Hose SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 529 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Brakes: 4C-5

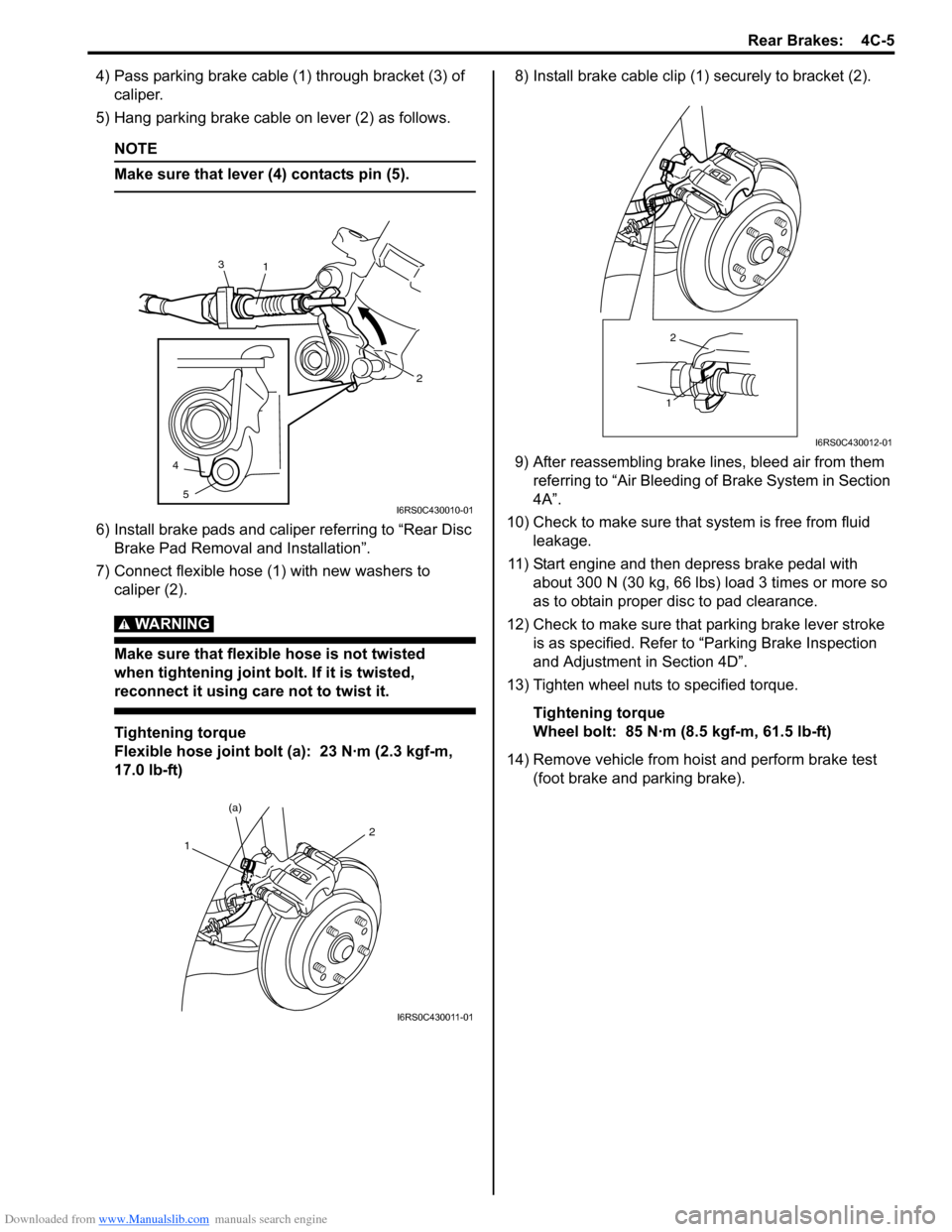

4) Pass parking brake cable (1) through bracket (3) of caliper.

5) Hang parking brake cable on lever (2) as follows.

NOTE

Make sure that lever (4) contacts pin (5).

6) Install brake pads and caliper referring to “Rear Disc Brake Pad Removal and Installation”.

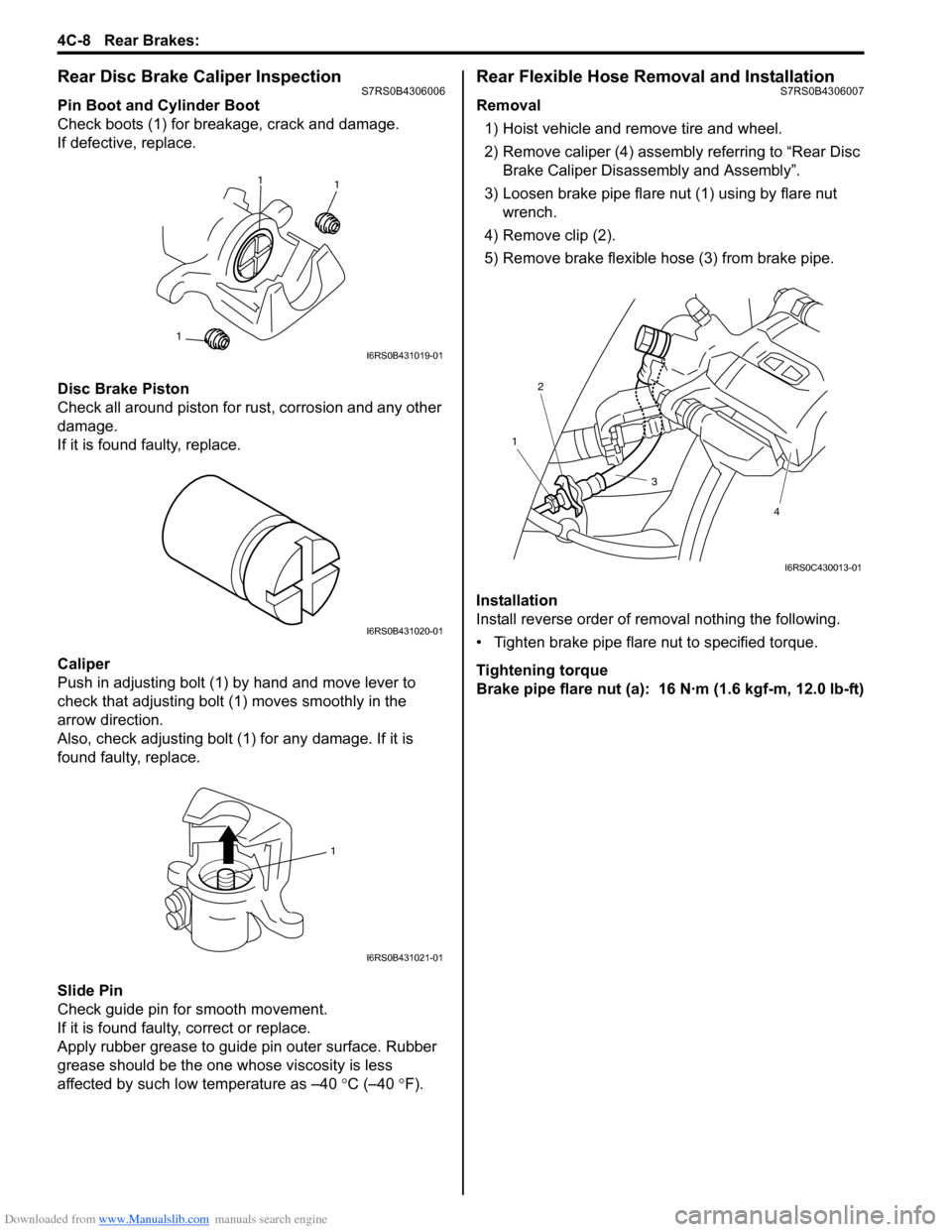

7) Connect flexible hose (1) with new washers to caliper (2).

WARNING!

Make sure that flexible hose is not twisted

when tightening joint bolt. If it is twisted,

reconnect it using care not to twist it.

Tightening torque

Flexible hose joint bolt (a): 23 N·m (2.3 kgf-m,

17.0 lb-ft) 8) Install brake cable clip (1) securely to bracket (2).

9) After reassembling brake lines, bleed air from them

referring to “Air Bleeding of Brake System in Section

4A”.

10) Check to make sure that system is free from fluid

leakage.

11) Start engine and then depress brake pedal with about 300 N (30 kg, 66 lbs) load 3 times or more so

as to obtain proper disc to pad clearance.

12) Check to make sure that parking brake lever stroke is as specified. Refer to “Parking Brake Inspection

and Adjustment in Section 4D”.

13) Tighten wheel nuts to specified torque.

Tightening torque

Wheel bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

14) Remove vehicle from hoist and perform brake test (foot brake and parking brake).

1

23

45

I6RS0C430010-01

1 (a)2

I6RS0C430011-01

1

2

I6RS0C430012-01

Page 532 of 1496

Downloaded from www.Manualslib.com manuals search engine 4C-8 Rear Brakes:

Rear Disc Brake Caliper InspectionS7RS0B4306006

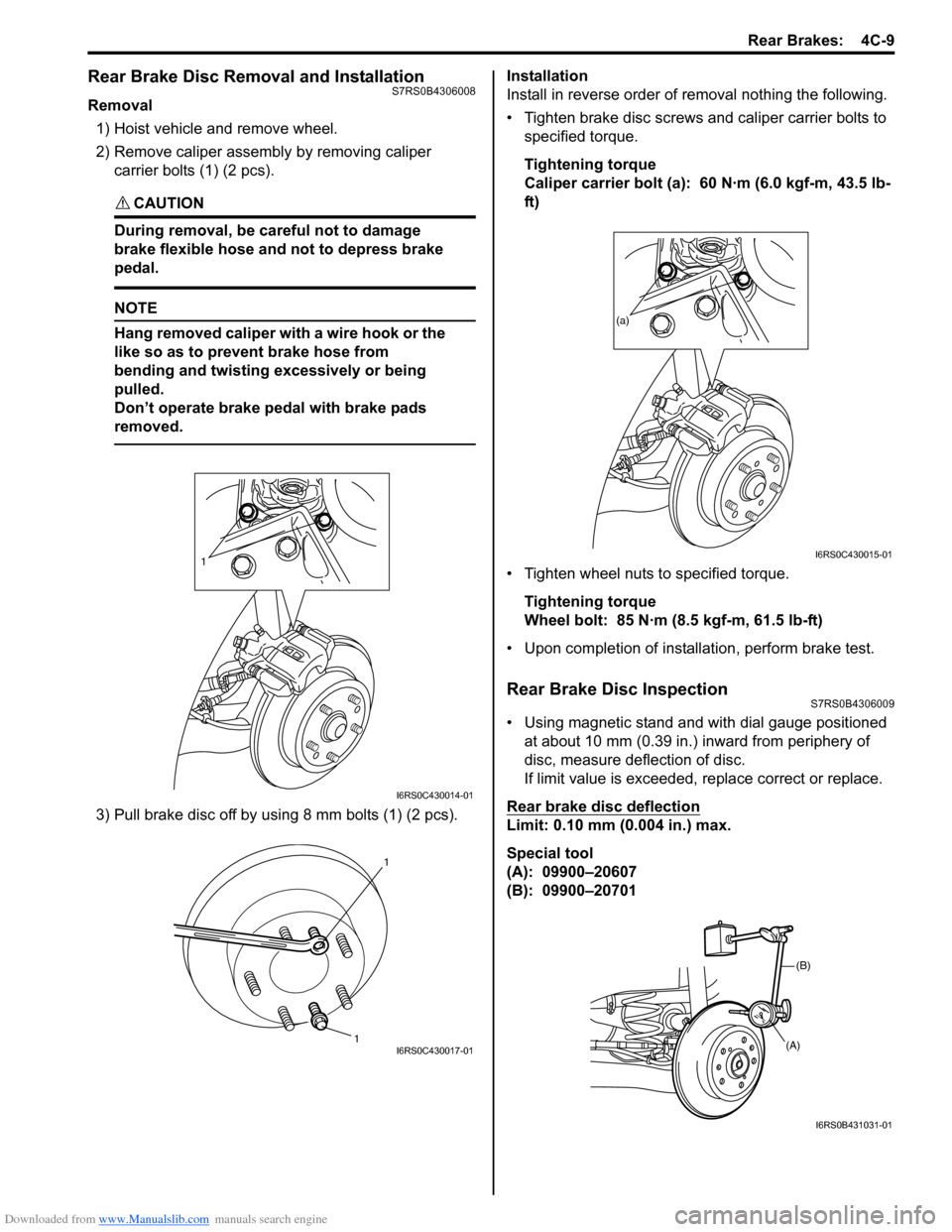

Pin Boot and Cylinder Boot

Check boots (1) for breakage, crack and damage.

If defective, replace.

Disc Brake Piston

Check all around piston for rust, corrosion and any other

damage.

If it is found faulty, replace.

Caliper

Push in adjusting bolt (1) by hand and move lever to

check that adjusting bolt (1) moves smoothly in the

arrow direction.

Also, check adjusting bolt (1) for any damage. If it is

found faulty, replace.

Slide Pin

Check guide pin for smooth movement.

If it is found faulty, correct or replace.

Apply rubber grease to guide pin outer surface. Rubber

grease should be the one whose viscosity is less

affected by such low temperature as –40 °C (–40 ° F).

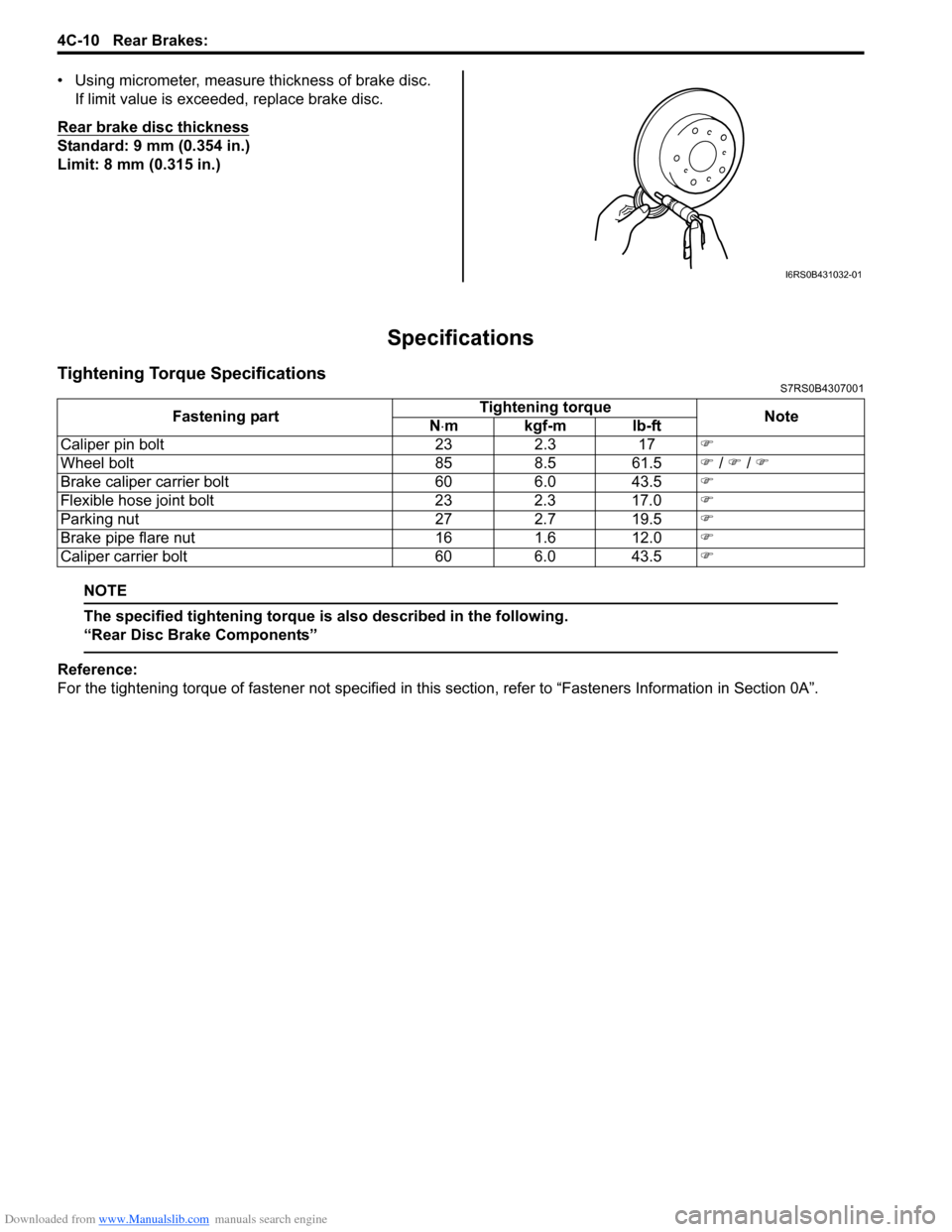

Rear Flexible Hose Removal and InstallationS7RS0B4306007

Removal

1) Hoist vehicle and remove tire and wheel.

2) Remove caliper (4) assembly referring to “Rear Disc Brake Caliper Disassembly and Assembly”.

3) Loosen brake pipe flare nut (1) using by flare nut wrench.

4) Remove clip (2).

5) Remove brake flexible hose (3) from brake pipe.

Installation

Install reverse order of removal nothing the following.

• Tighten brake pipe flare nut to specified torque.

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 12.0 lb-ft)

1 1

1

I6RS0B431019-01

I6RS0B431020-01

1

I6RS0B431021-01

1

2

3

4

I6RS0C430013-01

Page 533 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Brakes: 4C-9

Rear Brake Disc Removal and InstallationS7RS0B4306008

Removal1) Hoist vehicle and remove wheel.

2) Remove caliper assembly by removing caliper

carrier bolts (1) (2 pcs).

CAUTION!

During removal, be ca reful not to damage

brake flexible hose and not to depress brake

pedal.

NOTE

Hang removed caliper with a wire hook or the

like so as to prevent brake hose from

bending and twisting excessively or being

pulled.

Don’t operate brake pedal with brake pads

removed.

3) Pull brake disc off by using 8 mm bolts (1) (2 pcs). Installation

Install in reverse order of removal nothing the following.

• Tighten brake disc screws and caliper carrier bolts to

specified torque.

Tightening torque

Caliper carrier bolt (a): 60 N·m (6.0 kgf-m, 43.5 lb-

ft)

• Tighten wheel nuts to specified torque. Tightening torque

Wheel bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

• Upon completion of installation, perform brake test.

Rear Brake Disc InspectionS7RS0B4306009

• Using magnetic stand and with dial gauge positioned at about 10 mm (0.39 in.) inward from periphery of

disc, measure deflection of disc.

If limit value is exceeded, replace correct or replace.

Rear brake disc deflection

Limit: 0.10 mm (0.004 in.) max.

Special tool

(A): 09900–20607

(B): 09900–20701

1

I6RS0C430014-01

1 1I6RS0C430017-01

(a)

I6RS0C430015-01

(B)

(A)

I6RS0B431031-01

Page 534 of 1496

Downloaded from www.Manualslib.com manuals search engine 4C-10 Rear Brakes:

• Using micrometer, measure thickness of brake disc.If limit value is exceeded, replace brake disc.

Rear brake disc thickness

Standard: 9 mm (0.354 in.)

Limit: 8 mm (0.315 in.)

Specifications

Tightening Torque SpecificationsS7RS0B4307001

NOTE

The specified tightening torque is also described in the following.

“Rear Disc Brake Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

I6RS0B431032-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Caliper pin bolt 23 2.3 17 �)

Wheel bolt 85 8.5 61.5 �) / �) / �)

Brake caliper carrier bolt 60 6.0 43.5 �)

Flexible hose joint bolt 23 2.3 17.0 �)

Parking nut 27 2.7 19.5 �)

Brake pipe flare nut 16 1.6 12.0 �)

Caliper carrier bolt 60 6.0 43.5 �)

Page 540 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-1 ABS:

Brakes

ABS

Precautions

Precautions in Diagnosing TroublesS7RS0B4500001

To ensure that the trouble diagnosis is done accurately

and smoothly, observe the following and follow “ABS

Check”.

• Diagnostic information stored in ABS cont rol module

memory can be cleared as well as checked by using

SUZUKI scan tool. Before us ing scan tool, read its

Operator’s (Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

• If the vehicles was operated in any of the following ways, ABS warning light may light momentarily but

this does not indicate anything abnormal in ABS.

– The vehicle was driven with parking brake pulled.

– The vehicle was driven with brake dragging.

– The vehicle was stuck in mud, sand, etc.

– Wheel spin occurred while driving.

– Wheel(s) was rotated while the vehicle was jacked up.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• Be sure to use the trouble diagnosis procedure as described in “ABS Check”. Failure to follow it may

result in incorrect diagnosis. (Some other diagnosis

trouble code may be stored by mistake in the memory

of ABS control module during inspection.)

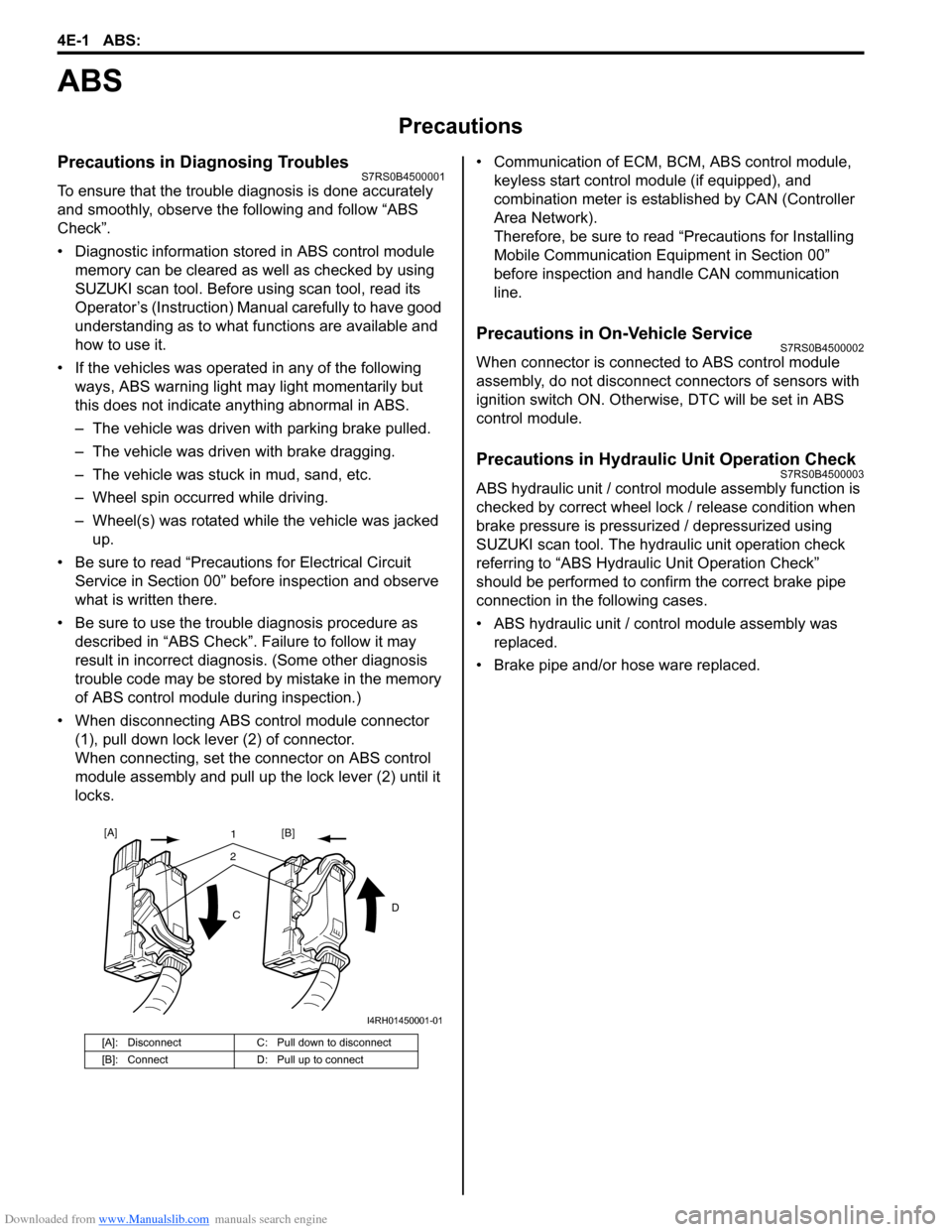

• When disconnecting ABS co ntrol module connector

(1), pull down lock lever (2) of connector.

When connecting, set the connector on ABS control

module assembly and pull up the lock lever (2) until it

locks. • Communication of ECM,

BCM, ABS control module,

keyless start control module (if equipped), and

combination meter is established by CAN (Controller

Area Network).

Therefore, be sure to read “Precautions for Installing

Mobile Communication Equipment in Section 00”

before inspection and handle CAN communication

line.

Precautions in On-Vehicle ServiceS7RS0B4500002

When connector is connected to ABS control module

assembly, do not disconnect connectors of sensors with

ignition switch ON. Otherwise, DTC will be set in ABS

control module.

Precautions in Hydraulic Unit Operation CheckS7RS0B4500003

ABS hydraulic unit / control module assembly function is

checked by correct wheel lock / release condition when

brake pressure is pressurized / depressurized using

SUZUKI scan tool. The hydraulic unit operation check

referring to “ABS Hydraulic Unit Operation Check”

should be performed to confirm the correct brake pipe

connection in the following cases.

• ABS hydraulic unit / cont rol module assembly was

replaced.

• Brake pipe and/or hose ware replaced.

[A]: Disconnect C: Pull down to disconnect

[B]: Connect D: Pull up to connect

21

C D

[A]

[B]

I4RH01450001-01

Page 541 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-2

General Description

ABS DescriptionS7RS0B4501001

The ABS (Antilock Brake System) controls the fluid

pressure applied to the wheel cylinder of each brake

from the master cylinder so that each wheel is not locked

even when hard braking is applied.

This ABS has also the following function.

While braking is applied, but before ABS control

becomes effective, braking force is distributed between

the front and rear so as to prevent the rear wheels from

being locked too early for better stability of the vehicle.

The main component parts of this ABS include the

following parts in addition to those of the conventional

brake system.

• Wheel speed sensor which senses revolution speed of each wheel and outputs its signal.

• ABS warning light which light s to inform abnormality

when system fails to operate properly.

• ABS hydraulic unit / cont rol module assembly is

incorporated ABS co ntrol module, ABS hydraulic unit

(actuator assembly), solenoid valve power supply

driver (transistor), solenoid valve driver (transistor),

pump motor driver (transistor).

– ABS control module which sends operation signal to ABS hydraulic unit to control fluid pressure

applied to each wheel cylinder based on signal

from each wheel speed sensor so as to prevent

wheel from locking.

– ABS hydraulic unit which operates according to signal from ABS control module to control fluid

pressure applied to wheel cylinder of each 4

wheels.

– Solenoid valve power supp ly driver (transistor)

which supplies power to solenoid valve in ABS

hydraulic unit.

– Solenoid valve driver (transistor) which controls each solenoid valves in ABS hydraulic unit.

– Pump motor driver (transistor) which supplies power to pump motor in ABS hydraulic unit.

This ABS is equipped with Electronic Brake force

Distribution (EBD) system that controls a fluid pressure

of rear wheels to best condition, which is the same

function as that of proportion ing valve, by the signal from

wheel sensor independently of change of load due to

load capacity and so on. An d if the EBD system fails to

operate properly, the brake warning light lights to inform

abnormality.

ABS Hydraulic Unit / Control Module Assembly

Description

S7RS0B4501002

ABS control module is a component of ABS hydraulic

unit / control module asse mbly and has the following

functions.

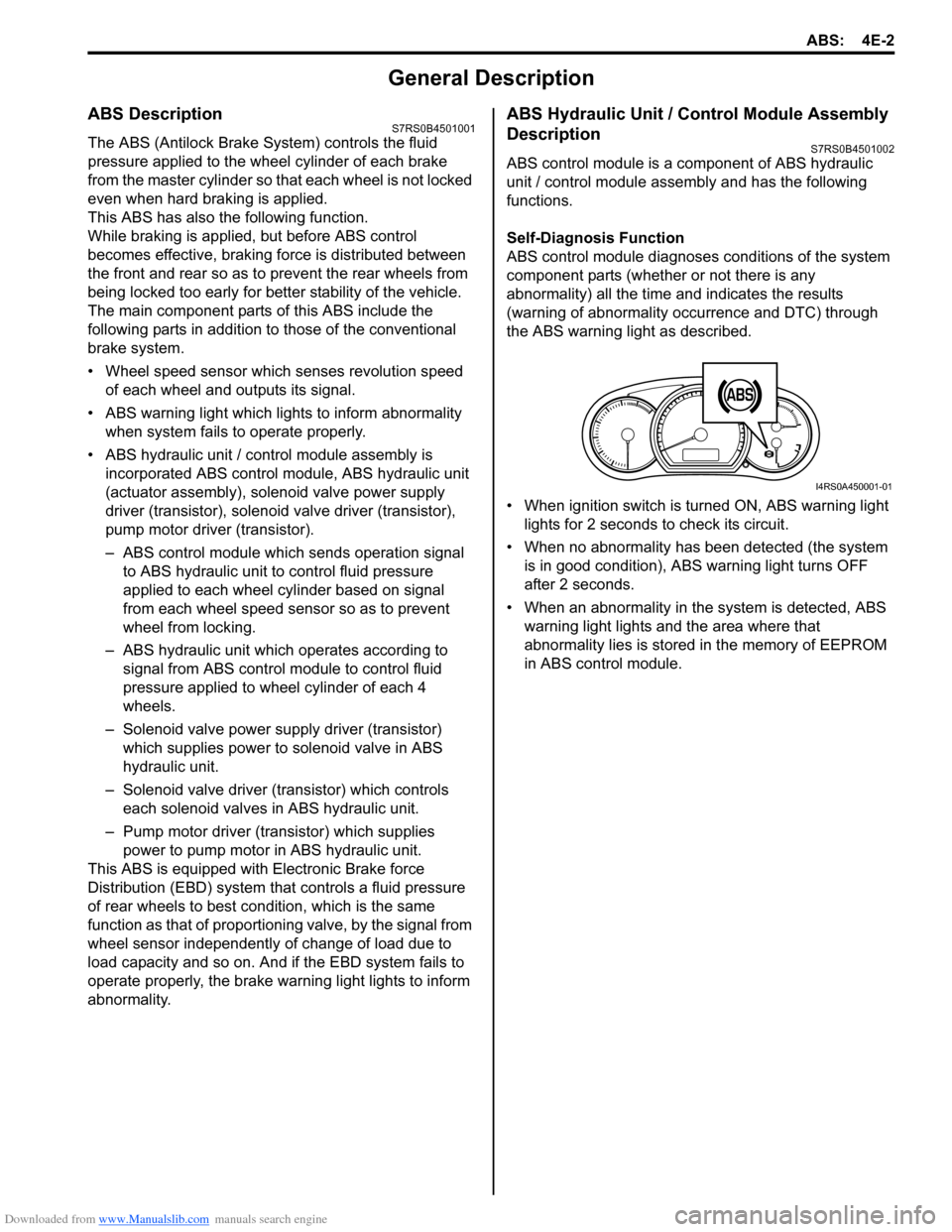

Self-Diagnosis Function

ABS control module diagnose s conditions of the system

component parts (whether or not there is any

abnormality) all the time and indicates the results

(warning of abnormality occurrence and DTC) through

the ABS warning light as described.

• When ignition switch is turned ON, ABS warning light lights for 2 seconds to check its circuit.

• When no abnormality has been detected (the system is in good condition), ABS warning light turns OFF

after 2 seconds.

• When an abnormality in th e system is detected, ABS

warning light lights and the area where that

abnormality lies is stored in the memory of EEPROM

in ABS control module.

1

I4RS0A450001-01

Page 565 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-26

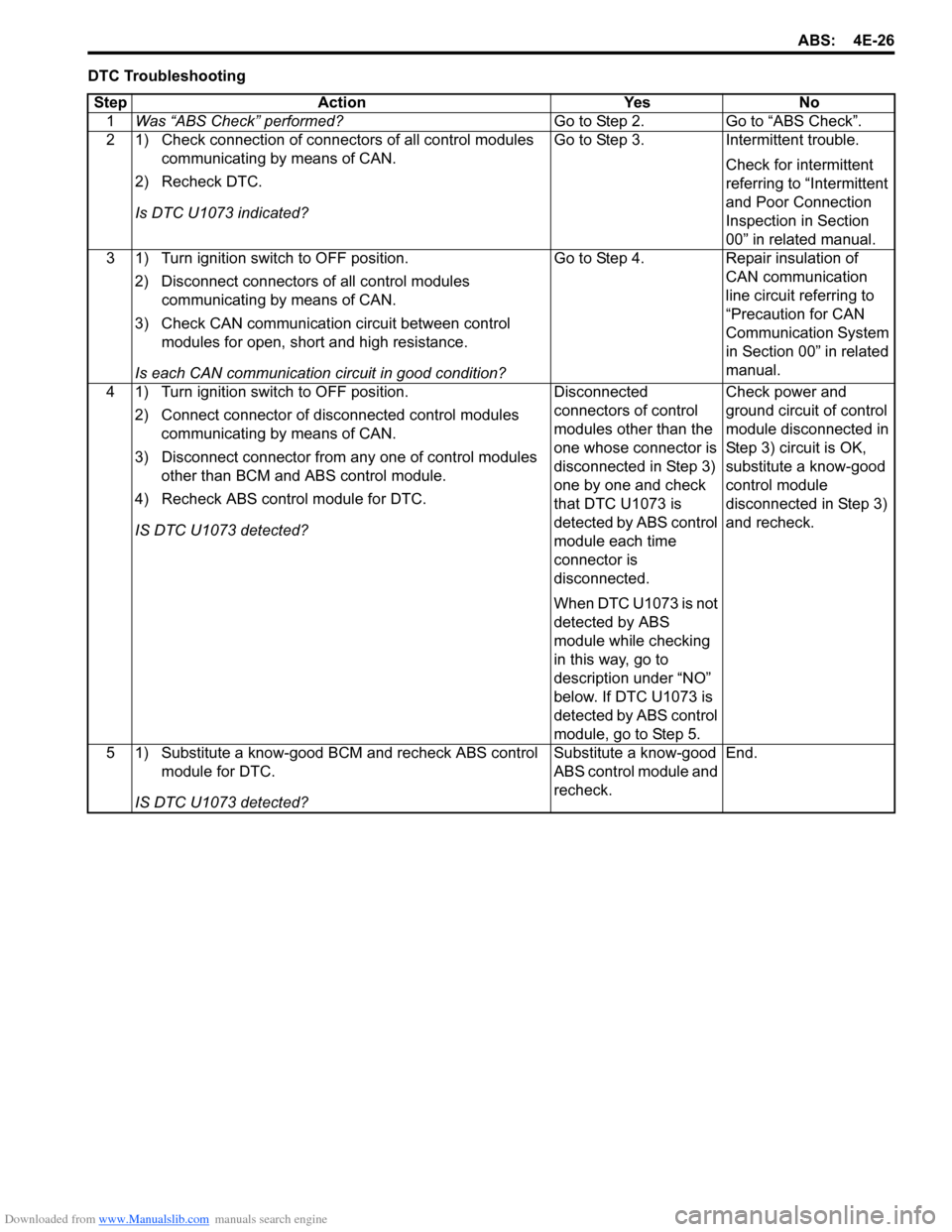

DTC TroubleshootingStep Action Yes No 1 Was “ABS Check” performed? Go to Step 2. Go to “ABS Check”.

2 1) Check connection of connectors of all control modules communicating by means of CAN.

2) Recheck DTC.

Is DTC U1073 indicated? Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00” in related manual.

3 1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 4. Repair insulation of

CAN communication

line circuit referring to

“Precaution for CAN

Communication System

in Section 00” in related

manual.

4 1) Turn ignition switch to OFF position.

2) Connect connector of disconnected control modules communicating by means of CAN.

3) Disconnect connector from any one of control modules other than BCM and ABS control module.

4) Recheck ABS contro l module for DTC.

IS DTC U1073 detected? Disconnected

connectors of control

modules other than the

one whose connector is

disconnected in Step 3)

one by one and check

that DTC U1073 is

detected by ABS control

module each time

connector is

disconnected.

When DTC U1073 is not

detected by ABS

module while checking

in this way, go to

description under “NO”

below. If DTC U1073 is

detected by ABS control

module, go to Step 5.Check power and

ground circuit of control

module disconnected in

Step 3) circuit is OK,

substitute a know-good

control module

disconnected in Step 3)

and recheck.

5 1) Substitute a know-good BCM and recheck ABS control module for DTC.

IS DTC U1073 detected? Substitute a know-good

ABS control module and

recheck.

End.

Page 566 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-27 ABS:

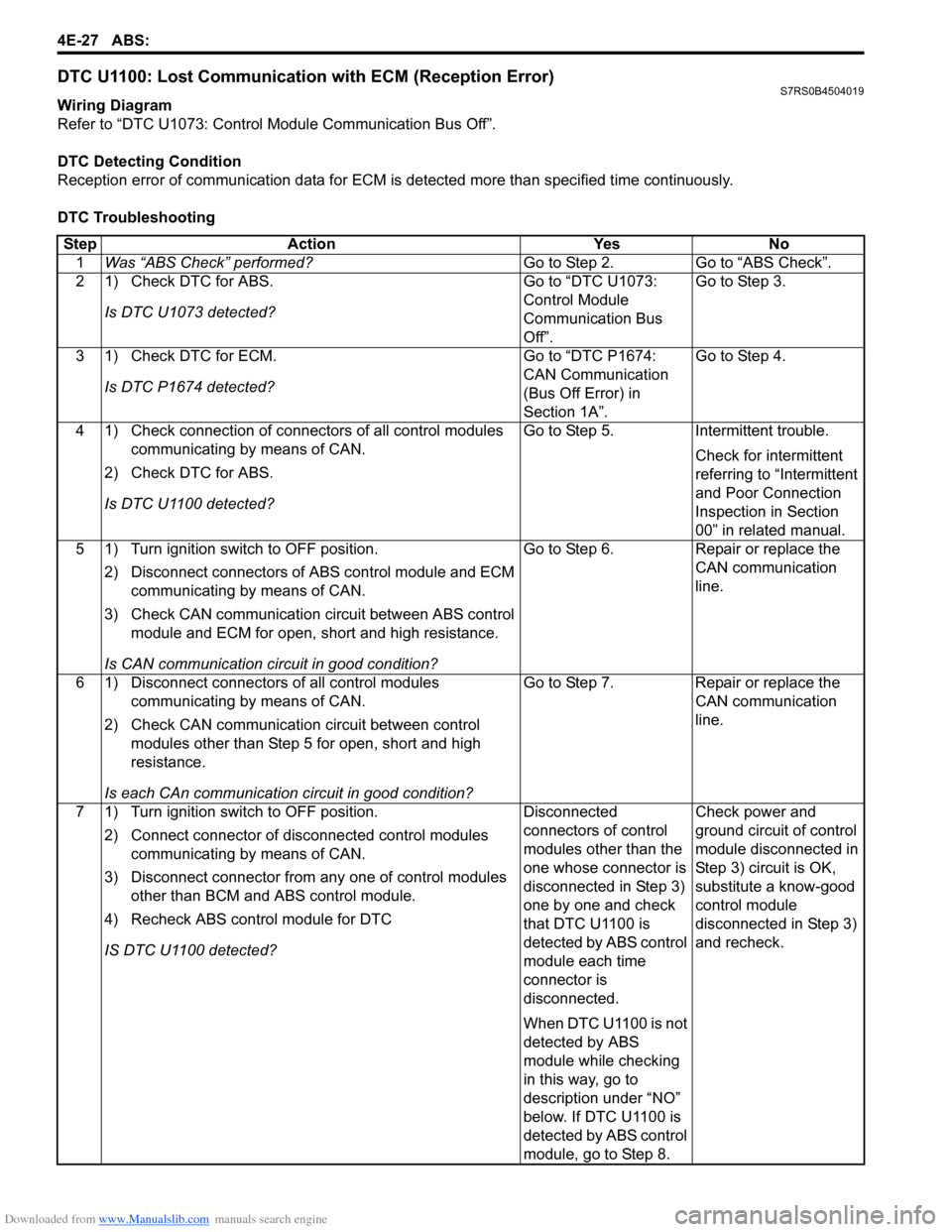

DTC U1100: Lost Communication with ECM (Reception Error)S7RS0B4504019

Wiring Diagram

Refer to “DTC U1073: Control Module Communication Bus Off”.

DTC Detecting Condition

Reception error of communication data for ECM is detected more than specified time continuously.

DTC Troubleshooting Step Action Yes No 1 Was “ABS Check” performed? Go to Step 2. Go to “ABS Check”.

2 1) Check DTC for ABS.

Is DTC U1073 detected? Go to “DTC U1073:

Control Module

Communication Bus

Off”.Go to Step 3.

3 1) Check DTC for ECM. Is DTC P1674 detected? Go to “DTC P1674:

CAN Communication

(Bus Off Error) in

Section 1A”.Go to Step 4.

4 1) Check connection of connectors of all control modules communicating by means of CAN.

2) Check DTC for ABS.

Is DTC U1100 detected? Go to Step 5. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00” in related manual.

5 1) Turn ignition switch to OFF position.

2) Disconnect connectors of ABS control module and ECM

communicating by means of CAN.

3) Check CAN communication circuit between ABS control module and ECM for open, short and high resistance.

Is CAN communication circuit in good condition? Go to Step 6. Repair or replace the

CAN communication

line.

6 1) Disconnect connectors of all control modules communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 5 for open, short and high

resistance.

Is each CAn communication circuit in good condition? Go to Step 7. Repair or replace the

CAN communication

line.

7 1) Turn ignition switch to OFF position. 2) Connect connector of disconnected control modules communicating by means of CAN.

3) Disconnect connector from any one of control modules other than BCM and ABS control module.

4) Recheck ABS contro l module for DTC

IS DTC U1100 detected? Disconnected

connectors of control

modules other than the

one whose connector is

disconnected in Step 3)

one by one and check

that DTC U1100 is

detected by ABS control

module each time

connector is

disconnected.

When DTC U1100 is not

detected by ABS

module while checking

in this way, go to

description under “NO”

below. If DTC U1100 is

detected by ABS control

module, go to Step 8.Check power and

ground circuit of control

module disconnected in

Step 3) circuit is OK,

substitute a know-good

control module

disconnected in Step 3)

and recheck.

Page 575 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-1

Brakes

Electronic Stability Program

Precautions

Precautions in Diagnosing TroublesS7RS0B4600001

To ensure that the trouble diagnosis is done accurately

and smoothly, observe the following and follow

“Electronic Stability Program System Check”.

• Diagnostic information stored in ESP® control module

memory can be cleared as well as checked by using

SUZUKI scan tool. Before us ing scan tool, read its

Operator’s (Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

• If the vehicles was operated in any of the following ways, ESP ® warning lamp may light momentarily but

this does not indicate anything abnormal in ESP ®.

– The vehicle was driven with parking brake pulled.

– The vehicle was driven with brake dragging.

– The vehicle was stuck in mud, sand, etc.

– Wheel spin occurred while driving.

– Wheel(s) was rotated while the vehicle was jacked up.

• Be sure to use the trouble diagnosis procedure as described in “Electronic Stability Program System

Check”. Failure to follow it may resu lt in incorrect

diagnosis. (Some other diagnosis trouble code may

be stored by mistake in the memory of ESP ® control

module during inspection.)

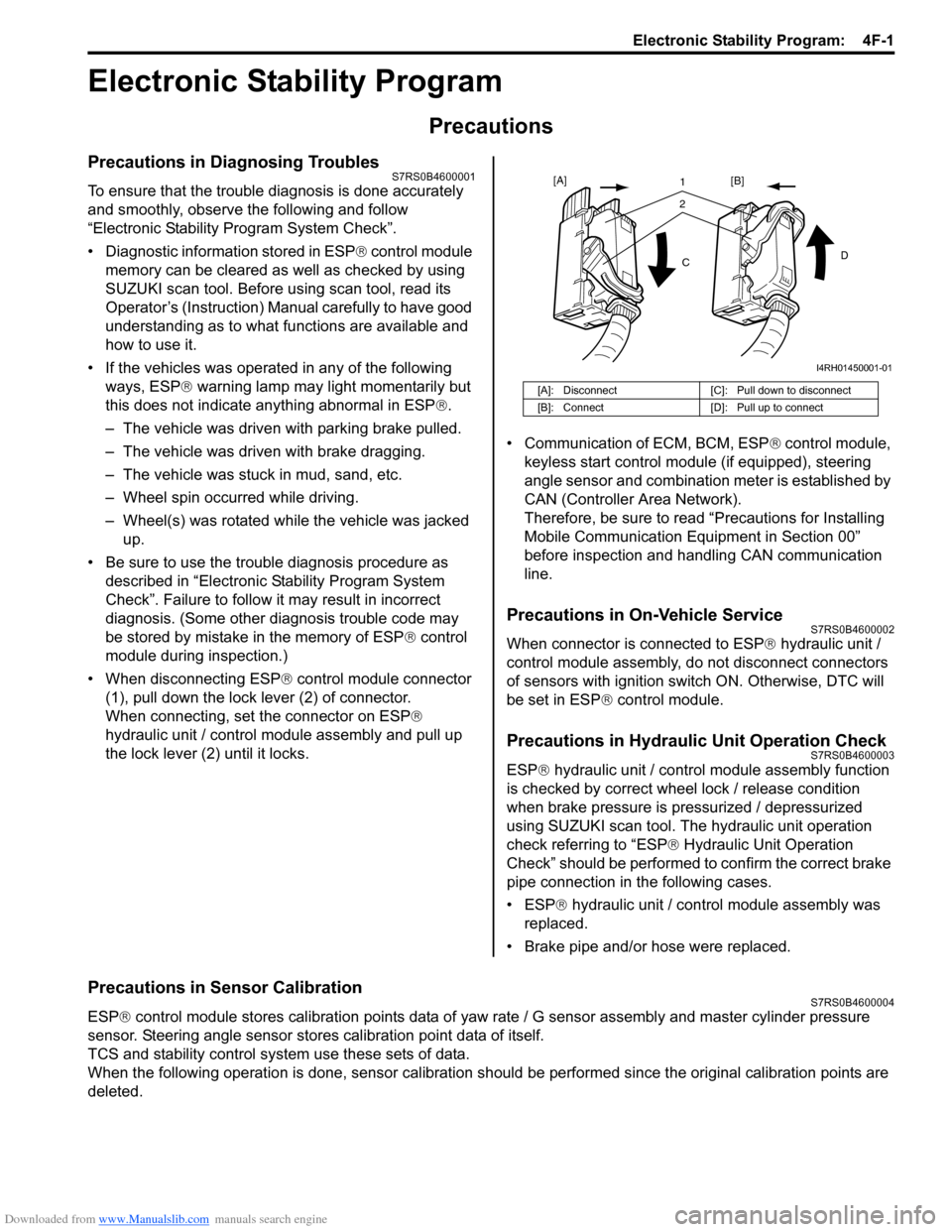

• When disconnecting ESP ® control module connector

(1), pull down the lock lever (2) of connector.

When connecting, set the connector on ESP ®

hydraulic unit / control module assembly and pull up

the lock lever (2) until it locks. • Communication of ECM, BCM, ESP

® control module,

keyless start control module (if equipped), steering

angle sensor and combination meter is established by

CAN (Controller Area Network).

Therefore, be sure to read “Precautions for Installing

Mobile Communication Equipment in Section 00”

before inspection and handling CAN communication

line.

Precautions in On-Vehicle ServiceS7RS0B4600002

When connector is connected to ESP ® hydraulic unit /

control module assembly, do not disconnect connectors

of sensors with ignition switch ON. Otherwise, DTC will

be set in ESP ® control module.

Precautions in Hydraulic Unit Operation CheckS7RS0B4600003

ESP® hydraulic unit / control module assembly function

is checked by correct wheel lock / release condition

when brake pressure is pressurized / depressurized

using SUZUKI scan tool. The hydraulic unit operation

check referring to “ESP ® Hydraulic Unit Operation

Check” should be performed to confirm the correct brake

pipe connection in the following cases.

• ESP® hydraulic unit / contro l module assembly was

replaced.

• Brake pipe and/or hose were replaced.

Precautions in Sensor CalibrationS7RS0B4600004

ESP ® control module stores calibration points data of yaw rate / G sensor assembly and master cylinder pressure

sensor. Steering angle sensor stores calibration point data of itself.

TCS and stability control system use these sets of data.

When the following operation is done, sensor calibration should be performed since the original calibration points are

deleted.

[A]: Disconnect [C]: Pull down to disconnect

[B]: Connect [D]: Pull up to connect

21

C D

[A]

[B]

I4RH01450001-01

Page 631 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-57

3) Remove front brake pipe referring to “Front Brake Hose / Pipe Removal and In stallation in Section 4A”.

4) Remove ESP ® hydraulic unit / control module with

bracket from vehicle by removing bracket bolts.

5) Remove bolt (4) and pull out ESP ® hydraulic unit /

control module assembly (1) from bracket (3) using

flat end rod or the like (2).

Installation 1) Install hydraulic unit / co ntrol module assembly and

by reversing removal procedure.

Tightening torque

Brake pipe flare nut: 16 N·m (1.6 kgf-m, 11.5 lb-

ft)

ESP ® hydraulic unit / control module assembly

bolt: 9 N·m (0.9 kgf-m, 6.5 lb-ft)

ESP ® hydraulic unit / control module assembly

bracket bolt: 25 N·m (2.5 kgf-m, 18.0 lb-ft)

2) Bleed air from brake system referring to “Air Bleeding of Brake System in Section 4A”.

3) Check each installed part for fluid leakage.

4) Connect SUZUKI Scan Tool.

5) Turn ignition switch to ON position. And SLIP indicator lamp flush. (Other than replace with new

one) If other than SLIP indicator lamp light, check

DTC and repair it.

6) Turn ignition switch to ON position. And ESP®

warning lamp, SLIP indicator lamp, ESP ® OFF

lamp, Brake warning lamp lights and ABS warning

lamp flush. (Replace new one)

7) Check DTC.

NOTE

If any DTC(s) other than C1075, C1076 or

C1078 are detected, sensor calibration can

not be completed. Repair the detected it(s)

first.

8) Perform “Sensor Calibration”.

9) Perform “ESP ® Hydraulic Unit Operation Check”.

10) Turn ignition switch to OFF position once and then

ON position. In this state, make sure that indicator

light and warning light turns off.

11) Check DTC(s) are not stored in hydraulic unit / control module.

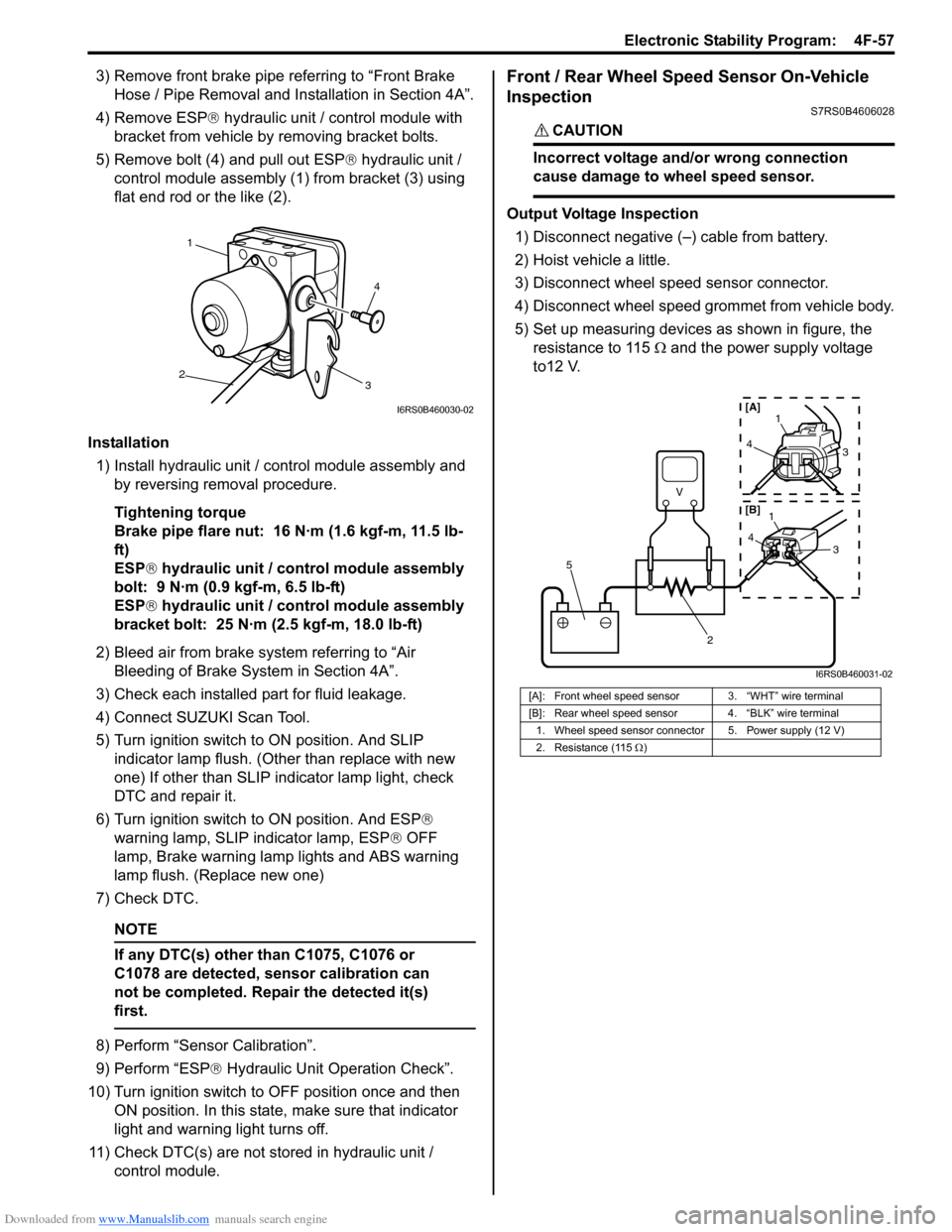

Front / Rear Wheel Speed Sensor On-Vehicle

Inspection

S7RS0B4606028

CAUTION!

Incorrect voltage and/or wrong connection

cause damage to wheel speed sensor.

Output Voltage Inspection

1) Disconnect negative (–) cable from battery.

2) Hoist vehicle a little.

3) Disconnect wheel speed sensor connector.

4) Disconnect wheel speed grommet from vehicle body.

5) Set up measuring devices as shown in figure, the resistance to 115 Ω and the power supply voltage

to12 V.

4

1

2 3

I6RS0B460030-02

[A]: Front wheel speed sensor 3. “WHT” wire terminal

[B]: Rear wheel speed sensor 4. “BLK” wire terminal

1. Wheel speed sensor connector 5. Power supply (12 V)

2. Resistance (115 Ω)

V

2

5

4 1

3

43

1

[A]

[B]

I6RS0B460031-02