clutch disc SUZUKI SWIFT 2008 2.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 791 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-147

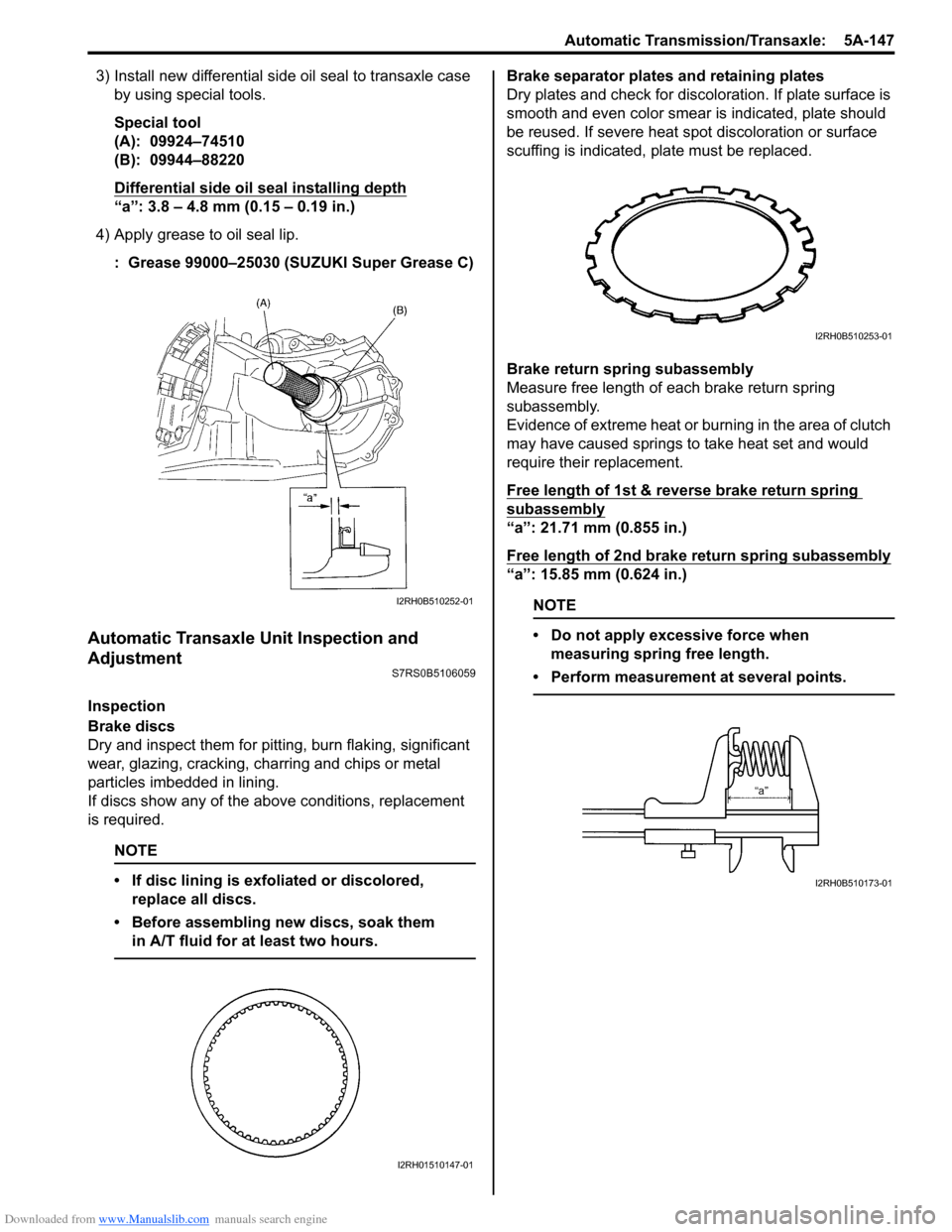

3) Install new differential side oil seal to transaxle case by using special tools.

Special tool

(A): 09924–74510

(B): 09944–88220

Differential side oil seal installing depth

“a”: 3.8 – 4.8 mm (0.15 – 0.19 in.)

4) Apply grease to oil seal lip. : Grease 99000–25030 (SUZUKI Super Grease C)

Automatic Transaxle Unit Inspection and

Adjustment

S7RS0B5106059

Inspection

Brake discs

Dry and inspect them for pitting, burn flaking, significant

wear, glazing, cracking, charring and chips or metal

particles imbedded in lining.

If discs show any of the ab ove conditions, replacement

is required.

NOTE

• If disc lining is exfoliated or discolored, replace all discs.

• Before assembling new discs, soak them in A/T fluid for at least two hours.

Brake separator plates and retaining plates

Dry plates and check for discol oration. If plate surface is

smooth and even color smear is indicated, plate should

be reused. If severe heat spot discoloration or surface

scuffing is indicated, plate must be replaced.

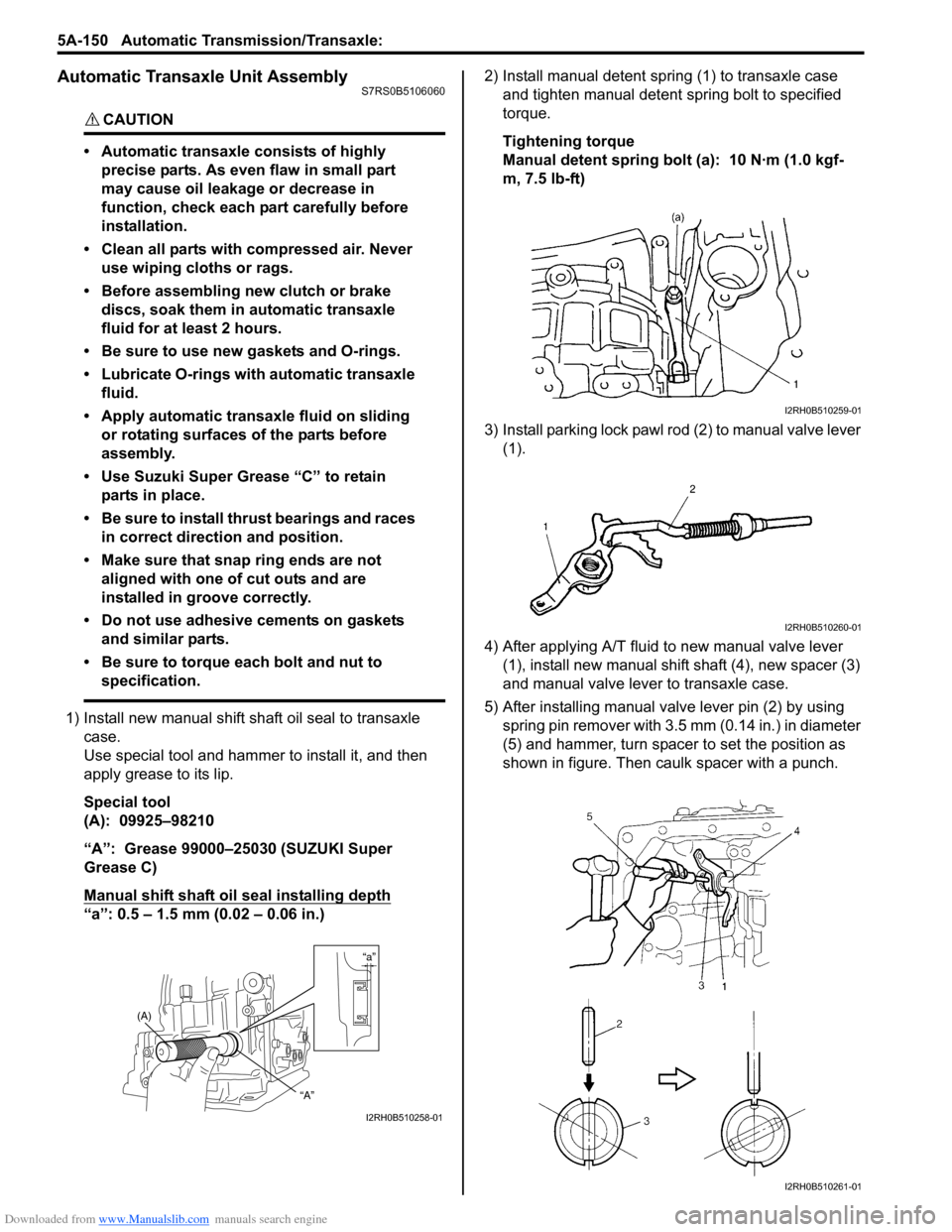

Brake return spring subassembly

Measure free length of each brake return spring

subassembly.

Evidence of extreme heat or burning in the area of clutch

may have caused springs to take heat set and would

require their replacement.

Free length of 1st & reverse brake return spring

subassembly

“a”: 21.71 mm (0.855 in.)

Free length of 2nd brake return spring subassembly

“a”: 15.85 mm (0.624 in.)

NOTE

• Do not apply excessive force when measuring spring free length.

• Perform measurement at several points.

I2RH0B510252-01

I2RH01510147-01

I2RH0B510253-01

I2RH0B510173-01

Page 794 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-150 Automatic Transmission/Transaxle:

Automatic Transaxle Unit AssemblyS7RS0B5106060

CAUTION!

• Automatic transaxle consists of highly precise parts. As even flaw in small part

may cause oil leakage or decrease in

function, check each part carefully before

installation.

• Clean all parts with compressed air. Never use wiping cloths or rags.

• Before assembling new clutch or brake discs, soak them in automatic transaxle

fluid for at least 2 hours.

• Be sure to use new gaskets and O-rings.

• Lubricate O-rings with automatic transaxle

fluid.

• Apply automatic transaxle fluid on sliding or rotating surfaces of the parts before

assembly.

• Use Suzuki Super Grease “C” to retain parts in place.

• Be sure to install thrust bearings and races in correct direction and position.

• Make sure that snap ring ends are not aligned with one of cut outs and are

installed in groove correctly.

• Do not use adhesive cements on gaskets and similar parts.

• Be sure to torque each bolt and nut to specification.

1) Install new manual shift sh aft oil seal to transaxle

case.

Use special tool and hammer to install it, and then

apply grease to its lip.

Special tool

(A): 09925–98210

“A”: Grease 99000–25030 (SUZUKI Super

Grease C)

Manual shift shaft oil seal installing depth

“a”: 0.5 – 1.5 mm (0.02 – 0.06 in.) 2) Install manual detent spring (1) to transaxle case

and tighten manual detent spring bolt to specified

torque.

Tightening torque

Manual detent spring bolt (a): 10 N·m (1.0 kgf-

m, 7.5 lb-ft)

3) Install parking lock pawl ro d (2) to manual valve lever

(1).

4) After applying A/T fluid to new manual valve lever (1), install new manual shift shaft (4), new spacer (3)

and manual valve lever to transaxle case.

5) After installing manual valve lever pin (2) by using spring pin remover with 3.5 mm (0.14 in.) in diameter

(5) and hammer, turn spacer to set the position as

shown in figure. Then caulk spacer with a punch.

“a”

(A)

“A”

I2RH0B510258-01

I2RH0B510259-01

I2RH0B510260-01

I2RH0B510261-01

Page 798 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-154 Automatic Transmission/Transaxle:

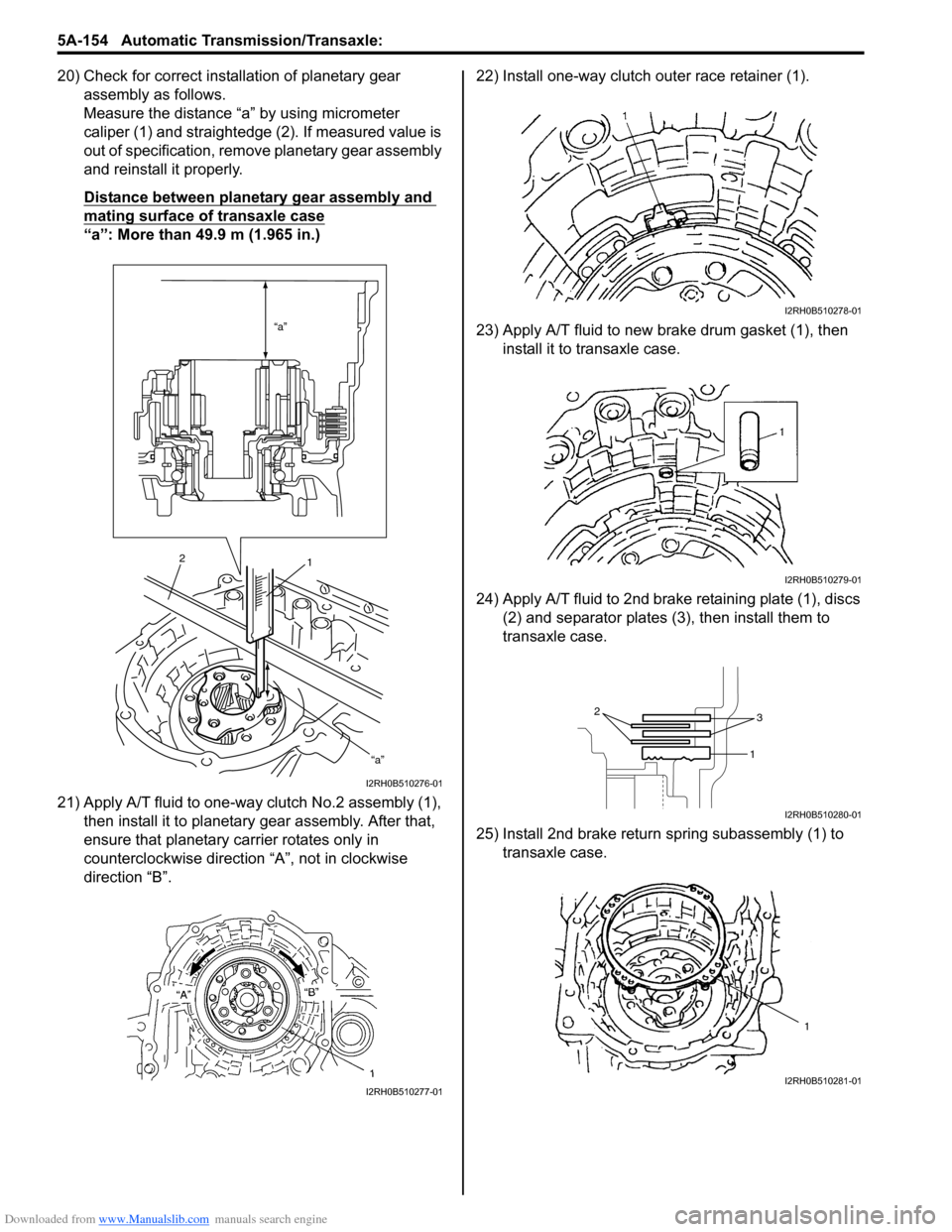

20) Check for correct installation of planetary gear assembly as follows.

Measure the distance “a” by using micrometer

caliper (1) and straightedge (2). If measured value is

out of specification, remove planetary gear assembly

and reinstall it properly.

Distance between planetary gear assembly and

mating surface of transaxle case

“a”: More than 49.9 m (1.965 in.)

21) Apply A/T fluid to one-way clutch No.2 assembly (1), then install it to planetar y gear assembly. After that,

ensure that planetary carrier rotates only in

counterclockwise direction “A”, not in clockwise

direction “B”. 22) Install one-way clutch outer race retainer (1).

23) Apply A/T fluid to new brake drum gasket (1), then

install it to transaxle case.

24) Apply A/T fluid to 2nd brak e retaining plate (1), discs

(2) and separator plates (3), then install them to

transaxle case.

25) Install 2nd brake return spring subassembly (1) to transaxle case.

“a”

“a”

2 1

I2RH0B510276-01

I2RH0B510277-01

I2RH0B510278-01

I2RH0B510279-01

2

3

1

I2RH0B510280-01

1

I2RH0B510281-01

Page 801 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-157

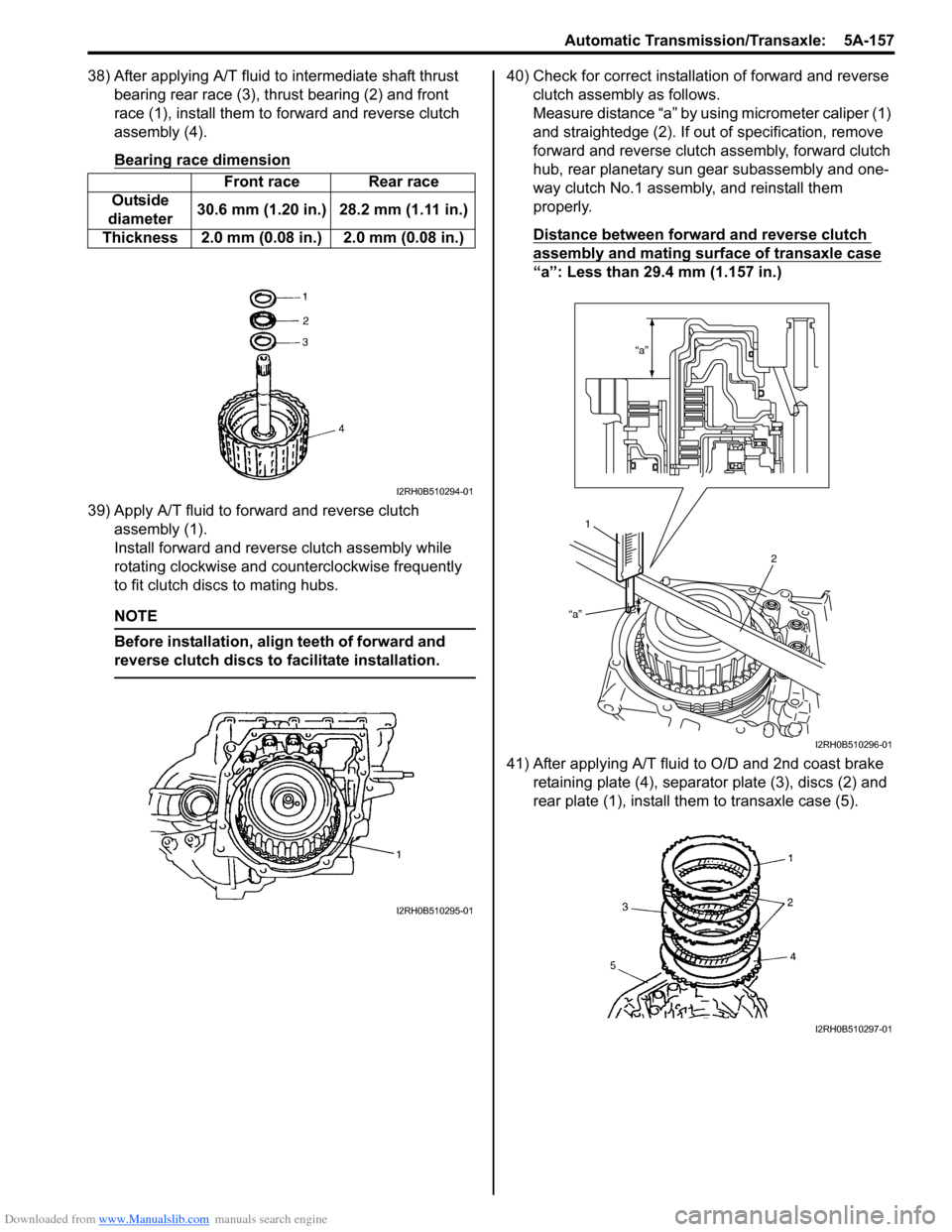

38) After applying A/T fluid to intermediate shaft thrust bearing rear race (3), thrust bearing (2) and front

race (1), install them to forward and reverse clutch

assembly (4).

Bearing race dimension

39) Apply A/T fluid to forward and reverse clutch assembly (1).

Install forward and revers e clutch assembly while

rotating clockwise and co unterclockwise frequently

to fit clutch discs to mating hubs.

NOTE

Before installation, align teeth of forward and

reverse clutch discs to facilitate installation.

40) Check for correct installation of forward and reverse clutch assembly as follows.

Measure distance “a” by using micrometer caliper (1)

and straightedge (2). If out of specification, remove

forward and reverse clutch assembly, forward clutch

hub, rear planetary sun gear subassembly and one-

way clutch No.1 assemb ly, and reinstall them

properly.

Distance between forward and reverse clutch

assembly and mating surface of transaxle case

“a”: Less than 29.4 mm (1.157 in.)

41) After applying A/T fluid to O/D and 2nd coast brake retaining plate (4), separator plate (3), discs (2) and

rear plate (1), install th em to transaxle case (5).

Front race Rear race

Outside

diameter 30.6 mm (1.20 in.) 28.2 mm (1.11 in.)

Thickness 2.0 mm (0.08 in.) 2.0 mm (0.08 in.)

I2RH0B510294-01

I2RH0B510295-01

“a”

“a”

1 2

I2RH0B510296-01

I2RH0B510297-01

Page 804 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-160 Automatic Transmission/Transaxle:

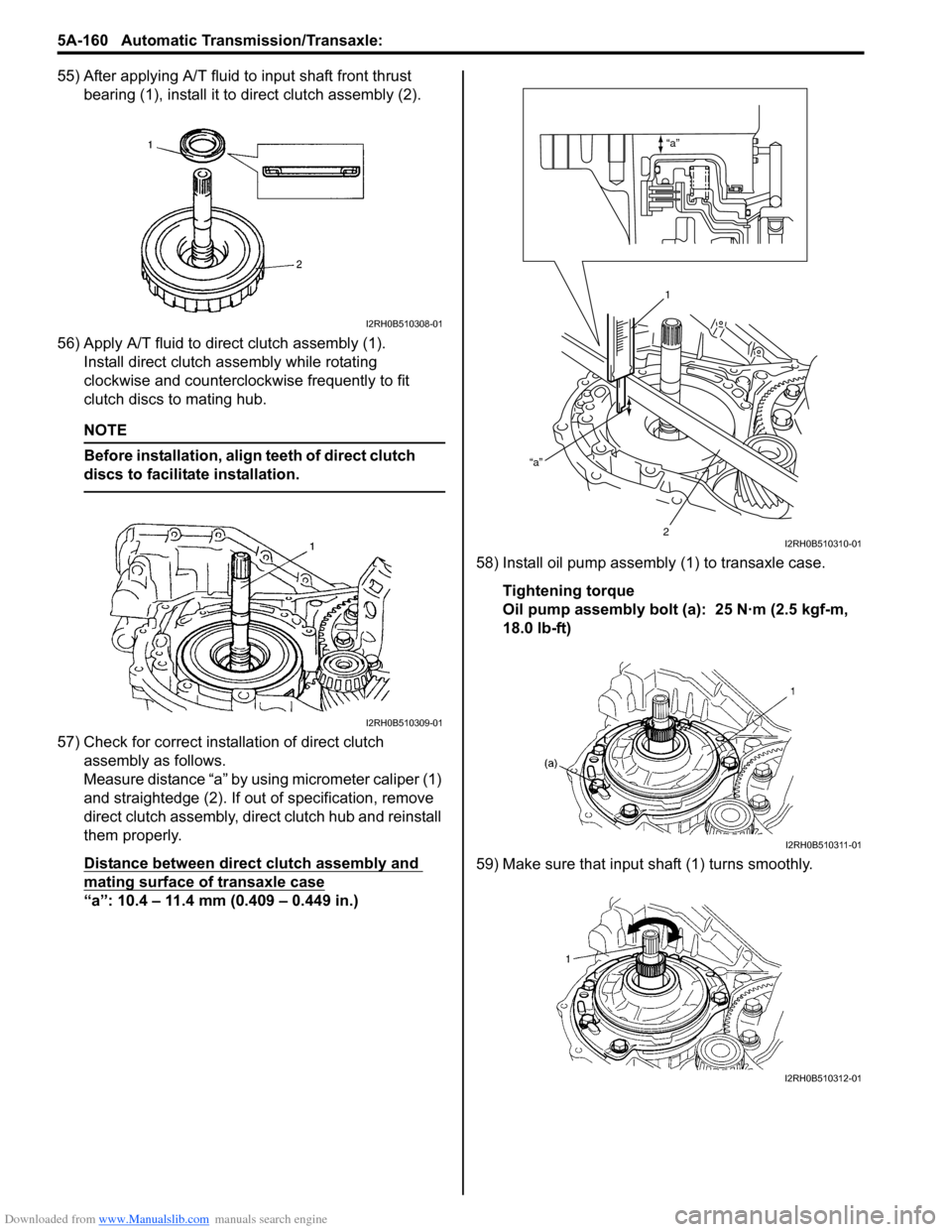

55) After applying A/T fluid to input shaft front thrust bearing (1), install it to direct clutch assembly (2).

56) Apply A/T fluid to direct clutch assembly (1). Install direct clutch a ssembly while rotating

clockwise and counterclockwise frequently to fit

clutch discs to mating hub.

NOTE

Before installation, align teeth of direct clutch

discs to facilitate installation.

57) Check for correct installation of direct clutch assembly as follows.

Measure distance “a” by using micrometer caliper (1)

and straightedge (2). If out of specification, remove

direct clutch assembly, direct clutch hub and reinstall

them properly.

Distance between direct clutch assembly and

mating surface of transaxle case

“a”: 10.4 – 11.4 mm (0.409 – 0.449 in.) 58) Install oil pump assembly

(1) to transaxle case.

Tightening torque

Oil pump assembly bolt (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

59) Make sure that input shaft (1) turns smoothly.

I2RH0B510308-01

I2RH0B510309-01

“a”

“a”

1

2

I2RH0B510310-01

I2RH0B510311-01

I2RH0B510312-01

Page 817 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-3

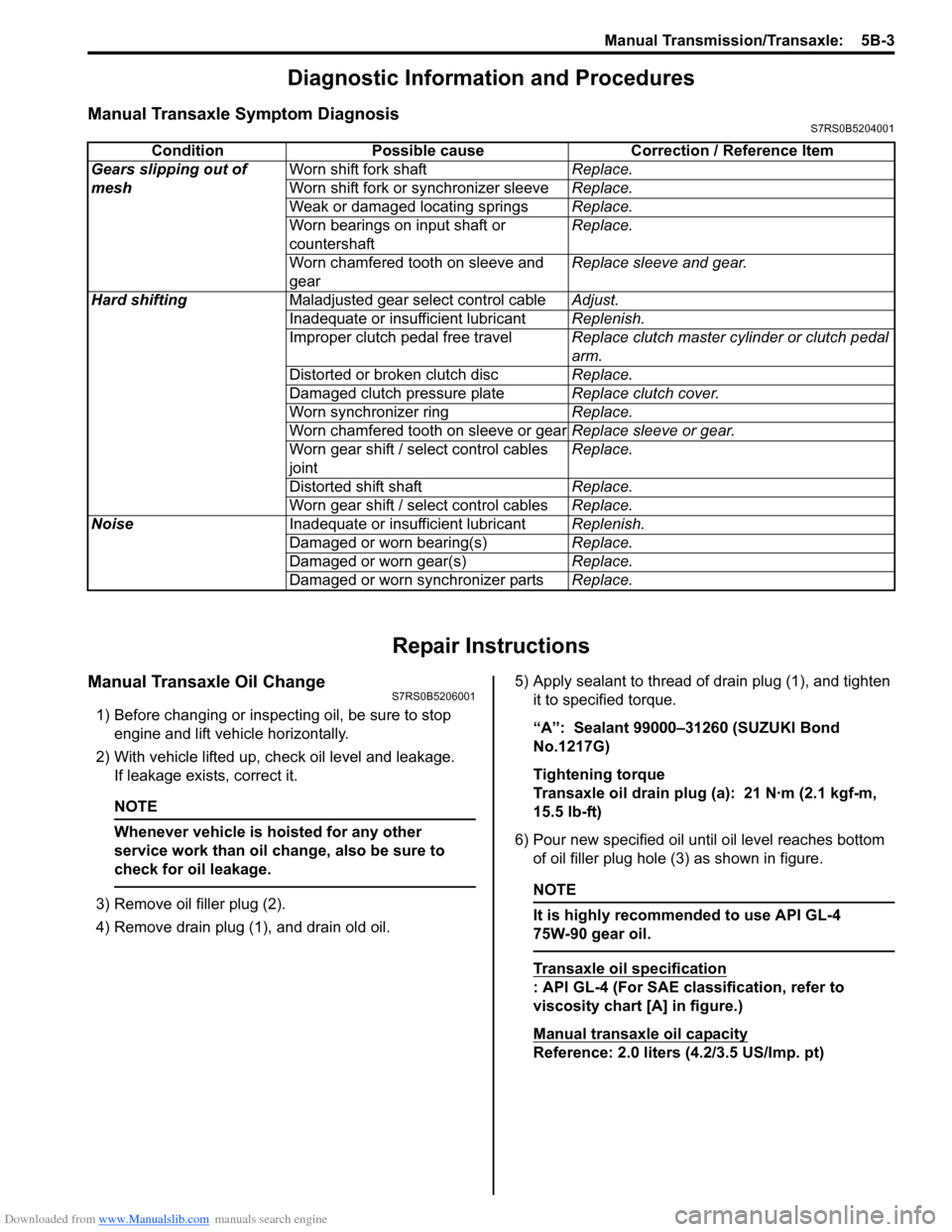

Diagnostic Information and Procedures

Manual Transaxle Symptom DiagnosisS7RS0B5204001

Repair Instructions

Manual Transaxle Oil ChangeS7RS0B5206001

1) Before changing or inspecting oil, be sure to stop engine and lift vehicle horizontally.

2) With vehicle lifted up, check oil level and leakage. If leakage exists, correct it.

NOTE

Whenever vehicle is hoisted for any other

service work than oil change, also be sure to

check for oil leakage.

3) Remove oil filler plug (2).

4) Remove drain plug (1), and drain old oil. 5) Apply sealant to thread of drain plug (1), and tighten

it to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Transaxle oil drain plug (a): 21 N·m (2.1 kgf-m,

15.5 lb-ft)

6) Pour new specified oil unt il oil level reaches bottom

of oil filler plug hole (3) as shown in figure.NOTE

It is highly recommended to use API GL-4

75W-90 gear oil.

Transaxle oil specification

: API GL-4 (For SAE classification, refer to

viscosity chart [A] in figure.)

Manual transaxle oil capacity

Reference: 2.0 liters (4.2/3.5 US/Imp. pt)

Condition Possible cause Correction / Reference Item

Gears slipping out of

mesh Worn shift fork shaft

Replace.

Worn shift fork or synchronizer sleeve Replace.

Weak or damaged locating springs Replace.

Worn bearings on input shaft or

countershaft Replace.

Worn chamfered tooth on sleeve and

gear Replace sleeve and gear.

Hard shifting Maladjusted gear select control cable Adjust.

Inadequate or insufficient lubricant Replenish.

Improper clutch pedal free travel Replace clutch master cylinder or clutch pedal

arm.

Distorted or broken clutch disc Replace.

Damaged clutch pressure plate Replace clutch cover.

Worn synchronizer ring Replace.

Worn chamfered tooth on sleeve or gear Replace sleeve or gear.

Worn gear shift / select control cables

joint Replace.

Distorted shift shaft Replace.

Worn gear shift / select control cables Replace.

Noise Inadequate or insufficient lubricant Replenish.

Damaged or worn bearing(s) Replace.

Damaged or worn gear(s) Replace.

Damaged or worn synchronizer parts Replace.

Page 823 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-9

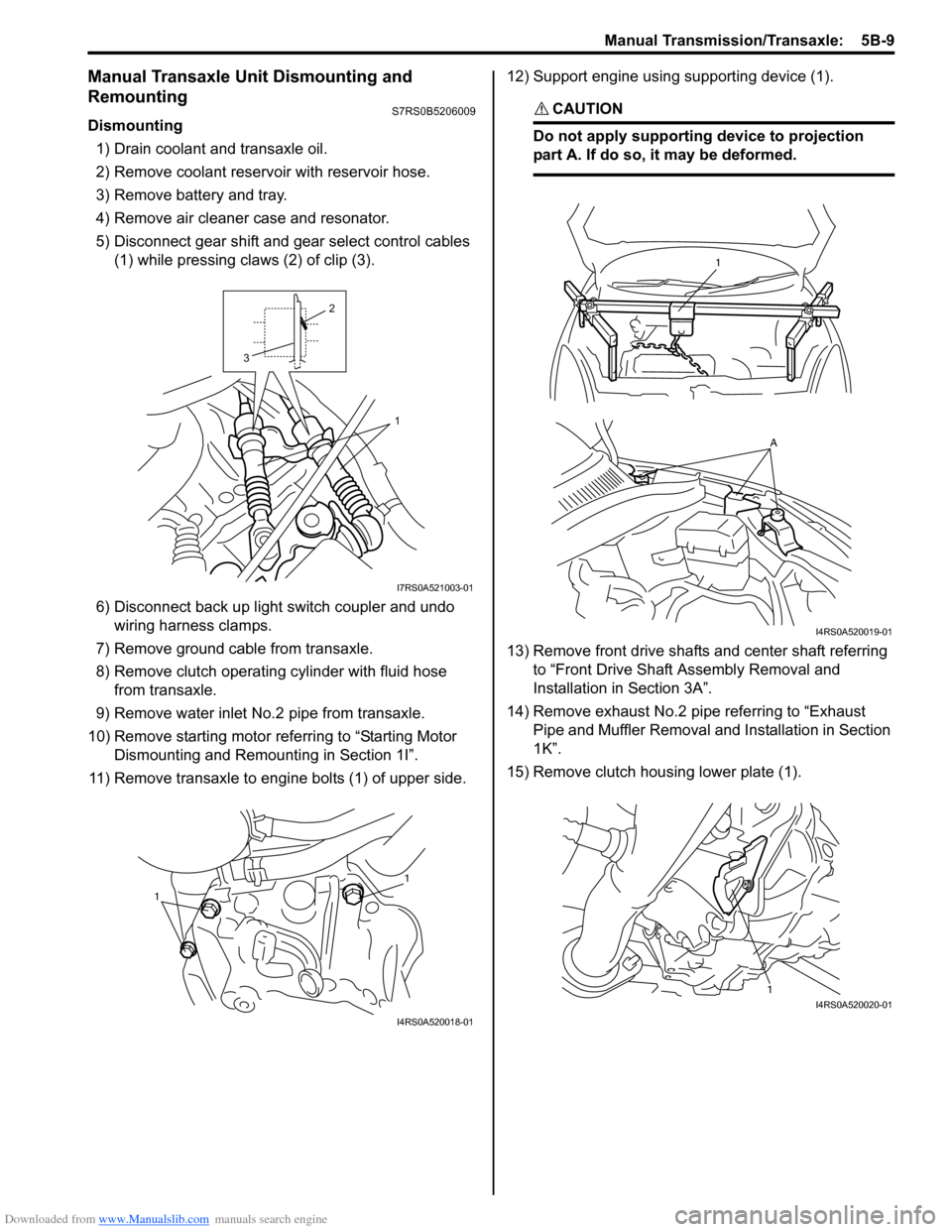

Manual Transaxle Unit Dismounting and

Remounting

S7RS0B5206009

Dismounting1) Drain coolant and transaxle oil.

2) Remove coolant reservoir with reservoir hose.

3) Remove battery and tray.

4) Remove air cleaner case and resonator.

5) Disconnect gear shift and gear select control cables (1) while pressing claws (2) of clip (3).

6) Disconnect back up light switch coupler and undo wiring harness clamps.

7) Remove ground cable from transaxle.

8) Remove clutch operating cylinder with fluid hose from transaxle.

9) Remove water inlet No.2 pipe from transaxle.

10) Remove starting motor re ferring to “Starting Motor

Dismounting and Remounting in Section 1I”.

11) Remove transaxle to engine bolts (1) of upper side. 12) Support engine using supporting device (1).

CAUTION!

Do not apply supporting device to projection

part A. If do so, it may be deformed.

13) Remove front drive shafts and center shaft referring

to “Front Drive Shaft Assembly Removal and

Installation in Section 3A”.

14) Remove exhaust No.2 pipe referring to “Exhaust Pipe and Muffler Removal a nd Installation in Section

1K”.

15) Remove clutch housing lower plate (1).

1

2

3

I7RS0A521003-01

1

1

I4RS0A520018-01

1

A

I4RS0A520019-01

1I4RS0A520020-01

Page 824 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-10 Manual Transmission/Transaxle:

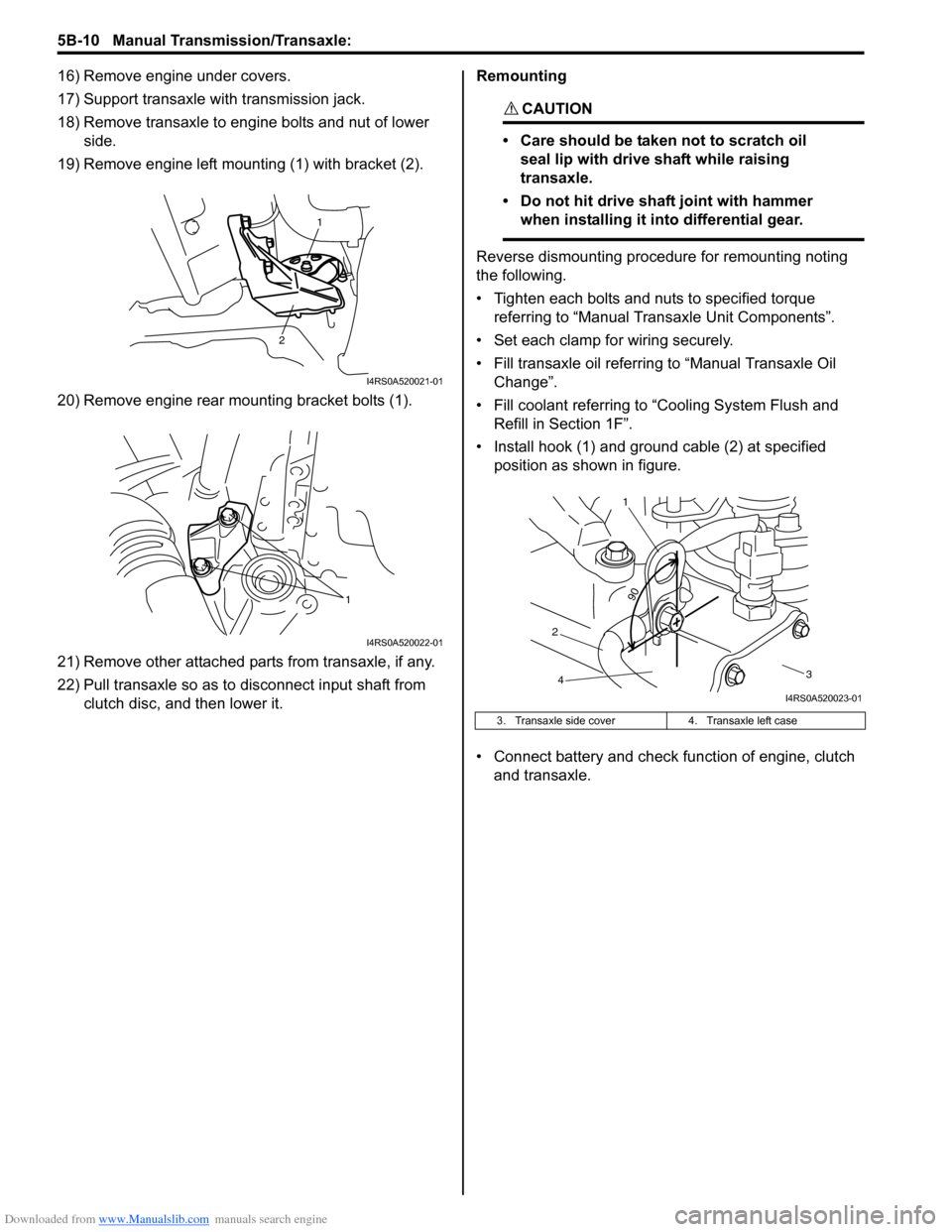

16) Remove engine under covers.

17) Support transaxle with transmission jack.

18) Remove transaxle to engine bolts and nut of lower side.

19) Remove engine left mounting (1) with bracket (2).

20) Remove engine rear mounting bracket bolts (1).

21) Remove other attached parts from transaxle, if any.

22) Pull transaxle so as to disconnect input shaft from clutch disc, and then lower it. Remounting

CAUTION!

• Care should be taken not to scratch oil

seal lip with drive shaft while raising

transaxle.

• Do not hit drive shaft joint with hammer when installing it into differential gear.

Reverse dismounting procedure for remounting noting

the following.

• Tighten each bolts and nuts to specified torque referring to “Manual Transaxle Unit Components”.

• Set each clamp for wiring securely.

• Fill transaxle oil referring to “Manual Transaxle Oil

Change”.

• Fill coolant referring to “Cooling System Flush and

Refill in Section 1F”.

• Install hook (1) and ground cable (2) at specified position as shown in figure.

• Connect battery and check function of engine, clutch

and transaxle.

1

2

I4RS0A520021-01

1

I4RS0A520022-01

3. Transaxle side cover 4. Transaxle left case

90

1

2 3

4

I4RS0A520023-01

Page 853 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-1

Transmission / Transaxle

Clutch

General Description

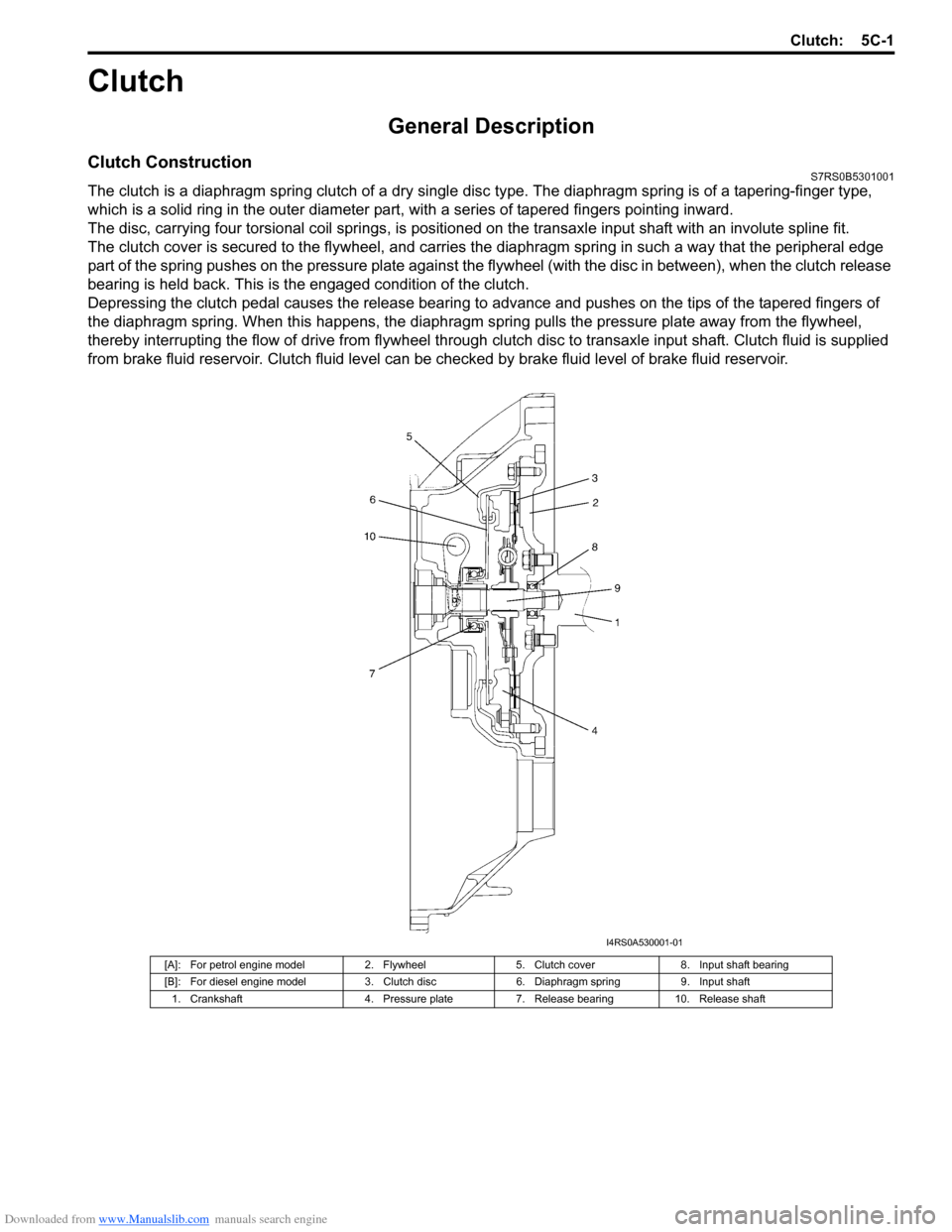

Clutch ConstructionS7RS0B5301001

The clutch is a diaphragm spring clutch of a dry single disc type. The diaphragm spring is of a tapering-finger type,

which is a solid ring in the outer diameter part, with a series of tapered fingers pointing inward.

The disc, carrying four torsional coil springs, is positione d on the transaxle input shaft with an involute spline fit.

The clutch cover is secured to the flywheel, and carries the diaphragm spring in such a way that the peripheral edge

part of the spring pushes on the pressure plate against the flywheel (with the disc in between), when the clutch release

bearing is held back. This is the engaged condition of the clutch.

Depressing the clutch pedal c auses the release bearing to advance and pushes on the tips of the tapered fingers of

the diaphragm spring. When this happens, the diaphragm sp ring pulls the pressure plate away from the flywheel,

thereby interrupting the flow of drive from flywheel through clutch disc to transaxle input shaft. Clutch fluid is supplied

from brake fluid reservoir. Clutch fluid level can be checked by brake fluid level of brake fluid reservoir.

[A]: For petrol engine model2. Flywheel5. Clutch cover 8. Input shaft bearing

[B]: For diesel engine model 3. Clutch disc6. Diaphragm spring 9. Input shaft

1. Crankshaft 4. Pressure plate7. Release bearing 10. Release shaft

I4RS0A530001-01

Page 854 of 1496

Downloaded from www.Manualslib.com manuals search engine 5C-2 Clutch:

Diagnostic Information and Procedures

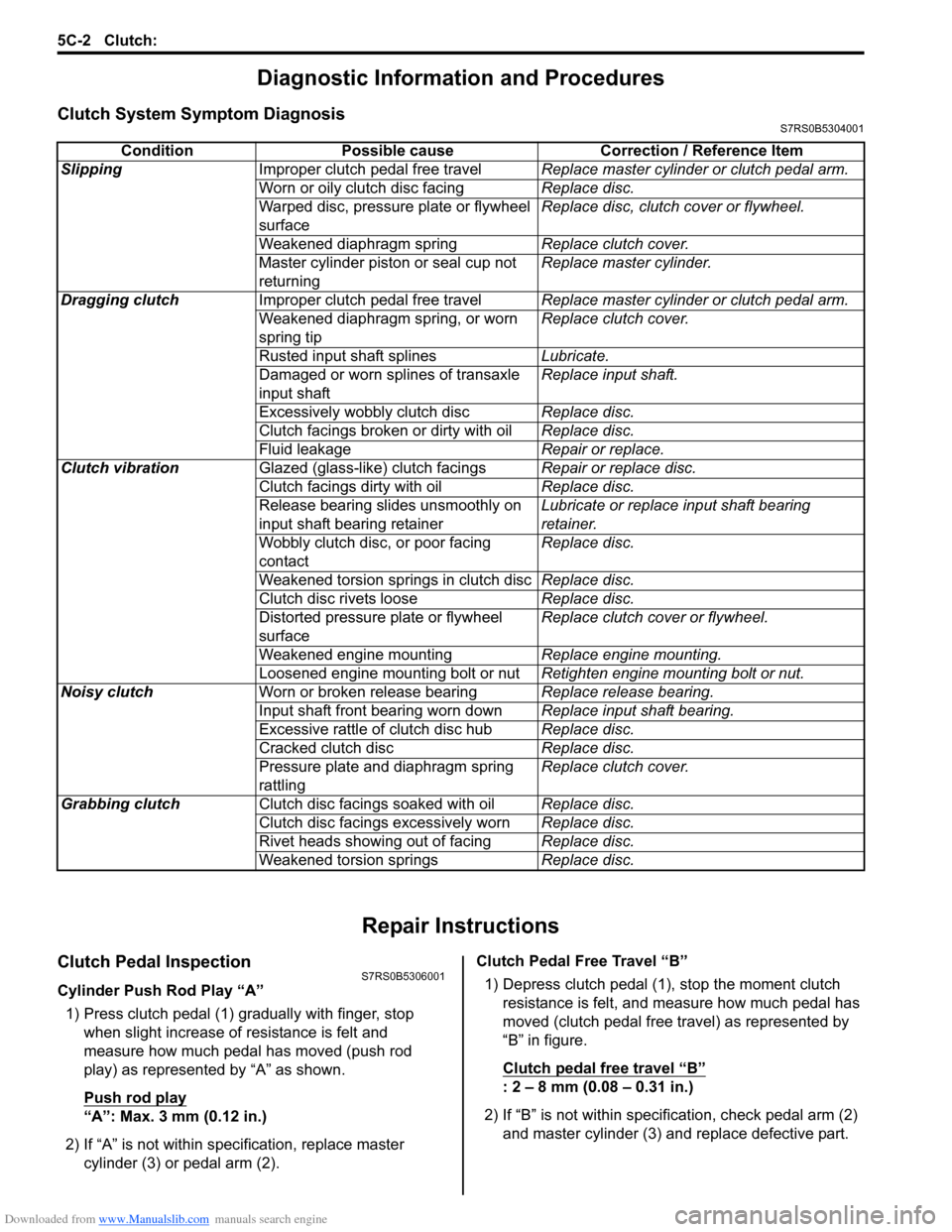

Clutch System Symptom DiagnosisS7RS0B5304001

Repair Instructions

Clutch Pedal InspectionS7RS0B5306001

Cylinder Push Rod Play “A”1) Press clutch pedal (1) gradually with finger, stop when slight increase of resistance is felt and

measure how much pedal has moved (push rod

play) as represented by “A” as shown.

Push rod play

“A”: Max. 3 mm (0.12 in.)

2) If “A” is not within specification, replace master cylinder (3) or pedal arm (2). Clutch Pedal Free Travel “B”

1) Depress clutch pedal (1), stop the moment clutch resistance is felt, and measure how much pedal has

moved (clutch pedal free travel) as represented by

“B” in figure.

Clutch pedal free travel

“B”

: 2 – 8 mm (0.08 – 0.31 in.)

2) If “B” is not within specification, check pedal arm (2) and master cylinder (3) and replace defective part.

Condition Possible cause Correction / Reference Item

Slipping Improper clutch pedal free travel Replace master cylinder or clutch pedal arm.

Worn or oily clutch disc facing Replace disc.

Warped disc, pressure plate or flywheel

surface Replace disc, clutch cover or flywheel.

Weakened diaphragm spring Replace clutch cover.

Master cylinder piston or seal cup not

returning Replace master cylinder.

Dragging clutch Improper clutch pedal free travel Replace master cylinder or clutch pedal arm.

Weakened diaphragm spring, or worn

spring tip Replace clutch cover.

Rusted input shaft splines Lubricate.

Damaged or worn splines of transaxle

input shaft Replace input shaft.

Excessively wobbly clutch disc Replace disc.

Clutch facings broken or dirty with oil Replace disc.

Fluid leakage Repair or replace.

Clutch vibration Glazed (glass-like) clutch facings Repair or replace disc.

Clutch facings dirty with oil Replace disc.

Release bearing slides unsmoothly on

input shaft bearing retainer Lubricate or replace input shaft bearing

retainer.

Wobbly clutch disc, or poor facing

contact Replace disc.

Weakened torsion springs in clutch disc Replace disc.

Clutch disc rivets loose Replace disc.

Distorted pressure plate or flywheel

surface Replace clutch cover or flywheel.

Weakened engine mounting Replace engine mounting.

Loosened engine mounting bolt or nut Retighten engine mounting bolt or nut.

Noisy clutch Worn or broken release bearing Replace release bearing.

Input shaft front bearing worn down Replace input shaft bearing.

Excessive rattle of clutch disc hub Replace disc.

Cracked clutch disc Replace disc.

Pressure plate and diaphragm spring

rattling Replace clutch cover.

Grabbing clutch Clutch disc facings soaked with oil Replace disc.

Clutch disc facings excessively worn Replace disc.

Rivet heads showing out of facing Replace disc.

Weakened torsion springs Replace disc.