section 9k SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 426 of 1496

Downloaded from www.Manualslib.com manuals search engine 1K-3 Exhaust System:

Exhaust Manifold Removal and InstallationS7RS0B1B06002

Removal

WARNING!

To avoid danger of being burned, do not

service exhaust system while it is still hot.

Service should be performed after system

cools down.

1) Disconnect negative cable at battery.

2) Remove engine cover.

3) Remove front bumper with front grille referring to

“Front Bumper and Rear Bumper Components in

Section 9K”.

4) Remove radiator referring to “Radiator Removal and Installation in Section 1F ” for equipped with A/C.

5) With hose connected, detach A/C condenser from vehicle body for equipped with A/C.

6) Remove exhaust manifold cover from exhaust manifold.

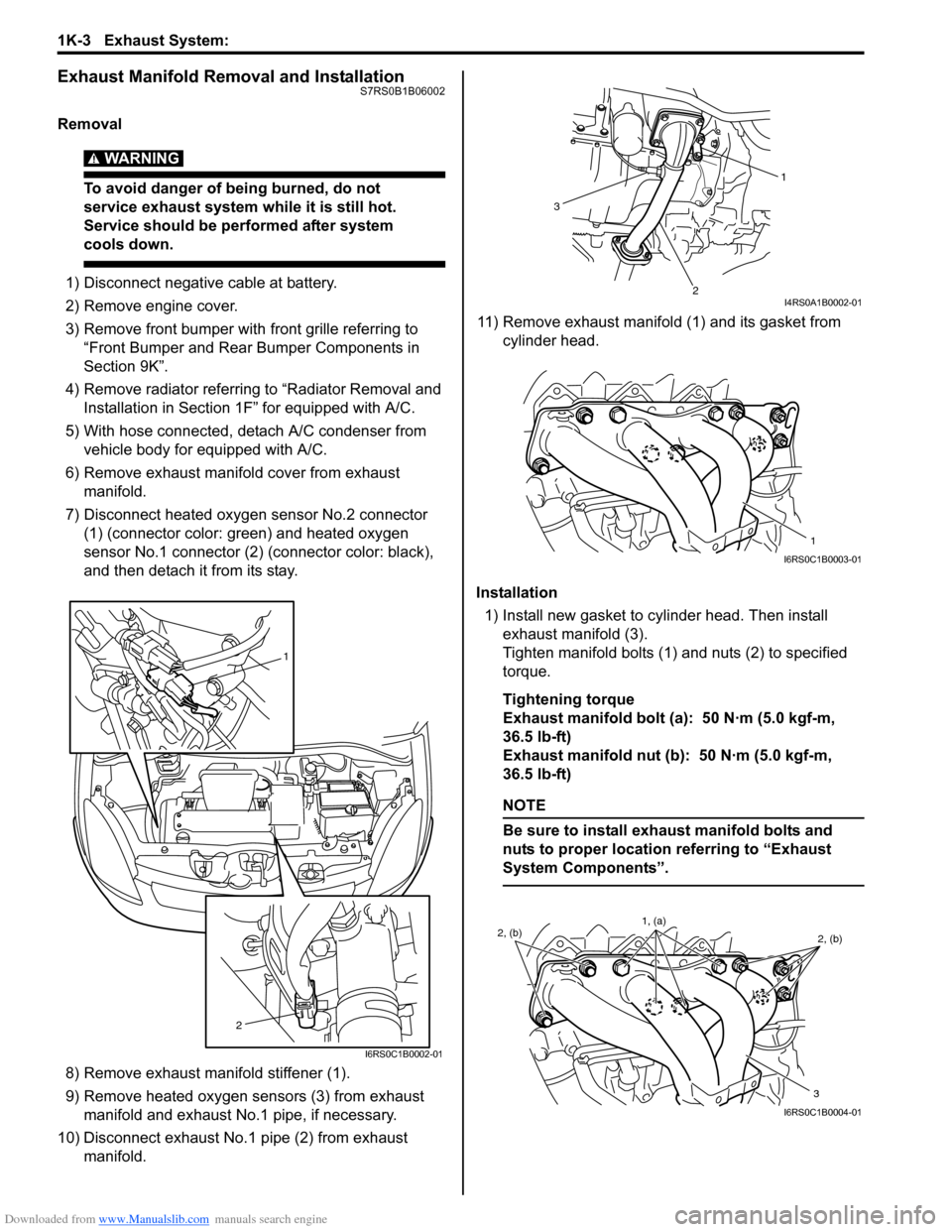

7) Disconnect heated oxygen sensor No.2 connector (1) (connector color: green) and heated oxygen

sensor No.1 connector (2) (connector color: black),

and then detach it from its stay.

8) Remove exhaust manifold stiffener (1).

9) Remove heated oxygen sensors (3) from exhaust manifold and exhaust No.1 pipe, if necessary.

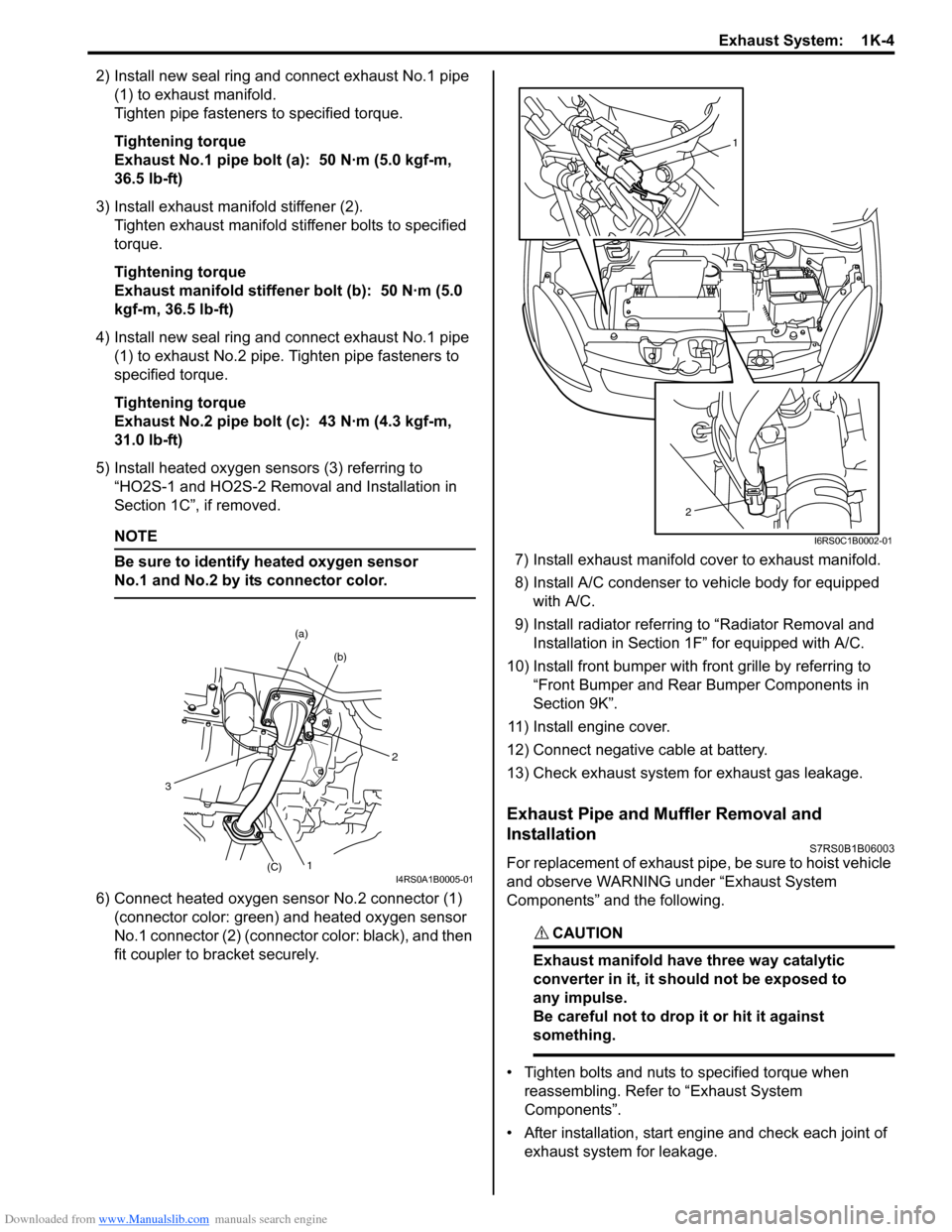

10) Disconnect exhaust No.1 pipe (2) from exhaust manifold. 11) Remove exhaust manifold (1) and its gasket from

cylinder head.

Installation 1) Install new gasket to cylinder head. Then install exhaust manifold (3).

Tighten manifold bolts (1) and nuts (2) to specified

torque.

Tightening torque

Exhaust manifold bolt (a): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

Exhaust manifold nut (b): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

NOTE

Be sure to install exhaust manifold bolts and

nuts to proper location referring to “Exhaust

System Components”.

1

2

I6RS0C1B0002-01

1

2

3

I4RS0A1B0002-01

1

I6RS0C1B0003-01

2, (b) 2, (b)

3

1, (a)

I6RS0C1B0004-01

Page 427 of 1496

Downloaded from www.Manualslib.com manuals search engine Exhaust System: 1K-4

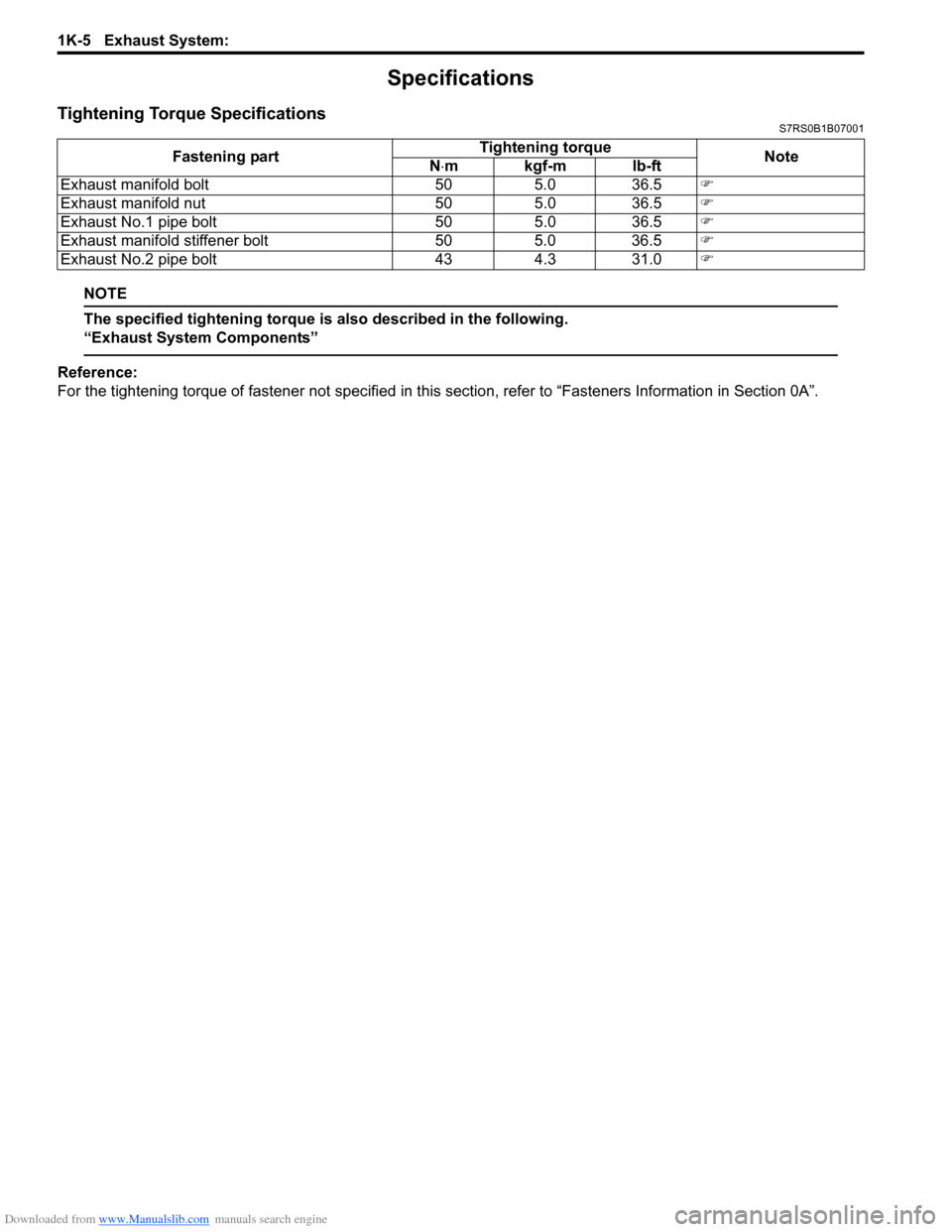

2) Install new seal ring and connect exhaust No.1 pipe (1) to exhaust manifold.

Tighten pipe fasteners to specified torque.

Tightening torque

Exhaust No.1 pipe bolt (a): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

3) Install exhaust manifold stiffener (2). Tighten exhaust manifold stiffener bolts to specified

torque.

Tightening torque

Exhaust manifold stiffener bolt (b): 50 N·m (5.0

kgf-m, 36.5 lb-ft)

4) Install new seal ring and connect exhaust No.1 pipe (1) to exhaust No.2 pipe. Tighten pipe fasteners to

specified torque.

Tightening torque

Exhaust No.2 pipe bolt (c): 43 N·m (4.3 kgf-m,

31.0 lb-ft)

5) Install heated oxygen sensors (3) referring to “HO2S-1 and HO2S-2 Removal and Installation in

Section 1C”, if removed.

NOTE

Be sure to identify heated oxygen sensor

No.1 and No.2 by its connector color.

6) Connect heated oxygen sensor No.2 connector (1)

(connector color: green) and heated oxygen sensor

No.1 connector (2) (connector color: black), and then

fit coupler to br acket securely. 7) Install exhaust manifold cover to exhaust manifold.

8) Install A/C condenser to vehicle body for equipped

with A/C.

9) Install radiator referrin g to “Radiator Removal and

Installation in Section 1F” for equipped with A/C.

10) Install front bumper with fr ont grille by referring to

“Front Bumper and Rear Bumper Components in

Section 9K”.

11) Install engine cover.

12) Connect negative cable at battery.

13) Check exhaust system for exhaust gas leakage.

Exhaust Pipe and Muffler Removal and

Installation

S7RS0B1B06003

For replacement of exhaust pipe, be sure to hoist vehicle

and observe WARNING under “Exhaust System

Components” and the following.

CAUTION!

Exhaust manifold have three way catalytic

converter in it, it should not be exposed to

any impulse.

Be careful not to drop it or hit it against

something.

• Tighten bolts and nuts to specified torque when reassembling. Refer to “Exhaust System

Components”.

• After installation, start engine and check each joint of exhaust system for leakage.

2

(b)

(a)

1(C)

3

I4RS0A1B0005-01

1

2

I6RS0C1B0002-01

Page 428 of 1496

Downloaded from www.Manualslib.com manuals search engine 1K-5 Exhaust System:

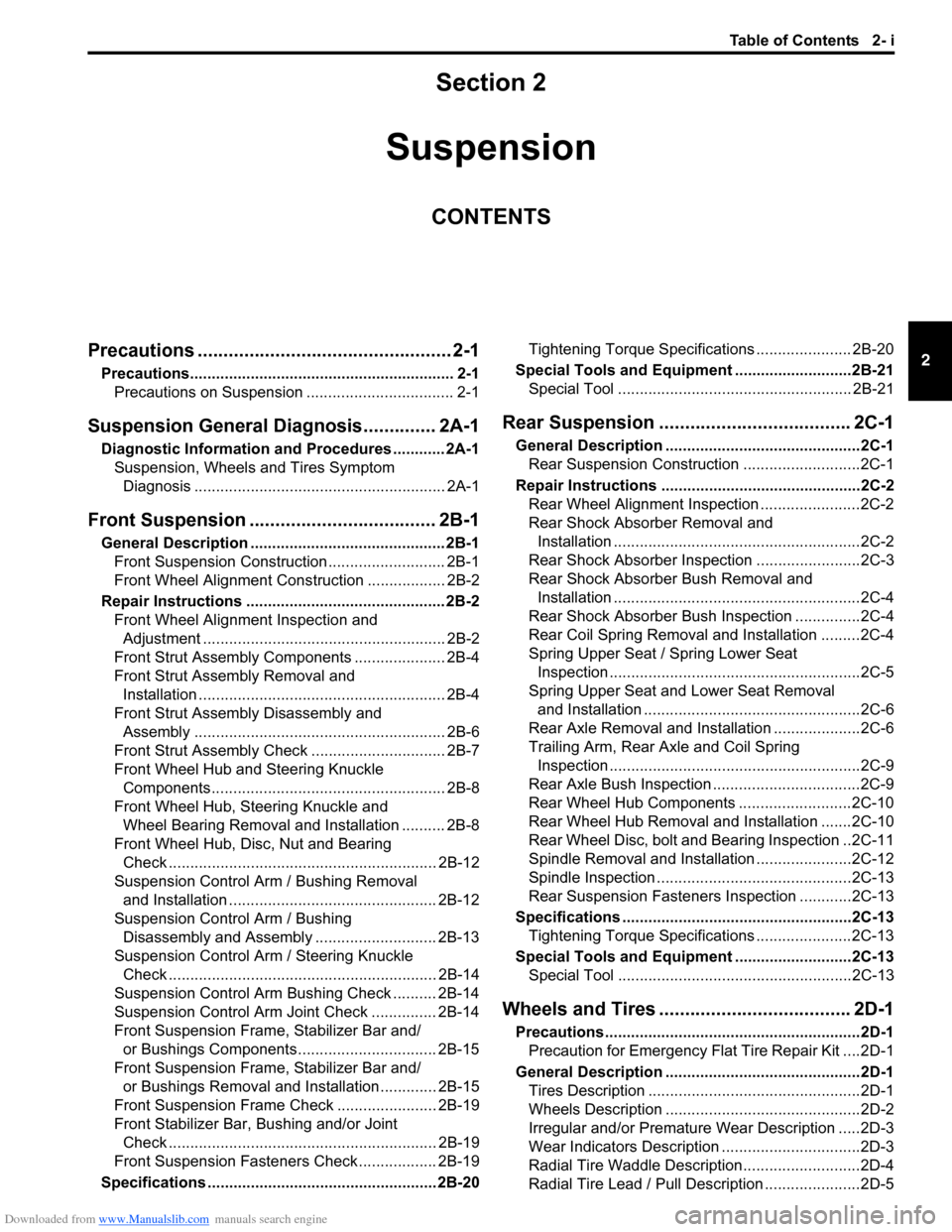

Specifications

Tightening Torque SpecificationsS7RS0B1B07001

NOTE

The specified tightening torque is also described in the following.

“Exhaust System Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Exhaust manifold bolt 505.0 36.5 �)

Exhaust manifold nut 505.0 36.5 �)

Exhaust No.1 pipe bolt 505.0 36.5 �)

Exhaust manifold stiffener bolt 505.0 36.5 �)

Exhaust No.2 pipe bolt 434.3 31.0 �)

Page 429 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 2- i

2

Section 2

CONTENTS

Suspension

Precautions ................................................. 2-1

Precautions............................................................. 2-1

Precautions on Suspension .................................. 2-1

Suspension General Dia gnosis.............. 2A-1

Diagnostic Information and Procedures ............ 2A-1

Suspension, Wheels and Tires Symptom Diagnosis .......................................................... 2A-1

Front Suspension ........... ......................... 2B-1

General Description ............................................. 2B-1

Front Suspension Construction ........................... 2B-1

Front Wheel Alignment Cons truction .................. 2B-2

Repair Instructions .............................................. 2B-2 Front Wheel Alignment Inspection and Adjustment ........................................................ 2B-2

Front Strut Assembly Comp onents ..................... 2B-4

Front Strut Assembly Removal and Installation ......................................................... 2B-4

Front Strut Assembly Disassembly and Assembly .......................................................... 2B-6

Front Strut Assembly Chec k ............................... 2B-7

Front Wheel Hub and Steering Knuckle Components...................................................... 2B-8

Front Wheel Hub, Steering Knuckle and Wheel Bearing Removal and Installation .......... 2B-8

Front Wheel Hub, Disc, Nut and Bearing Check .............................................................. 2B-12

Suspension Control Arm / Bushing Removal and Installation ................................................ 2B-12

Suspension Control Arm / Bushing Disassembly and Assembly ............................ 2B-13

Suspension Control Arm / Steering Knuckle Check .............................................................. 2B-14

Suspension Control Arm Bushing Check .......... 2B-14

Suspension Control Arm Joint Check ............... 2B-14

Front Suspension Fram e, Stabilizer Bar and/

or Bushings Components................................ 2B-15

Front Suspension Fram e, Stabilizer Bar and/

or Bushings Removal and Installation ............. 2B-15

Front Suspension Frame Ch eck ....................... 2B-19

Front Stabilizer Bar, Bushing and/or Joint Check .............................................................. 2B-19

Front Suspension Fastener s Check .................. 2B-19

Specifications ..................................................... 2B-20 Tightening Torque Specifications ...................... 2B-20

Special Tools and Equipmen t ...........................2B-21

Special Tool ...................................................... 2B-21

Rear Suspension ............ ......................... 2C-1

General Description .............................................2C-1

Rear Suspension Construction ...........................2C-1

Repair Instructions ........... ...................................2C-2

Rear Wheel Alignment Inspection .......................2C-2

Rear Shock Absorber Removal and Installation .........................................................2C-2

Rear Shock Absorber Ins pection ........................2C-3

Rear Shock Absorber Bush Removal and Installation .........................................................2C-4

Rear Shock Absorber Bush Inspection ...............2C-4

Rear Coil Spring Removal and Installation .........2C-4

Spring Upper Seat / Spring Lower Seat Inspection ..........................................................2C-5

Spring Upper Seat and Lower Seat Removal and Installation ..................................................2C-6

Rear Axle Removal and Inst allation ....................2C-6

Trailing Arm, Rear Axle and Coil Spring Inspection ..........................................................2C-9

Rear Axle Bush Inspection ..................................2C-9

Rear Wheel Hub Components ..........................2C-10

Rear Wheel Hub Removal an d Installation .......2C-10

Rear Wheel Disc, bolt and Bearing Inspection ..2C-11

Spindle Removal and Installation ......................2C-12

Spindle Inspection .............................................2C-13

Rear Suspension Fasteners Inspection ............2C-13

Specifications .................... .................................2C-13

Tightening Torque Specifications ......................2C-13

Special Tools and Equipmen t ...........................2C-13

Special Tool ......................................................2C-13

Wheels and Tires ............ ......................... 2D-1

Precautions...........................................................2D-1

Precaution for Emergency Flat Tire Repair Kit ....2D-1

General Description .............................................2D-1 Tires Description .................................................2D-1

Wheels Description .............................................2D-2

Irregular and/or Premature Wear Description .....2D-3

Wear Indicators Description ................................2D-3

Radial Tire Waddle Description...........................2D-4

Radial Tire Lead / Pull Description ......................2D-5

Page 431 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 2-1

Suspension

Precautions

Precautions

Precautions on SuspensionS7RS0B2000001

Emergency Flat Tire Repair Kit handle Warning

Refer to “Warning for Handling Emergency Flat Tire Repair Kit in Section 00”.

Suspension Caution

Refer to “Suspension Caution in Section 00”.

Wheels and Tires Caution

Refer to “Wheels and Tires Caution in Section 00”.

General Precautions

Refer to “General Precautions in Section 00”.

Vehicle Lifting Points

Refer to “Vehicle Lifting Points in Section 0A”.

Fastener Caution

Refer to “Fastener Caution in Section 00”.

Fastener Information

Refer to “Fasteners Information in Section 0A”.

Brake Caution

Refer to “Brake Caution in Section 00”.

Page 435 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-2

Front Wheel Alignment ConstructionS7RS0B2201002

Among factors for front wheel alignment, only toe setting

can be adjusted. Camber and caster are not adjustable.

Therefore, should camber or caster be out of

specification due to the damage caused by hazardous

road conditions or collision, whether the damage is in

body or in suspension should be determined and

damaged body should be repaired or damaged

suspension should be replaced.

Preliminary Checks Prior to Adjustment Front Wheel

Alignment

Steering and vibration complaints are not always the

result of improper wheel alignment. An additional item to

be checked is the possibility of tire lead due to worn or

improperly manufactured tires. “Lead” is the vehicle

deviation from a straight path on a level road without

hand pressure on the steering wheel. Refer to “Radial

Tire Lead / Pull Description in Section 2D” in order to

determine if the vehicle has a tire lead problem. Before

making any adjustment affecting wheel alignment, the

following checks and inspections should be made to

ensure correctness of alignment readings and alignment

adjustments:

• Check all tires for proper inflation pressures and approximately the same tread wear. • Check for loose of ball join

ts. Check tie-rod ends; if

excessive looseness is noted, it must be corrected

before adjusting.

• Check for run-out of wheels and tires.

• Check vehicle trim heights; if it is out of limit and a

correction is needed, it must be done before adjusting

toe.

• Check for loose of suspension control arms.

• Check for loose or missin g stabilizer bar attachments.

• Consideration must be given to excess loads, such as

tool boxes. If this excess load is normally carried in

vehicle, it should remain in vehicle during alignment

checks.

• Consider condition of equipment being used to check alignment and follow manufa cturer’s instructions.

• Regardless of equipment used to check alignment, vehicle must be placed on a level surface.

NOTE

To prevent possible incorrect reading of toe,

camber or caster, vehicle front and rear end

must be moved up and down a few times

before inspection.

Repair Instructions

Front Wheel Alignment Inspection and

Adjustment

S7RS0B2206001

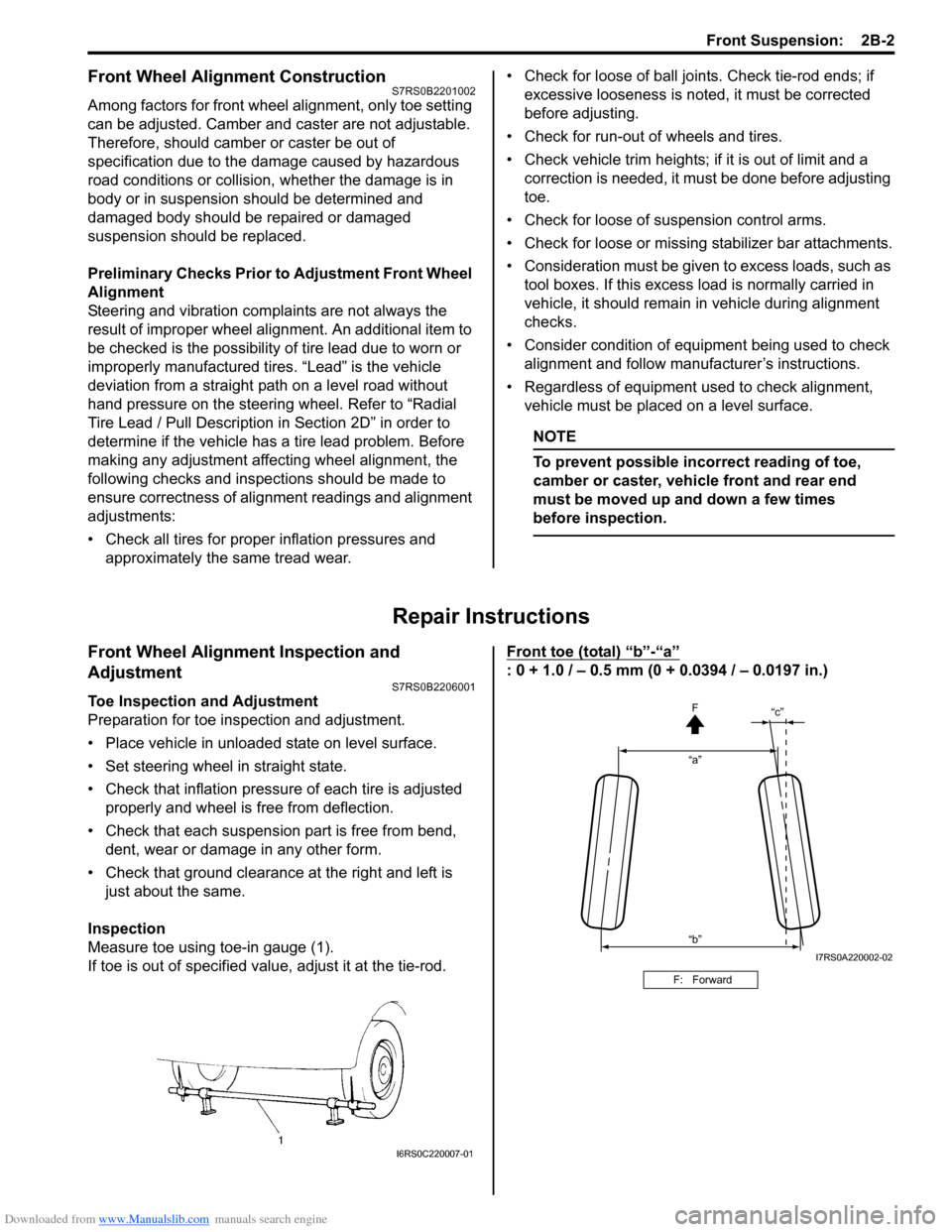

Toe Inspection and Adjustment

Preparation for toe inspection and adjustment.

• Place vehicle in unloaded state on level surface.

• Set steering wheel in straight state.

• Check that inflation pressure of each tire is adjusted properly and wheel is free from deflection.

• Check that each suspension part is free from bend, dent, wear or damage in any other form.

• Check that ground clearance at the right and left is just about the same.

Inspection

Measure toe using toe-in gauge (1).

If toe is out of specified value, adjust it at the tie-rod. Front toe (total) “b”-“a”

: 0 + 1.0 / – 0.5 mm (0 + 0.0394 / – 0.0197 in.)

I6RS0C220007-01

F: Forward

“a”

“c”

“b” F

I7RS0A220002-02

Page 437 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-4

Reference Information

Side slip

When checked with side slip tester, side slip should

satisfy following specification.Side slip

0 to IN 3.0 mm/m (0 to IN 0.118 in/3.3 ft)

If side slip is greatly di

fferent, toe or front wheel

alignment may not be correct.

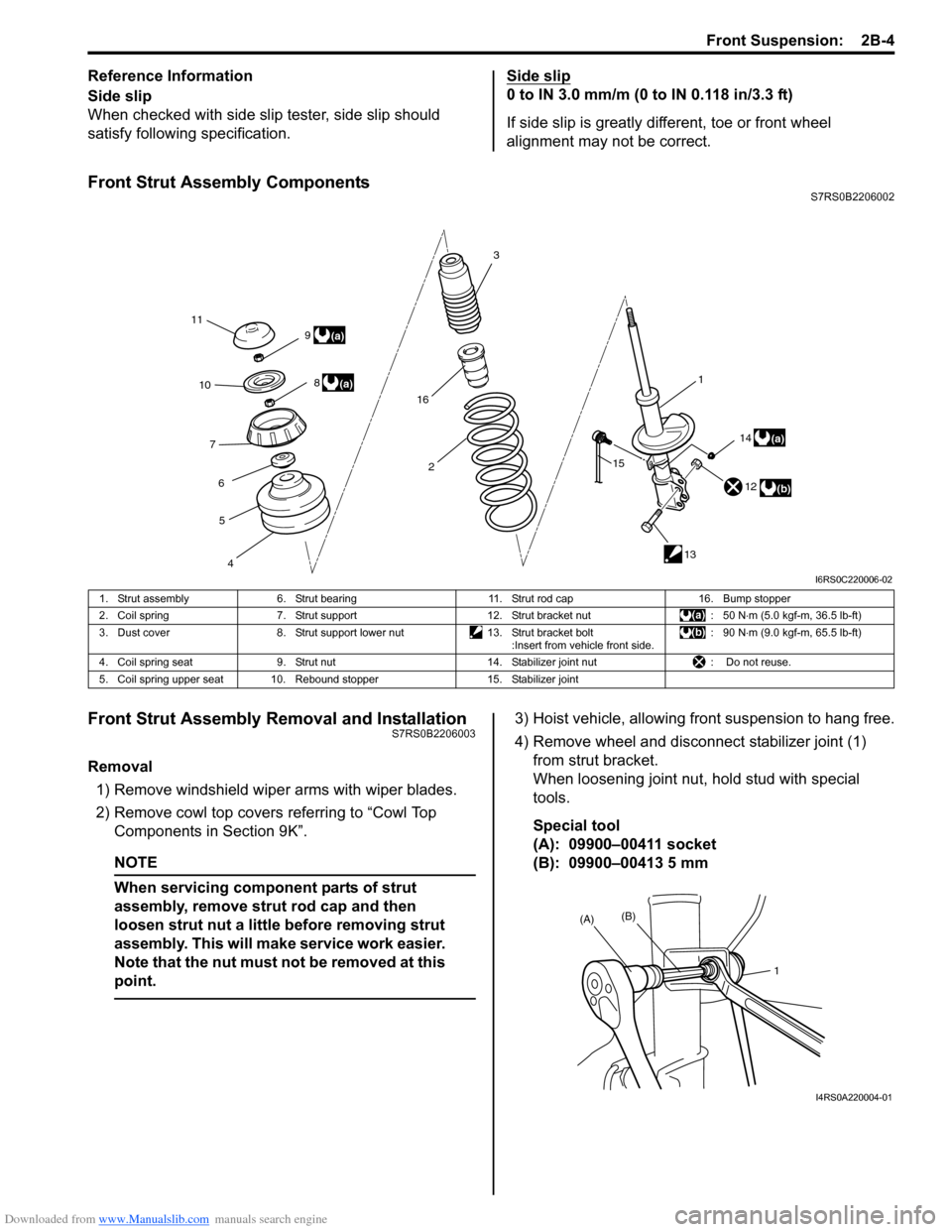

Front Strut Assembly ComponentsS7RS0B2206002

Front Strut Assembly Removal and InstallationS7RS0B2206003

Removal

1) Remove windshield wipe r arms with wiper blades.

2) Remove cowl top covers referring to “Cowl Top

Components in Section 9K”.

NOTE

When servicing component parts of strut

assembly, remove stru t rod cap and then

loosen strut nut a little before removing strut

assembly. This will make service work easier.

Note that the nut must not be removed at this

point.

3) Hoist vehicle, allowing front suspension to hang free.

4) Remove wheel and disconn ect stabilizer joint (1)

from strut bracket.

When loosening joint nu t, hold stud with special

tools.

Special tool

(A): 09900–00411 socket

(B): 09900–00413 5 mm

11 3

2 1

12

13

4

5

6

7

10

8(a)

(b)

9

(a)

14

15(a)

16

I6RS0C220006-02

1. Strut assembly

6. Strut bearing 11. Strut rod cap16. Bump stopper

2. Coil spring 7. Strut support 12. Strut bracket nut : 50 N⋅m (5.0 kgf-m, 36.5 lb-ft)

3. Dust cover 8. Strut support lower nut 13. Strut bracket bolt

:Insert from vehicle front side. : 90 N

⋅m (9.0 kgf-m, 65.5 lb-ft)

4. Coil spring seat 9. Strut nut 14. Stabilizer joint nut : Do not reuse.

5. Coil spring upper seat 10. Rebound stopper 15. Stabilizer joint

1

(A)

(B)

I4RS0A220004-01

Page 438 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-5 Front Suspension:

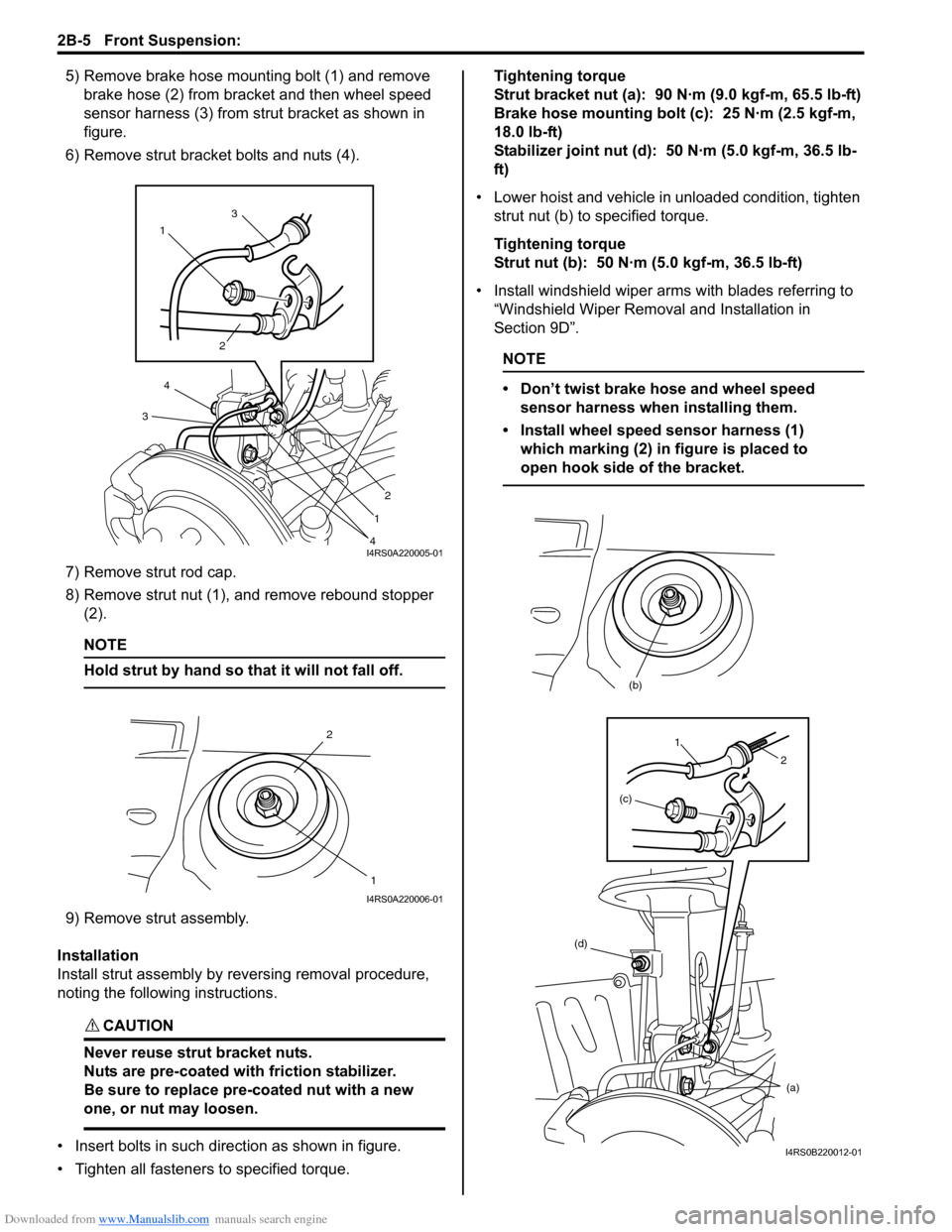

5) Remove brake hose mounting bolt (1) and remove brake hose (2) from bracket and then wheel speed

sensor harness (3) from strut bracket as shown in

figure.

6) Remove strut bracket bolts and nuts (4).

7) Remove strut rod cap.

8) Remove strut nut (1), and remove rebound stopper (2).

NOTE

Hold strut by hand so th at it will not fall off.

9) Remove strut assembly.

Installation

Install strut assembly by reversing removal procedure,

noting the following instructions.

CAUTION!

Never reuse strut bracket nuts.

Nuts are pre-coated with friction stabilizer.

Be sure to replace pre-coated nut with a new

one, or nut may loosen.

• Insert bolts in such direction as shown in figure.

• Tighten all fasteners to specified torque. Tightening torque

Strut bracket nut (a): 90 N·m (9.0 kgf-m, 65.5 lb-ft)

Brake hose mounting bolt (c): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

Stabilizer joint nut (d): 50 N·m (5.0 kgf-m, 36.5 lb-

ft)

• Lower hoist and vehicle in unloaded condition, tighten strut nut (b) to specified torque.

Tightening torque

Strut nut (b): 50 N·m (5.0 kgf-m, 36.5 lb-ft)

• Install windshield wiper arms with blades referring to

“Windshield Wiper Removal and Installation in

Section 9D”.

NOTE

• Don’t twist brake hose and wheel speed sensor harness when installing them.

• Install wheel speed sensor harness (1) which marking (2) in figure is placed to

open hook side of the bracket.

1 3

2

2

1

4

4

3

I4RS0A220005-01

2

1

I4RS0A220006-01

(d) (a)

(b)

(c)

1

2

I4RS0B220012-01

Page 441 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-8

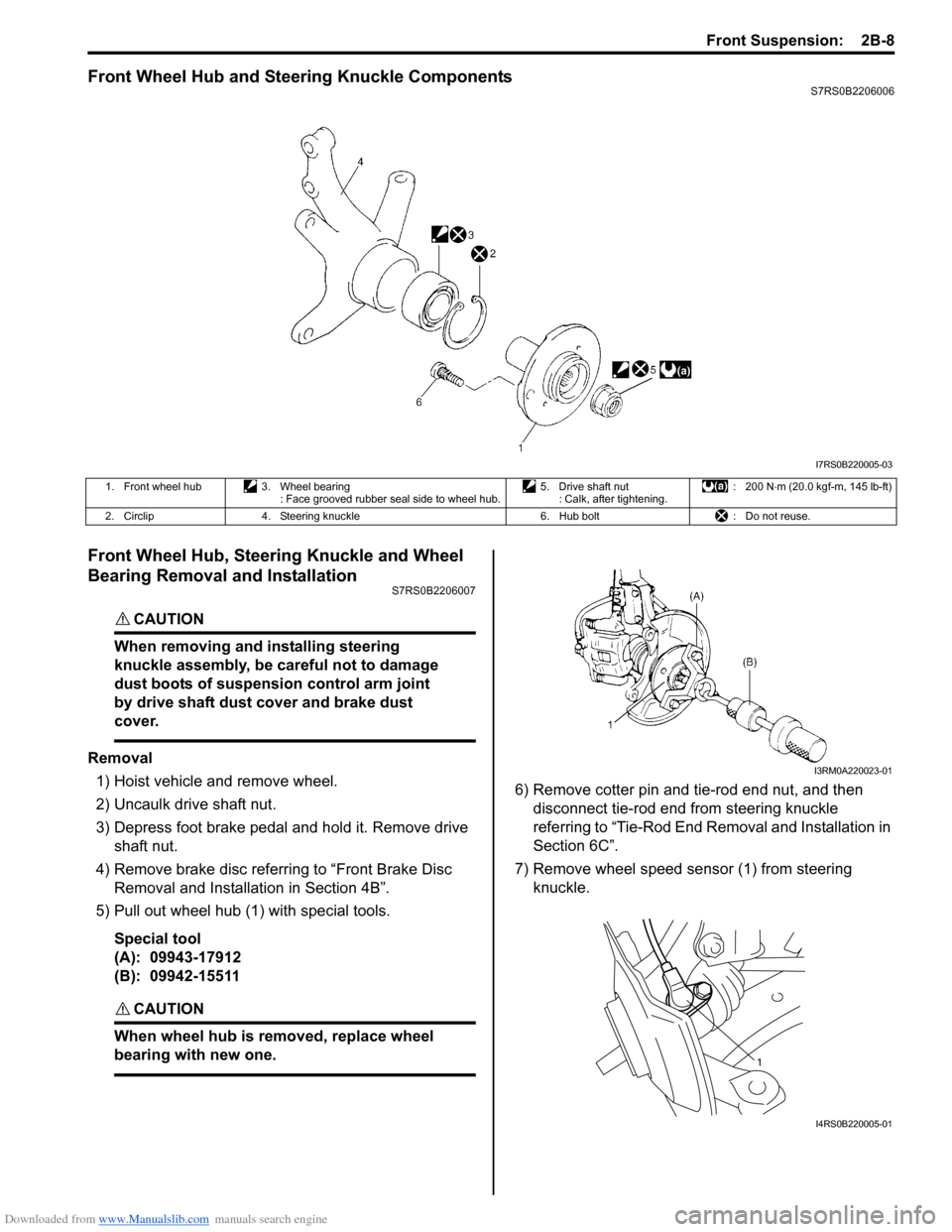

Front Wheel Hub and Steering Knuckle ComponentsS7RS0B2206006

Front Wheel Hub, Steering Knuckle and Wheel

Bearing Removal and Installation

S7RS0B2206007

CAUTION!

When removing and installing steering

knuckle assembly, be careful not to damage

dust boots of suspension control arm joint

by drive shaft dust cover and brake dust

cover.

Removal1) Hoist vehicle and remove wheel.

2) Uncaulk drive shaft nut.

3) Depress foot brake pedal and hold it. Remove drive shaft nut.

4) Remove brake disc referring to “Front Brake Disc Removal and Installa tion in Section 4B”.

5) Pull out wheel hub (1) with special tools.

Special tool

(A): 09943-17912

(B): 09942-15511

CAUTION!

When wheel hub is removed, replace wheel

bearing with new one.

6) Remove cotter pin and tie-rod end nut, and then disconnect tie-rod end from steering knuckle

referring to “Tie-Rod End Removal and Installation in

Section 6C”.

7) Remove wheel speed sensor (1) from steering knuckle.

I7RS0B220005-03

1. Front wheel hub 3. Wheel bearing

: Face grooved rubber seal side to wheel hub. 5. Drive shaft nut

: Calk, after tightening. : 200 N

⋅m (20.0 kgf-m, 145 lb-ft)

2. Circlip 4. Steering knuckle 6. Hub bolt: Do not reuse.

I3RM0A220023-01

1

I4RS0B220005-01

Page 444 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-11 Front Suspension:

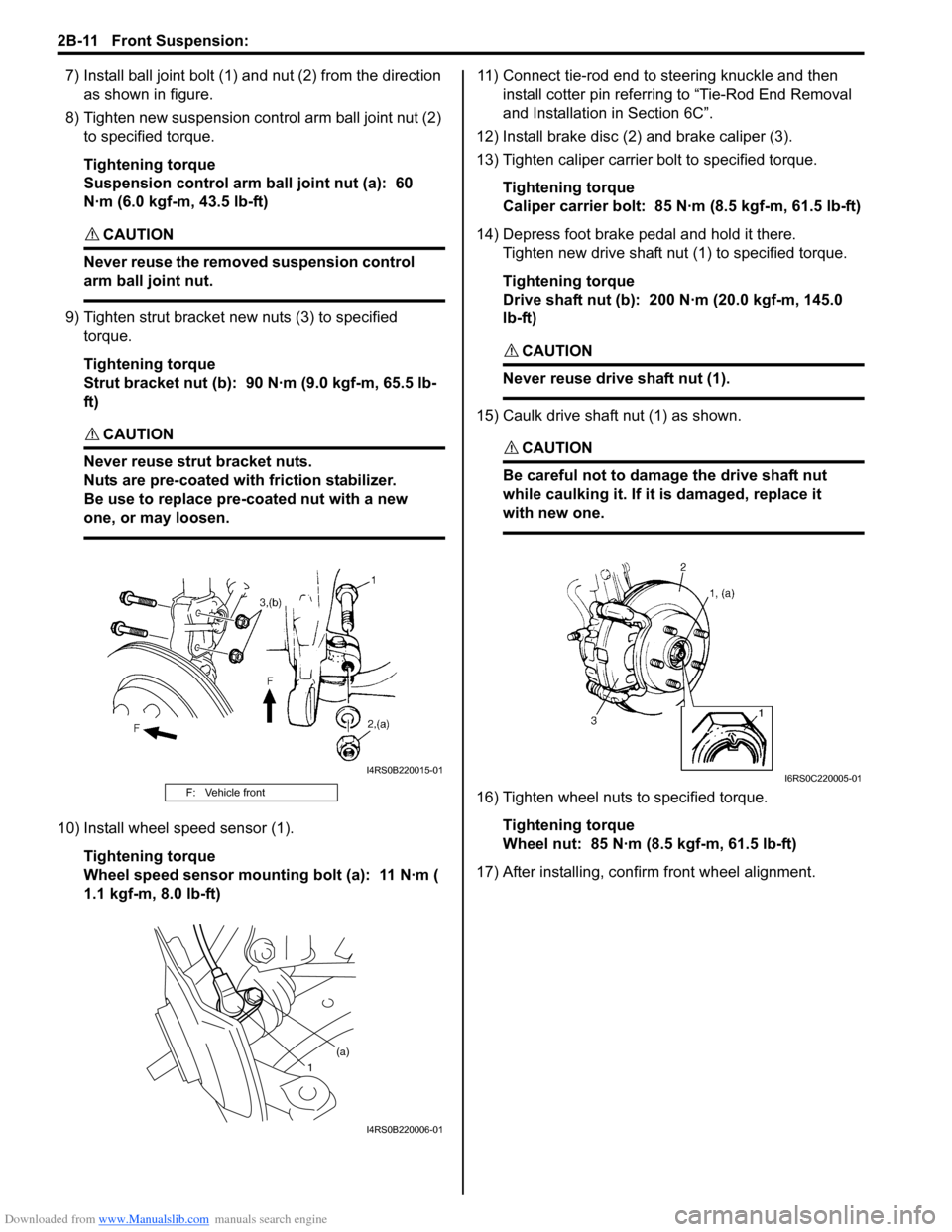

7) Install ball joint bolt (1) and nut (2) from the direction

as shown in figure.

8) Tighten new suspension co ntrol arm ball joint nut (2)

to specified torque.

Tightening torque

Suspension control arm ball joint nut (a): 60

N·m (6.0 kgf-m, 43.5 lb-ft)

CAUTION!

Never reuse the removed suspension control

arm ball joint nut.

9) Tighten strut bracket new nuts (3) to specified torque.

Tightening torque

Strut bracket nut (b): 90 N·m (9.0 kgf-m, 65.5 lb-

ft)

CAUTION!

Never reuse strut bracket nuts.

Nuts are pre-coated with friction stabilizer.

Be use to replace pre-coated nut with a new

one, or may loosen.

10) Install wheel speed sensor (1).

Tightening torque

Wheel speed sensor mounting bolt (a): 11 N·m (

1.1 kgf-m, 8.0 lb-ft) 11) Connect tie-rod end to steering knuckle and then

install cotter pin referrin g to “Tie-Rod End Removal

and Installation in Section 6C”.

12) Install brake disc (2) and brake caliper (3).

13) Tighten caliper carrier bolt to specified torque.

Tightening torque

Caliper carrier bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

14) Depress foot brake pedal and hold it there. Tighten new drive shaft nut (1) to specified torque.

Tightening torque

Drive shaft nut (b): 200 N·m (20.0 kgf-m, 145.0

lb-ft)

CAUTION!

Never reuse drive shaft nut (1).

15) Caulk drive shaft nut (1) as shown.

CAUTION!

Be careful not to damage the drive shaft nut

while caulking it. If it is damaged, replace it

with new one.

16) Tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

17) After installing, confirm front wheel alignment.F: Vehicle front

I4RS0B220015-01

1 (a)

I4RS0B220006-01

I6RS0C220005-01