tightening torque SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 781 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-137

Reassembly

Reverse disassembly procedure for assembly, noting the

following points.

• Use new seal rings and O-rings. Apply A/T fluid to seal rings and O-rings before installation.

• Tighten rear cover plugs to specified torque.

Tightening torque

Rear cover plug: 7.5 N·m (0.75 kgf-m, 5.5 lb-ft)

• Before installing rear cover seal ring, apply A/T fluid to ring.

First, tighten seal ring to 5 mm (0.197 in.), then install

seal ring.

• Do not open rear cover seal ring too wide to attach.

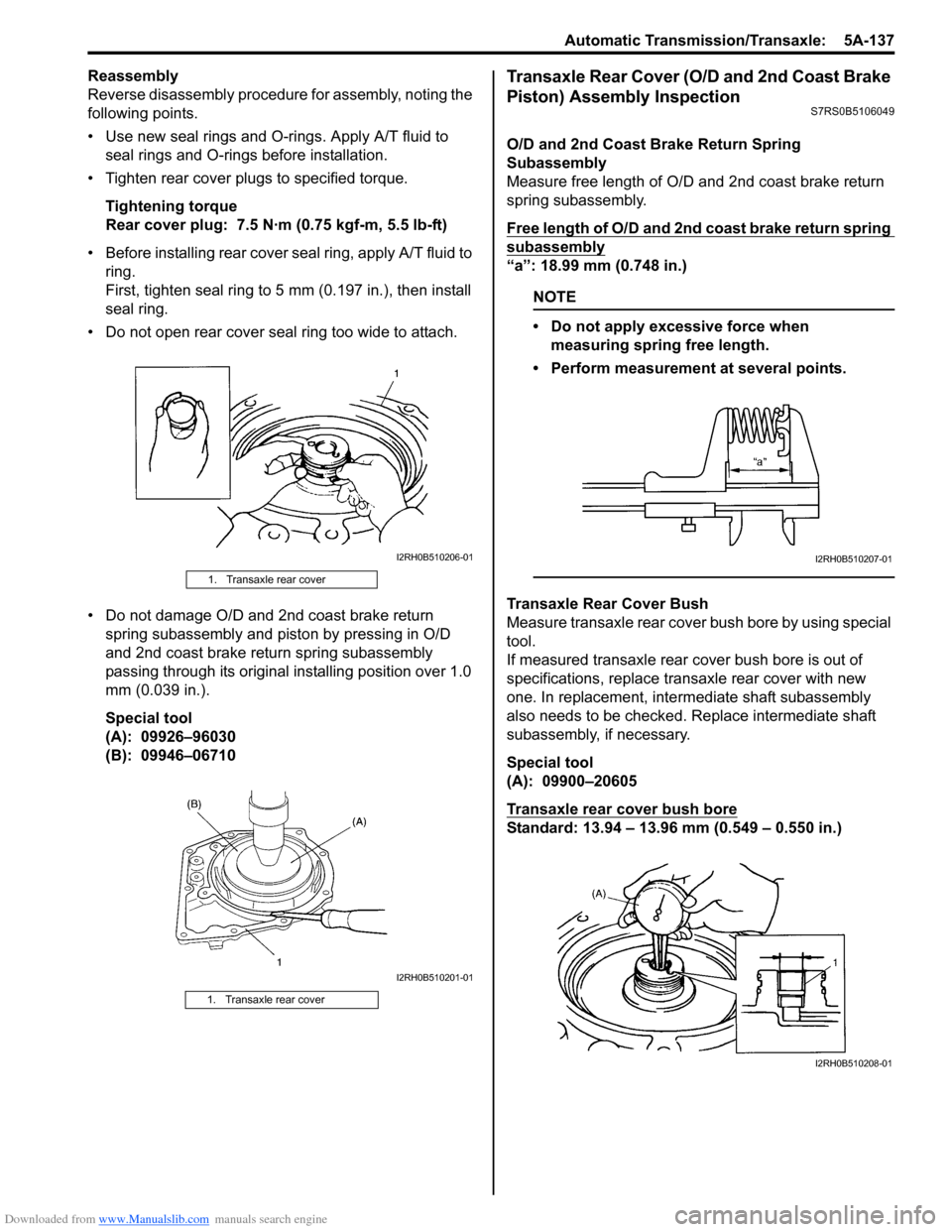

• Do not damage O/D and 2nd coast brake return spring subassembly and piston by pressing in O/D

and 2nd coast brake return spring subassembly

passing through its original installing position over 1.0

mm (0.039 in.).

Special tool

(A): 09926–96030

(B): 09946–06710Transaxle Rear Cover (O/D and 2nd Coast Brake

Piston) Assembly Inspection

S7RS0B5106049

O/D and 2nd Coast Brake Return Spring

Subassembly

Measure free length of O/D and 2nd coast brake return

spring subassembly.

Free length of O/D and 2nd coast brake return spring

subassembly

“a”: 18.99 mm (0.748 in.)

NOTE

• Do not apply excessive force when measuring spring free length.

• Perform measurement at several points.

Transaxle Rear Cover Bush

Measure transaxle rear cover bush bore by using special

tool.

If measured transaxle rear cover bush bore is out of

specifications, replace transaxle rear cover with new

one. In replacement, inte rmediate shaft subassembly

also needs to be checked. Replace intermediate shaft

subassembly, if necessary.

Special tool

(A): 09900–20605

Transaxle rear cover bush bore

Standard: 13.94 – 13.96 mm (0.549 – 0.550 in.)

1. Transaxle rear cover

1. Transaxle rear cover

I2RH0B510206-01

I2RH0B510201-01

I2RH0B510207-01

I2RH0B510208-01

Page 785 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-141

Reassembly

Reverse disassembly procedure for assembly, noting the

following points.

• Shift solenoid valve-A and -B are identical

• After applying A/T fluid to new O-rings, fit them to solenoid valves, then insta ll solenoid valves to valve

body.

• Tighten solenoid valve bolts to specified torque

Tightening torque

Solenoid valve bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

Solenoid valve bolt specification

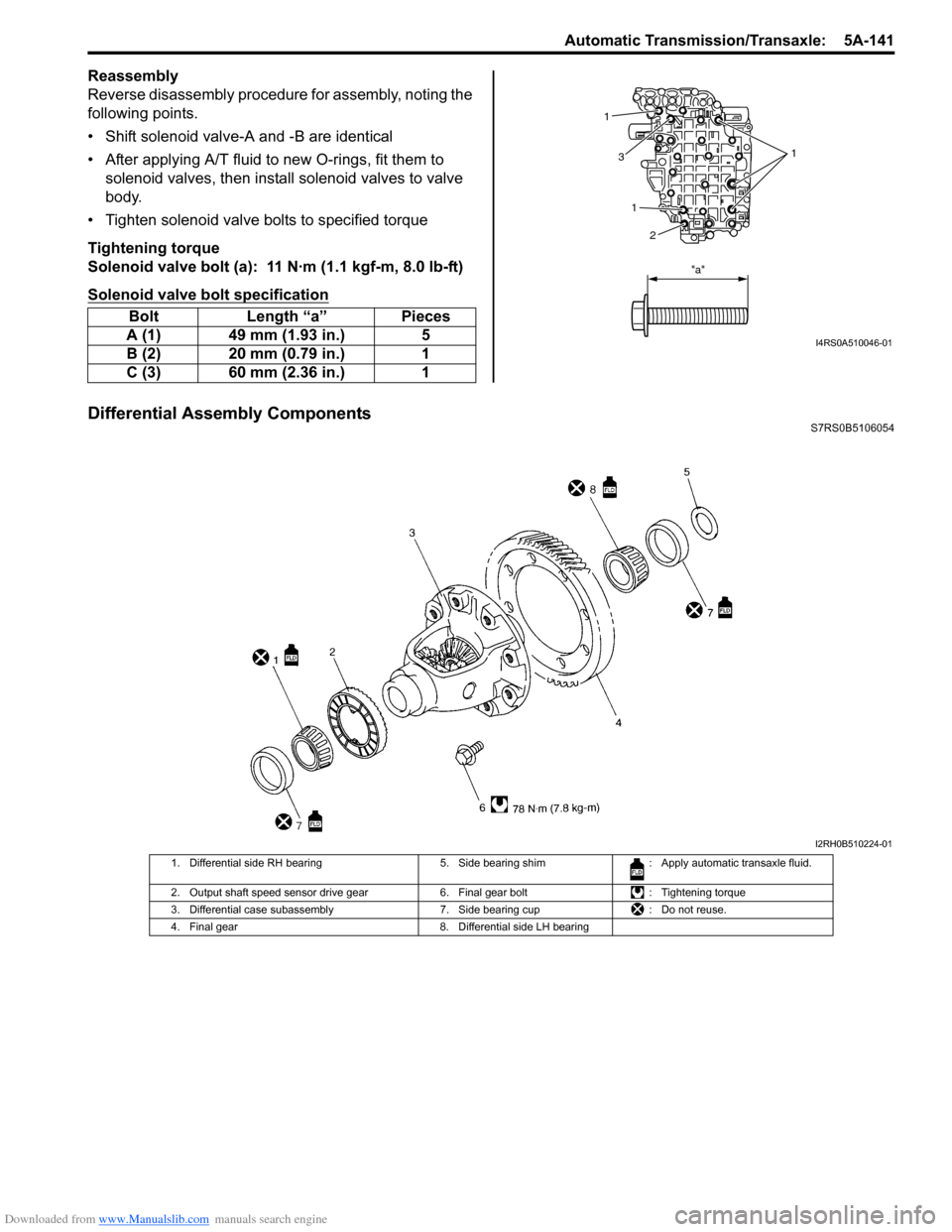

Differential Assembly ComponentsS7RS0B5106054

Bolt Length “a” Pieces

A (1) 49 mm (1.93 in.) 5

B (2) 20 mm (0.79 in.) 1

C (3) 60 mm (2.36 in.) 1

1

1

1

3

2

"a"

I4RS0A510046-01

I2RH0B510224-01

1. Differential side RH bearing 5. Side bearing shim: Apply automatic transaxle fluid.

2. Output shaft speed sensor drive gear 6. Final gear bolt: Tightening torque

3. Differential case subassembly 7. Side bearing cup: Do not reuse.

4. Final gear 8. Differential side LH bearing

Page 787 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-143

2) As shown in figure, facing groove (2) side upward, install final driven gear (1) to differential case.

3) Tighten final gear bolts (1) to specified torque.

NOTE

To avoid rust, apply A/T fluid to final driven

gear after installation.

Tightening torque

Final gear bolt (a): 78 N·m (7.8 kgf-m, 56.5 lb-ft)

4) After applying A/T fluid to output shaft speed sensor drive gear (1), install output shaft speed sensor drive

gear.

5) Install new differential side RH bearing (1) by using special tool and hydraulic press.

NOTE

Replace differential side RH bearing together

with bearing cup as a set.

Special tool

(A): 09913–70123 6) Install new differential side LH bearing (1) by using

special tool and hydraulic press.

NOTE

Replace differential side LH bearing together

with bearing cup as a set.

Special tool

(A): 09913–70123

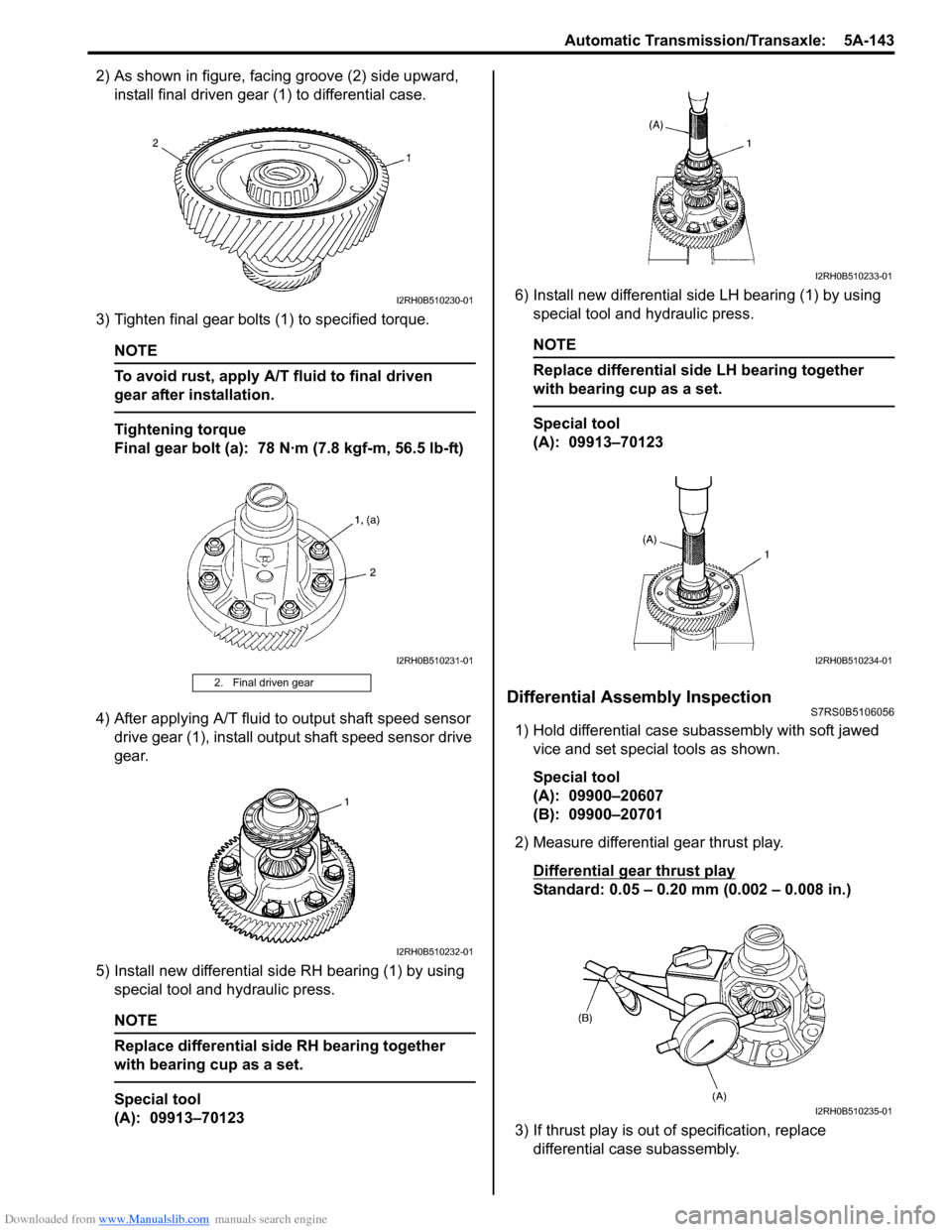

Differential Assembly InspectionS7RS0B5106056

1) Hold differential case subassembly with soft jawed

vice and set special tools as shown.

Special tool

(A): 09900–20607

(B): 09900–20701

2) Measure differential gear thrust play.

Differential gear thrust play

Standard: 0.05 – 0.20 mm (0.002 – 0.008 in.)

3) If thrust play is out of specification, replace differential case subassembly.

2. Final driven gear

I2RH0B510230-01

I2RH0B510231-01

I2RH0B510232-01

I2RH0B510233-01

I2RH0B510234-01

I2RH0B510235-01

Page 789 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-145

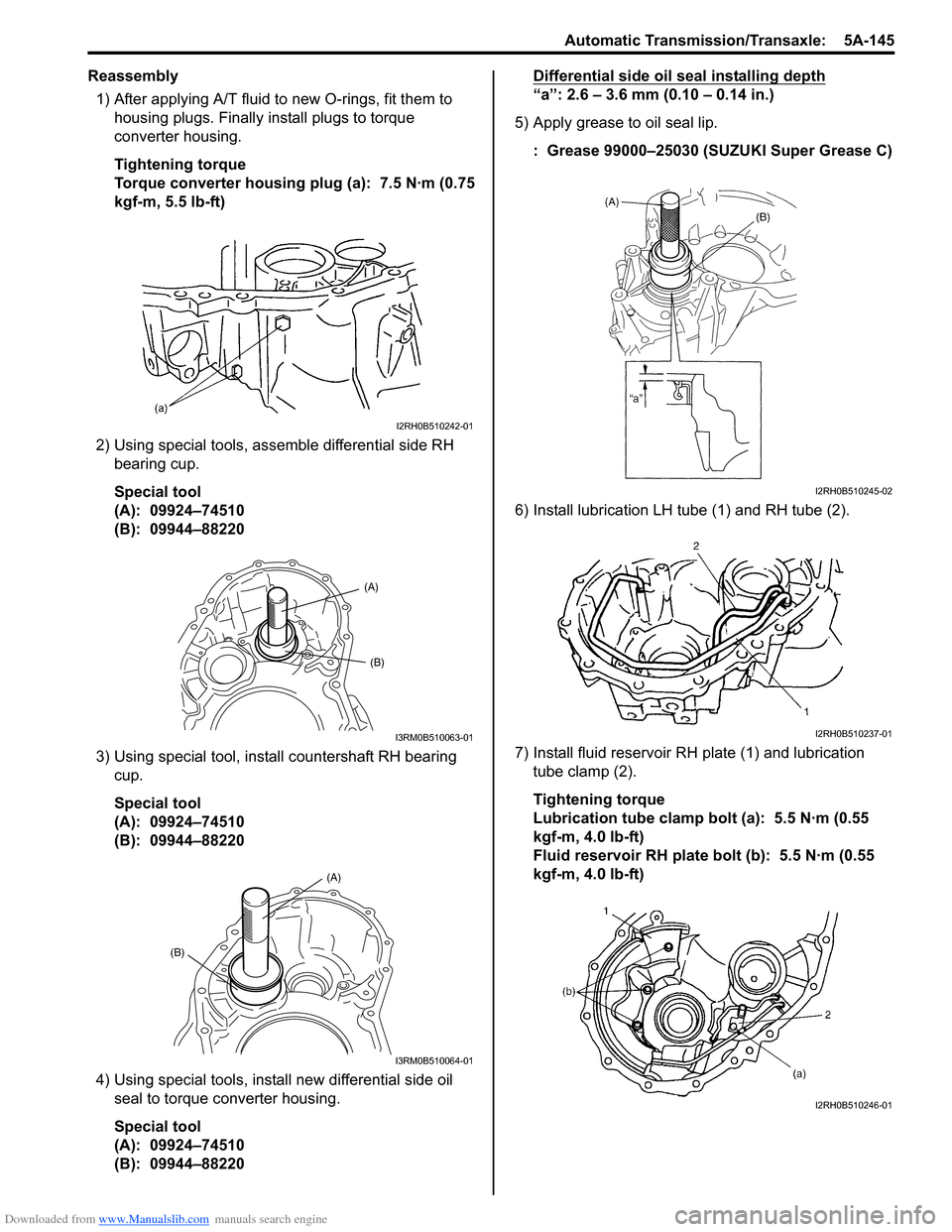

Reassembly1) After applying A/T fluid to new O-rings, fit them to housing plugs. Finally install plugs to torque

converter housing.

Tightening torque

Torque converter housing plug (a): 7.5 N·m (0.75

kgf-m, 5.5 lb-ft)

2) Using special tools, assemble differential side RH bearing cup.

Special tool

(A): 09924–74510

(B): 09944–88220

3) Using special tool, install countershaft RH bearing cup.

Special tool

(A): 09924–74510

(B): 09944–88220

4) Using special tools, install new differential side oil seal to torque converter housing.

Special tool

(A): 09924–74510

(B): 09944–88220 Differential side oil seal installing depth

“a”: 2.6 – 3.6 mm (0.10 – 0.14 in.)

5) Apply grease to oil seal lip. : Grease 99000–25030 (SUZUKI Super Grease C)

6) Install lubrication LH tube (1) and RH tube (2).

7) Install fluid reservoir RH plate (1) and lubrication tube clamp (2).

Tightening torque

Lubrication tube clamp bolt (a): 5.5 N·m (0.55

kgf-m, 4.0 lb-ft)

Fluid reservoir RH plate bolt (b): 5.5 N·m (0.55

kgf-m, 4.0 lb-ft)

I2RH0B510242-01

(A)

(B)

I3RM0B510063-01

(B) (A)

I3RM0B510064-01

I2RH0B510245-02

I2RH0B510237-01

I2RH0B510246-01

Page 792 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-148 Automatic Transmission/Transaxle:

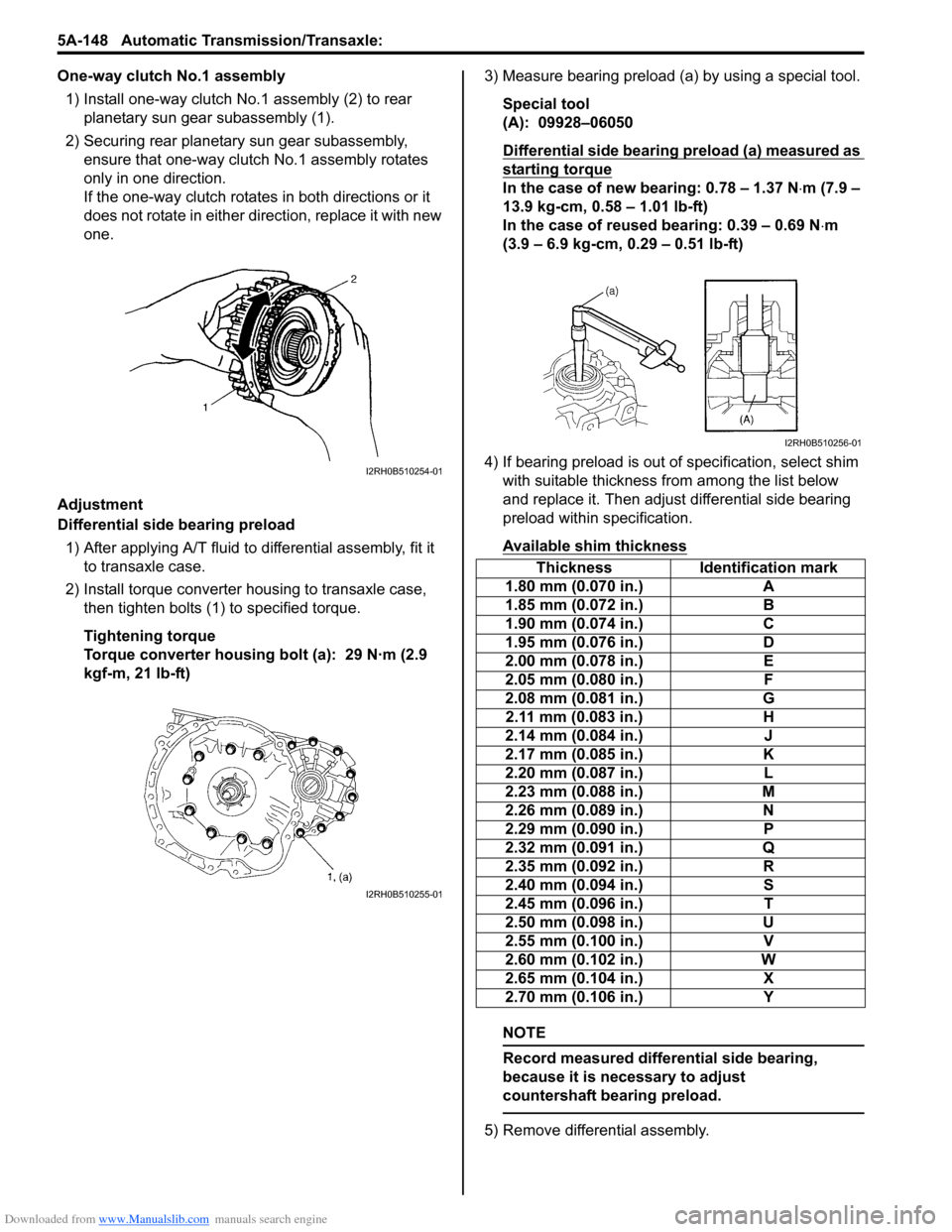

One-way clutch No.1 assembly1) Install one-way clutch No.1 assembly (2) to rear planetary sun gear subassembly (1).

2) Securing rear planetary sun gear subassembly, ensure that one-way clutch No.1 assembly rotates

only in one direction.

If the one-way clutch rotates in both directions or it

does not rotate in either direction, replace it with new

one.

Adjustment

Differential side bearing preload 1) After applying A/T fluid to differential assembly, fit it to transaxle case.

2) Install torque converter housing to transaxle case, then tighten bolts (1) to specified torque.

Tightening torque

Torque converter housing bolt (a): 29 N·m (2.9

kgf-m, 21 lb-ft) 3) Measure bearing preload (a) by using a special tool.

Special tool

(A): 09928–06050

Differential side bearing preload (a) measured as

starting torque

In the case of new bearing: 0.78 – 1.37 N ⋅m (7.9 –

13.9 kg-cm, 0.58 – 1.01 lb-ft)

In the case of reused bearing: 0.39 – 0.69 N ⋅m

(3.9 – 6.9 kg-cm, 0.29 – 0.51 lb-ft)

4) If bearing preload is out of specification, select shim with suitable thickness from among the list below

and replace it. Then adjust differential side bearing

preload within specification.

Available shim thickness

NOTE

Record measured differential side bearing,

because it is necessary to adjust

countershaft bearing preload.

5) Remove differential assembly.

I2RH0B510254-01

I2RH0B510255-01

Thickness Identification mark

1.80 mm (0.070 in.) A

1.85 mm (0.072 in.) B

1.90 mm (0.074 in.) C

1.95 mm (0.076 in.) D

2.00 mm (0.078 in.) E

2.05 mm (0.080 in.) F

2.08 mm (0.081 in.) G

2.11 mm (0.083 in.) H

2.14 mm (0.084 in.) J

2.17 mm (0.085 in.) K

2.20 mm (0.087 in.) L

2.23 mm (0.088 in.) M

2.26 mm (0.089 in.) N

2.29 mm (0.090 in.) P

2.32 mm (0.091 in.) Q

2.35 mm (0.092 in.) R

2.40 mm (0.094 in.) S

2.45 mm (0.096 in.) T

2.50 mm (0.098 in.) U

2.55 mm (0.100 in.) V

2.60 mm (0.102 in.) W

2.65 mm (0.104 in.) X

2.70 mm (0.106 in.) Y

I2RH0B510256-01

Page 793 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-149

Countershaft bearing preload1) After applying A/T fluid to countershaft assembly (1) and differential assembly (2), fit them.

2) Install torque converter housing to transaxle case, then tighten bolts to specified torque.

Tightening torque

Torque converter housing bolt: 29 N·m (2.9 kgf-

m, 21 lb-ft)

3) Measure bearing preload (b) by using special tool. Special tool

(A): 09928–06050

Countershaft bearing preload (b) measured as

starting torque

In the case of new bearing: 0.33 – 0.96 N⋅ m (3.3 –

9.8 kg-cm, 0.24 – 0.69 lb-ft)

In the case of reused bearing: 0.17 – 0.38 N ⋅m

(1.7 – 3.8 kg-cm, 0.12 – 0.28 lb-ft) 4) If bearing preload is out of specification, select shim

with suitable thickness from among the list below

and replace it. Then adjust countershaft bearing

preload within specification.

Available shim thickness

5) Remove differential assembly and countershaft assembly.

Countershaft bearing

preload =(b) – Differential side bearing

preload (a)

I2RH0B510257-01

I3RM0B510067-01

Thickness Identification mark

1.70 (0.066 in.) 1

1.75 (0.068 in.) 2

1.80 (0.070 in.) 3

1.85 (0.072 in.) 4

1.90 (0.074 in.) 5

1.93 (0.075 in.) 6

1.96 (0.077 in.) 7

1.99 (0.078 in.) A

2.02 (0.079 in.) B

2.05 (0.080 in.) C

2.08 (0.081 in.) D

2.11 (0.083 in.) E

2.14 (0.084 in.) F

2.17 (0.085 in.) G

2.20 (0.086 in.) H

2.25 (0.088 in.) K

2.30 (0.090 in.) L

2.35 (0.092 in.) M

2.40 (0.094 in.) N

2.45 (0.096 in.) P

2.50 (0.098 in.) Q

2.55 (0.100 in.) R

2.60 (0.102 in.) S

2.65 (0.104 in.) U

2.70 (0.106 in.) W

Page 794 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-150 Automatic Transmission/Transaxle:

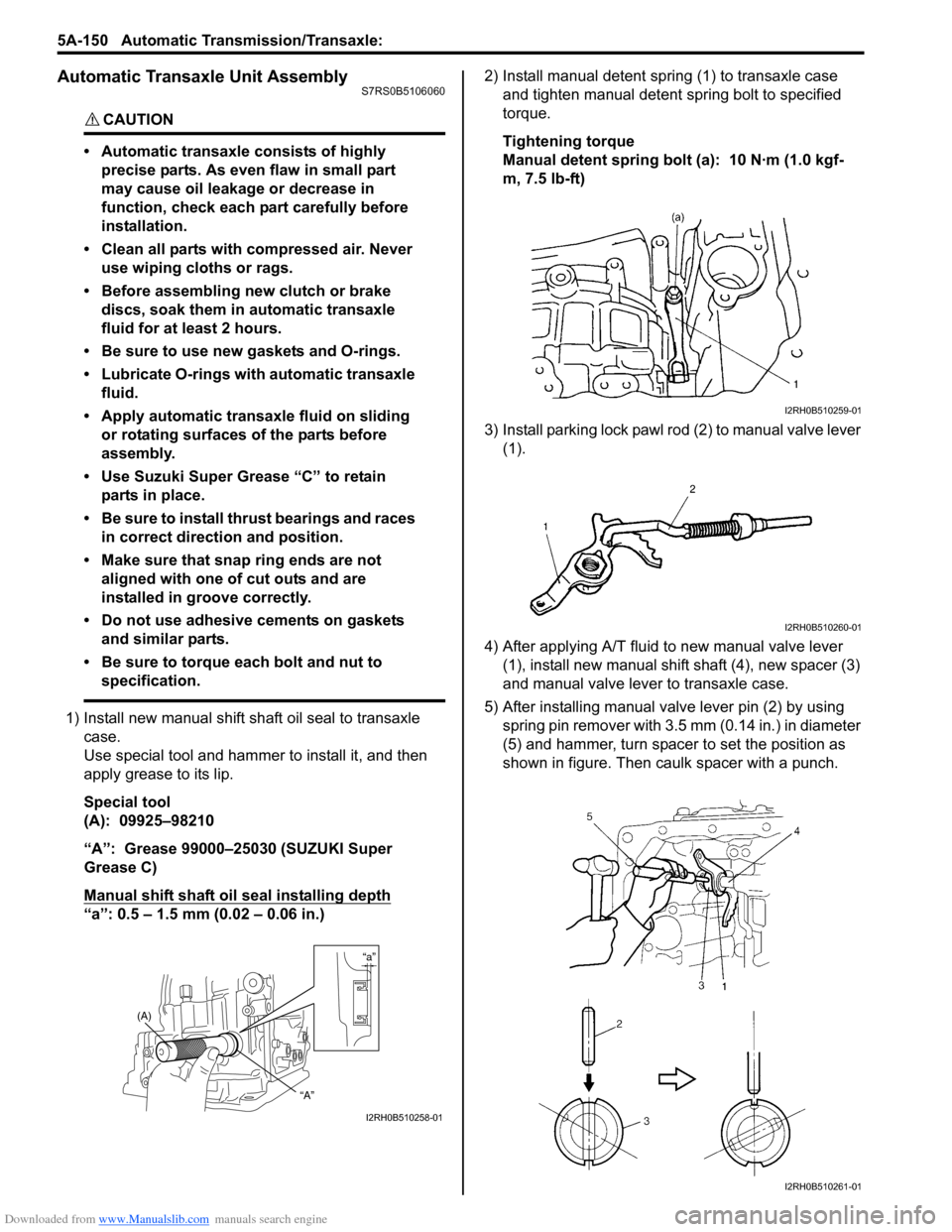

Automatic Transaxle Unit AssemblyS7RS0B5106060

CAUTION!

• Automatic transaxle consists of highly precise parts. As even flaw in small part

may cause oil leakage or decrease in

function, check each part carefully before

installation.

• Clean all parts with compressed air. Never use wiping cloths or rags.

• Before assembling new clutch or brake discs, soak them in automatic transaxle

fluid for at least 2 hours.

• Be sure to use new gaskets and O-rings.

• Lubricate O-rings with automatic transaxle

fluid.

• Apply automatic transaxle fluid on sliding or rotating surfaces of the parts before

assembly.

• Use Suzuki Super Grease “C” to retain parts in place.

• Be sure to install thrust bearings and races in correct direction and position.

• Make sure that snap ring ends are not aligned with one of cut outs and are

installed in groove correctly.

• Do not use adhesive cements on gaskets and similar parts.

• Be sure to torque each bolt and nut to specification.

1) Install new manual shift sh aft oil seal to transaxle

case.

Use special tool and hammer to install it, and then

apply grease to its lip.

Special tool

(A): 09925–98210

“A”: Grease 99000–25030 (SUZUKI Super

Grease C)

Manual shift shaft oil seal installing depth

“a”: 0.5 – 1.5 mm (0.02 – 0.06 in.) 2) Install manual detent spring (1) to transaxle case

and tighten manual detent spring bolt to specified

torque.

Tightening torque

Manual detent spring bolt (a): 10 N·m (1.0 kgf-

m, 7.5 lb-ft)

3) Install parking lock pawl ro d (2) to manual valve lever

(1).

4) After applying A/T fluid to new manual valve lever (1), install new manual shift shaft (4), new spacer (3)

and manual valve lever to transaxle case.

5) After installing manual valve lever pin (2) by using spring pin remover with 3.5 mm (0.14 in.) in diameter

(5) and hammer, turn spacer to set the position as

shown in figure. Then caulk spacer with a punch.

“a”

(A)

“A”

I2RH0B510258-01

I2RH0B510259-01

I2RH0B510260-01

I2RH0B510261-01

Page 795 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-151

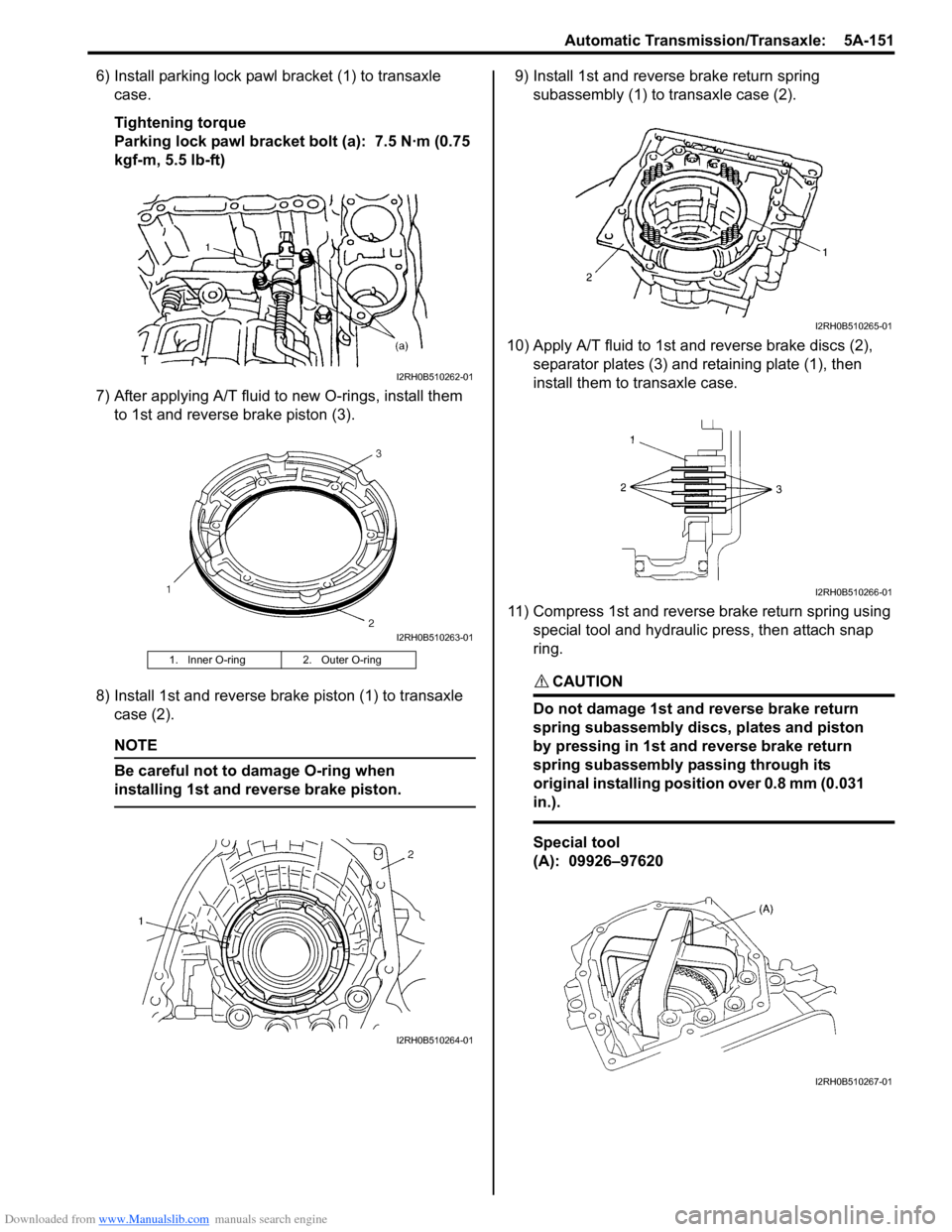

6) Install parking lock pawl bracket (1) to transaxle

case.

Tightening torque

Parking lock pawl bracket bolt (a): 7.5 N·m (0.75

kgf-m, 5.5 lb-ft)

7) After applying A/T fluid to new O-rings, install them to 1st and reverse brake piston (3).

8) Install 1st and reverse brake piston (1) to transaxle case (2).

NOTE

Be careful not to damage O-ring when

installing 1st and reverse brake piston.

9) Install 1st and reverse brake return spring subassembly (1) to transaxle case (2).

10) Apply A/T fluid to 1st and reverse brake discs (2), separator plates (3) and retaining plate (1), then

install them to transaxle case.

11) Compress 1st and reverse brake return spring using special tool and hydraulic press, then attach snap

ring.

CAUTION!

Do not damage 1st and reverse brake return

spring subassembly discs, plates and piston

by pressing in 1st and reverse brake return

spring subassembly passing through its

original installing position over 0.8 mm (0.031

in.).

Special tool

(A): 09926–97620

1. Inner O-ring 2. Outer O-ring

I2RH0B510262-01

I2RH0B510263-01

I2RH0B510264-01

I2RH0B510265-01

I2RH0B510266-01

I2RH0B510267-01

Page 803 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-159

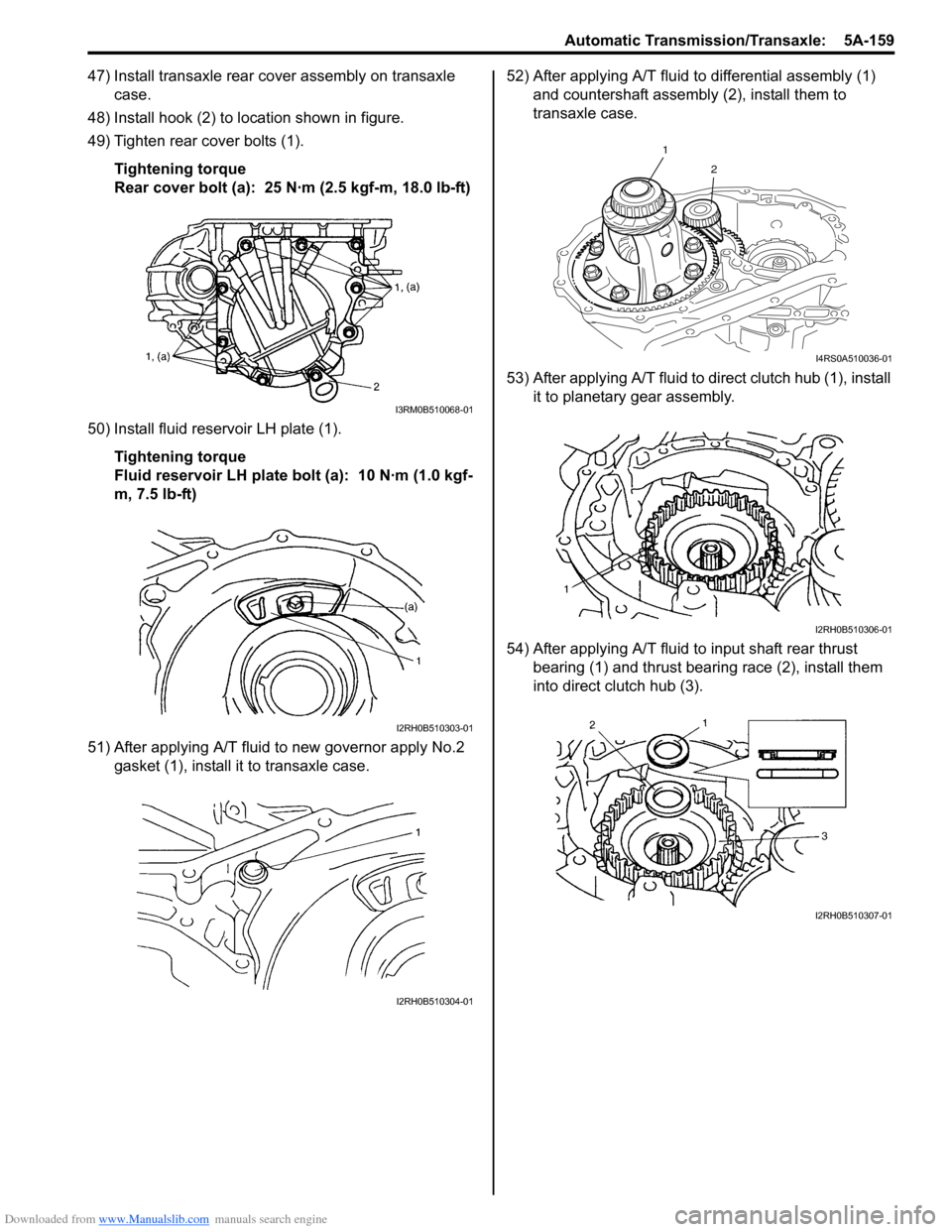

47) Install transaxle rear cover assembly on transaxle case.

48) Install hook (2) to location shown in figure.

49) Tighten rear cover bolts (1).

Tightening torque

Rear cover bolt (a): 25 N·m (2.5 kgf-m, 18.0 lb-ft)

50) Install fluid reservoir LH plate (1). Tightening torque

Fluid reservoir LH plate bolt (a): 10 N·m (1.0 kgf-

m, 7.5 lb-ft)

51) After applying A/T fluid to new governor apply No.2 gasket (1), install it to transaxle case. 52) After applying A/T fluid to differential assembly (1)

and countershaft assembly (2), install them to

transaxle case.

53) After applying A/T fluid to di rect clutch hub (1), install

it to planetary gear assembly.

54) After applying A/T fluid to input shaft rear thrust

bearing (1) and thrust bearing race (2), install them

into direct clutch hub (3).

I3RM0B510068-01

I2RH0B510303-01

I2RH0B510304-01

1

2

I4RS0A510036-01

I2RH0B510306-01

I2RH0B510307-01

Page 804 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-160 Automatic Transmission/Transaxle:

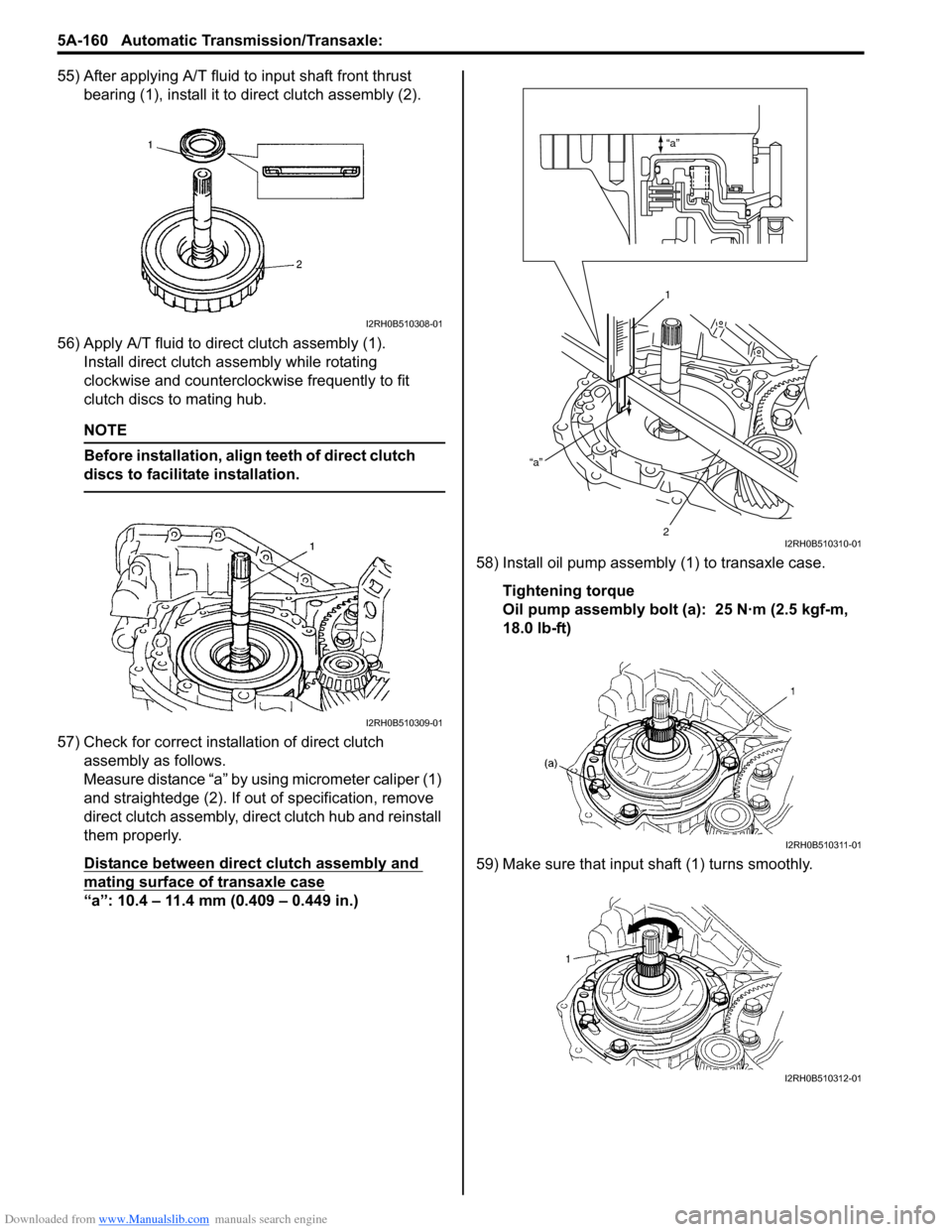

55) After applying A/T fluid to input shaft front thrust bearing (1), install it to direct clutch assembly (2).

56) Apply A/T fluid to direct clutch assembly (1). Install direct clutch a ssembly while rotating

clockwise and counterclockwise frequently to fit

clutch discs to mating hub.

NOTE

Before installation, align teeth of direct clutch

discs to facilitate installation.

57) Check for correct installation of direct clutch assembly as follows.

Measure distance “a” by using micrometer caliper (1)

and straightedge (2). If out of specification, remove

direct clutch assembly, direct clutch hub and reinstall

them properly.

Distance between direct clutch assembly and

mating surface of transaxle case

“a”: 10.4 – 11.4 mm (0.409 – 0.449 in.) 58) Install oil pump assembly

(1) to transaxle case.

Tightening torque

Oil pump assembly bolt (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

59) Make sure that input shaft (1) turns smoothly.

I2RH0B510308-01

I2RH0B510309-01

“a”

“a”

1

2

I2RH0B510310-01

I2RH0B510311-01

I2RH0B510312-01