AIR CON SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 432 of 1496

Downloaded from www.Manualslib.com manuals search engine 2A-1 Suspension General Diagnosis:

Suspension

Suspension General Diagnosis

Diagnostic Information and Procedures

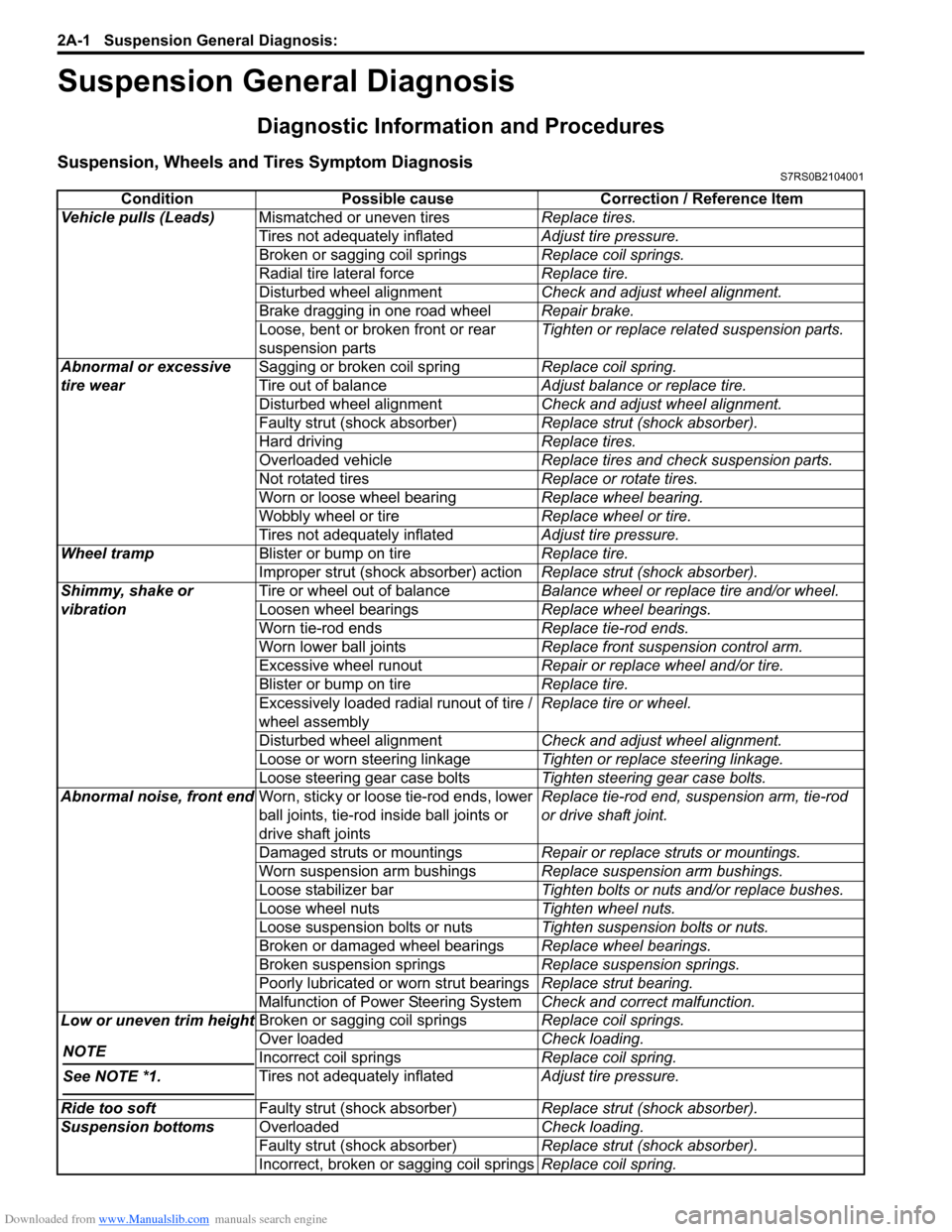

Suspension, Wheels and Tires Symptom DiagnosisS7RS0B2104001

ConditionPossible cause Correction / Reference Item

Vehicle pulls (Leads) Mismatched or uneven tires Replace tires.

Tires not adequately inflated Adjust tire pressure.

Broken or sagging coil springs Replace coil springs.

Radial tire lateral force Replace tire.

Disturbed wheel alignment Check and adjust wheel alignment.

Brake dragging in one road wheel Repair brake.

Loose, bent or broken front or rear

suspension parts Tighten or replace related suspension parts.

Abnormal or excessive

tire wear Sagging or broken coil spring

Replace coil spring.

Tire out of balance Adjust balance or replace tire.

Disturbed wheel alignment Check and adjust wheel alignment.

Faulty strut (shock absorber) Replace strut (shock absorber).

Hard driving Replace tires.

Overloaded vehicle Replace tires and check suspension parts.

Not rotated tires Replace or rotate tires.

Worn or loose wheel bearing Replace wheel bearing.

Wobbly wheel or tire Replace wheel or tire.

Tires not adequately inflated Adjust tire pressure.

Wheel tramp Blister or bump on tire Replace tire.

Improper strut (shock absorber) action Replace strut (shock absorber).

Shimmy, shake or

vibration Tire or wheel out of balance

Balance wheel or replace tire and/or wheel.

Loosen wheel bearings Replace wheel bearings.

Worn tie-rod ends Replace tie-rod ends.

Worn lower ball joints Replace front suspension control arm.

Excessive wheel runout Repair or replace wheel and/or tire.

Blister or bump on tire Replace tire.

Excessively loaded radial runout of tire /

wheel assembly Replace tire or wheel.

Disturbed wheel alignment Check and adjust wheel alignment.

Loose or worn steering linkage Tighten or replace steering linkage.

Loose steering gear case bolts Tighten steering gear case bolts.

Abnormal noise, front end Worn, sticky or loose tie-rod ends, lower

ball joints, tie-rod in side ball joints or

drive shaft joints Replace tie-rod end, su

spension arm, tie-rod

or drive shaft joint.

Damaged struts or mountings Repair or replace struts or mountings.

Worn suspension arm bushings Replace suspension arm bushings.

Loose stabilizer bar Tighten bolts or nuts and/or replace bushes.

Loose wheel nuts Tighten wheel nuts.

Loose suspension bolts or nuts Tighten suspension bolts or nuts.

Broken or damaged wheel bearings Replace wheel bearings.

Broken suspension springs Replace suspension springs.

Poorly lubricated or worn strut bearings Replace strut bearing.

Malfunction of Power Steering System Check and correct malfunction.

Low or uneven trim height

NOTE

See NOTE *1.

Broken or sagging coil springs Replace coil springs.

Over loaded Check loading.

Incorrect coil springs Replace coil spring.

Tires not adequately inflated Adjust tire pressure.

Ride too soft Faulty strut (shock absorber) Replace strut (shock absorber).

Suspension bottoms Overloaded Check loading.

Faulty strut (shock absorber) Replace strut (shock absorber).

Incorrect, broken or sagging coil springs Replace coil spring.

Page 435 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-2

Front Wheel Alignment ConstructionS7RS0B2201002

Among factors for front wheel alignment, only toe setting

can be adjusted. Camber and caster are not adjustable.

Therefore, should camber or caster be out of

specification due to the damage caused by hazardous

road conditions or collision, whether the damage is in

body or in suspension should be determined and

damaged body should be repaired or damaged

suspension should be replaced.

Preliminary Checks Prior to Adjustment Front Wheel

Alignment

Steering and vibration complaints are not always the

result of improper wheel alignment. An additional item to

be checked is the possibility of tire lead due to worn or

improperly manufactured tires. “Lead” is the vehicle

deviation from a straight path on a level road without

hand pressure on the steering wheel. Refer to “Radial

Tire Lead / Pull Description in Section 2D” in order to

determine if the vehicle has a tire lead problem. Before

making any adjustment affecting wheel alignment, the

following checks and inspections should be made to

ensure correctness of alignment readings and alignment

adjustments:

• Check all tires for proper inflation pressures and approximately the same tread wear. • Check for loose of ball join

ts. Check tie-rod ends; if

excessive looseness is noted, it must be corrected

before adjusting.

• Check for run-out of wheels and tires.

• Check vehicle trim heights; if it is out of limit and a

correction is needed, it must be done before adjusting

toe.

• Check for loose of suspension control arms.

• Check for loose or missin g stabilizer bar attachments.

• Consideration must be given to excess loads, such as

tool boxes. If this excess load is normally carried in

vehicle, it should remain in vehicle during alignment

checks.

• Consider condition of equipment being used to check alignment and follow manufa cturer’s instructions.

• Regardless of equipment used to check alignment, vehicle must be placed on a level surface.

NOTE

To prevent possible incorrect reading of toe,

camber or caster, vehicle front and rear end

must be moved up and down a few times

before inspection.

Repair Instructions

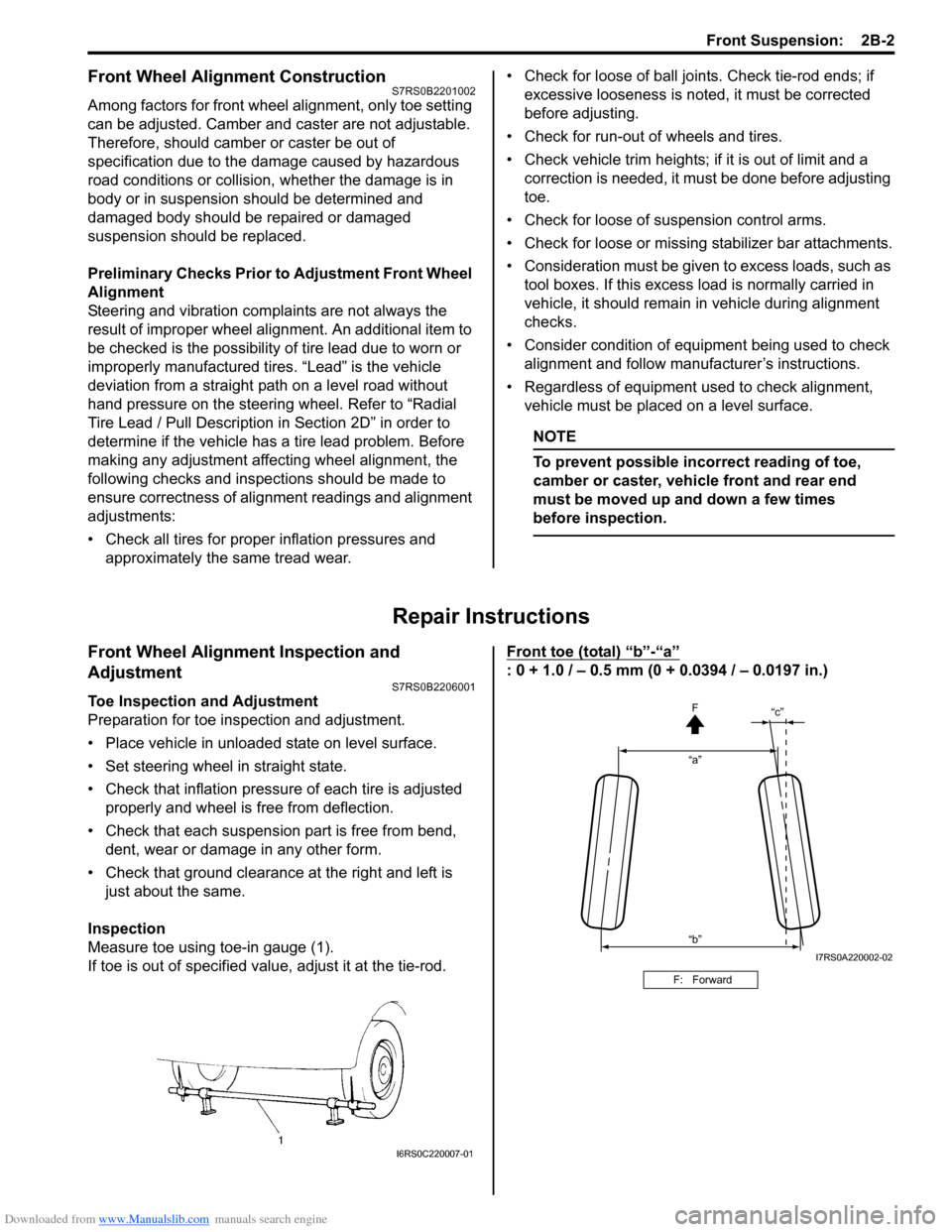

Front Wheel Alignment Inspection and

Adjustment

S7RS0B2206001

Toe Inspection and Adjustment

Preparation for toe inspection and adjustment.

• Place vehicle in unloaded state on level surface.

• Set steering wheel in straight state.

• Check that inflation pressure of each tire is adjusted properly and wheel is free from deflection.

• Check that each suspension part is free from bend, dent, wear or damage in any other form.

• Check that ground clearance at the right and left is just about the same.

Inspection

Measure toe using toe-in gauge (1).

If toe is out of specified value, adjust it at the tie-rod. Front toe (total) “b”-“a”

: 0 + 1.0 / – 0.5 mm (0 + 0.0394 / – 0.0197 in.)

I6RS0C220007-01

F: Forward

“a”

“c”

“b” F

I7RS0A220002-02

Page 448 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-15 Front Suspension:

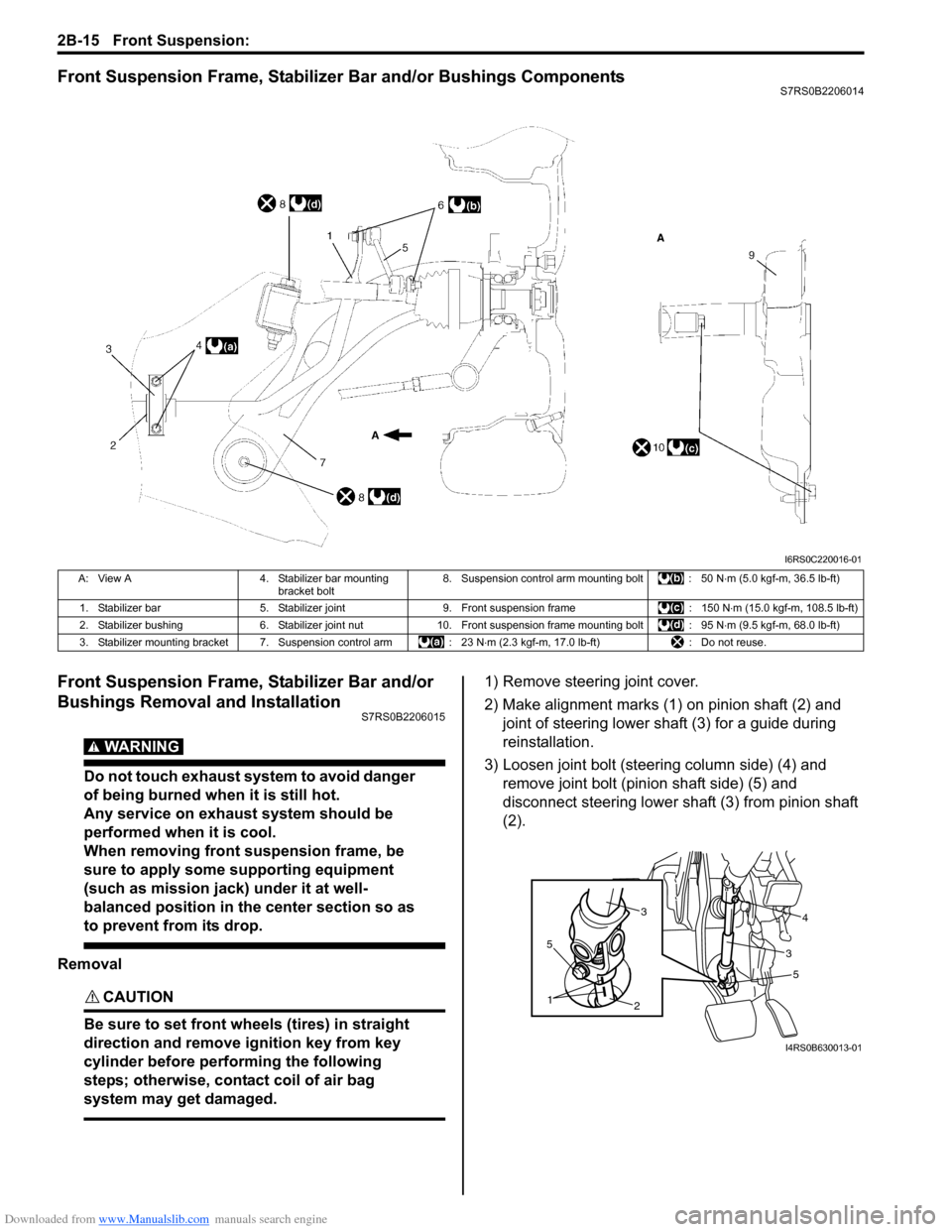

Front Suspension Frame, Stabilizer Bar and/or Bushings ComponentsS7RS0B2206014

Front Suspension Frame, Stabilizer Bar and/or

Bushings Removal and Installation

S7RS0B2206015

WARNING!

Do not touch exhaust system to avoid danger

of being burned when it is still hot.

Any service on exhaust system should be

performed when it is cool.

When removing front suspension frame, be

sure to apply some supporting equipment

(such as mission jack) under it at well-

balanced position in the center section so as

to prevent from its drop.

Removal

CAUTION!

Be sure to set front wheels (tires) in straight

direction and remove ignition key from key

cylinder before performing the following

steps; otherwise, contact coil of air bag

system may get damaged.

1) Remove steering joint cover.

2) Make alignment marks (1) on pinion shaft (2) and joint of steering lower shaft (3) for a guide during

reinstallation.

3) Loosen joint bolt (steering column side) (4) and remove joint bolt (pin ion shaft side) (5) and

disconnect steering lower shaft (3) from pinion shaft

(2).

I6RS0C220016-01

A: View A 4. Stabilizer bar mounting

bracket bolt 8. Suspension control arm mounting bolt : 50 N

⋅m (5.0 kgf-m, 36.5 lb-ft)

1. Stabilizer bar 5. Stabilizer joint 9. Front suspension frame : 150 N⋅m (15.0 kgf-m, 108.5 lb-ft)

2. Stabilizer bushing 6. Stabilizer joint nut10. Front suspension frame mounting bolt : 95 N ⋅m (9.5 kgf-m, 68.0 lb-ft)

3. Stabilizer mounting bracket 7. Suspension control arm : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft) : Do not reuse.

5

2

1

5

34

3

I4RS0B630013-01

Page 463 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-9

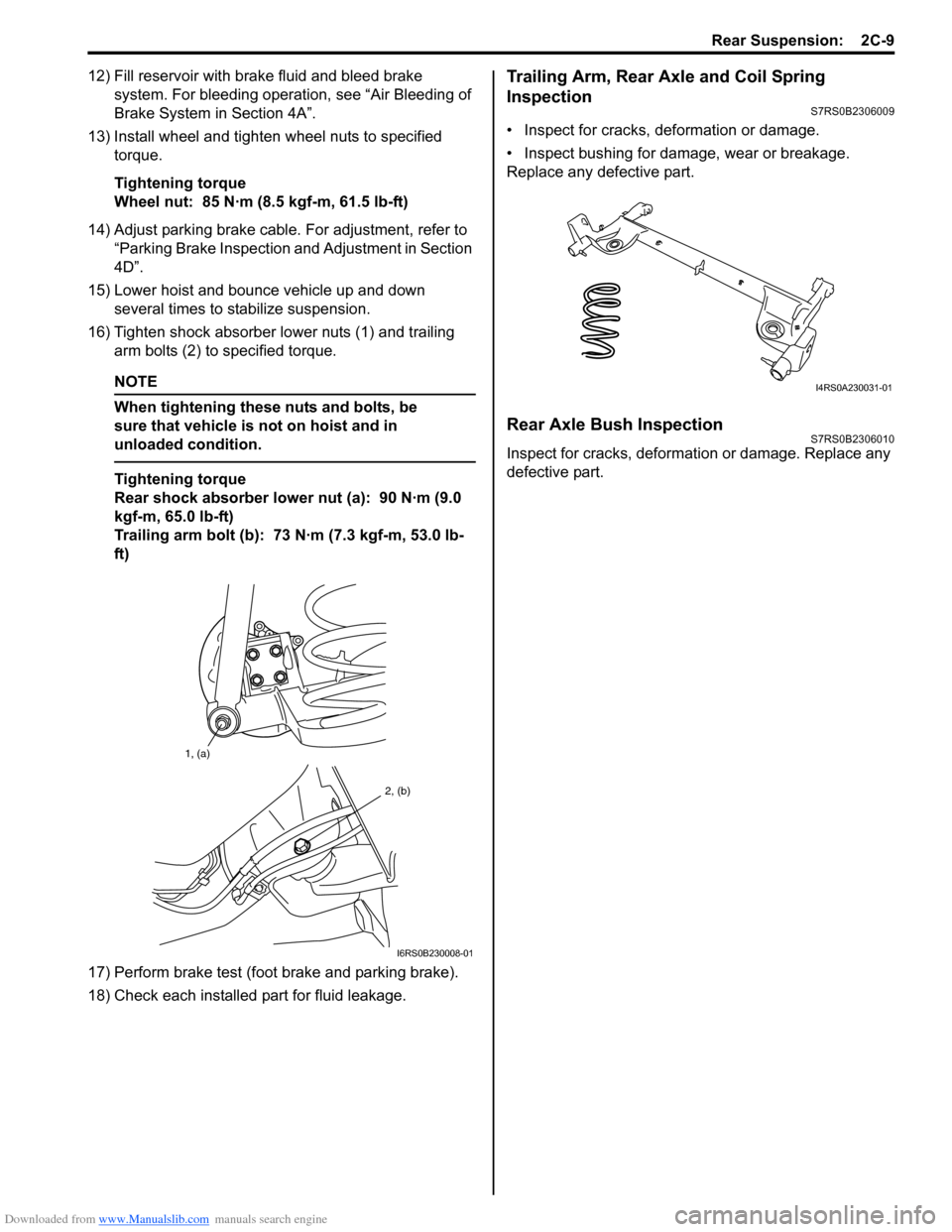

12) Fill reservoir with brake fluid and bleed brake system. For bleeding operation, see “Air Bleeding of

Brake System in Section 4A”.

13) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

14) Adjust parking brake cable. For adjustment, refer to “Parking Brake Inspection and Adjustment in Section

4D”.

15) Lower hoist and bounce vehicle up and down several times to stabilize suspension.

16) Tighten shock ab sorber lower nuts (1) and trailing

arm bolts (2) to specified torque.

NOTE

When tightening these nuts and bolts, be

sure that vehicle is not on hoist and in

unloaded condition.

Tightening torque

Rear shock absorber lower nut (a): 90 N·m (9.0

kgf-m, 65.0 lb-ft)

Trailing arm bolt (b): 73 N·m (7.3 kgf-m, 53.0 lb-

ft)

17) Perform brake test (foot brake and parking brake).

18) Check each installed part for fluid leakage.

Trailing Arm, Rear Axle and Coil Spring

Inspection

S7RS0B2306009

• Inspect for cracks, deformation or damage.

• Inspect bushing for damage, wear or breakage.

Replace any defective part.

Rear Axle Bush InspectionS7RS0B2306010

Inspect for cracks, deformation or damage. Replace any

defective part.

1, (a)

2, (b)

I6RS0B230008-01

I4RS0A230031-01

Page 468 of 1496

Downloaded from www.Manualslib.com manuals search engine 2D-1 Wheels and Tires:

Suspension

Wheels and Tires

Precautions

Precaution for Emergency Flat Tire Repair KitS7RS0B2400001

WARNING!

Flat tire repair sealant including in kit is

harmful. Be sure to observe the following.

Otherwise, your health may be ruined.

• If swallowed, get medical attention immediately.

• Keep out of reach of children.

• Select place where there is good ventilation for this work.

• If it enters eye or contacts skin, wash thoroughly with water. If anything

abnormal still rema ins, get medical

attention immediately.

• Do not discard tire containing sealant as it is. Make sure to remove sealant from tire,

referring to “Tire Repair for Emergency

Repaired-Tire with Sealant”.

• Dispose of sealant as waste oil.

CAUTION!

• When tire repaired with Emergency Flat Tire Repair Kit is brought in, remove flat

tire repair sealant from tire and repair flat

tire referring to “Tire Repair for Emergency

Repaired-Tire with Sealant”.

• Sealant expiration date is printed on bottle label. if it expires, sealant should be

replaced with a new one to ensure

emergency flat tire repair.

General Description

Tires DescriptionS7RS0B2401001

The tire is of tubeless type. The tire is designed to

operate satisfactorily with loads up to the full rated load

capacity when inflated to the recommended inflation

pressures.

Correct tire pressures and driving habits have an

important influence on tire life. Heavy cornering,

excessively rapid acceleration, and unnecessary sharp

braking increase tire wear.

Tire Placard

The “Tire Placard” is located on the left or right door lock

pillar and should be referred to tire information.

The placard lists the maximum load, tire size and cold

tire pressure where applicable.

NOTE

Whether rim size and/or maximum load are

listed or not depends on regulations of each

country.

Inflation of Tires

The pressure recommended for any model is carefully

calculated to give a satisfacto ry ride, stability, steering,

tread wear, tire life and resistance to bruises.

Tire pressure, with tires cold, (after vehicle has set for 3

hours or more, or driven less than one mile) should be

checked monthly or before any extended trip. Set to the

specifications on the “Tire Placard” located on the left

door lock pillar.

It is normal for tire pressure to increase when the tires

become hot during driving.

Do not bleed or reduce tire pressure after driving.

Bleeding reduces the “Cold Inflation Pressure”.

Higher than recommended pressure can cause:

• Hard ride

• Tire bruising or carcass damage

• Rapid tread wear at center of tire

Unequal pressure on same axle can cause:

• Uneven braking

• Steering lead

• Reduced handling

• Swerve on acceleration

Page 469 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-2

Lower than recommended pressure can cause:

• Tire squeal on turns

• Hard Steering

• Rapid and uneven wear on the edges of the tread

• Tire rim bruises and rupture

• Tire cord breakage

• High tire temperature

• Reduced handling

• High fuel consumption

Replacement Tires

When replacement is necessary, the original equipment

type tire should be used. Refer to the Tire Placard.

Replacement tires should be of the same size, load

range and construction as those originally on the vehicle.

Use of any other size or type tire may affect ride,

handling, speedometer / odometer calibration, vehicle

ground clearance and tire or snow chain clearance to the

body and chassis.

It is recommended that new tires be installed in pairs on

the same axle. If necessary to replace only one tire, it

should be paired with the tire having the most tread, to

equalize braking traction.

WARNING!

Do not mix different types of tires on the

same vehicle such as radial, bias and bias-

belted tires except in emergencies, because

handling may be seriously affected and may

result in loss of control.

The metric term for tire infl ation pressure is the kilo

pascal (kPa). Tire pressures is usually printed in both

kPa and kgf/cm

2 on the “Tire Placard”.

Metric tire gauges are available from tool suppliers.

The chart, shown the table, converts commonly used

inflation pressures from kPa to kgf/cm

2 and psi.

Wheels DescriptionS7RS0B2401002

Wheel Maintenance

Wheel repairs that use welding, heating, or peening are

not approved. All damaged wheels should be replaced.

Replacement Wheels

Wheels must be replaced if they are bent, dented, have

excessive lateral or radial runout, air leak through welds,

have elongated bolt holes, if lug wheel bolts won’t stay

tight, or if they are heavily rusted. Wheels with greater

runout than shown in the following may cause

objectional vibrations.

Replacement wheels must be equivalent to the original

equipment wheels in load capacity, diameter, rim with

offset and mounting configuration. A wheel of improper

size or type may affect wheel and bearing life, brake

cooling, speedometer / odometer calibration, vehicle

ground clearance and tire clearance to body and

chassis.

How to Measure Wheel Runout

To measure the wheel runout, it is necessary to use an

accurate dial indicator. The tire may be on or off the

wheel. The wheel should be installed to the wheel

balancer of the like for proper measurement.

Take measurements of both lateral runout “a” and radial

runout “b” at both inside an d outside of the rim flange.

With the dial indicator set in place securely, turn the

wheel one full revolution slowly and record every reading

of the indicator.

When the measured runout exceeds the specification

and correction by the balancer adjustment is impossible,

replace the wheel. If the reading is affected by welding,

paint or scratch, it should be ignored.

Lateral runout limit “a”

: 0.3 mm (0.012 in.)

Radial runout limit “b”

: 0.3 mm (0.012 in.)

kPa kgf/cm2psi

Conversion: 1 psi =

6.895 kPa 1 kgf/cm

2 =

98.066 kPa 160 1.6 23

180 1.8 26

200 2.0 29

220 2.2 32

240 2.4 35

260 2.6 38

280 2.8 41

300 3.0 44

I4RS0A240001-01

Page 473 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-6

Repair Instructions

General Balance ProceduresS7RS0B2406001

Deposits of mud, etc. must be cleaned from inside of rim.

WARNING!

Stones should be removed from the tread in

order to avoid operator injury during spin

balancing and to obtain good balance.

Each tire should be inspected for any damage, then

balanced according to equipment manufacturer’s

recommendation.

Off-Vehicle Balancing

Most electronic off-vehicle balancers are more accurate

than the on-vehicle spin balancers. They are easy to use

and give a dynamic (two plane) balance. Although they

do not correct for drum or disc unbalance as does on-

vehicle spin balancing, this is overcome by their

accuracy, usually to within 1/8 ounce.

On-Vehicle Balancing

On-vehicle balancing methods vary with equipment and

tool manufacturers. Be sure to follow each

manufacturer’s instructions during balancing operation.

WARNING!

Wheel spin should be limited to 55 km/h (35

mph) as indicated on speedometer.

This limit is necessary because speedometer

only indicates one-half of actual wheel speed

when one drive wheel is spinning and the

other drive wheel is stopped.

Unless care is taken in limiting drive wheel

spin, spinning wheel can reach excessive

speeds. This can result in possible tire

disintegration or differential failure, which

could cause serious personal injury or

extensive vehicle damage.

CAUTION!

Using on-vehicle balancing method with

ignition switch ON may set malfunction

diagnostic trouble code (DTC) of ESP® and

ABS even when system is in good condition.

Never turn ignition swit ch ON while spinning

wheel.

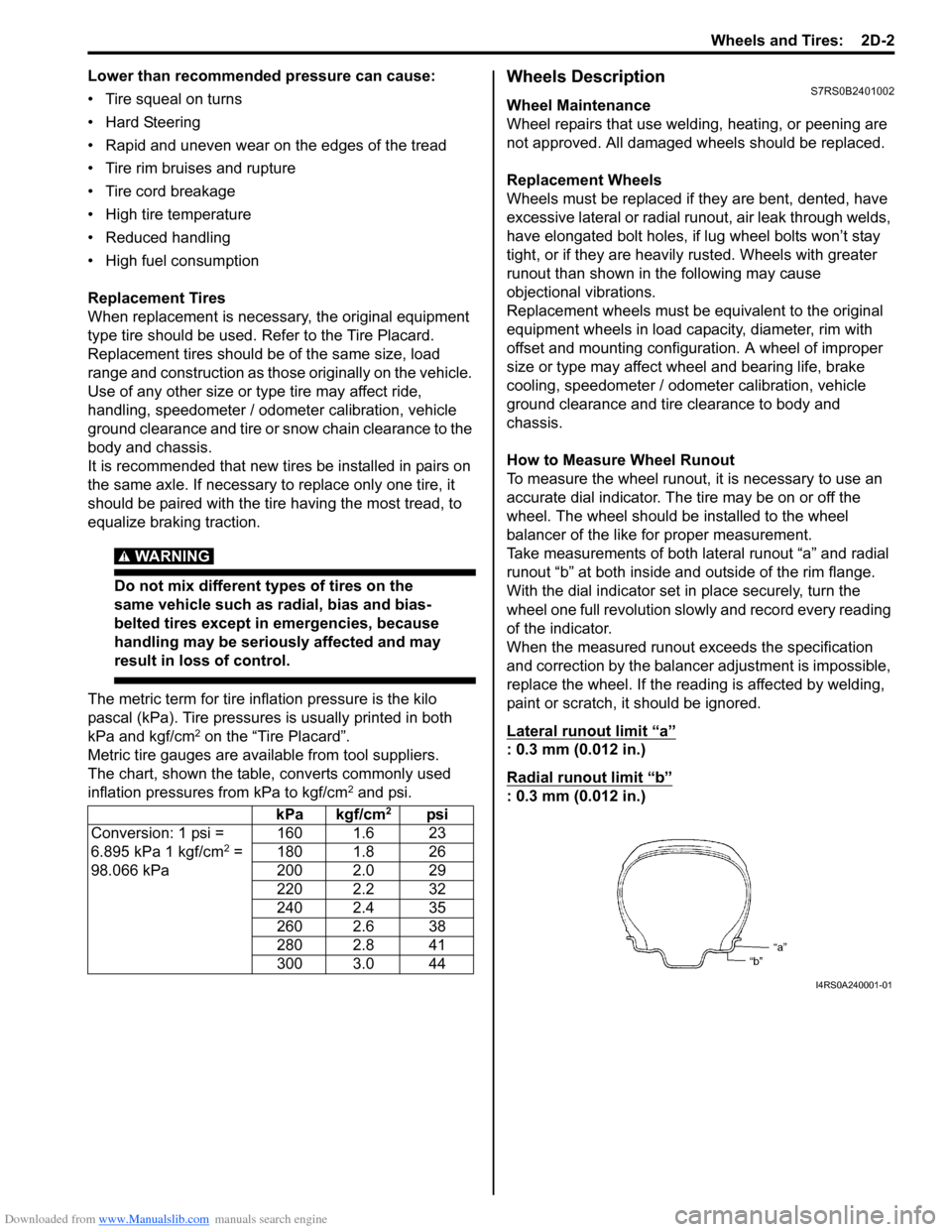

Tire RotationS7RS0B2406002

To equalize wear, rotate tires according to figure. Radial

tires should be rotated periodi cally. Set tire pressure.

[A]: Rotation direction is not indicated.

[B]: Rotation direction is indicated.

I6RS0C240002-01

Page 475 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-8

Tire Mounting and DismountingS7RS0B2406004

CAUTION!

When installing tire which has arrow

indicating tire rotation direction to wheel,

make sure that this tire rotation direction is

same as actual tire rotation direction when

vehicle is moving forward. Otherwise, it is

not possible to install wheel with tire to

vehicle in specified direction.

Use a tire changing machine to mount or dismount tires.

Follow equipment manufacturer’s instructions. Do not

use hand tools or tire irons al one to change tires as they

may damage tire beads or wheel rim.

Rim bead seats should be cleaned with a wire brush or

coarse steel wool to remove lubricants, old rubber and

light rust. Before mounting or dismounting a tire, bead

area should be well lubricated with approved tire

lubricant.

After mounting, inflate to specified pressure shown on

tire placard so that beads are completely seated.

WARNING!

Do not stand over tire when inflating. Bead

may break when bead snaps over rim’s safety

hump and cause serious personal injury.

Do not exceed 330 kpa (47.9 psi) pressure

when inflating. If 330 kpa (47.9 psi) pressure

will not seat beads, deflate, re-lubricate and

reinflate.

Over inflation may cause bead to break and

cause serious personal injury.

Install valve core and inflate to proper pressure.

Tire RepairS7RS0B2406005

There are many different materials and techniques on

the market to repair tires. As not all of these work on all

types of tires, tire manufacturers have published detailed

instructions on how and when to repair tires. These

instructions can be obtained from each tire

manufacturer.

Tire Repair for Emergency Repaired-Tire with

Sealant

S7RS0B2406006

WARNING!

Be sure to observe “Precaution for

Emergency Flat Tire Repair Kit”. Otherwise,

your health may be ruined.

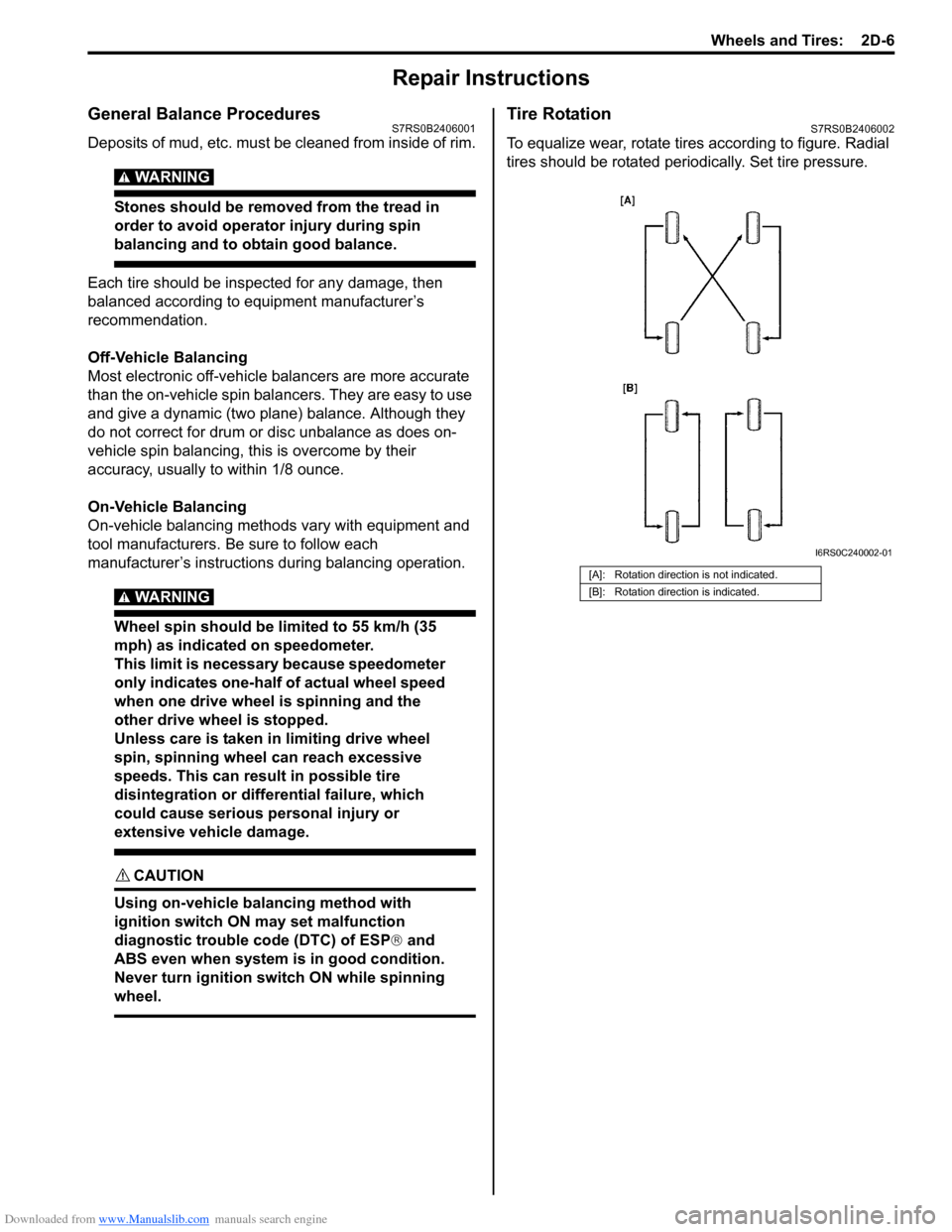

1) Remove flat tire repair sealant from tire using plug (1), filler hose (2), sealant bottle (3) and extension

hose (4) in kit as follows.

a) Remove plug from fille r hose of sealant bottle.

Then connect ext ension hose to tip of filler hose.

b) Remove tire containing flat tire repair sealant from vehicle.

c) Loosen valve core carefully to release air.

WARNING!

Take care not to make sealant blast out from

valve. Otherwise, your health may be ruined.

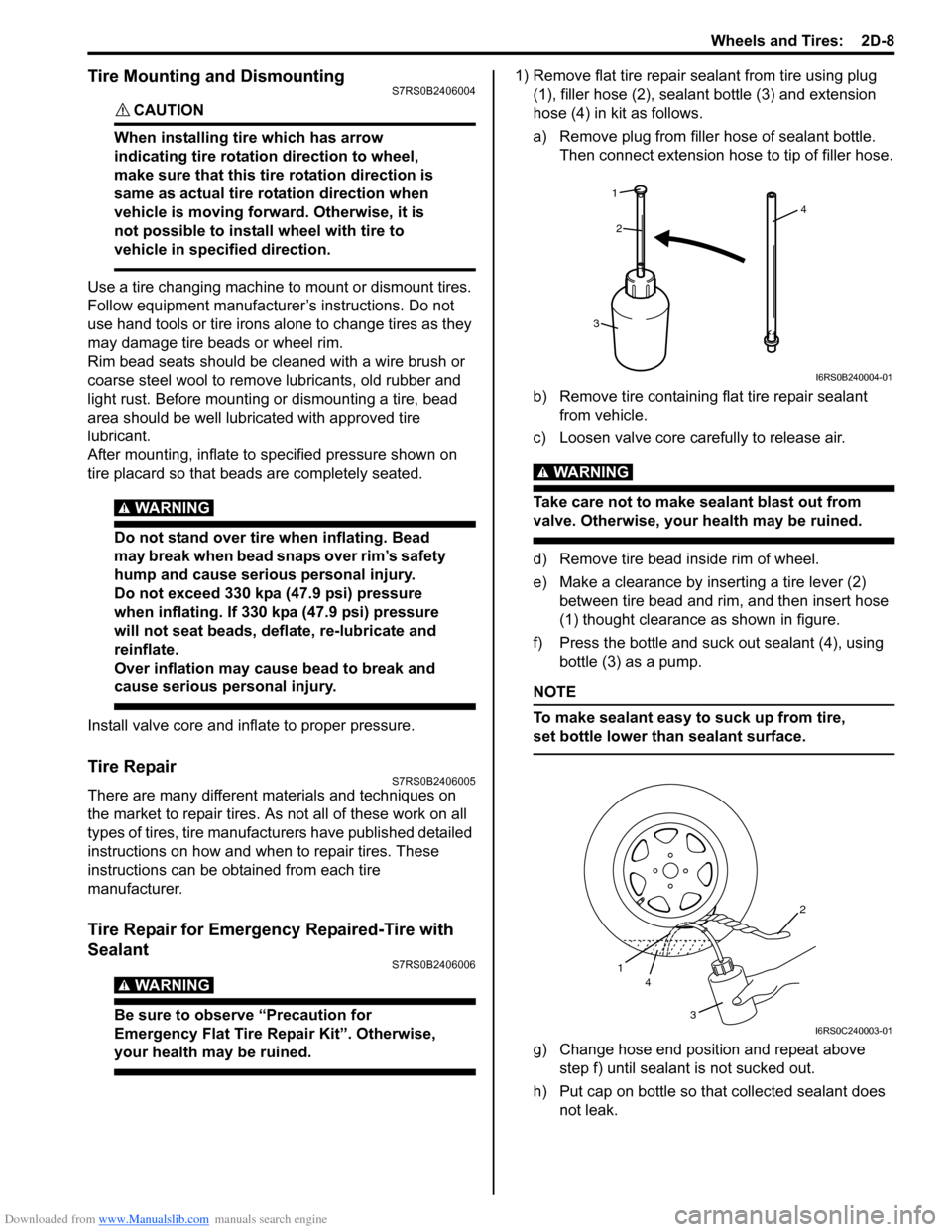

d) Remove tire bead inside rim of wheel.

e) Make a clearance by inserting a tire lever (2) between tire bead and rim, and then insert hose

(1) thought clearance as shown in figure.

f) Press the bottle and suck out sealant (4), using bottle (3) as a pump.

NOTE

To make sealant easy to suck up from tire,

set bottle lower than sealant surface.

g) Change hose end position and repeat above step f) until sealant is not sucked out.

h) Put cap on bottle so that collected sealant does not leak.

4

1

2

3

I6RS0B240004-01

1 4

3 2

I6RS0C240003-01

Page 477 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 3- i

3

Section 3

CONTENTS

Driveline / Axle

Precautions ................................................. 3-1

Precautions............................................................. 3-1

Precautions for Driveline / Axle ............................. 3-1

Drive Shaft / Axle .......... ........................... 3A-1

General Description ............................................. 3A-1

Front Drive Shaft Construction ............................ 3A-1

Component Locatio n ........................................... 3A-1

Front Drive Shaft Assembly Components Location ............................................................ 3A-1

Diagnostic Information and Procedures ............ 3A-2 Front Drive Shaft Symptom Diagnosis ................ 3A-2

Repair Instructions .............................................. 3A-3 Front Drive Shaft Components ........................... 3A-3 Front Drive Shaft Assembly On-Vehicle

Inspection .......................................................... 3A-4

Front Drive Shaft Assembly Removal and Installation ......................................................... 3A-4

Front Drive Shaft Disassembly and Reassembly ...................................................... 3A-6

Center Shaft and Center Bearing Support Disassembly and Reassembly ........................ 3A-14

Specifications .................... .................................3A-15

Tightening Torque Specifications ...................... 3A-15

Special Tools and Equipmen t ...........................3A-15

Recommended Service Material ....................... 3A-15

Special Tool ...................................................... 3A-15

Page 495 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 4- i

4

Section 4

CONTENTS

Brakes

Precautions ................................................. 4-1

Precautions............................................................. 4-1

Precautions for Brakes .......................................... 4-1

Brake Control System and Diagnosis ... 4A-1

Precautions........................................................... 4A-1Precautions on Brake .......................................... 4A-1

General Description ............................................. 4A-1 Brakes Construction ............................................ 4A-1

Brake Pedal Foot Protection System Construction ...................................................... 4A-2

Front Brake Hose / Pipe Co nstruction................. 4A-3

Rear Brake Hose / Pipe Construction ................. 4A-4

Diagnostic Information and Procedures ............ 4A-4 Brakes Diagnosis Note ....................................... 4A-4

Brakes Symptom Diagnosis ................................ 4A-5

Repair Instructions .............................................. 4A-7 Brake Pedal Components ................................... 4A-7

Brake Pedal Free Height Inspection ................... 4A-7

Brake Pedal Play Inspection ............................... 4A-7

Excessive Pedal Travel Inspection ..................... 4A-8

Brake Fluid Level Inspection ............................... 4A-8

Stop Light Switch Adjustment ............................. 4A-8

Air Bleeding of Brake System ............................. 4A-9

Front Brake Hose / Pipe Removal and Installation ....................................................... 4A-10

Rear Brake Hose / Pipe Removal and Installation ....................................................... 4A-10

Brake Hose and Pipe Inspection ....................... 4A-11

Master Cylinder Components............................ 4A-11

Master Cylinder Assembly Removal and Installation ....................................................... 4A-12

Master Cylinder Rese rvoir Removal and

Installation ....................................................... 4A-13

Master Cylinder Assemb ly Disassembly and

Assembly ........................................................ 4A-14

Master Cylinder Assembly Inspection ............... 4A-15

Brake Booster Components .............................. 4A-15

Booster Operation Inspection ........................... 4A-16

Brake Booster Removal and Installation ........... 4A-17

Brake Booster Inspection and Adjustment ........ 4A-18

Specifications ..................................................... 4A-18

Tightening Torque Specifications ...................... 4A-18

Special Tools and Equipmen t ........................... 4A-18 Recommended Service Material ....................... 4A-18

Front Brakes .......

..................................... 4B-1

Repair Instructions ........... ...................................4B-1

Front Disc Brake Components ............................ 4B-1

Front Disc Brake Pad On-Vehicle Inspection ...... 4B-2

Front Disc Brake Pad Removal and Installation ......................................................... 4B-2

Front Disc Brake Pad Inspection......................... 4B-3

Front Disc Brake Ca liper Removal and

Installation ......................................................... 4B-3

Front Disc Brake Caliper Disassembly and Assembly........................................................... 4B-4

Front Disc Brake Caliper In spection.................... 4B-6

Front Brake Disc Removal and Installation ......... 4B-6

Front Brake Disc Inspection ................................ 4B-7

Specifications .................... ...................................4B-8

Tightening Torque Specifications ........................ 4B-8

Special Tools and Equipmen t .............................4B-8

Recommended Service Material ......................... 4B-8

Special Tool ........................................................ 4B-8

Rear Brakes................... ........................... 4C-1

Repair Instructions ........... ...................................4C-1

Rear Disc Brake Components.............................4C-1

Rear Disc Brake Pad Removal and Installation .........................................................4C-2

Rear Disc Brake Caliper Removal and Installation .........................................................4C-3

Rear Disc Brake Pad Inspection .........................4C-6

Rear Disc Brake Caliper Disassembly and Assembly...........................................................4C-6

Rear Disc Brake Caliper Inspection ....................4C-8

Rear Flexible Hose Remova l and Installation .....4C-8

Rear Brake Disc Removal and Installation..........4C-9

Rear Brake Disc Inspection.................................4C-9

Specifications .................... .................................4C-10

Tightening Torque Specifications ......................4C-10

Special Tools and Equipmen t ...........................4C-11

Recommended Service Material .......................4C-11

Special Tool ......................................................4C-11

Parking Brake ................. ......................... 4D-1

General Description .............................................4D-1

Parking Brake Cable Construction ......................4D-1