charging SUZUKI SWIFT 2008 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 416 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-6 Charging System:

Generator Test (Overcharged Battery Check)S7RS0B1A04004

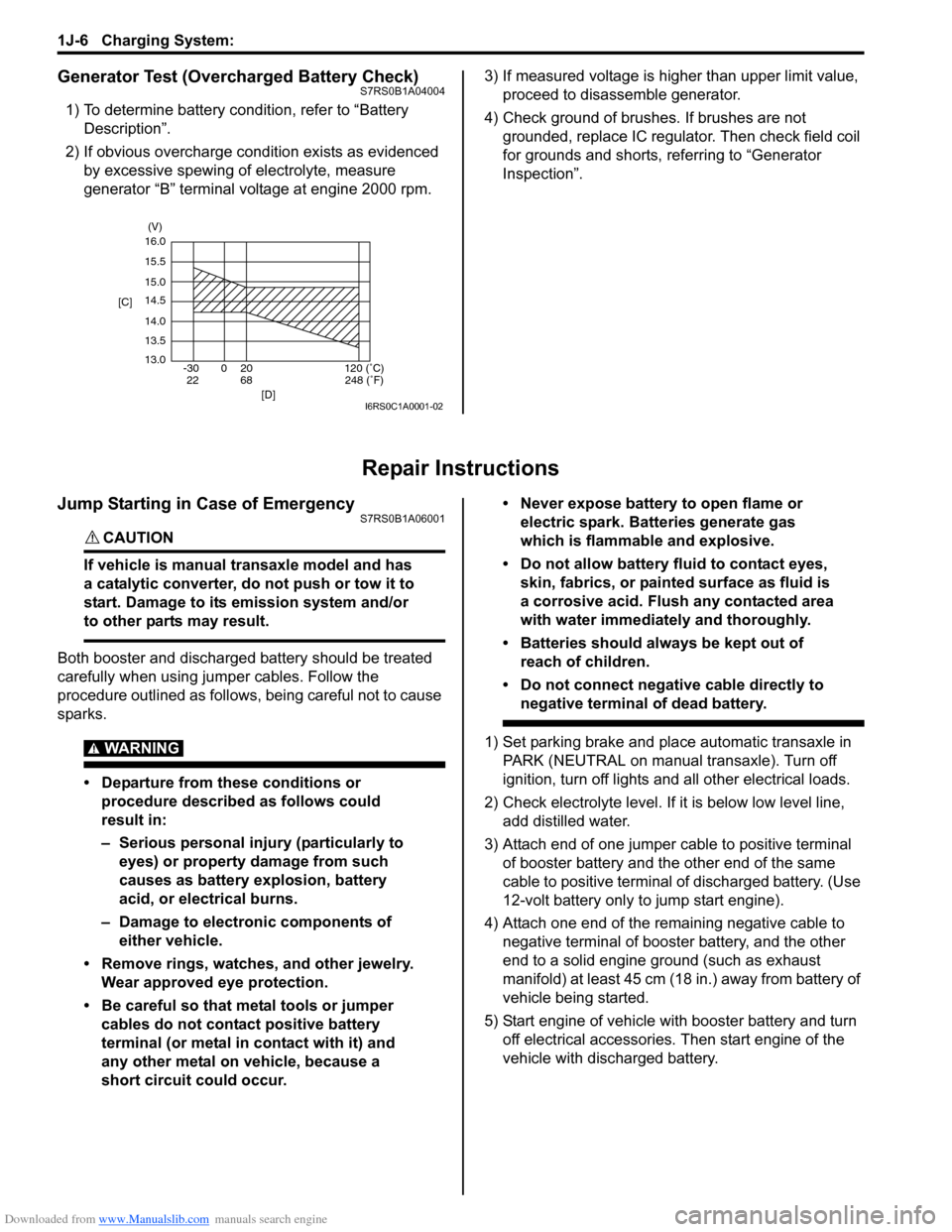

1) To determine battery condition, refer to “Battery Description”.

2) If obvious overcharge condition exists as evidenced by excessive spewing of electrolyte, measure

generator “B” terminal voltage at engine 2000 rpm. 3) If measured voltage is higher than upper limit value,

proceed to disassemble generator.

4) Check ground of brushes. If brushes are not grounded, replace IC regulator. Then check field coil

for grounds and shorts, referring to “Generator

Inspection”.

Repair Instructions

Jump Starting in Case of EmergencyS7RS0B1A06001

CAUTION!

If vehicle is manual transaxle model and has

a catalytic converter, do not push or tow it to

start. Damage to its emission system and/or

to other parts may result.

Both booster and discharged battery should be treated

carefully when using ju mper cables. Follow the

procedure outlined as follows, being careful not to cause

sparks.

WARNING!

• Departure from these conditions or procedure described as follows could

result in:

– Serious personal injury (particularly to eyes) or property damage from such

causes as battery explosion, battery

acid, or electrical burns.

– Damage to electronic components of either vehicle.

• Remove rings, watches, and other jewelry. Wear approved eye protection.

• Be careful so that metal tools or jumper cables do not contact positive battery

terminal (or metal in contact with it) and

any other metal on vehicle, because a

short circuit could occur. • Never expose battery to open flame or

electric spark. Batteries generate gas

which is flammable and explosive.

• Do not allow battery fluid to contact eyes, skin, fabrics, or painted surface as fluid is

a corrosive acid. Flush any contacted area

with water immediately and thoroughly.

• Batteries should always be kept out of reach of children.

• Do not connect negative cable directly to negative terminal of dead battery.

1) Set parking brake and place automatic transaxle in PARK (NEUTRAL on manual transaxle). Turn off

ignition, turn off lights and all other electrical loads.

2) Check electrolyte level. If it is below low level line, add distilled water.

3) Attach end of one jumper cable to positive terminal of booster battery and the other end of the same

cable to positive terminal of discharged battery. (Use

12-volt battery only to jump start engine).

4) Attach one end of the remaining negative cable to negative terminal of booster battery, and the other

end to a solid engine ground (such as exhaust

manifold) at least 45 cm (18 in.) away from battery of

vehicle being started.

5) Start engine of vehicle with booster battery and turn off electrical accessories. Then start engine of the

vehicle with discharged battery.

16.0

15.5

15.0

14.5

14.0

13.5

13.0 -30 0 20

[C]

[D]

68

22120 (˚C)

248 (˚F)

(V)

I6RS0C1A0001-02

Page 417 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-7

With Charging Equipment

CAUTION!

When jump starting engine with charging

equipment, be sure equipment used is 12-

volt and negative ground. Do not use 24-volt

charging equipment. Using such equipment

can cause serious damage to electrical

system or electronic parts.

Battery Dismounting and RemountingS7RS0B1A06002

WARNING!

When handling battery, following safety

precautions should be followed:

• Hydrogen gas is produced by battery. A flame or spark near battery may cause the

gas to ignite.

• Battery fluid is highly acidic. Avoid spilling on clothing or other fabric. Any spilled

electrolyte should be flushed with large

quantity of water and cleaned immediately.

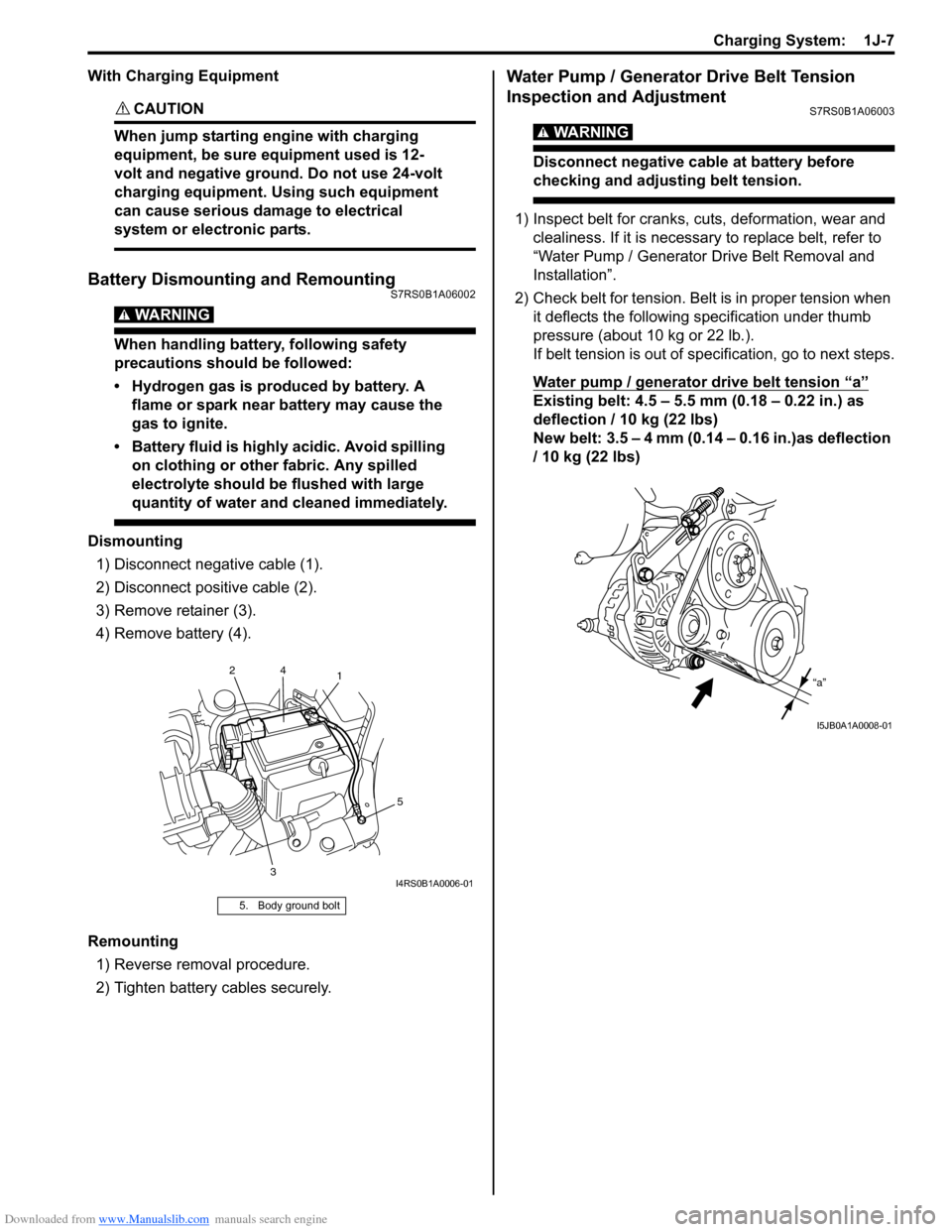

Dismounting

1) Disconnect negative cable (1).

2) Disconnect positive cable (2).

3) Remove retainer (3).

4) Remove battery (4).

Remounting 1) Reverse removal procedure.

2) Tighten battery cables securely.

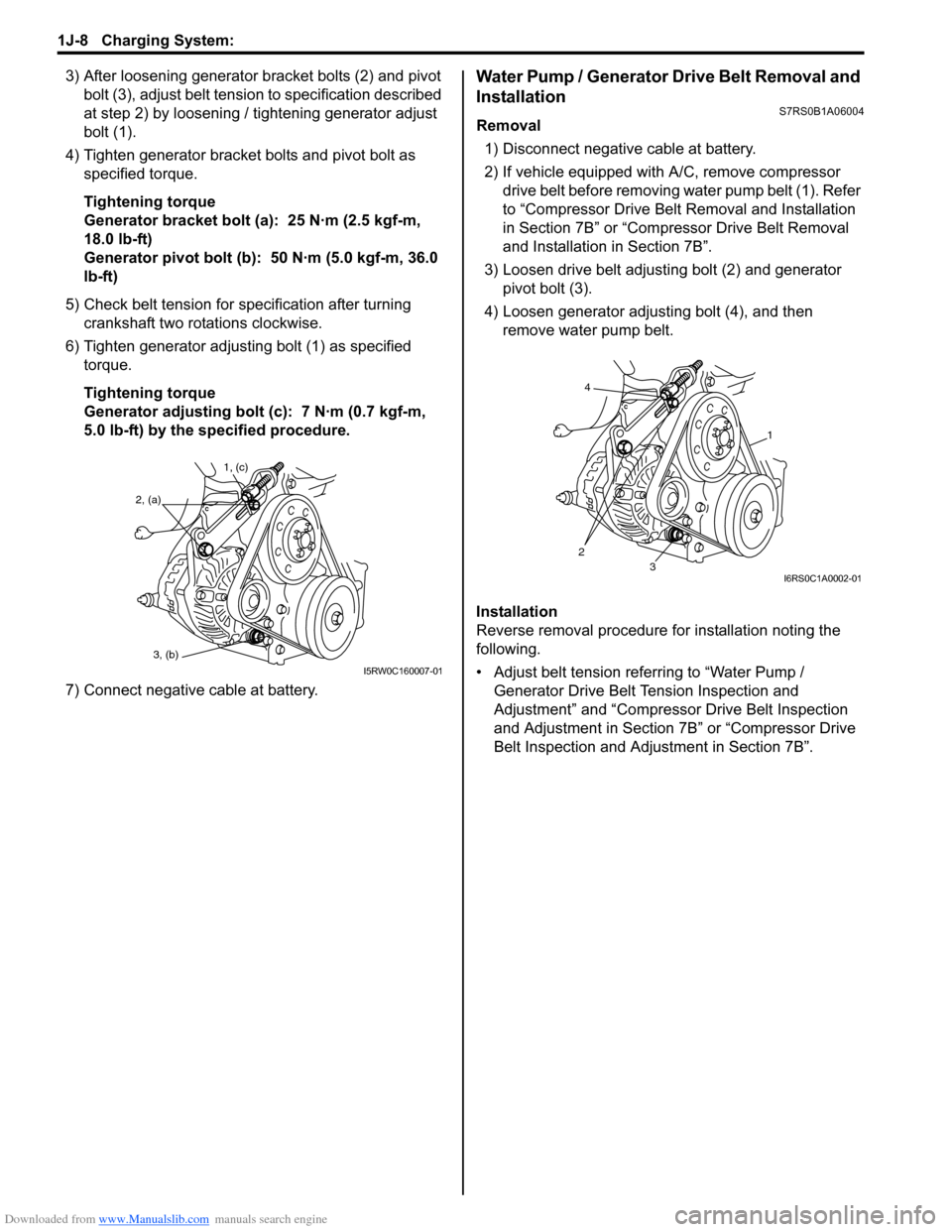

Water Pump / Generator Drive Belt Tension

Inspection and Adjustment

S7RS0B1A06003

WARNING!

Disconnect negative cable at battery before

checking and adjusting belt tension.

1) Inspect belt for cranks, cuts, deformation, wear and clealiness. If it is necessary to replace belt, refer to

“Water Pump / Generator Drive Belt Removal and

Installation”.

2) Check belt for tension. Belt is in proper tension when it deflects the following specification under thumb

pressure (about 10 kg or 22 lb.).

If belt tension is out of spec ification, go to next steps.

Water pump / generator drive belt tension

“a”

Existing belt: 4.5 – 5.5 mm (0.18 – 0.22 in.) as

deflection / 10 kg (22 lbs)

New belt: 3.5 – 4 mm (0.14 – 0.16 in.)as deflection

/ 10 kg (22 lbs)

5. Body ground bolt

1

3 5

2

4

I4RS0B1A0006-01

“a”

I5JB0A1A0008-01

Page 418 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-8 Charging System:

3) After loosening generator bracket bolts (2) and pivot bolt (3), adjust belt tensio n to specification described

at step 2) by loosening / tightening generator adjust

bolt (1).

4) Tighten generator bracket bolts and pivot bolt as specified torque.

Tightening torque

Generator bracket bolt (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

Generator pivot bolt (b): 50 N·m (5.0 kgf-m, 36.0

lb-ft)

5) Check belt tension for specification after turning crankshaft two rotations clockwise.

6) Tighten generator adjusting bolt (1) as specified torque.

Tightening torque

Generator adjusting bolt (c): 7 N·m (0.7 kgf-m,

5.0 lb-ft) by the specified procedure.

7) Connect negative cable at battery.Water Pump / Generator Drive Belt Removal and

Installation

S7RS0B1A06004

Removal 1) Disconnect negative cable at battery.

2) If vehicle equipped with A/C, remove compressor drive belt before removing water pump belt (1). Refer

to “Compressor Drive Belt Removal and Installation

in Section 7B” or “Compr essor Drive Belt Removal

and Installation in Section 7B”.

3) Loosen drive belt adjusting bolt (2) and generator pivot bolt (3).

4) Loosen generator adjusting bolt (4), and then remove water pump belt.

Installation

Reverse removal procedure for installation noting the

following.

• Adjust belt tension referring to “Water Pump / Generator Drive Belt Tension Inspection and

Adjustment” and “Compressor Drive Belt Inspection

and Adjustment in Section 7B” or “Compressor Drive

Belt Inspection and Adjustment in Section 7B”.

1, (c)

2, (a)

3, (b)

I5RW0C160007-01

4

23

1

I6RS0C1A0002-01

Page 419 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-9

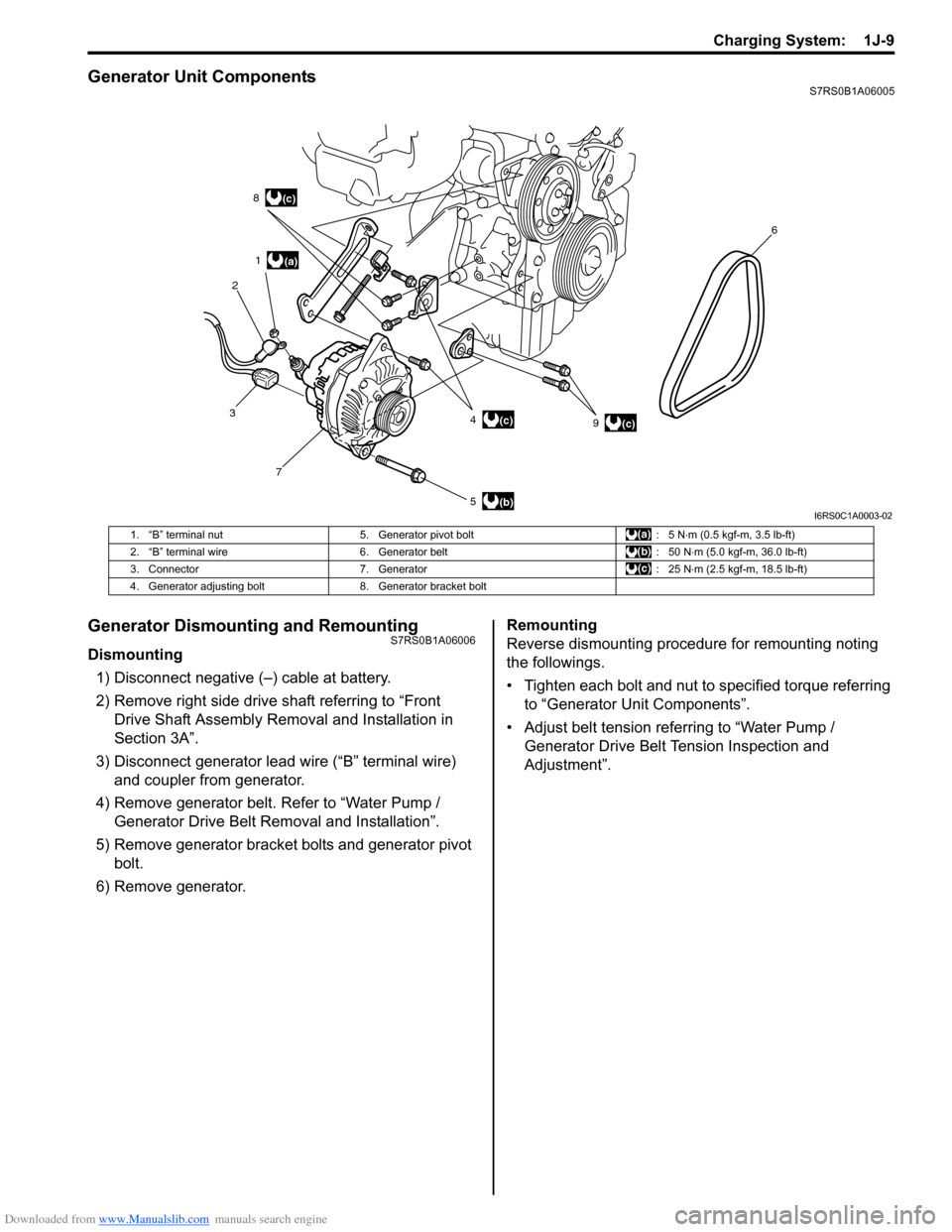

Generator Unit ComponentsS7RS0B1A06005

Generator Dismounting and RemountingS7RS0B1A06006

Dismounting1) Disconnect negative (–) cable at battery.

2) Remove right side drive shaft referring to “Front Drive Shaft Assembly Removal and Installation in

Section 3A”.

3) Disconnect generator lead wire (“B” terminal wire) and coupler from generator.

4) Remove generator belt. Refer to “Water Pump / Generator Drive Belt Re moval and Installation”.

5) Remove generator bracket bolts and generator pivot bolt.

6) Remove generator. Remounting

Reverse dismounting procedure for remounting noting

the followings.

• Tighten each bolt and nut to specified torque referring

to “Generator Unit Components”.

• Adjust belt tension referring to “Water Pump / Generator Drive Belt Tension Inspection and

Adjustment”.

(a)

(b)

(c)

1

2 8

3 7 5 49 6(c)

(c)

I6RS0C1A0003-02

1. “B” terminal nut

5. Generator pivot bolt : 5 N⋅m (0.5 kgf-m, 3.5 lb-ft)

2. “B” terminal wire 6. Generator belt : 50 N⋅m (5.0 kgf-m, 36.0 lb-ft)

3. Connector 7. Generator : 25 N⋅m (2.5 kgf-m, 18.5 lb-ft)

4. Generator adjusting bolt 8. Generator bracket bolt

Page 420 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-10 Charging System:

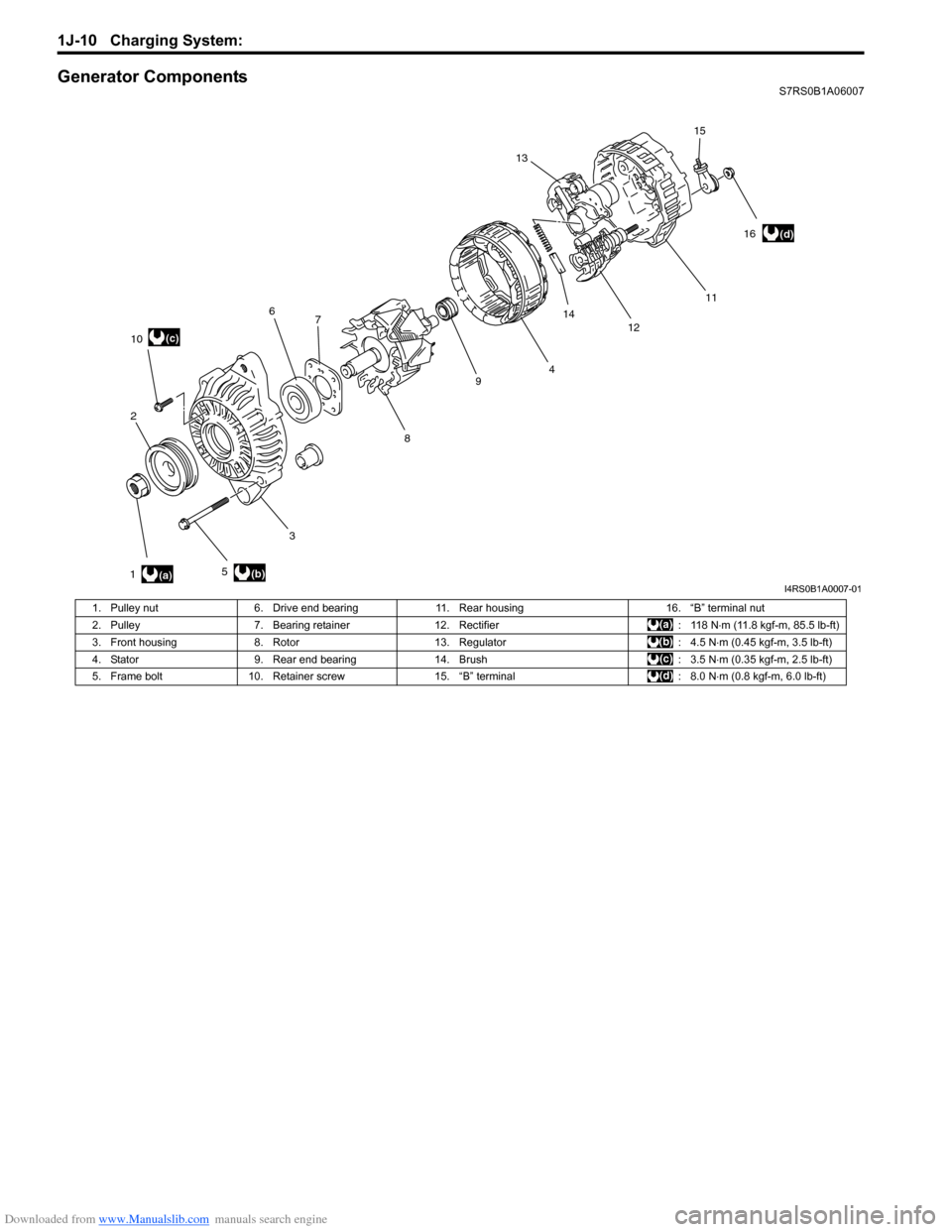

Generator ComponentsS7RS0B1A06007

1211

13

14

(a)(b)

(c)

(d)

1 2

3 4

56

7

89

10 15

16

I4RS0B1A0007-01

1. Pulley nut 6. Drive end bearing 11. Rear housing 16. “B” terminal nut

2. Pulley 7. Bearing retainer 12. Rectifier : 118 N⋅m (11.8 kgf-m, 85.5 lb-ft)

3. Front housing 8. Rotor 13. Regulator : 4.5 N⋅m (0.45 kgf-m, 3.5 lb-ft)

4. Stator 9. Rear end bearing 14. Brush : 3.5 N⋅m (0.35 kgf-m, 2.5 lb-ft)

5. Frame bolt 10. Retainer screw 15. “B” terminal : 8.0 N⋅m (0.8 kgf-m, 6.0 lb-ft)

Page 421 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-11

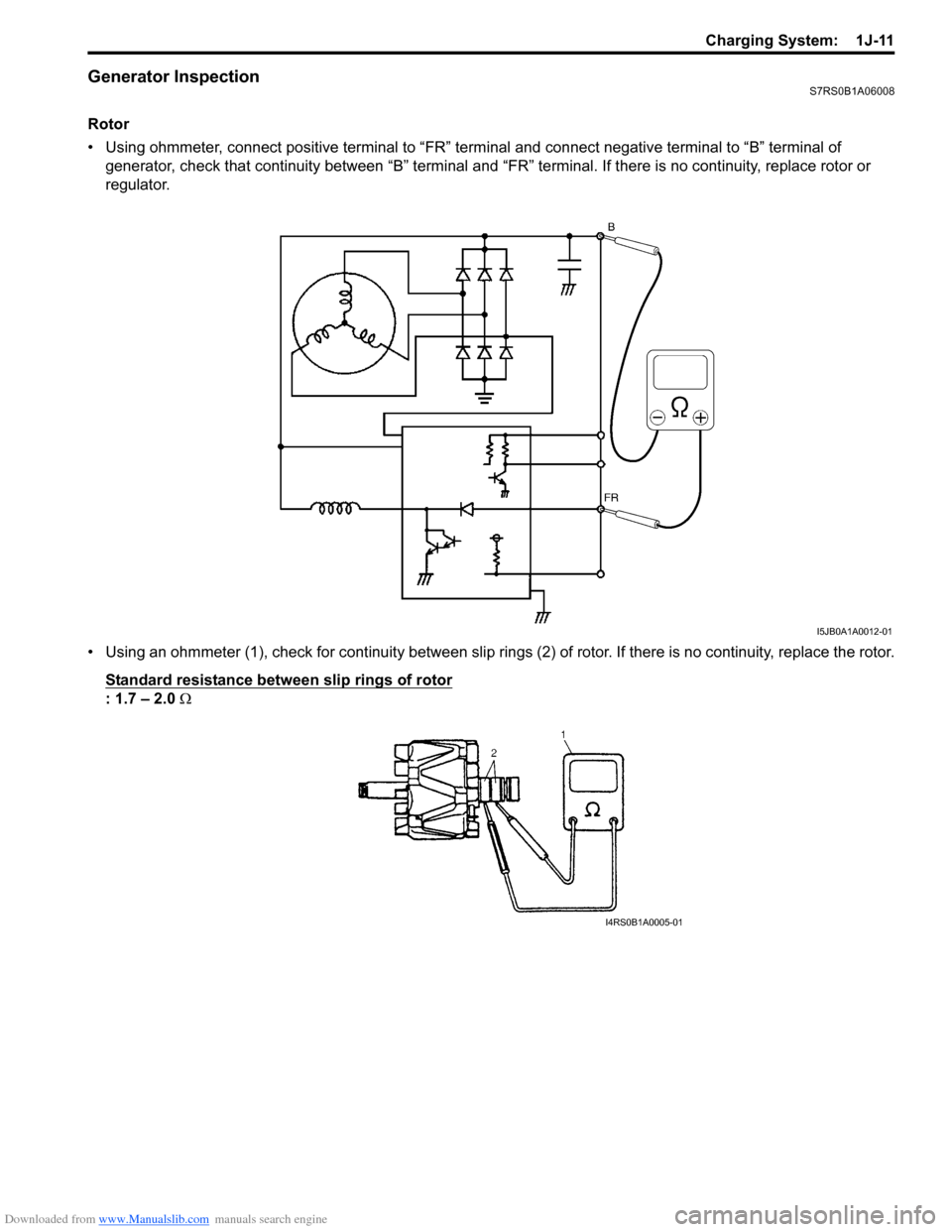

Generator InspectionS7RS0B1A06008

Rotor

• Using ohmmeter, connect positive terminal to “FR” terminal and connect negative terminal to “B” terminal of generator, check that continuity between “B” terminal and “FR” terminal. If there is no continuity, replace rotor or

regulator.

• Using an ohmmeter (1), check for continuity between slip ring s (2) of rotor. If there is no continuity, replace the rotor.

Standard resistance between slip rings of rotor

: 1.7 – 2.0 Ω

I5JB0A1A0012-01

I4RS0B1A0005-01

Page 422 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-12 Charging System:

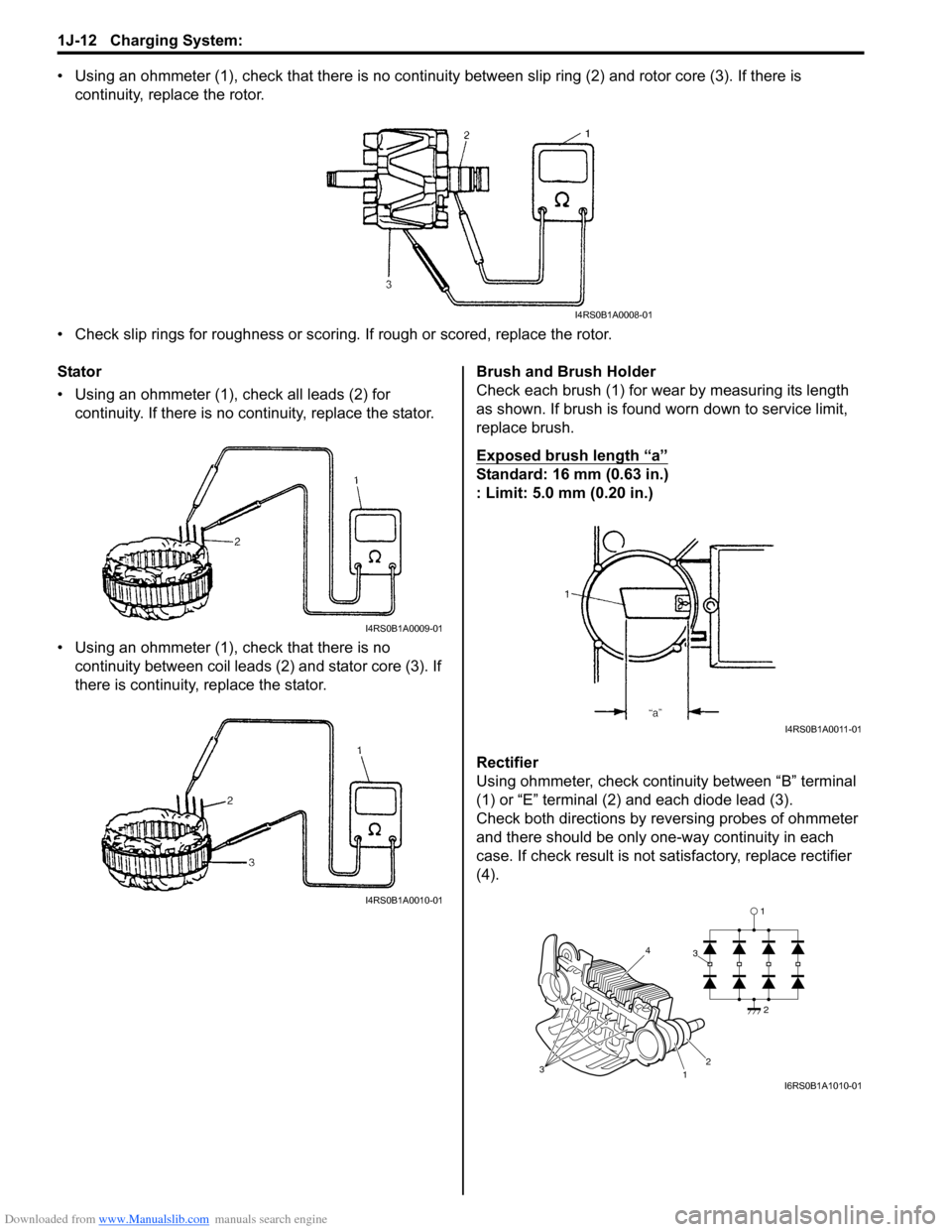

• Using an ohmmeter (1), check that there is no continuity between slip ring (2) and rotor core (3). If there is

continuity, replace the rotor.

• Check slip rings for roughness or scoring. If rough or scored, replace the rotor.

Stator

• Using an ohmmeter (1), check all leads (2) for continuity. If there is no co ntinuity, replace the stator.

• Using an ohmmeter (1), check that there is no continuity between coil leads (2) and stator core (3). If

there is continuity, replace the stator. Brush and Brush Holder

Check each brush (1) for wear by measuring its length

as shown. If brush is found worn down to service limit,

replace brush.

Exposed brush length “a”

Standard: 16 mm (0.63 in.)

: Limit: 5.0 mm (0.20 in.)

Rectifier

Using ohmmeter, check continuity between “B” terminal

(1) or “E” terminal (2) and each diode lead (3).

Check both directions by reversing probes of ohmmeter

and there should be only one-way continuity in each

case. If check result is not satisfactory, replace rectifier

(4).

I4RS0B1A0008-01

I4RS0B1A0009-01

I4RS0B1A0010-01

I4RS0B1A0011-01

1

1

3 3

2

2

4

I6RS0B1A1010-01

Page 423 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-13

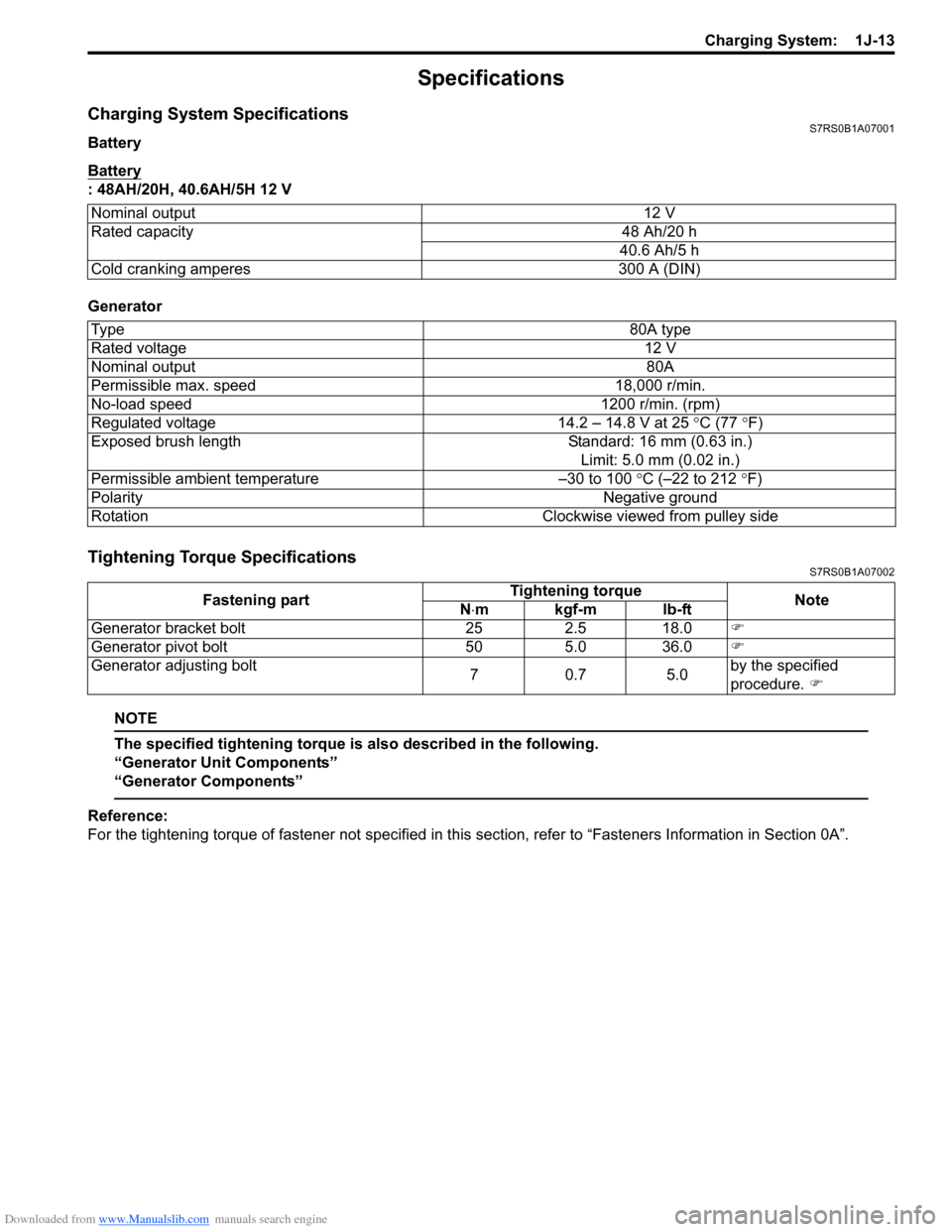

Specifications

Charging System SpecificationsS7RS0B1A07001

Battery

Battery

: 48AH/20H, 40.6AH/5H 12 V

Generator

Tightening Torque SpecificationsS7RS0B1A07002

NOTE

The specified tightening torque is also described in the following.

“Generator Unit Components”

“Generator Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Nominal output

12 V

Rated capacity 48 Ah/20 h

40.6 Ah/5 h

Cold cranking amperes 300 A (DIN)

Ty p e 80A type

Rated voltage 12 V

Nominal output 80A

Permissible max. speed 18,000 r/min.

No-load speed 1200 r/min. (rpm)

Regulated voltage 14.2 – 14.8 V at 25 ° C (77 °F)

Exposed brush length Standard: 16 mm (0.63 in.)

Limit: 5.0 mm (0.02 in.)

Permissible ambient temperature –30 to 100 °C (–22 to 212 °F)

Polarity Negative ground

Rotation Clockwise viewed from pulley side

Fastening partTightening torque

Note

N ⋅mkgf-mlb-ft

Generator bracket bolt 25 2.5 18.0 �)

Generator pivot bolt 50 5.0 36.0 �)

Generator adjusting bolt 70.7 5.0by the specified

procedure.

�)

Page 516 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-18 Brake Control System and Diagnosis:

10) Check pedal height and play referring to “Brake Pedal Free Height Inspection” and “Brake Pedal

Play Inspection”.

11) Check each installed part for fluid leakage and perform brake test.

12) Evacuate and charge refrigerant by referring to “Evacuating of A/C Syst em” and “Procedure of

Charging” under “Operation Procedure for

Refrigerant Charge in Section 7B” or “Operation

Procedure for Refrigerant Charge in Section 7B”.

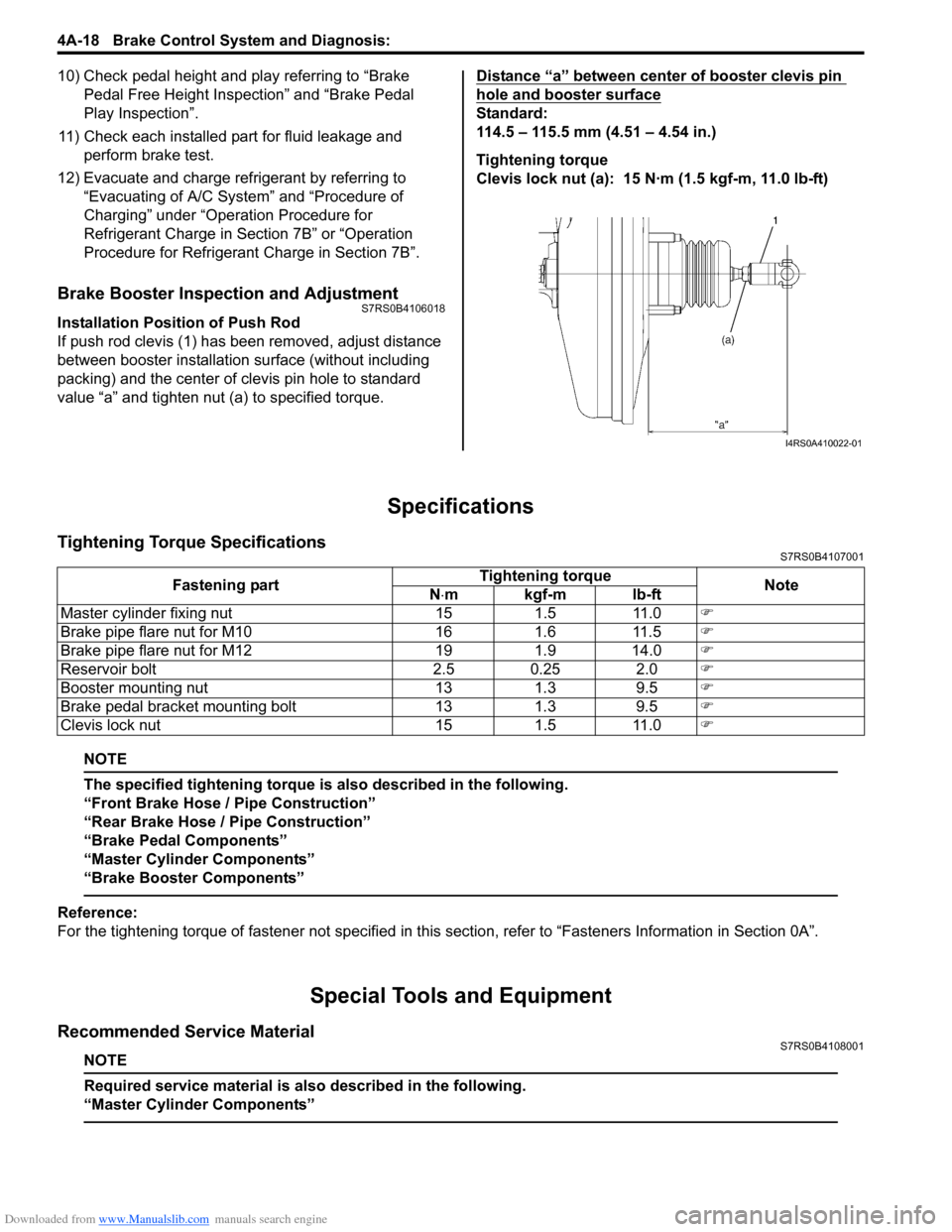

Brake Booster Inspection and AdjustmentS7RS0B4106018

Installation Position of Push Rod

If push rod clevis (1) has b een removed, adjust distance

between booster installation surface (without including

packing) and the center of clevis pin hole to standard

value “a” and tighten nut (a) to specified torque. Distance “a” between center of booster clevis pin

hole and booster surface

Standard:

114.5 – 115.5 mm (4.51 – 4.54 in.)

Tightening torque

Clevis lock nut (a): 15 N·m (1.5 kgf-m, 11.0 lb-ft)

Specifications

Tightening Torque SpecificationsS7RS0B4107001

NOTE

The specified tightening torque is also described in the following.

“Front Brake Hose / Pipe Construction”

“Rear Brake Hose / Pipe Construction”

“Brake Pedal Components”

“Master Cylinder Components”

“Brake Booster Components”

Reference:

For the tightening torque of fastener not specified in this

section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B4108001

NOTE

Required service material is also described in the following.

“Master Cylinder Components”

I4RS0A410022-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Master cylinder fixing nut 15 1.5 11.0 �)

Brake pipe flare nut for M10 16 1.6 11.5 �)

Brake pipe flare nut for M12 19 1.9 14.0 �)

Reservoir bolt 2.5 0.25 2.0 �)

Booster mounting nut 13 1.3 9.5 �)

Brake pedal bracket mounting bolt 13 1.3 9.5 �)

Clevis lock nut 15 1.5 11.0 �)

Page 560 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-21 ABS:

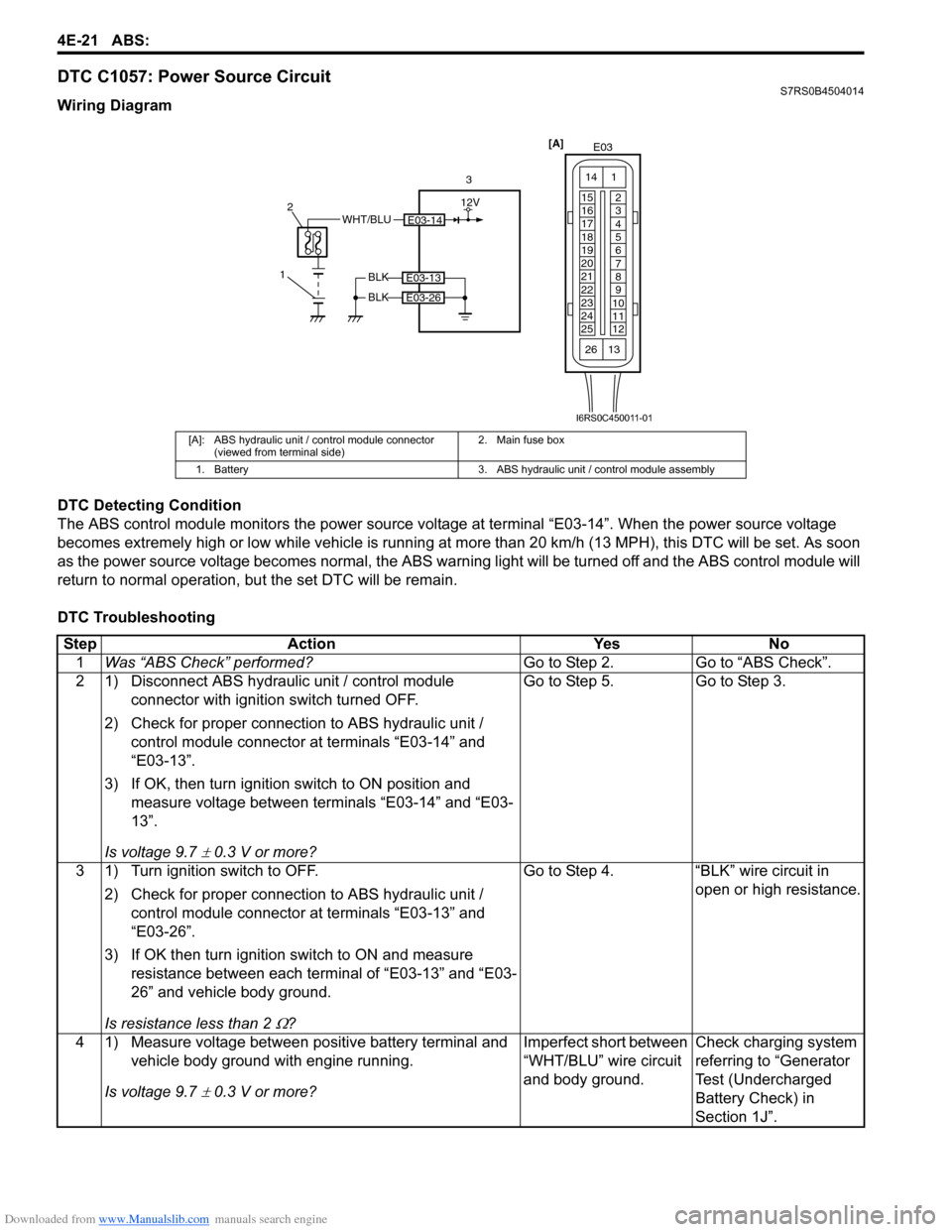

DTC C1057: Power Source CircuitS7RS0B4504014

Wiring Diagram

DTC Detecting Condition

The ABS control module monitors the power source voltage at terminal “E03-14”. When the power source voltage

becomes extremely high or low while vehicle is running at more than 20 km/h (13 MPH), this DTC will be set. As soon

as the power source volta ge becomes normal, the ABS warning light will be turned off and the ABS control module will

return to normal operation, bu t the set DTC will be remain.

DTC Troubleshooting

[A]: ABS hydraulic unit / control module connector (viewed from terminal side) 2. Main fuse box

1. Battery 3. ABS hydraulic unit / control module assembly

E03-14WHT/BLU

1 2

3

BLK

BLK

E03-13

E03-26

[A]

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

12V

I6RS0C450011-01

Step

Action YesNo

1 Was “ABS Check” performed? Go to Step 2.Go to “ABS Check”.

2 1) Disconnect ABS hydraulic unit / control module connector with ignition switch turned OFF.

2) Check for proper connection to ABS hydraulic unit / control module connector at terminals “E03-14” and

“E03-13”.

3) If OK, then turn ignition switch to ON position and measure voltage between terminals “E03-14” and “E03-

13”.

Is voltage 9.7

± 0.3 V or more? Go to Step 5. Go to Step 3.

3 1) Turn ignition switch to OFF. 2) Check for proper connection to ABS hydraulic unit / control module connector at terminals “E03-13” and

“E03-26”.

3) If OK then turn ignition switch to ON and measure resistance between each terminal of “E03-13” and “E03-

26” and vehicle body ground.

Is resistance less than 2

Ω? Go to Step 4. “BLK” wire circuit in

open or high resistance.

4 1) Measure voltage between positive battery terminal and vehicle body ground with engine running.

Is voltage 9.7

± 0.3 V or more? Imperfect short between

“WHT/BLU” wire circuit

and body ground.

Check charging system

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J”.