tightening torque SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 857 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-5

Clutch Pedal Position (CPP) Switch Inspection

and Adjustment

S7RS0B5306005

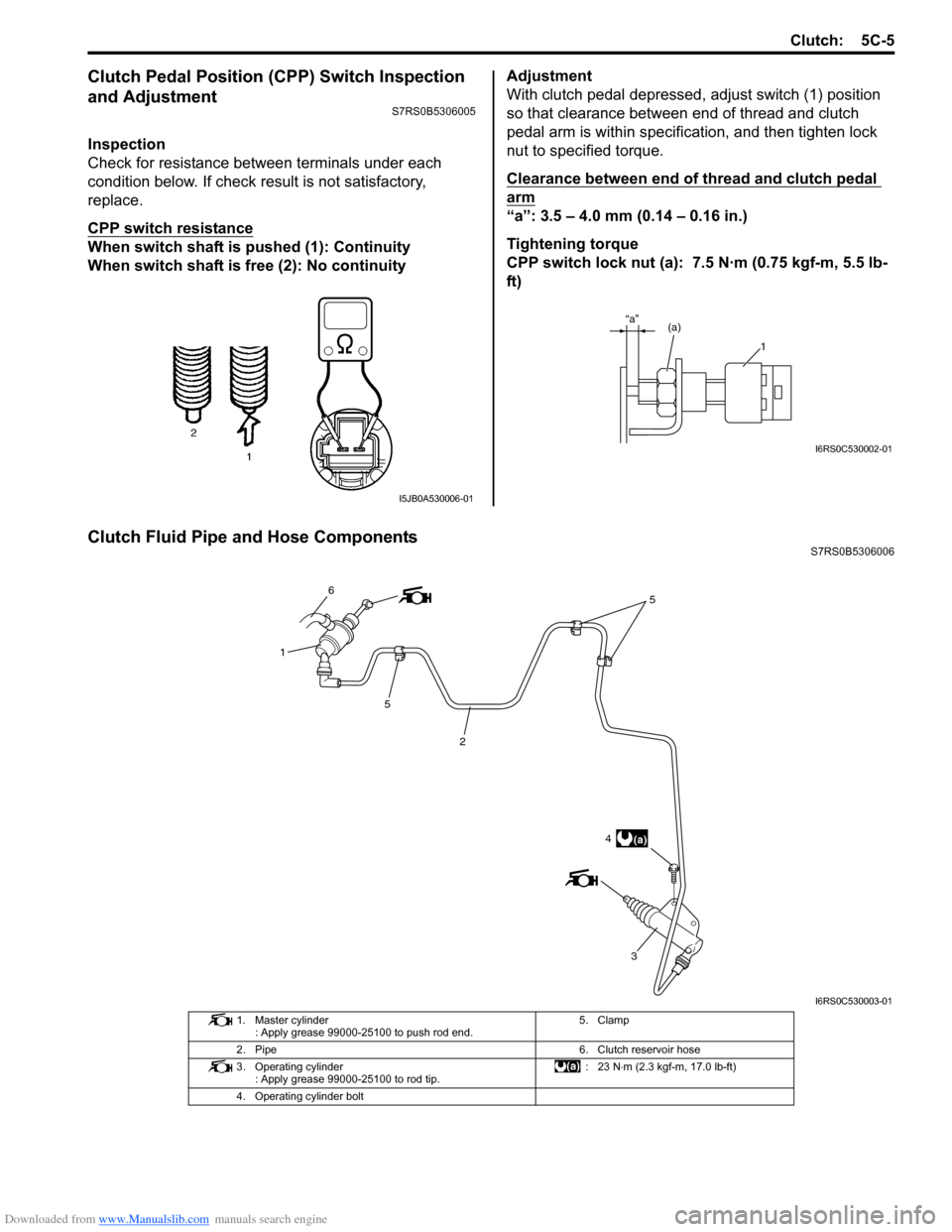

Inspection

Check for resistance between terminals under each

condition below. If check result is not satisfactory,

replace.

CPP switch resistance

When switch shaft is pushed (1): Continuity

When switch shaft is free (2): No continuityAdjustment

With clutch pedal depressed,

adjust switch (1) position

so that clearance between end of thread and clutch

pedal arm is within specification, and then tighten lock

nut to specified torque.

Clearance between end of thread and clutch pedal

arm

“a”: 3.5 – 4.0 mm (0.14 – 0.16 in.)

Tightening torque

CPP switch lock nut (a): 7.5 N·m (0.75 kgf-m, 5.5 lb-

ft)

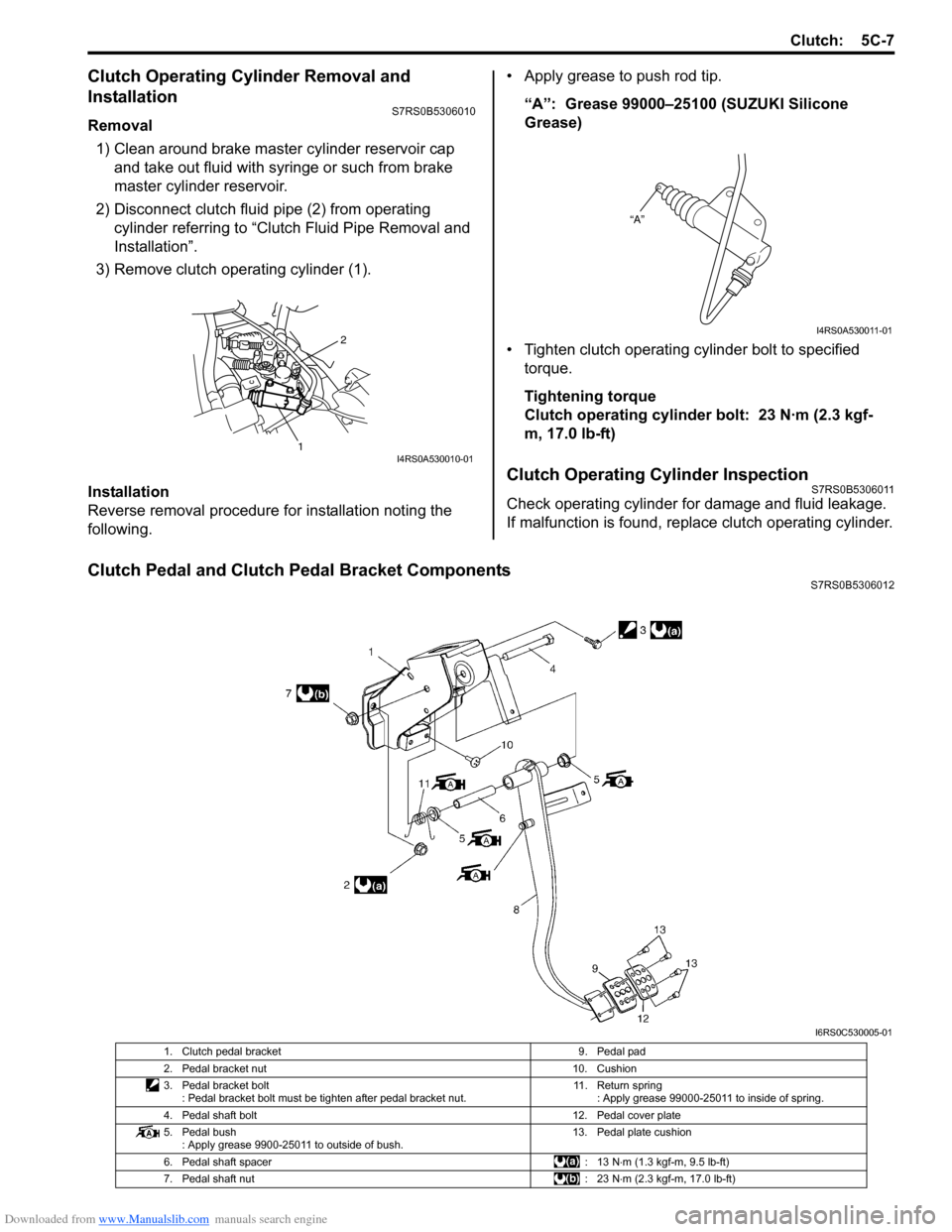

Clutch Fluid Pipe and Hose ComponentsS7RS0B5306006

I5JB0A530006-01

(a)

1

“a”

I6RS0C530002-01

6

1

5

2 5

4(a)

3

I6RS0C530003-01

1. Master cylinder

: Apply grease 99000-25100 to push rod end. 5. Clamp

2. Pipe 6. Clutch reservoir hose

3. Operating cylinder : Apply grease 99000-25100 to rod tip. : 23 N

⋅m (2.3 kgf-m, 17.0 lb-ft)

4. Operating cylinder bolt

Page 859 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-7

Clutch Operating Cylinder Removal and

Installation

S7RS0B5306010

Removal1) Clean around brake master cylinder reservoir cap and take out fluid with syringe or such from brake

master cylinder reservoir.

2) Disconnect clutch fluid pipe (2) from operating cylinder referring to “Clutch Fluid Pipe Removal and

Installation”.

3) Remove clutch operating cylinder (1).

Installation

Reverse removal procedure for installation noting the

following. • Apply grease to push rod tip.

“A”: Grease 99000–25100 (SUZUKI Silicone

Grease)

• Tighten clutch operating cylinder bolt to specified torque.

Tightening torque

Clutch operating cylinder bolt: 23 N·m (2.3 kgf-

m, 17.0 lb-ft)

Clutch Operating Cylinder InspectionS7RS0B5306011

Check operating cylinder for damage and fluid leakage.

If malfunction is found, repl ace clutch operating cylinder.

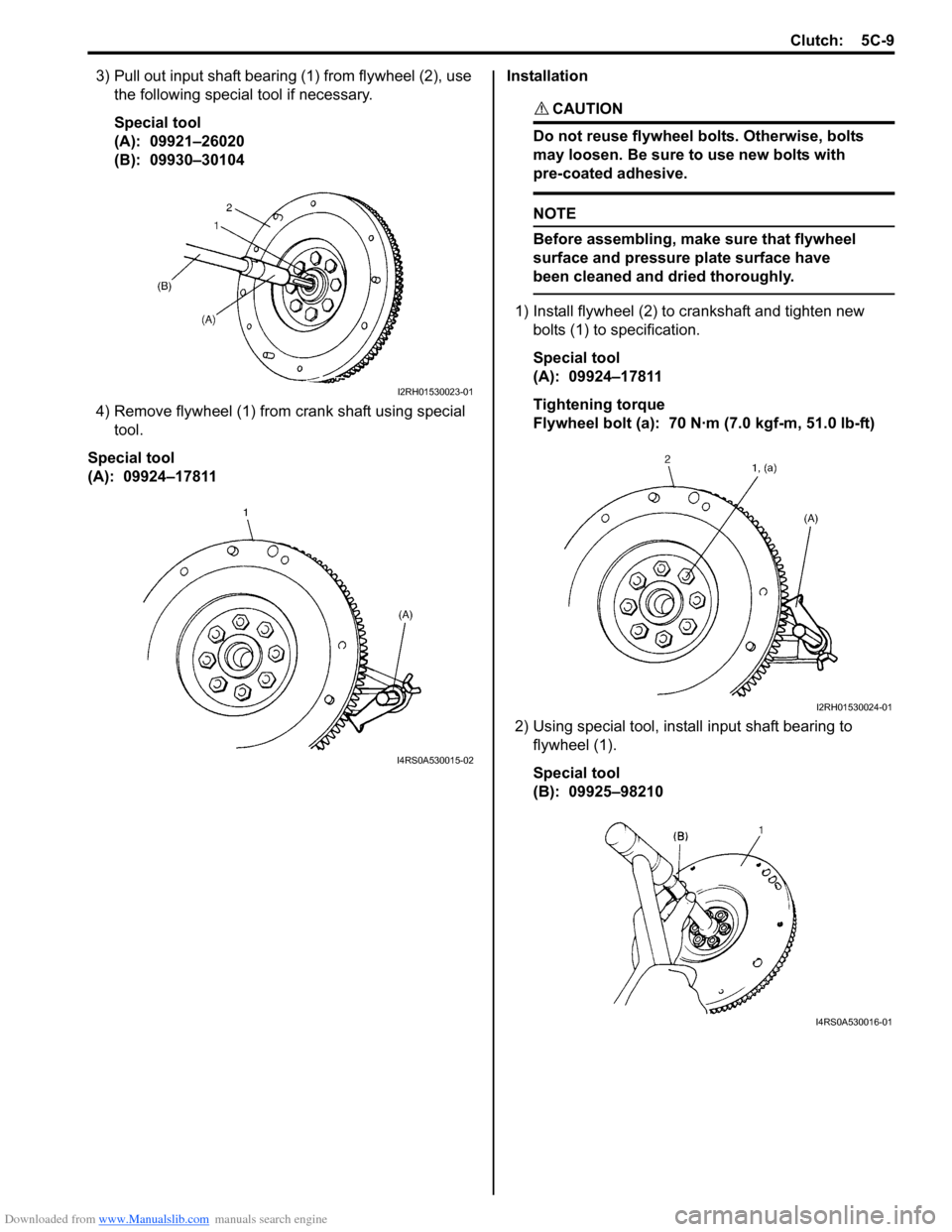

Clutch Pedal and Clutch Pedal Bracket ComponentsS7RS0B5306012

2

1I4RS0A530010-01

“A”

I4RS0A530011-01

I6RS0C530005-01

1. Clutch pedal bracket 9. Pedal pad

2. Pedal bracket nut 10. Cushion

3. Pedal bracket bolt : Pedal bracket bolt must be tighten after pedal bracket nut. 11. Return spring

: Apply grease 99000-25011 to inside of spring.

4. Pedal shaft bolt 12. Pedal cover plate

5. Pedal bush : Apply grease 9900-25011 to outside of bush. 13. Pedal plate cushion

6. Pedal shaft spacer : 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

7. Pedal shaft nut : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

Page 861 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-9

3) Pull out input shaft bearing (1) from flywheel (2), use the following special tool if necessary.

Special tool

(A): 09921–26020

(B): 09930–30104

4) Remove flywheel (1) from crank shaft using special tool.

Special tool

(A): 09924–17811 Installation

CAUTION!

Do not reuse flywheel bolts. Otherwise, bolts

may loosen. Be sure to use new bolts with

pre-coated adhesive.

NOTE

Before assembling, make

sure that flywheel

surface and pressure plate surface have

been cleaned and dried thoroughly.

1) Install flywheel (2) to crankshaft and tighten new bolts (1) to specification.

Special tool

(A): 09924–17811

Tightening torque

Flywheel bolt (a): 70 N·m (7.0 kgf-m, 51.0 lb-ft)

2) Using special tool, install input shaft bearing to flywheel (1).

Special tool

(B): 09925–98210

I2RH01530023-01

I4RS0A530015-02

I2RH01530024-01

I4RS0A530016-01

Page 862 of 1496

Downloaded from www.Manualslib.com manuals search engine 5C-10 Clutch:

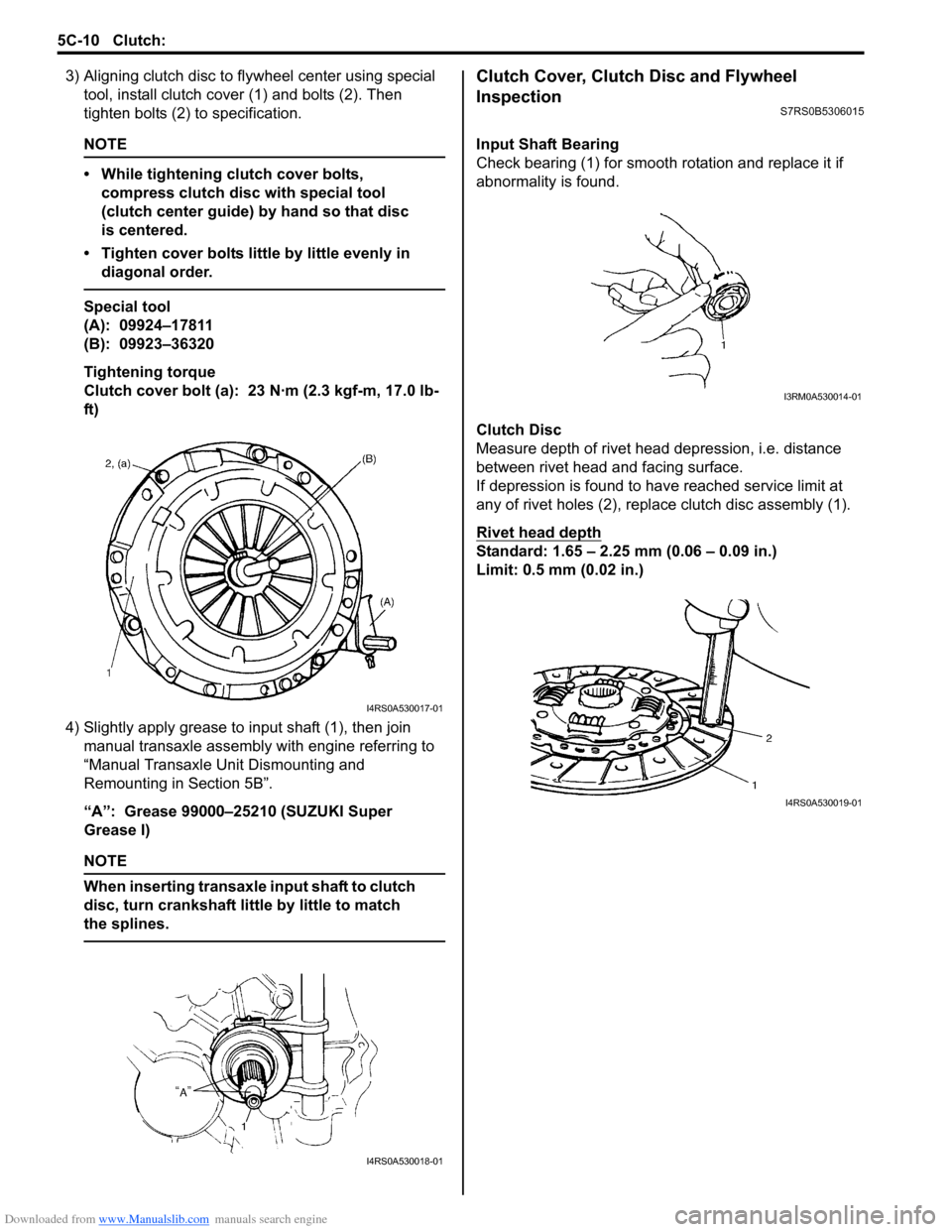

3) Aligning clutch disc to flywheel center using special

tool, install clutch cover (1) and bolts (2). Then

tighten bolts (2) to specification.

NOTE

• While tightening clutch cover bolts, compress clutch disc with special tool

(clutch center guide) by hand so that disc

is centered.

• Tighten cover bolts little by little evenly in diagonal order.

Special tool

(A): 09924–17811

(B): 09923–36320

Tightening torque

Clutch cover bolt (a): 23 N·m (2.3 kgf-m, 17.0 lb-

ft)

4) Slightly apply grease to input shaft (1), then join manual transaxle assembly with engine referring to

“Manual Transaxle Unit Dismounting and

Remounting in Section 5B”.

“A”: Grease 99000–25210 (SUZUKI Super

Grease I)

NOTE

When inserting transaxle input shaft to clutch

disc, turn crankshaft li ttle by little to match

the splines.

Clutch Cover, Clutch Disc and Flywheel

Inspection

S7RS0B5306015

Input Shaft Bearing

Check bearing (1) for smooth ro tation and replace it if

abnormality is found.

Clutch Disc

Measure depth of rivet head depression, i.e. distance

between rivet head and facing surface.

If depression is found to hav e reached service limit at

any of rivet holes (2), repl ace clutch disc assembly (1).

Rivet head depth

Standard: 1.65 – 2.25 mm (0.06 – 0.09 in.)

Limit: 0.5 mm (0.02 in.)

I4RS0A530017-01

I4RS0A530018-01

I3RM0A530014-01

I4RS0A530019-01

Page 864 of 1496

Downloaded from www.Manualslib.com manuals search engine 5C-12 Clutch:

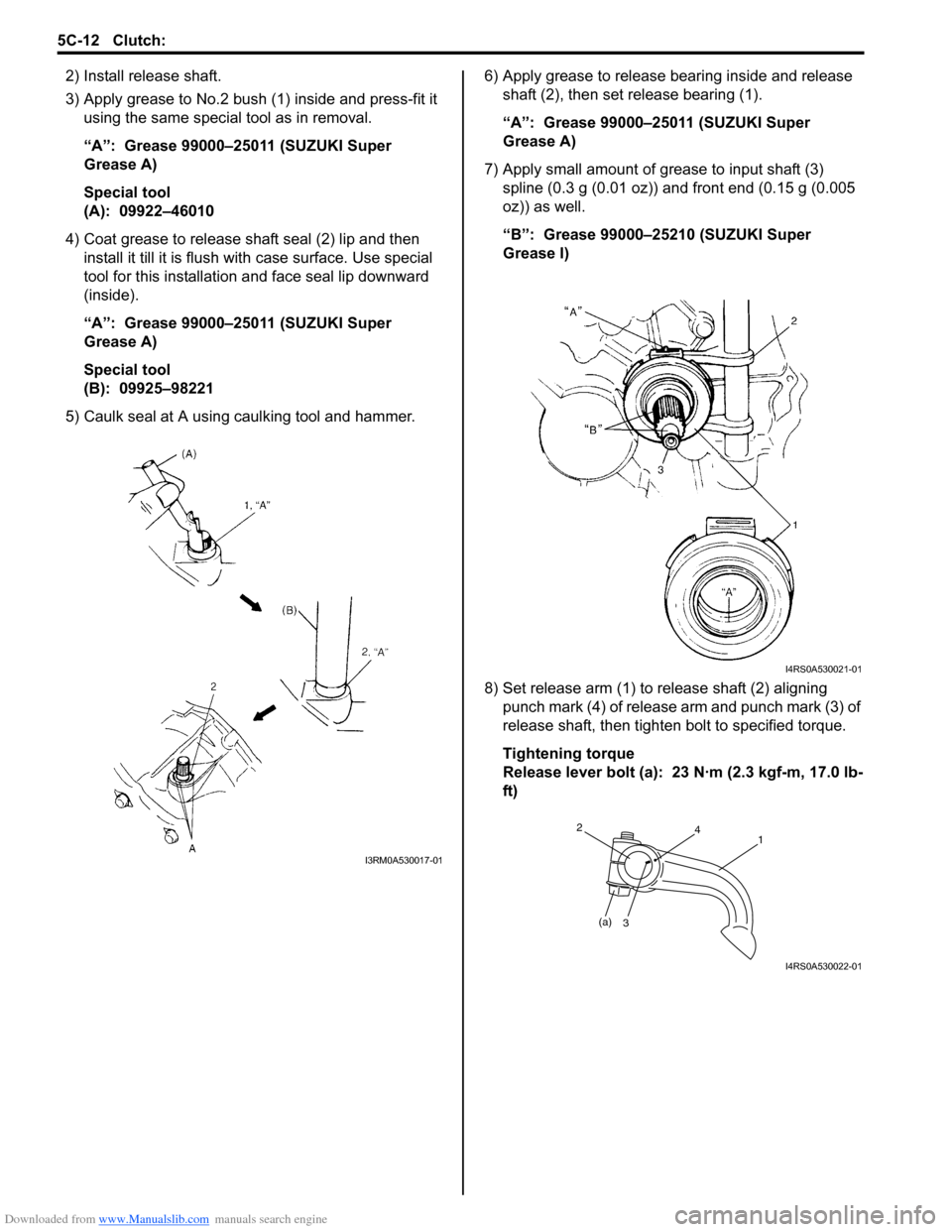

2) Install release shaft.

3) Apply grease to No.2 bush (1) inside and press-fit it using the same special tool as in removal.

“A”: Grease 99000–25011 (SUZUKI Super

Grease A)

Special tool

(A): 09922–46010

4) Coat grease to release shaft seal (2) lip and then install it till it is flush wit h case surface. Use special

tool for this installation a nd face seal lip downward

(inside).

“A”: Grease 99000–25011 (SUZUKI Super

Grease A)

Special tool

(B): 09925–98221

5) Caulk seal at A using caulking tool and hammer. 6) Apply grease to release bearing inside and release

shaft (2), then set release bearing (1).

“A”: Grease 99000–25011 (SUZUKI Super

Grease A)

7) Apply small amount of grease to input shaft (3) spline (0.3 g (0.01 oz)) and front end (0.15 g (0.005

oz)) as well.

“B”: Grease 99000–25210 (SUZUKI Super

Grease I)

8) Set release arm (1) to release shaft (2) aligning punch mark (4) of release arm and punch mark (3) of

release shaft, then tighten bolt to specified torque.

Tightening torque

Release lever bolt (a): 23 N·m (2.3 kgf-m, 17.0 lb-

ft)

I3RM0A530017-01

I4RS0A530021-01

(a)3

241

I4RS0A530022-01

Page 865 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-13

Clutch Release System InspectionS7RS0B5306017

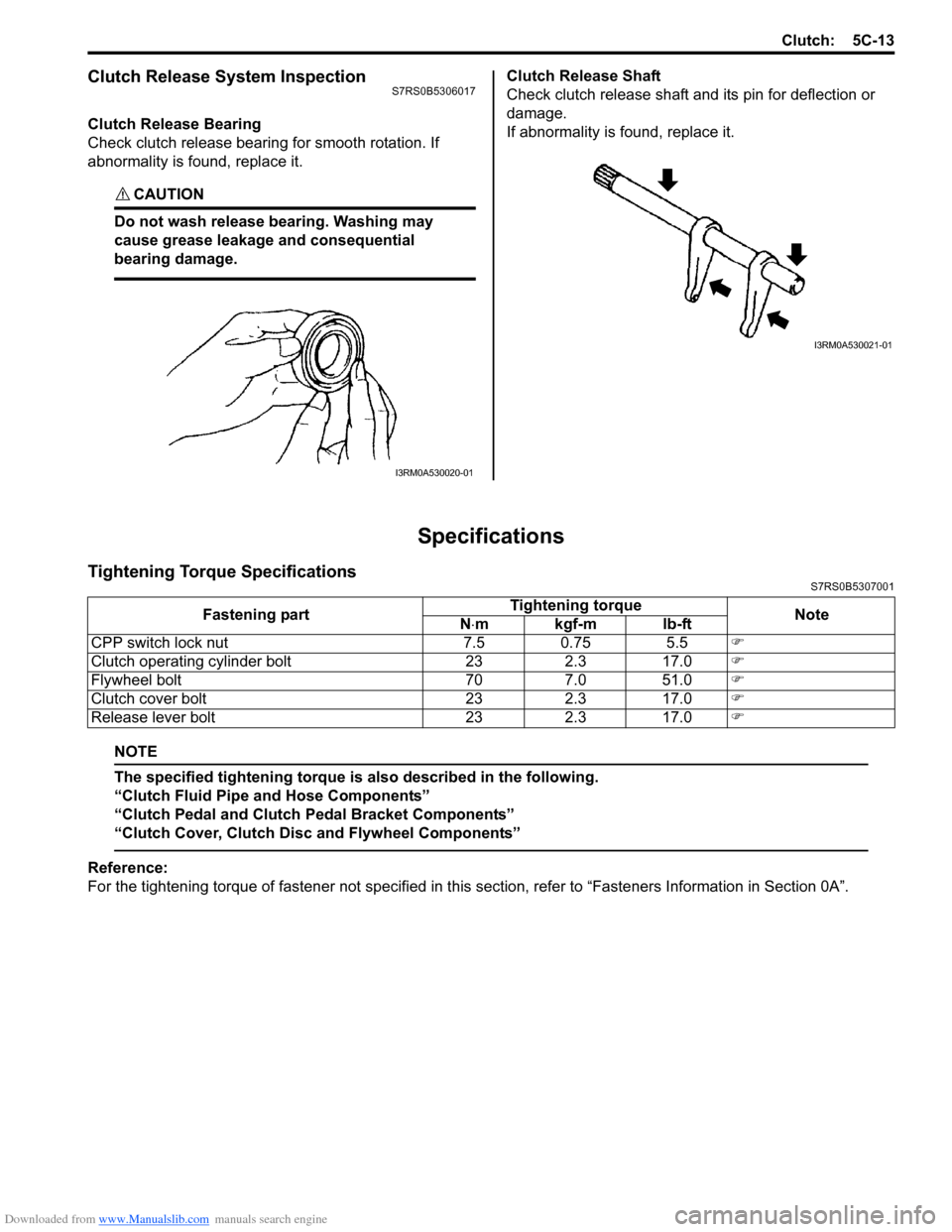

Clutch Release Bearing

Check clutch release bearing for smooth rotation. If

abnormality is found, replace it.

CAUTION!

Do not wash release bearing. Washing may

cause grease leakage and consequential

bearing damage.

Clutch Release Shaft

Check clutch release shaft and its pin for deflection or

damage.

If abnormality is found, replace it.

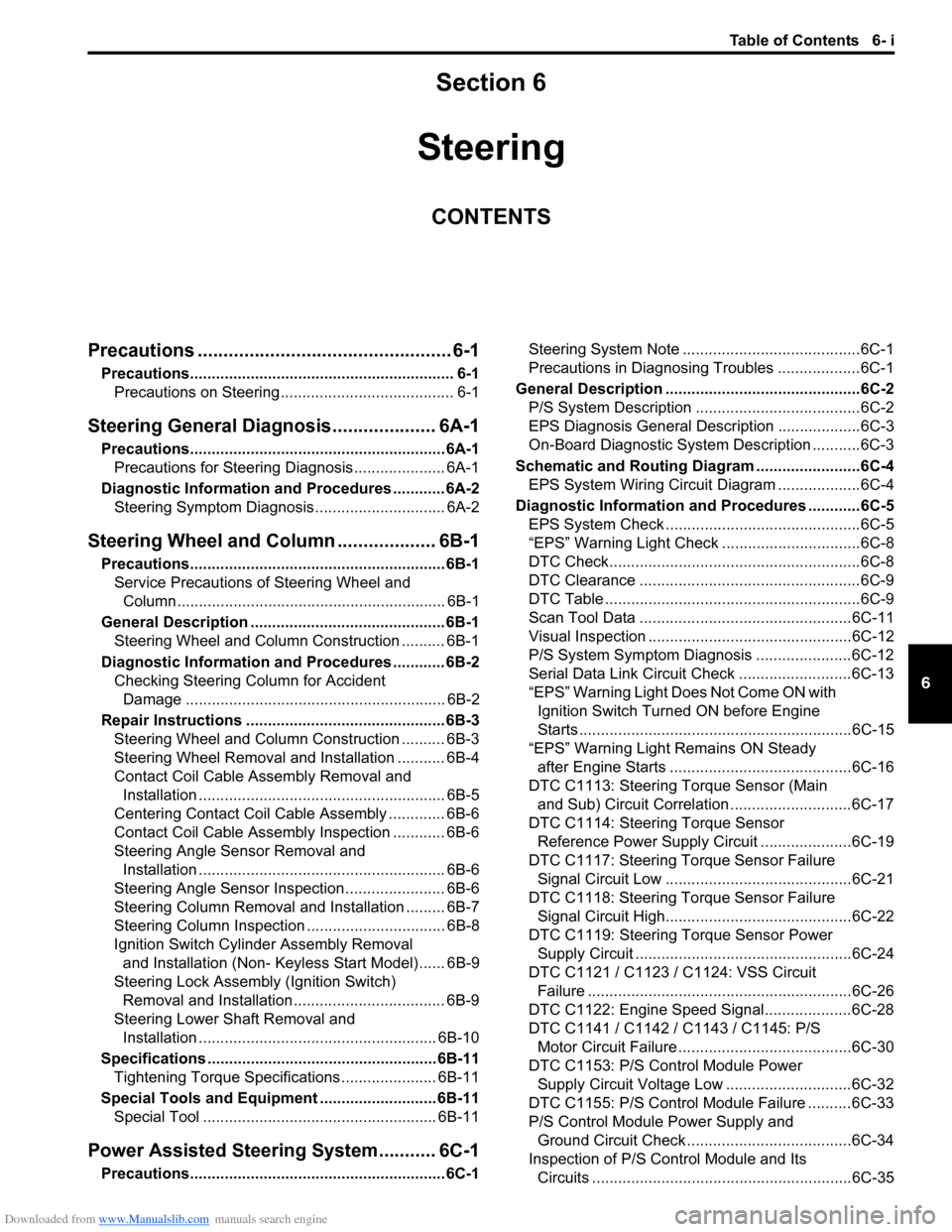

Specifications

Tightening Torque SpecificationsS7RS0B5307001

NOTE

The specified tightening torque is also described in the following.

“Clutch Fluid Pipe and Hose Components”

“Clutch Pedal and Clutch Pedal Bracket Components”

“Clutch Cover, Clutch Disc and Flywheel Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

I3RM0A530020-01

I3RM0A530021-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

CPP switch lock nut 7.5 0.75 5.5 �)

Clutch operating cylinder bolt 23 2.3 17.0 �)

Flywheel bolt 70 7.0 51.0 �)

Clutch cover bolt 23 2.3 17.0 �)

Release lever bolt 23 2.3 17.0 �)

Page 867 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 6- i

6

Section 6

CONTENTS

Steering

Precautions ................................................. 6-1

Precautions............................................................. 6-1

Precautions on Steering........................................ 6-1

Steering General Diagnosi s.................... 6A-1

Precautions........................................................... 6A-1

Precautions for Steering Diagnosis ..................... 6A-1

Diagnostic Information and Procedures ............ 6A-2 Steering Symptom Diagnosis .............................. 6A-2

Steering Wheel and Column ................... 6B-1

Precautions........................................................... 6B-1

Service Precautions of Steering Wheel and Column.............................................................. 6B-1

General Description ............................................. 6B-1 Steering Wheel and Column Construction .......... 6B-1

Diagnostic Information and Procedures ............ 6B-2 Checking Steering Column for Accident Damage ............................................................ 6B-2

Repair Instructions .............................................. 6B-3 Steering Wheel and Column Construction .......... 6B-3

Steering Wheel Removal and Installation ........... 6B-4

Contact Coil Cable Assembly Removal and Installation ......................................................... 6B-5

Centering Contact Coil Cable Assembly ............. 6B-6

Contact Coil Cable Assembly Inspection ............ 6B-6

Steering Angle Sensor Removal and Installation ......................................................... 6B-6

Steering Angle Sensor Inspection ....................... 6B-6

Steering Column Removal and Installation ......... 6B-7

Steering Column Inspecti on ................................ 6B-8

Ignition Switch Cylinder Assembly Removal and Installation (Non- Keyless Start Model)...... 6B-9

Steering Lock Assembly (Ignition Switch) Removal and Installation................................... 6B-9

Steering Lower Shaft Removal and Installation ....................................................... 6B-10

Specifications ..................................................... 6B-11

Tightening Torque Specifications ...................... 6B-11

Special Tools and Equipmen t ........................... 6B-11

Special Tool ...................................................... 6B-11

Power Assisted Steering System........... 6C-1

Precautions........................................................... 6C-1 Steering System Note .........................................6C-1

Precautions in Diagnosing Troubles ...................6C-1

General Description .............................................6C-2 P/S System Description ......................................6C-2

EPS Diagnosis General Descr iption ...................6C-3

On-Board Diagnostic System Description ...........6C-3

Schematic and Routing Diagram ........................6C-4 EPS System Wiring Circuit Diagram ...................6C-4

Diagnostic Information and Procedures ............6C-5 EPS System Check .............. ...............................6C-5

“EPS” Warning Light Check . ...............................6C-8

DTC Check..........................................................6C-8

DTC Clearance ...................................................6C-9

DTC Table ...........................................................6C-9

Scan Tool Data .................................................6C-11

Visual Inspection ...............................................6C-12

P/S System Symptom Diagnosis ......................6C-12

Serial Data Link Circuit Check ..........................6C-13

“EPS” Warning Light Do es Not Come ON with

Ignition Switch Turn ed ON before Engine

Starts ...............................................................6C-15

“EPS” Warning Light Remains ON Steady after Engine Starts ..........................................6C-16

DTC C1113: Steering Torque Sensor (Main and Sub) Circuit Correlation ............................6C-17

DTC C1114: Steering Torque Sensor Reference Power Supply Circuit .....................6C-19

DTC C1117: Steering Torque Sensor Failure Signal Circuit Low ...........................................6C-21

DTC C1118: Steering Torque Sensor Failure Signal Circuit High...........................................6C-22

DTC C1119: Steering Torque Sensor Power Supply Circuit ..................................................6C-24

DTC C1121 / C1123 / C1124: VSS Circuit

Failure .............................................................6C-26

DTC C1122: Engine Speed Signal....................6C-28

DTC C1141 / C1142 / C1143 / C1145: P/S Motor Circuit Failure ........................................6C-30

DTC C1153: P/S Control Module Power Supply Circuit Voltage Low .............................6C-32

DTC C1155: P/S Control Module Failure ..........6C-33

P/S Control Module Power Supply and Ground Circuit Check ......................................6C-34

Inspection of P/S Control Module and Its Circuits ............................................................6C-35

Page 868 of 1496

Downloaded from www.Manualslib.com manuals search engine 6-ii Table of Contents

Steering Wheel Play Check ..............................6C-39

Steering Force Check .......................................6C-39

Repair Instructions ........... .................................6C-40

Steering Gear Case Assembly Components ....6C-40

Tie-Rod End Boot On-Vehic le Inspection .........6C-41

Tie-Rod End Removal and Installation..............6C-41

Tie-Rod End Inspection.....................................6C-42

Steering Shaft Joint On-Vehicle Inspection.......6C-42

Steering Gear Case Assembly Removal and Installation .......................................................6C-42

Steering Rack Boot Inspec tion ..........................6C-43

Tie-Rod / Rack Boot Removal and Installation ..6C-43 Steering Rack Plunger Removal and

Installation .......................................................6C-45

Steering Rack Plunger Inspection .....................6C-45

P/S Control Module Removal and Installation...6C-46

Torque Sensor and Its Circuit Inspection ..........6C-46

P/S Motor and Its Circuit Inspection ..................6C-47

Specifications ..................... ................................6C-48

Tightening Torque Specifications ......................6C-48

Special Tools and Equipmen t ...........................6C-49

Recommended Service Material .......................6C-49

Special Tool ......................................................6C-49

Page 875 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-4

Steering Wheel Removal and InstallationS7RS0B6206002

CAUTION!

Do not turn the contact coil more than

allowable number of turns (about two and a

half turns from the center position clockwise

or counterclockwise respectively) with

steering wheel removed, or coil will break.

Removal

CAUTION!

Do not hammer the end of the shaft.

Hammering it will loosen the plastic shear

pins which maintain the column length and

impair the collapsible design of the column.

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air

Bag System in Section 8B”.

3) Remove driver air bag (inflator) module from steering wheel. Refer to “Driver Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Disconnect horn connector and audio control switch connector, if equipped.

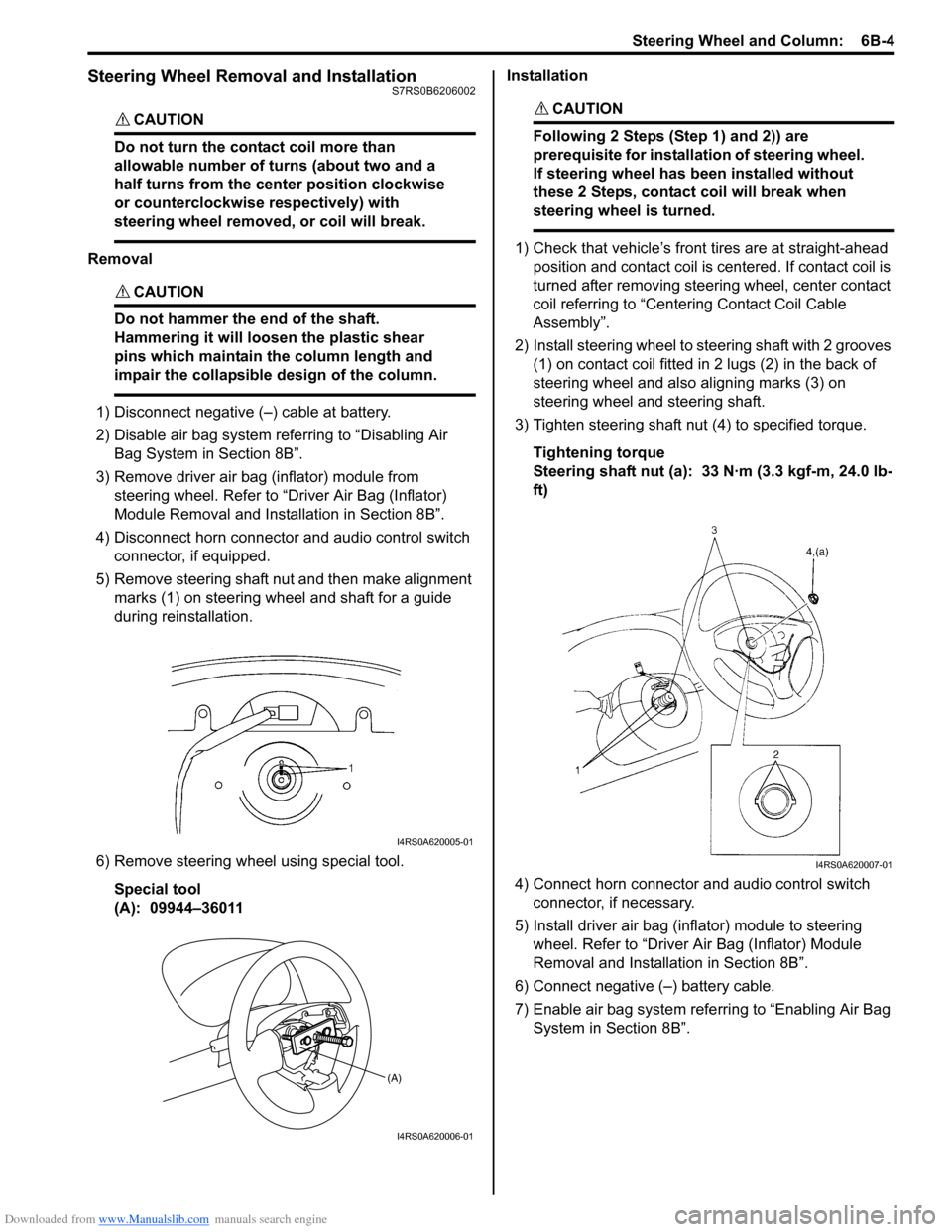

5) Remove steering shaft nut and then make alignment marks (1) on steering wheel and shaft for a guide

during reinstallation.

6) Remove steering wheel using special tool. Special tool

(A): 09944–36011 Installation

CAUTION!

Following 2 Steps (Step 1) and 2)) are

prerequisite for installation of steering wheel.

If steering wheel has

been installed without

these 2 Steps, contact coil will break when

steering wheel is turned.

1) Check that vehicle’s front tires are at straight-ahead position and contact coil is centered. If contact coil is

turned after removing steering wheel, center contact

coil referring to “Centering Contact Coil Cable

Assembly”.

2) Install steering wheel to steering shaft with 2 grooves (1) on contact coil fitted in 2 lugs (2) in the back of

steering wheel and also aligning marks (3) on

steering wheel and steering shaft.

3) Tighten steering shaft nut (4) to specified torque.

Tightening torque

Steering shaft nut (a): 33 N·m (3.3 kgf-m, 24.0 lb-

ft)

4) Connect horn connector and audio control switch connector, if necessary.

5) Install driver air bag (inflator) module to steering wheel. Refer to “Driver Air Bag (Inflator) Module

Removal and Installati on in Section 8B”.

6) Connect negative (–) battery cable.

7) Enable air bag system refe rring to “Enabling Air Bag

System in Section 8B”.

I4RS0A620005-01

(A)

I4RS0A620006-01

I4RS0A620007-01

Page 879 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-8

Installation

CAUTION!

After tightening steering column mounting

nuts, shaft joint bolts should be tightened.

Wrong tightening order could cause a

damage to shaft joint.

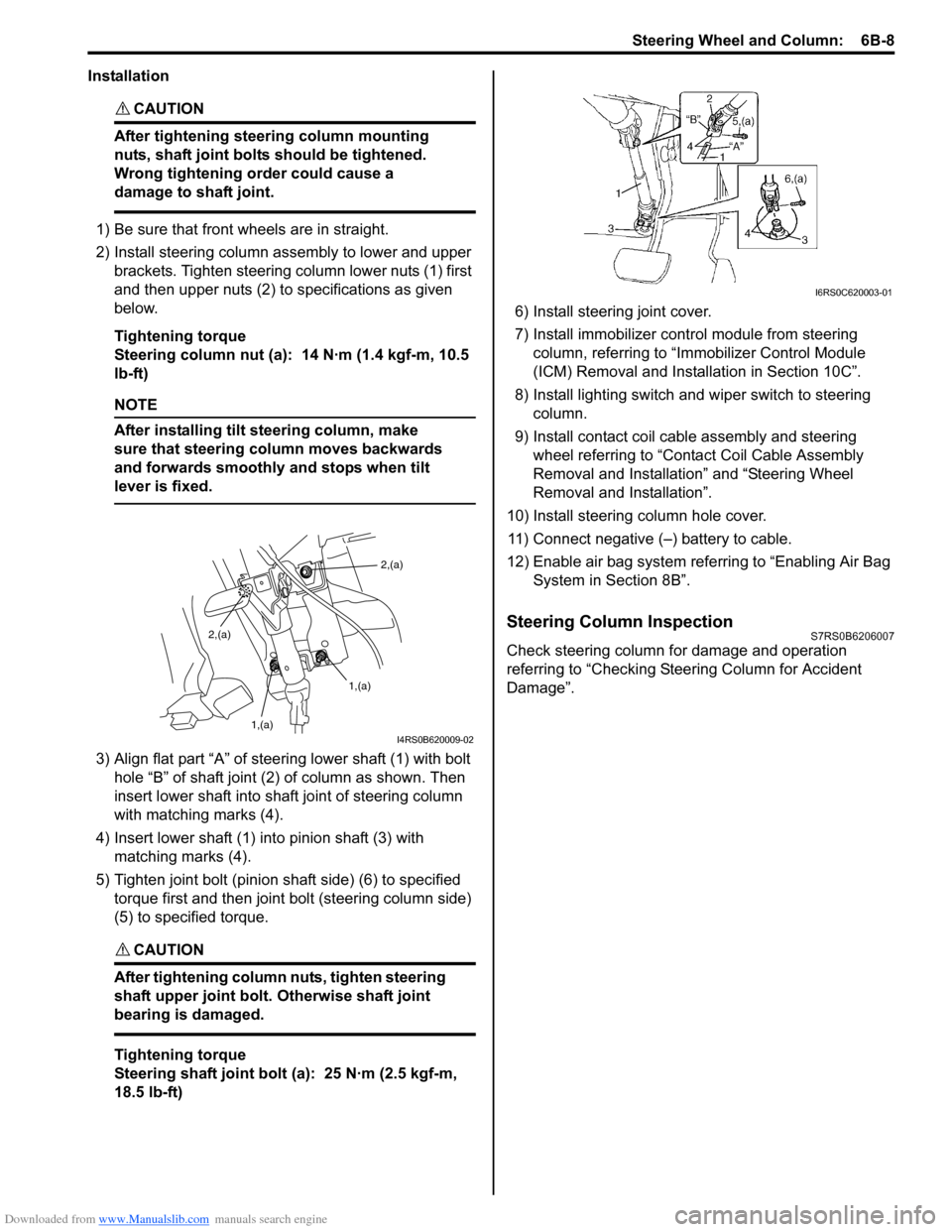

1) Be sure that front wheels are in straight.

2) Install steering column assembly to lower and upper brackets. Tighten steering column lower nuts (1) first

and then upper nuts (2) to specifications as given

below.

Tightening torque

Steering column nut (a): 14 N·m (1.4 kgf-m, 10.5

lb-ft)

NOTE

After installing tilt steering column, make

sure that steering column moves backwards

and forwards smoothly and stops when tilt

lever is fixed.

3) Align flat part “A” of stee ring lower shaft (1) with bolt

hole “B” of shaft joint (2) of column as shown. Then

insert lower shaft into shaf t joint of steering column

with matching marks (4).

4) Insert lower shaft (1) into pinion shaft (3) with matching marks (4).

5) Tighten joint bolt (pinion shaft side) (6) to specified torque first and then joint bolt (steering column side)

(5) to specified torque.

CAUTION!

After tightening column nuts, tighten steering

shaft upper joint bolt. Otherwise shaft joint

bearing is damaged.

Tightening torque

Steering shaft joint bolt (a): 25 N·m (2.5 kgf-m,

18.5 lb-ft) 6) Install steering joint cover.

7) Install immobilizer cont

rol module from steering

column, referring to “Immo bilizer Control Module

(ICM) Removal and Installation in Section 10C”.

8) Install lighting switch and wiper switch to steering column.

9) Install contact coil cable assembly and steering wheel referring to “Conta ct Coil Cable Assembly

Removal and Installation” and “Steering Wheel

Removal and Installation”.

10) Install steering column hole cover. 11) Connect negative (–) battery to cable.

12) Enable air bag system refe rring to “Enabling Air Bag

System in Section 8B”.

Steering Column InspectionS7RS0B6206007

Check steering column for damage and operation

referring to “Checking Steering Column for Accident

Damage”.

2,(a)

1,(a)

1,(a)

2,(a)

I4RS0B620009-02

I6RS0C620003-01