AIR CON SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 496 of 1496

Downloaded from www.Manualslib.com manuals search engine 4-ii Table of Contents

Repair Instructions ..............................................4D-2Parking Brake Inspection and Adjustment ..........4D-2

Parking Brake Cable Removal and Installation ......................................................... 4D-3

Parking Brake Lever Removal and Installation ....4D-3

Specifications .... ...................................................4D-4

Tightening Torque Specifications ........................4D-4

ABS ........................................... .................4E-1

Precautions........................................................... 4E-1

Precautions in Diagnosing Troubles ................... 4E-1

Precautions in On-Vehicle Service...................... 4E-1

Precautions in Hydraulic Unit Operation Check ................................................................ 4E-1

General Description ............................................. 4E-2 ABS Description .................................................. 4E-2

ABS Hydraulic Unit / Control Module Assembly Description ....................................... 4E-2

CAN Communication System Description........... 4E-3

Schematic and Routing Diagram ........................ 4E-4 ABS Schematic ................................................... 4E-4

ABS Wiring Circuit Diagram ................................ 4E-5

Component Location ........... ................................ 4E-7

ABS Components Location ................................. 4E-7

Front Wheel Speed Sensor Components Location ............................................................ 4E-7

Rear Wheel Speed Sensor Components Location ............................................................ 4E-8

Diagnostic Information and Procedures ............ 4E-8 ABS Check .......................................................... 4E-8

ABS Warning Light Check................................. 4E-10

EBD Warning Light (Brake Warning Light) Check .............................................................. 4E-10

DTC Check........................................................ 4E-11

DTC Table ......................................................... 4E-11

DTC Clearance ................................................. 4E-12

Scan Tool Data ................................................. 4E-12

ABS Warning Light Does Not Come ON at Ignition Switch ON .......................................... 4E-13

ABS Warning Light Comes ON Steady ............. 4E-14

EBD Warning Light (Brake Warning Light) Comes ON Steady .......................................... 4E-15

Serial Data Link Circuit Check .......................... 4E-16

DTC C1021, C1022 / C1025, C1026 / C1031, C1032 / C1035, C1036: Right-Front / Left-

Front / Right-Rear / Left-Rear Wheel Speed

Sensor Circuit or Sensor Ring ........................ 4E-18

DTC C1041 / C1045 / C1051 / C1055, DTC C1042 / C1046 / C1052 / C1056: Right-Front

/ Left-Front / Right-Rear / Left-Rear Inlet

Solenoid Circuit, Right-Front / Left-Front /

Right-Rear / Left-Rear Outlet Solenoid

Circuit .............................................................. 4E-20

DTC C1057: Power Source Circuit ................... 4E-21

DTC C1061: ABS Pump Motor and/or Motor Driver Circuit ................................................... 4E-22

DTC C1063: Solenoid Valve Power Supply Driver Circuit ................................................... 4E-23

DTC C1071: ABS Control Module..................... 4E-24 DTC U1073: Control Module Communication

Bus Off ............................................................ 4E-25

DTC U1100: Lost Communication with ECM (Reception Error)............................................. 4E-27

Repair Instructions ............ ................................ 4E-28

ABS Hydraulic Unit Operati on Check................ 4E-28

ABS Hydraulic Unit / Control Module

Assembly Components ...... ............................. 4E-29

ABS Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4E-29

ABS Hydraulic Unit / Control Module

Assembly Removal and Inst allation ................ 4E-29

Front / Rear Wheel Speed Sensor On-Vehicle Inspection ........................................................ 4E-31

Front Wheel Speed Sensor Removal and Installation ....................................................... 4E-32

Front Wheel Speed Sensor Inspection ............. 4E-32

Rear Wheel Speed Sensor Removal and Installation ....................................................... 4E-33

Rear Wheel Speed Sensor Inspection .............. 4E-34

Front Wheel Encoder On-Veh icle Inspection .... 4E-34

Front wheel Enco der Removal and

Installation ....................................................... 4E-34

Rear Wheel Encoder On-Veh icle Inspection..... 4E-34

Rear Wheel Encoder Removal and Installation ....................................................... 4E-34

Specifications ..................... ................................ 4E-35

Tightening Torque Specifications ...................... 4E-35

Special Tools and Equipmen t ........................... 4E-35

Special Tool ...................................................... 4E-35

Electronic Stability Prog ram ...................4F-1

Precautions ........................................................... 4F-1

Precautions in Diagnosing Troubles ................... 4F-1

Precautions in On-Vehicle Service...................... 4F-1

Precautions in Hydraulic Unit Operation Check ................................................................ 4F-1

Precautions in Sensor Calibration ....................... 4F-1

Precautions in Speedometer Test or Other Tests ................................................................. 4F-2

General Description ............................................. 4F-2 Electronic Stability Program Description ............. 4F-2

Electronic Stability Program Construction ........... 4F-3

ESP® Hydraulic Unit / Control Module

Assembly Description........................................ 4F-5

Warning Lamp, Indicator Lamp Description ........ 4F-6

CAN Communication System Description........... 4F-6

CAN Communication System For Electronic Stability Program Description ............................ 4F-7

Schematic and Routing Diagram ........................ 4F-8 Electronic Stability Program Schematic .............. 4F-8

Electronic Stability Program Wiring Circuit Diagram............................................................. 4F-9

Component Location ............ ............................. 4F-11

Electronic Stability Program Component

Location........................................................... 4F-11

Diagnostic Information and Procedures .......... 4F-12 Electronic Stability Program System Check ...... 4F-12

ESP® Warning lamp Check .............................. 4F-14

Page 497 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 4-iii

ABS Warning Lamp Check ............................... 4F-14

EBD Warning Lamp (Brake Warning Lamp) Check .............................................................. 4F-15

DTC Check ....................................................... 4F-15

DTC Table ......................................................... 4F-15

DTC Clearance ................................................. 4F-18

Fail-Safe Table ................ .................................. 4F-19

Scan Tool Data ................................................. 4F-20

Visual Inspection ............................................... 4F-21

ESP ® Warning Lamp Does Not Come ON at

Ignition Switch ON .......................................... 4F-21

ESP ® Warning Lamp Comes ON Steady......... 4F-22

ABS Warning Lamp Does Not Come ON at Ignition Switch ON .......................................... 4F-23

ABS Warning Lamp Comes ON Steady............ 4F-24

EBD Warning Lamp (Brake Warning Lamp) Comes ON Steady .......................................... 4F-24

Serial Data Link Circuit Check .......................... 4F-26

DTC C1016: Stop Lamp Swit ch Circuit Failure .. 4F-28

DTC C1017 / C1023: Yaw Rate / G Sensor Assembly Failure ............................................ 4F-29

DTC C1018: Brake Fluid Le vel Switch Failure .. 4F-30

DTC 1020: Master Cylinder Pressure Sensor Power Supply Failure ...................................... 4F-31

DTC C1021, C1022 / C1025, C1026 / C1031, C1032 / C1035, C1036: Wheel Speed

Sensor Circuit or Encode r Failure ................... 4F-32

DTC C1024: Steering Angle Sensor Circuit

Failure ............................................................. 4F-34

DTC C1027: ESP ® OFF Switch Circuit

Failure ............................................................. 4F-34

DTC C1028: Master Cylinder Pressure Sensor Circuit Failure ....... .............................. 4F-35

DTC C1034: Yaw Rate / G Sensor Assembly Power Supply Failure ...................................... 4F-36

DTC C1037: Steering Angle Sensor Power Supply Failure ................................................. 4F-37

DTC C1038: Steering Angle Sensor Detect Rolling Counter Fa ilure from ESP® Control

Module ............................................................ 4F-38

DTC C1039: Yaw Rate / G Sensor Assembly Internal Failure .............. .................................. 4F-39

DTC C1040: Stability Control System Function Failure .............................................. 4F-39

DTC C1041 / C1042 / C1043 / C1044 / C1045 / C1046 / C1051 / C1052 / C1053 / C1054 /

C1055 / C1056: Solenoid Circuit Failure ......... 4F-40

DTC C1057: ESP ® Control Module Power

Supply Circuit Failure .... .................................. 4F-41

DTC C1061: Pump Motor and/or Motor Driver Circuit Failure .................................................. 4F-42

DTC C1063: Solenoid Valve Power Supply Driver Circuit Failure ....................................... 4F-43

DTC 1071: ESP ® Control Module Internal

Defect.............................................................. 4F-44 DTC C1073: Lost Communication With Yaw

Rate / G Sensor Assembly .............................. 4F-45

DTC C1075 / 1076 / 1078: Sensor Calibration Incomplete.......................... ............................. 4F-46

DTC C1090: Invalid Communication with

ECM ................................................................ 4F-47

DTC C1091 / C1094: ECM Data in CAN Line Failure / Invalid Torque Control

Communication with ECM .. ............................. 4F-48

DTC U1073: Control Module Communication Bus Off ............................................................ 4F-49

DTC U1100: Lost Communication with ECM (Reception Error)............................................. 4F-50

DTC U1126: Lost Communication with Steering Angle Sensor (Reception Error)........ 4F-51

DTC U1140: Lost Communication with BCM (Reception Error)............................................. 4F-52

Repair Instructions ........... ................................. 4F-54

ESP® Hydraulic Unit Operation Check ............. 4F-54

Sensor Calibration............................................. 4F-54

ESP® Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4F-55

ESP ® Hydraulic

Unit / Control Module

Assembly Removal and Inst allation ................ 4F-56

Front / Rear Wheel Speed Sensor On-Vehicle Inspection ........................................................ 4F-57

Front Wheel Speed Sensor Removal and Installation ....................................................... 4F-58

Front Wheel Speed Sensor Inspection ............. 4F-59

Rear Wheel Speed Sensor Removal and Installation ....................................................... 4F-59

Rear Wheel Speed Sensor Inspection .............. 4F-60

Front Wheel Encode r On-Vehicle Inspection .... 4F-61

Front Wheel Encoder Removal and Installation ....................................................... 4F-61

Rear Wheel Encoder On-Veh icle Inspection..... 4F-61

Rear Wheel Encoder Removal and Installation ....................................................... 4F-61

Master Cylinder Pressure Sensor On-Vehicle

Inspection ........................................................ 4F-61

Yaw Rate / G Sensor Assembly On-Vehicle Inspection ........................................................ 4F-62

Yaw Rate / G Sensor Assembly Removal and Installation ....................................................... 4F-63

Yaw Rate / G Sensor Inspection ....................... 4F-64

Steering Angle Sensor On-Vehicle Inspection .. 4F-64

Steering Angle Sensor Removal and Installation ....................................................... 4F-65

Steering Angle Sensor Inspection ..................... 4F-65

ESP® OFF Switch Removal an d Installation .... 4F-65

ESP® OFF Switch Inspection ........................... 4F-65

Specifications .................... ................................. 4F-66

Tightening Torque Specifications ...................... 4F-66

Special Tools and Equipmen t ........................... 4F-66

Special Tool ...................................................... 4F-66

Page 499 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-1

Brakes

Brake Control System and Diagnosis

Precautions

Precautions on BrakeS7RS0B4100001

Air Bag Warning

Refer to “Air Bag System Service Warning in Section 00”.

Brakes Diagnosis Note

Refer to “Brakes Diagnosis Note”.

General Description

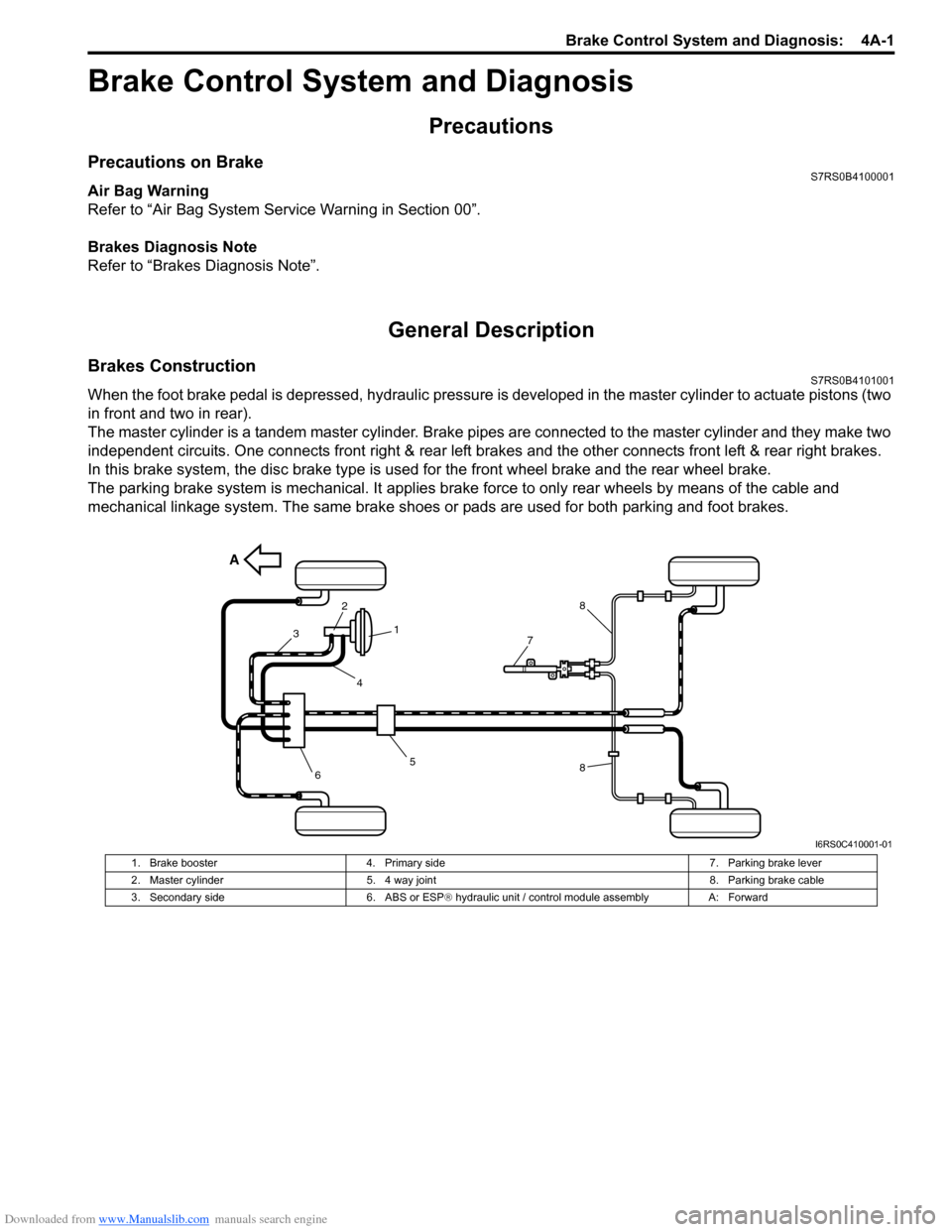

Brakes ConstructionS7RS0B4101001

When the foot brake pedal is depressed, hydraulic pressure is developed in the master cylinder to actuate pistons (two

in front and two in rear).

The master cylinder is a tandem master cylinder. Brake pipes are connected to the master cylinder and they make two

independent circuits. One connects front right & rear left brakes and the other connects front left & rear right brakes.

In this brake system, the disc brake type is used for the front wheel brake and the rear wheel brake.

The parking brake system is mechanical. It applies brake force to only rear wheels by means of the cable and

mechanical linkage system. The same brake shoes or pads are used for both parking and foot brakes.

A

5

3

2

1

4

8

8

6

7

I6RS0C410001-01

1. Brake booster 4. Primary side 7. Parking brake lever

2. Master cylinder 5. 4 way joint 8. Parking brake cable

3. Secondary side 6. ABS or ESP® hydraulic unit / control module assembly A: Forward

Page 503 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-5

If deterioration of rubber is evident, disassemble all

hydraulic parts and wash with alcohol. Dry these parts

with compressed air before assembly to keep alcohol out

of the system. Replace all rubber parts in the system,

including hoses. Also, when working on the brake

mechanisms, check for fluid on the linings.

If excessive fluid is found, replace the pads. If master cylinder piston seals

are satisfactory, check for

leakage or excessive heat co nditions. If leakage is not

found, drain fluid, flush with brake fluid, refill and bleed

system.

The system must be flushed if there is any doubt as to

the grade of fluid in the system or if fluid has been used

which contained parts that have been subjected to

contaminated fluid.

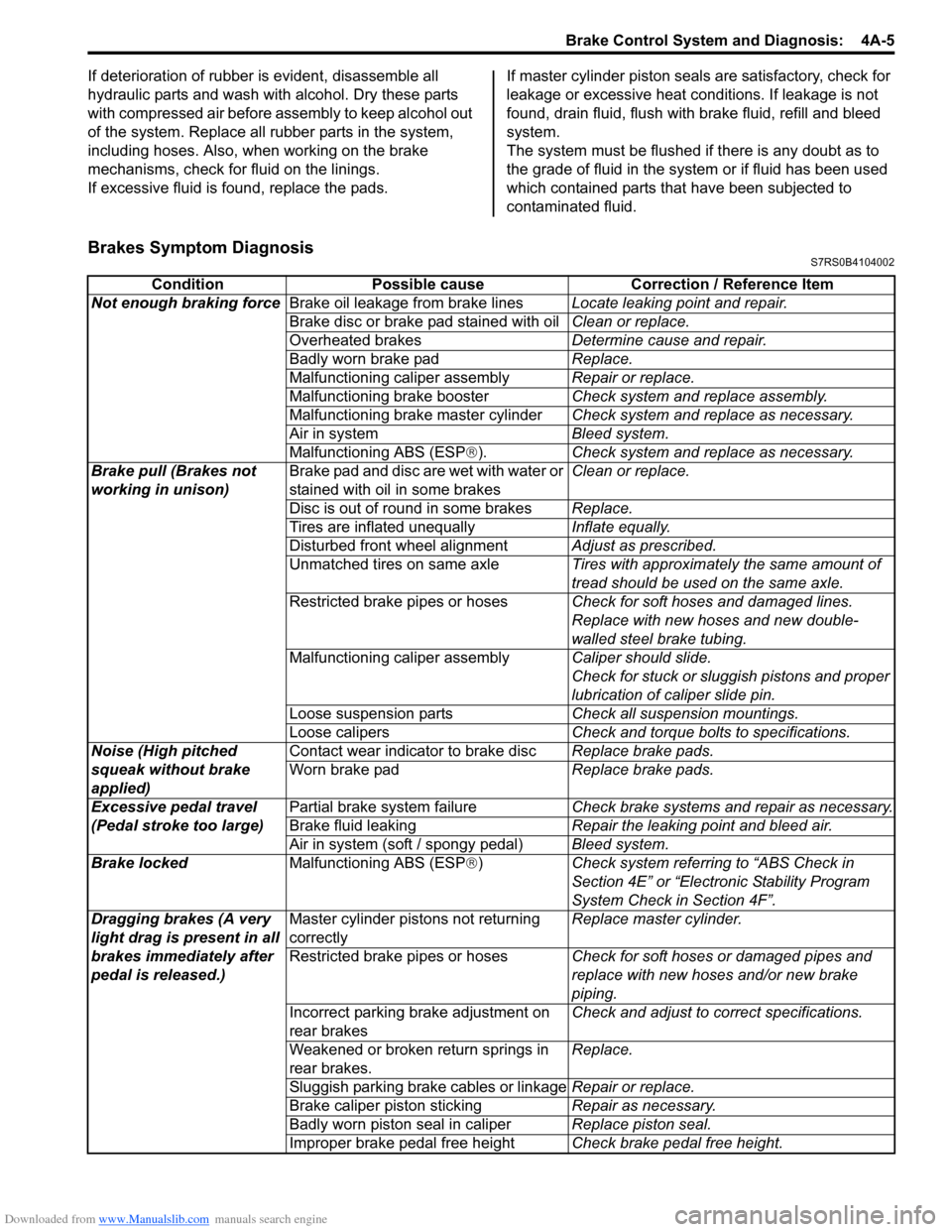

Brakes Symptom DiagnosisS7RS0B4104002

Condition Possible cause Correction / Reference Item

Not enough braking force Brake oil leakage from brake lines Locate leaking point and repair.

Brake disc or brake pad stained with oil Clean or replace.

Overheated brakes Determine cause and repair.

Badly worn brake pad Replace.

Malfunctioning caliper assembly Repair or replace.

Malfunctioning brake booster Check system and replace assembly.

Malfunctioning brake master cylinder Check system and replace as necessary.

Air in system Bleed system.

Malfunctioning ABS (ESP ®). Check system and replace as necessary.

Brake pull (Brakes not

working in unison) Brake pad and disc are wet with water or

stained with oil in some brakes Clean or replace.

Disc is out of round in some brakes Replace.

Tires are inflated unequally Inflate equally.

Disturbed front wheel alignment Adjust as prescribed.

Unmatched tires on same axle Tires with approximately the same amount of

tread should be used on the same axle.

Restricted brake pipes or hoses Check for soft hoses and damaged lines.

Replace with new hoses and new double-

walled steel brake tubing.

Malfunctioning caliper assembly Caliper should slide.

Check for stuck or sluggish pistons and proper

lubrication of caliper slide pin.

Loose suspension parts Check all suspension mountings.

Loose calipers Check and torque bolts to specifications.

Noise (High pitched

squeak without brake

applied) Contact wear indicator to brake disc

Replace brake pads.

Worn brake pad Replace brake pads.

Excessive pedal travel

(Pedal stroke too large) Partial brake system failure

Check brake systems and repair as necessary.

Brake fluid leaking Repair the leaking point and bleed air.

Air in system (soft / spongy pedal) Bleed system.

Brake locked Malfunctioning ABS (ESP®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

Dragging brakes (A very

light drag is present in all

brakes immediately after

pedal is released.) Master cylinder pistons not returning

correctly

Replace master cylinder.

Restricted brake pipes or hoses Check for soft hoses or damaged pipes and

replace with new hoses and/or new brake

piping.

Incorrect parking brake adjustment on

rear brakes Check and adjust to correct specifications.

Weakened or broken return springs in

rear brakes. Replace.

Sluggish parking brake cables or linkage Repair or replace.

Brake caliper piston sticking Repair as necessary.

Badly worn piston seal in caliper Replace piston seal.

Improper brake pedal free height Check brake pedal free height.

Page 504 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-6 Brake Control System and Diagnosis:

Pedal pulsation (Pedal

pulsates when depressed

for braking)Damaged or loose wheel bearings

Replace wheel bearings.

Distorted steering knuckle or rear wheel

spindle Replace knuckle or rear wheel spindle.

Excessive disc lateral runout Check per instructions. If not within

specifications, replace or machine disc.

Parallelism between brake pad and disc

not within specifications Check per instructions. If not within

specifications, replace or machine disc.

Brake caliper piston sticking Repair as necessary.

Braking noise Worn or distorted brake pad Replace pads.

Loose front wheel bearings Replace wheel bearings.

Distorted backing plates or loose

mounting bolts Replace or retighten securing bolts.

Contact wear indicator to brake disc Replace brake pad.

Brake warning light lights

after engine start Parking brake applied

Release parking brake and check that brake

warning light turns off.

Insufficient amount of brake fluid Investigate leaky point, correct it and add

brake fluid.

Brake fluid leaking Investigate leaky point, correct it and add

brake fluid.

Brake warning light circuit faulty Repair circuit.

Malfunctioning EBD system Check system referring to “EBD Warning Light

(Brake Warning Light) Comes ON Steady in

Section 4E”.

Brake warning light turns

on when brake is applied Brake fluid leaking

Investigate leaky point, correct it and add

brake fluid.

Insufficient amount of brake fluid Investigate leaky point, correct it and add

brake fluid.

Brake warning light fails

to turn on even when

parking brake is applied Brake warning light circuit faulty

Replace bulb or repair circuit.

ABS warning light or

ESP

® warning light turns

on after engine start Malfunctioning ABS (ESP

®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light or

ESP

® warning light turns

on when brake is applied Malfunctioning ABS (ESP

®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light or

ESP

® warning light does

not turn on for 2 sec. after

ignition switch has turned

ON Bulb burnt out

Replace bulb.

Malfunctioning ABS (ESP ®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light flashes New ABS hydraulic unit / control module

assembly installed. Perform “ABS Hydraulic

Unit Operation Check

in Section 4E”.

Condition Possible cause Correction / Reference Item

Page 505 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-7

Repair Instructions

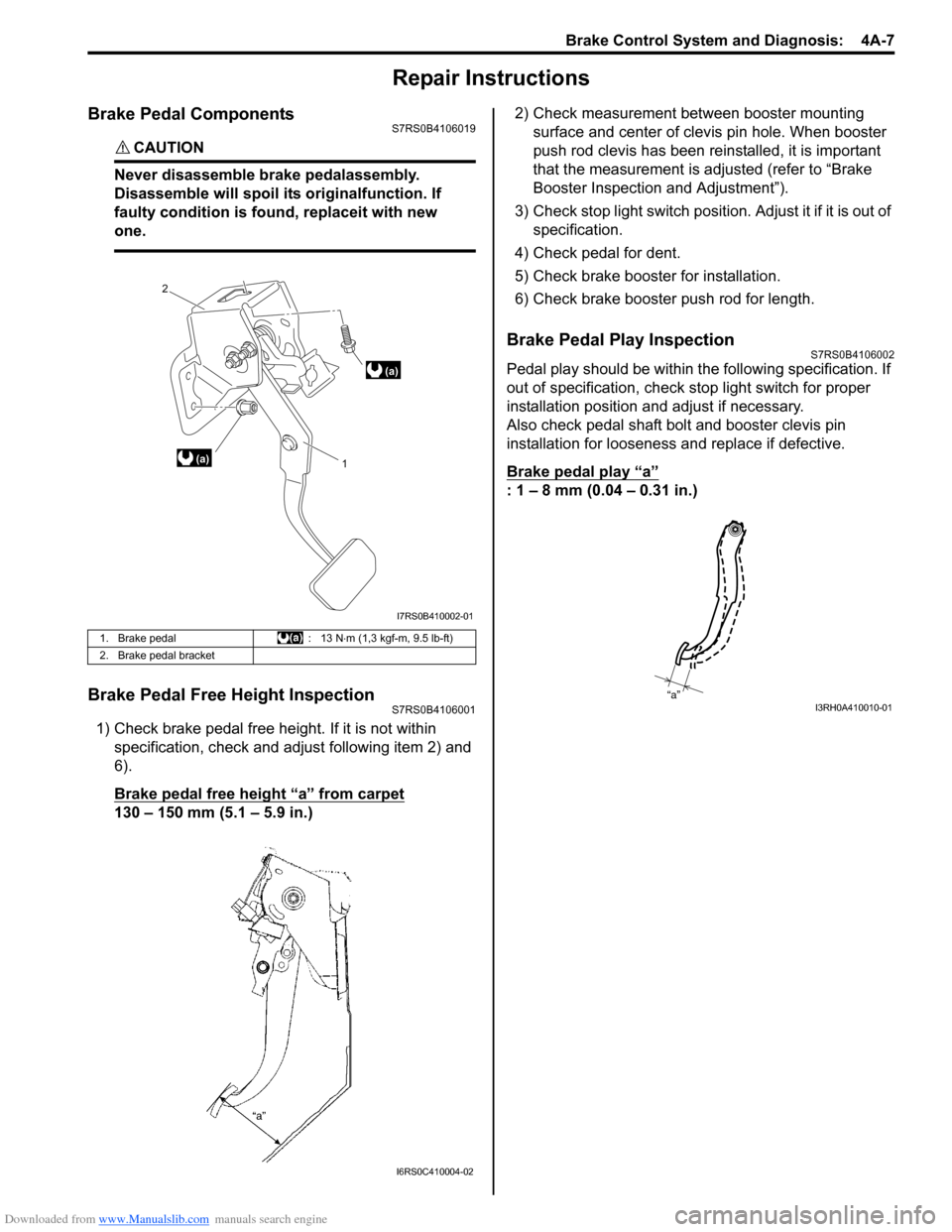

Brake Pedal ComponentsS7RS0B4106019

CAUTION!

Never disassemble brake pedalassembly.

Disassemble will spoil its originalfunction. If

faulty condition is found, replaceit with new

one.

Brake Pedal Free Height InspectionS7RS0B4106001

1) Check brake pedal free height. If it is not within specification, check and ad just following item 2) and

6).

Brake pedal free height “a” from carpet

130 – 150 mm (5.1 – 5.9 in.) 2) Check measurement between booster mounting

surface and center of clevis pin hole. When booster

push rod clevis has been reinstalled, it is important

that the measurement is adj usted (refer to “Brake

Booster Inspection and Adjustment”).

3) Check stop light switch position . Adjust it if it is out of

specification.

4) Check pedal for dent.

5) Check brake booster for installation.

6) Check brake booster push rod for length.

Brake Pedal Play InspectionS7RS0B4106002

Pedal play should be within the following specification. If

out of specification, check stop light switch for proper

installation position and adjust if necessary.

Also check pedal shaft bolt and booster clevis pin

installation for looseness and replace if defective.

Brake pedal play

“a”

: 1 – 8 mm (0.04 – 0.31 in.)

1. Brake pedal : 13 N⋅m (1,3 kgf-m, 9.5 lb-ft)

2. Brake pedal bracket

(a) 1

2

(a)

I7RS0B410002-01

I6RS0C410004-02

“a”I3RH0A410010-01

Page 506 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-8 Brake Control System and Diagnosis:

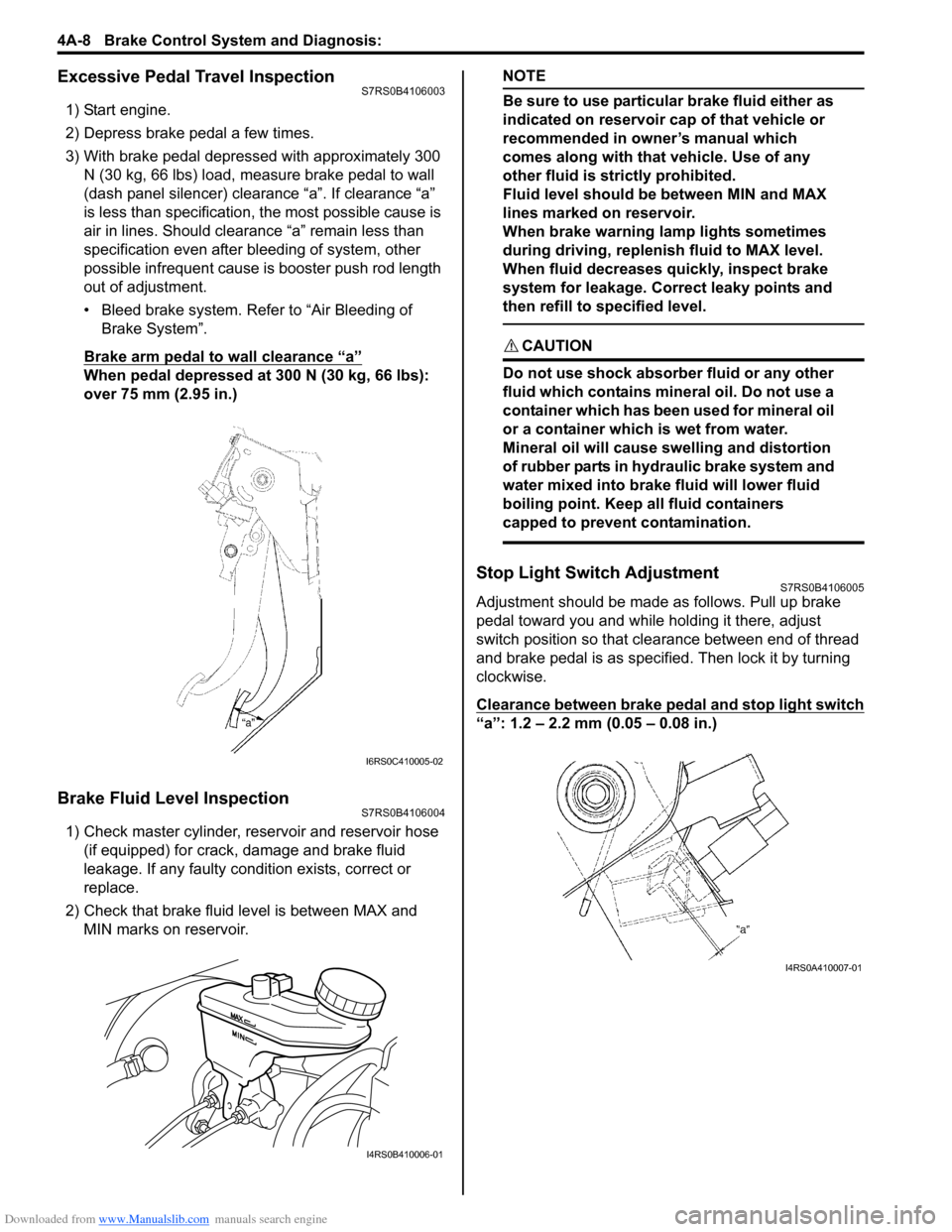

Excessive Pedal Travel InspectionS7RS0B4106003

1) Start engine.

2) Depress brake pedal a few times.

3) With brake pedal depressed with approximately 300 N (30 kg, 66 lbs) load, measure brake pedal to wall

(dash panel silencer) clearance “a”. If clearance “a”

is less than specification, the most possible cause is

air in lines. Should clearance “a” remain less than

specification even after bleeding of system, other

possible infrequent cause is booster push rod length

out of adjustment.

• Bleed brake system. Refer to “Air Bleeding of Brake System”.

Brake arm pedal to wall clearance “a”

When pedal depressed at 300 N (30 kg, 66 lbs):

over 75 mm (2.95 in.)

Brake Fluid Level InspectionS7RS0B4106004

1) Check master cylinder, reservoir and reservoir hose (if equipped) for crack, damage and brake fluid

leakage. If any faulty condition exists, correct or

replace.

2) Check that brake fluid level is between MAX and MIN marks on reservoir.

NOTE

Be sure to use particular brake fluid either as

indicated on reservoir cap of that vehicle or

recommended in owner’s manual which

comes along with that vehicle. Use of any

other fluid is strictly prohibited.

Fluid level should be between MIN and MAX

lines marked on reservoir.

When brake warning lamp lights sometimes

during driving, replenis h fluid to MAX level.

When fluid decreases quickly, inspect brake

system for leakage. Correct leaky points and

then refill to specified level.

CAUTION!

Do not use shock absorber fluid or any other

fluid which contains mineral oil. Do not use a

container which has been used for mineral oil

or a container which is wet from water.

Mineral oil will cause swelling and distortion

of rubber parts in hydraulic brake system and

water mixed into brake fluid will lower fluid

boiling point. Keep all fluid containers

capped to prevent contamination.

Stop Light Switch AdjustmentS7RS0B4106005

Adjustment should be made as follows. Pull up brake

pedal toward you and while holding it there, adjust

switch position so that clea rance between end of thread

and brake pedal is as specified. Then lock it by turning

clockwise.

Clearance between brake pedal and stop light switch

“a”: 1.2 – 2.2 mm (0.05 – 0.08 in.)

I6RS0C410005-02

I4RS0B410006-01

I4RS0A410007-01

Page 507 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-9

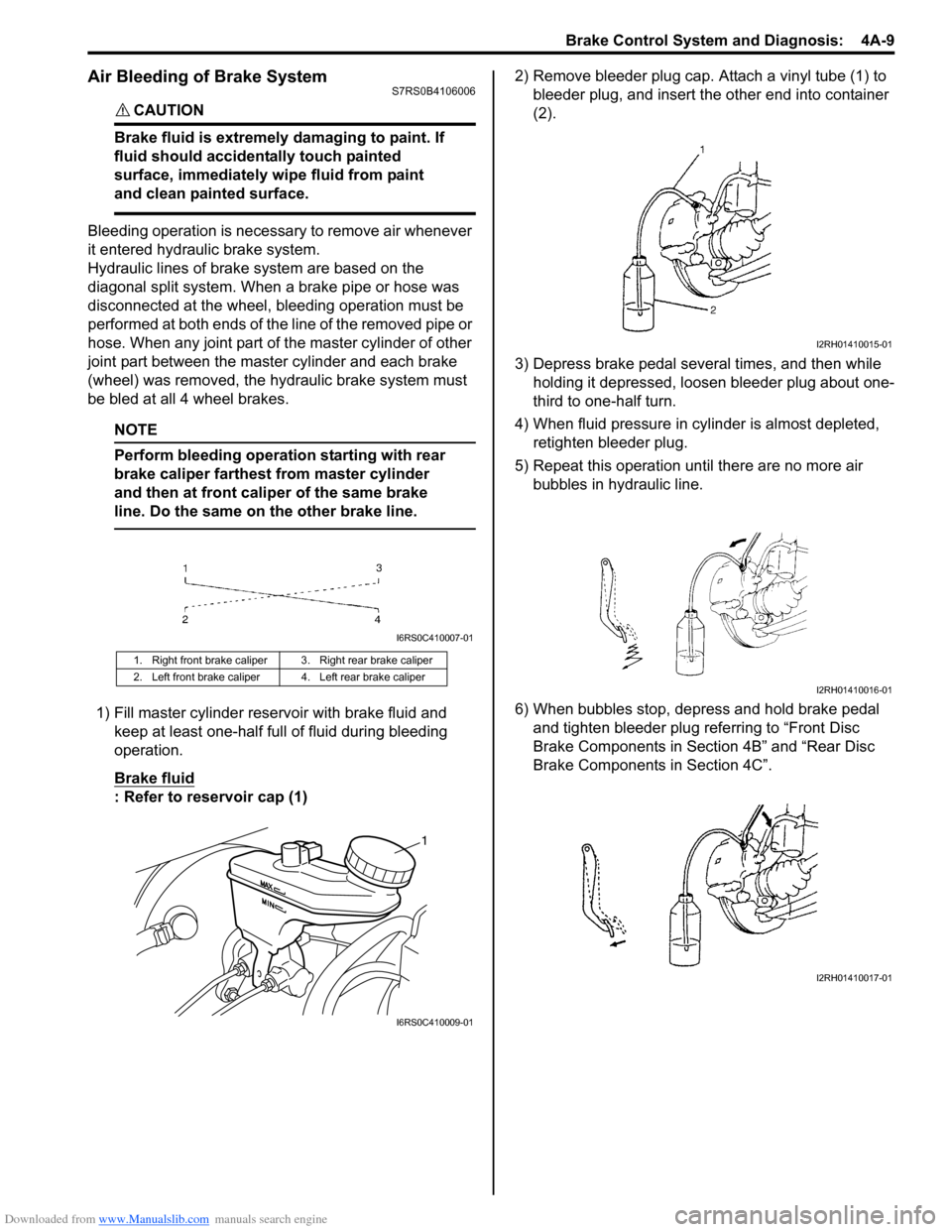

Air Bleeding of Brake SystemS7RS0B4106006

CAUTION!

Brake fluid is extremely damaging to paint. If

fluid should accidentally touch painted

surface, immediately wipe fluid from paint

and clean painted surface.

Bleeding operation is necessary to remove air whenever

it entered hydraulic brake system.

Hydraulic lines of brake system are based on the

diagonal split system. When a brake pipe or hose was

disconnected at the wheel, bleeding operation must be

performed at both ends of the line of the removed pipe or

hose. When any joint part of the master cylinder of other

joint part between the master cylinder and each brake

(wheel) was removed, the hydraulic brake system must

be bled at all 4 wheel brakes.

NOTE

Perform bleeding operation starting with rear

brake caliper farthest from master cylinder

and then at front caliper of the same brake

line. Do the same on the other brake line.

1) Fill master cylinder rese rvoir with brake fluid and

keep at least one-half full of fluid during bleeding

operation.

Brake fluid

: Refer to reservoir cap (1) 2) Remove bleeder plug cap. Attach a vinyl tube (1) to

bleeder plug, and insert the other end into container

(2).

3) Depress brake pedal several times, and then while holding it depressed, loosen bleeder plug about one-

third to one-half turn.

4) When fluid pressure in cy linder is almost depleted,

retighten bleeder plug.

5) Repeat this operation until there are no more air bubbles in hydraulic line.

6) When bubbles stop, depress and hold brake pedal and tighten bleeder plug referring to “Front Disc

Brake Components in Section 4B” and “Rear Disc

Brake Components in Section 4C”.

1. Right front brake caliper 3. Right rear brake caliper

2. Left front brake caliper 4. Left rear brake caliper

I6RS0C410007-01

1

I6RS0C410009-01

I2RH01410015-01

I2RH01410016-01

I2RH01410017-01

Page 508 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-10 Brake Control System and Diagnosis:

7) Then attach bleeder plug cap.

8) After completing bleeding operation, apply fluid pressure to pipe line and check for leakage.

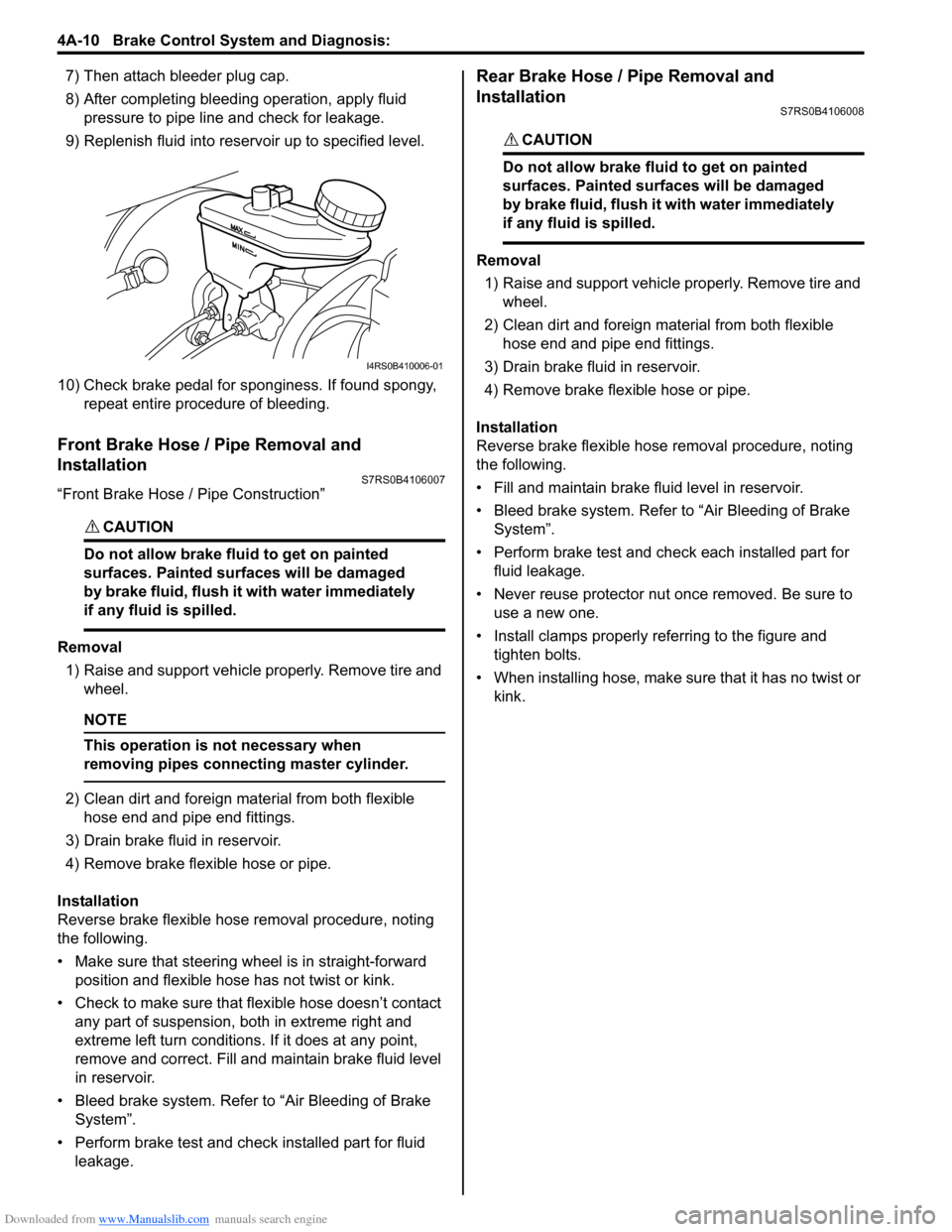

9) Replenish fluid into reserv oir up to specified level.

10) Check brake pedal for sponginess. If found spongy, repeat entire procedure of bleeding.

Front Brake Hose / Pipe Removal and

Installation

S7RS0B4106007

“Front Brake Hose / Pipe Construction”

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Raise and support vehicle properly. Remove tire and wheel.

NOTE

This operation is not necessary when

removing pipes connecting master cylinder.

2) Clean dirt and foreign mate rial from both flexible

hose end and pipe end fittings.

3) Drain brake fluid in reservoir.

4) Remove brake flexible hose or pipe.

Installation

Reverse brake flexible hose removal procedure, noting

the following.

• Make sure that steering wh eel is in straight-forward

position and flexible hose has not twist or kink.

• Check to make sure that flexible hose doesn’t contact any part of suspension, both in extreme right and

extreme left turn conditions. If it does at any point,

remove and correct. Fill and maintain brake fluid level

in reservoir.

• Bleed brake system. Refer to “Air Bleeding of Brake System”.

• Perform brake test and check installed part for fluid leakage.

Rear Brake Hose / Pipe Removal and

Installation

S7RS0B4106008

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Raise and support vehicle properly. Remove tire and wheel.

2) Clean dirt and foreign material from both flexible hose end and pipe end fittings.

3) Drain brake fluid in reservoir.

4) Remove brake flexible hose or pipe.

Installation

Reverse brake flexible hose removal procedure, noting

the following.

• Fill and maintain brake fluid level in reservoir.

• Bleed brake system. Refer to “Air Bleeding of Brake System”.

• Perform brake test and check each installed part for fluid leakage.

• Never reuse protector nut once removed. Be sure to use a new one.

• Install clamps properly referring to the figure and tighten bolts.

• When installing hose, make sure that it has no twist or

kink.

I4RS0B410006-01

Page 511 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-13

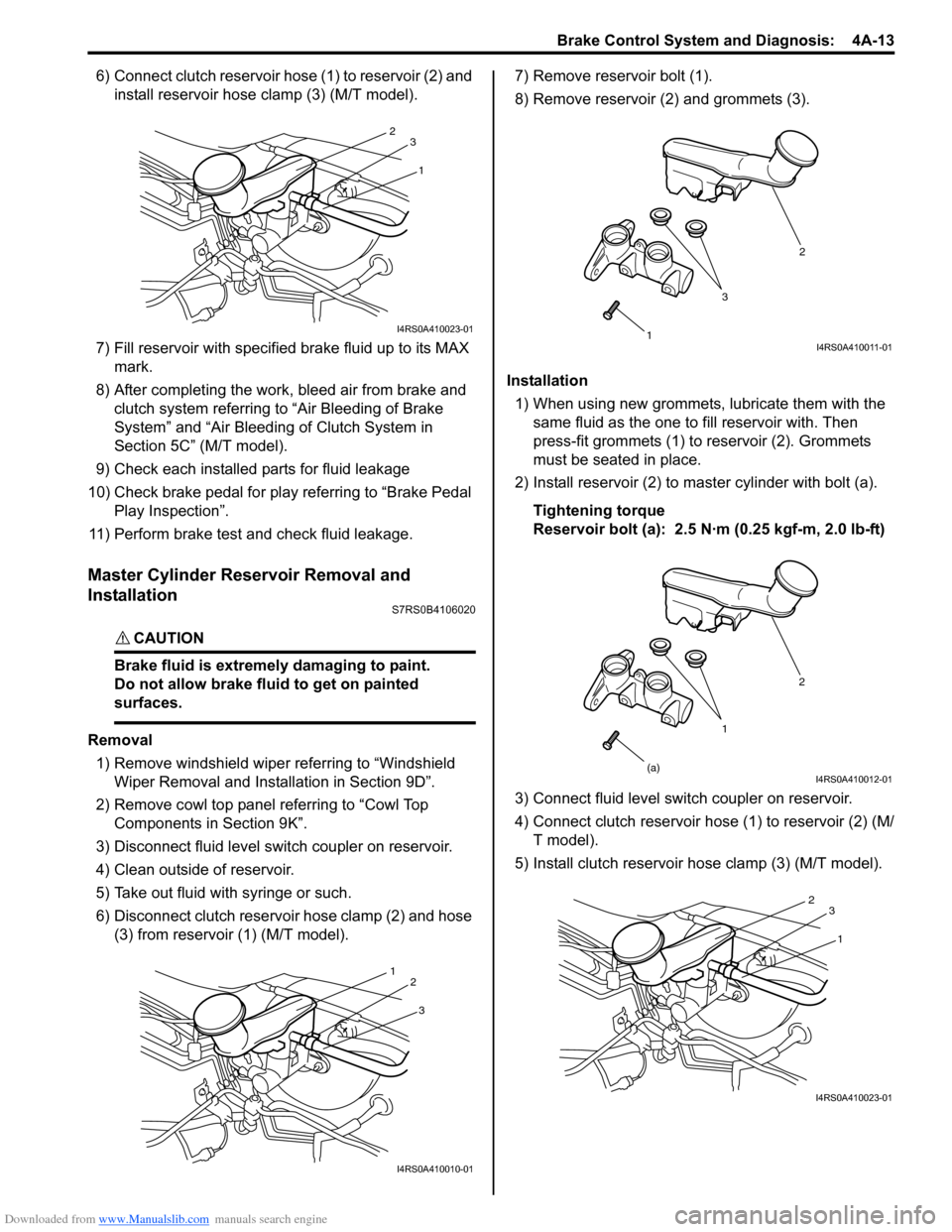

6) Connect clutch reservoir hose (1) to reservoir (2) and install reservoir hose clamp (3) (M/T model).

7) Fill reservoir with specified brake fluid up to its MAX

mark.

8) After completing the work, bleed air from brake and clutch system referring to “Air Bleeding of Brake

System” and “Air Bleeding of Clutch System in

Section 5C” (M/T model).

9) Check each installed parts for fluid leakage

10) Check brake pedal for play referring to “Brake Pedal Play Inspection”.

11) Perform brake test and check fluid leakage.

Master Cylinder Reservoir Removal and

Installation

S7RS0B4106020

CAUTION!

Brake fluid is extremely damaging to paint.

Do not allow brake fluid to get on painted

surfaces.

Removal 1) Remove windshield wiper referring to “Windshield Wiper Removal and Insta llation in Section 9D”.

2) Remove cowl top panel referring to “Cowl Top Components in Section 9K”.

3) Disconnect fluid level s witch coupler on reservoir.

4) Clean outside of reservoir.

5) Take out fluid with syringe or such.

6) Disconnect clutch reservoir hose clamp (2) and hose (3) from reservoir (1) (M/T model). 7) Remove reservoir bolt (1).

8) Remove reservoir (2) and grommets (3).

Installation 1) When using new grommets, lubricate them with the same fluid as the one to fill reservoir with. Then

press-fit grommets (1) to reservoir (2). Grommets

must be seated in place.

2) Install reservoir (2) to master cylinder with bolt (a).

Tightening torque

Reservoir bolt (a): 2.5 N·m (0.25 kgf-m, 2.0 lb-ft)

3) Connect fluid level switch coupler on reservoir.

4) Connect clutch reservoir hose (1) to reservoir (2) (M/ T model).

5) Install clutch reservoir hose clamp (3) (M/T model).

1

2

3

I4RS0A410023-01

3

1

2

I4RS0A410010-01

1 2

3I4RS0A410011-01

1 2

(a)

I4RS0A410012-01

1

2

3

I4RS0A410023-01