AIR CON SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 549 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-10

Problem symptom confirmation

Check if what the customer claimed in “Customer

Questionnaire” is actually found in the vehicle and if that

symptom is found, whether it is identified as a failure.

(This step should be shared with the customer if

possible.) Check warning lights related to brake system

referring to “EBD Warning Light (Brake Warning Light)

Check” and “ABS Warning Light Check”.

DTC check, record and clearance

Perform “DTC Check” proced ure, record it and then

clear it referring to “DTC Clearance”.

Recheck DTC referring to “DTC Check”.

When DTC which is recorded at DTC check procedure is

detected again after performi ng DTC clearance, go to

“Step 4: ABS Check: ” to proceed the diagnosis.

When DTC which is recorded at DTC check procedure is

not indicated anymore after performing DTC clearance,

ABS control module does not perform the system

diagnosis, or temporary abnormality may occur,

therefore go to “Step 2: Driving Test: ” to proceed the

diagnosis.

Step 2: Driving Test

Test drive the vehicle at 40 km/h for more than a minute

and check if any trouble symptom (such as abnormal

lighting of ABS warn ing light) exists.

If the malfunction DTC is co nfirmed again at ignition

switch ON, driving test as described is not necessary.

Proceed to Step 3.

Step 3: DTC Check

Recheck DTC referring to “DTC Check”.

Step 4: ABS Check

According to ABS Check for the DTC confirmation in

Step 3, locate the cause of the trouble, namely in a

sensor, switch, wire harness, connector, actuator

assembly or other part and repair or replace faulty parts.

Step 5: Brakes Diagnosis

Check the parts or system suspected as a possible

cause referring to “Brakes Symptom Diagnosis in

Section 4A” and based on symptoms appearing on the

vehicle (symptom obtained through Steps 1 and 2 and

repair or replace faulty parts, if any).

Step 6: Check for Intermittent Problem

Check parts where an intermittent trouble is easy to

occur (e.g., wire harness, con nector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of trouble code recorded in Step 1

to 3.

Step 7: Final Confirmation Test

Confirm that the problem symptom has gone and the

ABS is free from any abnormal conditions. If what has

been repaired is related to the malfunction DTC, clear

the DTC once referring to “DTC Clearance” and perform

test driving and confirm that no DTC is indicated.ABS Warning Light CheckS7RS0B4504002

1) Turn ignition switch ON.

2) Check that ABS warning light (1) comes ON for

about 2 seconds and then goes off.

If any faulty condition is found, advance to “ABS

Warning Light Does Not Come ON at Ignition Switch

ON” or “ABS Warning Light Comes ON Steady”.

EBD Warning Light (Brake Warning Light)

Check

S7RS0B4504003

NOTE

Perform this check on a level place.

1) Turn ignition switch ON with parking brake applied.

2) Check that EBD warning lig ht (brake warning light)

(1) is turned ON.

3) Release parking brake with ignition switch ON and check that EBD warning lig ht (brake warning light)

goes off.

If it doesn’t go off, go to “EBD Warning Light (Brake

Warning Light) Comes ON Steady”.

11

I4RS0A450007-01

BRAKE

1

I4RS0A450008-01

Page 551 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-12

DTC ClearanceS7RS0B4504006

WARNING!

When performing a driving test, select a safe

place where there is neither any traffic nor

any traffic accident possibility and be very

careful during testing to avoid occurrence of

an accident.

After repair or replace malfunction part(s), clear all DTCs

by performing the following procedure or using SUZUKI

scan tool.

1) Connect SUZUKI scan tool to data link connector in the same manner as when making this connection

for DTC check.

2) Turn ignition switch to ON position.

3) Erase DTC according to instructions displayed on scan tool. Refer to scan tool operator’s manual for

further derails.

NOTE

For DTC C 1021, C1022, C1025, C1026, C1031,

C1032, C1035, C1036 and C1061, confirm that

ABS warning light turns off after performing

Step 2 of “Test Driving” under “ABS Check”,

and then clear the DTCs.

4) After completing the clear ance, turn ignition switch

OFF and disconnect scan tool from data link

connector.

5) Perform “Driving Test” (S tep 2 of “ABS Check”) and

“DTC Check” and confirm that NO DTC is displayed

on scan tool.

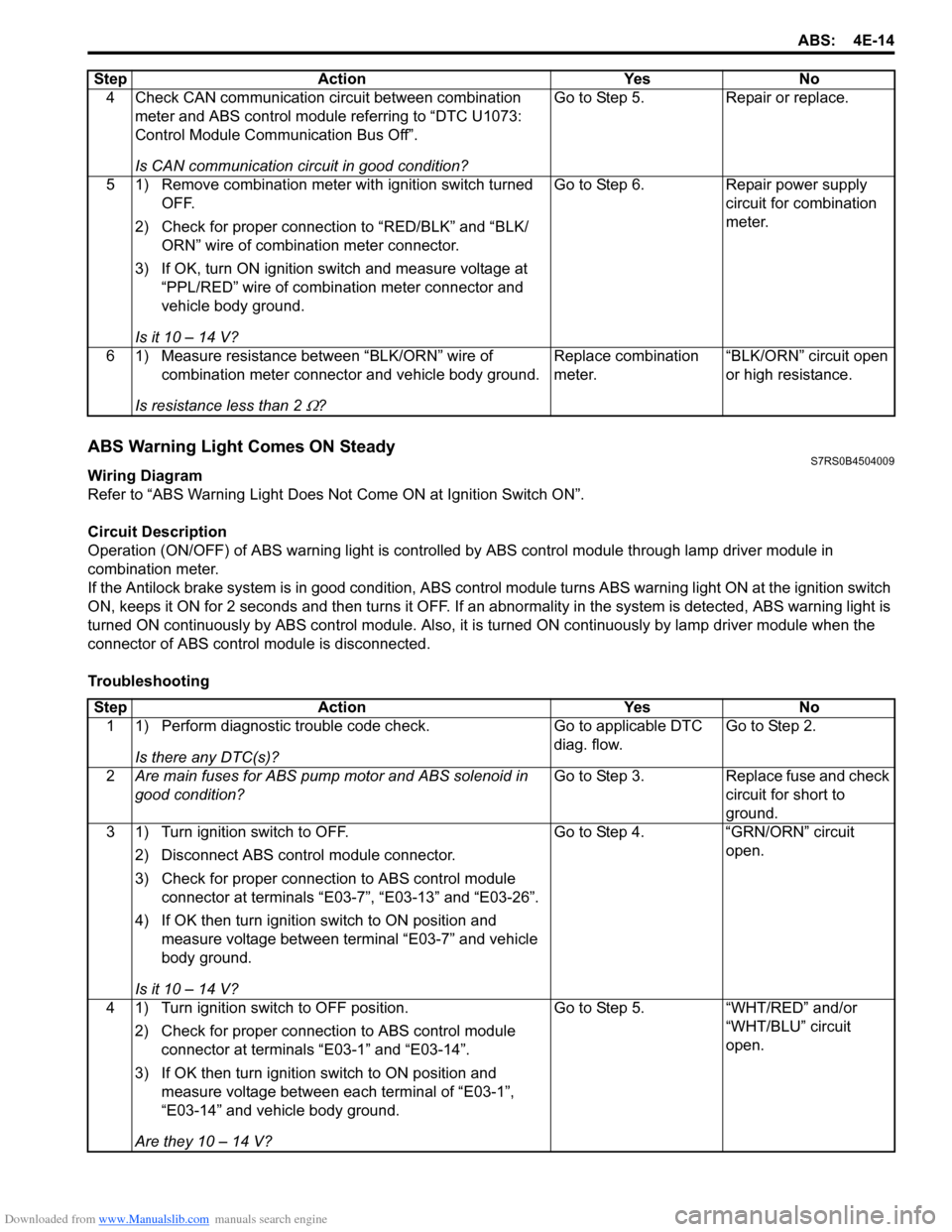

Scan Tool DataS7RS0B4504007

The parameter data below are values measured with the

scan tool when the normally operating vehicle is under

the following conditions. When taking measurements for

comparison by using the scan tool, be sure to check that

the vehicle is under the following conditions.

• Apply parking brake and block wheels.

• Ignition switch ON.

• Turn OFF air conditioner (if equipped).

• Apply no load to power steering (if equipped). (Don’t turn it)

• Turn OFF all electric loads (except ignition).

• No DTC.

• ABS is not operated. (N ormal braking operation)

Scan Tool Data Definition

Battery Volt (V): Battery Voltage is an analog input

signal read by the ABS control module. Certain ABS

control module function s will be modified if the

battery voltage falls below or rises above

programmed thresholds.

Pump Motor Driver (V): This parameter indicates the

operational condition of the pump motor driver

(transistor).

RF Wheel Speed, LF Wheel Speed, RR Wheel Speed and LF Wheel Speed (km/h, MPH): Wheel speed

is an ABS control module inte rnal parameter. It is

computed by reference pulses from the wheel speed

sensor.

Brake Switch (ON, OFF): This switch signal informs

the ABS control modu le whether the brake is active

or not.

Scan Tool

Data Standards Condition

Battery

Voltage 10.0 – 18.0 V —

Pump Motor

Driver 0.0 V —

RF Wheel

Sp ee d 0 km/h, 0.0 MPH Vehicle stop

LF Wheel

Sp ee d 0 km/h, 0.0 MPH Vehicle stop

RR Wheel

Sp ee d 0 km/h, 0.0 MPH Vehicle stop

LR Wheel

Sp ee d 0 km/h, 0.0 MPH Vehicle stop

Brake Switch ONBrake pedal

depressed

OFF Brake pedal released

Page 553 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-14

ABS Warning Light Comes ON SteadyS7RS0B4504009

Wiring Diagram

Refer to “ABS Warning Light Does Not Come ON at Ignition Switch ON”.

Circuit Description

Operation (ON/OFF) of ABS wa rning light is controlled by ABS contro l module through lamp driver module in

combination meter.

If the Antilock brake system is in good condition, ABS control module turns ABS warning lig ht ON at the ignition switch

ON, keeps it ON for 2 seconds and then turns it OFF. If an abnormality in the system is detected, ABS warning light is

turned ON continuously by ABS c ontrol module. Also, it is turned ON continuously by la mp driver module when the

connector of ABS control module is disconnected.

Troubleshooting 4 Check CAN communication circuit between combination

meter and ABS control module referring to “DTC U1073:

Control Module Communication Bus Off”.

Is CAN communication circuit in good condition? Go to Step 5.

Repair or replace.

5 1) Remove combination meter wit h ignition switch turned

OFF.

2) Check for proper connection to “RED/BLK” and “BLK/ ORN” wire of combinat ion meter connector.

3) If OK, turn ON ignition switch and measure voltage at “PPL/RED” wire of combi nation meter connector and

vehicle body ground.

Is it 10 – 14 V? Go to Step 6.

Repair power supply

circuit for combination

meter.

6 1) Measure resistance between “BLK/ORN” wire of combination meter connector and vehicle body ground.

Is resistance less than 2

Ω? Replace combination

meter.

“BLK/ORN” circuit open

or high resistance.

Step Action Yes No

Step

Action YesNo

1 1) Perform diagnostic trouble code check.

Is there any DTC(s)? Go to applicable DTC

diag. flow.

Go to Step 2.

2 Are main fuses for ABS pump motor and ABS solenoid in

good condition? Go to Step 3.

Replace fuse and check

circuit for short to

ground.

3 1) Turn ignition switch to OFF.

2) Disconnect ABS control module connector.

3) Check for proper connection to ABS control module connector at terminals “E03-7”, “E03-13” and “E03-26”.

4) If OK then turn ignition switch to ON position and measure voltage between terminal “E03-7” and vehicle

body ground.

Is it 10 – 14 V? Go to Step 4.

“GRN/ORN” circuit

open.

4 1) Turn ignition switch to OFF position. 2) Check for proper connection to ABS control module connector at terminals “E03-1” and “E03-14”.

3) If OK then turn ignition switch to ON position and measure voltage between each terminal of “E03-1”,

“E03-14” and vehicle body ground.

Are they 10 – 14 V? Go to Step 5.

“WHT/RED” and/or

“WHT/BLU” circuit

open.

Page 554 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-15 ABS:

EBD Warning Light (Brake Warning Light) Comes ON SteadyS7RS0B4504010

Wiring Diagram

Refer to “ABS Warning Light Does Not Come ON at Ignition Switch ON”.

Circuit Description

EBD warning light (brake warn ing light) is controlled by parking brake switch, brake fluid level switch and ABS

hydraulic unit / control module assembly throug h lamp driver module in combination meter.

EBD warning light turns ON when parki ng brake switch is ON and/or brake fluid level is lower than minimum level.

The information of parking brake switch and brake fluid leve l are transmitted from BCM to lamp driver module in

combination meter through CAN communication line.

Troubleshooting 5 1) Turn ignition switch to OFF and measure resistance

between each terminal of “E03-13”, “E03-26” and vehicle

body ground.

Is resistance less than 2

Ω? Go to Step 6. Ground circuit for ABS

hydraulic unit / control

module open or high

resistance.

6 Check CAN communication circuit between combination meter and ABS control module referring to “DTC U1073:

Control Module Communication Bus Off”.

Is CAN communication circuit in good condition? Substitute a known-

good combination meter

and recheck. If ABS

warning light remains

ON, substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.Repair or replace.

Step Action Yes No

Step

Action YesNo

1 1) Make sure that:

• Parking brake is completely released.

• Brake fluid level is upper than the minimum level.

Are the check results OK? Go to Step 2.

Release parking brake

completely and/or

replenish brake fluid.

2 1) Turn ignition switch to ON position. Does “ABS” warning light come on steady? Perform “ABS Warning

Light Comes ON

Steady” previously

outlined.Go to Step 3.

3 1) CAN communication circuit between combination meter, ABS hydraulic unit / control module and BCM referring to

“DTC U1073: Control Module Communication Bus Off”.

Is CAN communication circuit in good condition? Substitute a known-

good combination meter

and recheck. If ABS

warning light remains

ON, substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.Repair or replace.

Page 556 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-17 ABS:

5 1) Turn ignition switch to OFF position.2) Check for proper connection to ABS hydraulic unit / control module connector at terminals “E03-13” and

“E03-26”.

3) If OK, measure resistance between each terminal of “E03-13”, “E03-26” and vehicle body ground.

Are resistance less than 2

Ω? Go to Step 6. Ground circuit for ABS

hydraulic unit / control

module open or high

resistance.

6 1) Check if communication is possible by trying communication with other controller (ECM, BCM or

SDM).

Is it possible to commun icate with other controller? Go to Step 7. Repair open in common

section of serial data

circuit (“PPL/WHT” wire

circuit) used by all

controllers or short to

ground or power circuit

which has occurred

somewhere in serial

data circuit (“PPL/WHT”

wire circuit).

7 1) Turn ignition switch to ON position.

2) Measure voltage between terminal B of data link connector and vehicle body ground.

Is voltage 10 – 12 V? Go to step 8. Terminal B circuit open

or shorted to ground.

8 1) Turn ignition switch to OFF position. 2) Measure resistance between the following terminals;• Terminal G of data link connector and vehicle body ground.

• Terminal G1 of data link connector and vehicle body ground.

Is each resistance 1

Ω or less? Go to step 9. Terminal G and/or G1

circuit open or high

resistance.

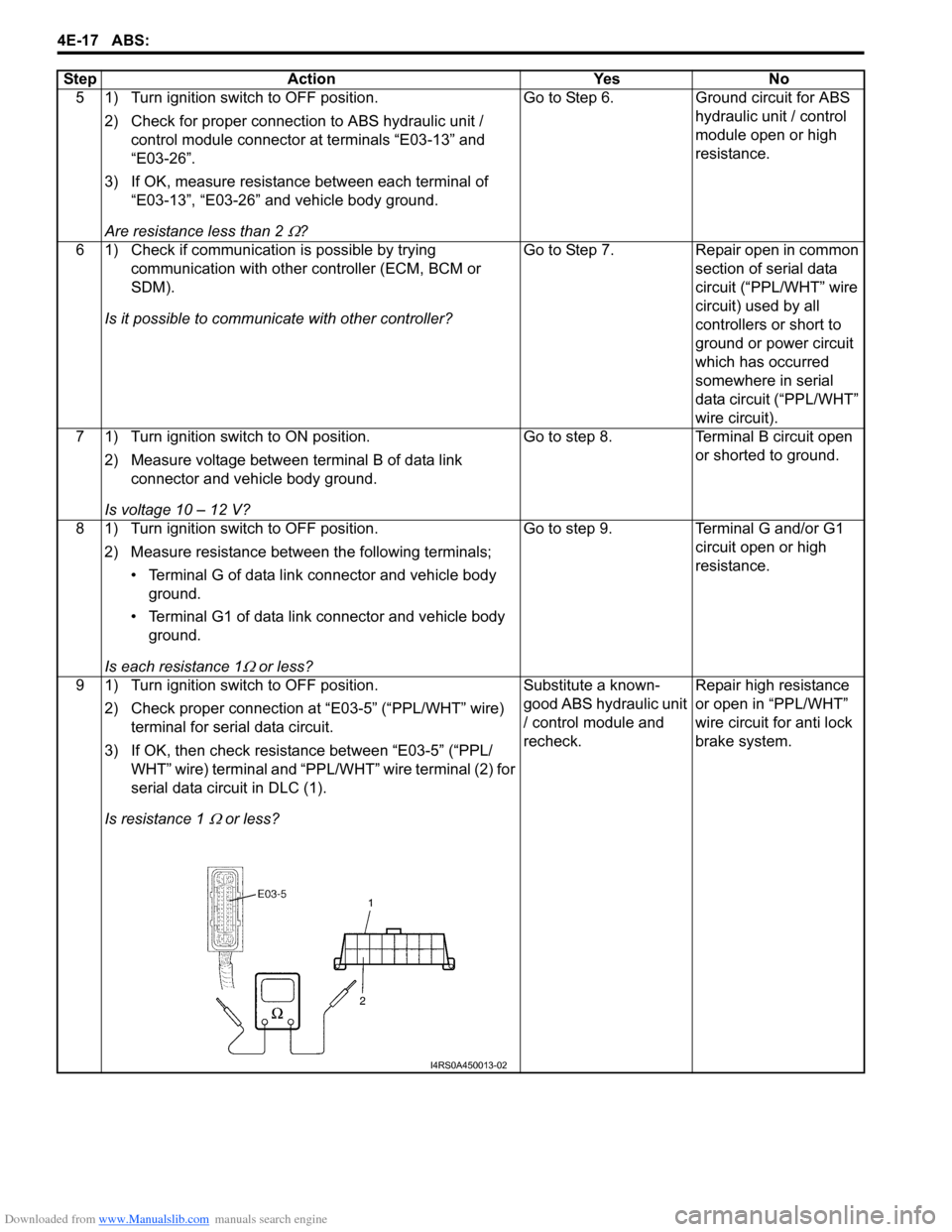

9 1) Turn ignition switch to OFF position. 2) Check proper connection at “E03-5” (“PPL/WHT” wire) terminal for serial data circuit.

3) If OK, then check resistance between “E03-5” (“PPL/ WHT” wire) terminal and “PPL/WHT” wire terminal (2) for

serial data circuit in DLC (1).

Is resistance 1

Ω or less? Substitute a known-

good ABS hydraulic unit

/ control module and

recheck.

Repair high resistance

or open in “PPL/WHT”

wire circuit for anti lock

brake system.

Step Action Yes No

I4RS0A450013-02

Page 558 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-19 ABS:

DTC TroubleshootingStep Action Yes No 1 Was “ABS Check” performed? Go to Step 2. Go to “ABS Check”.

2 1) Disconnect applicable ABS wheel speed sensor coupler with ignition switch OFF.

2) Measure resistance betw een terminals of ABS wheel

speed sensor. Refer to “Front Wheel Speed Sensor

Inspection” and/or “Front Wheel Encoder On-Vehicle

Inspection”.

Is measured resistance value as specified? Go to Step 3. Replace ABS wheel

speed sensor assembly.

3 1) Turn ignition switch OFF. 2) Connect applicable ABS wh eel speed sensor coupler.

3) Disconnect ABS hydraulic unit / control module connector.

4) Check for proper connection to ABS control module at each sensor terminal.

5) If OK, then turn ignition switch ON and measure voltage between applicable sensor terminal of module connector

and body ground.

Is it 0 V? Go to Step 4. ABS wheel speed

sensor circuit shorted to

power.

4 1) Turn ignition switch OFF. 2) Measure resistance between the following points.• Both ABS hydraulic unit / control module connector terminals of the correspo nding sensor. This check

result should be the same as Step 2).

• Either terminal of wheel speed sensor coupler and body ground. This check result should be no

continuity.

Are both check results OK? Go to Step 5. Circuit open or shorted

to ground.

5 1) Remove applicable ABS wheel speed sensor. 2) Check sensor for damage or foreign material attached.

Is it in good condition? Go to Step 6. Clean, repair or replace.

6 Check front and/or rear sensor ring for the following (remove rear drum as necessary):

• Sensor ring serration (teeth) neither missing nor damaged

• No foreign material being attached

• Sensor ring not being eccentric

• Wheel bearing free from excessive play

Are they in good condition? Go to Step 7. Clean, repair or replace.

7 1) Install ABS wheel speed sensor to knuckle. 2) Tighten sensor bolt to specified torque and check that there is no clearance between sensor and knuckle.

Is it OK? Go to Step 8. Replace ABS wheel

speed sensor.

8 Refer to “Front / Rear Wheel Speed Sensor On-Vehicle Inspection” and/or “Rear Wheel Speed Sensor Removal and

Installation”, check output voltage or waveform.

Is specified voltage and/or waveform obtained? Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.

Replace sensor and

recheck.

Page 563 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-24

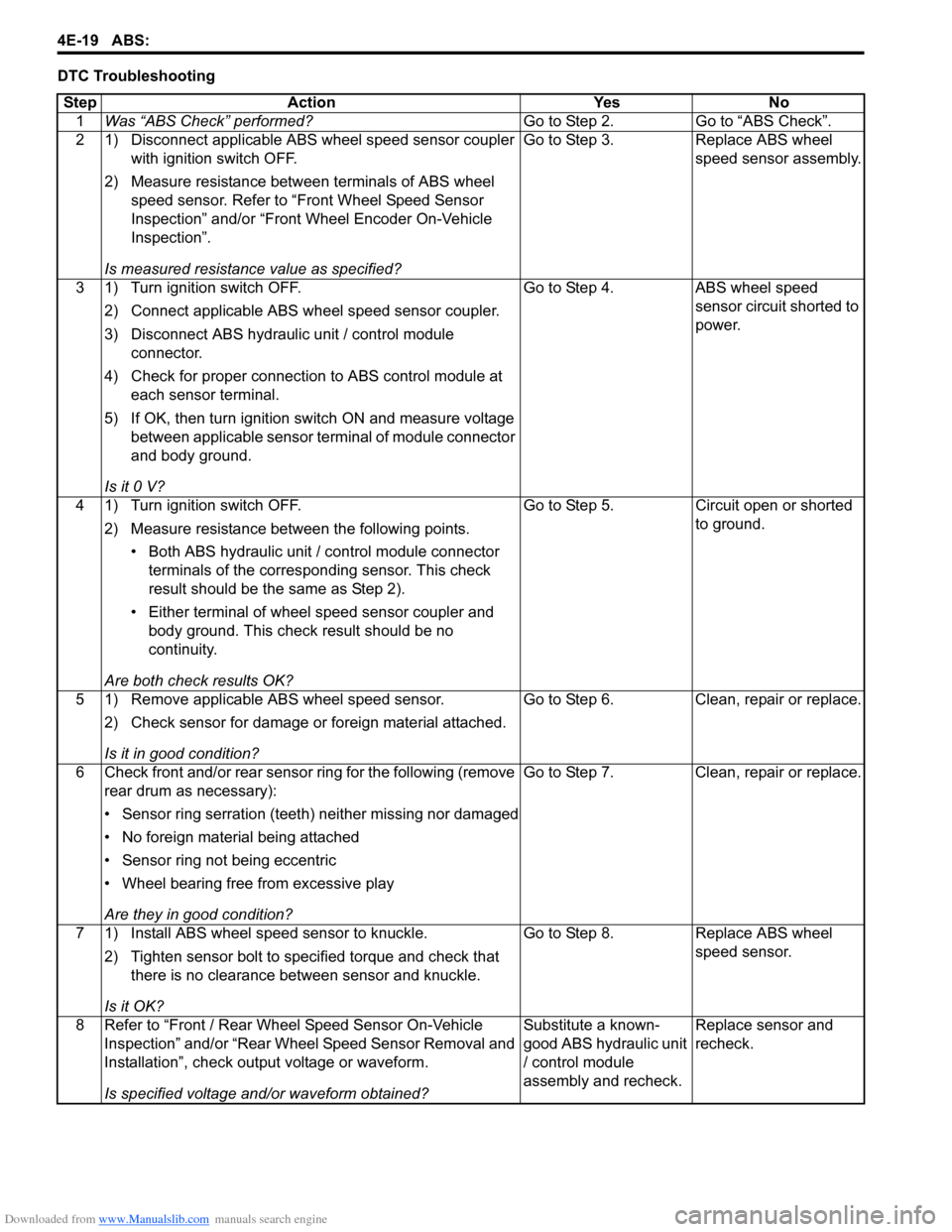

DTC C1071: ABS Control ModuleS7RS0B4504017

Wiring Diagram

DTC Detecting Condition

This DTC will be set when an internal malfunction is detected in the ABS control module.

DTC Troubleshooting

1

2

WHT/RED

12VM

3

4

E03-1

E03-14

BLK

BLK

E03-13

E03-26

WHT/BLU [A]

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

I6RS0C450014-01

[A]: ABS hydraulic unit / control module connector

(viewed from terminal side) 2. Main fuse box 4. ABS hydraulic unit / control module assembly

1. Battery 3. ABS power control module

Step Action YesNo

1 Was “ABS Check” performed? Go to Step 2.Go to “ABS Check”.

2 Clear all DTCs and check DTC.

Is it DTC C1071? Go to Step 3.

Could be a temporary

malfunction of the ABS

control module.

3 1) Check for proper connection of ABS hydraulic unit / control module connector.

2) If OK, disconnect ABS hydr aulic unit / control module

connector and check the following.

• Voltage “E03-1” terminal: 10 – 14 V

• Voltage “E03-14” terminal: 10 – 14 V

• Resistance between “E03-13” and body ground: Continuity

• Resistance between “E03-26” and body ground: Continuity

Are the check result as specified? Replace ABS hydraulic

unit / control module

assembly.

Repair “WHT/RED”,

“WHT/BLU” and/or

“BLK” circuit and

recheck.

Page 565 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-26

DTC TroubleshootingStep Action Yes No 1 Was “ABS Check” performed? Go to Step 2. Go to “ABS Check”.

2 1) Check connection of connectors of all control modules communicating by means of CAN.

2) Recheck DTC.

Is DTC U1073 indicated? Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00” in related manual.

3 1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 4. Repair insulation of

CAN communication

line circuit referring to

“Precaution for CAN

Communication System

in Section 00” in related

manual.

4 1) Turn ignition switch to OFF position.

2) Connect connector of disconnected control modules communicating by means of CAN.

3) Disconnect connector from any one of control modules other than BCM and ABS control module.

4) Recheck ABS contro l module for DTC.

IS DTC U1073 detected? Disconnected

connectors of control

modules other than the

one whose connector is

disconnected in Step 3)

one by one and check

that DTC U1073 is

detected by ABS control

module each time

connector is

disconnected.

When DTC U1073 is not

detected by ABS

module while checking

in this way, go to

description under “NO”

below. If DTC U1073 is

detected by ABS control

module, go to Step 5.Check power and

ground circuit of control

module disconnected in

Step 3) circuit is OK,

substitute a know-good

control module

disconnected in Step 3)

and recheck.

5 1) Substitute a know-good BCM and recheck ABS control module for DTC.

IS DTC U1073 detected? Substitute a know-good

ABS control module and

recheck.

End.

Page 566 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-27 ABS:

DTC U1100: Lost Communication with ECM (Reception Error)S7RS0B4504019

Wiring Diagram

Refer to “DTC U1073: Control Module Communication Bus Off”.

DTC Detecting Condition

Reception error of communication data for ECM is detected more than specified time continuously.

DTC Troubleshooting Step Action Yes No 1 Was “ABS Check” performed? Go to Step 2. Go to “ABS Check”.

2 1) Check DTC for ABS.

Is DTC U1073 detected? Go to “DTC U1073:

Control Module

Communication Bus

Off”.Go to Step 3.

3 1) Check DTC for ECM. Is DTC P1674 detected? Go to “DTC P1674:

CAN Communication

(Bus Off Error) in

Section 1A”.Go to Step 4.

4 1) Check connection of connectors of all control modules communicating by means of CAN.

2) Check DTC for ABS.

Is DTC U1100 detected? Go to Step 5. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00” in related manual.

5 1) Turn ignition switch to OFF position.

2) Disconnect connectors of ABS control module and ECM

communicating by means of CAN.

3) Check CAN communication circuit between ABS control module and ECM for open, short and high resistance.

Is CAN communication circuit in good condition? Go to Step 6. Repair or replace the

CAN communication

line.

6 1) Disconnect connectors of all control modules communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 5 for open, short and high

resistance.

Is each CAn communication circuit in good condition? Go to Step 7. Repair or replace the

CAN communication

line.

7 1) Turn ignition switch to OFF position. 2) Connect connector of disconnected control modules communicating by means of CAN.

3) Disconnect connector from any one of control modules other than BCM and ABS control module.

4) Recheck ABS contro l module for DTC

IS DTC U1100 detected? Disconnected

connectors of control

modules other than the

one whose connector is

disconnected in Step 3)

one by one and check

that DTC U1100 is

detected by ABS control

module each time

connector is

disconnected.

When DTC U1100 is not

detected by ABS

module while checking

in this way, go to

description under “NO”

below. If DTC U1100 is

detected by ABS control

module, go to Step 8.Check power and

ground circuit of control

module disconnected in

Step 3) circuit is OK,

substitute a know-good

control module

disconnected in Step 3)

and recheck.

Page 567 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-28

Repair Instructions

ABS Hydraulic Unit Operation CheckS7RS0B4506001

1) Check that basic brake system other than ABS is in good condition.

2) Check that battery voltage is 11 V or higher.

3) Lift up vehicle.

4) Set transmission to neutral and release parking brake.

5) Turn each wheel gradually by hand to check if brake dragging occurs. If it does, correct.

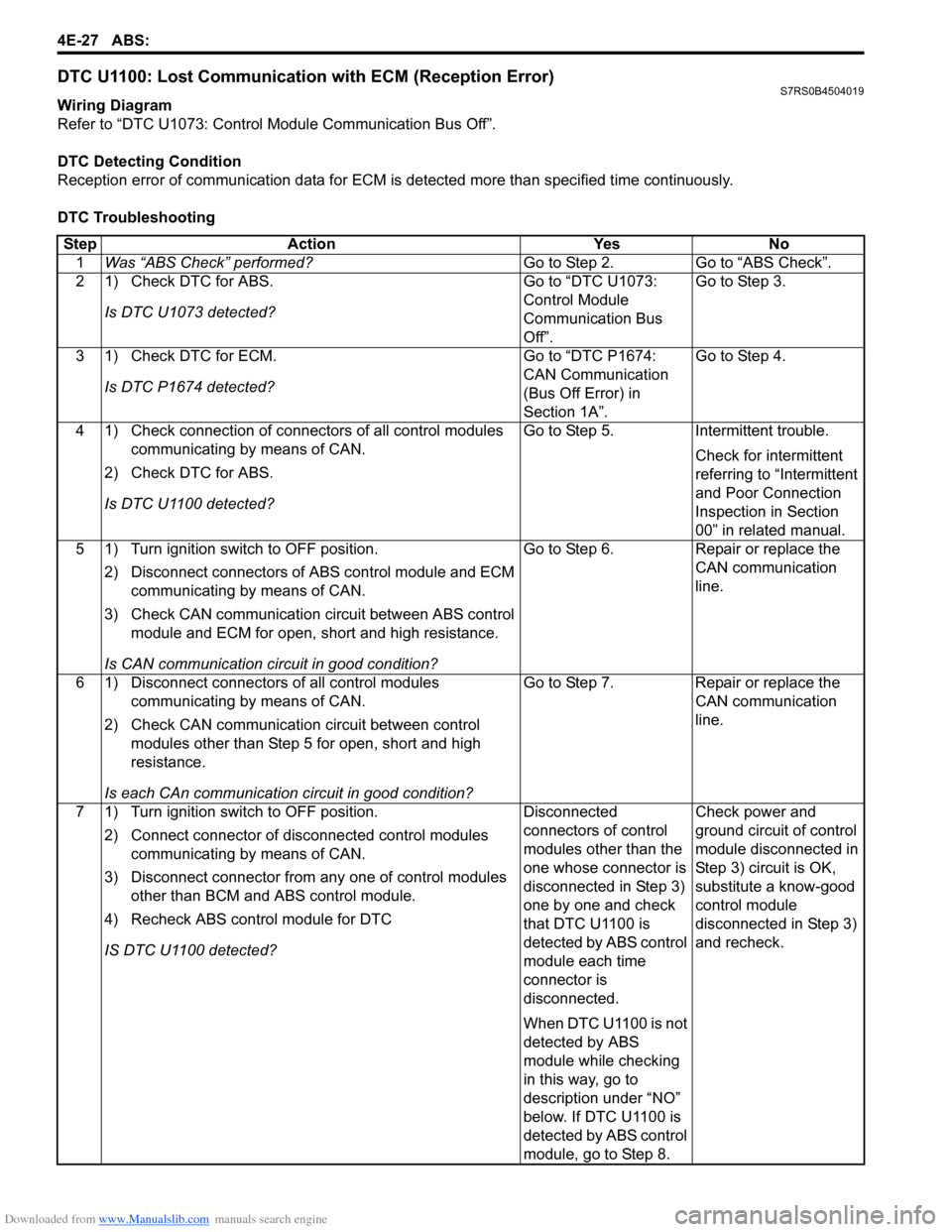

6) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool 7) Turn ignition switch to ON position and select menu

to “HYDRAULIC CONTROL TEST” under

“miscellaneous test” (“MISC. TEST”) mode of

SUZUKI scan tool.

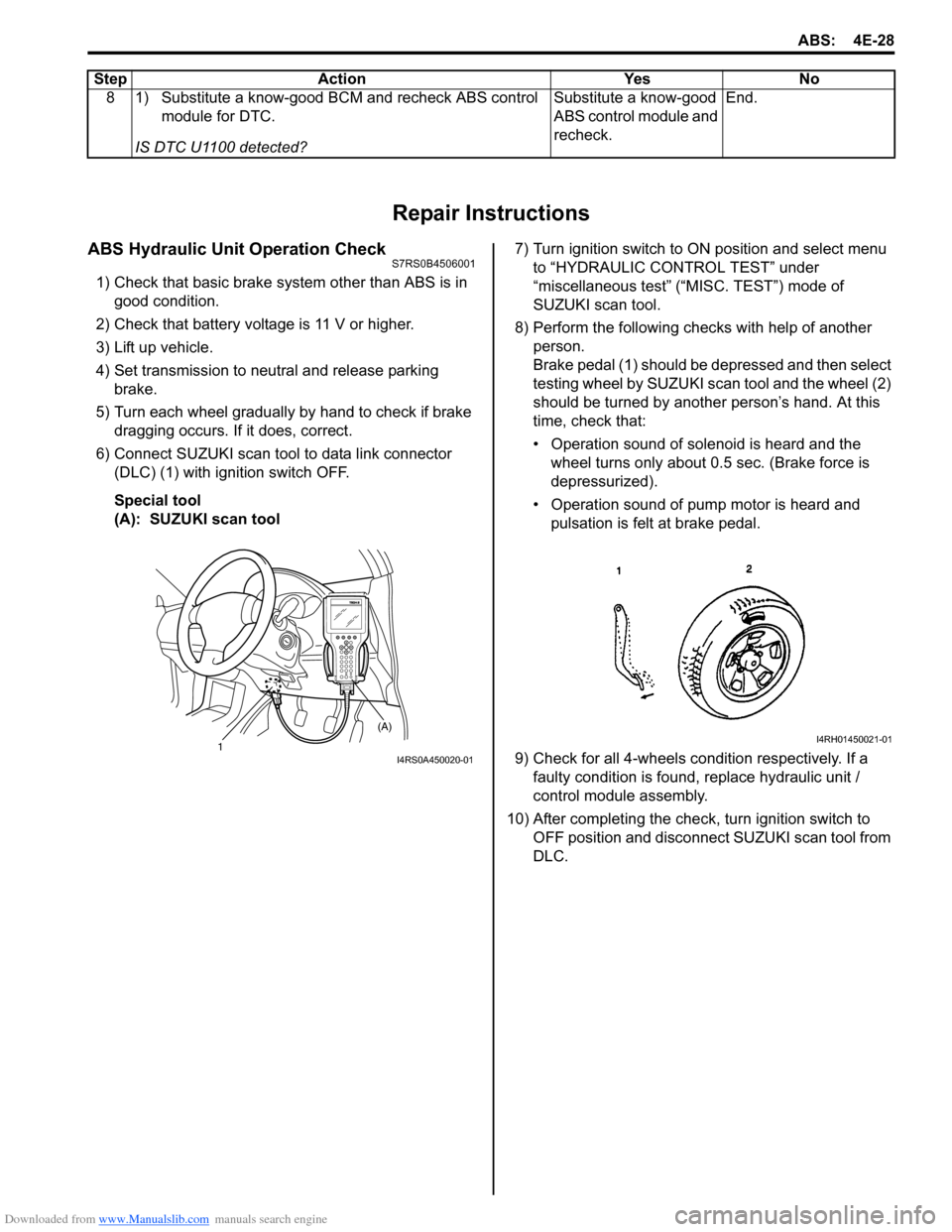

8) Perform the following checks with help of another person.

Brake pedal (1) should be depressed and then select

testing wheel by SUZUKI scan tool and the wheel (2)

should be turned by another person’s hand. At this

time, check that:

• Operation sound of solenoid is heard and the wheel turns only about 0.5 sec. (Brake force is

depressurized).

• Operation sound of pump motor is heard and pulsation is felt at brake pedal.

9) Check for all 4-wheels co ndition respectively. If a

faulty condition is found, replace hydraulic unit /

control module assembly.

10) After completing the check, turn ignition switch to OFF position and disconnect SUZUKI scan tool from

DLC.

8 1) Substitute a know-good BCM and recheck ABS control

module for DTC.

IS DTC U1100 detected? Substitute a know-good

ABS control module and

recheck.

End.

Step Action Yes No

1 (A)I4RS0A450020-01

I4RH01450021-01