outside air temperature SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 469 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-2

Lower than recommended pressure can cause:

• Tire squeal on turns

• Hard Steering

• Rapid and uneven wear on the edges of the tread

• Tire rim bruises and rupture

• Tire cord breakage

• High tire temperature

• Reduced handling

• High fuel consumption

Replacement Tires

When replacement is necessary, the original equipment

type tire should be used. Refer to the Tire Placard.

Replacement tires should be of the same size, load

range and construction as those originally on the vehicle.

Use of any other size or type tire may affect ride,

handling, speedometer / odometer calibration, vehicle

ground clearance and tire or snow chain clearance to the

body and chassis.

It is recommended that new tires be installed in pairs on

the same axle. If necessary to replace only one tire, it

should be paired with the tire having the most tread, to

equalize braking traction.

WARNING!

Do not mix different types of tires on the

same vehicle such as radial, bias and bias-

belted tires except in emergencies, because

handling may be seriously affected and may

result in loss of control.

The metric term for tire infl ation pressure is the kilo

pascal (kPa). Tire pressures is usually printed in both

kPa and kgf/cm

2 on the “Tire Placard”.

Metric tire gauges are available from tool suppliers.

The chart, shown the table, converts commonly used

inflation pressures from kPa to kgf/cm

2 and psi.

Wheels DescriptionS7RS0B2401002

Wheel Maintenance

Wheel repairs that use welding, heating, or peening are

not approved. All damaged wheels should be replaced.

Replacement Wheels

Wheels must be replaced if they are bent, dented, have

excessive lateral or radial runout, air leak through welds,

have elongated bolt holes, if lug wheel bolts won’t stay

tight, or if they are heavily rusted. Wheels with greater

runout than shown in the following may cause

objectional vibrations.

Replacement wheels must be equivalent to the original

equipment wheels in load capacity, diameter, rim with

offset and mounting configuration. A wheel of improper

size or type may affect wheel and bearing life, brake

cooling, speedometer / odometer calibration, vehicle

ground clearance and tire clearance to body and

chassis.

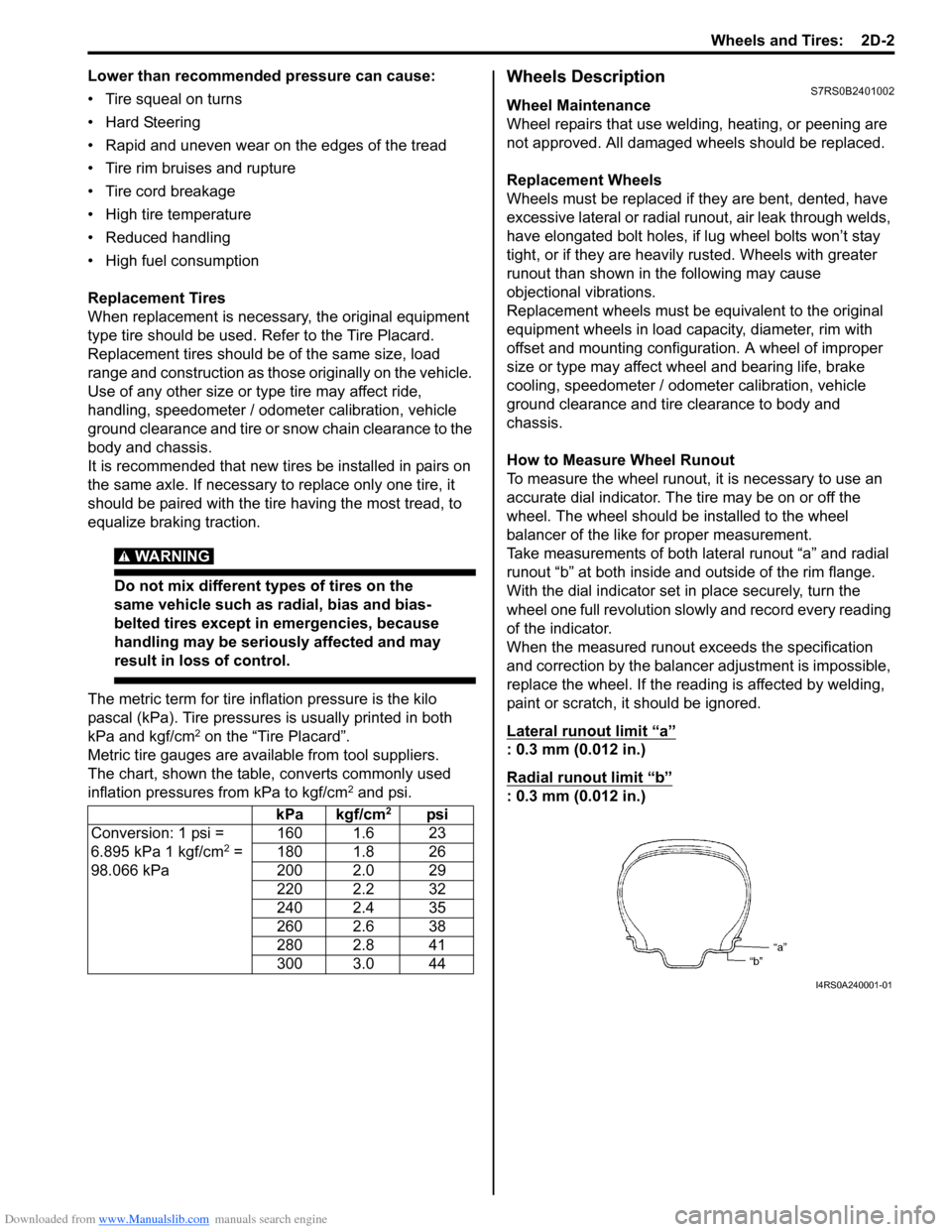

How to Measure Wheel Runout

To measure the wheel runout, it is necessary to use an

accurate dial indicator. The tire may be on or off the

wheel. The wheel should be installed to the wheel

balancer of the like for proper measurement.

Take measurements of both lateral runout “a” and radial

runout “b” at both inside an d outside of the rim flange.

With the dial indicator set in place securely, turn the

wheel one full revolution slowly and record every reading

of the indicator.

When the measured runout exceeds the specification

and correction by the balancer adjustment is impossible,

replace the wheel. If the reading is affected by welding,

paint or scratch, it should be ignored.

Lateral runout limit “a”

: 0.3 mm (0.012 in.)

Radial runout limit “b”

: 0.3 mm (0.012 in.)

kPa kgf/cm2psi

Conversion: 1 psi =

6.895 kPa 1 kgf/cm

2 =

98.066 kPa 160 1.6 23

180 1.8 26

200 2.0 29

220 2.2 32

240 2.4 35

260 2.6 38

280 2.8 41

300 3.0 44

I4RS0A240001-01

Page 934 of 1496

Downloaded from www.Manualslib.com manuals search engine 7-ii Table of Contents

Recommended Service Material ....................... 7B-33

Special Tool ...................................................... 7B-33

Automatic Type .................... .................................7B-34

Precautions.........................................................7B-34 A/C System Caution .......................................... 7B-34

Precautions in Diagnosing Trouble ................... 7B-34

Precautions on Servicing A/C System .............. 7B-34

General Description .......... .................................7B-34

Auto A/C System Descript ion ............................ 7B-34

HVAC Control Module Operation Description ... 7B-36

Refrigerant Type Identifica tion .......................... 7B-36

Sub-Cool A/C System Description .................... 7B-36

A/C Operation Description ................................ 7B-36

On-Board Diagnostic System Description ......... 7B-37

Schematic and Routing Diagram ......................7B-37 Major Components of A/C System .................... 7B-37

A/C System Wiring Diagra m ............................. 7B-38

Diagnostic Information and Procedures ..........7B-39 A/C System Symptom Diagnosis ...................... 7B-39

Abnormal Noise Sympto m Diagnosis of A/C

System ............................................................ 7B-42

DTC Check........................................................ 7B-42

DTC Clearance ................................................. 7B-43

DTC Table ......................................................... 7B-44

Fail-Safe Table ................. ................................. 7B-45

Scan Tool Data ................................................. 7B-46

Air Conditioning System Check......................... 7B-47

Visual Inspection ............................................... 7B-49

DTC B1502: Inside Air Temperature Sensor and/or Its Circuit Malfunction .......................... 7B-49

DTC B1503: A/C Evaporator Air Temperature Sensor and/or Its Circuit Malfunction .............. 7B-50

DTC B1504: Sunload Sensor and/or Its Circuit Malfunction ......... ................................. 7B-52

DTC B1511: Temperature Control Actuator (Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-53

DTC B1512: Air flow Control Actuator (Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-55

DTC B1513: Temperature Control Actuator and/or Its Circuit Malfunction .......................... 7B-57

DTC B1514: Air Flow Co ntrol Actuator and/or

Its Circuit Malfunction ...................................... 7B-60

DTC B1541: HVAC Control Module Back-Up Power Supply Malfunction .............................. 7B-62

DTC B1546: A/C Refrigerant Pressure Malfunction ...................................................... 7B-63

DTC B1551: Serial Communication Circuit Malfunction ...................................................... 7B-63

DTC B1552: Serial Communication Signal Malfunction ...................................................... 7B-64

DTC B1553: CAN Communication Signal Malfunction ...................................................... 7B-65

DTC B1557: Vehicle Speed Sensor Signal Malfunction ...................................................... 7B-65

DTC B1561: Engine Coolant Temperature Sensor Signal Malfunctio n .............................. 7B-66 DTC B1562: Outside Air Temperature Sensor

Signal Malfunction ........................................... 7B-66

DTC B1563: A/C Refr igerant Pressure

Sensor Signal Malfunction .............................. 7B-66

Inspection of HVAC Control Module and Its Circuit .............................................................. 7B-67

A/C System Performance Inspection ................ 7B-70

A/C System Inspection at ECM ......................... 7B-70

Repair Instructions ............ ................................7B-71

Operation Procedure for Refrigerant Charge .... 7B-71

HVAC Unit Components ................................... 7B-72

HVAC Unit Removal and In stallation ................ 7B-73

Temperature Control Actuator Removal and Installation ....................................................... 7B-73

Temperature Control Actuat or Inspection ......... 7B-73

Air Flow Control Actuator Removal and Installation ....................................................... 7B-74

Air Flow Control Actuator Inspection ................. 7B-74

Air Intake Control Actuator Removal and Installation ....................................................... 7B-75

Air Intake Control Actuator Inspection............... 7B-75

Actuator Linkage Inspection .............................. 7B-76

Blower Motor Controller Removal and Installation ....................................................... 7B-76

Blower Motor Controller Inspection ................... 7B-76

HVAC Control Module Removal and Installation ....................................................... 7B-77

Sunload Sensor Removal and Installation ........ 7B-77

Sunload Sensor Inspection ............................... 7B-77

Outside Air Temperature Sensor Removal and Installation ................................................ 7B-77

Outside Air Temperature Sensor Inspection ..... 7B-77

Inside Air Temperature Sensor Removal and Installation ....................................................... 7B-78

Inside Air Temperature Sens or Inspection ........ 7B-78

Condenser Assembly On-Vehicle Inspection .... 7B-78

Condenser Assembly Removal and Installation ....................................................... 7B-78

Receiver/Dryer Removal and Installation .......... 7B-78

Evaporator Inspection ....................................... 7B-78

Evaporator Temperature Sensor Removal and Installation ................................................ 7B-78

Evaporator Temperature Se nsor Inspection ..... 7B-78

Expansion Valve Removal an d Installation ....... 7B-78

Expansion Valve Inspection .............................. 7B-78

A/C Refrigerant Pressure Sensor and Its Circuit Inspection............................................. 7B-78

A/C Refrigerant Pressu re Sensor Removal

and Installation ................................................ 7B-78

Compressor Relay Inspection .

.......................... 7B-78

Compressor Drive Belt Inspection and Adjustment ...................................................... 7B-78

Compressor Drive Belt Removal and Installation ....................................................... 7B-79

Compressor Assembly Removal and Installation ....................................................... 7B-79

Compressor Assembly Components................. 7B-79

Magnet Clutch Removal and Installation........... 7B-79

Magnet Clutch Inspection.................................. 7B-79

Relief Valve Inspection...................................... 7B-79

Page 949 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-1

HVAC

Air Conditioning System

Manual Type

Precautions

A/C System CautionS7RS0B7210001

CAUTION!

• The air conditioning system of this vehicle uses refrigerant HFC-134a (R-134a).

None of refrigerant, compressor oil and component parts is interchangeable between two types of

A/C: one using refrigerant HFC-134a (R-134a) and the other using refrigerant CFC-12 (R-12).

Be sure to check which refrigerant is used be fore any service work including inspection and

maintenance. For identification between these two types, refer to “Refrigerant Type Identification”.

When replenishing or changing refrigerant and comp ressor oil and when replacing parts, make sure

that the material or the part to be used is appropriate to the A/C installed in the vehicle being

serviced.

Use of incorrect one will result in leakage of refrigerant, damage in parts or other faulty condition.

• When servicing the compressor, keep dirt or foreign material away from getting on or into the compressor parts and system. Clean tools and a clean work area are important for proper service.

The compressor connection and the outside of the compressor should be cleaned before any “On

vehicle” repair or before removal of the compressor. The parts must be kept clean at all times and

any parts to be reassembled should be cleaned with trichloromethane, naphtha, kerosene or

equivalent solvent and dried with dry air. Use only lint free cloths to wipe parts.

• When compressor is removed from the vehicle for servicing, the oil remaining in the compressor

should be discarded and new refrigerant oil added to the compressor.

Minor repair procedures may be done on the vehicle without discharging the system. Major repair

procedures require that the system be discharged of refrigerant.

Precautions on Servicing A/C SystemS7RS0B7210002

WARNING!

Should refrigerant HFC-134a (R-134a) is exposed to your eye(s), consult a doctor immediately.

• Do not use your hand to rub affected eye(s). Instead, use fresh cold water to splash it over affected area to thus gradually raise its temperature above the freezing point.

• Obtain proper treatment as soon as possible from a doctor or eye specialist. Should liquid refrigerant HFC-134a (R-134a) is exposed to your skin, such affected part should be treated in the

same manner as when skin is frostbitten or frozen.

Handling Refrigerant HFC-134a (R-134a)

• Always wear goggles to protect your eyes.

• Avoid direct contact to liquid refrigerant.

• Do not heat refrigerant container higher than 40 °C (104 ° F).

• Do not discharge refrigerant into atmosphere.

• Do not expose bright metals to liquid refrigerant. Refrig erant combined with moisture is corrosive and tarnishes

surfaces of bright metals including chrome.

Page 982 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-34 Air Conditioning System: Automatic Type

Automatic Type

Precautions

A/C System CautionS7RS0B7220001

Refer to “A/C System Caution”.

Precautions in Diagnosing TroubleS7RS0B7220002

• Do not disconnect couplers from HVAC control module, battery cable from battery, HVAC control module ground

wire harness from body or main fuse before confirming diagnostic information (diagnostic trouble code) stored in

HVAC control module memory.

• Diagnostic information (diagnostic trouble code) stored in HVAC control module can be checked by display of HVAC

control module. Also, it can be checked by using SU ZUKI scan tool. Before checking diagnostic information

(diagnostic trouble code), read this manual and operator's manual for SUZUKI scan tool to know how to read

diagnostic information (diagnostic trouble code).

• When trouble is diagnosed using diagnostic information (diagnostic trouble code) on display of HVAC control

module, keep in your mind that each diagnostic inform ation (diagnostic trouble code) has priority, and only

diagnostic information (diagnostic troub le code) which has the highest priority is indicated. Therefore, after

troubleshooting the malfunction, make sure if there exists any other diagnostic information (diagnostic trouble

code).

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” before inspection.

Precautions on Servicing A/C SystemS7RS0B7220003

Refer to “Precautions on Servicing A/C System”.

General Description

Auto A/C System DescriptionS7RS0B7221001

The automatic type air conditioning system (auto A/C) is pr ovided with the function to automatically control the inside

air temperature, fan speed, air flow outl et direction and air intake position by HVAC control module in addition to

functions of the manual type air conditioning system (manua l A/C). Once the inside air temperature is set using the

temperature selector, HVAC control module automatically controls the inside air temperature at the constant level at all

times based on the inside air temperature, outside ai r temperature, amount of sunlight and engine coolant

temperature detected respectively by the inside air te mperature sensor, outside air temperature sensor, sunload

sensor and ECT sensor. At this time, “FULL AUTO A/ C” appears on the display of HVAC control module.

With the air intake selector pushed in the above state, it is possible to select any position of the air intake actuator.

Then, “FULL AUTO A/C” on the display changes to “AUTO A/C”.

Page 983 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-35

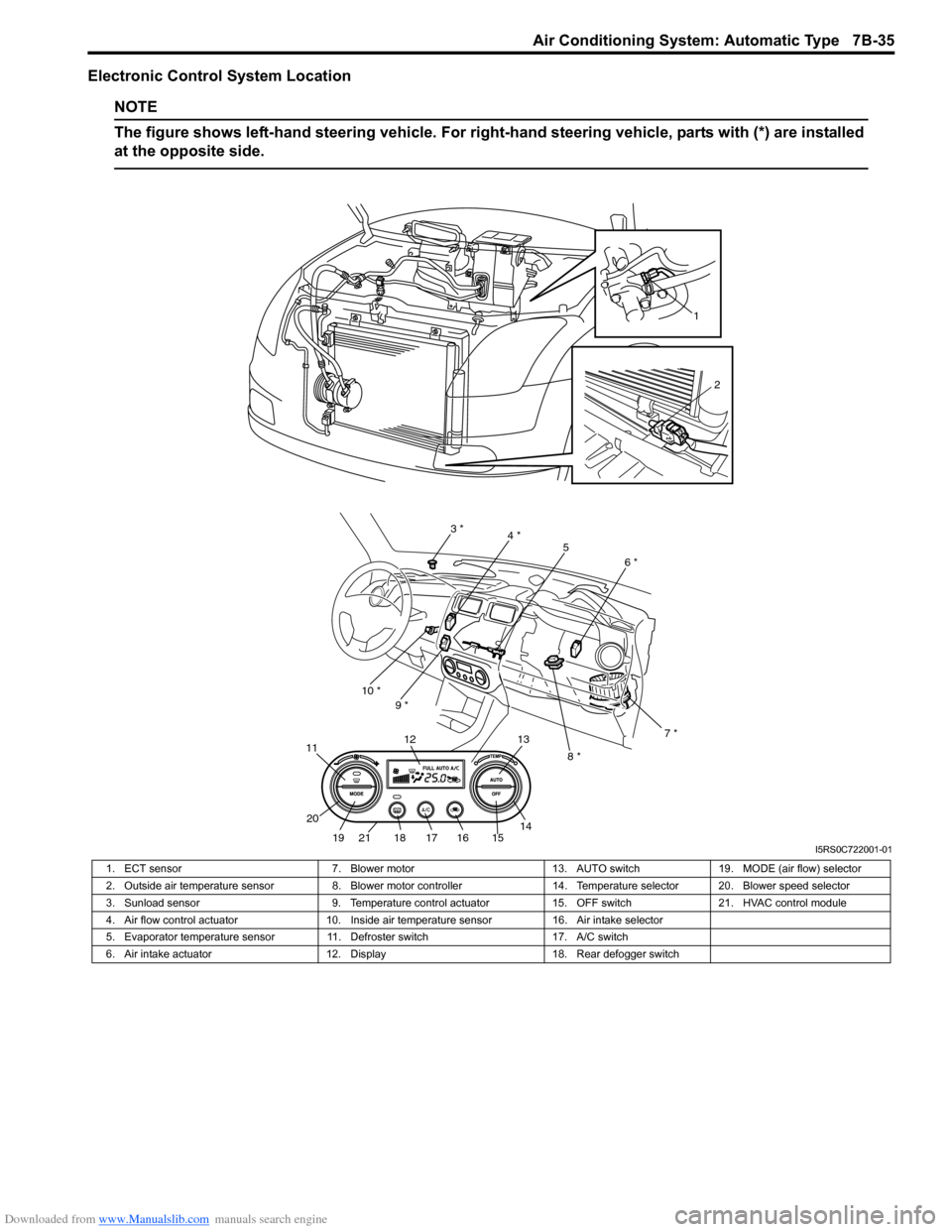

Electronic Control System Location

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

1

2

3 * 4 *

5

6 *

7 *

8 *

9 *

10 *

21

11

12 13

14

15161718

19

20

I5RS0C722001-01

1. ECT sensor

7. Blower motor13. AUTO switch19. MODE (air flow) selector

2. Outside air temperature sensor 8. Blower motor controller 14. Temperature selector 20. Blower speed selector

3. Sunload sensor 9. Temperature control actuator15. OFF switch21. HVAC control module

4. Air flow control actuator 10. Inside air temperature sensor 16. Air intake selector

5. Evaporator temperature sensor 11. Defroster switch 17. A/C switch

6. Air intake actuator 12. Display 18. Rear defogger switch

Page 984 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-36 Air Conditioning System: Automatic Type

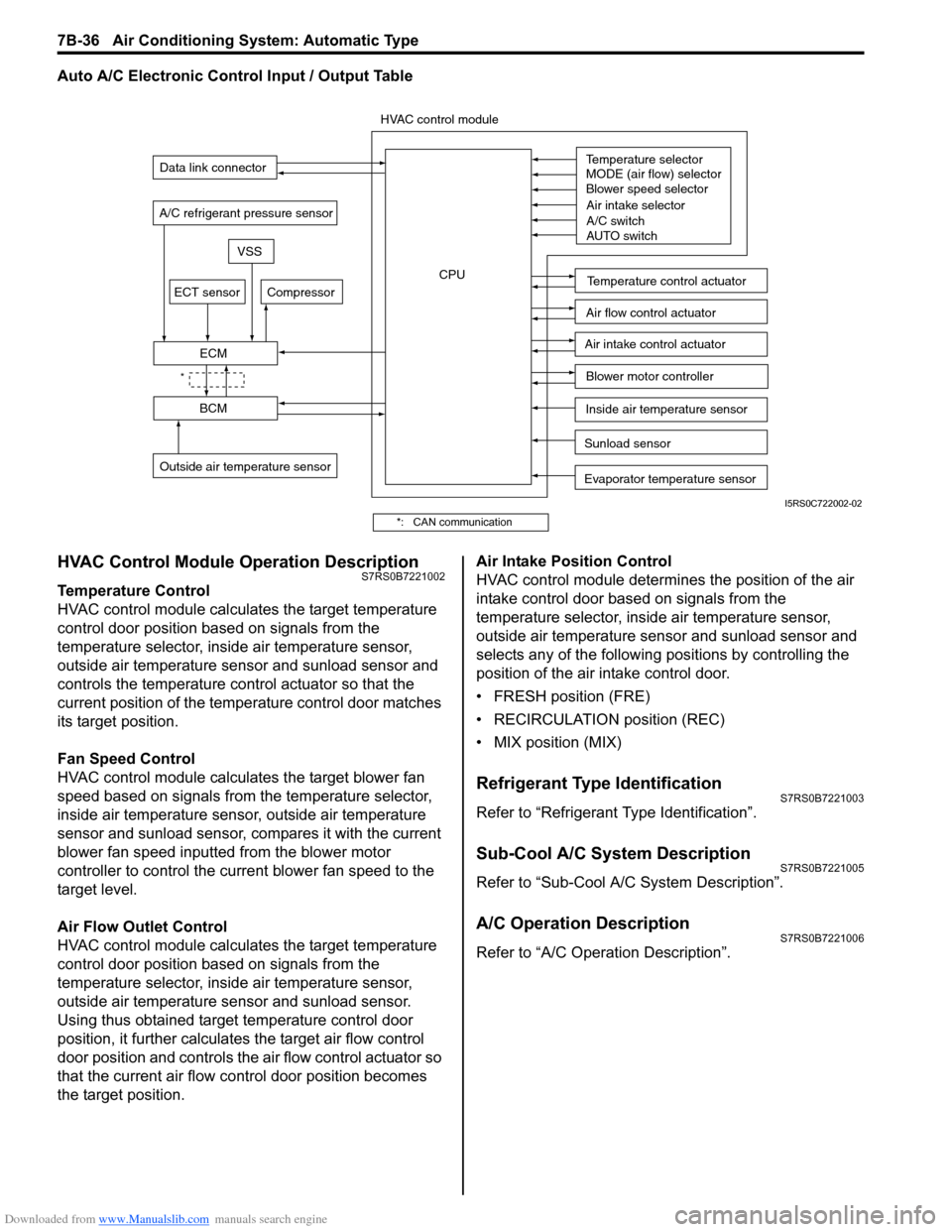

Auto A/C Electronic Control Input / Output Table

HVAC Control Module Operation DescriptionS7RS0B7221002

Temperature Control

HVAC control module calculates the target temperature

control door position based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor and

controls the temperature control actuator so that the

current position of the temperature control door matches

its target position.

Fan Speed Control

HVAC control module calculates the target blower fan

speed based on signals from the temperature selector,

inside air temperature sensor, outside air temperature

sensor and sunload sensor, compares it with the current

blower fan speed inputted from the blower motor

controller to control the current blower fan speed to the

target level.

Air Flow Outlet Control

HVAC control module calculates the target temperature

control door position based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor.

Using thus obtained target temperature control door

position, it further calculates the target air flow control

door position and controls the ai r flow control actuator so

that the current air flow c ontrol door position becomes

the target position. Air Intake Position Control

HVAC control module determines the position of the air

intake control door based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor and

selects any of the following positions by controlling the

position of the air intake control door.

• FRESH position (FRE)

• RECIRCULATION position (REC)

• MIX position (MIX)

Refrigerant Type IdentificationS7RS0B7221003

Refer to “Refrigerant Type Identification”.

Sub-Cool A/C System DescriptionS7RS0B7221005

Refer to “Sub-Cool A/C System Description”.

A/C Operation DescriptionS7RS0B7221006

Refer to “A/C Operation Description”.

Sunload sensor

Outside air temperature sensor Evaporator temperature sensor

A/C refrigerant pressure sensor

Temperature selector

MODE (air flow) selector

Blower speed selector

Air intake selector

AUTO switch

A/C switch

Compressor

Blower motor controller

Temperature control actuator

Air flow control actuator

Air intake control actuator

BCM

ECM

Data link connector

HVAC control module

CPU

ECT sensor

Inside air temperature sensor

VSS

*

I5RS0C722002-02

*: CAN communication

Page 985 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-37

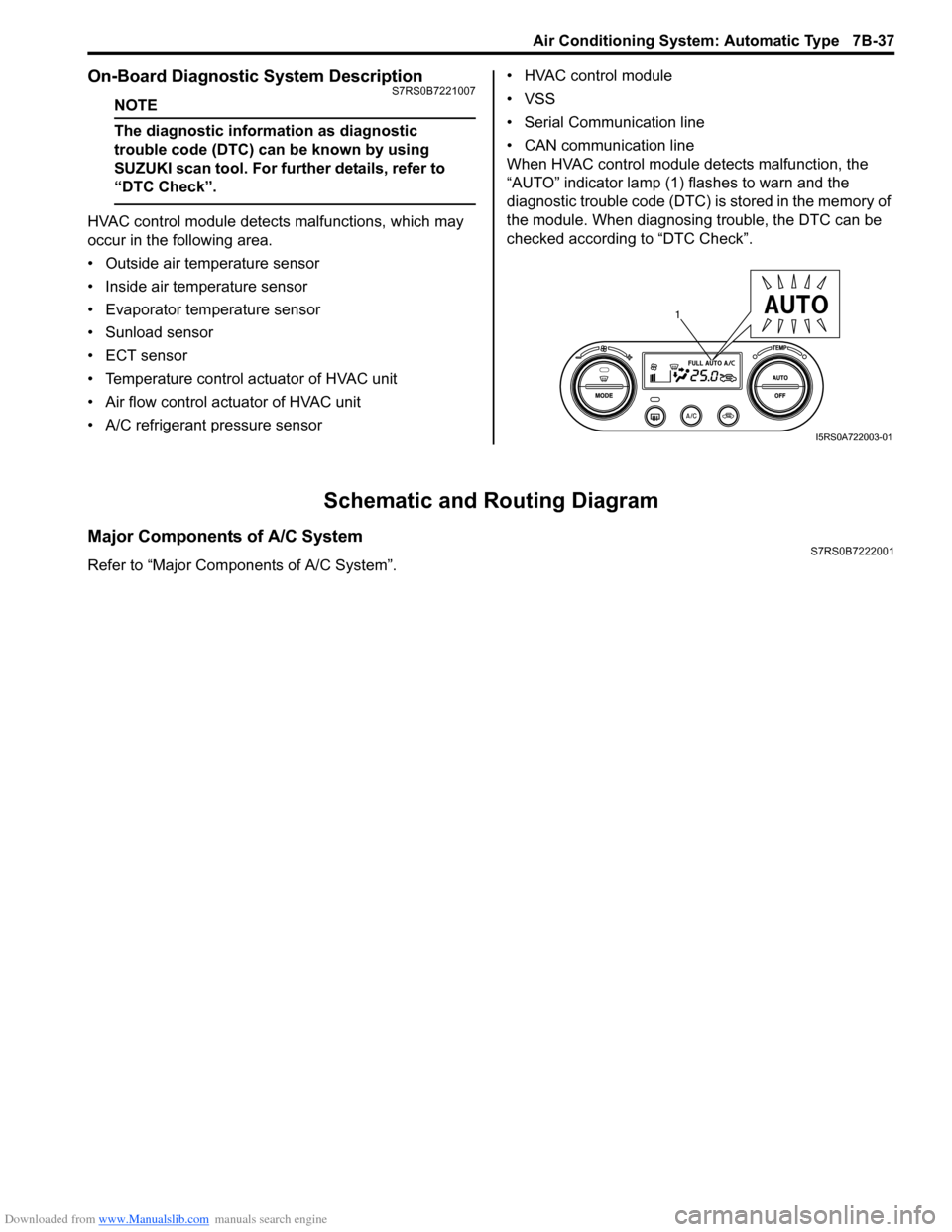

On-Board Diagnostic System DescriptionS7RS0B7221007

NOTE

The diagnostic information as diagnostic

trouble code (DTC) can be known by using

SUZUKI scan tool. For further details, refer to

“DTC Check”.

HVAC control module detect s malfunctions, which may

occur in the following area.

• Outside air temperature sensor

• Inside air temperature sensor

• Evaporator temperature sensor

• Sunload sensor

• ECT sensor

• Temperature control actuator of HVAC unit

• Air flow control actuator of HVAC unit

• A/C refrigerant pressure sensor • HVAC control module

• VSS

• Serial Communication line

• CAN communication line

When HVAC control module detects malfunction, the

“AUTO” indicator lamp (1) flashes to warn and the

diagnostic trouble code (DTC) is stored in the memory of

the module. When diagnosing trouble, the DTC can be

checked according to “DTC Check”.

Schematic and Routing Diagram

Major Components of A/C SystemS7RS0B7222001

Refer to “Major Components of A/C System”.

1

I5RS0A722003-01

Page 986 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-38 Air Conditioning System: Automatic Type

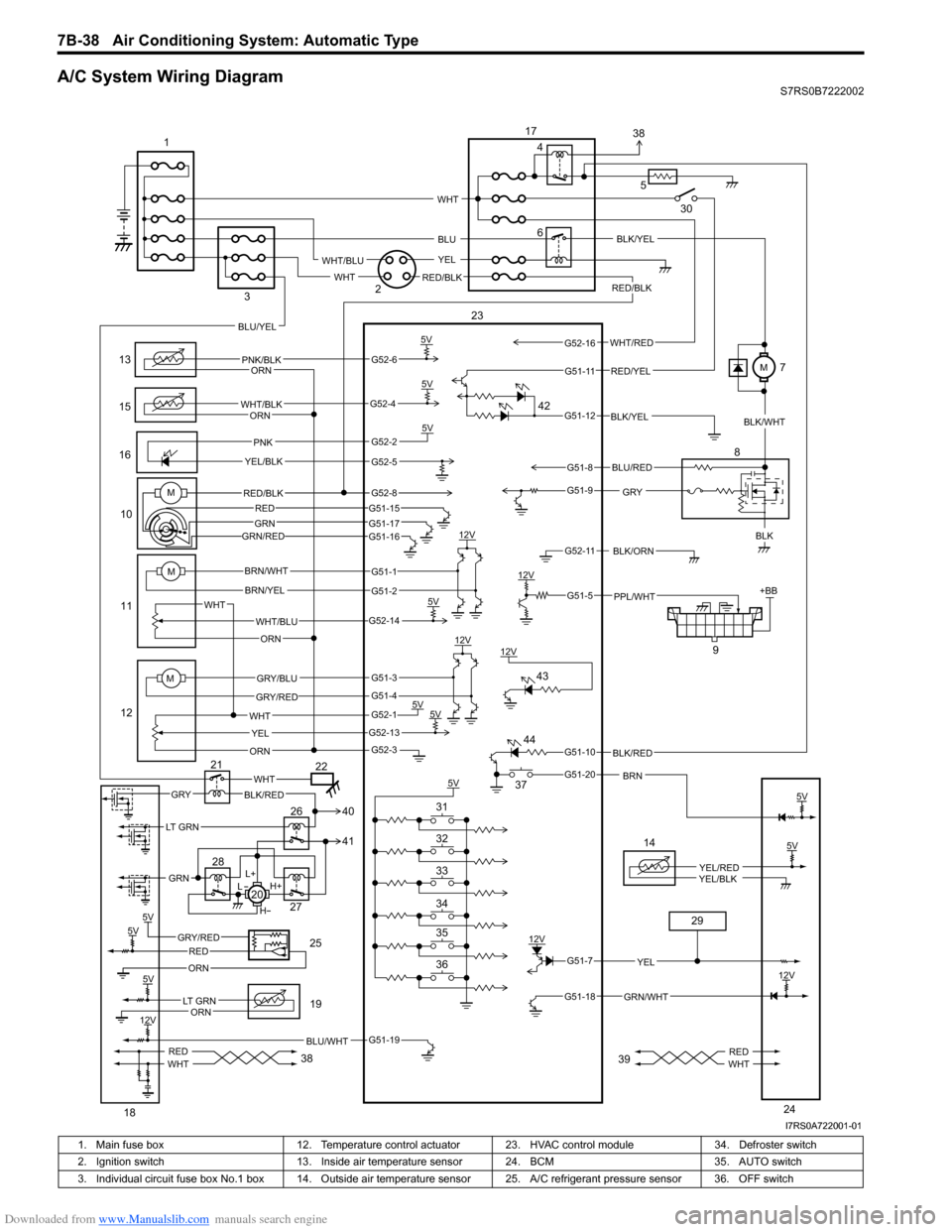

A/C System Wiring DiagramS7RS0B7222002

6

13

15

1610

11

12 9

12V

5V

5V5V

12V

12V

5V 5V

5V +BB

PNK/BLK

WHT/BLK

GRYBLK

WHT/BLU

WHT YEL

ORN

BRN/WHT

BRN/YEL

GRY/BLU

GRY/RED

PNK

YEL/BLK

BLK/ORN

PPL/WHT

12V BLK/YEL

WHT

ORN

ORN

ORN

5V

BLK/RED

BRN

RED/BLK

5V

5VGRY/REDRED

ORN

BLU/WHT

14

YEL/REDYEL/BLK

GRN/WHT

12V

YEL

L+

H+

L

H

WHTGRYBLK/RED

REDWHTREDWHT

M

M

WHT/RED

5

BLU

YEL

WHT

WHT/BLU

RED/BLKWHT

RED/YEL

BLU/YEL

LT GRN

GRN

BLU/RED

G52-6

G52-4

G52-2

G52-5

G51-1

G51-2

G52-14

G51-3

G51-4

G52-1

G52-13

G52-3

G51-19

G51-7

G51-18

G51-10

G51-20

G51-5

G52-11

G51-9

G51-8

G51-12

G51-11

G52-16

5V

12V

5V

12V

LT GRNORN

5V

23

1

2

3 4

8

17

18 19

20

21

22

24

25

26

27

28

29

30

36 35 34 33 32 31 37

38 3938

41 40

42

43

44

MRED/BLK

GRN/RED

G52-8G51-15

G51-17G51-16

REDGRN

BLK/YEL

BLK/WHT

M7

I7RS0A722001-01

1. Main fuse box 12. Temperature control actuator 23. HVAC control module 34. Defroster switch

2. Ignition switch 13. Inside air temperature sensor 24. BCM 35. AUTO switch

3. Individual circuit fuse box No.1 box 14. Outside air temper ature sensor 25. A/C refrigerant pressure sensor 36. OFF switch

Page 993 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-45

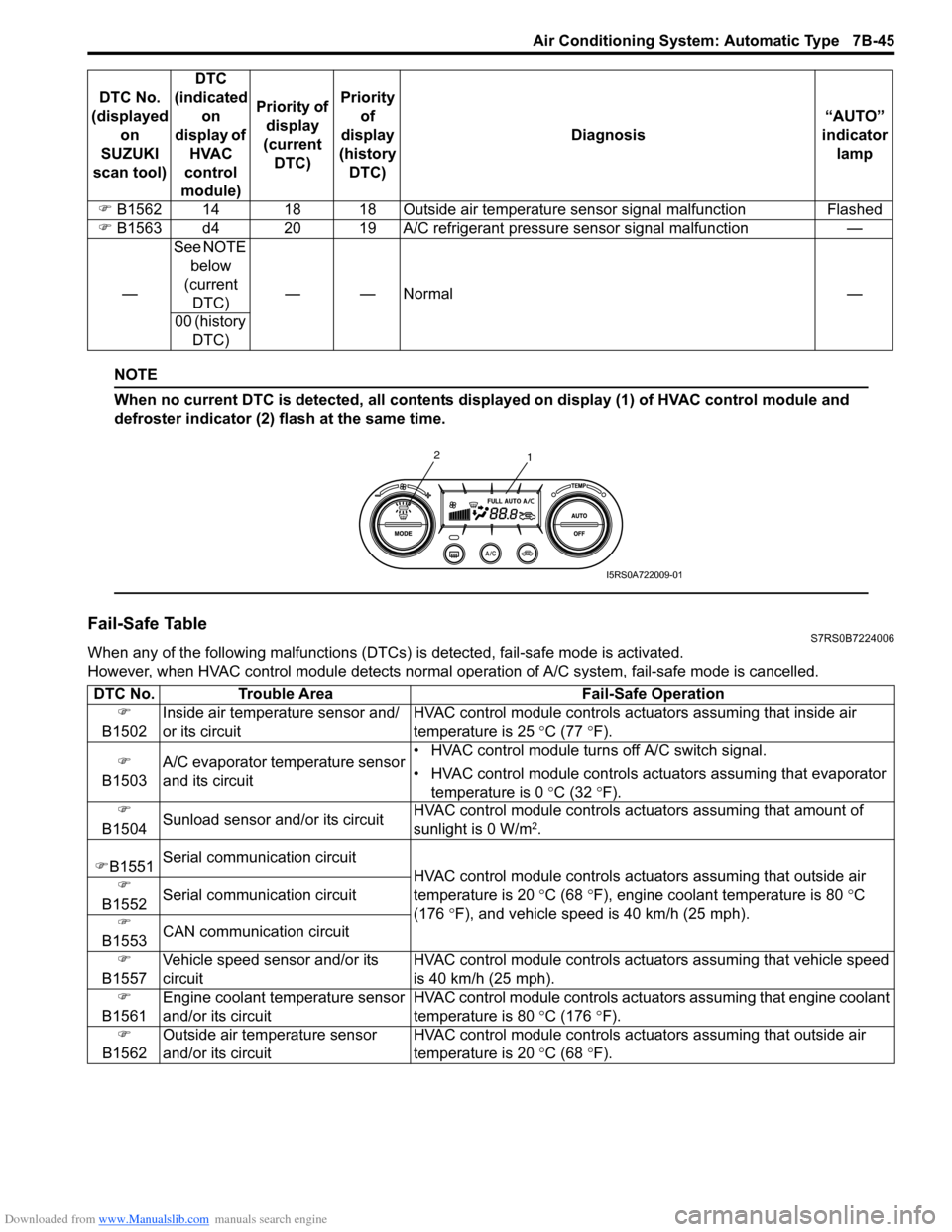

NOTE

When no current DTC is detected, all contents displayed on display (1) of HVAC control module and

defroster indicator (2) flash at the same time.

Fail-Safe TableS7RS0B7224006

When any of the following malfunctions (DTCs) is detected, fail-safe mode is activated.

However, when HVAC control module detects normal ope ration of A/C system, fail-safe mode is cancelled.

�)

B1562 14 18 18 Outside air temperatur e sensor signal malfunction Flashed

�) B1563 d4 20 19 A/C refrigerant pressure sensor signal malfunction —

— See NOTE

below

(current DTC) ——Normal —

00 (history DTC)

DTC No.

(displayed on

SUZUKI

scan tool) DTC

(indicated on

display of HVAC

control

module) Priority of

display

(current DTC) Priority

of

display

(history DTC) Diagnosis

“AUTO”

indicator lamp

1

2

I5RS0A722009-01

DTC No.

Trouble Area Fail-Safe Operation

�)

B1502 Inside air temperature sensor and/

or its circuit HVAC control module controls actu

ators assuming that inside air

temperature is 25 ° C (77 °F).

�)

B1503 A/C evaporator temperature sensor

and its circuit • HVAC control module turn

s off A/C switch signal.

• HVAC control module controls actu ators assuming that evaporator

temperature is 0 ° C (32 °F).

�)

B1504 Sunload sensor and/or its circuit HVAC control module controls actu

ators assuming that amount of

sunlight is 0 W/m

2.

�) B1551 Serial communication circuit

HVAC control module controls actuators assuming that outside air

temperature is 20 ° C (68 °F), engine coolant temperature is 80 °C

(176 °F), and vehicle speed is 40 km/h (25 mph).

�)

B1552 Serial communication circuit

�)

B1553 CAN communication circuit

�)

B1557 Vehicle speed sensor and/or its

circuit HVAC control module controls act

uators assuming that vehicle speed

is 40 km/h (25 mph).

�)

B1561 Engine coolant temperature sensor

and/or its circuit HVAC control module controls act

uators assuming that engine coolant

temperature is 80 ° C (176 °F).

�)

B1562 Outside air temperature sensor

and/or its circuit HVAC control module controls actu

ators assuming that outside air

temperature is 20 ° C (68 °F).

Page 994 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-46 Air Conditioning System: Automatic Type

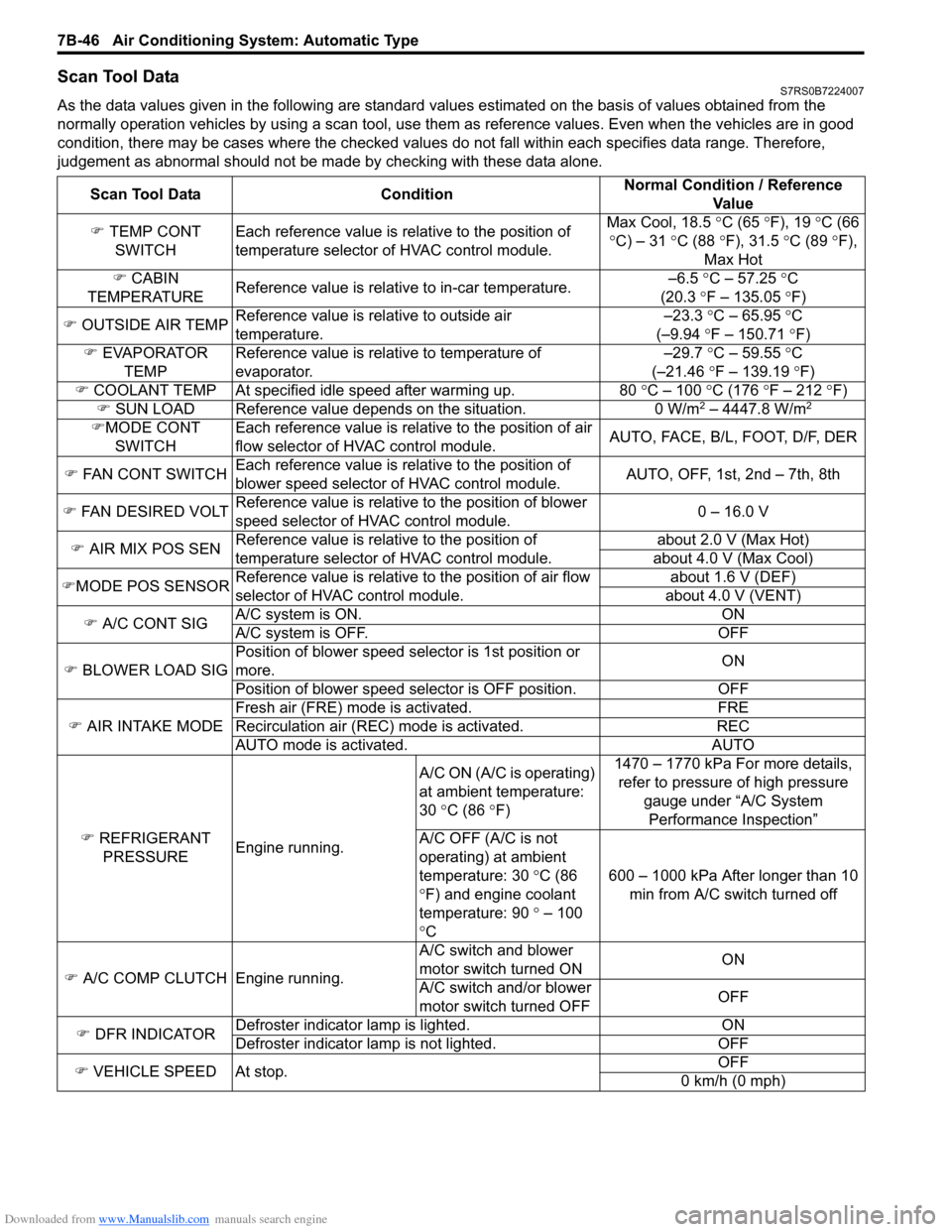

Scan Tool DataS7RS0B7224007

As the data values given in the following are standard values estimated on the basis of values obtained from the

normally operation vehicles by using a scan tool, use them as reference values. Even when the vehicles are in good

condition, there may be cases where the checked values do not fall within each specifies data range. Therefore,

judgement as abnormal should not be ma de by checking with these data alone.

Scan Tool Data Condition Normal Condition / Reference

Va l u e

�) TEMP CONT

SWITCH Each reference value is relative to the position of

temperature selector of HVAC control module. Max Cool, 18.5

°C (65 ° F), 19 °C (66

° C) – 31 °C (88 °F), 31.5 °C (89 °F),

Max Hot

�) CABIN

TEMPERATURE Reference value is relative to in-car temperature. –6.5

°C – 57.25 ° C

(20.3 °F – 135.05 °F)

�) OUTSIDE AIR TEMP Reference value is relative to outside air

temperature. –23.3

°C – 65.95 °C

(–9.94 °F – 150.71 °F)

�) EVAPORATOR

TEMP Reference value is relative to temperature of

evaporator. –29.7

°C – 59.55 °C

(–21.46 °F – 139.19 °F)

�) COOLANT TEMP At specified id le speed after warming up. 80 °C – 100 °C (176 ° F – 212 ° F)

�) SUN LOAD Reference value depends on the situation. 0 W/m

2 – 4447.8 W/m2

�)MODE CONT

SWITCH Each reference value is relative to the position of air

flow selector of HVAC control module.

AUTO, FACE, B/L, FOOT, D/F, DER

�) FAN CONT SWITCH Each reference value is relative to the position of

blower speed selector of HVAC control module. AUTO, OFF, 1st, 2nd – 7th, 8th

�) FAN DESIRED VOLT Reference value is relative to the position of blower

speed selector of HVAC control module. 0 – 16.0 V

�) AIR MIX POS SEN Reference value is relative to the position of

temperature selector of HVAC control module. about 2.0 V (Max Hot)

about 4.0 V (Max Cool)

�) MODE POS SENSOR Reference value is relative to the position of air flow

selector of HVAC control module. about 1.6 V (DEF)

about 4.0 V (VENT)

�) A/C CONT SIG A/C system is ON. ON

A/C system is OFF. OFF

�) BLOWER LOAD SIG Position of blower speed selector is 1st position or

more.

ON

Position of blower speed selector is OFF position. OFF

�) AIR INTAKE MODE Fresh air (FRE) mode is activated. FRE

Recirculation air (REC) mode is activated. REC

AUTO mode is activated. AUTO

�) REFRIGERANT

PRESSURE Engine running. A/C ON (A/C is operating)

at ambient temperature:

30

°C (86 °F) 1470 – 1770 kPa For more details,

refer to pressure of high pressure

gauge under “A/C System Performance Inspection”

A/C OFF (A/C is not

operating) at ambient

temperature: 30 °C (86

° F) and engine coolant

temperature: 90 ° – 100

° C 600 – 1000 kPa After longer than 10

min from A/C switch turned off

�) A/C COMP CLUTCH Engine running. A/C switch and blower

motor switch turned ON

ON

A/C switch and/or blower

motor switch turned OFF OFF

�) DFR INDICATOR Defroster indicator

lamp is lighted. ON

Defroster indicator la mp is not lighted. OFF

�) VEHICLE SPEED At stop. OFF

0 km/h (0 mph)