Lower SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1095 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-57

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The resistance of driver or passenger seat belt pretensioner initiator circuit is above a specified value for specified

time.

Flow Test Description

Step 1: Check if malfunction is in seat belt pretensioner.

Step 2: Check seat belt pretensioner initiator circuit.

DTC Troubleshooting

Step Action YesNo

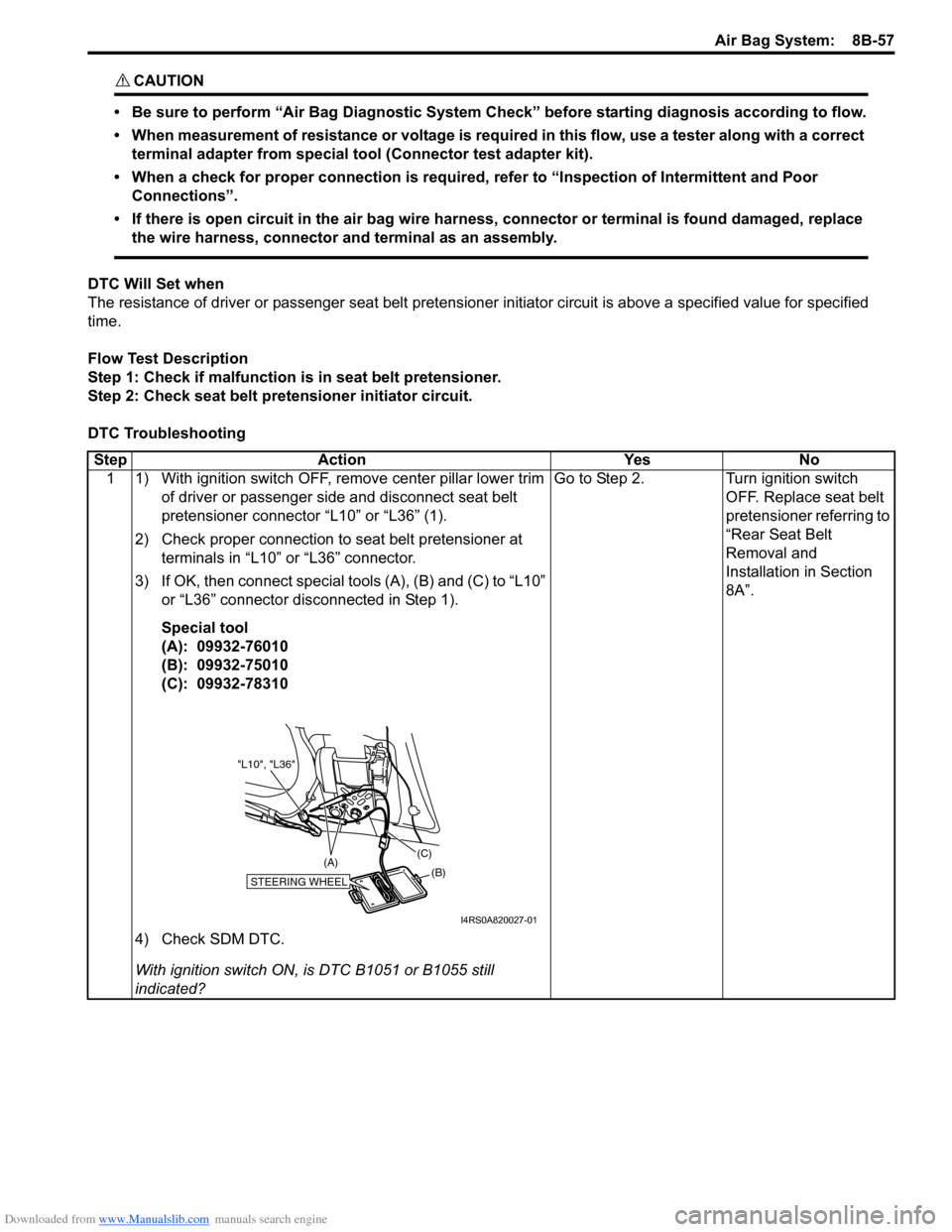

1 1) With ignition switch OFF, re move center pillar lower trim

of driver or passenger side and disconnect seat belt

pretensioner connector “L10” or “L36” (1).

2) Check proper connection to seat belt pretensioner at terminals in “L10” or “L36” connector.

3) If OK, then connect special tools (A), (B) and (C) to “L10” or “L36” connector disconnected in Step 1).

Special tool

(A): 09932-76010

(B): 09932-75010

(C): 09932-78310

4) Check SDM DTC.

With ignition switch ON, is DTC B1051 or B1055 still

indicated? Go to Step 2.

Turn ignition switch

OFF. Replace seat belt

pretensioner referring to

“Rear Seat Belt

Removal and

Installation in Section

8A”.

STEERING WHEEL(B)

(C)

(A)

"L10", "L36"

I4RS0A820027-01

Page 1097 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-59

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The resistance of driver or passenger seat belt pretensioner initiator circuit is below a specified value for specified

time.

Flow Test Description

Step 1: Check if malfunction is in seat belt pretensioner.

Step 2: Check seat belt pretensioner initiator circuit.

DTC Troubleshooting

Step Action YesNo

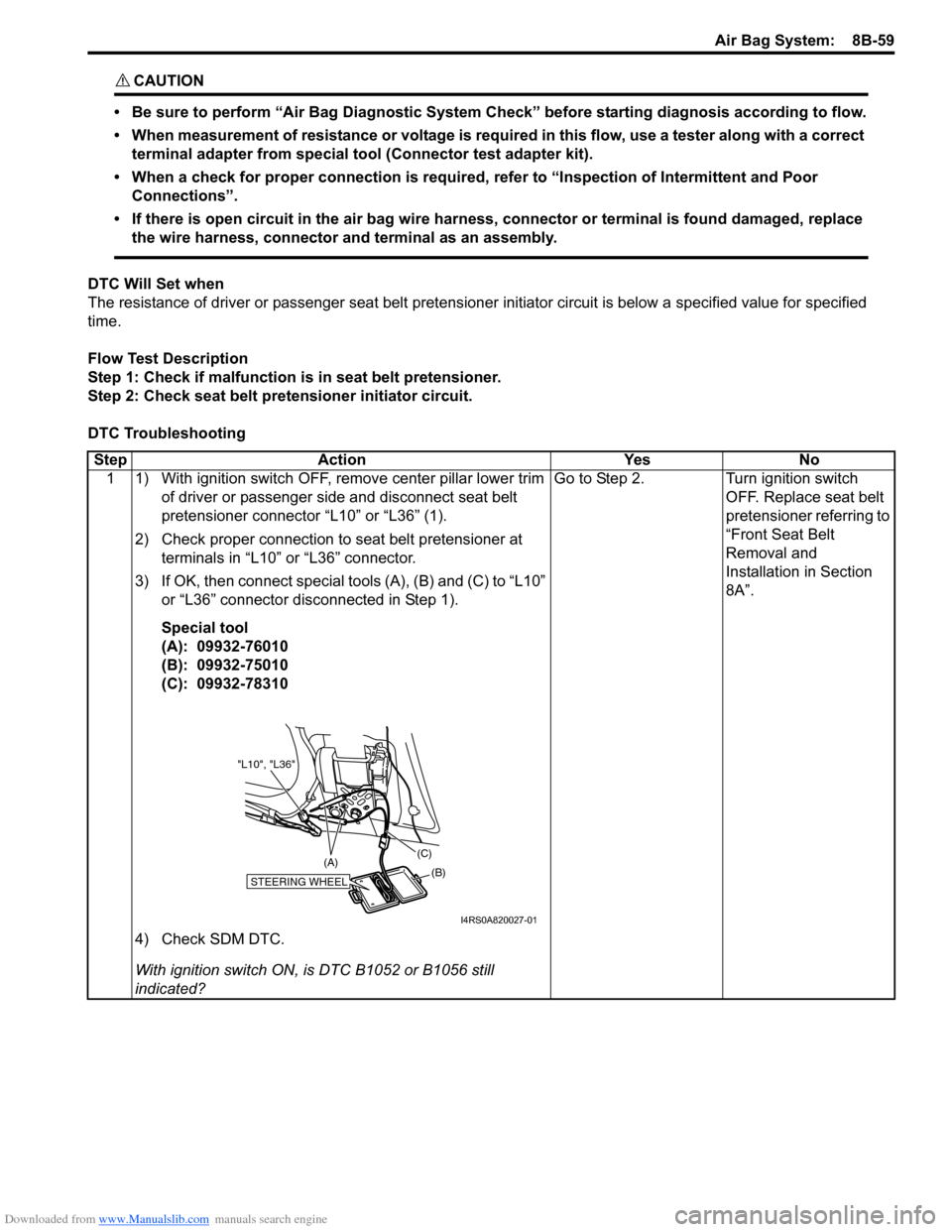

1 1) With ignition switch OFF, re move center pillar lower trim

of driver or passenger side and disconnect seat belt

pretensioner connector “L10” or “L36” (1).

2) Check proper connection to seat belt pretensioner at terminals in “L10” or “L36” connector.

3) If OK, then connect special tools (A), (B) and (C) to “L10” or “L36” connector disconnected in Step 1).

Special tool

(A): 09932-76010

(B): 09932-75010

(C): 09932-78310

4) Check SDM DTC.

With ignition switch ON, is DTC B1052 or B1056 still

indicated? Go to Step 2.

Turn ignition switch

OFF. Replace seat belt

pretensioner referring to

“Front Seat Belt

Removal and

Installation in Section

8A”.

STEERING WHEEL(B)

(C)

(A)

"L10", "L36"

I4RS0A820027-01

Page 1099 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-61

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The voltage measured at driver or passenger seat belt pr etensioner initiator circuit is below a specified value for

specified time.

Flow Test Description

Step 1: Check if malfunction is in seat belt pretensioner.

Step 2: Check seat belt pretensioner initiator circuit.

DTC Troubleshooting

Step Action YesNo

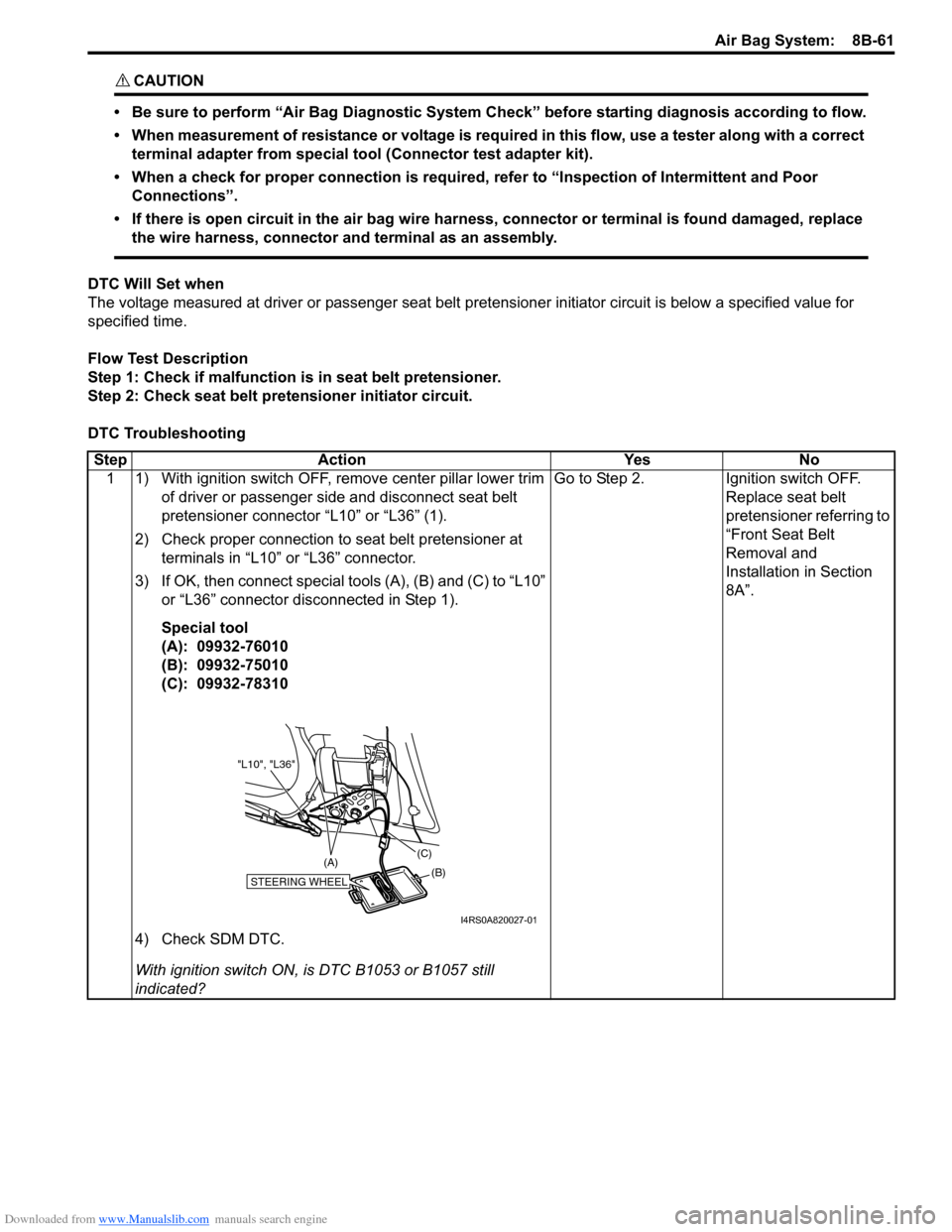

1 1) With ignition switch OFF, re move center pillar lower trim

of driver or passenger side and disconnect seat belt

pretensioner connector “L10” or “L36” (1).

2) Check proper connection to seat belt pretensioner at terminals in “L10” or “L36” connector.

3) If OK, then connect special tools (A), (B) and (C) to “L10” or “L36” connector disconnected in Step 1).

Special tool

(A): 09932-76010

(B): 09932-75010

(C): 09932-78310

4) Check SDM DTC.

With ignition switch ON, is DTC B1053 or B1057 still

indicated? Go to Step 2.

Ignition switch OFF.

Replace seat belt

pretensioner referring to

“Front Seat Belt

Removal and

Installation in Section

8A”.

STEERING WHEEL(B)

(C)

(A)

"L10", "L36"

I4RS0A820027-01

Page 1101 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-63

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The voltage measured at driver or passenger seat belt pr etensioner initiator circuit is above a specified value for

specified time.

Flow Test Description

Step 1: Check if malfunction is in seat belt pretensioner.

Step 2: Check seat belt pretensioner initiator circuit.

DTC Troubleshooting

Step Action YesNo

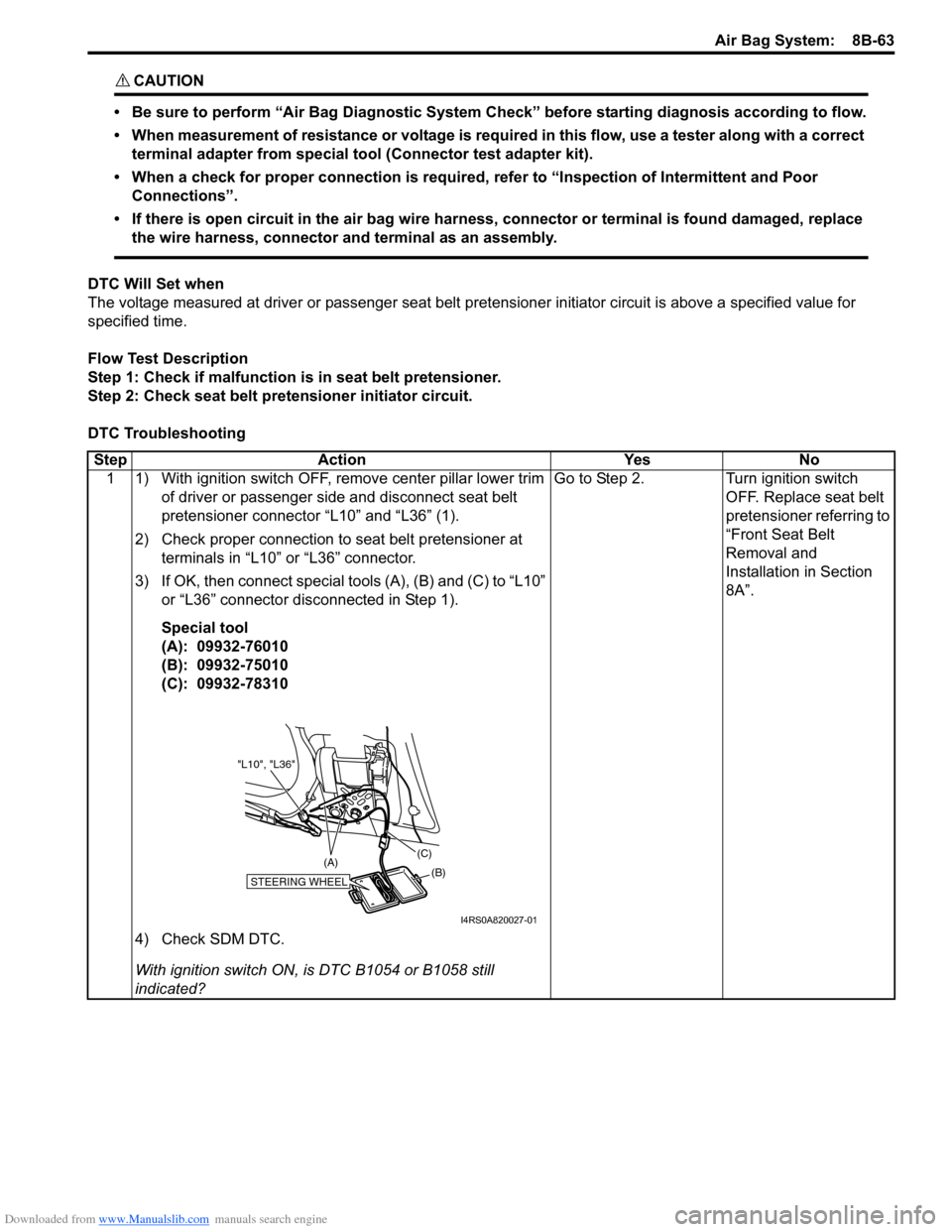

1 1) With ignition switch OFF, re move center pillar lower trim

of driver or passenger side and disconnect seat belt

pretensioner connector “L10” and “L36” (1).

2) Check proper connection to seat belt pretensioner at terminals in “L10” or “L36” connector.

3) If OK, then connect special tools (A), (B) and (C) to “L10” or “L36” connector disconnected in Step 1).

Special tool

(A): 09932-76010

(B): 09932-75010

(C): 09932-78310

4) Check SDM DTC.

With ignition switch ON, is DTC B1054 or B1058 still

indicated? Go to Step 2.

Turn ignition switch

OFF. Replace seat belt

pretensioner referring to

“Front Seat Belt

Removal and

Installation in Section

8A”.

STEERING WHEEL(B)

(C)

(A)

"L10", "L36"

I4RS0A820027-01

Page 1142 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-104 Air Bag System:

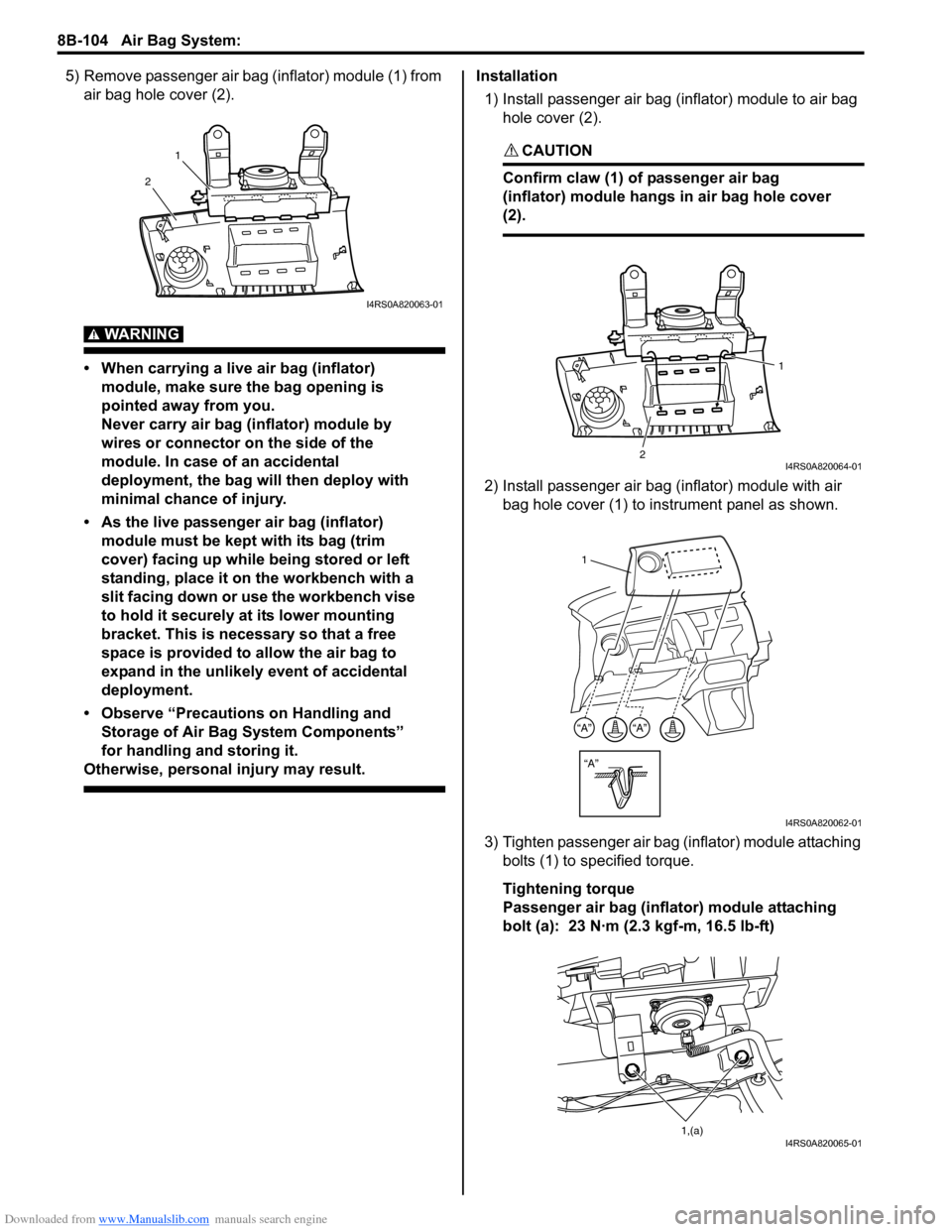

5) Remove passenger air bag (inflator) module (1) from air bag hole cover (2).

WARNING!

• When carrying a live air bag (inflator) module, make sure the bag opening is

pointed away from you.

Never carry air bag (inflator) module by

wires or connector on the side of the

module. In case of an accidental

deployment, the bag will then deploy with

minimal chance of injury.

• As the live passenger air bag (inflator) module must be kept with its bag (trim

cover) facing up while being stored or left

standing, place it on the workbench with a

slit facing down or use the workbench vise

to hold it securely at its lower mounting

bracket. This is necessary so that a free

space is provided to allow the air bag to

expand in the unlikely event of accidental

deployment.

• Observe “Precautions on Handling and Storage of Air Bag System Components”

for handling and storing it.

Otherwise, personal injury may result.

Installation

1) Install passenger air bag (inflator) module to air bag hole cover (2).

CAUTION!

Confirm claw (1) of passenger air bag

(inflator) module hangs in air bag hole cover

(2).

2) Install passenger air bag (inflator) module with air bag hole cover (1) to instrument panel as shown.

3) Tighten passenger air bag (inflator) module attaching bolts (1) to sp ecified torque.

Tightening torque

Passenger air bag (inflator) module attaching

bolt (a): 23 N·m (2.3 kgf-m, 16.5 lb-ft)

1

2

I4RS0A820063-01

2 1I4RS0A820064-01

“A”

“A”“A”

1

I4RS0A820062-01

1,(a)I4RS0A820065-01

Page 1152 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-114 Air Bag System:

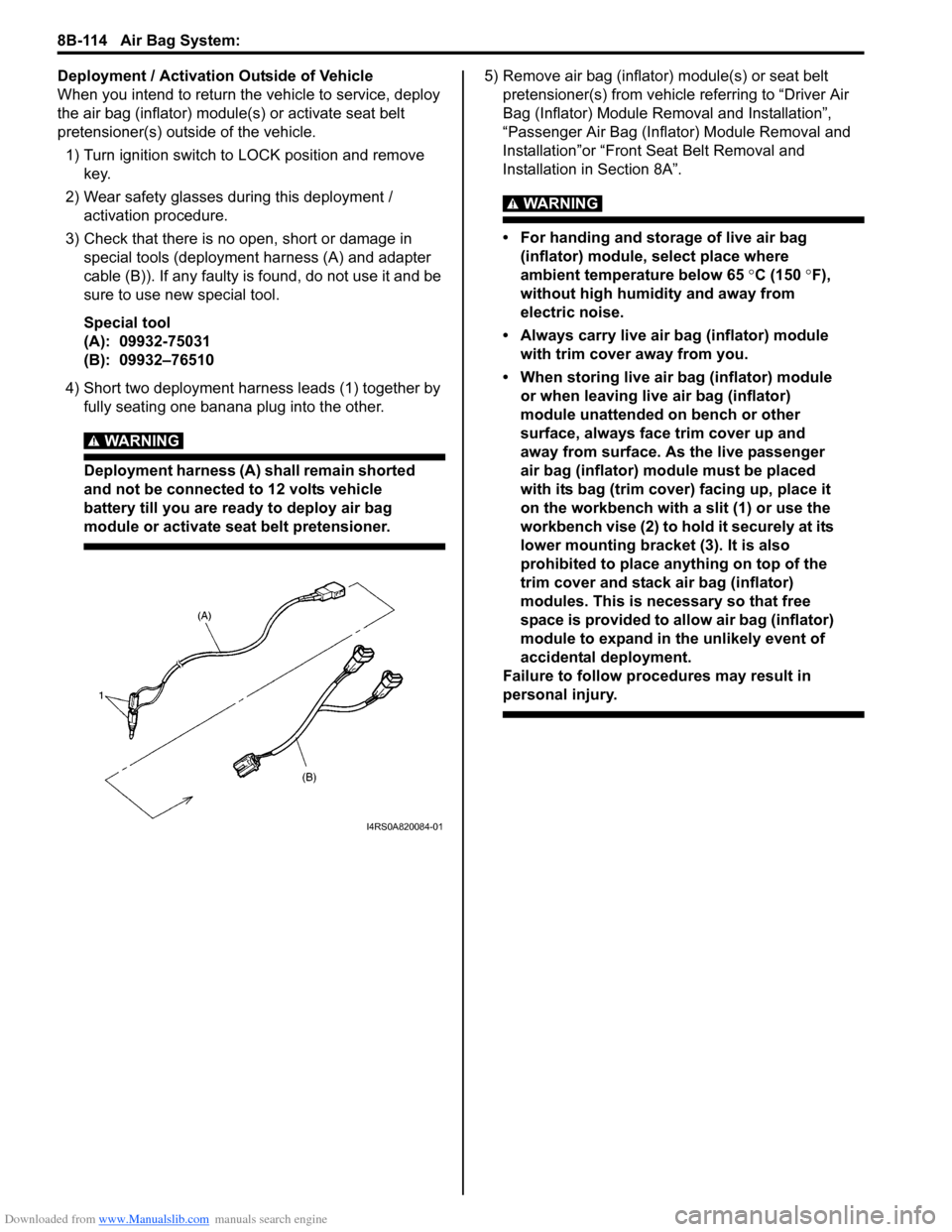

Deployment / Activation Outside of Vehicle

When you intend to return the vehicle to service, deploy

the air bag (inflator) module(s) or activate seat belt

pretensioner(s) outside of the vehicle.1) Turn ignition switch to LOCK position and remove key.

2) Wear safety glasses during this deployment / activation procedure.

3) Check that there is no open, short or damage in special tools (deployment harness (A) and adapter

cable (B)). If any faulty is found, do not use it and be

sure to use new special tool.

Special tool

(A): 09932-75031

(B): 09932–76510

4) Short two deployment harness leads (1) together by fully seating one banana plug into the other.

WARNING!

Deployment harness (A) shall remain shorted

and not be connected to 12 volts vehicle

battery till you are ready to deploy air bag

module or activate seat belt pretensioner.

5) Remove air bag (inflator) module(s) or seat belt pretensioner(s) from vehicle referring to “Driver Air

Bag (Inflator) Module Re moval and Installation”,

“Passenger Air Bag (Inflator) Module Removal and

Installation”or “Front Seat Belt Removal and

Installation in Section 8A”.

WARNING!

• For handing and storage of live air bag (inflator) module, select place where

ambient temperature below 65 °C (150 °F),

without high humidity and away from

electric noise.

• Always carry live air bag (inflator) module with trim cover away from you.

• When storing live air bag (inflator) module or when leaving live air bag (inflator)

module unattended on bench or other

surface, always face trim cover up and

away from surface. As the live passenger

air bag (inflator) module must be placed

with its bag (trim cover) facing up, place it

on the workbench with a slit (1) or use the

workbench vise (2) to hold it securely at its

lower mounting bracket (3). It is also

prohibited to place anything on top of the

trim cover and stack air bag (inflator)

modules. This is necessary so that free

space is provided to allow air bag (inflator)

module to expand in the unlikely event of

accidental deployment.

Failure to follow procedures may result in

personal injury.

I4RS0A820084-01

Page 1153 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-115

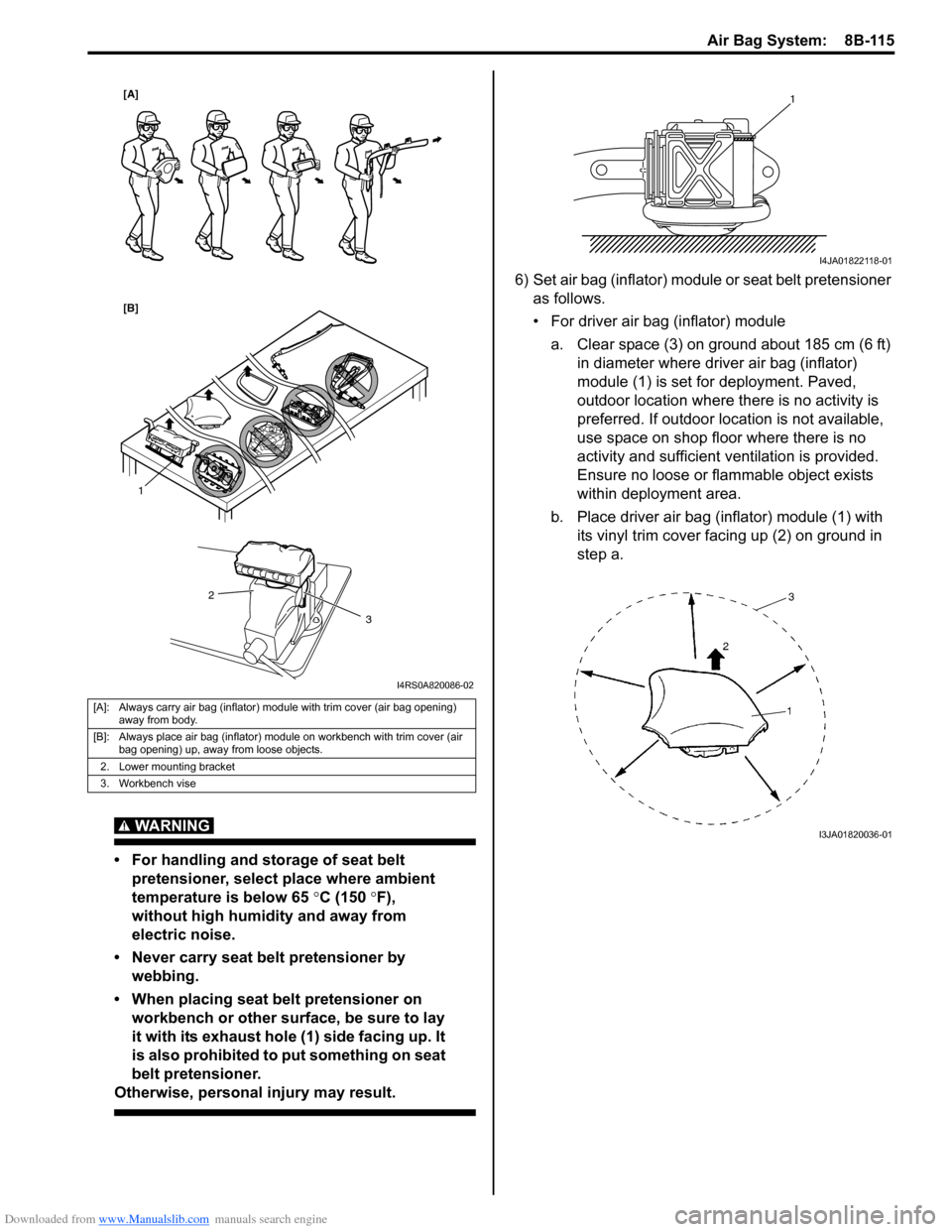

WARNING!

• For handling and storage of seat belt pretensioner, select place where ambient

temperature is below 65 °C (150 °F),

without high humidity and away from

electric noise.

• Never carry seat belt pretensioner by webbing.

• When placing seat belt pretensioner on workbench or other surface, be sure to lay

it with its exhaust hole (1) side facing up. It

is also prohibited to put something on seat

belt pretensioner.

Otherwise, personal injury may result.

6) Set air bag (inflator) module or seat belt pretensioner

as follows.

• For driver air bag (inflator) module

a. Clear space (3) on ground about 185 cm (6 ft) in diameter where driver air bag (inflator)

module (1) is set for deployment. Paved,

outdoor location where there is no activity is

preferred. If outdoor location is not available,

use space on shop floor where there is no

activity and sufficient ventilation is provided.

Ensure no loose or flammable object exists

within deployment area.

b. Place driver air bag (inflator) module (1) with its vinyl trim cover facing up (2) on ground in

step a.

[A]: Always carry air bag (inflator) module with trim cover (air bag opening) away from body.

[B]: Always place air bag (inflator) module on workbench with trim cover (air bag opening) up, away from loose objects.

2. Lower mounting bracket

3. Workbench vise

1

2

3

[A]

[B]

I4RS0A820086-02

1

I4JA01822118-01

I3JA01820036-01

Page 1159 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-121

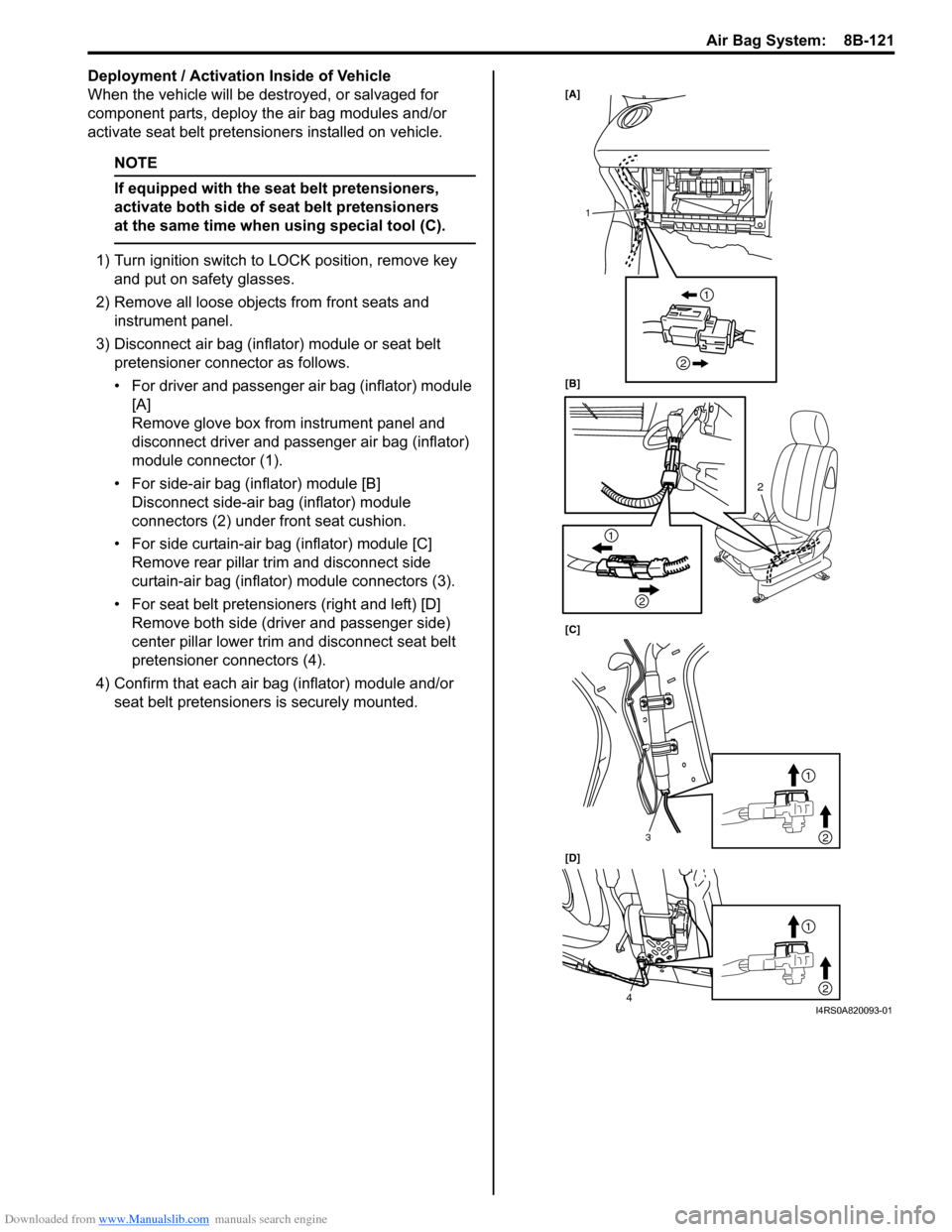

Deployment / Activation Inside of Vehicle

When the vehicle will be destroyed, or salvaged for

component parts, deploy the air bag modules and/or

activate seat belt pretensioners installed on vehicle.

NOTE

If equipped with the seat belt pretensioners,

activate both side of seat belt pretensioners

at the same time when using special tool (C).

1) Turn ignition switch to LOCK position, remove key

and put on safety glasses.

2) Remove all loose objects from front seats and instrument panel.

3) Disconnect air bag (inflator) module or seat belt pretensioner connector as follows.

• For driver and passenger air bag (inflator) module [A]

Remove glove box from instrument panel and

disconnect driver and passenger air bag (inflator)

module connector (1).

• For side-air bag (inflator) module [B] Disconnect side-air bag (inflator) module

connectors (2) under front seat cushion.

• For side curtain-air bag (inflator) module [C] Remove rear pillar trim and disconnect side

curtain-air bag (inflator) module connectors (3).

• For seat belt pretensioners (right and left) [D] Remove both side (driver and passenger side)

center pillar lower trim an d disconnect seat belt

pretensioner connectors (4).

4) Confirm that each air bag (inflator) module and/or seat belt pretensioners is securely mounted.

[A]

[B]

[C]

[D]

2

1

3

4

1

2

1

2

1

2

1

2

I4RS0A820093-01

Page 1189 of 1496

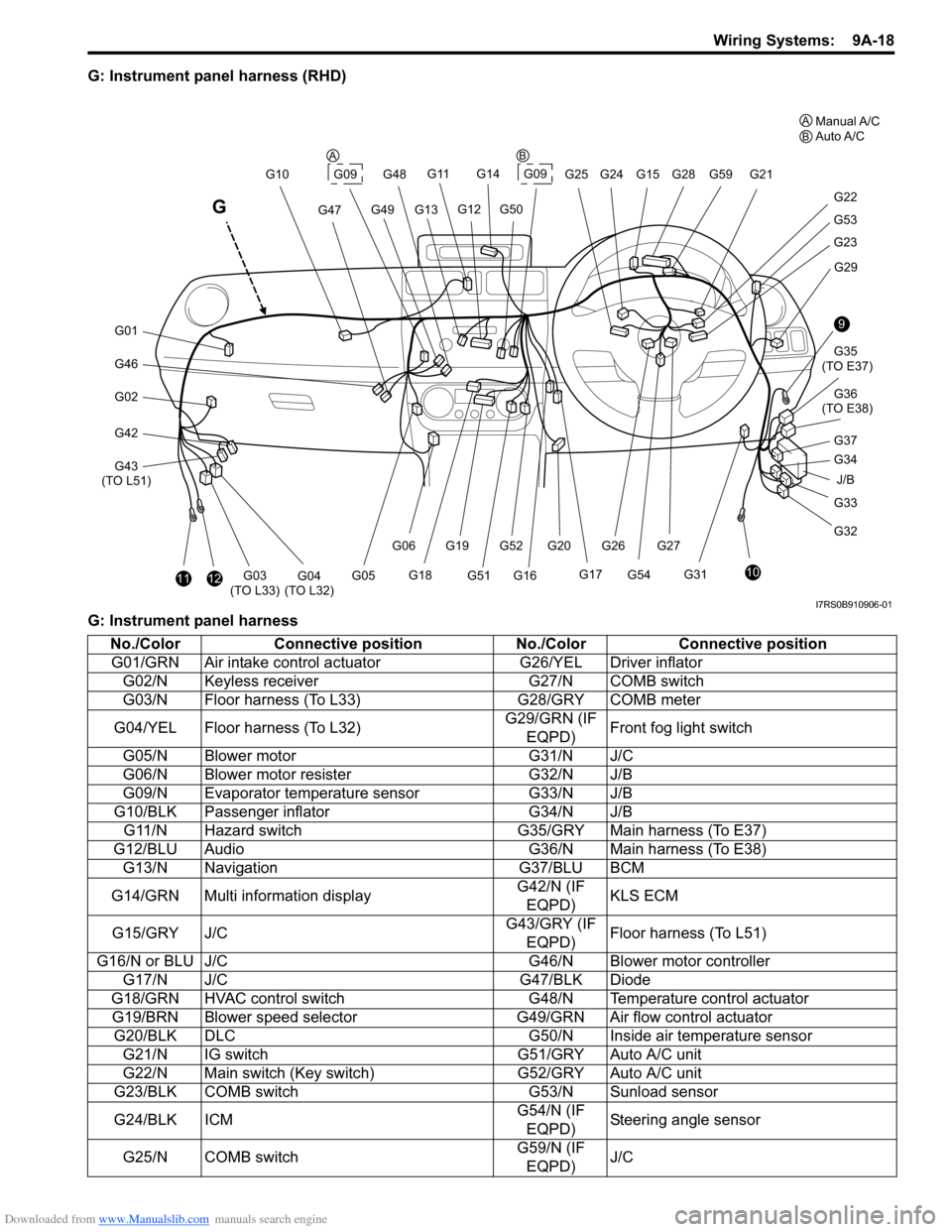

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-18

G: Instrument panel harness (RHD)

G: Instrument panel harness

J/B

9

10

G33

G32 G34 G35

(TO E37)

G36

(TO E38)

G31 G29

G23

G53

G22

G21

G28G59

G20G52G27

G54

G261112G03

(TO L33)G04

(TO L32)

G46

G01

G02

G42

G43

(TO L51) G10

G47

G11

G13G49

G14

G09G25 G24G15

G12G50

G48

G17

G16G51

G19

G18

G06

G05

G

G09

G37

A

BManual A/C

Auto A/C

AB

I7RS0B910906-01

No./Color Connective position No./ColorConnective position

G01/GRN Air intake control ac tuatorG26/YEL Driver inflator

G02/N Keyless receiver G27/N COMB switch

G03/N Floor harness (To L33) G28/GRY COMB meter

G04/YEL Floor harness (To L32) G29/GRN (IF

EQPD) Front fog light switch

G05/N Blower motor G31/N J/C

G06/N Blower motor resister G32/N J/B

G09/N Evaporator temperature sensor G33/N J/B

G10/BLK Passenger inflator G34/N J/B

G11/N Hazard switch G35/GRY Main harness (To E37)

G12/BLU Audio G36/N Main harness (To E38)

G13/N Navigation G37/BLU BCM

G14/GRN Multi information display G42/N (IF

EQPD) KLS ECM

G15/GRY J/C G43/GRY (IF

EQPD) Floor harness (To L51)

G16/N or BLU J/C G46/N Blower motor controller

G17/N J/C G47/BLK Diode

G18/GRN HVAC control switch G48/N Temperature control actuator

G19/BRN Blower speed selector G49/GRN Air flow control actuator

G20/BLK DLC G50/N Inside air temperature sensor

G21/N IG switch G51/GRY Auto A/C unit

G22/N Main switch (Key switch) G52/GRY Auto A/C unit

G23/BLK COMB switch G53/N Sunload sensor

G24/BLK ICM G54/N (IF

EQPD) Steering angle sensor

G25/N COMB switch G59/N (IF

EQPD) J/C

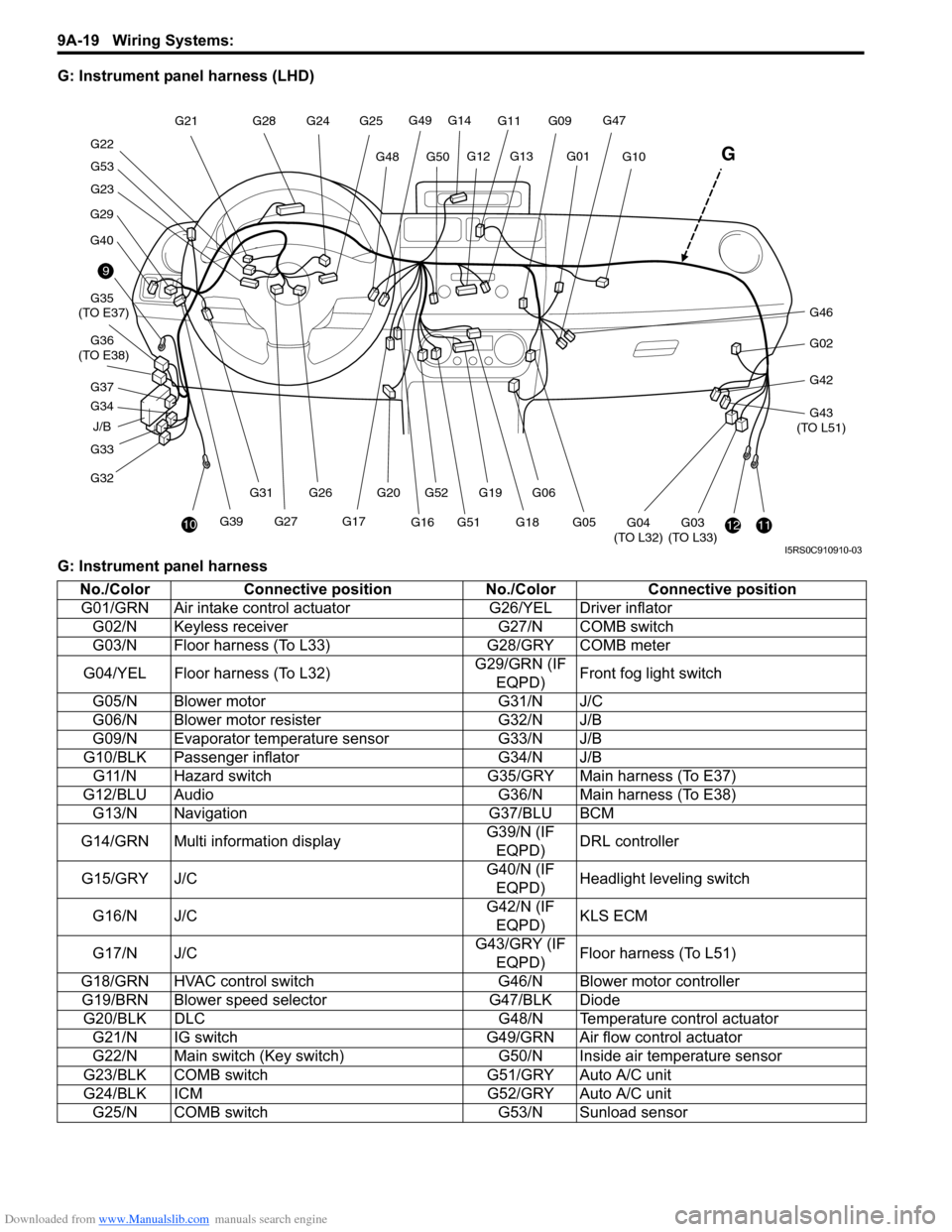

Page 1190 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-19 Wiring Systems:

G: Instrument panel harness (LHD)

G: Instrument panel harness

J/B

9

10

G33

G32 G34 G35

(TO E37)

G36

(TO E38)

G29

G40

G23

G53

G22 G21

G28

G20G52

G27G39 G26

G31

1112G03

(TO L33)G04

(TO L32)

G46

G02

G42

G43

(TO L51)

G10

G47G11

G13G01

G14

G49

G50G48

G25

G24

G12

G17

G16G51G19

G18

G06

G05

G

G09

G37

I5RS0C910910-03

No./Color Connective position No./ColorConnective position

G01/GRN Air intake control ac tuatorG26/YEL Driver inflator

G02/N Keyless receiver G27/N COMB switch

G03/N Floor harness (To L33) G28/GRY COMB meter

G04/YEL Floor harness (To L32) G29/GRN (IF

EQPD) Front fog light switch

G05/N Blower motor G31/N J/C

G06/N Blower motor resister G32/N J/B

G09/N Evaporator temperature sensor G33/N J/B

G10/BLK Passenger inflator G34/N J/B

G11/N Hazard switch G35/GRY Main harness (To E37)

G12/BLU Audio G36/N Main harness (To E38)

G13/N Navigation G37/BLU BCM

G14/GRN Multi information display G39/N (IF

EQPD) DRL controller

G15/GRY J/C G40/N (IF

EQPD) Headlight leveling switch

G16/N J/C G42/N (IF

EQPD) KLS ECM

G17/N J/C G43/GRY (IF

EQPD) Floor harness (To L51)

G18/GRN HVAC control switch G46/N Blower motor controller

G19/BRN Blower speed selector G47/BLK Diode

G20/BLK DLC G48/N Temperature control actuator

G21/N IG switch G49/GRN Air flow control actuator

G22/N Main switch (Key switch) G50/N Inside air temperature sensor

G23/BLK COMB switch G51/GRY Auto A/C unit

G24/BLK ICM G52/GRY Auto A/C unit

G25/N COMB switch G53/N Sunload sensor