35

[A]

I4RS0A510012-01

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Check input shaft speed sensor circuit

1) Disconnect TCM connectors with ignition switch OFF.

2) Check for proper connection to input shaft speed sensor

at “C35-6” and “C35-16” terminals.

3) If OK, check resistance of sensor circuit.

Input shaft speed sensor specification

Between terminals “C35-6” and “C35-16”: 560 – 680

Ω at 20 °C (68 °F)

Between terminal “C35-6” / “C35-16” and ground: No

continuity

Are check result satisfactory? Go to Step 4. Go to Step 3.

Page 753 of 1496

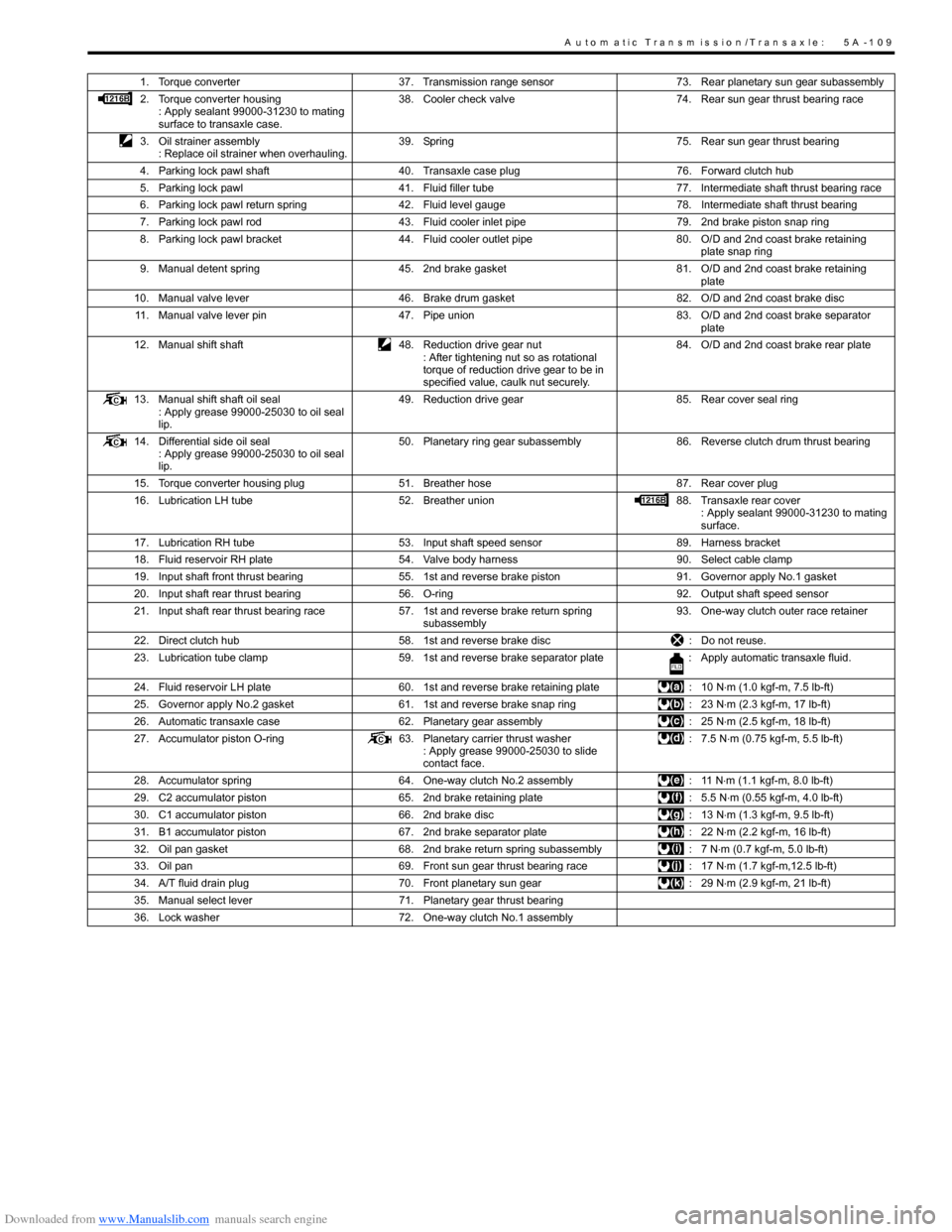

Downloaded from www.Manualslib.com manuals search engine A u to m a tic Tra n s m is s io n /Tra n s a x le : 5 A -1 0 9

1. Torque converter37. Transmission range sensor 73. Rear planetary sun gear subassembly

2. Torque converter housing : Apply sealant 99000-31230 to mating

surface to transaxle case. 38. Cooler check valve

74. Rear sun gear thrust bearing race

3. Oil strainer assembly : Replace oil strainer when overhauling. 39. Spring

75. Rear sun gear thrust bearing

4. Parking lock pawl shaft 40. Transaxle case plug 76. Forward clutch hub

5. Parking lock pawl 41. Fluid filler tube 77. Intermediate shaft thrust bearing race

6. Parking lock pawl return spring 42. Fluid level gauge 78. Intermediate shaft thrust bearing

7. Parking lock pawl rod 43. Fluid cooler inlet pipe 79. 2nd brake piston snap ring

8. Parking lock pawl bracket 44. Fluid cooler outlet pipe 80. O/D and 2nd coast brake retaining

plate snap ring

9. Manual detent spring 45. 2nd brake gasket 81. O/D and 2nd coast brake retaining

plate

10. Manual valve lever 46. Brake drum gasket 82. O/D and 2nd coast brake disc

11. Manual valve lever pin 47. Pipe union 83. O/D and 2nd coast brake separator

plate

12. Manual shift shaft 48. Reduction drive gear nut

: After tightening nut so as rotational

torque of reduction drive gear to be in

specified value, caulk nut securely. 84. O/D and 2nd coast brake rear plate

13. Manual shift shaft oil seal : Apply grease 99000-25030 to oil seal

lip. 49. Reduction drive gear

85. Rear cover seal ring

14. Differential side oil seal : Apply grease 99000-25030 to oil seal

lip. 50. Planetary ring gear subassembly

86. Reverse clutch drum thrust bearing

15. Torque converter housing plug 51. Breather hose 87. Rear cover plug

16. Lubrication LH tube 52. Breather union 88. Transaxle rear cover

: Apply sealant 99000-31230 to mating

surface.

17. Lubrication RH tube 53. Input shaft speed sensor 89. Harness bracket

18. Fluid reservoir RH plate 54. Valve body harness 90. Select cable clamp

19. Input shaft front thrust bearing 55. 1st and reverse brake piston 91. Governor apply No.1 gasket

20. Input shaft rear thrust bearing 56. O-ring 92. Output shaft speed sensor

21. Input shaft rear thrust bearing race 57. 1st and reverse brake return spring

subassembly 93. One-way clutch outer race retainer

22. Direct clutch hub 58. 1st and reverse brake disc : Do not reuse.

23. Lubrication tube clamp 59. 1st and reverse brake separator plate : Apply automatic transaxle fluid.

24. Fluid reservoir LH plate 60. 1st and reverse brake retaining plate : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

25. Governor apply No.2 gasket 61. 1st and reverse brake snap ring : 23 N⋅m (2.3 kgf-m, 17 lb-ft)

26. Automatic transaxle case 62. Planetary gear assembly : 25 N⋅m (2.5 kgf-m, 18 lb-ft)

27. Accumulator piston O-ring 63. Planetary carrier thrust washer

: Apply grease 99000-25030 to slide

contact face. : 7.5 N

⋅m (0.75 kgf-m, 5.5 lb-ft)

28. Accumulator spring 64. One-way clutch No.2 assembly : 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

29. C2 accumulator piston 65. 2nd brake retaining plate : 5.5 N⋅m (0.55 kgf-m, 4.0 lb-ft)

30. C1 accumulator piston 66. 2nd brake disc : 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

31. B1 accumulator piston 67. 2nd brake separator plate : 22 N⋅m (2.2 kgf-m, 16 lb-ft)

32. Oil pan gasket 68. 2nd brake return spring subassembly : 7 N⋅m (0.7 kgf-m, 5.0 lb-ft)

33. Oil pan 69. Front sun gear thrust bearing race : 17 N⋅m (1.7 kgf-m,12.5 lb-ft)

34. A/T fluid drain plug 70. Front planetary sun gear : 29 N⋅m (2.9 kgf-m, 21 lb-ft)

35. Manual select lever 71. Planetary gear thrust bearing

36. Lock washer 72. One-way clutch No.1 assembly

Page 759 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-115

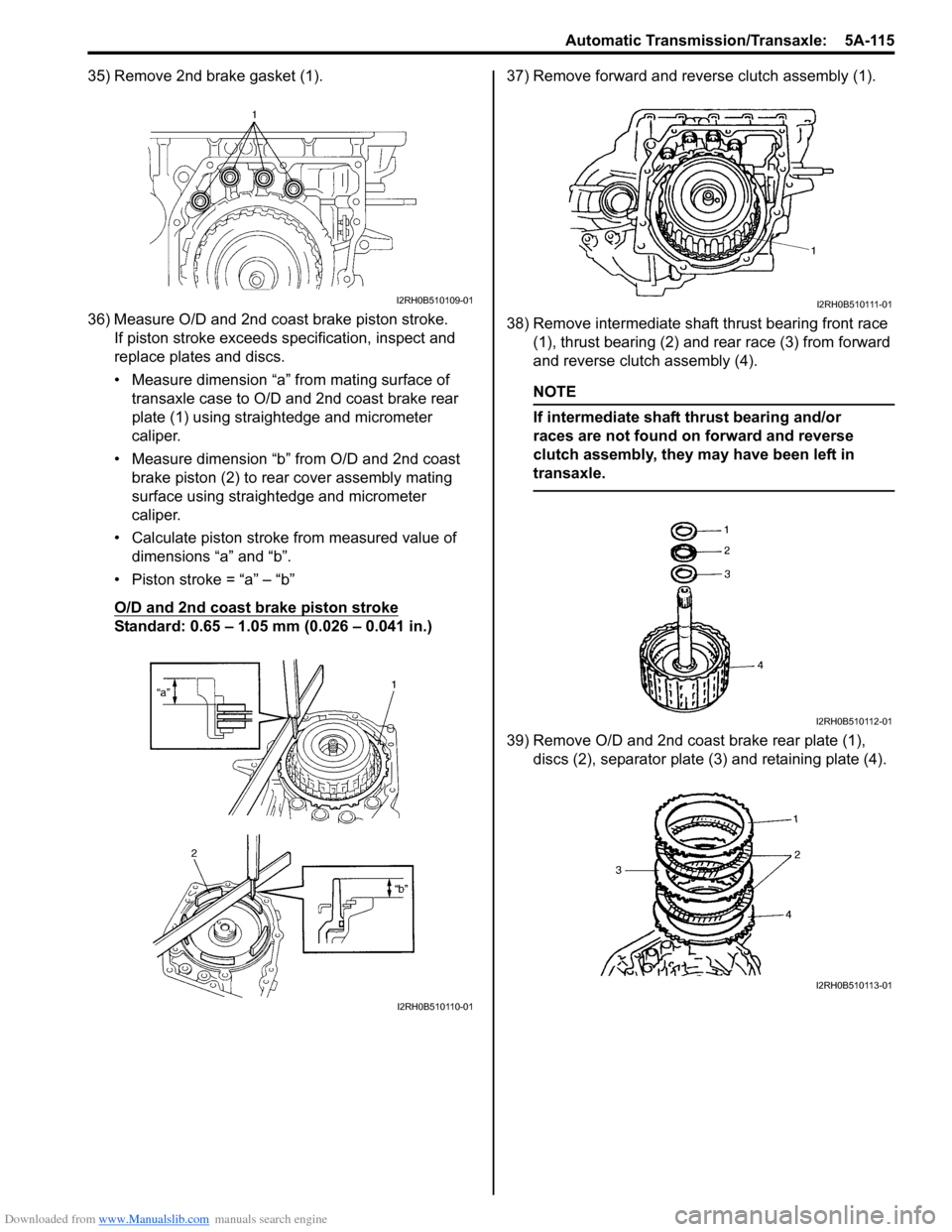

35) Remove 2nd brake gasket (1).

36) Measure O/D and 2nd coast brake piston stroke.If piston stroke exceeds specification, inspect and

replace plates and discs.

• Measure dimension “a” from mating surface of transaxle case to O/D and 2nd coast brake rear

plate (1) using straightedge and micrometer

caliper.

• Measure dimension “b” from O/D and 2nd coast brake piston (2) to rear cover assembly mating

surface using straightedge and micrometer

caliper.

• Calculate piston stroke from measured value of dimensions “a” and “b”.

• Piston stroke = “a” – “b”

O/D and 2nd coast brake piston stroke

Standard: 0.65 – 1.05 mm (0.026 – 0.041 in.) 37) Remove forward and reverse clutch assembly (1).

38) Remove intermediate shaft thrust bearing front race

(1), thrust bearing (2) and rear race (3) from forward

and reverse clutch assembly (4).

NOTE

If intermediate shaft thrust bearing and/or

races are not found on forward and reverse

clutch assembly, they may have been left in

transaxle.

39) Remove O/D and 2nd coast brake rear plate (1), discs (2), separator plate (3) and retaining plate (4).

I2RH0B510109-01

I2RH0B510110-01

I2RH0B510111-01

I2RH0B510112-01

I2RH0B510113-01