section 9k SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 396 of 1496

Downloaded from www.Manualslib.com manuals search engine 1H-4 Ignition System:

Diagnostic Information and Procedures

Ignition System Symptom DiagnosisS7RS0B1804001

Reference Waveform of Ignition SystemS7RS0B1804002

Refer to “Reference waveform No.5”, “Reference waveform No.6” and “Reference waveform No.7” under “Inspection

of ECM and Its Circuits in Section 1A” for waveform of Ignition trigger signal.

Ignition System CheckS7RS0B1804003

Condition Possible cause Correction / Reference Item

Engine cranks, but will

not start or hard to start

(No spark) Blown fuse for ignition coil

Replace.

Loose connection or disconnection of

lead wire or high-tension cord(s) Connect securely.

Faulty high-tension cord(s) Replace.

Faulty spark plug(s) Replace.

Faulty ignition coil Replace ignition coil assembly.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaft Clean, tighten or replace.

Faulty ECM Replace.

Poor fuel economy or

engine performance Incorrect ignition timing

Check related sensors and CKP sensor plate.

Faulty spark plug(s) or high-tension

cord(s) Adjust, clean or replace.

Faulty ignition coil assembly Replace.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaft Clean, tighten or replace.

Faulty knock sensor Replace.

Faulty ECM Replace.

StepAction YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check in

Section 1A”.

2 Ignition spark test

1) Check all spark plugs for condition and type referring to

“Spark Plug Inspection”.

2) If OK, perform ignition spark test referring to “Ignition Spar k Tes t”.

Is spark emitted from all spark plugs? Go to Step 13. Go to Step 3.

3 DTC check

1) Perform DTC check referring to “DTC Check in Section

1A”.

Is DTC stored in ECM? Go to applicable DTC

diag. flow.

Go to Step 4.

4 Electrical connection check

1) Check ignition coil assemblies and high-tension cords

for electrical connection.

Are they connected securely? Go to Step 5.

Connect securely.

5 High-tension cords check

1) Check high-tension cord for resistance referring to

“High-Tension Cord Inspection”.

Is check result satisfactory? Go to Step 6.

Replace high-tension

cord(s).

Page 397 of 1496

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-5

6Ignition coil assembly power supply and ground circuit

check

1) Check ignition coil assembly power supply and ground

circuits for open and short.

Are circuits in good condition? Go to Step 7.

Repair or replace.

7 Ignition coil assembly check

1) Check ignition coil for resistance referring to “Ignition

Coil Assembly (Including ignitor) Inspection”.

Is check result satisfactory? Go to Step 8.

Replace ignition coil

assembly.

8 CKP sensor check

1) Check CKP sensor referring to “CKP Sensor Inspection

in Section 1C”.

Is check result satisfactory? Go to Step 9.

Tighten CKP sensor

bolt, replace CKP

sensor or CKP sensor

plate.

9 CMP sensor check

1) Check CMP sensor referring to “Camshaft Position

(CMP) Sensor Inspection in Section 1C”.

Is check result satisfactory? Go to Step 10. Tighten CMP sensor

bolt, replace CMP

sensor or intake

camshaft.

10 Ignition trigger signal circuit check

1) Check ignition trigger signal wire for open, short and

poor connection.

Is circuit in good condition? Go to Step 11. Repair or replace.

11 A known-good ignition coil assembly substitution

1) Substitute a known-good ignition coil assembly and then

repeat Step 2.

Is check result of Step 2 satisfactory? Go to Step 12. Substitute a known-

good ECM and then

repeat Step 2.

12 Knock sensor check

1) Confirm that knock sensor circuit is in good condition

referring to “DTC P0327 / P0328: Knock Sensor 1 Circuit

Low / High in Section 1A”.

2) Check oscilloscope waveform of knock sensor signal

referring to “Reference waveform No.25” and

“Reference waveform No.26” under “Inspection of ECM

and Its Circuits in Section 1A”.

Is check result satisfactory? Go to Step 13. Substitute a known-

good knock sensor and

recheck.

13 Ignition timing check

1) Check initial ignition timing and ignition timing advance

referring to “Ignition Timing Inspection”.

Is check result satisfactory? System is in good

condition.

Check CMP sensor,

CMP sensor rotor tooth

of camshaft, CKP

sensor, CKP sensor

plate and/or input

signals related to this

system.

Step

Action YesNo

Page 400 of 1496

Downloaded from www.Manualslib.com manuals search engine 1H-8 Ignition System:

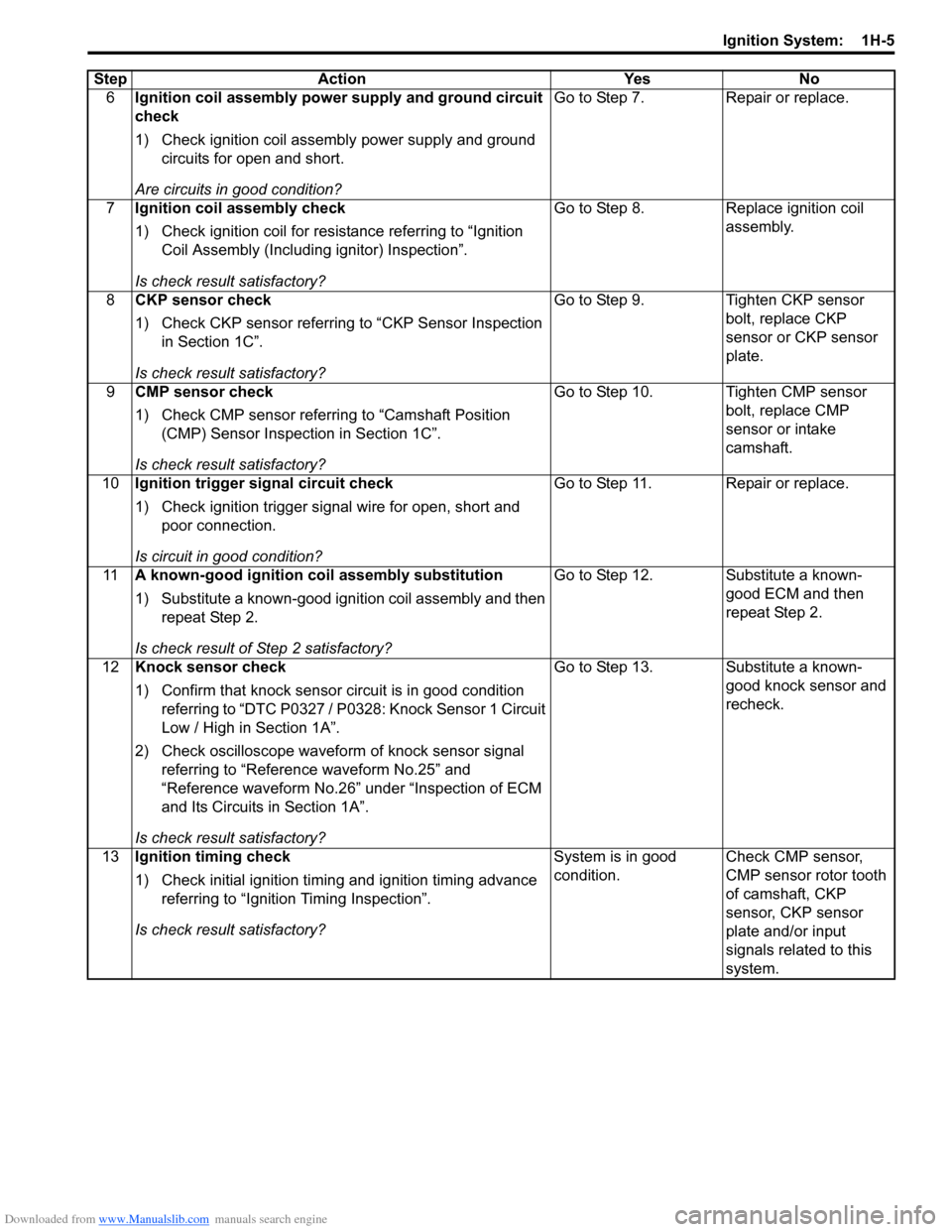

Ignition Coil Assembly (Including ignitor)

Removal and Installation

S7RS0B1806005

Removal1) Disconnect negative (–) cable at battery.

2) Remove air cleaner assembly with air intake pipe and cylinder head upper cover.

3) Disconnect ignition coil coupler.

4) Disconnect high-tension cord (3) from ignition coil assembly (2).

5) Remove ignition coil bolts (1) and then pull out ignition coil assembly.

Installation 1) Install ignition coil assembly (2).

2) Tighten ignition coil bolts (1) to specified torque, and then connect igni tion coil coupler.

Tightening torque

Ignition coil bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

3) Install high-tension cord (3) to ignition coil assembly while gripping its cap.

4) Install cylinder head upper cover and air cleaner assembly with air intake pipe.

5) Connect negative (–) cable to battery.

Ignition Coil Assembly (Including ignitor)

Inspection

S7RS0B1806006

Measure secondary coil for resistance.

If resistance is out of specification, replace ignition coil

assembly.

Secondary coil resistance

7.5 – 10.3 k Ω at 20 °C, 68 ° F

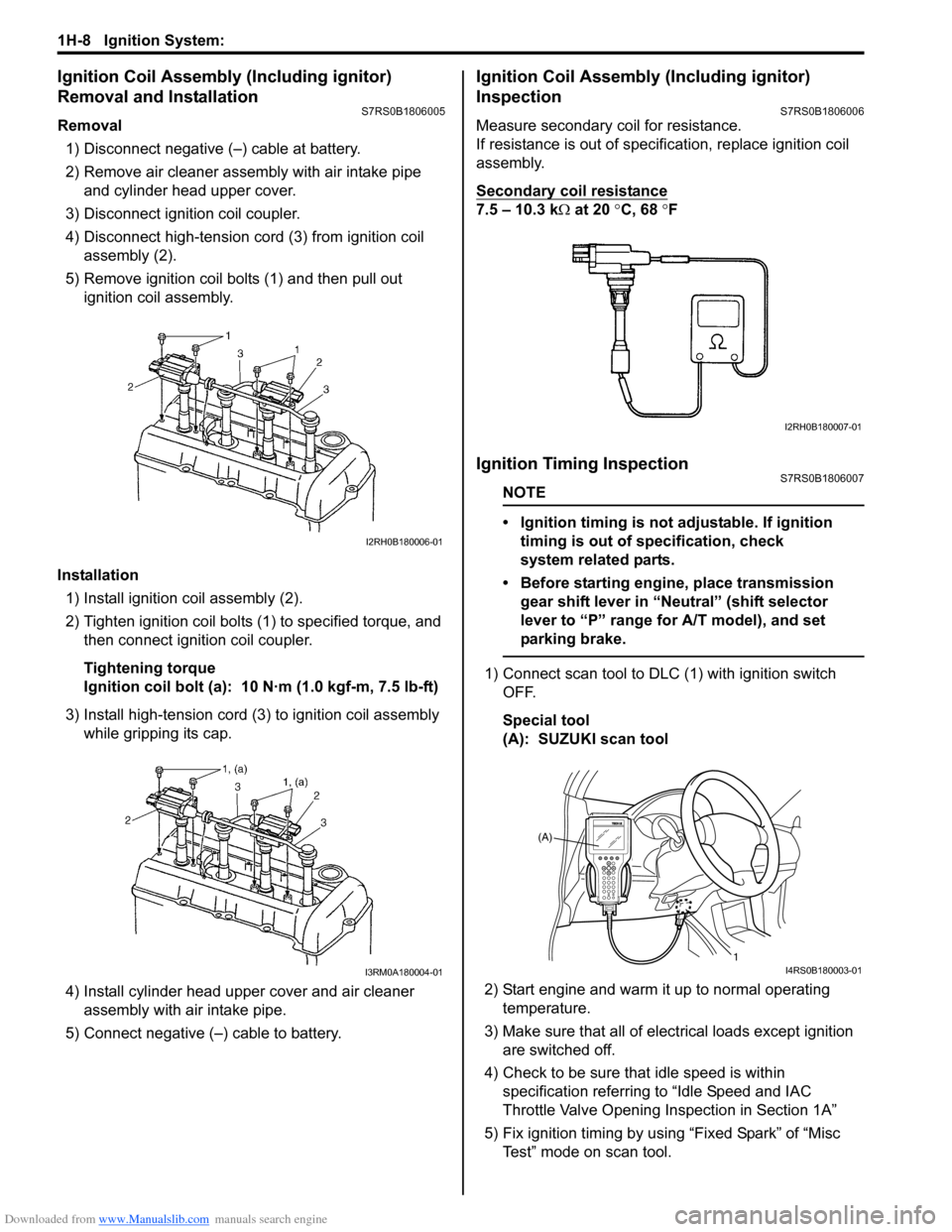

Ignition Timing InspectionS7RS0B1806007

NOTE

• Ignition timing is not adjustable. If ignition

timing is out of specification, check

system related parts.

• Before starting engine, place transmission gear shift lever in “Neutral” (shift selector

lever to “P” range for A/T model), and set

parking brake.

1) Connect scan tool to DLC (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

2) Start engine and warm it up to normal operating temperature.

3) Make sure that all of electrical loads except ignition are switched off.

4) Check to be sure that idle speed is within specification referring to “Idle Speed and IAC

Throttle Valve Opening Inspection in Section 1A”

5) Fix ignition timing by using “Fixed Spark” of “Misc Test” mode on scan tool.

I2RH0B180006-01

I3RM0A180004-01

I2RH0B180007-01

(A)

1

I4RS0B180003-01

Page 401 of 1496

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-9

6) Set timing light (1) to high-tension cord for No.1 cylinder and check that ignition timing is within

specification.

Initial ignition timing

Fixed with SUZUKI scan tool: 5 ± 3° BTDC (at

specified idle speed)

Ignition order

1 – 3 – 4 – 2

Special tool

(A): 09930–76420 7) If ignition timing is out

of specification, check the

followings.

• CKP sensor

• CKP sensor plate

• CMP sensor

• CMP sensor rotor tooth of camshaft

• VSS

• Timing chain cover installation

8) After checking initial igniti on timing, release ignition

timing fixation by using scan tool.

9) With engine idling (throttl e opening at closed position

and vehicle stopped), check that ignition timing is

about 3 ° – 13° BTDC. (Constant variation within a

few degrees from 3 ° – 13° BTDC indicates no

abnormality but proves operation of electronic timing

control system.) Also, check that increasing engine

speed advances ignition timing.

If the check results are not satisfactory, check CKP

sensor and ECM.

Specifications

Tightening Torque SpecificationsS7RS0B1807001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS7RS0B1808001

1, (A)10

0I3RB0A180004-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Spark plug 25 2.5 18.0 �)

Ignition coil bolt 10 1.0 7.5 �)

09930–76420SUZUKI scan tool

Timing-light (dry cell type) —

�) This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. �)

Page 403 of 1496

Downloaded from www.Manualslib.com manuals search engine Starting System: 1I-2

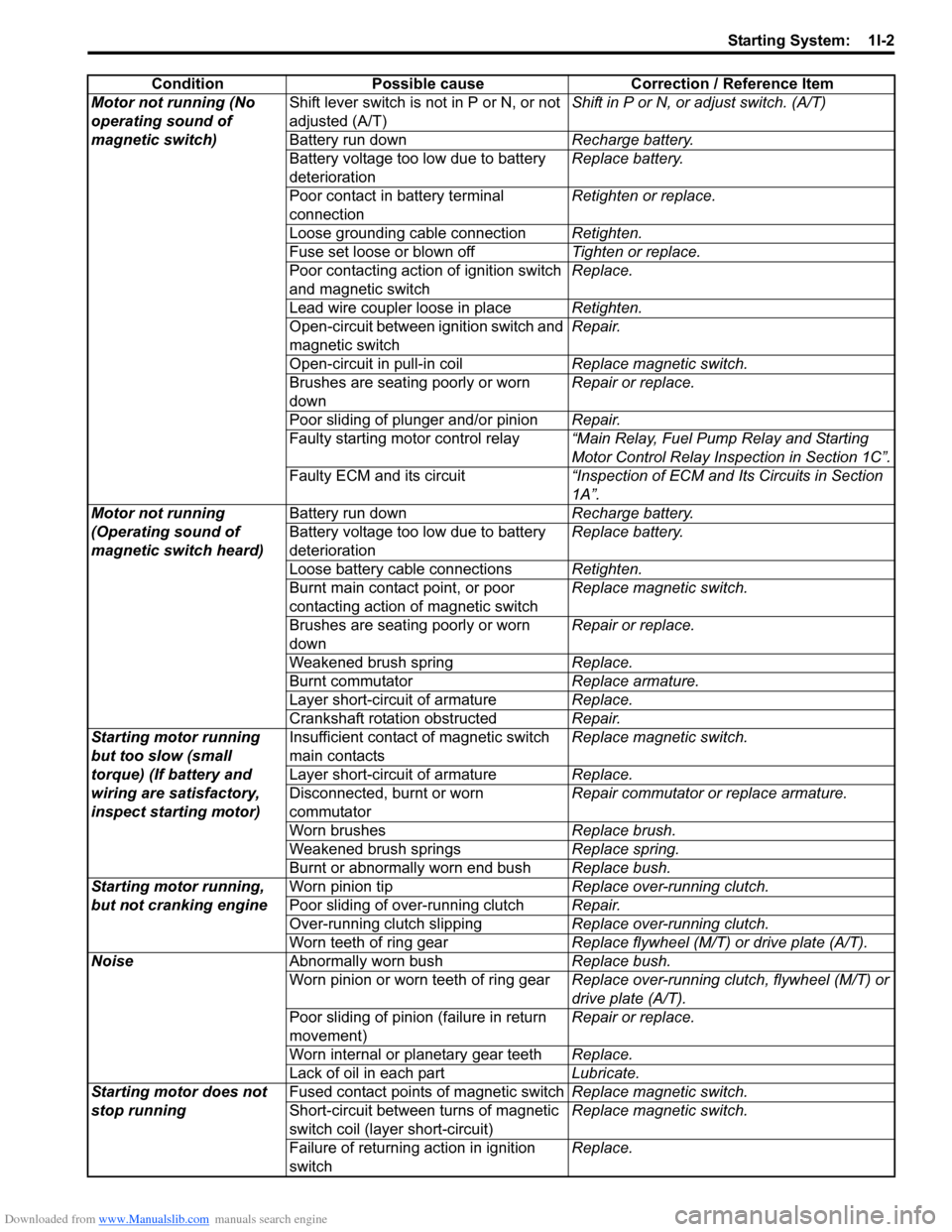

ConditionPossible cause Correction / Reference Item

Motor not running (No

operating sound of

magnetic switch) Shift lever switch is not in P or N, or not

adjusted (A/T)

Shift in P or N, or

adjust switch. (A/T)

Battery run down Recharge battery.

Battery voltage too low due to battery

deterioration Replace battery.

Poor contact in battery terminal

connection Retighten or replace.

Loose grounding cable connection Retighten.

Fuse set loose or blown off Tighten or replace.

Poor contacting action of ignition switch

and magnetic switch Replace.

Lead wire coupler loose in place Retighten.

Open-circuit between ignition switch and

magnetic switch Repair.

Open-circuit in pull-in coil Replace magnetic switch.

Brushes are seating poorly or worn

down Repair or replace.

Poor sliding of plunger and/or pinion Repair.

Faulty starting motor control relay “Main Relay, Fuel Pump Relay and Starting

Motor Control Relay Inspection in Section 1C”.

Faulty ECM and its circuit “Inspection of ECM and Its Circuits in Section

1A”.

Motor not running

(Operating sound of

magnetic switch heard) Battery run down

Recharge battery.

Battery voltage too low due to battery

deterioration Replace battery.

Loose battery cable connections Retighten.

Burnt main contact point, or poor

contacting action of magnetic switch Replace magnetic switch.

Brushes are seating poorly or worn

down Repair or replace.

Weakened brush spring Replace.

Burnt commutator Replace armature.

Layer short-circuit of armature Replace.

Crankshaft rotation obstructed Repair.

Starting motor running

but too slow (small

torque) (If battery and

wiring are satisfactory,

inspect starting motor) Insufficient contact

of magnetic switch

main contacts Replace magnetic switch.

Layer short-circuit of armature Replace.

Disconnected, burnt or worn

commutator Repair commutator or replace armature.

Worn brushes Replace brush.

Weakened brush springs Replace spring.

Burnt or abnormally worn end bush Replace bush.

Starting motor running,

but not cranking engine Worn pinion tip

Replace over-running clutch.

Poor sliding of over-running clutch Repair.

Over-running clutch slipping Replace over-running clutch.

Worn teeth of ring gear Replace flywheel (M/T) or drive plate (A/T).

Noise Abnormally worn bush Replace bush.

Worn pinion or worn teeth of ring gear Replace over-running clutch, flywheel (M/T) or

drive plate (A/T).

Poor sliding of pinion (failure in return

movement) Repair or replace.

Worn internal or planetary gear teeth Replace.

Lack of oil in each part Lubricate.

Starting motor does not

stop running Fused contact points of magnetic switch

Replace magnetic switch.

Short-circuit between turns of magnetic

switch coil (layer short-circuit) Replace magnetic switch.

Failure of returning action in ignition

switch Replace.

Page 410 of 1496

Downloaded from www.Manualslib.com manuals search engine 1I-9 Starting System:

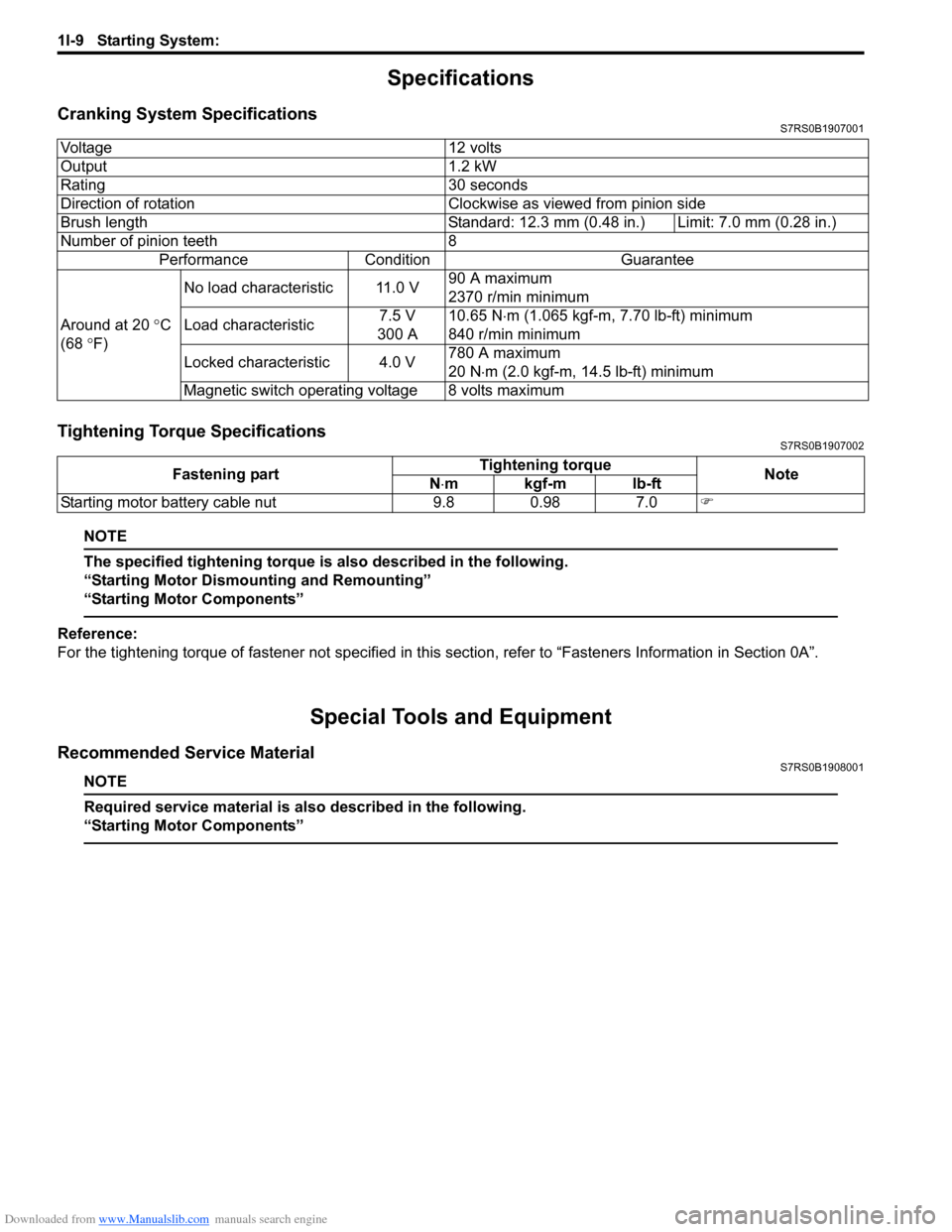

Specifications

Cranking System SpecificationsS7RS0B1907001

Tightening Torque SpecificationsS7RS0B1907002

NOTE

The specified tightening torque is also described in the following.

“Starting Motor Dismounting and Remounting”

“Starting Motor Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B1908001

NOTE

Required service material is also described in the following.

“Starting Motor Components”

Voltage 12 volts

Output 1.2 kW

Rating 30 seconds

Direction of rotation Clockwise as viewed from pinion side

Brush length Standard: 12.3 mm (0.48 in.) Limit: 7.0 mm (0.28 in.)

Number of pinion teeth 8

Performance Condition Guarantee

Around at 20 °C

(68 °F) No load characteristic 11.0 V

90 A maximum

2370 r/min minimum

Load characteristic 7.5 V

300 A 10.65 N

⋅m (1.065 kgf-m, 7.70 lb-ft) minimum

840 r/min minimum

Locked characteristic 4.0 V 780 A maximum

20 N

⋅m (2.0 kgf-m, 14.5 lb-ft) minimum

Magnetic switch operating voltage 8 volts maximum

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Starting motor battery cable nut 9.8 0.98 7.0 �)

Page 413 of 1496

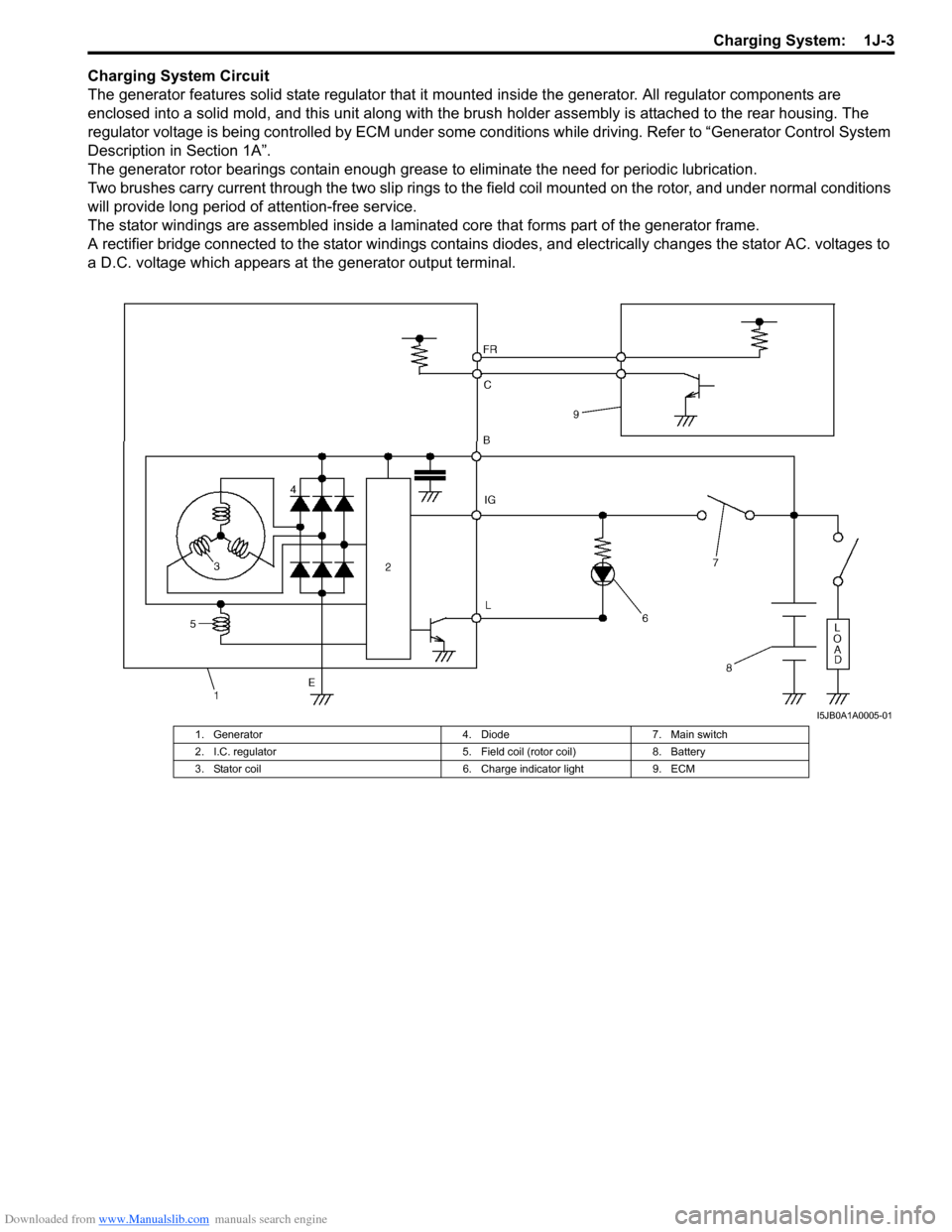

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-3

Charging System Circuit

The generator features solid state regulator that it mounted inside the generator. All regulator components are

enclosed into a solid mold, and this unit along with the brus h holder assembly is attached to the rear housing. The

regulator voltage is being controlled by ECM under some cond itions while driving. Refer to “Generator Control System

Description in Section 1A”.

The generator rotor bearings contain enough grease to eliminate the need for periodic lubrication.

Two brushes carry current through the two slip rings to the field coil mounted on the rotor, and under normal conditions

will provide long period of attention-free service.

The stator windings are assembled inside a laminate d core that forms part of the generator frame.

A rectifier bridge connected to the stator windings contains diodes, and electrically changes the stator AC. voltages to

a D.C. voltage which appears at the generator output terminal.

I5JB0A1A0005-01

1. Generator 4. Diode7. Main switch

2. I.C. regulator 5. Field coil (rotor coil)8. Battery

3. Stator coil 6. Charge indicator light9. ECM

Page 418 of 1496

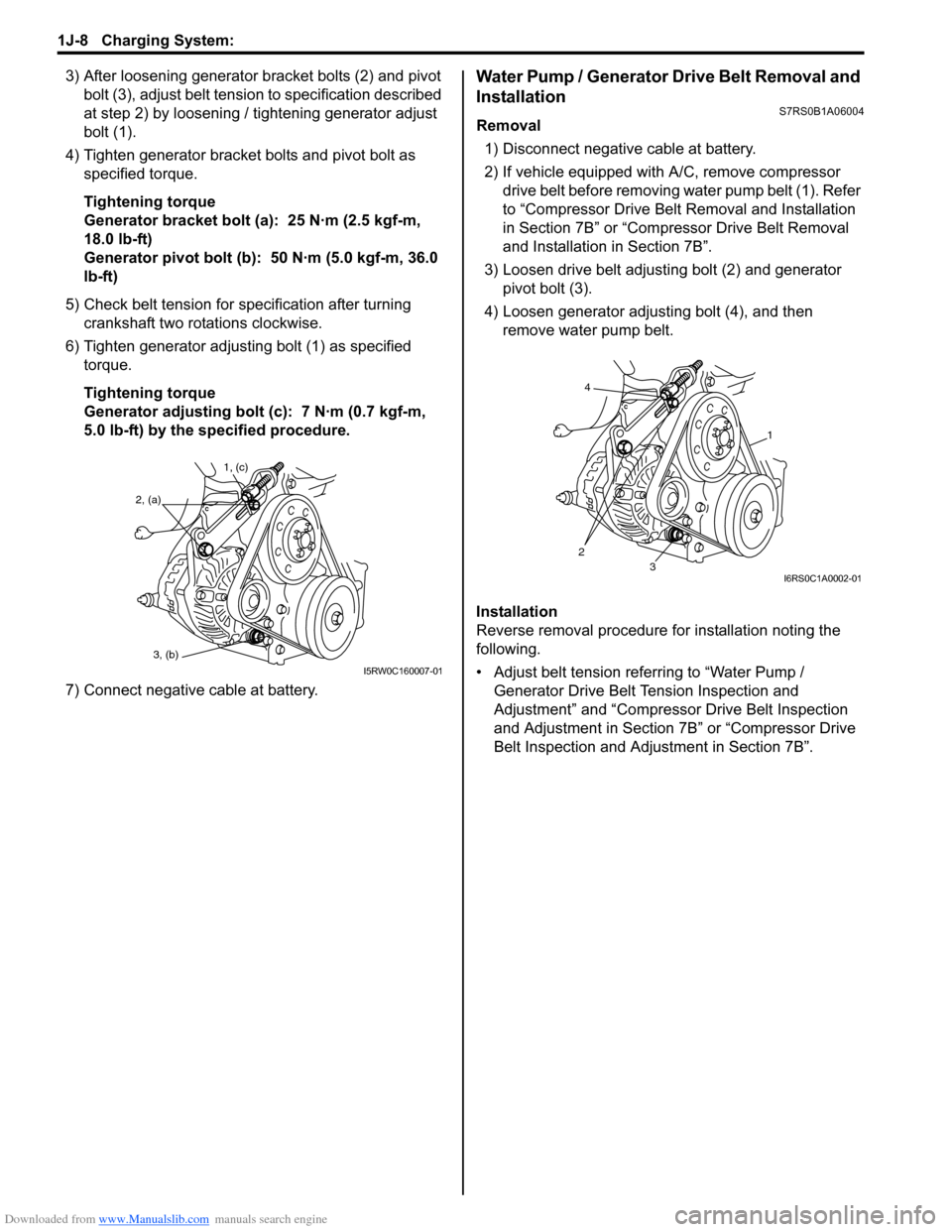

Downloaded from www.Manualslib.com manuals search engine 1J-8 Charging System:

3) After loosening generator bracket bolts (2) and pivot bolt (3), adjust belt tensio n to specification described

at step 2) by loosening / tightening generator adjust

bolt (1).

4) Tighten generator bracket bolts and pivot bolt as specified torque.

Tightening torque

Generator bracket bolt (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

Generator pivot bolt (b): 50 N·m (5.0 kgf-m, 36.0

lb-ft)

5) Check belt tension for specification after turning crankshaft two rotations clockwise.

6) Tighten generator adjusting bolt (1) as specified torque.

Tightening torque

Generator adjusting bolt (c): 7 N·m (0.7 kgf-m,

5.0 lb-ft) by the specified procedure.

7) Connect negative cable at battery.Water Pump / Generator Drive Belt Removal and

Installation

S7RS0B1A06004

Removal 1) Disconnect negative cable at battery.

2) If vehicle equipped with A/C, remove compressor drive belt before removing water pump belt (1). Refer

to “Compressor Drive Belt Removal and Installation

in Section 7B” or “Compr essor Drive Belt Removal

and Installation in Section 7B”.

3) Loosen drive belt adjusting bolt (2) and generator pivot bolt (3).

4) Loosen generator adjusting bolt (4), and then remove water pump belt.

Installation

Reverse removal procedure for installation noting the

following.

• Adjust belt tension referring to “Water Pump / Generator Drive Belt Tension Inspection and

Adjustment” and “Compressor Drive Belt Inspection

and Adjustment in Section 7B” or “Compressor Drive

Belt Inspection and Adjustment in Section 7B”.

1, (c)

2, (a)

3, (b)

I5RW0C160007-01

4

23

1

I6RS0C1A0002-01

Page 419 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-9

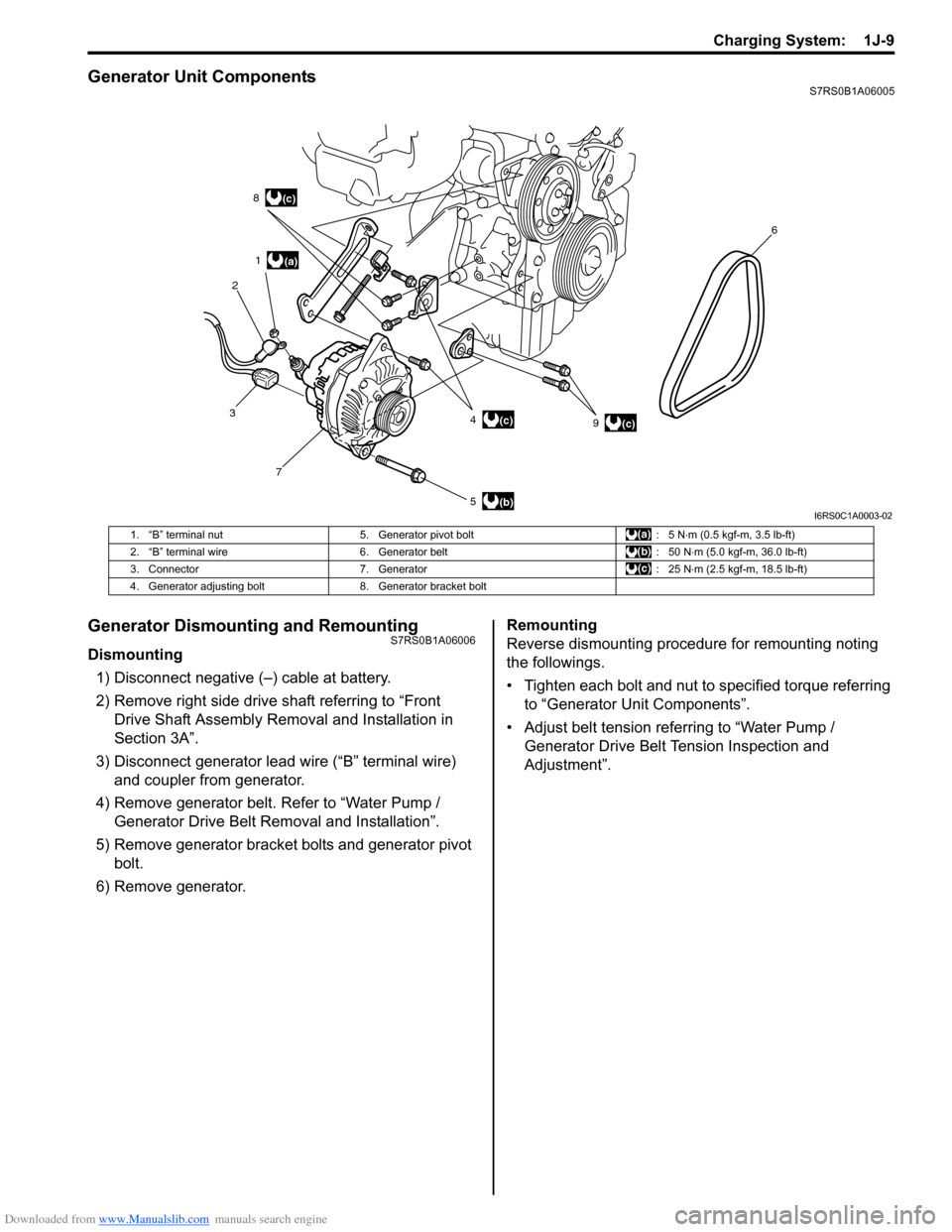

Generator Unit ComponentsS7RS0B1A06005

Generator Dismounting and RemountingS7RS0B1A06006

Dismounting1) Disconnect negative (–) cable at battery.

2) Remove right side drive shaft referring to “Front Drive Shaft Assembly Removal and Installation in

Section 3A”.

3) Disconnect generator lead wire (“B” terminal wire) and coupler from generator.

4) Remove generator belt. Refer to “Water Pump / Generator Drive Belt Re moval and Installation”.

5) Remove generator bracket bolts and generator pivot bolt.

6) Remove generator. Remounting

Reverse dismounting procedure for remounting noting

the followings.

• Tighten each bolt and nut to specified torque referring

to “Generator Unit Components”.

• Adjust belt tension referring to “Water Pump / Generator Drive Belt Tension Inspection and

Adjustment”.

(a)

(b)

(c)

1

2 8

3 7 5 49 6(c)

(c)

I6RS0C1A0003-02

1. “B” terminal nut

5. Generator pivot bolt : 5 N⋅m (0.5 kgf-m, 3.5 lb-ft)

2. “B” terminal wire 6. Generator belt : 50 N⋅m (5.0 kgf-m, 36.0 lb-ft)

3. Connector 7. Generator : 25 N⋅m (2.5 kgf-m, 18.5 lb-ft)

4. Generator adjusting bolt 8. Generator bracket bolt

Page 423 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-13

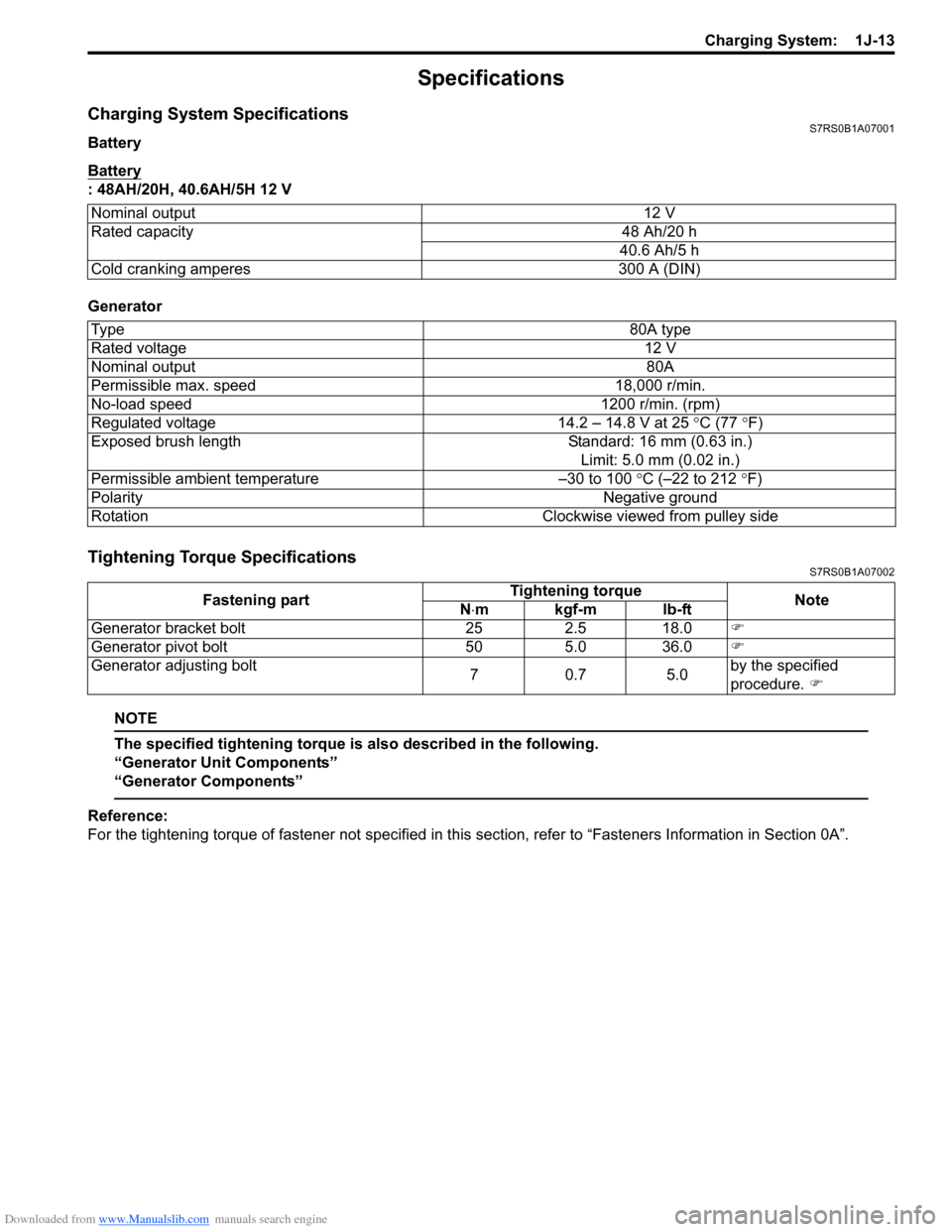

Specifications

Charging System SpecificationsS7RS0B1A07001

Battery

Battery

: 48AH/20H, 40.6AH/5H 12 V

Generator

Tightening Torque SpecificationsS7RS0B1A07002

NOTE

The specified tightening torque is also described in the following.

“Generator Unit Components”

“Generator Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Nominal output

12 V

Rated capacity 48 Ah/20 h

40.6 Ah/5 h

Cold cranking amperes 300 A (DIN)

Ty p e 80A type

Rated voltage 12 V

Nominal output 80A

Permissible max. speed 18,000 r/min.

No-load speed 1200 r/min. (rpm)

Regulated voltage 14.2 – 14.8 V at 25 ° C (77 °F)

Exposed brush length Standard: 16 mm (0.63 in.)

Limit: 5.0 mm (0.02 in.)

Permissible ambient temperature –30 to 100 °C (–22 to 212 °F)

Polarity Negative ground

Rotation Clockwise viewed from pulley side

Fastening partTightening torque

Note

N ⋅mkgf-mlb-ft

Generator bracket bolt 25 2.5 18.0 �)

Generator pivot bolt 50 5.0 36.0 �)

Generator adjusting bolt 70.7 5.0by the specified

procedure.

�)