Hose SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 516 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-18 Brake Control System and Diagnosis:

10) Check pedal height and play referring to “Brake Pedal Free Height Inspection” and “Brake Pedal

Play Inspection”.

11) Check each installed part for fluid leakage and perform brake test.

12) Evacuate and charge refrigerant by referring to “Evacuating of A/C Syst em” and “Procedure of

Charging” under “Operation Procedure for

Refrigerant Charge in Section 7B” or “Operation

Procedure for Refrigerant Charge in Section 7B”.

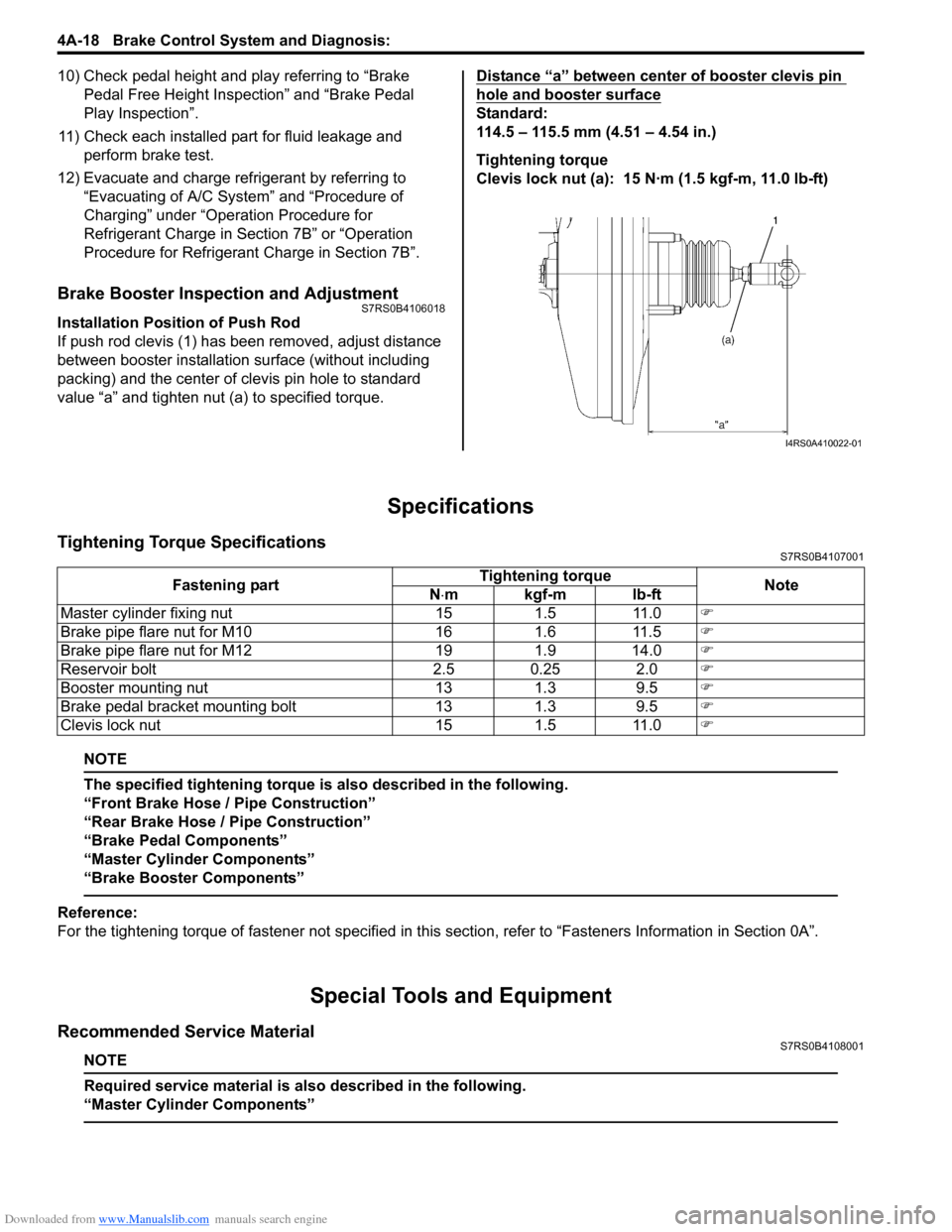

Brake Booster Inspection and AdjustmentS7RS0B4106018

Installation Position of Push Rod

If push rod clevis (1) has b een removed, adjust distance

between booster installation surface (without including

packing) and the center of clevis pin hole to standard

value “a” and tighten nut (a) to specified torque. Distance “a” between center of booster clevis pin

hole and booster surface

Standard:

114.5 – 115.5 mm (4.51 – 4.54 in.)

Tightening torque

Clevis lock nut (a): 15 N·m (1.5 kgf-m, 11.0 lb-ft)

Specifications

Tightening Torque SpecificationsS7RS0B4107001

NOTE

The specified tightening torque is also described in the following.

“Front Brake Hose / Pipe Construction”

“Rear Brake Hose / Pipe Construction”

“Brake Pedal Components”

“Master Cylinder Components”

“Brake Booster Components”

Reference:

For the tightening torque of fastener not specified in this

section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B4108001

NOTE

Required service material is also described in the following.

“Master Cylinder Components”

I4RS0A410022-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Master cylinder fixing nut 15 1.5 11.0 �)

Brake pipe flare nut for M10 16 1.6 11.5 �)

Brake pipe flare nut for M12 19 1.9 14.0 �)

Reservoir bolt 2.5 0.25 2.0 �)

Booster mounting nut 13 1.3 9.5 �)

Brake pedal bracket mounting bolt 13 1.3 9.5 �)

Clevis lock nut 15 1.5 11.0 �)

Page 517 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Brakes: 4B-1

Brakes

Front Brakes

Repair Instructions

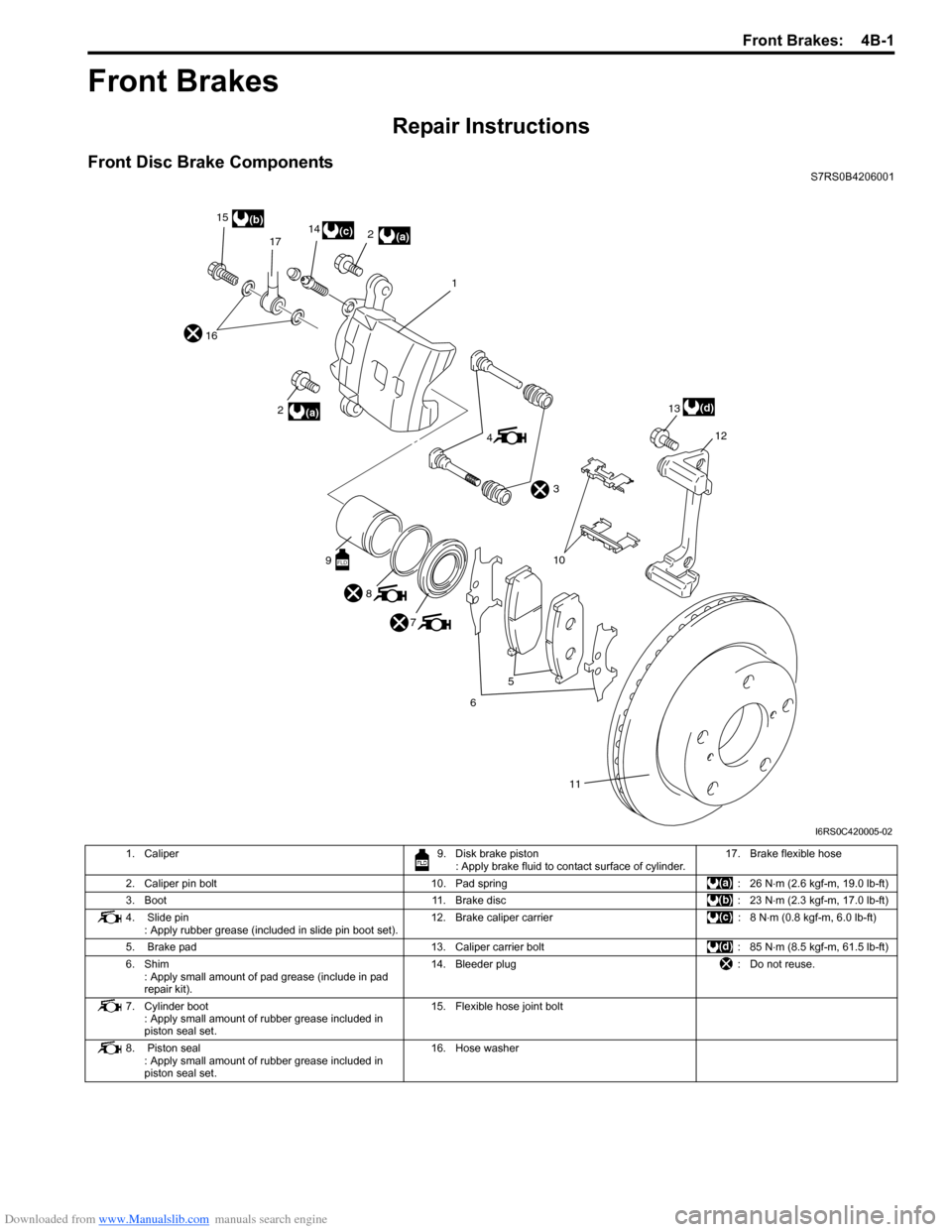

Front Disc Brake ComponentsS7RS0B4206001

11

5

6

10

4

1

16

17

12

8

7

3

2(a)

15

(b)

14(c)2(a)

13

(d)

9

FLD

I6RS0C420005-02

1. Caliper 9. Disk brake piston

: Apply brake fluid to contact surface of cylinder. 17. Brake flexible hose

2. Caliper pin bolt 10. Pad spring : 26 N⋅m (2.6 kgf-m, 19.0 lb-ft)

3. Boot 11. Brake disc: 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

4. Slide pin : Apply rubber grease (included in slide pin boot set). 12. Brake caliper carrier

: 8 N⋅m (0.8 kgf-m, 6.0 lb-ft)

5. Brake pad 13. Caliper carrier bolt : 85 N⋅m (8.5 kgf-m, 61.5 lb-ft)

6. Shim : Apply small amount of pad grease (include in pad

repair kit). 14. Bleeder plug

: Do not reuse.

7. Cylinder boot : Apply small amount of rubber grease included in

piston seal set. 15. Flexible hose joint bolt

8. Piston seal : Apply small amount of rubber grease included in

piston seal set. 16. Hose washer

Page 518 of 1496

Downloaded from www.Manualslib.com manuals search engine 4B-2 Front Brakes:

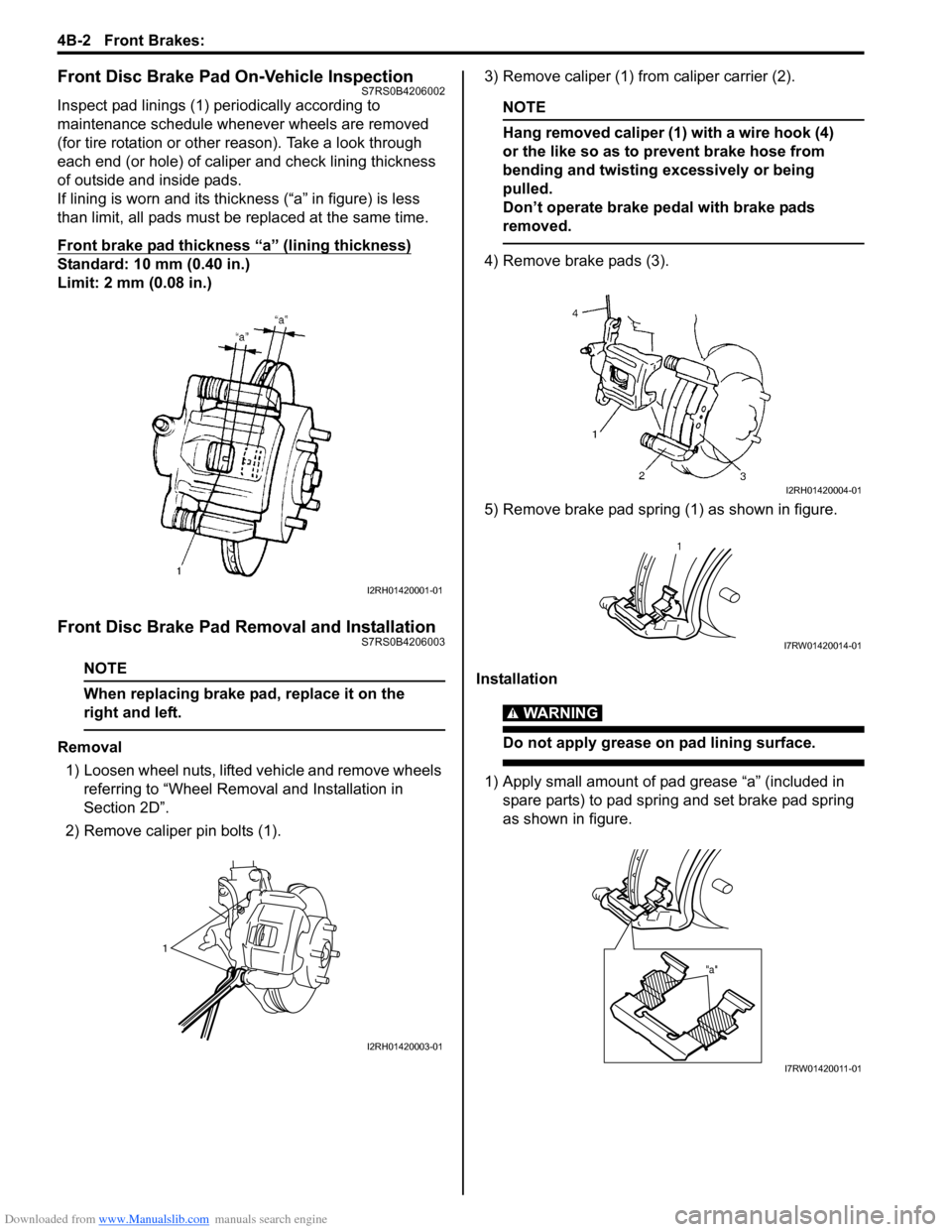

Front Disc Brake Pad On-Vehicle InspectionS7RS0B4206002

Inspect pad linings (1) periodically according to

maintenance schedule whenever wheels are removed

(for tire rotation or other reason). Take a look through

each end (or hole) of caliper and check lining thickness

of outside and inside pads.

If lining is worn and its thic kness (“a” in figure) is less

than limit, all pads must be replaced at the same time.

Front brake pad thickness “a” (lining thickness)

Standard: 10 mm (0.40 in.)

Limit: 2 mm (0.08 in.)

Front Disc Brake Pad Removal and InstallationS7RS0B4206003

NOTE

When replacing brake pad, replace it on the

right and left.

Removal

1) Loosen wheel nuts, lifted vehicle and remove wheels referring to “Wheel Remova l and Installation in

Section 2D”.

2) Remove caliper pin bolts (1). 3) Remove caliper (1) from caliper carrier (2).

NOTE

Hang removed caliper (1) with a wire hook (4)

or the like so as to prevent brake hose from

bending and twisting excessively or being

pulled.

Don’t operate brake pedal with brake pads

removed.

4) Remove brake pads (3).

5) Remove brake pad spring (1) as shown in figure.

Installation

WARNING!

Do not apply grease on pad lining surface.

1) Apply small amount of pad grease “a” (included in spare parts) to pad spring and set brake pad spring

as shown in figure.

I2RH01420001-01

1

I2RH01420003-01

I2RH01420004-01

1

I7RW01420014-01

"a"

I7RW01420011-01

Page 519 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Brakes: 4B-3

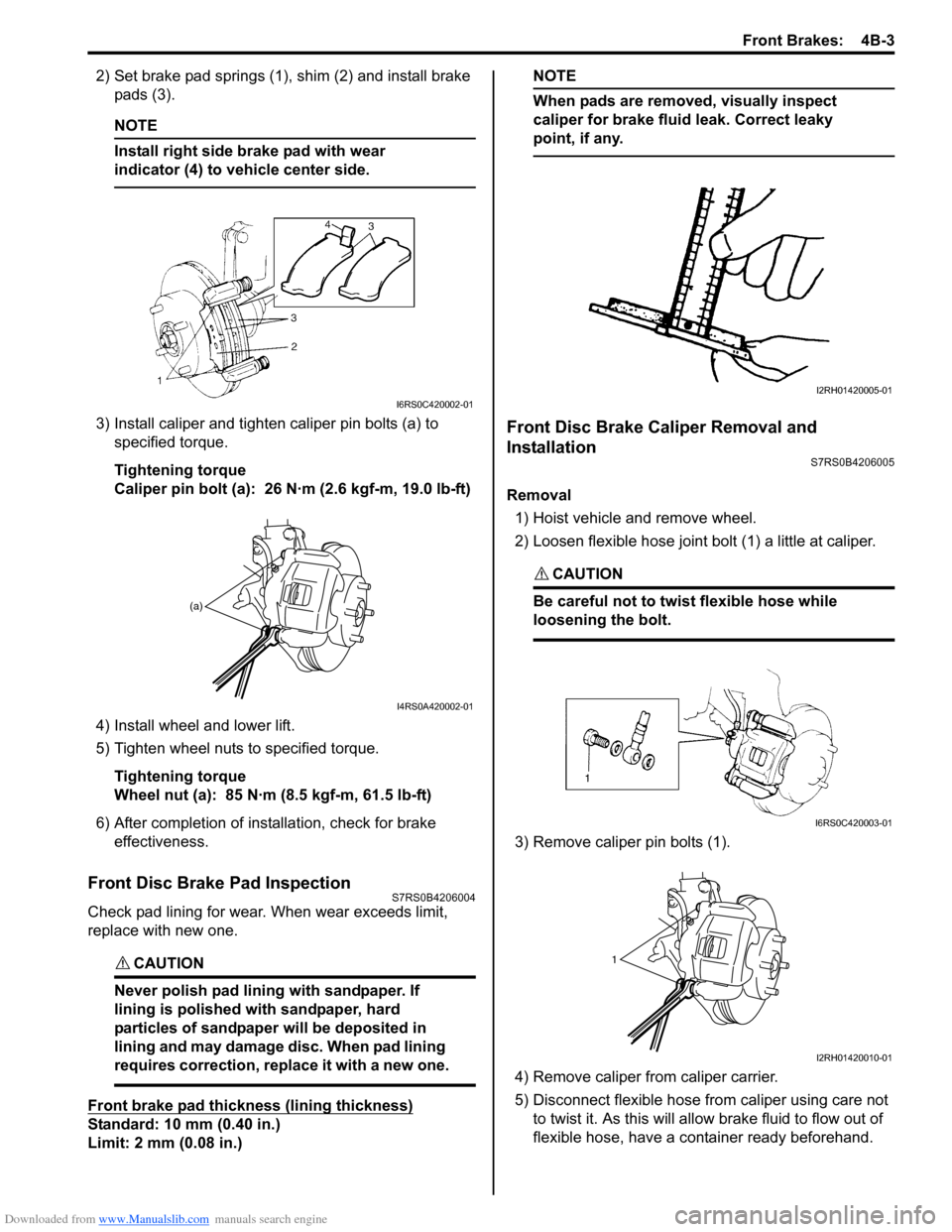

2) Set brake pad springs (1), shim (2) and install brake pads (3).

NOTE

Install right side brake pad with wear

indicator (4) to vehicle center side.

3) Install caliper and tighten caliper pin bolts (a) to specified torque.

Tightening torque

Caliper pin bolt (a): 26 N·m (2.6 kgf-m, 19.0 lb-ft)

4) Install wheel and lower lift.

5) Tighten wheel nuts to specified torque. Tightening torque

Wheel nut (a): 85 N·m (8.5 kgf-m, 61.5 lb-ft)

6) After completion of installation, check for brake effectiveness.

Front Disc Brake Pad InspectionS7RS0B4206004

Check pad lining for wear. When wear exceeds limit,

replace with new one.

CAUTION!

Never polish pad lining with sandpaper. If

lining is polished with sandpaper, hard

particles of sandpaper will be deposited in

lining and may damage disc. When pad lining

requires correction, replace it with a new one.

Front brake pad thickness (lining thickness)

Standard: 10 mm (0.40 in.)

Limit: 2 mm (0.08 in.)

NOTE

When pads are removed, visually inspect

caliper for brake fluid leak. Correct leaky

point, if any.

Front Disc Brake Caliper Removal and

Installation

S7RS0B4206005

Removal

1) Hoist vehicle and remove wheel.

2) Loosen flexible hose joint bolt (1) a little at caliper.

CAUTION!

Be careful not to twist flexible hose while

loosening the bolt.

3) Remove caliper pin bolts (1).

4) Remove caliper fr om caliper carrier.

5) Disconnect flexible hose fr om caliper using care not

to twist it. As this will allow brake fluid to flow out of

flexible hose, have a container ready beforehand.

I6RS0C420002-01

(a)

I4RS0A420002-01

I2RH01420005-01

I6RS0C420003-01

1

I2RH01420010-01

Page 520 of 1496

Downloaded from www.Manualslib.com manuals search engine 4B-4 Front Brakes:

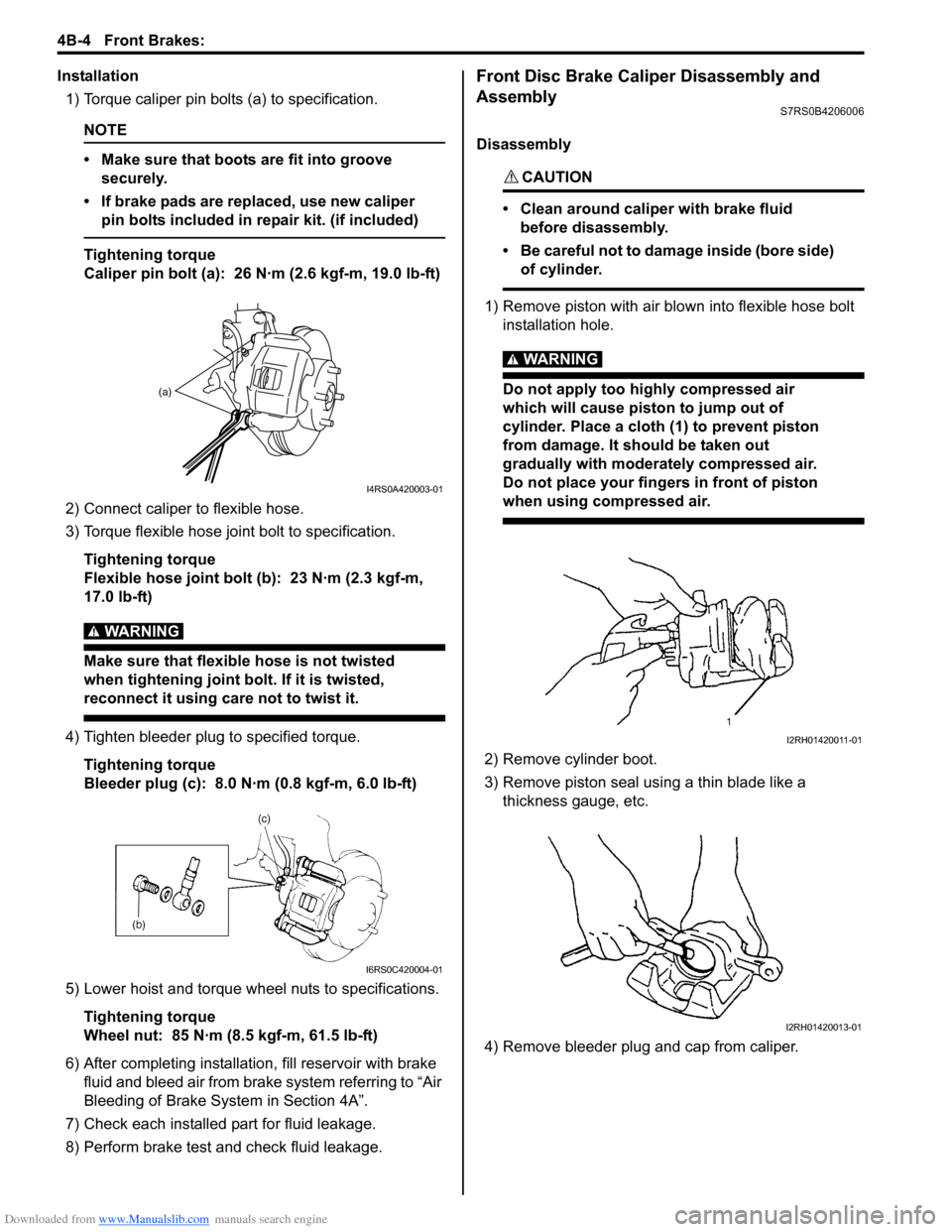

Installation1) Torque caliper pin bolts (a) to specification.

NOTE

• Make sure that boots are fit into groove securely.

• If brake pads are replaced, use new caliper pin bolts included in repair kit. (if included)

Tightening torque

Caliper pin bolt (a): 26 N·m (2.6 kgf-m, 19.0 lb-ft)

2) Connect caliper to flexible hose.

3) Torque flexible hose jo int bolt to specification.

Tightening torque

Flexible hose joint bolt (b): 23 N·m (2.3 kgf-m,

17.0 lb-ft)

WARNING!

Make sure that flexible hose is not twisted

when tightening joint bolt. If it is twisted,

reconnect it using care not to twist it.

4) Tighten bleeder plug to specified torque. Tightening torque

Bleeder plug (c): 8.0 N·m (0.8 kgf-m, 6.0 lb-ft)

5) Lower hoist and torque wheel nuts to specifications. Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

6) After completing installation, fill reservoir with brake

fluid and bleed air from brake system referring to “Air

Bleeding of Brake System in Section 4A”.

7) Check each installed part for fluid leakage.

8) Perform brake test and check fluid leakage.

Front Disc Brake Caliper Disassembly and

Assembly

S7RS0B4206006

Disassembly

CAUTION!

• Clean around caliper with brake fluid before disassembly.

• Be careful not to damage inside (bore side) of cylinder.

1) Remove piston with air blown into flexible hose bolt installation hole.

WARNING!

Do not apply too highly compressed air

which will cause piston to jump out of

cylinder. Place a cloth (1) to prevent piston

from damage. It should be taken out

gradually with moderately compressed air.

Do not place your fingers in front of piston

when using compressed air.

2) Remove cylinder boot.

3) Remove piston seal using a thin blade like a thickness gauge, etc.

4) Remove bleeder plug and cap from caliper.

(a)

I4RS0A420003-01

I6RS0C420004-01

I2RH01420011-01

I2RH01420013-01

Page 522 of 1496

Downloaded from www.Manualslib.com manuals search engine 4B-6 Front Brakes:

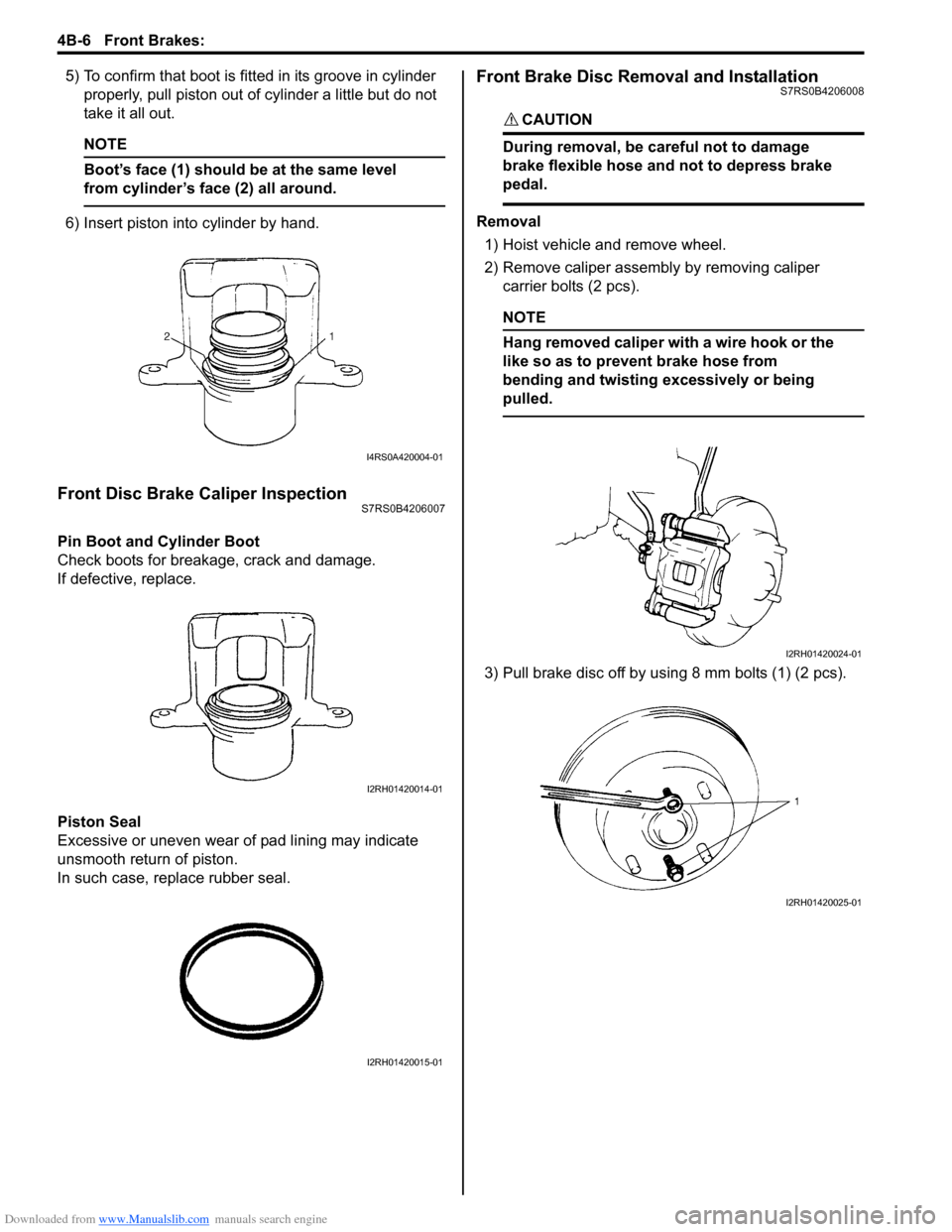

5) To confirm that boot is fitted in its groove in cylinder

properly, pull piston out of cylinder a little but do not

take it all out.

NOTE

Boot’s face (1) should be at the same level

from cylinder’s face (2) all around.

6) Insert piston into cylinder by hand.

Front Disc Brake Caliper InspectionS7RS0B4206007

Pin Boot and Cylinder Boot

Check boots for breakage, crack and damage.

If defective, replace.

Piston Seal

Excessive or uneven wear of pad lining may indicate

unsmooth return of piston.

In such case, replace rubber seal.

Front Brake Disc Removal and InstallationS7RS0B4206008

CAUTION!

During removal, be care ful not to damage

brake flexible hose and not to depress brake

pedal.

Removal

1) Hoist vehicle and remove wheel.

2) Remove caliper assembly by removing caliper carrier bolts (2 pcs).

NOTE

Hang removed caliper with a wire hook or the

like so as to prevent brake hose from

bending and twisting excessively or being

pulled.

3) Pull brake disc off by using 8 mm bolts (1) (2 pcs).

I4RS0A420004-01

I2RH01420014-01

I2RH01420015-01

I2RH01420024-01

I2RH01420025-01

Page 524 of 1496

Downloaded from www.Manualslib.com manuals search engine 4B-8 Front Brakes:

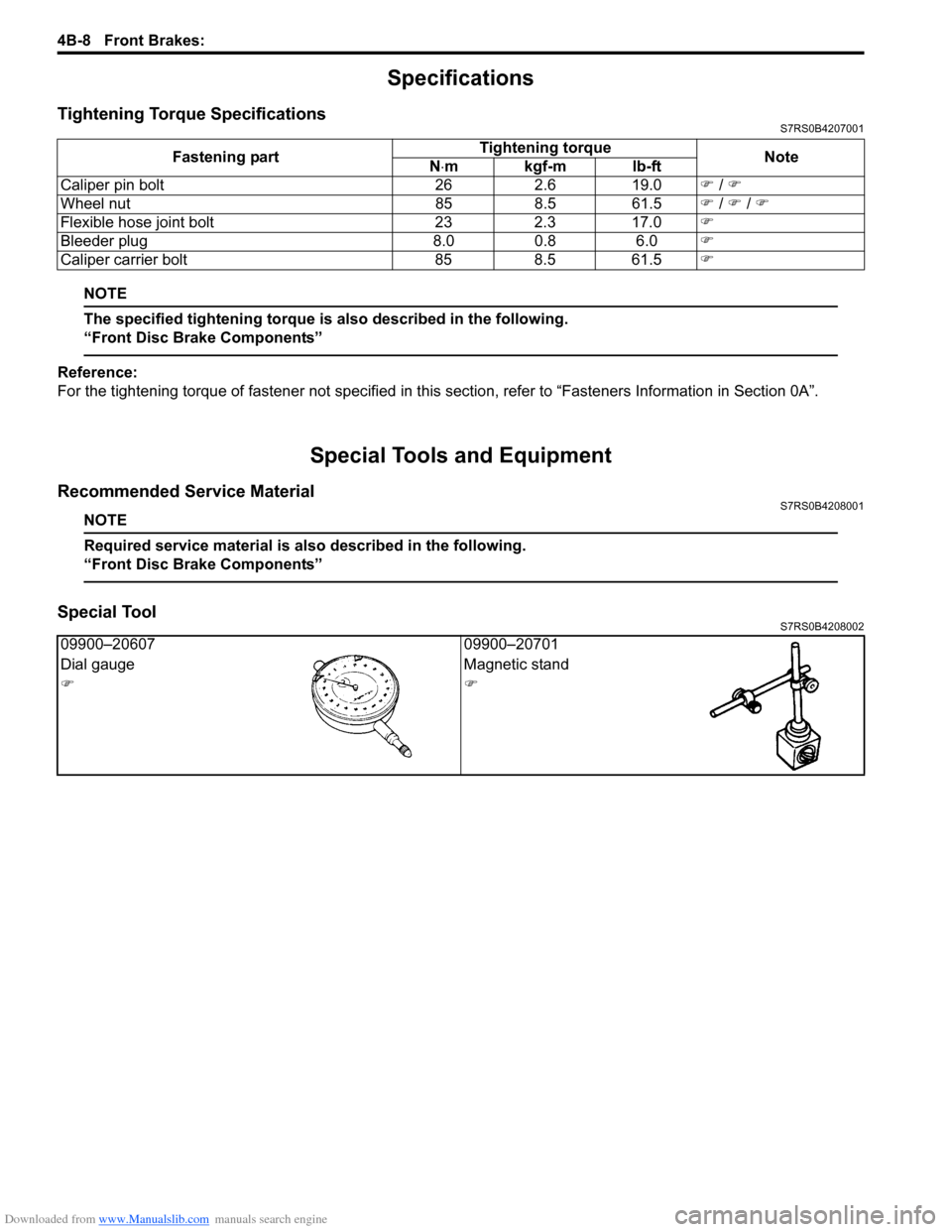

Specifications

Tightening Torque SpecificationsS7RS0B4207001

NOTE

The specified tightening torque is also described in the following.

“Front Disc Brake Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B4208001

NOTE

Required service material is also described in the following.

“Front Disc Brake Components”

Special ToolS7RS0B4208002

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Caliper pin bolt 26 2.6 19.0 �) / �)

Wheel nut 85 8.5 61.5 �) / �) / �)

Flexible hose joint bolt 23 2.3 17.0 �)

Bleeder plug 8.0 0.8 6.0 �)

Caliper carrier bolt 85 8.5 61.5 �)

09900–2060709900–20701

Dial gauge Magnetic stand

�)�)

Page 525 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Brakes: 4C-1

Brakes

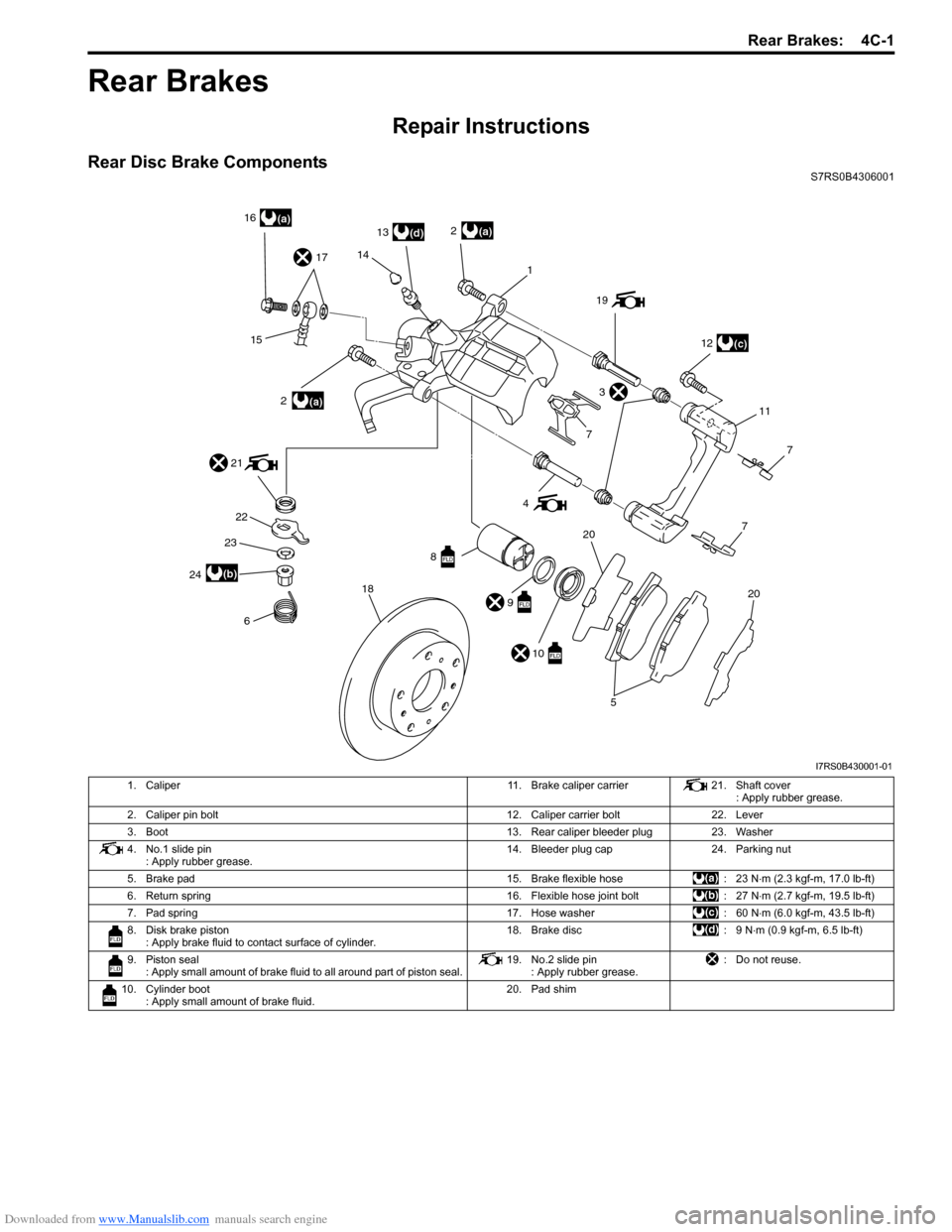

Rear Brakes

Repair Instructions

Rear Disc Brake ComponentsS7RS0B4306001

(d)

(c)

(a)

(a)

(a)16171413

2

1

15 2 19

12

117

7

3

7

4

20 20

5

10

9

8

(b)

18

6

24

23

22

21

I7RS0B430001-01

1. Caliper

11. Brake caliper carrier21. Shaft cover

: Apply rubber grease.

2. Caliper pin bolt 12. Caliper carrier bolt22. Lever

3. Boot 13. Rear caliper bleeder plug23. Washer

4. No.1 slide pin : Apply rubber grease. 14. Bleeder plug cap

24. Parking nut

5. Brake pad 15. Brake flexible hose: 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

6. Return spring 16. Flexible hose joint bolt: 27 N⋅m (2.7 kgf-m, 19.5 lb-ft)

7. Pad spring 17. Hose washer: 60 N⋅m (6.0 kgf-m, 43.5 lb-ft)

8. Disk brake piston : Apply brake fluid to contact surface of cylinder. 18. Brake disc

: 9 N⋅m (0.9 kgf-m, 6.5 lb-ft)

9. Piston seal : Apply small amount of brake fluid to all around part of piston seal. 19. No.2 slide pin

: Apply rubber grease. : Do not reuse.

10. Cylinder boot : Apply small amount of brake fluid. 20. Pad shim

Page 526 of 1496

Downloaded from www.Manualslib.com manuals search engine 4C-2 Rear Brakes:

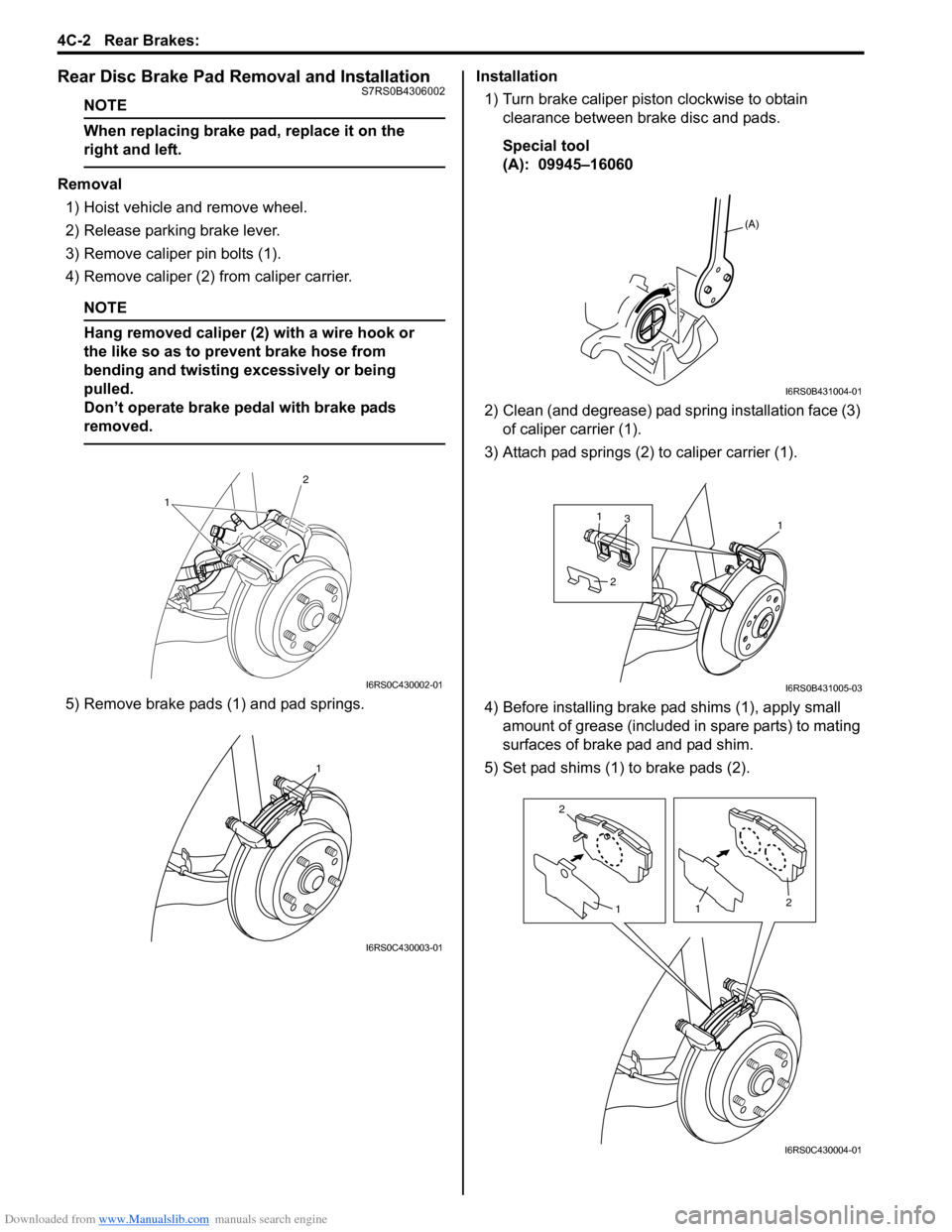

Rear Disc Brake Pad Removal and InstallationS7RS0B4306002

NOTE

When replacing brake pad, replace it on the

right and left.

Removal1) Hoist vehicle and remove wheel.

2) Release parking brake lever.

3) Remove caliper pin bolts (1).

4) Remove caliper (2) from caliper carrier.

NOTE

Hang removed caliper (2) with a wire hook or

the like so as to prevent brake hose from

bending and twisting excessively or being

pulled.

Don’t operate brake pedal with brake pads

removed.

5) Remove brake pads (1) and pad springs. Installation

1) Turn brake caliper piston clockwise to obtain clearance between brake disc and pads.

Special tool

(A): 09945–16060

2) Clean (and degrease) pad spring installation face (3) of caliper carrier (1).

3) Attach pad springs (2) to caliper carrier (1).

4) Before installing brake p ad shims (1), apply small

amount of grease (included in spare parts) to mating

surfaces of brake pad and pad shim.

5) Set pad shims (1) to brake pads (2).

1 2

I6RS0C430002-01

1

I6RS0C430003-01

(A)

I6RS0B431004-01

113

2

I6RS0B431005-03

2

1

1 2

I6RS0C430004-01

Page 527 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Brakes: 4C-3

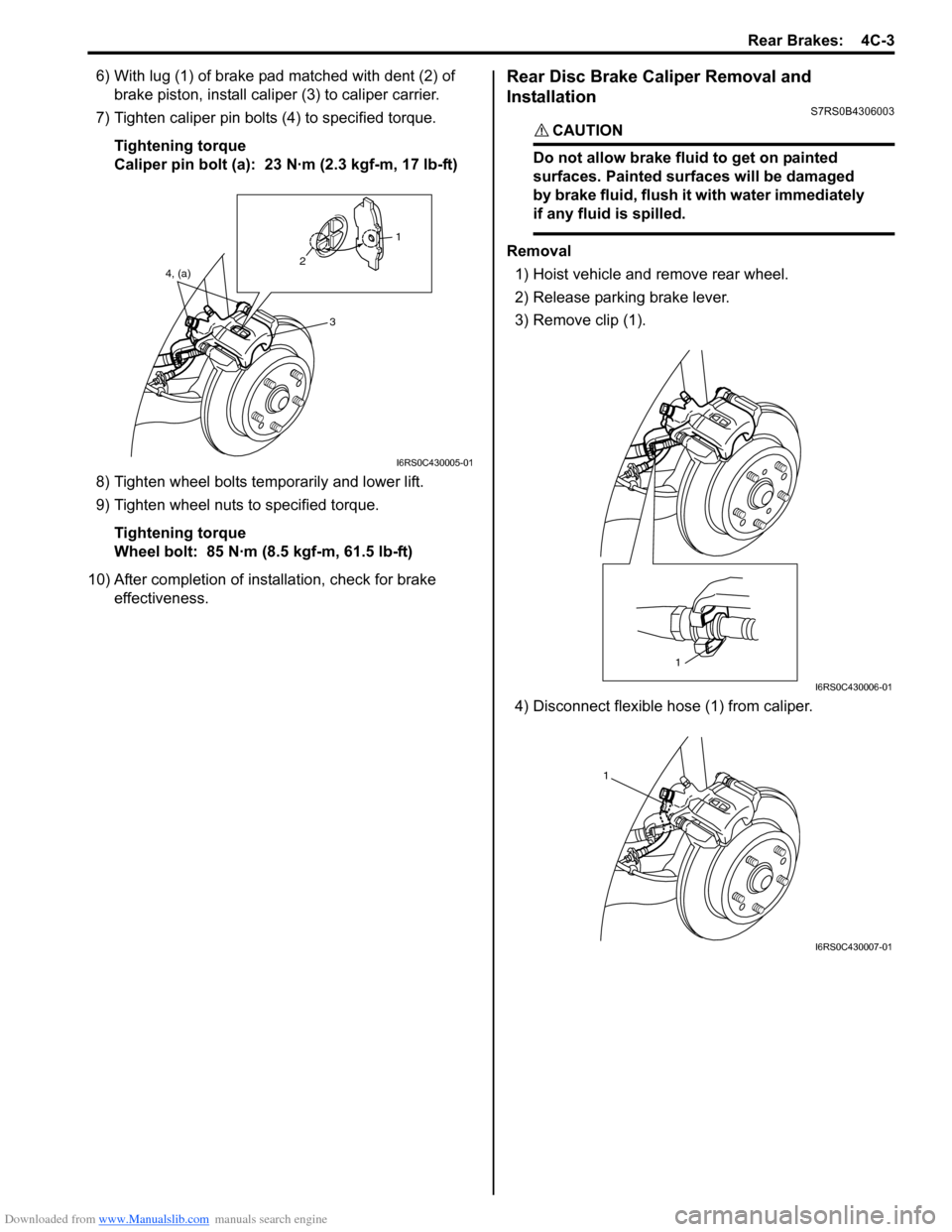

6) With lug (1) of brake pad matched with dent (2) of brake piston, install caliper (3) to caliper carrier.

7) Tighten caliper pin bolts (4) to specified torque.

Tightening torque

Caliper pin bolt (a): 23 N·m (2.3 kgf-m, 17 lb-ft)

8) Tighten wheel bolts temporarily and lower lift.

9) Tighten wheel nuts to specified torque. Tightening torque

Wheel bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

10) After completion of installation, check for brake effectiveness.Rear Disc Brake Caliper Removal and

Installation

S7RS0B4306003

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Hoist vehicle and remove rear wheel.

2) Release parking brake lever.

3) Remove clip (1).

4) Disconnect flexible hose (1) from caliper.

4, (a) 21

3

I6RS0C430005-01

1

I6RS0C430006-01

1

I6RS0C430007-01