Hose SUZUKI SWIFT 2008 2.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 502 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-4 Brake Control System and Diagnosis:

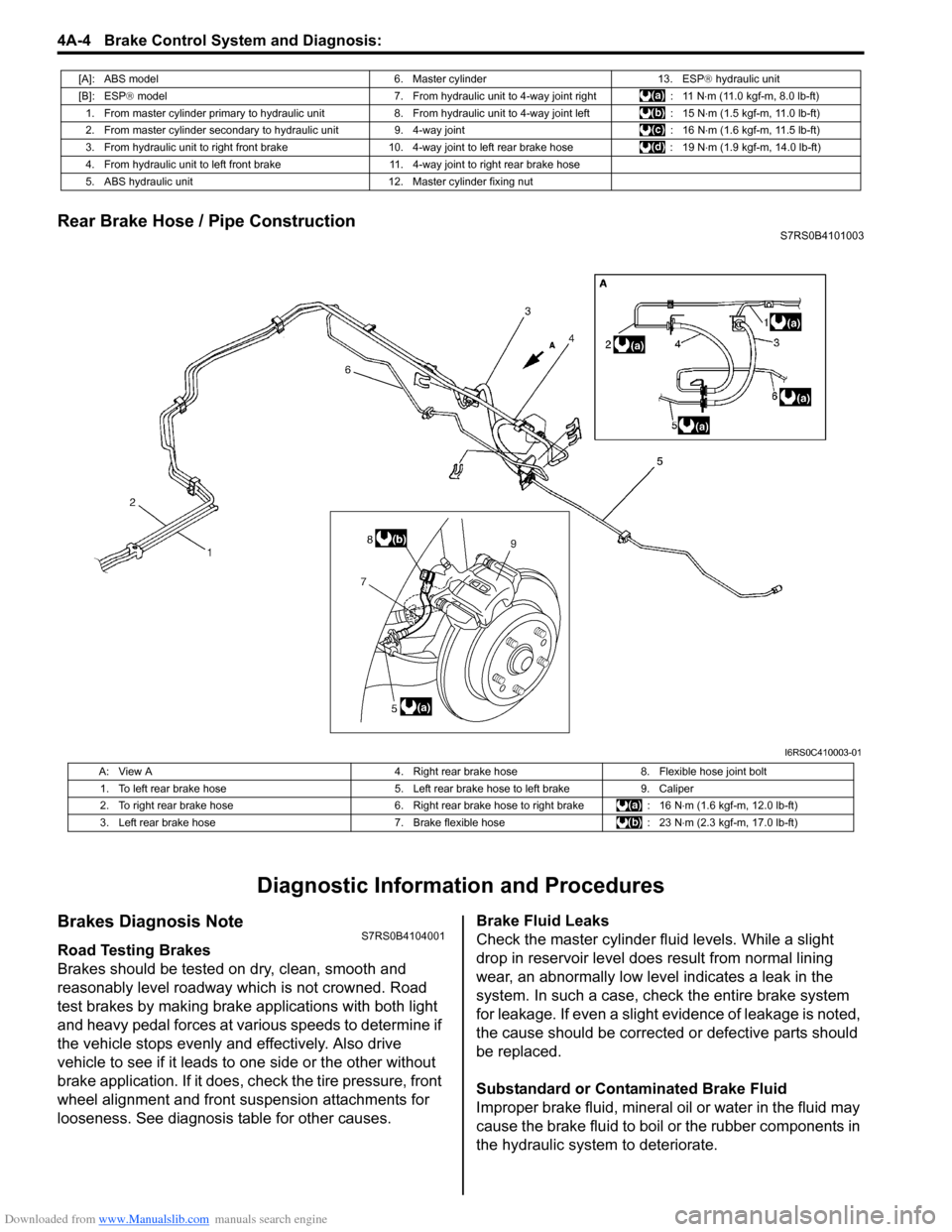

Rear Brake Hose / Pipe ConstructionS7RS0B4101003

Diagnostic Information and Procedures

Brakes Diagnosis NoteS7RS0B4104001

Road Testing Brakes

Brakes should be tested on dry, clean, smooth and

reasonably level roadway which is not crowned. Road

test brakes by making brake applications with both light

and heavy pedal forces at vari ous speeds to determine if

the vehicle stops evenly and effectively. Also drive

vehicle to see if it leads to one side or the other without

brake application. If it does, check the tire pressure, front

wheel alignment and front suspension attachments for

looseness. See diagnosis table for other causes. Brake Fluid Leaks

Check the master cylinder fl

uid levels. While a slight

drop in reservoir level does result from normal lining

wear, an abnormally low leve l indicates a leak in the

system. In such a case, chec k the entire brake system

for leakage. If even a slight ev idence of leakage is noted,

the cause should be corrected or defective parts should

be replaced.

Substandard or Contaminated Brake Fluid

Improper brake fluid, mineral oil or water in the fluid may

cause the brake fluid to boil or the rubber components in

the hydraulic system to deteriorate.

[A]: ABS model 6. Master cylinder13. ESP® hydraulic unit

[B]: ESP ® model 7. From hydraulic unit to 4-way joint right : 11 N⋅m (11.0 kgf-m, 8.0 lb-ft)

1. From master cylinder primary to hydraulic unit 8. From hydraulic unit to 4-way joint left: 15 N⋅m (1.5 kgf-m, 11.0 lb-ft)

2. From master cylinder secondary to hydraulic unit 9. 4-way joint: 16 N⋅m (1.6 kgf-m, 11.5 lb-ft)

3. From hydraulic unit to right front brake 10.4-way joint to left rear brake hose : 19 N⋅m (1.9 kgf-m, 14.0 lb-ft)

4. From hydraulic unit to left front brake 11. 4-way joint to right rear brake hose

5. ABS hydraulic unit 12. Master cylinder fixing nut

I6RS0C410003-01

A: View A4. Right rear brake hose8. Flexible hose joint bolt

1. To left rear brake hose 5. Left rear brake hose to left brake9. Caliper

2. To right rear brake hose 6. Right rear brake hose to right brake: 16 N⋅m (1.6 kgf-m, 12.0 lb-ft)

3. Left rear brake hose 7. Brake flexible hose: 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

Page 503 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-5

If deterioration of rubber is evident, disassemble all

hydraulic parts and wash with alcohol. Dry these parts

with compressed air before assembly to keep alcohol out

of the system. Replace all rubber parts in the system,

including hoses. Also, when working on the brake

mechanisms, check for fluid on the linings.

If excessive fluid is found, replace the pads. If master cylinder piston seals

are satisfactory, check for

leakage or excessive heat co nditions. If leakage is not

found, drain fluid, flush with brake fluid, refill and bleed

system.

The system must be flushed if there is any doubt as to

the grade of fluid in the system or if fluid has been used

which contained parts that have been subjected to

contaminated fluid.

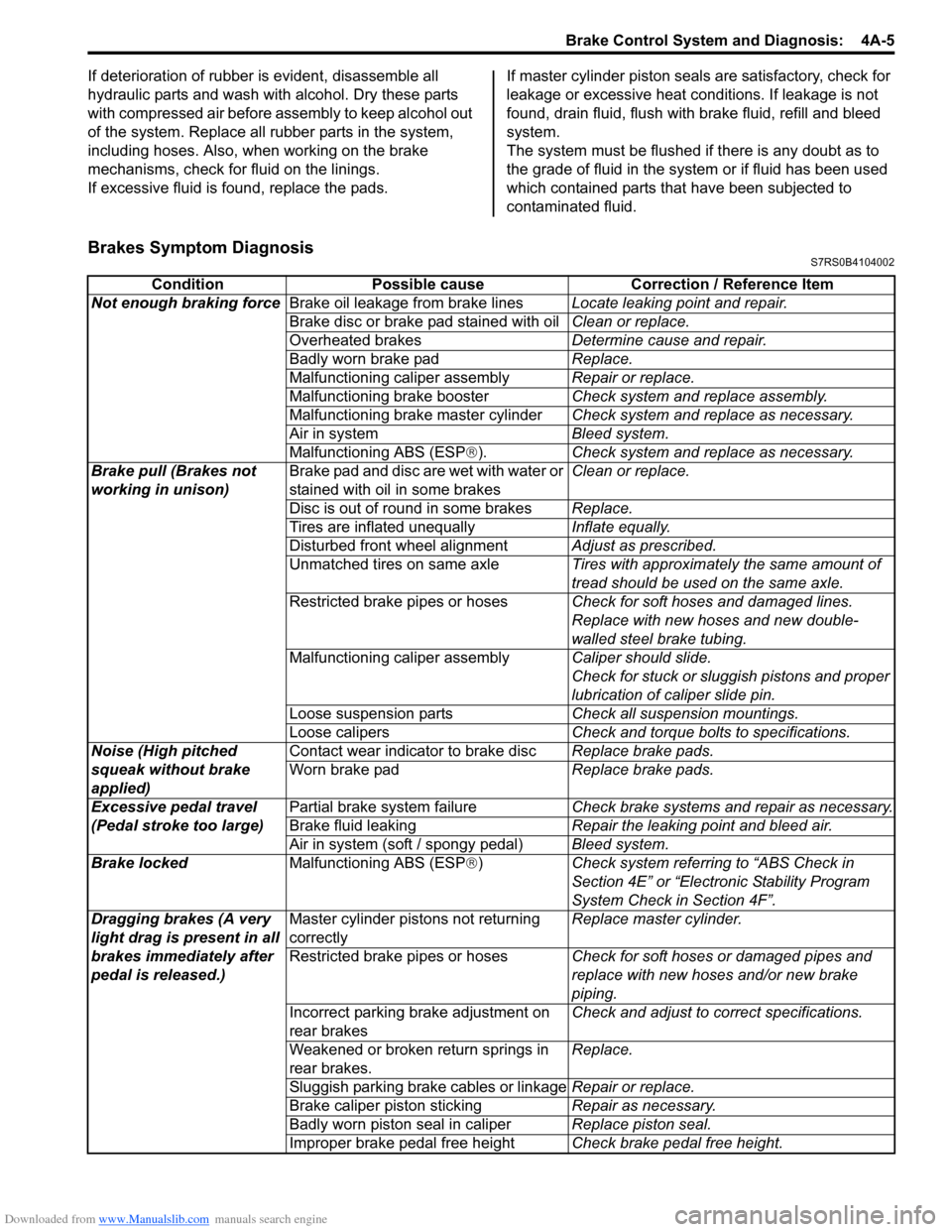

Brakes Symptom DiagnosisS7RS0B4104002

Condition Possible cause Correction / Reference Item

Not enough braking force Brake oil leakage from brake lines Locate leaking point and repair.

Brake disc or brake pad stained with oil Clean or replace.

Overheated brakes Determine cause and repair.

Badly worn brake pad Replace.

Malfunctioning caliper assembly Repair or replace.

Malfunctioning brake booster Check system and replace assembly.

Malfunctioning brake master cylinder Check system and replace as necessary.

Air in system Bleed system.

Malfunctioning ABS (ESP ®). Check system and replace as necessary.

Brake pull (Brakes not

working in unison) Brake pad and disc are wet with water or

stained with oil in some brakes Clean or replace.

Disc is out of round in some brakes Replace.

Tires are inflated unequally Inflate equally.

Disturbed front wheel alignment Adjust as prescribed.

Unmatched tires on same axle Tires with approximately the same amount of

tread should be used on the same axle.

Restricted brake pipes or hoses Check for soft hoses and damaged lines.

Replace with new hoses and new double-

walled steel brake tubing.

Malfunctioning caliper assembly Caliper should slide.

Check for stuck or sluggish pistons and proper

lubrication of caliper slide pin.

Loose suspension parts Check all suspension mountings.

Loose calipers Check and torque bolts to specifications.

Noise (High pitched

squeak without brake

applied) Contact wear indicator to brake disc

Replace brake pads.

Worn brake pad Replace brake pads.

Excessive pedal travel

(Pedal stroke too large) Partial brake system failure

Check brake systems and repair as necessary.

Brake fluid leaking Repair the leaking point and bleed air.

Air in system (soft / spongy pedal) Bleed system.

Brake locked Malfunctioning ABS (ESP®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

Dragging brakes (A very

light drag is present in all

brakes immediately after

pedal is released.) Master cylinder pistons not returning

correctly

Replace master cylinder.

Restricted brake pipes or hoses Check for soft hoses or damaged pipes and

replace with new hoses and/or new brake

piping.

Incorrect parking brake adjustment on

rear brakes Check and adjust to correct specifications.

Weakened or broken return springs in

rear brakes. Replace.

Sluggish parking brake cables or linkage Repair or replace.

Brake caliper piston sticking Repair as necessary.

Badly worn piston seal in caliper Replace piston seal.

Improper brake pedal free height Check brake pedal free height.

Page 506 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-8 Brake Control System and Diagnosis:

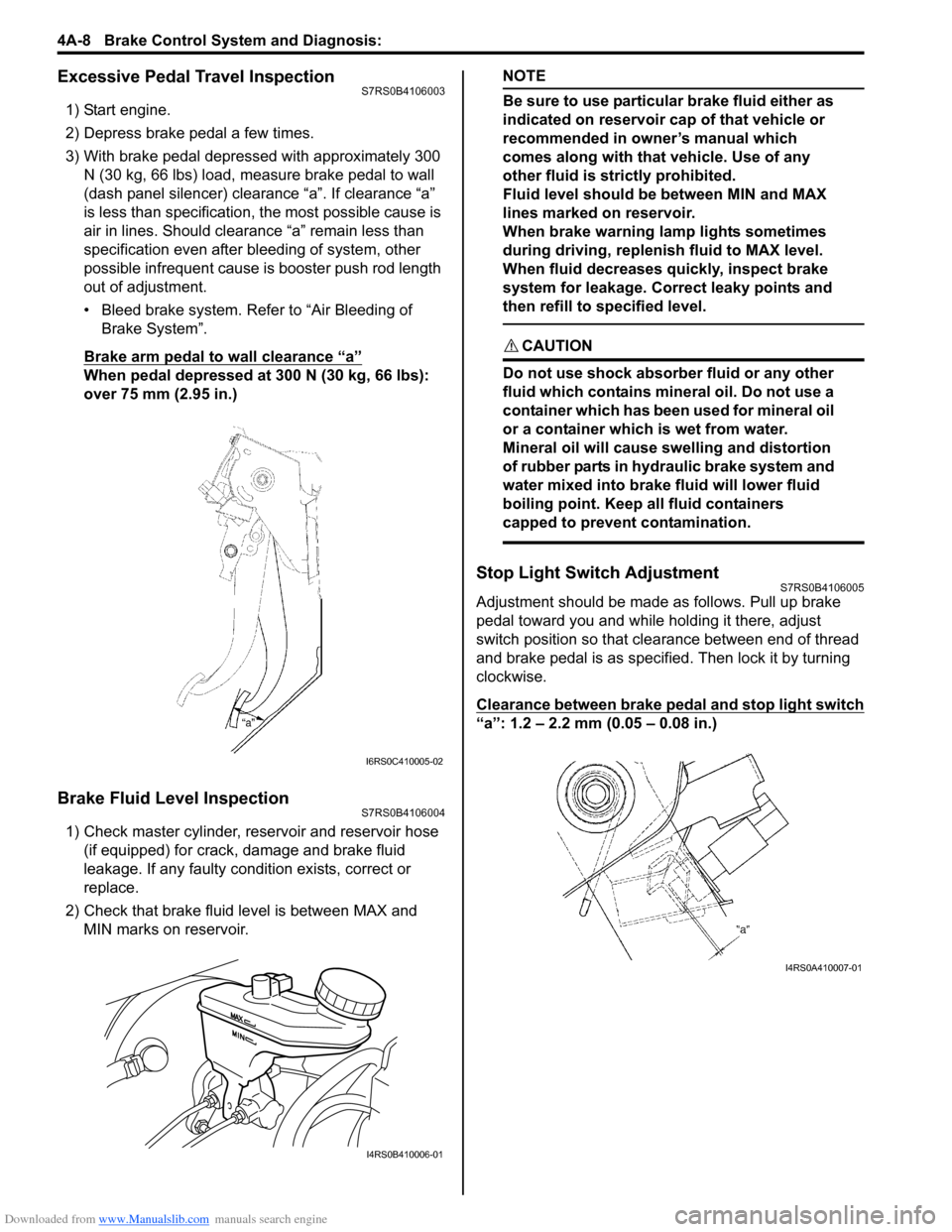

Excessive Pedal Travel InspectionS7RS0B4106003

1) Start engine.

2) Depress brake pedal a few times.

3) With brake pedal depressed with approximately 300 N (30 kg, 66 lbs) load, measure brake pedal to wall

(dash panel silencer) clearance “a”. If clearance “a”

is less than specification, the most possible cause is

air in lines. Should clearance “a” remain less than

specification even after bleeding of system, other

possible infrequent cause is booster push rod length

out of adjustment.

• Bleed brake system. Refer to “Air Bleeding of Brake System”.

Brake arm pedal to wall clearance “a”

When pedal depressed at 300 N (30 kg, 66 lbs):

over 75 mm (2.95 in.)

Brake Fluid Level InspectionS7RS0B4106004

1) Check master cylinder, reservoir and reservoir hose (if equipped) for crack, damage and brake fluid

leakage. If any faulty condition exists, correct or

replace.

2) Check that brake fluid level is between MAX and MIN marks on reservoir.

NOTE

Be sure to use particular brake fluid either as

indicated on reservoir cap of that vehicle or

recommended in owner’s manual which

comes along with that vehicle. Use of any

other fluid is strictly prohibited.

Fluid level should be between MIN and MAX

lines marked on reservoir.

When brake warning lamp lights sometimes

during driving, replenis h fluid to MAX level.

When fluid decreases quickly, inspect brake

system for leakage. Correct leaky points and

then refill to specified level.

CAUTION!

Do not use shock absorber fluid or any other

fluid which contains mineral oil. Do not use a

container which has been used for mineral oil

or a container which is wet from water.

Mineral oil will cause swelling and distortion

of rubber parts in hydraulic brake system and

water mixed into brake fluid will lower fluid

boiling point. Keep all fluid containers

capped to prevent contamination.

Stop Light Switch AdjustmentS7RS0B4106005

Adjustment should be made as follows. Pull up brake

pedal toward you and while holding it there, adjust

switch position so that clea rance between end of thread

and brake pedal is as specified. Then lock it by turning

clockwise.

Clearance between brake pedal and stop light switch

“a”: 1.2 – 2.2 mm (0.05 – 0.08 in.)

I6RS0C410005-02

I4RS0B410006-01

I4RS0A410007-01

Page 507 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-9

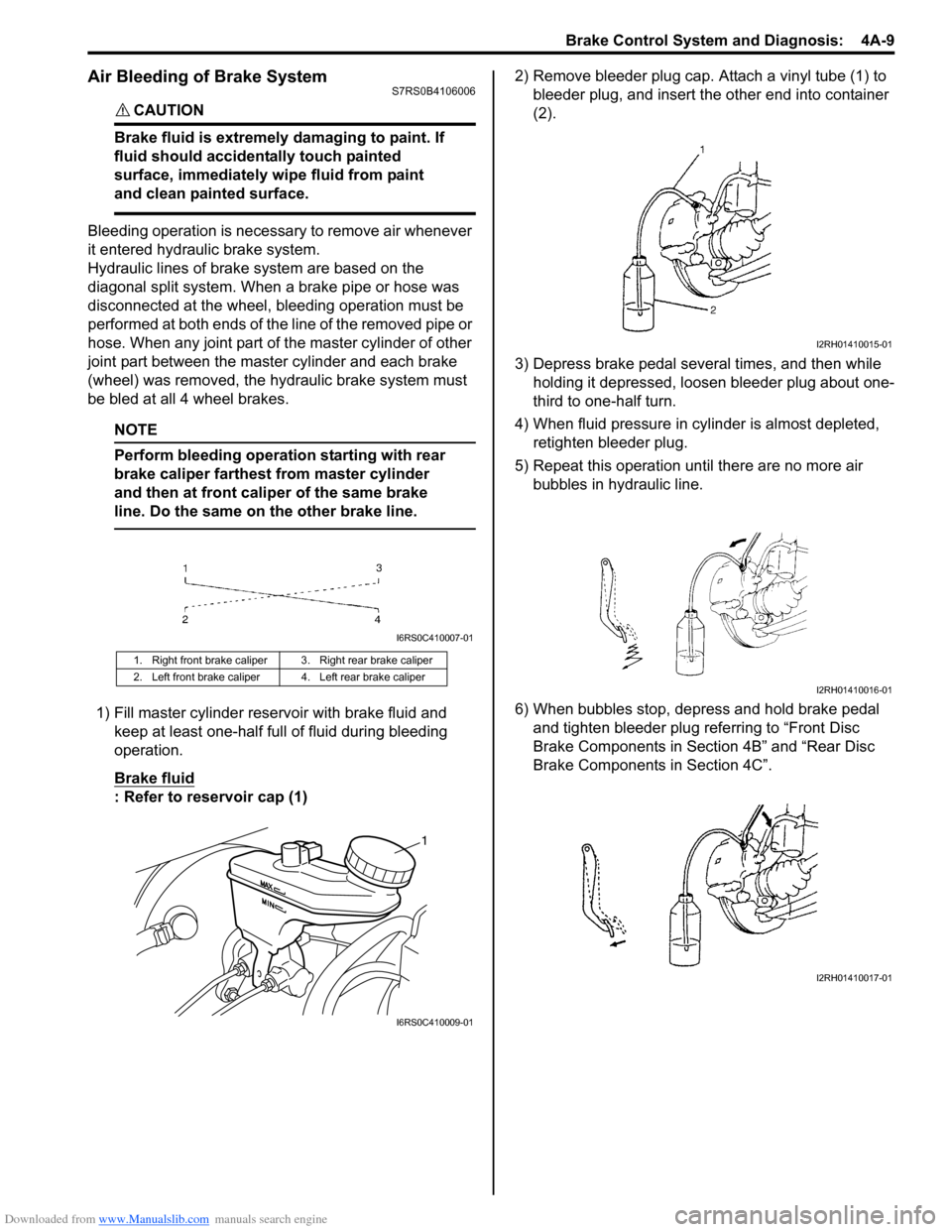

Air Bleeding of Brake SystemS7RS0B4106006

CAUTION!

Brake fluid is extremely damaging to paint. If

fluid should accidentally touch painted

surface, immediately wipe fluid from paint

and clean painted surface.

Bleeding operation is necessary to remove air whenever

it entered hydraulic brake system.

Hydraulic lines of brake system are based on the

diagonal split system. When a brake pipe or hose was

disconnected at the wheel, bleeding operation must be

performed at both ends of the line of the removed pipe or

hose. When any joint part of the master cylinder of other

joint part between the master cylinder and each brake

(wheel) was removed, the hydraulic brake system must

be bled at all 4 wheel brakes.

NOTE

Perform bleeding operation starting with rear

brake caliper farthest from master cylinder

and then at front caliper of the same brake

line. Do the same on the other brake line.

1) Fill master cylinder rese rvoir with brake fluid and

keep at least one-half full of fluid during bleeding

operation.

Brake fluid

: Refer to reservoir cap (1) 2) Remove bleeder plug cap. Attach a vinyl tube (1) to

bleeder plug, and insert the other end into container

(2).

3) Depress brake pedal several times, and then while holding it depressed, loosen bleeder plug about one-

third to one-half turn.

4) When fluid pressure in cy linder is almost depleted,

retighten bleeder plug.

5) Repeat this operation until there are no more air bubbles in hydraulic line.

6) When bubbles stop, depress and hold brake pedal and tighten bleeder plug referring to “Front Disc

Brake Components in Section 4B” and “Rear Disc

Brake Components in Section 4C”.

1. Right front brake caliper 3. Right rear brake caliper

2. Left front brake caliper 4. Left rear brake caliper

I6RS0C410007-01

1

I6RS0C410009-01

I2RH01410015-01

I2RH01410016-01

I2RH01410017-01

Page 508 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-10 Brake Control System and Diagnosis:

7) Then attach bleeder plug cap.

8) After completing bleeding operation, apply fluid pressure to pipe line and check for leakage.

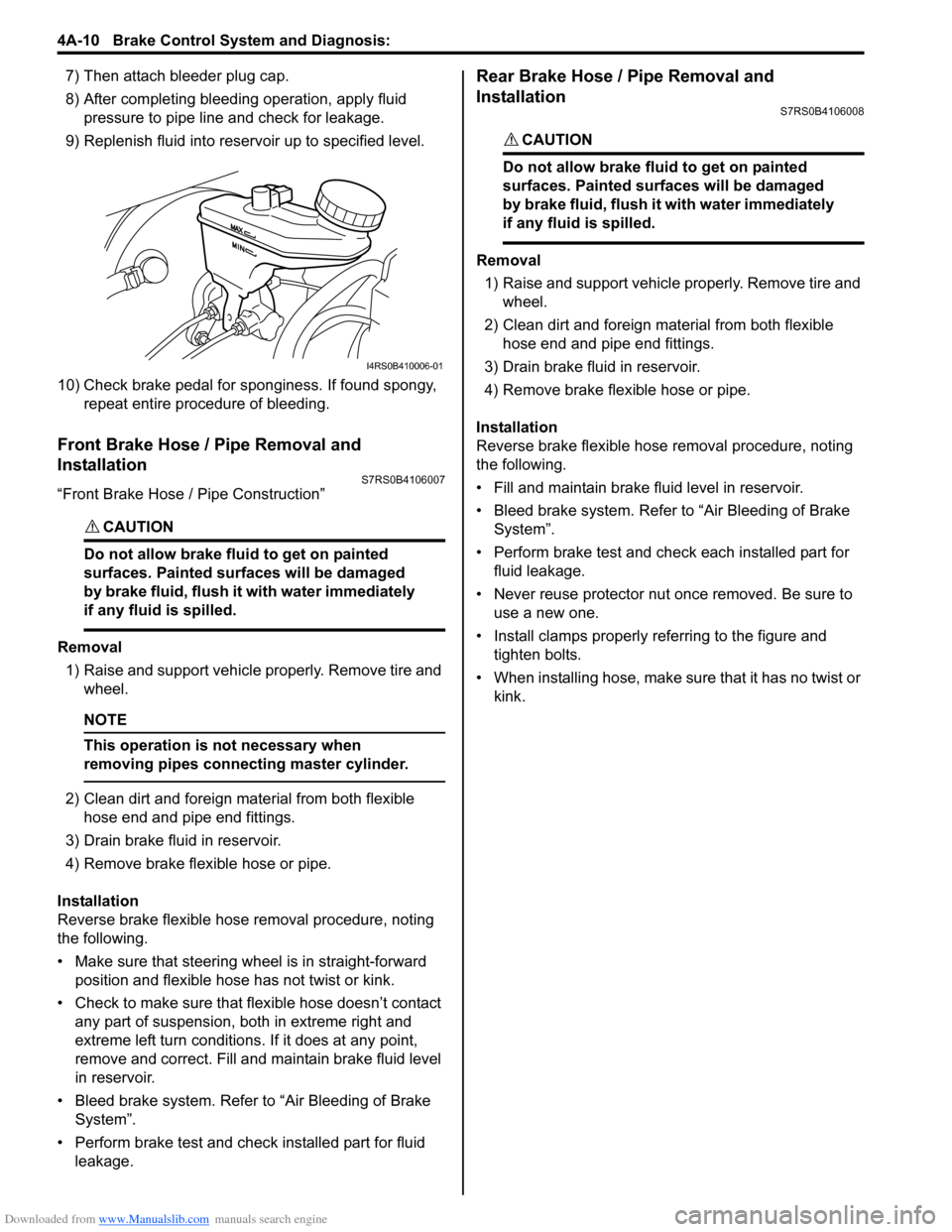

9) Replenish fluid into reserv oir up to specified level.

10) Check brake pedal for sponginess. If found spongy, repeat entire procedure of bleeding.

Front Brake Hose / Pipe Removal and

Installation

S7RS0B4106007

“Front Brake Hose / Pipe Construction”

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Raise and support vehicle properly. Remove tire and wheel.

NOTE

This operation is not necessary when

removing pipes connecting master cylinder.

2) Clean dirt and foreign mate rial from both flexible

hose end and pipe end fittings.

3) Drain brake fluid in reservoir.

4) Remove brake flexible hose or pipe.

Installation

Reverse brake flexible hose removal procedure, noting

the following.

• Make sure that steering wh eel is in straight-forward

position and flexible hose has not twist or kink.

• Check to make sure that flexible hose doesn’t contact any part of suspension, both in extreme right and

extreme left turn conditions. If it does at any point,

remove and correct. Fill and maintain brake fluid level

in reservoir.

• Bleed brake system. Refer to “Air Bleeding of Brake System”.

• Perform brake test and check installed part for fluid leakage.

Rear Brake Hose / Pipe Removal and

Installation

S7RS0B4106008

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Raise and support vehicle properly. Remove tire and wheel.

2) Clean dirt and foreign material from both flexible hose end and pipe end fittings.

3) Drain brake fluid in reservoir.

4) Remove brake flexible hose or pipe.

Installation

Reverse brake flexible hose removal procedure, noting

the following.

• Fill and maintain brake fluid level in reservoir.

• Bleed brake system. Refer to “Air Bleeding of Brake System”.

• Perform brake test and check each installed part for fluid leakage.

• Never reuse protector nut once removed. Be sure to use a new one.

• Install clamps properly referring to the figure and tighten bolts.

• When installing hose, make sure that it has no twist or

kink.

I4RS0B410006-01

Page 509 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-11

Brake Hose and Pipe InspectionS7RS0B4106009

Hose

The brake hose assembly should be checked for road

hazard damage, for cracks and chafing of outer cover,

for leaks and blisters. A light and mirror may be needed

for an adequate inspection. If any above conditions are

observed on brake hose, it is necessary to replace it.

Pipe

Inspect the pipe for damage, cracks, dents and

corrosion. If any defect is found, replace it.

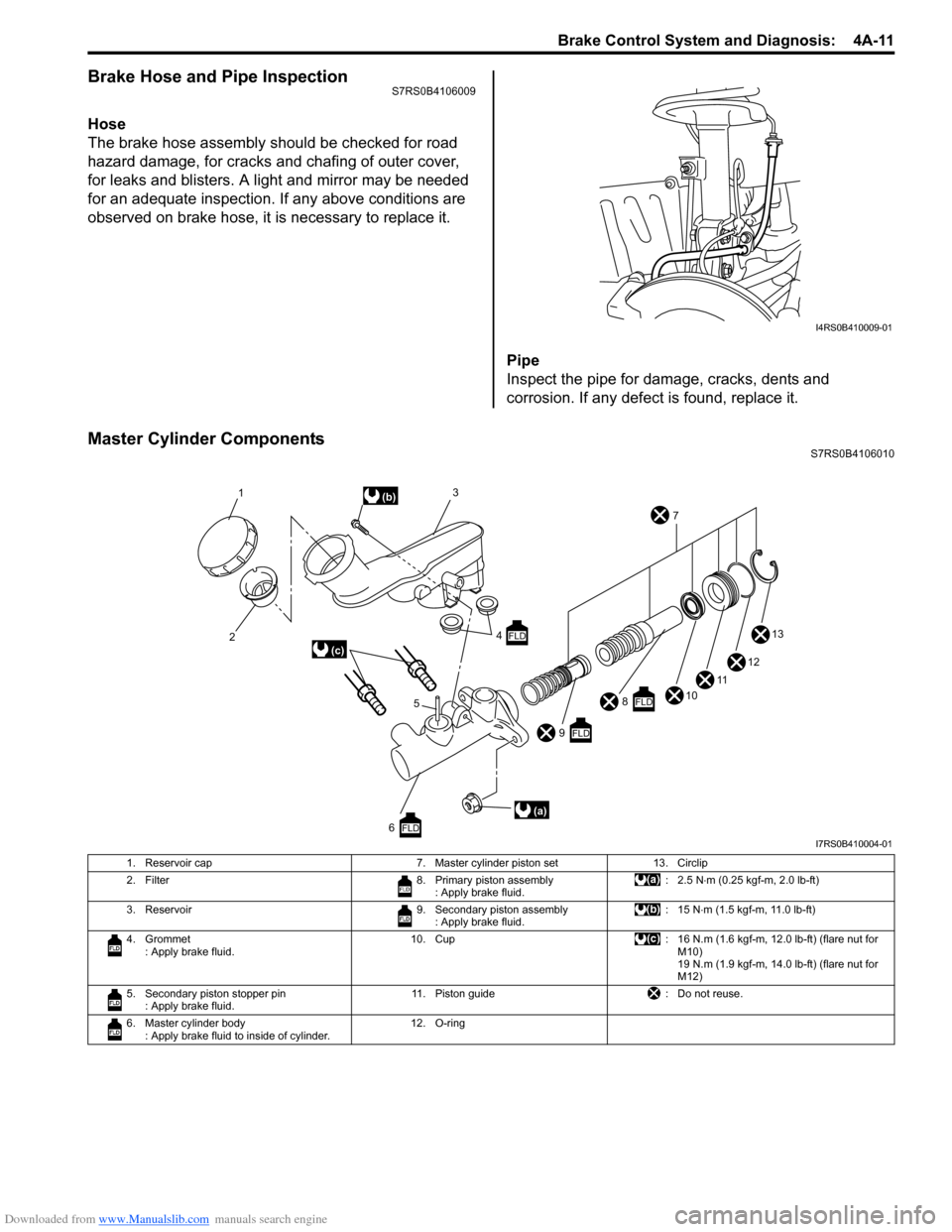

Master Cylinder ComponentsS7RS0B4106010

I4RS0B410009-01

10

11

1

2 3

4

5 7

13

12

9

FLD

8FLD

6FLD

(b)

(a)

(c)FLD

I7RS0B410004-01

1. Reservoir cap 7. Master cylinder piston set13. Circlip

2. Filter 8. Primary piston assembly

: Apply brake fluid. :2.5 N

⋅m (0.25 kgf-m, 2.0 lb-ft)

3. Reservoir 9. Secondary piston assembly

: Apply brake fluid. : 15 N

⋅m (1.5 kgf-m, 11.0 lb-ft)

4. Grommet : Apply brake fluid. 10. Cup

: 16 N.m (1.6 kgf-m, 12.0 lb-ft) (flare nut for

M10)

19 N.m (1.9 kgf-m, 14.0 lb-ft) (flare nut for

M12)

5. Secondary piston stopper pin : Apply brake fluid. 11. Piston guide

: Do not reuse.

6. Master cylinder body : Apply brake fluid to inside of cylinder. 12. O-ring

Page 510 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-12 Brake Control System and Diagnosis:

Master Cylinder Assembly Removal and

Installation

S7RS0B4106011

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

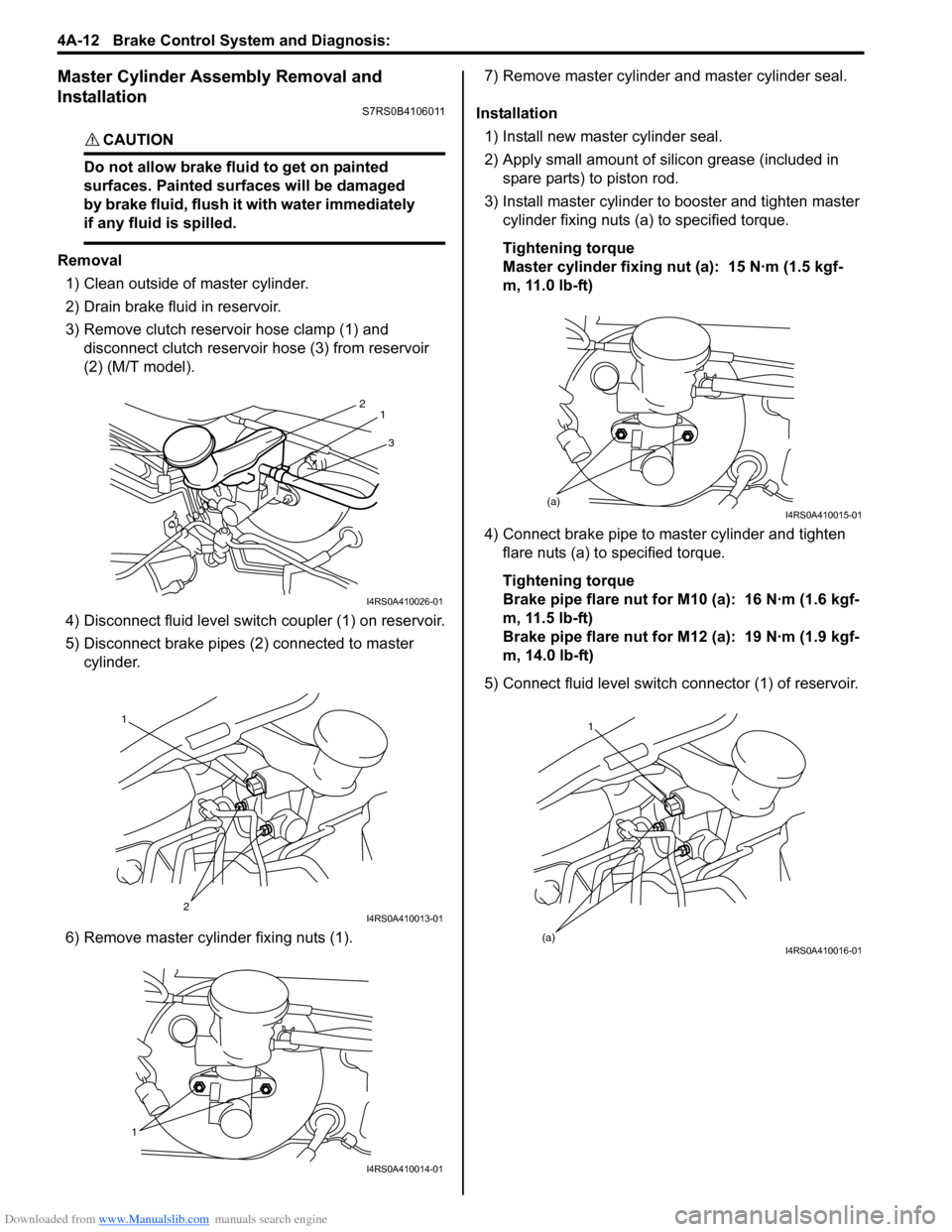

1) Clean outside of master cylinder.

2) Drain brake fluid in reservoir.

3) Remove clutch reservoir hose clamp (1) and disconnect clutch reservoir hose (3) from reservoir

(2) (M/T model).

4) Disconnect fluid level switch coupler (1) on reservoir.

5) Disconnect brake pipes (2) connected to master cylinder.

6) Remove master cylinder fixing nuts (1). 7) Remove master cylinder and master cylinder seal.

Installation 1) Install new master cylinder seal.

2) Apply small amount of silic on grease (included in

spare parts) to piston rod.

3) Install master cylinder to booster and tighten master cylinder fixing nuts (a) to specified torque.

Tightening torque

Master cylinder fixing nut (a): 15 N·m (1.5 kgf-

m, 11.0 lb-ft)

4) Connect brake pipe to master cylinder and tighten flare nuts (a) to specified torque.

Tightening torque

Brake pipe flare nut for M10 (a): 16 N·m (1.6 kgf-

m, 11.5 lb-ft)

Brake pipe flare nut for M12 (a): 19 N·m (1.9 kgf-

m, 14.0 lb-ft)

5) Connect fluid level switch connector (1) of reservoir.

3

2

1

I4RS0A410026-01

1

2

I4RS0A410013-01

1

I4RS0A410014-01

(a)I4RS0A410015-01

1

(a)

I4RS0A410016-01

Page 511 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-13

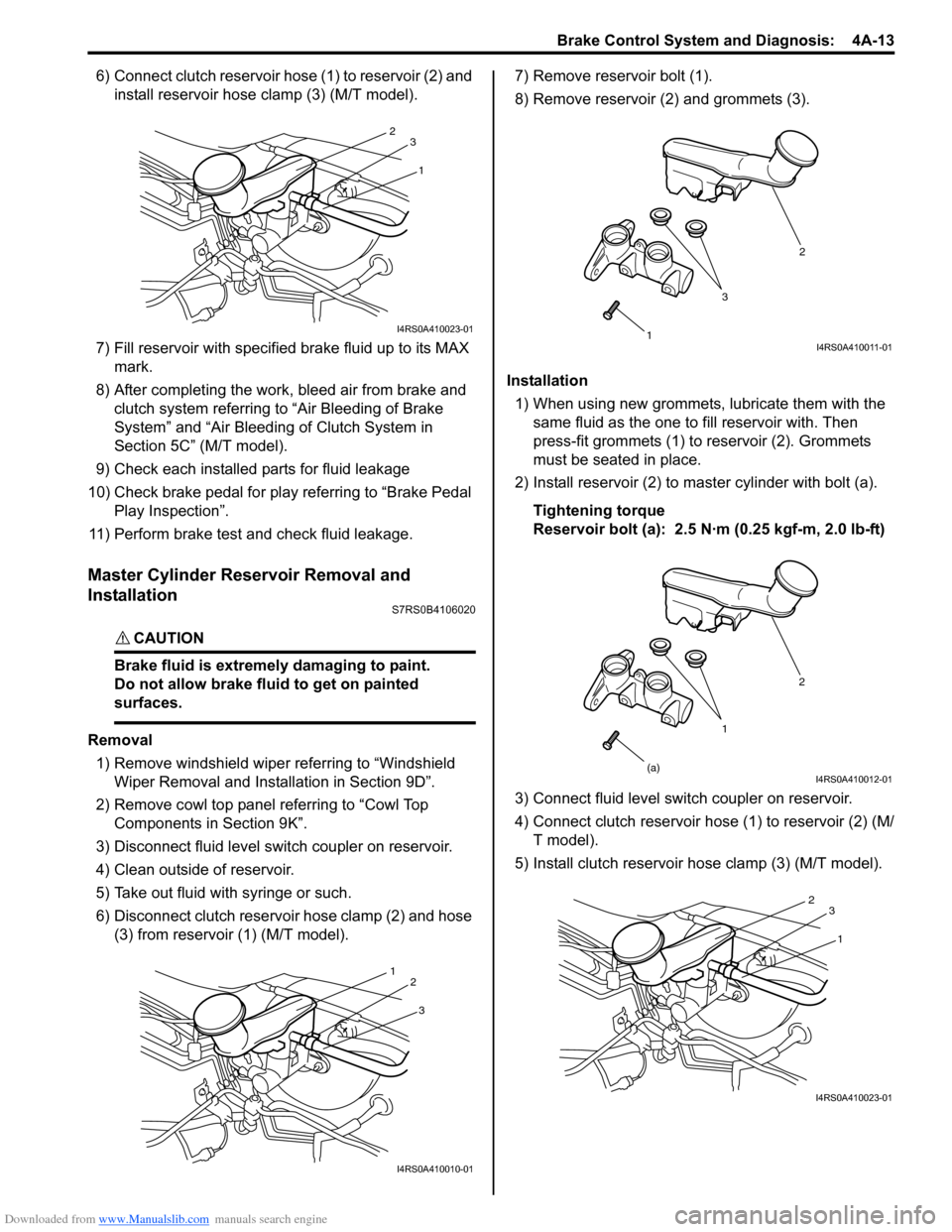

6) Connect clutch reservoir hose (1) to reservoir (2) and install reservoir hose clamp (3) (M/T model).

7) Fill reservoir with specified brake fluid up to its MAX

mark.

8) After completing the work, bleed air from brake and clutch system referring to “Air Bleeding of Brake

System” and “Air Bleeding of Clutch System in

Section 5C” (M/T model).

9) Check each installed parts for fluid leakage

10) Check brake pedal for play referring to “Brake Pedal Play Inspection”.

11) Perform brake test and check fluid leakage.

Master Cylinder Reservoir Removal and

Installation

S7RS0B4106020

CAUTION!

Brake fluid is extremely damaging to paint.

Do not allow brake fluid to get on painted

surfaces.

Removal 1) Remove windshield wiper referring to “Windshield Wiper Removal and Insta llation in Section 9D”.

2) Remove cowl top panel referring to “Cowl Top Components in Section 9K”.

3) Disconnect fluid level s witch coupler on reservoir.

4) Clean outside of reservoir.

5) Take out fluid with syringe or such.

6) Disconnect clutch reservoir hose clamp (2) and hose (3) from reservoir (1) (M/T model). 7) Remove reservoir bolt (1).

8) Remove reservoir (2) and grommets (3).

Installation 1) When using new grommets, lubricate them with the same fluid as the one to fill reservoir with. Then

press-fit grommets (1) to reservoir (2). Grommets

must be seated in place.

2) Install reservoir (2) to master cylinder with bolt (a).

Tightening torque

Reservoir bolt (a): 2.5 N·m (0.25 kgf-m, 2.0 lb-ft)

3) Connect fluid level switch coupler on reservoir.

4) Connect clutch reservoir hose (1) to reservoir (2) (M/ T model).

5) Install clutch reservoir hose clamp (3) (M/T model).

1

2

3

I4RS0A410023-01

3

1

2

I4RS0A410010-01

1 2

3I4RS0A410011-01

1 2

(a)

I4RS0A410012-01

1

2

3

I4RS0A410023-01

Page 513 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-15

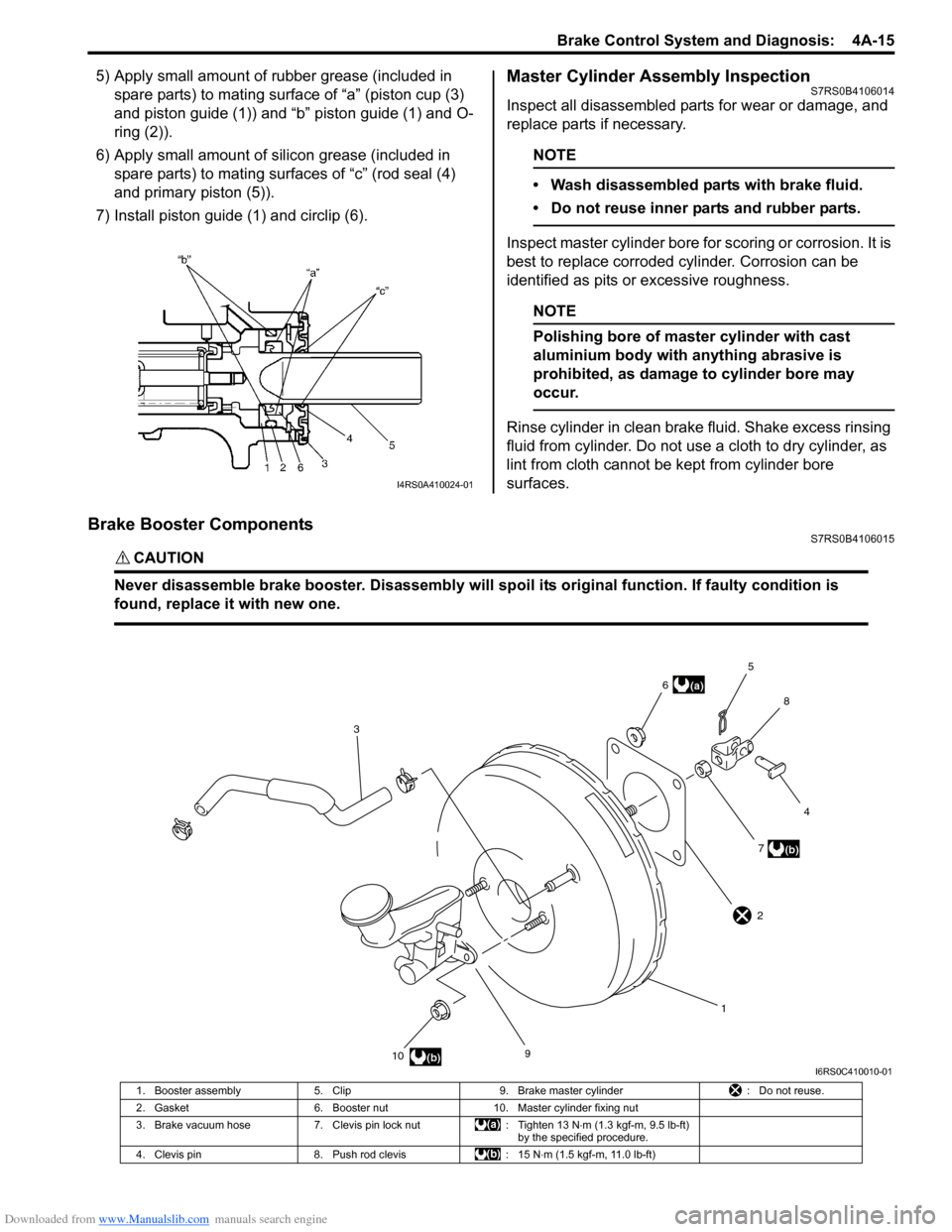

5) Apply small amount of rubber grease (included in spare parts) to mating surface of “a” (piston cup (3)

and piston guide (1)) and “b” piston guide (1) and O-

ring (2)).

6) Apply small amount of s ilicon grease (included in

spare parts) to mating surfaces of “c” (rod seal (4)

and primary piston (5)).

7) Install piston guide (1) and circlip (6).Master Cylinder Assembly InspectionS7RS0B4106014

Inspect all disassembled parts for wear or damage, and

replace parts if necessary.

NOTE

• Wash disassembled parts with brake fluid.

• Do not reuse inner parts and rubber parts.

Inspect master cylinder bore for scoring or corrosion. It is

best to replace corroded cylinder. Corrosion can be

identified as pits or excessive roughness.

NOTE

Polishing bore of master cylinder with cast

aluminium body with anything abrasive is

prohibited, as damage to cylinder bore may

occur.

Rinse cylinder in clean brake fluid. Shake excess rinsing

fluid from cylinder. Do not use a cloth to dry cylinder, as

lint from cloth cannot be kept from cylinder bore

surfaces.

Brake Booster ComponentsS7RS0B4106015

CAUTION!

Never disassemble brake booster. Disassembly will spoi l its original function. If faulty condition is

found, replace it with new one.

I4RS0A410024-01

9

10 17

4

8

5

6

3

(b)

(a)

(b)

2

I6RS0C410010-01

1. Booster assembly 5. Clip 9. Brake master cylinder : Do not reuse.

2. Gasket 6. Booster nut 10. Master cylinder fixing nut

3. Brake vacuum hose 7. Clevis pin lock nut : Tighten 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

by the specified procedure.

4. Clevis pin 8. Push rod clevis : 15 N⋅m (1.5 kgf-m, 11.0 lb-ft)

Page 515 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-17

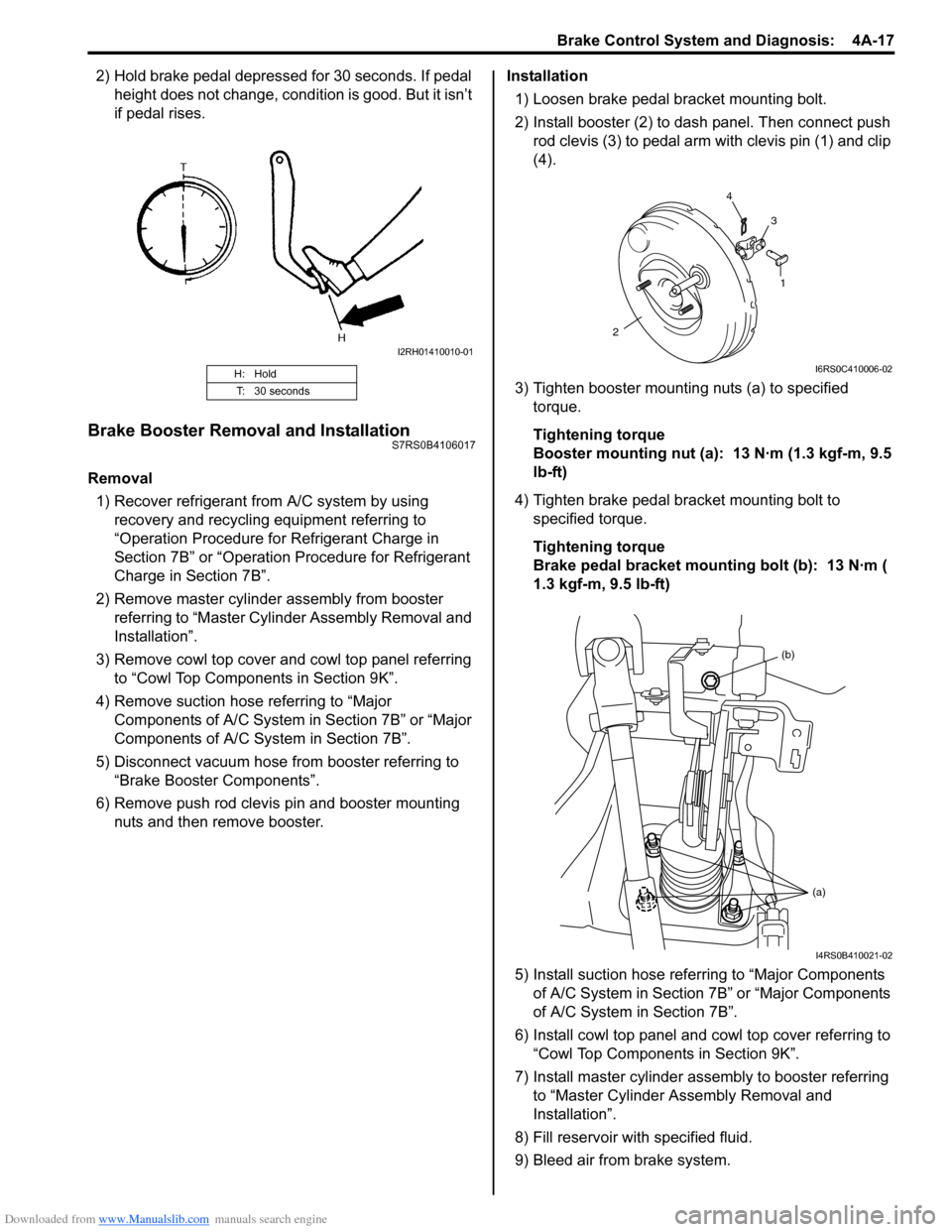

2) Hold brake pedal depressed for 30 seconds. If pedal height does not change, condition is good. But it isn’t

if pedal rises.

Brake Booster Removal and InstallationS7RS0B4106017

Removal

1) Recover refrigerant from A/C system by using recovery and recycling equipment referring to

“Operation Procedure for Refrigerant Charge in

Section 7B” or “Operation Procedure for Refrigerant

Charge in Section 7B”.

2) Remove master cylinder assembly from booster referring to “Master Cylin der Assembly Removal and

Installation”.

3) Remove cowl top cover and cowl top panel referring to “Cowl Top Components in Section 9K”.

4) Remove suction hose referring to “Major Components of A/C System in Section 7B” or “Major

Components of A/C System in Section 7B”.

5) Disconnect vacuum hose from booster referring to “Brake Booster Components”.

6) Remove push rod clevis pin and booster mounting nuts and then remove booster. Installation

1) Loosen brake pedal bracket mounting bolt.

2) Install booster (2) to dash panel. Then connect push rod clevis (3) to pedal arm with clevis pin (1) and clip

(4).

3) Tighten booster mounting nuts (a) to specified torque.

Tightening torque

Booster mounting nut (a): 13 N·m (1.3 kgf-m, 9.5

lb-ft)

4) Tighten brake pedal bracket mounting bolt to specified torque.

Tightening torque

Brake pedal bracket mounting bolt (b): 13 N·m (

1.3 kgf-m, 9.5 lb-ft)

5) Install suction hose referring to “Major Components of A/C System in Section 7B” or “Major Components

of A/C System in Section 7B”.

6) Install cowl top panel and cowl top cover referring to

“Cowl Top Components in Section 9K”.

7) Install master cylinder assembly to booster referring to “Master Cylinder Assembly Removal and

Installation”.

8) Fill reservoir with specified fluid.

9) Bleed air from brake system.

H: Hold

T: 30 seconds

I2RH01410010-01

1

2 4

3

I6RS0C410006-02

(b)

(a)

I4RS0B410021-02