Drive SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 710 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-66 Automatic Transmission/Transaxle:

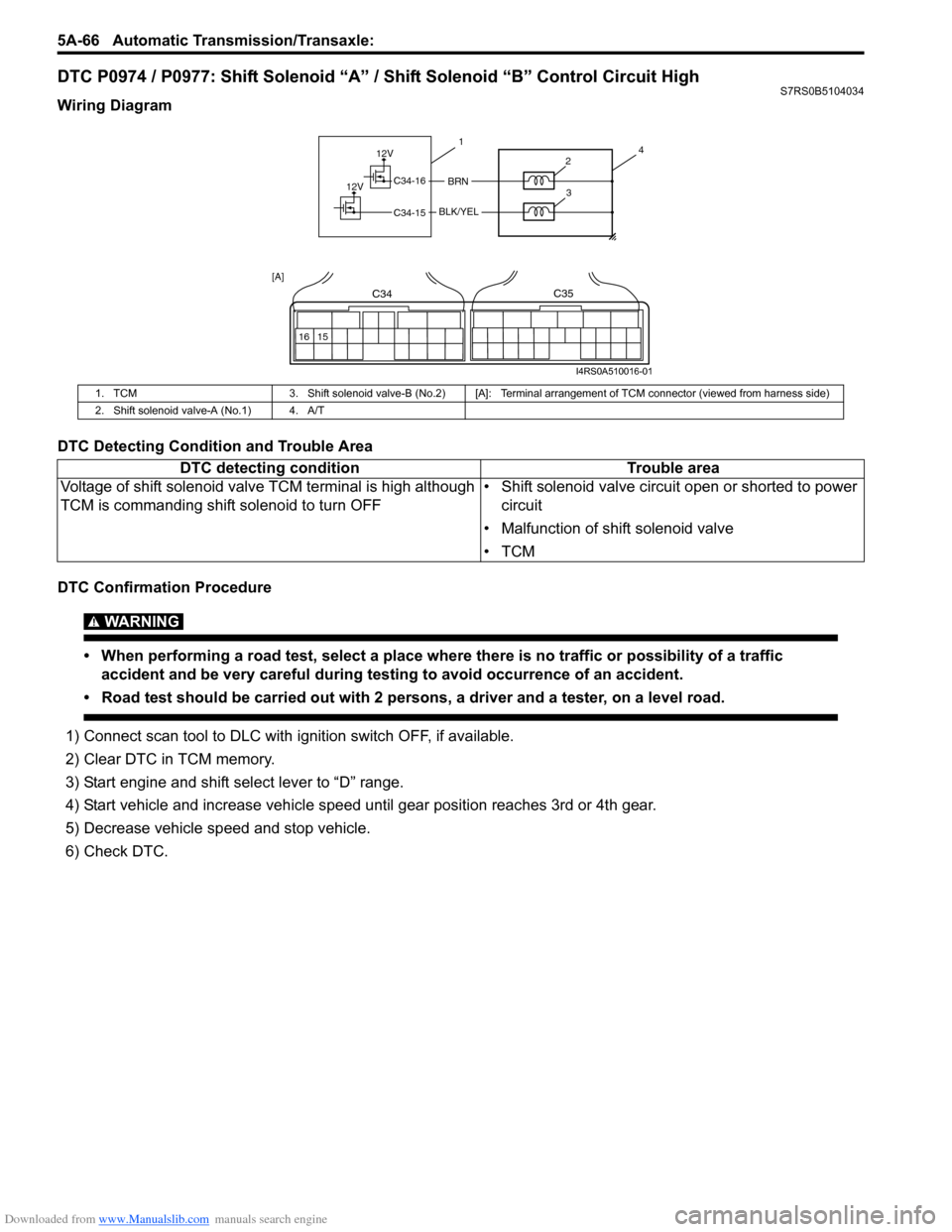

DTC P0974 / P0977: Shift Solenoid “A” / Shift Solenoid “B” Control Circuit HighS7RS0B5104034

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine and shift select lever to “D” range.

4) Start vehicle and increase vehicle speed until gear position reaches 3rd or 4th gear.

5) Decrease vehicle sp eed and stop vehicle.

6) Check DTC.

1. TCM 3. Shift solenoid valve-B (No.2) [A]: Terminal arra ngement of TCM connector (viewed from harness side)

2. Shift solenoid valve-A (No.1) 4. A/T

DTC detecting condition Trouble area

Voltage of shift solenoid valve TCM terminal is high although

TCM is commanding shift solenoid to turn OFF • Shift solenoid valve circuit open or shorted to power

circuit

• Malfunction of shift solenoid valve

•TCM

12V

12VBRNC34-16

C34-15BLK/YEL

41

2

3

16 15

C34C35

[A]

I4RS0A510016-01

Page 719 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-75

DTC P1878: Torque Converter Clutch ShudderS7RS0B5104042

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTCs in TCM and ECM memories by using scan tool.

3) Start engine and warm it up to normal operating temperature.

4) Drive vehicle with 3rd or 4th gear in “D” range and slip c ontrolled lock-up ON for 20 seconds or longer referring to

“Automatic Gear Shift Table”.

5) Stop vehicle.

6) Check DTC, pending DTC and freeze-frame data.

DTC Troubleshooting DTC detecting condition

Trouble area

The acceleration slip control function stops when the variation in the output

revolution speed of the specified amp litude and specified cycle is detected

within a specified period of time. When t he specified variation is not detected

after the acceleration slip control stops. • Mismatching ATF

• Torque converter clutch malfunction

• Valve body

•TCM

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Change A/T fluid referring to “A/T Fluid Change”. Check DTC after performing “DTC Confirmation Procedure”.

Is DTC P1878 still indicated? Faulty torque converter

clutch.

Replace torque

converter.System is in good

condition.

Page 722 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-78 Automatic Transmission/Transaxle:

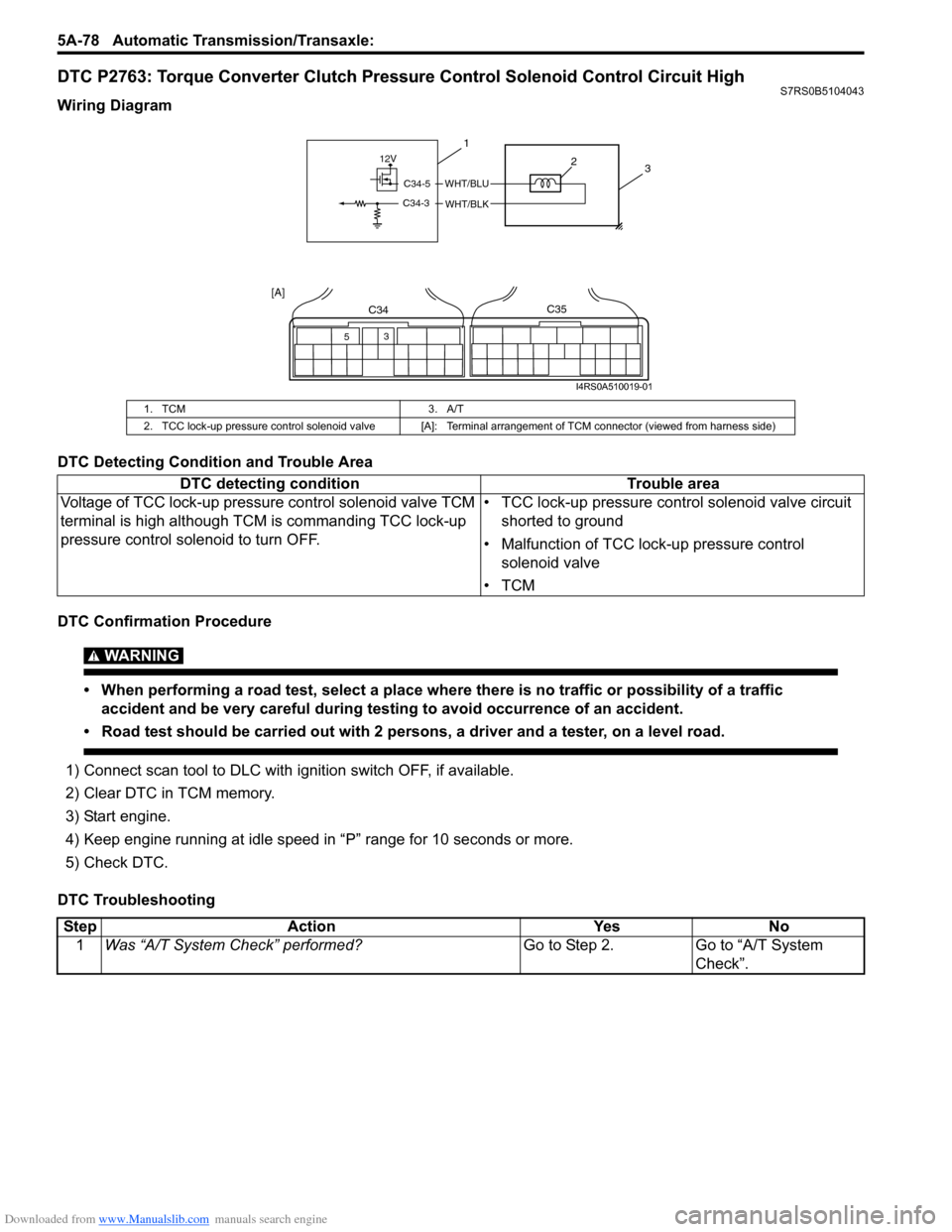

DTC P2763: Torque Converter Clutch Pressure Control Solenoid Control Circuit HighS7RS0B5104043

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed in “P” range for 10 seconds or more.

5) Check DTC.

DTC Troubleshooting

1. TCM 3. A/T

2. TCC lock-up pressure control solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting conditionTrouble area

Voltage of TCC lock-up pressure control solenoid valve TCM

terminal is high although TCM is commanding TCC lock-up

pressure control sole noid to turn OFF. • TCC lock-up pressure contro

l solenoid valve circuit

shorted to ground

• Malfunction of TCC lock-up pressure control solenoid valve

•TCM

12V

C34-5

C34-3

WHT/BLU

WHT/BLK

3

1

2

53

C34C35

[A]

I4RS0A510019-01

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

Page 724 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-80 Automatic Transmission/Transaxle:

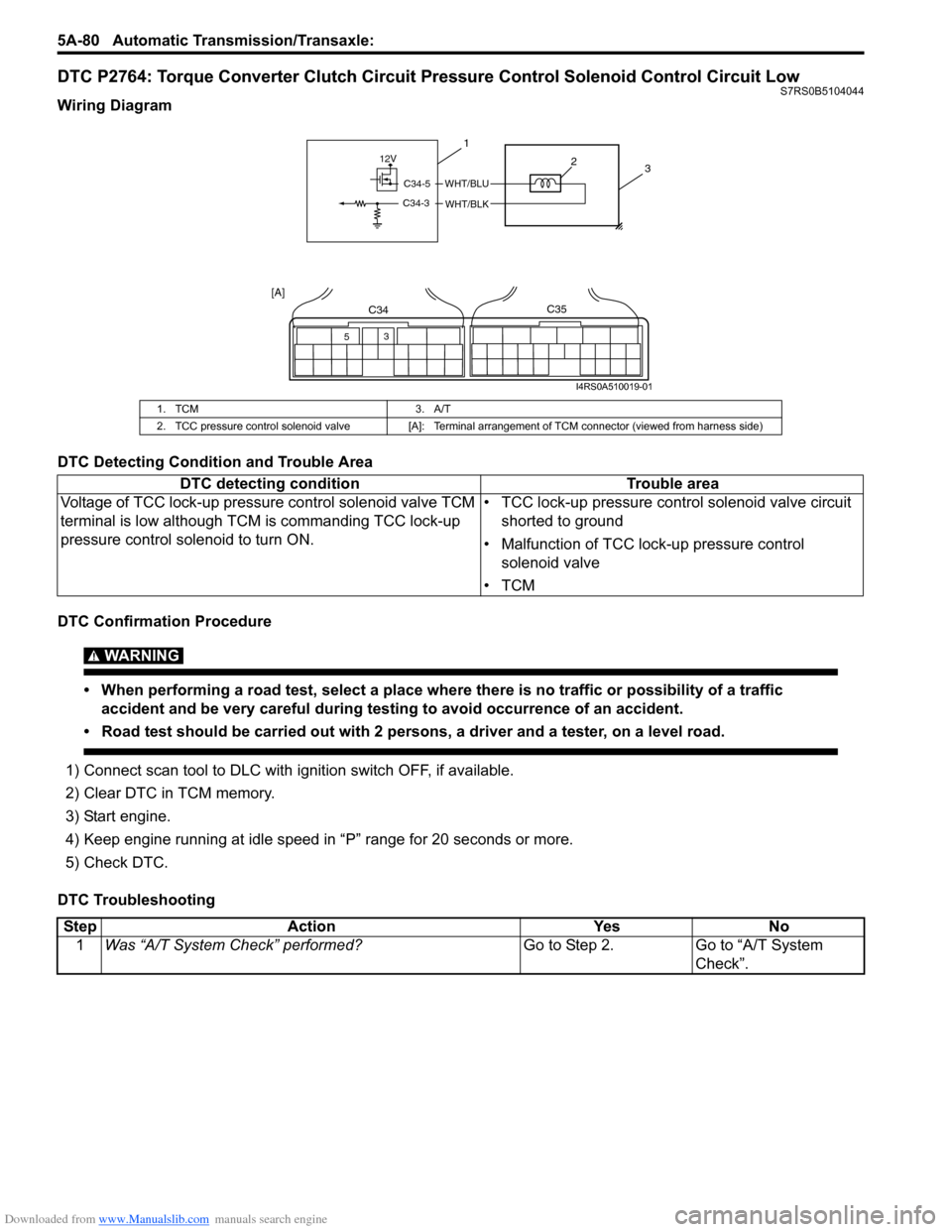

DTC P2764: Torque Converter Clutch Circuit Pressure Control Solenoid Control Circuit LowS7RS0B5104044

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed in “P” range for 20 seconds or more.

5) Check DTC.

DTC Troubleshooting

1. TCM 3. A/T

2. TCC pressure control solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Voltage of TCC lock-up pressure control solenoid valve TCM

terminal is low although TCM is commanding TCC lock-up

pressure control sole noid to turn ON. • TCC lock-up pressure contro

l solenoid valve circuit

shorted to ground

• Malfunction of TCC lock-up pressure control solenoid valve

•TCM

12V

C34-5

C34-3

WHT/BLU

WHT/BLK

3

1

2

53

C34C35

[A]

I4RS0A510019-01

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

Page 730 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-86 Automatic Transmission/Transaxle:

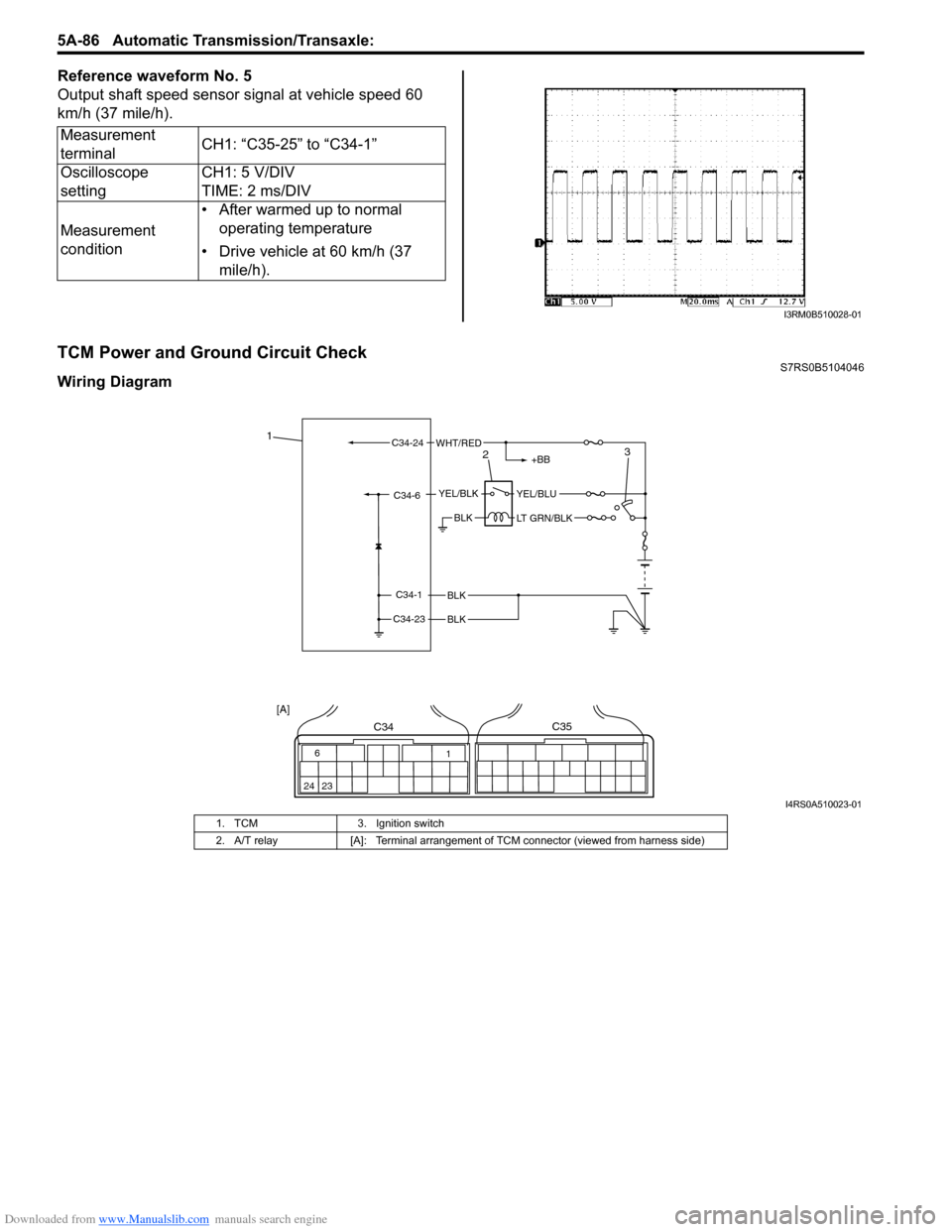

Reference waveform No. 5

Output shaft speed sensor signal at vehicle speed 60

km/h (37 mile/h).

TCM Power and Ground Circuit CheckS7RS0B5104046

Wiring DiagramMeasurement

terminal

CH1: “C35-25” to “C34-1”

Oscilloscope

setting CH1: 5 V/DIV

TIME: 2 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Drive vehicle at 60 km/h (37 mile/h).

I3RM0B510028-01

BLK

BLK

BLK

C34-1

C34-23

C34-6YEL/BLKYEL/BLU

LT GRN/BLK

+BB

C34-24WHT/RED1

23

6

24 23 1

C34C35

[A]

I4RS0A510023-01

1. TCM

3. Ignition switch

2. A/T relay [A]: Terminal arrangement of TCM connector (viewed from harness side)

Page 733 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-89

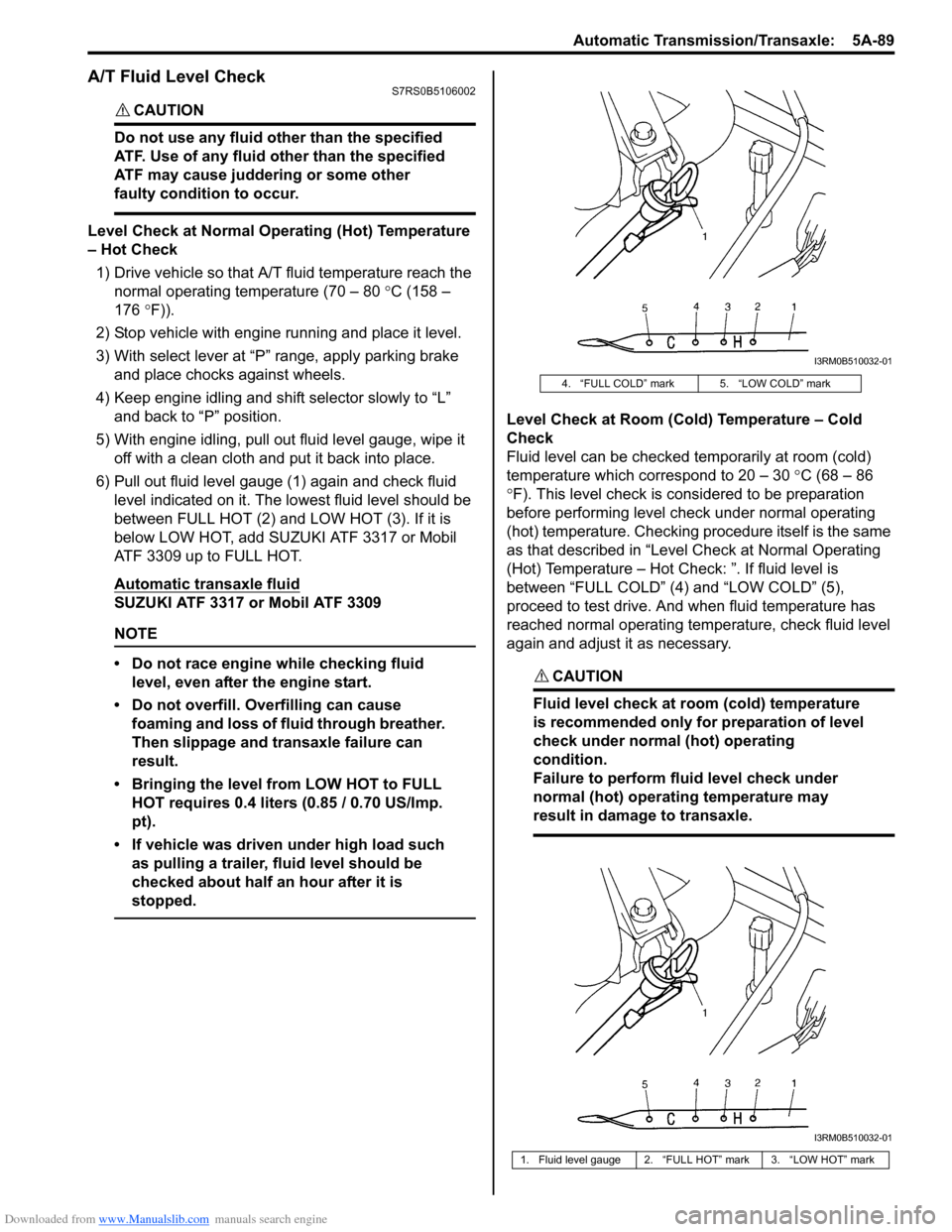

A/T Fluid Level CheckS7RS0B5106002

CAUTION!

Do not use any fluid other than the specified

ATF. Use of any fluid other than the specified

ATF may cause juddering or some other

faulty condition to occur.

Level Check at Normal Operating (Hot) Temperature

– Hot Check1) Drive vehicle so that A/T fluid temperature reach the

normal operating temperature (70 – 80 °C (158 –

176 °F)).

2) Stop vehicle with engine running and place it level.

3) With select lever at “P” range, apply parking brake and place chocks against wheels.

4) Keep engine idling and shift selector slowly to “L” and back to “P” position.

5) With engine idling, pull out fluid level gauge, wipe it off with a clean cloth and put it back into place.

6) Pull out fluid level gauge (1) again and check fluid level indicated on it. The lo west fluid level should be

between FULL HOT (2) and LOW HOT (3). If it is

below LOW HOT, add SUZUKI ATF 3317 or Mobil

ATF 3309 up to FULL HOT.

Automatic transaxle fluid

SUZUKI ATF 3317 or Mobil ATF 3309

NOTE

• Do not race engine while checking fluid level, even after the engine start.

• Do not overfill. Overfilling can cause foaming and loss of fluid through breather.

Then slippage and transaxle failure can

result.

• Bringing the level from LOW HOT to FULL HOT requires 0.4 liters (0.85 / 0.70 US/Imp.

pt).

• If vehicle was driven under high load such as pulling a trailer, fluid level should be

checked about half an hour after it is

stopped.

Level Check at Room (Cold) Temperature – Cold

Check

Fluid level can be checked temporarily at room (cold)

temperature which correspond to 20 – 30 °C (68 – 86

° F). This level check is considered to be preparation

before performing level check under normal operating

(hot) temperature. Checking procedure itself is the same

as that described in “Level Check at Normal Operating

(Hot) Temperature – Hot Check: ”. If fluid level is

between “FULL COLD” (4) and “LOW COLD” (5),

proceed to test drive. And when fluid temperature has

reached normal operating temp erature, check fluid level

again and adjust it as necessary.

CAUTION!

Fluid level check at room (cold) temperature

is recommended only for preparation of level

check under normal (hot) operating

condition.

Failure to perform fluid level check under

normal (hot) operating temperature may

result in damage to transaxle.

4. “FULL COLD” mark 5. “LOW COLD” mark

1. Fluid level gauge 2. “FULL HOT” mark 3. “LOW HOT” mark

I3RM0B510032-01

I3RM0B510032-01

Page 737 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-93

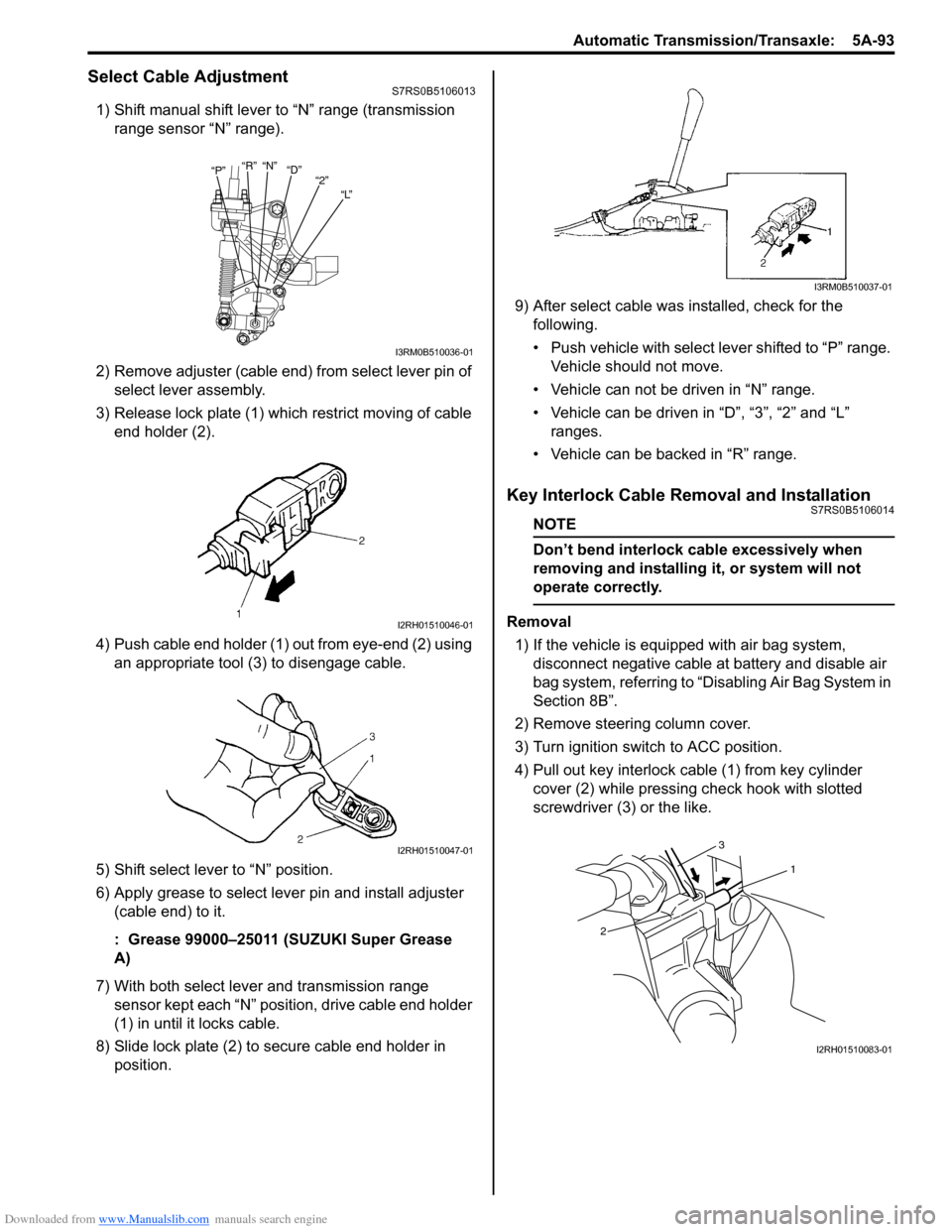

Select Cable AdjustmentS7RS0B5106013

1) Shift manual shift lever to “N” range (transmission range sensor “N” range).

2) Remove adjuster (cable end) from select lever pin of select lever assembly.

3) Release lock plate (1) which restrict moving of cable end holder (2).

4) Push cable end holder (1) out from eye-end (2) using an appropriate tool (3) to disengage cable.

5) Shift select lever to “N” position.

6) Apply grease to select lever pin and install adjuster (cable end) to it.

: Grease 99000–25011 (SUZUKI Super Grease

A)

7) With both select lever and transmission range sensor kept each “N” position, drive cable end holder

(1) in until it locks cable.

8) Slide lock plate (2) to secure cable end holder in position. 9) After select cable was

installed, check for the

following.

• Push vehicle with select lever shifted to “P” range. Vehicle should not move.

• Vehicle can not be driven in “N” range.

• Vehicle can be driven in “D”, “3”, “2” and “L” ranges.

• Vehicle can be backed in “R” range.

Key Interlock Cable Removal and InstallationS7RS0B5106014

NOTE

Don’t bend interlock cable excessively when

removing and installing it, or system will not

operate correctly.

Removal

1) If the vehicle is equipped with air bag system, disconnect negative cable at battery and disable air

bag system, referring to “Disabling Air Bag System in

Section 8B”.

2) Remove steering column cover.

3) Turn ignition switch to ACC position.

4) Pull out key interlock cable (1) from key cylinder cover (2) while pressing check hook with slotted

screwdriver (3) or the like.

“P” “R”

“N”

“D”

“2”

“L”

I3RM0B510036-01

I2RH01510046-01

I2RH01510047-01

I3RM0B510037-01

1

2 3

I2RH01510083-01

Page 739 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-95

5) Shift select lever to “N” position.

NOTE

If select lever is in “P” position, shift select

lever referring to “Select Lever Inspection”.

6) Install cable casing cap (3) to selector bracket (4).

7) Connect cable end (1) to interlock cam (2) with ignition switch turned to ACC position.

8) Drive lock button (5) in cable end until it locks cable expansion and contraction.

9) With select lever set at “P ” position, turn ignition key

to ACC position and then check for the following

conditions.

• With knob button released, ignition key can be turned from ACC position to LOCK position.

• With knob button pressed, ignition key cannot be

turned from ACC position to LOCK position.

10) Install steering column cover. 11) If the vehicle is equipped with air bag system, connect negative cable at battery and enable air bag

system, referring to “Enabling Air Bag System in

Section 8B”.

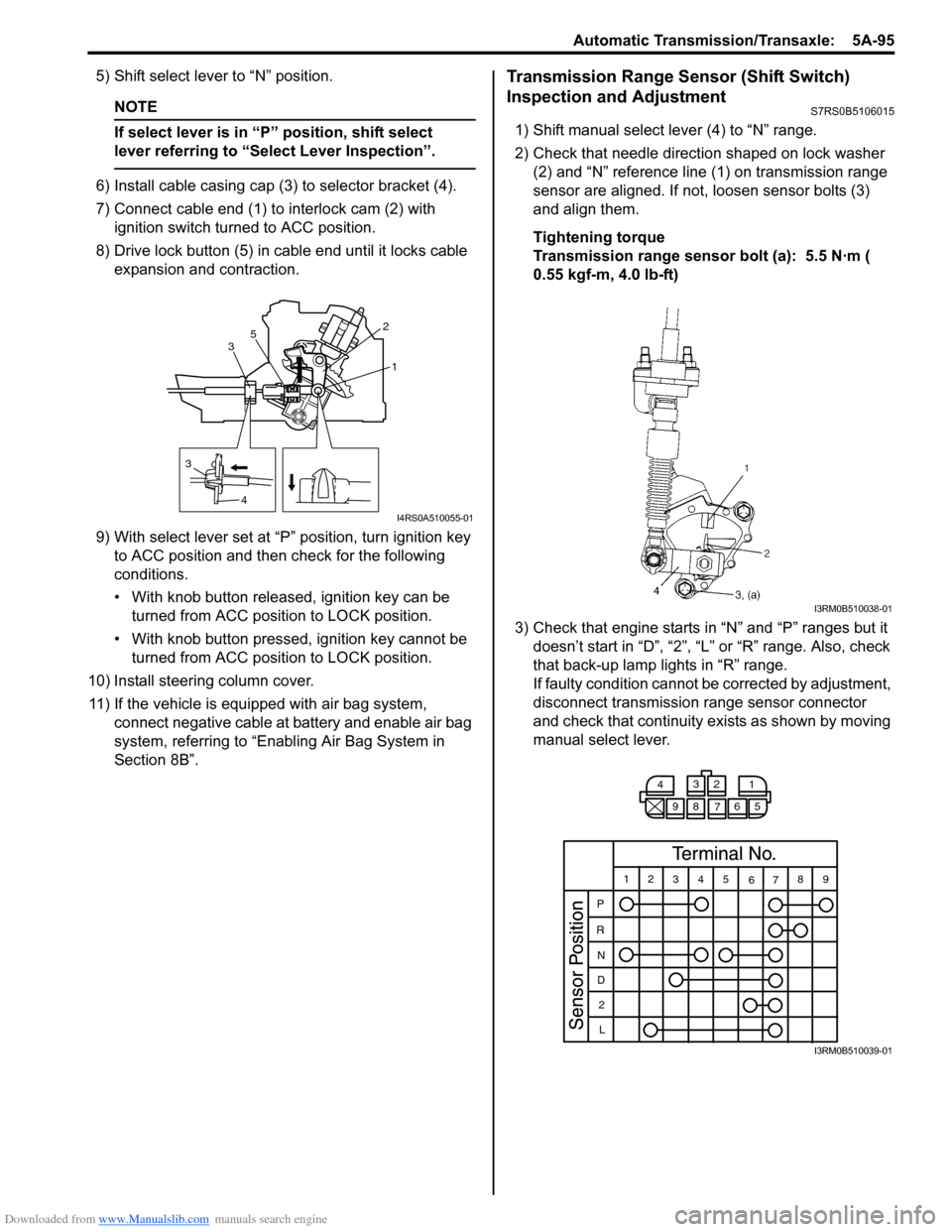

Transmission Range Sensor (Shift Switch)

Inspection and Adjustment

S7RS0B5106015

1) Shift manual select lever (4) to “N” range.

2) Check that needle direction shaped on lock washer (2) and “N” reference line (1) on transmission range

sensor are aligned. If not, loosen sensor bolts (3)

and align them.

Tightening torque

Transmission range sensor bolt (a): 5.5 N·m (

0.55 kgf-m, 4.0 lb-ft)

3) Check that engine starts in “N” and “P” ranges but it doesn’t start in “D”, “2”, “L” or “R” range. Also, check

that back-up lamp lights in “R” range.

If faulty condition cannot be corrected by adjustment,

disconnect transmission range sensor connector

and check that continuity ex ists as shown by moving

manual select lever.

3

4 1

2

3 5

I4RS0A510055-01

I3RM0B510038-01

4

3

2

1

98 76 5

12 345

6789

P

R N

D 2

L

I3RM0B510039-01

Page 740 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-96 Automatic Transmission/Transaxle:

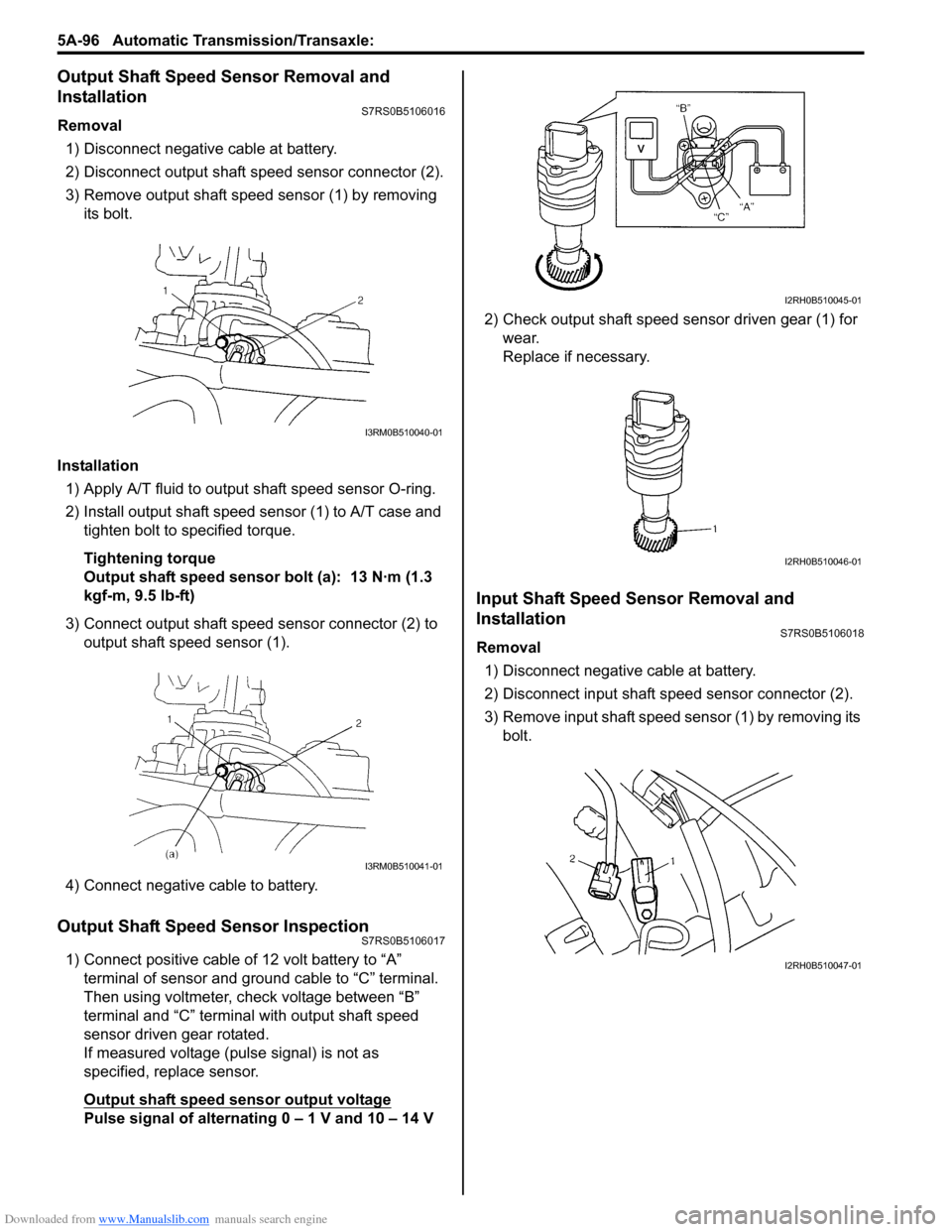

Output Shaft Speed Sensor Removal and

Installation

S7RS0B5106016

Removal

1) Disconnect negative cable at battery.

2) Disconnect output shaft speed sensor connector (2).

3) Remove output shaft speed sensor (1) by removing its bolt.

Installation 1) Apply A/T fluid to output shaft speed sensor O-ring.

2) Install output shaft speed sensor (1) to A/T case and tighten bolt to specified torque.

Tightening torque

Output shaft speed sensor bolt (a): 13 N·m (1.3

kgf-m, 9.5 lb-ft)

3) Connect output shaft speed sensor connector (2) to output shaft speed sensor (1).

4) Connect negative cable to battery.

Output Shaft Speed Sensor InspectionS7RS0B5106017

1) Connect positive cable of 12 volt battery to “A” terminal of sensor and ground cable to “C” terminal.

Then using voltmeter, check voltage between “B”

terminal and “C” terminal with output shaft speed

sensor driven gear rotated.

If measured voltage (pulse signal) is not as

specified, replace sensor.

Output shaft speed sensor output voltage

Pulse signal of alternating 0 – 1 V and 10 – 14 V 2) Check output shaft speed sensor driven gear (1) for

wear.

Replace if necessary.

Input Shaft Speed Sensor Removal and

Installation

S7RS0B5106018

Removal

1) Disconnect negative cable at battery.

2) Disconnect input shaft speed sensor connector (2).

3) Remove input shaft speed sensor (1) by removing its bolt.

I3RM0B510040-01

I3RM0B510041-01

I2RH0B510045-01

I2RH0B510046-01

I2RH0B510047-01

Page 747 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-103

Installation

Reverse removal procedure noting the following.

• Connect TCM connectors securely.

• If the vehicle is equipped with air bag system, be sure to enable air bag system after TCM is back in place.

Refer to “Enabling Air Bag System in Section 8B”.

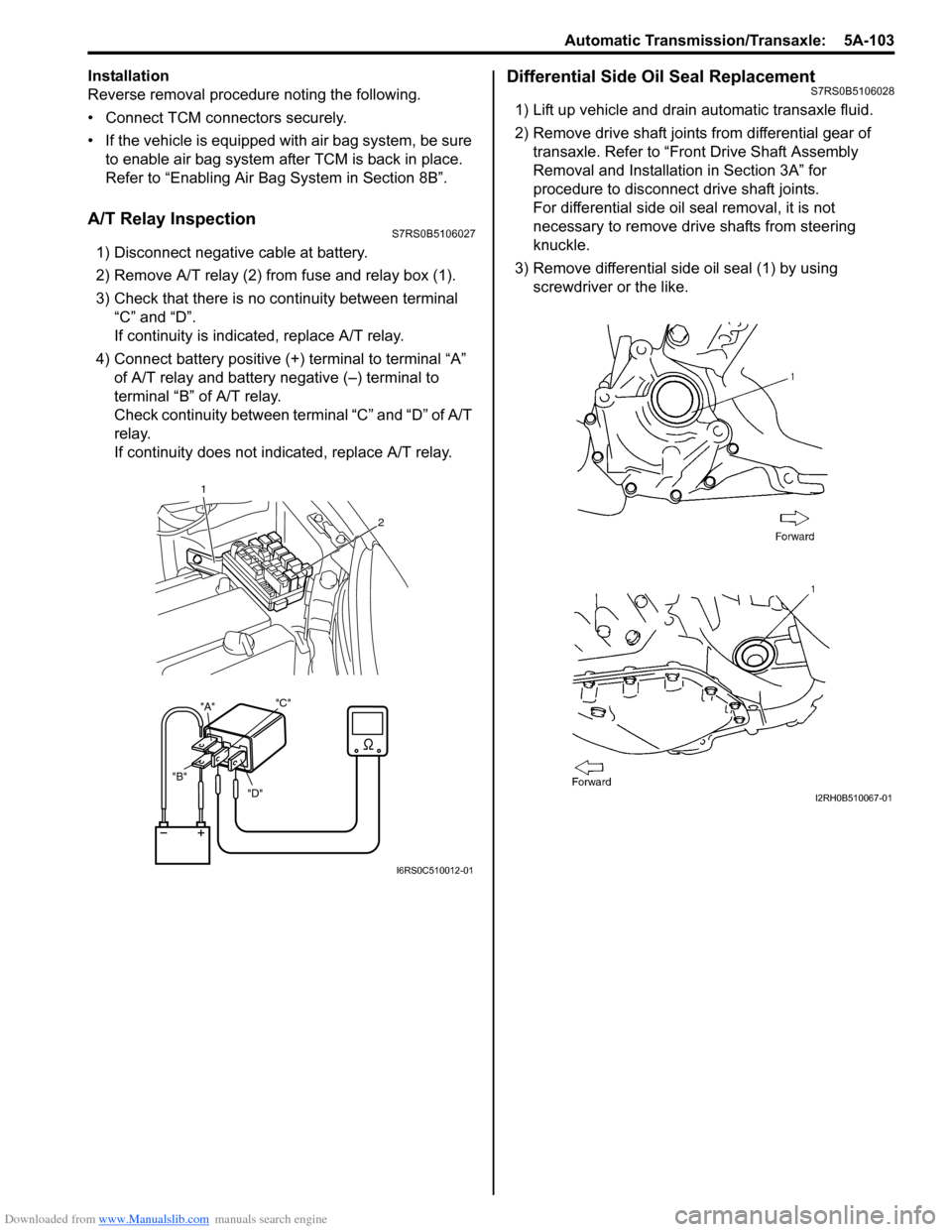

A/T Relay InspectionS7RS0B5106027

1) Disconnect negative cable at battery.

2) Remove A/T relay (2) from fuse and relay box (1).

3) Check that there is no continuity between terminal “C” and “D”.

If continuity is indicated, replace A/T relay.

4) Connect battery positive (+ ) terminal to terminal “A”

of A/T relay and battery negative (–) terminal to

terminal “B” of A/T relay.

Check continuity between terminal “C” and “D” of A/T

relay.

If continuity does not indicated, replace A/T relay.

Differential Side Oil Seal ReplacementS7RS0B5106028

1) Lift up vehicle and drain automatic transaxle fluid.

2) Remove drive shaft joints from differential gear of transaxle. Refer to “Front Drive Shaft Assembly

Removal and Installation in Section 3A” for

procedure to disconnect drive shaft joints.

For differential side oil seal removal, it is not

necessary to remove drive shafts from steering

knuckle.

3) Remove differential side oil seal (1) by using screwdriver or the like.

"D"

"B" "A"

"C"

1

2

I6RS0C510012-01

I2RH0B510067-01