tightening torque SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1146 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-108 Air Bag System:

4) Remove side curtain-air bag (inflator) module fixing bolts (1) and clips (2).

5) Remove side curtain-air bag (inflator) module.

WARNING!

• When carrying a live air bag (inflator) module, make sure the bag opening is

pointed away from you.

Never carry air bag (inflator) module by

wires or connector on the side of the

module. In case of an accidental

deployment, the bag will then deploy with

minimal chance of injury.

• As the live curtain air bag (inflator) module must be kept with it s bag facing up while

being stored or left standing. This is

necessary so that a free space is provided

to allow the air bag to expand in the

unlikely event of accidental deployment.

• Observe “Precautions on Handling and Storage of Air Bag System Components”

for handling and storing it.

Otherwise, personal injury may result.

Installation

WARNING!

Do not install side curtain-air bag (inflator)

module while twisted or bended. Otherwise,

side curtain-air bag (inflator) module may not

deploy and injury may result.

1) Install side curtain-air bag (inflator) module (1) with

clips and new bolts.

2) Tighten side curtain-air bag (inflator) module attaching bolts (1) to specified torque.

Tightening torque

Side curtain-air bag (inflator) module attaching

bolts (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Connect side curtain-air bag (inflator) module connector (1) securely as shown in figure.

a) Connect connector.

b) Lock connector wi th lock button (2).

4) Install head lining referring to “Head Lining Removal and Installation in Section 9H”.

5) Enable air bag system. Refer to “Enabling Air Bag System”.1 2

2

22

1

I4RS0A820076-01

1,(a) 1,(a)

I4RS0A820110-01

1

2

a)

b)

I4RS0A820055-01

Page 1148 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-110 Air Bag System:

Installation

CAUTION!

Proper operation of forward-sensor requires

sensor be rigidly attached to vehicle

structure and that the arrow on sensor be

pointing toward the front of the vehicle.

1) Check that none of the following faulty conditions exists.

• Bend, deformity or rust of front panel.

• Foreign matter on mating surface of sensor.

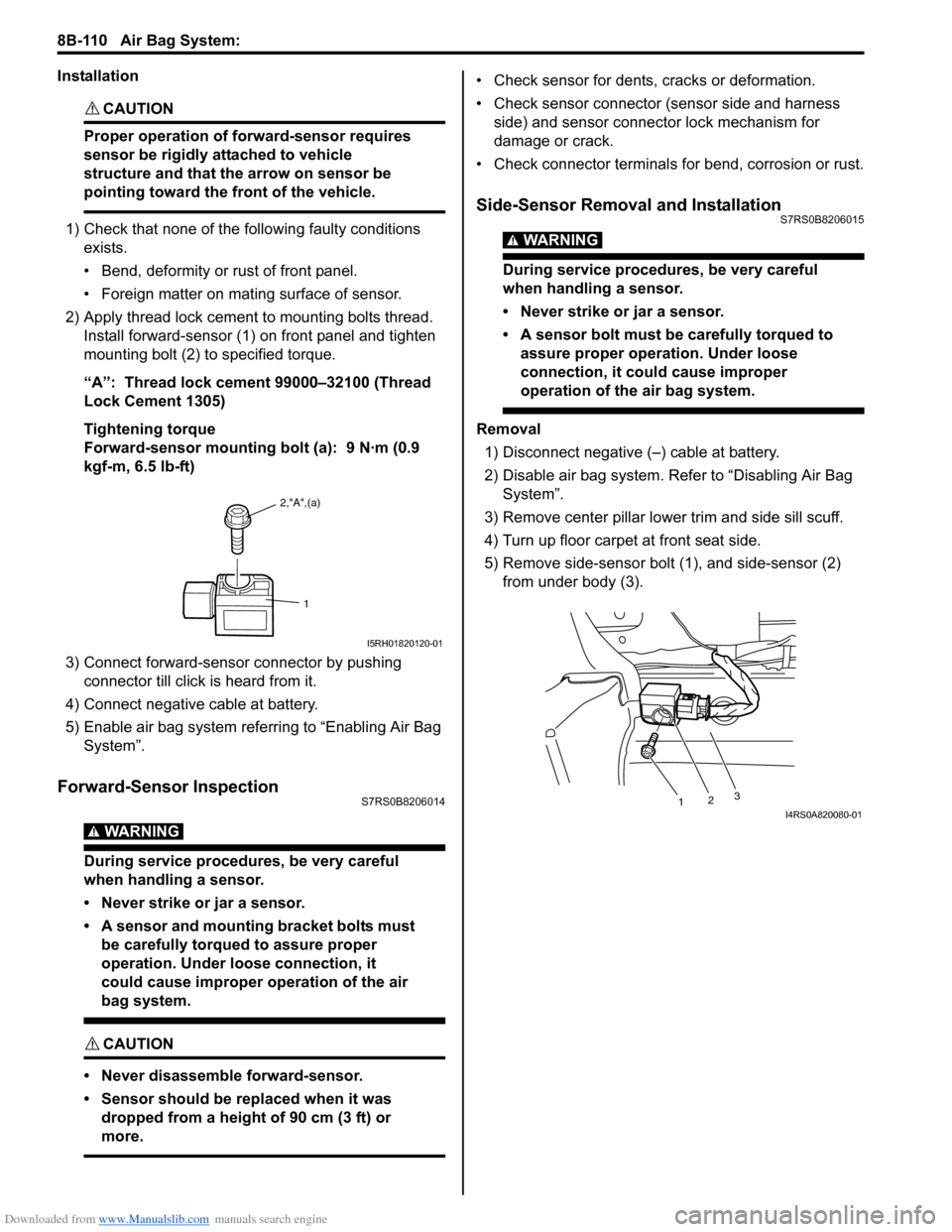

2) Apply thread lock cement to mounting bolts thread. Install forward-sensor (1) on front panel and tighten

mounting bolt (2) to specified torque.

“A”: Thread lock cement 99000–32100 (Thread

Lock Cement 1305)

Tightening torque

Forward-sensor mounting bolt (a): 9 N·m (0.9

kgf-m, 6.5 lb-ft)

3) Connect forward-sensor connector by pushing connector till click is heard from it.

4) Connect negative cable at battery.

5) Enable air bag system referring to “Enabling Air Bag System”.

Forward-Sensor InspectionS7RS0B8206014

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor and mounting bracket bolts must be carefully torqued to assure proper

operation. Under loose connection, it

could cause improper operation of the air

bag system.

CAUTION!

• Never disassemble forward-sensor.

• Sensor should be replaced when it was dropped from a height of 90 cm (3 ft) or

more.

• Check sensor for dents, cracks or deformation.

• Check sensor connector (sensor side and harness side) and sensor connector lock mechanism for

damage or crack.

• Check connector terminals for bend, corrosion or rust.

Side-Sensor Removal and InstallationS7RS0B8206015

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor bolt must be carefully torqued to assure proper operation. Under loose

connection, it could cause improper

operation of the air bag system.

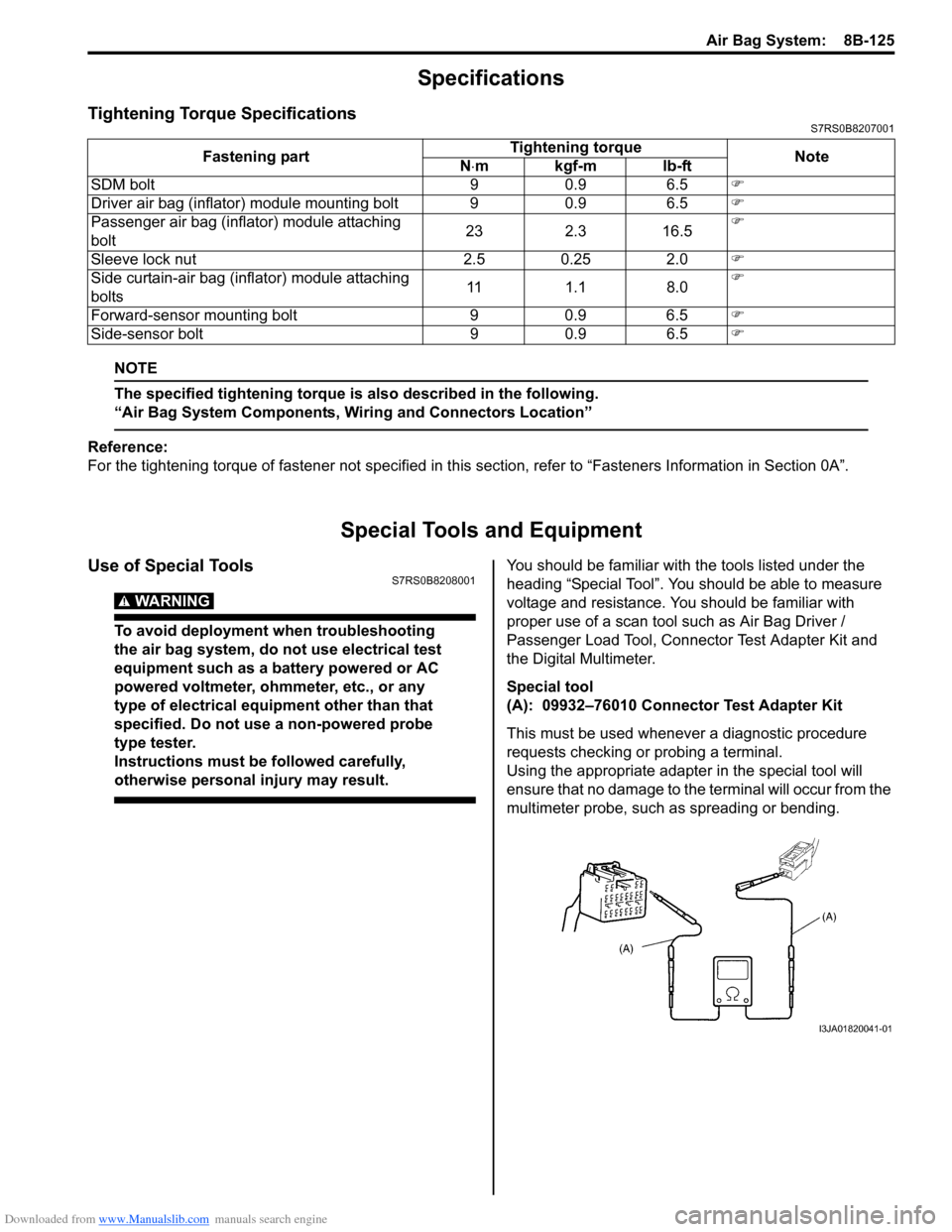

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Re fer to “Disabling Air Bag

System”.

3) Remove center pillar lowe r trim and side sill scuff.

4) Turn up floor carpet at front seat side.

5) Remove side-sensor bolt (1), and side-sensor (2) from under body (3).

2,"A",(a)

1

I5RH01820120-01

1 23I4RS0A820080-01

Page 1149 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-111

6) Disconnect side-sensor connector sliding connector

outer (1) as shown.

Installation

CAUTION!

Proper operation of side-sensor requires

sensor be rigidly attached to specified

position.

1) Check that none of following faulty conditions exists.

• Bend, deformity or rust of under body.

• Foreign matter on mating surface of sensor.

2) Install side-sensor (1) on under body (2) and tighten side-sensor bolt (3) to specified torque.

Tightening torque

Side-sensor bolt (a): 9 N·m (0.9 kgf-m, 6.5 lb-ft) 3) Connect side-sensor connector pushing connector

inner (1) as shown.

4) Connect negative cable at battery.

5) Enable air bag system. Refer to “Enabling Air Bag System”.

Side-Sensor InspectionS7RS0B8206016

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor and mounting bracket bolts must be carefully torqued to assure proper

operation. Under loose connection, it

could cause improper operation of the air

bag system.

CAUTION!

• Never disassemble side-sensor.

• Sensor should be replaced when it was dropped from a height of 90 cm (3 ft) or

more.

1

1

I4RS0A820109-01

1 2

3, (a)I4RS0A820081-01

1

1

I4RS0A820106-01

Page 1163 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-125

Specifications

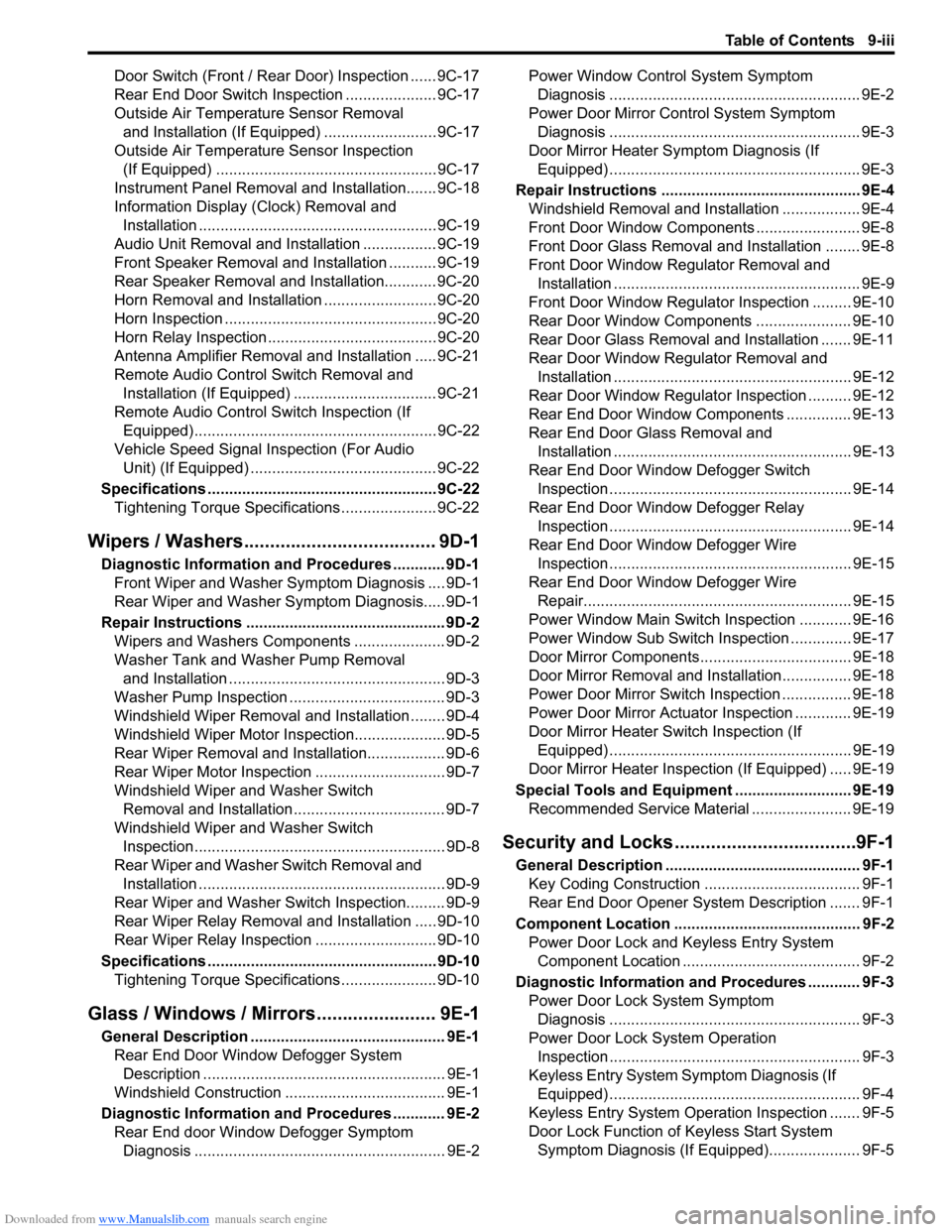

Tightening Torque SpecificationsS7RS0B8207001

NOTE

The specified tightening torque is also described in the following.

“Air Bag System Components, Wiring and Connectors Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

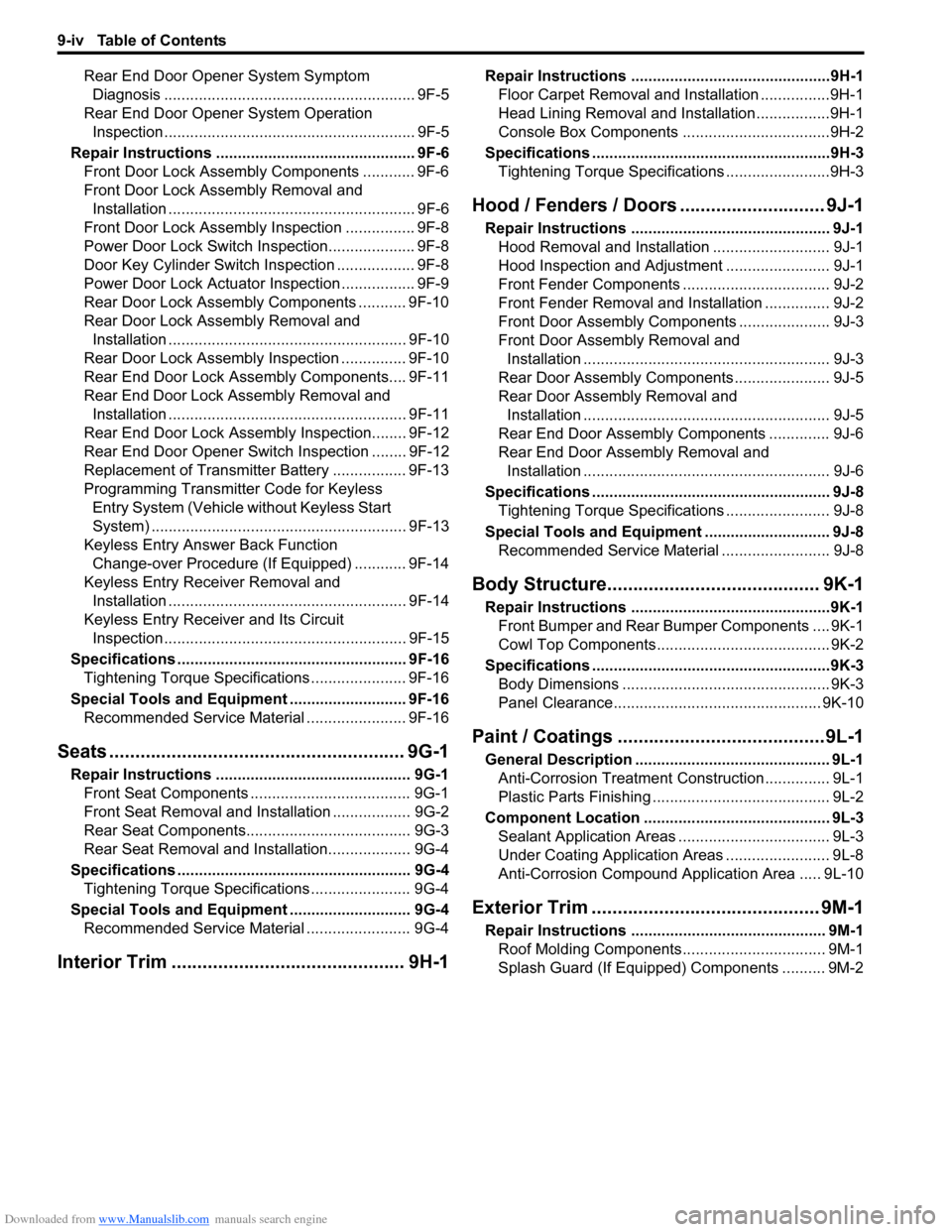

Special Tools and Equipment

Use of Special ToolsS7RS0B8208001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified. Do not use a non-powered probe

type tester.

Instructions must be followed carefully,

otherwise personal injury may result.

You should be familiar with the tools listed under the

heading “Special Tool”. You should be able to measure

voltage and resistance. You should be familiar with

proper use of a scan tool such as Air Bag Driver /

Passenger Load Tool, Connector Test Adapter Kit and

the Digital Multimeter.

Special tool

(A): 09932–76010 Connector Test Adapter Kit

This must be used whenever a diagnostic procedure

requests checking or probing a terminal.

Using the appropriate adapter in the special tool will

ensure that no damage to the terminal will occur from the

multimeter probe, such as spreading or bending.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

SDM bolt 9 0.9 6.5 �)

Driver air bag (inflator) module mounting bolt 9 0.9 6.5 �)

Passenger air bag (inflator) module attaching

bolt 23 2.3 16.5�)

Sleeve lock nut 2.5 0.25 2.0 �)

Side curtain-air bag (inflator) module attaching

bolts 11 1.1 8.0�)

Forward-sensor mounting bolt 9 0.9 6.5 �)

Side-sensor bolt 9 0.9 6.5 �)

I3JA01820041-01

Page 1169 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 9-iii

Door Switch (Front / Rear Door) Inspection ...... 9C-17

Rear End Door Switch Inspection ..................... 9C-17

Outside Air Temperature Sensor Removal and Installation (If Equipped) .......................... 9C-17

Outside Air Temperature Sensor Inspection (If Equipped) ................................................... 9C-17

Instrument Panel Removal and Installation....... 9C-18

Information Display (Clock) Removal and Installation ....................................................... 9C-19

Audio Unit Removal and In stallation ................. 9C-19

Front Speaker Removal and Installation ........... 9C-19

Rear Speaker Removal and Installation............ 9C-20

Horn Removal and Installation .......................... 9C-20

Horn Inspection ................................................. 9C-20

Horn Relay Inspection ....................................... 9C-20

Antenna Amplifier Removal and Installation ..... 9C-21

Remote Audio Control Switch Removal and Installation (If Equipped) ................................. 9C-21

Remote Audio Control Switch Inspection (If Equipped)........................................................ 9C-22

Vehicle Speed Signal Inspection (For Audio Unit) (If Equipped) ........................................... 9C-22

Specifications ..................................................... 9C-22

Tightening Torque Specifications ...................... 9C-22

Wipers / Washers............ ......................... 9D-1

Diagnostic Information and Procedures ............ 9D-1

Front Wiper and Washer Symptom Diagnosis .... 9D-1

Rear Wiper and Washer Symptom Diagnosis..... 9D-1

Repair Instructions .............................................. 9D-2 Wipers and Washers Components ..................... 9D-2

Washer Tank and Washer Pump Removal and Installation .................................................. 9D-3

Washer Pump Inspection .................................... 9D-3

Windshield Wiper Removal and Installation ........ 9D-4

Windshield Wiper Motor Inspection..................... 9D-5

Rear Wiper Removal and Installation.................. 9D-6

Rear Wiper Motor Inspection .............................. 9D-7

Windshield Wiper and Washer Switch Removal and Installation................................... 9D-7

Windshield Wiper and Washer Switch Inspection.......................................................... 9D-8

Rear Wiper and Washer Switch Removal and Installation ......................................................... 9D-9

Rear Wiper and Washer Switch Inspection......... 9D-9

Rear Wiper Relay Removal and Installation ..... 9D-10

Rear Wiper Relay Inspection ............................ 9D-10

Specifications ..................................................... 9D-10

Tightening Torque Specifications ...................... 9D-10

Glass / Windows / Mirrors.. ..................... 9E-1

General Description ............................................. 9E-1

Rear End Door Window Defogger System Description ........................................................ 9E-1

Windshield Construction ..................................... 9E-1

Diagnostic Information and Procedures ............ 9E-2 Rear End door Window Defogger Symptom Diagnosis .......................................................... 9E-2 Power Window Control System Symptom

Diagnosis .......................................................... 9E-2

Power Door Mirror Control System Symptom Diagnosis .......................................................... 9E-3

Door Mirror Heater Symptom Diagnosis (If

Equipped) .......................................................... 9E-3

Repair Instructions ........... ................................... 9E-4

Windshield Removal and In stallation .................. 9E-4

Front Door Window Components ........................ 9E-8

Front Door Glass Removal and Installation ........ 9E-8

Front Door Window Re gulator Removal and

Installation ......................................................... 9E-9

Front Door Window Regula tor Inspection ......... 9E-10

Rear Door Window Components ...................... 9E-10

Rear Door Glass Removal and Installation ....... 9E-11

Rear Door Window Regulator Removal and Installation ....................................................... 9E-12

Rear Door Window Regulato r Inspection .......... 9E-12

Rear End Door Window Components ............... 9E-13

Rear End Door Glass Removal and Installation ....................................................... 9E-13

Rear End Door Window Defogger Switch Inspection ........................................................ 9E-14

Rear End Door Window Defogger Relay Inspection ........................................................ 9E-14

Rear End Door Window Defogger Wire Inspection ........................................................ 9E-15

Rear End Door Window Defogger Wire

Repair.............................................................. 9E-15

Power Window Main Switch Inspection ............ 9E-16

Power Window Sub Switch Inspection .............. 9E-17

Door Mirror Components.. ................................. 9E-18

Door Mirror Removal and In stallation................ 9E-18

Power Door Mirror Switch Inspection ................ 9E-18

Power Door Mirror Actuator Inspection ............. 9E-19

Door Mirror Heater Switch Inspection (If Equipped) ........................................................ 9E-19

Door Mirror Heater Inspec tion (If Equipped) ..... 9E-19

Special Tools and Equipmen t ........................... 9E-19

Recommended Service Material ....................... 9E-19

Security and Locks......... ..........................9F-1

General Description ............................................. 9F-1

Key Coding Construction .................................... 9F-1

Rear End Door Opener System Description ....... 9F-1

Component Location ............ ............................... 9F-2

Power Door Lock and Keyless Entry System

Component Location ......................................... 9F-2

Diagnostic Information and Procedures ............ 9F-3 Power Door Lock System Symptom Diagnosis .......................................................... 9F-3

Power Door Lock System Operation Inspection .......................................................... 9F-3

Keyless Entry System Symptom Diagnosis (If

Equipped) .......................................................... 9F-4

Keyless Entry System Operation Inspection ....... 9F-5

Door Lock Function of Keyless Start System Symptom Diagnosis (If Equipped)..................... 9F-5

Page 1170 of 1496

Downloaded from www.Manualslib.com manuals search engine 9-iv Table of Contents

Rear End Door Opener System Symptom Diagnosis .......................................................... 9F-5

Rear End Door Opener System Operation Inspection .......................................................... 9F-5

Repair Instructions ........... ................................... 9F-6

Front Door Lock Assembly Components ............ 9F-6

Front Door Lock Assembly Removal and Installation ......................................................... 9F-6

Front Door Lock Assembly Inspection ................ 9F-8

Power Door Lock Switch In spection.................... 9F-8

Door Key Cylinder Switch Inspection .................. 9F-8

Power Door Lock Actuator Inspection ................. 9F-9

Rear Door Lock Assembly Components ........... 9F-10

Rear Door Lock Assembly Removal and Installation ....................................................... 9F-10

Rear Door Lock Assembly Inspection ............... 9F-10

Rear End Door Lock Assembly Components.... 9F-11

Rear End Door Lock Assembly Removal and Installation ....................................................... 9F-11

Rear End Door Lock Assembly Inspection........ 9F-12

Rear End Door Opener Switch Inspection ........ 9F-12

Replacement of Transmitte r Battery ................. 9F-13

Programming Transmitter Code for Keyless Entry System (Vehicle without Keyless Start

System) ........................................................... 9F-13

Keyless Entry Answer Back Function

Change-over Procedure (If Equipped) ............ 9F-14

Keyless Entry Receiver Removal and

Installation ....................................................... 9F-14

Keyless Entry Receiver and Its Circuit Inspection ........................................................ 9F-15

Specifications .... ................................................. 9F-16

Tightening Torque Specifications ...................... 9F-16

Special Tools and Equipmen t ........................... 9F-16

Recommended Service Material ....................... 9F-16

Seats ............. ............................................ 9G-1

Repair Instructions ............................................. 9G-1

Front Seat Components ..................................... 9G-1

Front Seat Removal and In stallation .................. 9G-2

Rear Seat Components...................................... 9G-3

Rear Seat Removal and Installation................... 9G-4

Specifications .... .................................................. 9G-4

Tightening Torque Specifications ....................... 9G-4

Special Tools and Equipmen t ............................ 9G-4

Recommended Service Material ........................ 9G-4

Interior Trim ................. ............................ 9H-1

Repair Instructions ............ ..................................9H-1

Floor Carpet Removal and Installation ................9H-1

Head Lining Removal and Installation.................9H-1

Console Box Components ..................................9H-2

Specifications ..................... ..................................9H-3

Tightening Torque Specifications ........................9H-3

Hood / Fenders / Doors ...... ...................... 9J-1

Repair Instructions ............ .................................. 9J-1

Hood Removal and Installation ........................... 9J-1

Hood Inspection and Adjustment ........................ 9J-1

Front Fender Components .................................. 9J-2

Front Fender Removal and Installation ............... 9J-2

Front Door Assembly Comp onents ..................... 9J-3

Front Door Assembly Removal and Installation ......................................................... 9J-3

Rear Door Assembly Components...................... 9J-5

Rear Door Assembly Removal and Installation ......................................................... 9J-5

Rear End Door Assembly Components .............. 9J-6

Rear End Door Assembly Removal and Installation ......................................................... 9J-6

Specifications ..................... .................................. 9J-8

Tightening Torque Specifications ........................ 9J-8

Special Tools and Equipmen t ............................. 9J-8

Recommended Service Material ......................... 9J-8

Body Structure............... .......................... 9K-1

Repair Instructions ............ ..................................9K-1

Front Bumper and Rear Bumper Components .... 9K-1

Cowl Top Components........................................ 9K-2

Specifications ..................... ..................................9K-3

Body Dimensions ................................................ 9K-3

Panel Clearance................................................ 9K-10

Paint / Coatings ............. ...........................9L-1

General Description ............................................. 9L-1

Anti-Corrosion Treatment Construction............... 9L-1

Plastic Parts Finishing ......................................... 9L-2

Component Location ............ ............................... 9L-3

Sealant Application Areas ................................... 9L-3

Under Coating Application Areas ........................ 9L-8

Anti-Corrosion Compound Application Area ..... 9L-10

Exterior Trim ...... ...................................... 9M-1

Repair Instructions ......... .................................... 9M-1

Roof Molding Components................................. 9M-1

Splash Guard (If Equipped) Components .......... 9M-2

Page 1314 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-19 Instrumentation / Driver Info. / Horn:

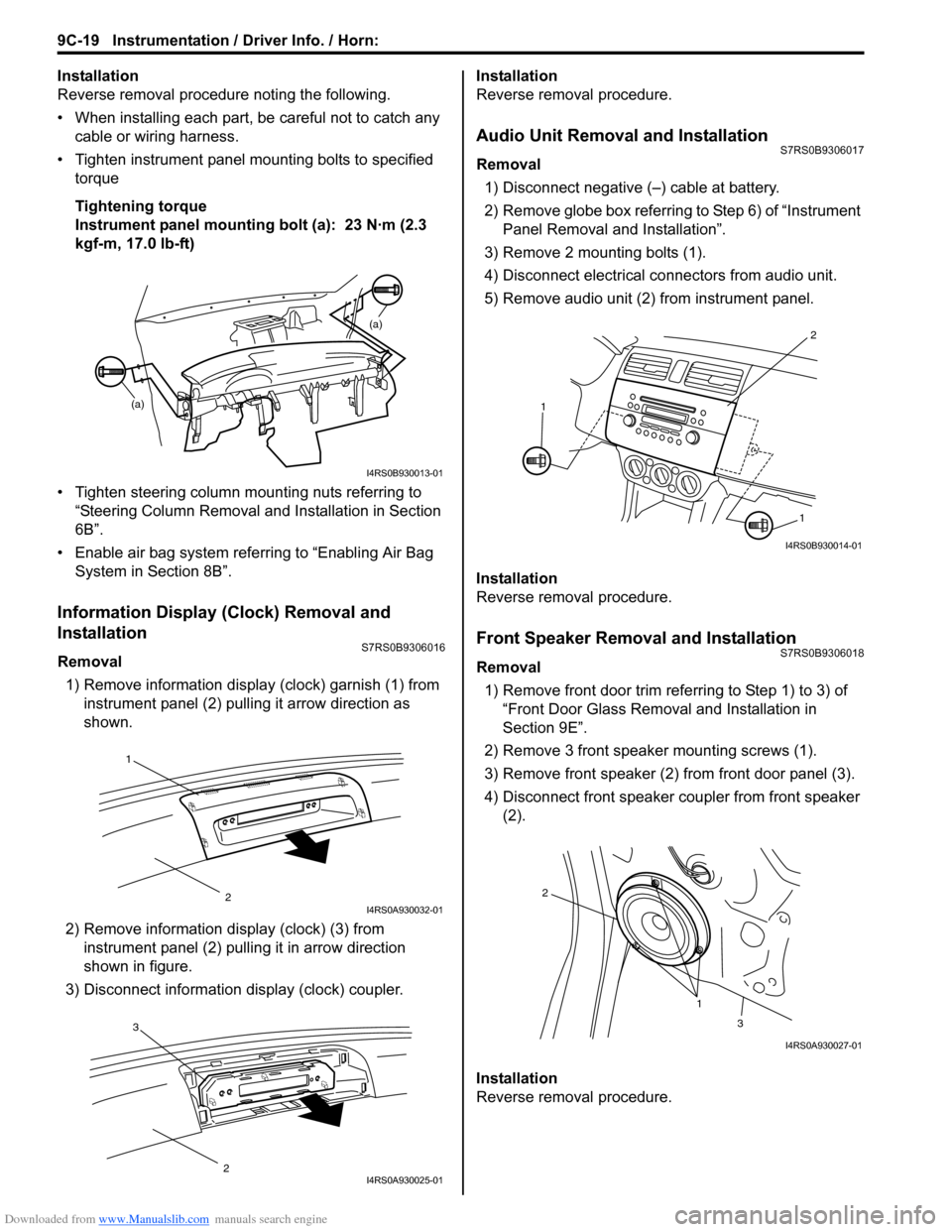

Installation

Reverse removal procedure noting the following.

• When installing each part, be careful not to catch any

cable or wiring harness.

• Tighten instrument panel mounting bolts to specified

torque

Tightening torque

Instrument panel mounting bolt (a): 23 N·m (2.3

kgf-m, 17.0 lb-ft)

• Tighten steering column mounting nuts referring to “Steering Column Removal an d Installation in Section

6B”.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Information Display (Clock) Removal and

Installation

S7RS0B9306016

Removal

1) Remove information display (clock) garnish (1) from instrument panel (2) pulling it arrow direction as

shown.

2) Remove information di splay (clock) (3) from

instrument panel (2) pulli ng it in arrow direction

shown in figure.

3) Disconnect information display (clock) coupler. Installation

Reverse removal procedure.

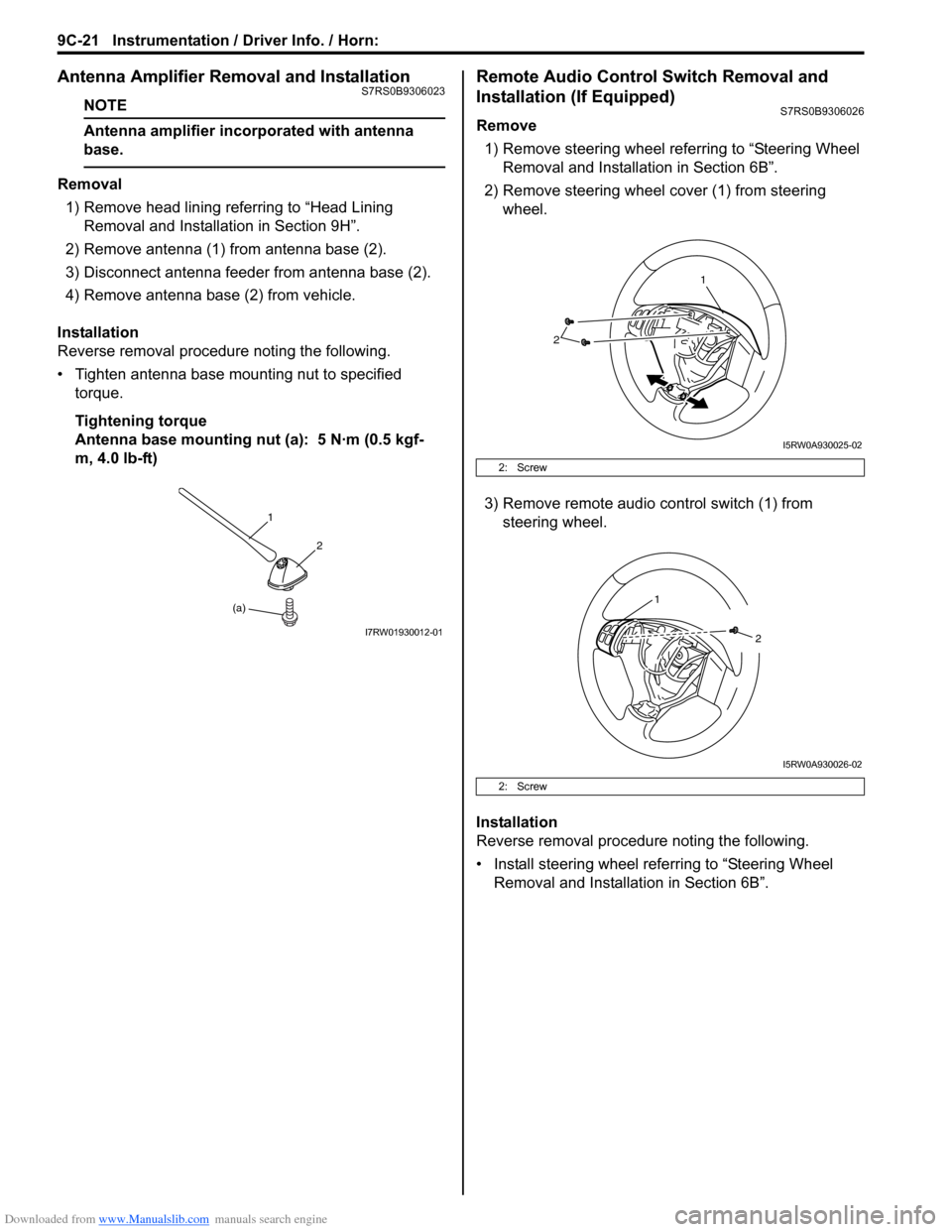

Audio Unit Removal and InstallationS7RS0B9306017

Removal

1) Disconnect negative (–) cable at battery.

2) Remove globe box referring to Step 6) of “Instrument Panel Removal and Installation”.

3) Remove 2 mounting bolts (1).

4) Disconnect electrical connectors from audio unit.

5) Remove audio unit (2) from instrument panel.

Installation

Reverse removal procedure.

Front Speaker Removal and InstallationS7RS0B9306018

Removal 1) Remove front door trim refe rring to Step 1) to 3) of

“Front Door Glass Remo val and Installation in

Section 9E”.

2) Remove 3 front speaker mounting screws (1).

3) Remove front speaker (2) from front door panel (3).

4) Disconnect front speaker coupler from front speaker (2).

Installation

Reverse removal procedure.

(a) (a)

I4RS0B930013-01

1

2I4RS0A930032-01

3

2I4RS0A930025-01

2

1

1

I4RS0B930014-01

1

2

3

I4RS0A930027-01

Page 1316 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-21 Instrumentation / Driver Info. / Horn:

Antenna Amplifier Removal and InstallationS7RS0B9306023

NOTE

Antenna amplifier incorporated with antenna

base.

Removal1) Remove head lining referring to “Head Lining Removal and Installa tion in Section 9H”.

2) Remove antenna (1) from antenna base (2).

3) Disconnect antenna feeder from antenna base (2).

4) Remove antenna base (2) from vehicle.

Installation

Reverse removal procedure noting the following.

• Tighten antenna base mounting nut to specified torque.

Tightening torque

Antenna base mounting nut (a): 5 N·m (0.5 kgf-

m, 4.0 lb-ft)

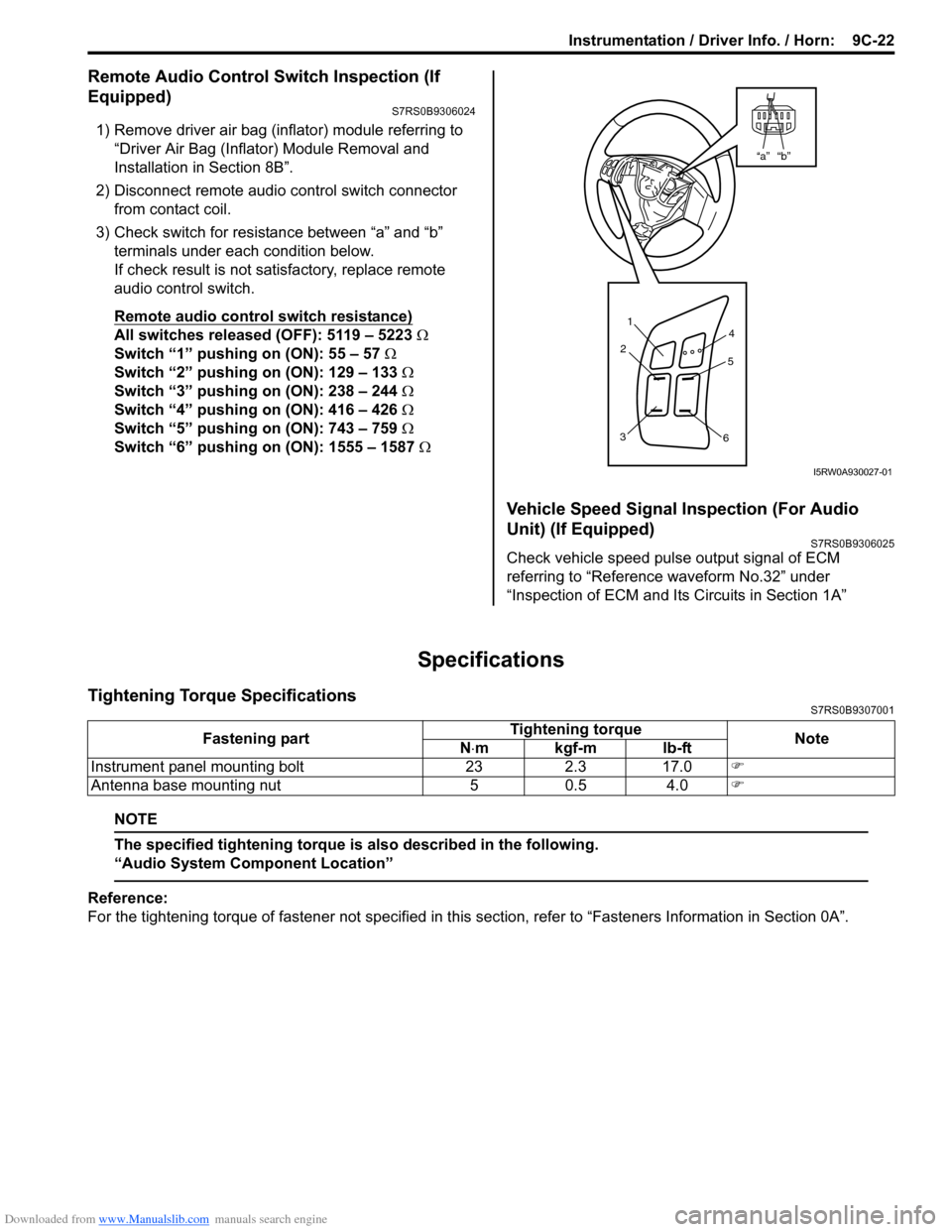

Remote Audio Control Switch Removal and

Installation (If Equipped)

S7RS0B9306026

Remove

1) Remove steering wheel re ferring to “Steering Wheel

Removal and Installati on in Section 6B”.

2) Remove steering wheel cover (1) from steering wheel.

3) Remove remote audio control switch (1) from steering wheel.

Installation

Reverse removal procedure noting the following.

• Install steering wheel referring to “Steering Wheel Removal and Installati on in Section 6B”.

(a)1

2

I7RW01930012-01

2: Screw

2: Screw

2

1

I5RW0A930025-02

1

2

I5RW0A930026-02

Page 1317 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-22

Remote Audio Control Switch Inspection (If

Equipped)

S7RS0B9306024

1) Remove driver air bag (inflator) module referring to

“Driver Air Bag (Inflator) Module Removal and

Installation in Section 8B”.

2) Disconnect remote audio control switch connector

from contact coil.

3) Check switch for resistance between “a” and “b” terminals under each condition below.

If check result is not satisfactory, replace remote

audio control switch.

Remote audio control switch resistance)

All switches released (OFF): 5119 – 5223 Ω

Switch “1” pushing on (ON): 55 – 57 Ω

Switch “2” pushing on (ON): 129 – 133 Ω

Switch “3” pushing on (ON): 238 – 244 Ω

Switch “4” pushing on (ON): 416 – 426 Ω

Switch “5” pushing on (ON): 743 – 759 Ω

Switch “6” pushing on (ON): 1555 – 1587 Ω

Vehicle Speed Signal Inspection (For Audio

Unit) (If Equipped)

S7RS0B9306025

Check vehicle speed pulse output signal of ECM

referring to “Reference waveform No.32” under

“Inspection of ECM and Its Circuits in Section 1A”

Specifications

Tightening Torque SpecificationsS7RS0B9307001

NOTE

The specified tightening torque is also described in the following.

“Audio System Component Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

“b”“a”

1

2

3 4

5

6

I5RW0A930027-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Instrument panel mounting bolt 23 2.3 17.0 �)

Antenna base mounting nut 5 0.5 4.0 �)

Page 1320 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-3 Wipers / Washers:

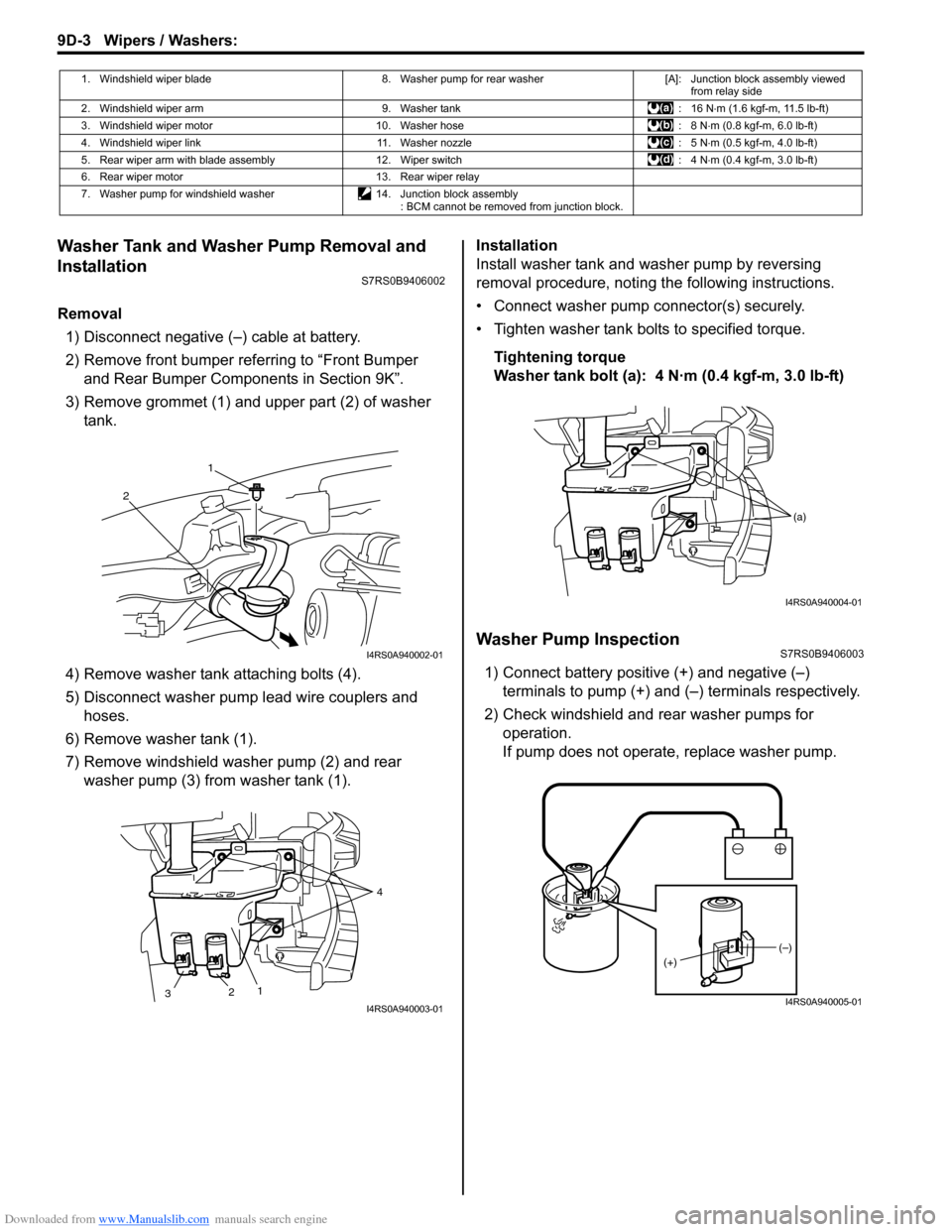

Washer Tank and Washer Pump Removal and

Installation

S7RS0B9406002

Removal1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Remove grommet (1) and upper part (2) of washer tank.

4) Remove washer tank attaching bolts (4).

5) Disconnect washer pump lead wire couplers and hoses.

6) Remove washer tank (1).

7) Remove windshield washer pump (2) and rear washer pump (3) from washer tank (1). Installation

Install washer tank and washer pump by reversing

removal procedure, noting the following instructions.

• Connect washer pump connector(s) securely.

• Tighten washer tank bolts to specified torque.

Tightening torque

Washer tank bolt (a): 4 N·m (0.4 kgf-m, 3.0 lb-ft)

Washer Pump InspectionS7RS0B9406003

1) Connect battery positive (+) and negative (–) terminals to pump (+) and (–) terminals respectively.

2) Check windshield and rear washer pumps for

operation.

If pump does not operate, replace washer pump.

1. Windshield wiper blade 8. Washer pump for rear washer[A]: Junction block assembly viewed

from relay side

2. Windshield wiper arm 9. Washer tank: 16 N⋅m (1.6 kgf-m, 11.5 lb-ft)

3. Windshield wiper motor 10. Washer hose : 8 N⋅m (0.8 kgf-m, 6.0 lb-ft)

4. Windshield wiper link 11. Washer nozzle : 5 N⋅m (0.5 kgf-m, 4.0 lb-ft)

5. Rear wiper arm with blade assembly 12. Wiper switch : 4 N⋅m (0.4 kgf-m, 3.0 lb-ft)

6. Rear wiper motor 13. Rear wiper relay

7. Washer pump for windshield washer 14. Junction block assembly

: BCM cannot be removed from junction block.

1

2

I4RS0A940002-01

2 1 4

3

I4RS0A940003-01

(a)

I4RS0A940004-01

(–)

(+)

I4RS0A940005-01