Ac system SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 463 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-9

12) Fill reservoir with brake fluid and bleed brake system. For bleeding operation, see “Air Bleeding of

Brake System in Section 4A”.

13) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

14) Adjust parking brake cable. For adjustment, refer to “Parking Brake Inspection and Adjustment in Section

4D”.

15) Lower hoist and bounce vehicle up and down several times to stabilize suspension.

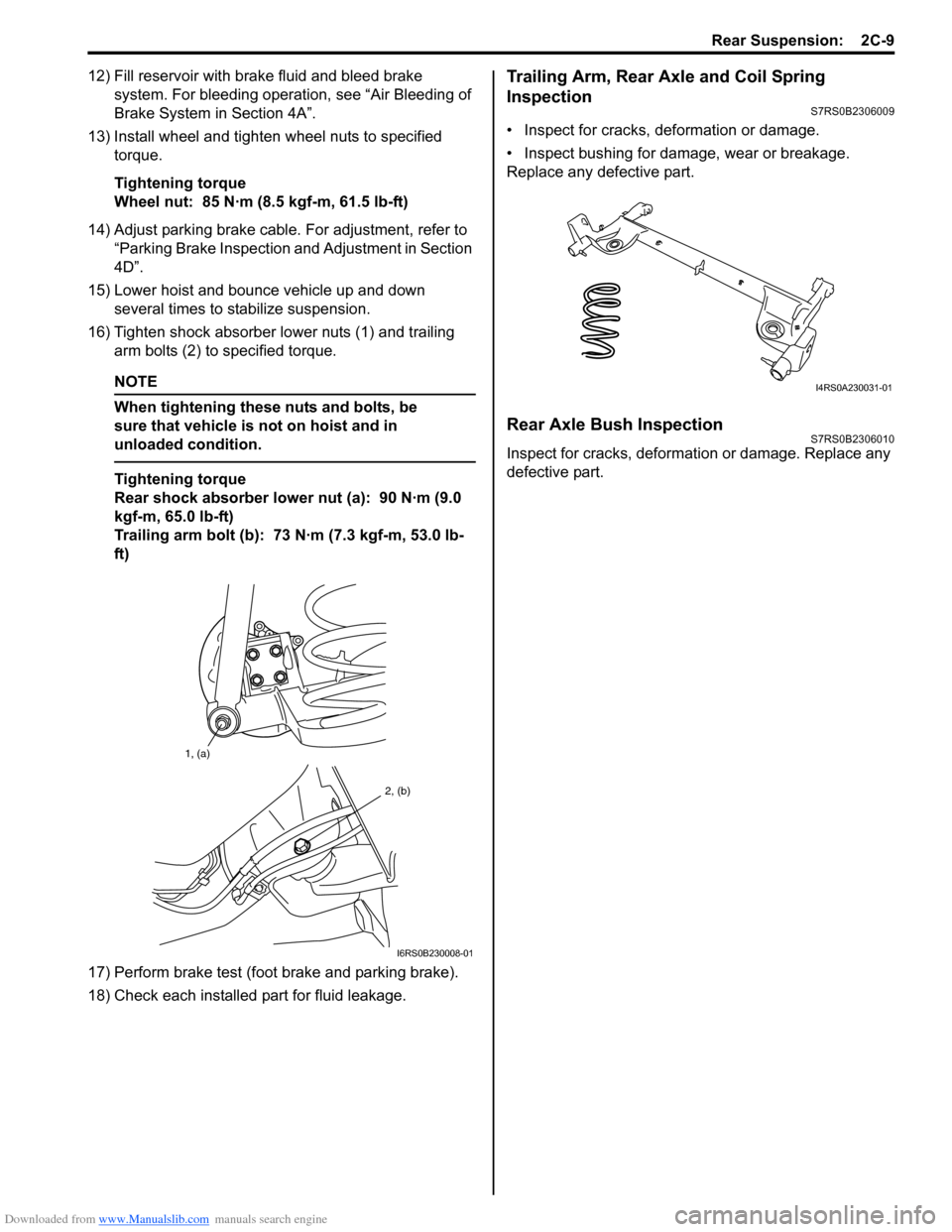

16) Tighten shock ab sorber lower nuts (1) and trailing

arm bolts (2) to specified torque.

NOTE

When tightening these nuts and bolts, be

sure that vehicle is not on hoist and in

unloaded condition.

Tightening torque

Rear shock absorber lower nut (a): 90 N·m (9.0

kgf-m, 65.0 lb-ft)

Trailing arm bolt (b): 73 N·m (7.3 kgf-m, 53.0 lb-

ft)

17) Perform brake test (foot brake and parking brake).

18) Check each installed part for fluid leakage.

Trailing Arm, Rear Axle and Coil Spring

Inspection

S7RS0B2306009

• Inspect for cracks, deformation or damage.

• Inspect bushing for damage, wear or breakage.

Replace any defective part.

Rear Axle Bush InspectionS7RS0B2306010

Inspect for cracks, deformation or damage. Replace any

defective part.

1, (a)

2, (b)

I6RS0B230008-01

I4RS0A230031-01

Page 473 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-6

Repair Instructions

General Balance ProceduresS7RS0B2406001

Deposits of mud, etc. must be cleaned from inside of rim.

WARNING!

Stones should be removed from the tread in

order to avoid operator injury during spin

balancing and to obtain good balance.

Each tire should be inspected for any damage, then

balanced according to equipment manufacturer’s

recommendation.

Off-Vehicle Balancing

Most electronic off-vehicle balancers are more accurate

than the on-vehicle spin balancers. They are easy to use

and give a dynamic (two plane) balance. Although they

do not correct for drum or disc unbalance as does on-

vehicle spin balancing, this is overcome by their

accuracy, usually to within 1/8 ounce.

On-Vehicle Balancing

On-vehicle balancing methods vary with equipment and

tool manufacturers. Be sure to follow each

manufacturer’s instructions during balancing operation.

WARNING!

Wheel spin should be limited to 55 km/h (35

mph) as indicated on speedometer.

This limit is necessary because speedometer

only indicates one-half of actual wheel speed

when one drive wheel is spinning and the

other drive wheel is stopped.

Unless care is taken in limiting drive wheel

spin, spinning wheel can reach excessive

speeds. This can result in possible tire

disintegration or differential failure, which

could cause serious personal injury or

extensive vehicle damage.

CAUTION!

Using on-vehicle balancing method with

ignition switch ON may set malfunction

diagnostic trouble code (DTC) of ESP® and

ABS even when system is in good condition.

Never turn ignition swit ch ON while spinning

wheel.

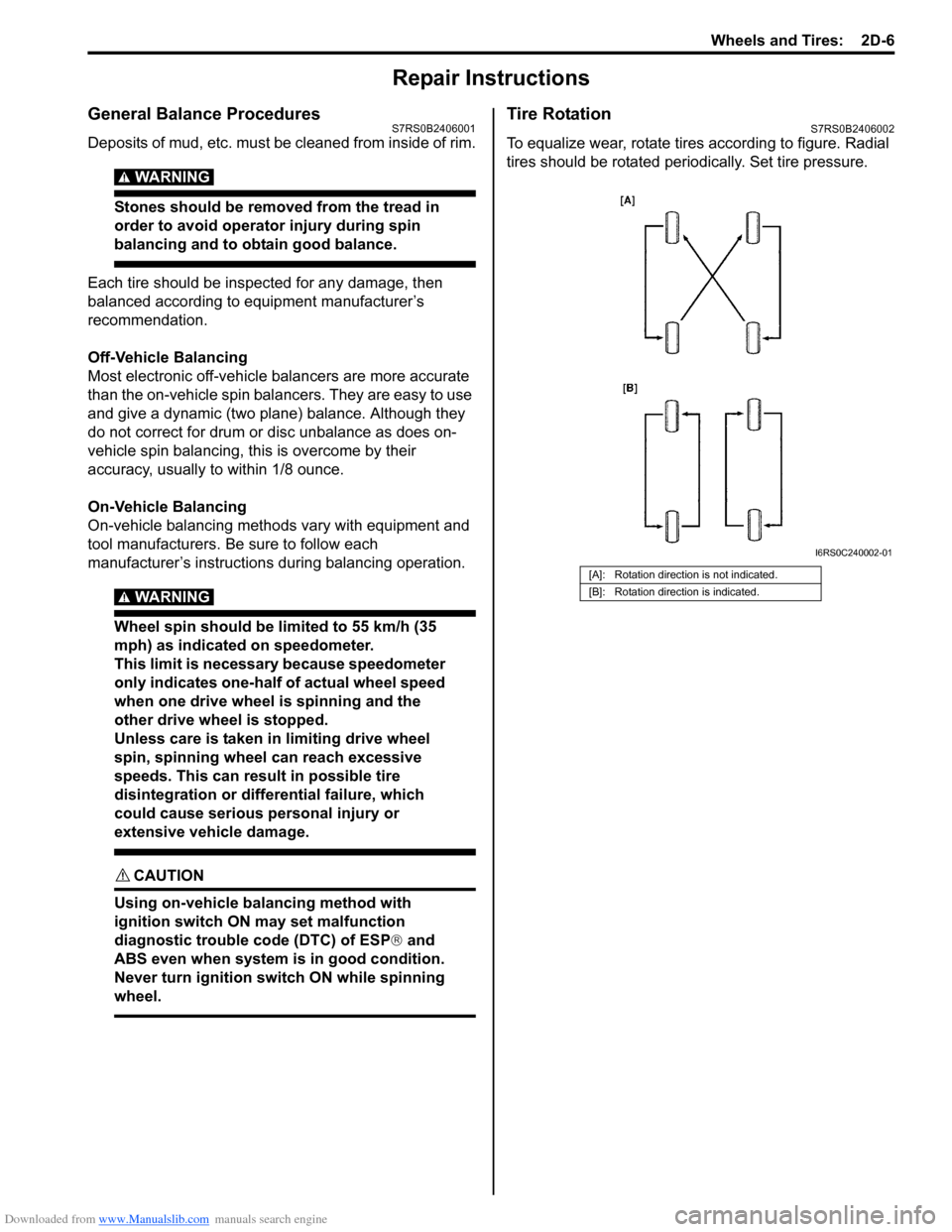

Tire RotationS7RS0B2406002

To equalize wear, rotate tires according to figure. Radial

tires should be rotated periodi cally. Set tire pressure.

[A]: Rotation direction is not indicated.

[B]: Rotation direction is indicated.

I6RS0C240002-01

Page 495 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 4- i

4

Section 4

CONTENTS

Brakes

Precautions ................................................. 4-1

Precautions............................................................. 4-1

Precautions for Brakes .......................................... 4-1

Brake Control System and Diagnosis ... 4A-1

Precautions........................................................... 4A-1Precautions on Brake .......................................... 4A-1

General Description ............................................. 4A-1 Brakes Construction ............................................ 4A-1

Brake Pedal Foot Protection System Construction ...................................................... 4A-2

Front Brake Hose / Pipe Co nstruction................. 4A-3

Rear Brake Hose / Pipe Construction ................. 4A-4

Diagnostic Information and Procedures ............ 4A-4 Brakes Diagnosis Note ....................................... 4A-4

Brakes Symptom Diagnosis ................................ 4A-5

Repair Instructions .............................................. 4A-7 Brake Pedal Components ................................... 4A-7

Brake Pedal Free Height Inspection ................... 4A-7

Brake Pedal Play Inspection ............................... 4A-7

Excessive Pedal Travel Inspection ..................... 4A-8

Brake Fluid Level Inspection ............................... 4A-8

Stop Light Switch Adjustment ............................. 4A-8

Air Bleeding of Brake System ............................. 4A-9

Front Brake Hose / Pipe Removal and Installation ....................................................... 4A-10

Rear Brake Hose / Pipe Removal and Installation ....................................................... 4A-10

Brake Hose and Pipe Inspection ....................... 4A-11

Master Cylinder Components............................ 4A-11

Master Cylinder Assembly Removal and Installation ....................................................... 4A-12

Master Cylinder Rese rvoir Removal and

Installation ....................................................... 4A-13

Master Cylinder Assemb ly Disassembly and

Assembly ........................................................ 4A-14

Master Cylinder Assembly Inspection ............... 4A-15

Brake Booster Components .............................. 4A-15

Booster Operation Inspection ........................... 4A-16

Brake Booster Removal and Installation ........... 4A-17

Brake Booster Inspection and Adjustment ........ 4A-18

Specifications ..................................................... 4A-18

Tightening Torque Specifications ...................... 4A-18

Special Tools and Equipmen t ........................... 4A-18 Recommended Service Material ....................... 4A-18

Front Brakes .......

..................................... 4B-1

Repair Instructions ........... ...................................4B-1

Front Disc Brake Components ............................ 4B-1

Front Disc Brake Pad On-Vehicle Inspection ...... 4B-2

Front Disc Brake Pad Removal and Installation ......................................................... 4B-2

Front Disc Brake Pad Inspection......................... 4B-3

Front Disc Brake Ca liper Removal and

Installation ......................................................... 4B-3

Front Disc Brake Caliper Disassembly and Assembly........................................................... 4B-4

Front Disc Brake Caliper In spection.................... 4B-6

Front Brake Disc Removal and Installation ......... 4B-6

Front Brake Disc Inspection ................................ 4B-7

Specifications .................... ...................................4B-8

Tightening Torque Specifications ........................ 4B-8

Special Tools and Equipmen t .............................4B-8

Recommended Service Material ......................... 4B-8

Special Tool ........................................................ 4B-8

Rear Brakes................... ........................... 4C-1

Repair Instructions ........... ...................................4C-1

Rear Disc Brake Components.............................4C-1

Rear Disc Brake Pad Removal and Installation .........................................................4C-2

Rear Disc Brake Caliper Removal and Installation .........................................................4C-3

Rear Disc Brake Pad Inspection .........................4C-6

Rear Disc Brake Caliper Disassembly and Assembly...........................................................4C-6

Rear Disc Brake Caliper Inspection ....................4C-8

Rear Flexible Hose Remova l and Installation .....4C-8

Rear Brake Disc Removal and Installation..........4C-9

Rear Brake Disc Inspection.................................4C-9

Specifications .................... .................................4C-10

Tightening Torque Specifications ......................4C-10

Special Tools and Equipmen t ...........................4C-11

Recommended Service Material .......................4C-11

Special Tool ......................................................4C-11

Parking Brake ................. ......................... 4D-1

General Description .............................................4D-1

Parking Brake Cable Construction ......................4D-1

Page 496 of 1496

Downloaded from www.Manualslib.com manuals search engine 4-ii Table of Contents

Repair Instructions ..............................................4D-2Parking Brake Inspection and Adjustment ..........4D-2

Parking Brake Cable Removal and Installation ......................................................... 4D-3

Parking Brake Lever Removal and Installation ....4D-3

Specifications .... ...................................................4D-4

Tightening Torque Specifications ........................4D-4

ABS ........................................... .................4E-1

Precautions........................................................... 4E-1

Precautions in Diagnosing Troubles ................... 4E-1

Precautions in On-Vehicle Service...................... 4E-1

Precautions in Hydraulic Unit Operation Check ................................................................ 4E-1

General Description ............................................. 4E-2 ABS Description .................................................. 4E-2

ABS Hydraulic Unit / Control Module Assembly Description ....................................... 4E-2

CAN Communication System Description........... 4E-3

Schematic and Routing Diagram ........................ 4E-4 ABS Schematic ................................................... 4E-4

ABS Wiring Circuit Diagram ................................ 4E-5

Component Location ........... ................................ 4E-7

ABS Components Location ................................. 4E-7

Front Wheel Speed Sensor Components Location ............................................................ 4E-7

Rear Wheel Speed Sensor Components Location ............................................................ 4E-8

Diagnostic Information and Procedures ............ 4E-8 ABS Check .......................................................... 4E-8

ABS Warning Light Check................................. 4E-10

EBD Warning Light (Brake Warning Light) Check .............................................................. 4E-10

DTC Check........................................................ 4E-11

DTC Table ......................................................... 4E-11

DTC Clearance ................................................. 4E-12

Scan Tool Data ................................................. 4E-12

ABS Warning Light Does Not Come ON at Ignition Switch ON .......................................... 4E-13

ABS Warning Light Comes ON Steady ............. 4E-14

EBD Warning Light (Brake Warning Light) Comes ON Steady .......................................... 4E-15

Serial Data Link Circuit Check .......................... 4E-16

DTC C1021, C1022 / C1025, C1026 / C1031, C1032 / C1035, C1036: Right-Front / Left-

Front / Right-Rear / Left-Rear Wheel Speed

Sensor Circuit or Sensor Ring ........................ 4E-18

DTC C1041 / C1045 / C1051 / C1055, DTC C1042 / C1046 / C1052 / C1056: Right-Front

/ Left-Front / Right-Rear / Left-Rear Inlet

Solenoid Circuit, Right-Front / Left-Front /

Right-Rear / Left-Rear Outlet Solenoid

Circuit .............................................................. 4E-20

DTC C1057: Power Source Circuit ................... 4E-21

DTC C1061: ABS Pump Motor and/or Motor Driver Circuit ................................................... 4E-22

DTC C1063: Solenoid Valve Power Supply Driver Circuit ................................................... 4E-23

DTC C1071: ABS Control Module..................... 4E-24 DTC U1073: Control Module Communication

Bus Off ............................................................ 4E-25

DTC U1100: Lost Communication with ECM (Reception Error)............................................. 4E-27

Repair Instructions ............ ................................ 4E-28

ABS Hydraulic Unit Operati on Check................ 4E-28

ABS Hydraulic Unit / Control Module

Assembly Components ...... ............................. 4E-29

ABS Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4E-29

ABS Hydraulic Unit / Control Module

Assembly Removal and Inst allation ................ 4E-29

Front / Rear Wheel Speed Sensor On-Vehicle Inspection ........................................................ 4E-31

Front Wheel Speed Sensor Removal and Installation ....................................................... 4E-32

Front Wheel Speed Sensor Inspection ............. 4E-32

Rear Wheel Speed Sensor Removal and Installation ....................................................... 4E-33

Rear Wheel Speed Sensor Inspection .............. 4E-34

Front Wheel Encoder On-Veh icle Inspection .... 4E-34

Front wheel Enco der Removal and

Installation ....................................................... 4E-34

Rear Wheel Encoder On-Veh icle Inspection..... 4E-34

Rear Wheel Encoder Removal and Installation ....................................................... 4E-34

Specifications ..................... ................................ 4E-35

Tightening Torque Specifications ...................... 4E-35

Special Tools and Equipmen t ........................... 4E-35

Special Tool ...................................................... 4E-35

Electronic Stability Prog ram ...................4F-1

Precautions ........................................................... 4F-1

Precautions in Diagnosing Troubles ................... 4F-1

Precautions in On-Vehicle Service...................... 4F-1

Precautions in Hydraulic Unit Operation Check ................................................................ 4F-1

Precautions in Sensor Calibration ....................... 4F-1

Precautions in Speedometer Test or Other Tests ................................................................. 4F-2

General Description ............................................. 4F-2 Electronic Stability Program Description ............. 4F-2

Electronic Stability Program Construction ........... 4F-3

ESP® Hydraulic Unit / Control Module

Assembly Description........................................ 4F-5

Warning Lamp, Indicator Lamp Description ........ 4F-6

CAN Communication System Description........... 4F-6

CAN Communication System For Electronic Stability Program Description ............................ 4F-7

Schematic and Routing Diagram ........................ 4F-8 Electronic Stability Program Schematic .............. 4F-8

Electronic Stability Program Wiring Circuit Diagram............................................................. 4F-9

Component Location ............ ............................. 4F-11

Electronic Stability Program Component

Location........................................................... 4F-11

Diagnostic Information and Procedures .......... 4F-12 Electronic Stability Program System Check ...... 4F-12

ESP® Warning lamp Check .............................. 4F-14

Page 497 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 4-iii

ABS Warning Lamp Check ............................... 4F-14

EBD Warning Lamp (Brake Warning Lamp) Check .............................................................. 4F-15

DTC Check ....................................................... 4F-15

DTC Table ......................................................... 4F-15

DTC Clearance ................................................. 4F-18

Fail-Safe Table ................ .................................. 4F-19

Scan Tool Data ................................................. 4F-20

Visual Inspection ............................................... 4F-21

ESP ® Warning Lamp Does Not Come ON at

Ignition Switch ON .......................................... 4F-21

ESP ® Warning Lamp Comes ON Steady......... 4F-22

ABS Warning Lamp Does Not Come ON at Ignition Switch ON .......................................... 4F-23

ABS Warning Lamp Comes ON Steady............ 4F-24

EBD Warning Lamp (Brake Warning Lamp) Comes ON Steady .......................................... 4F-24

Serial Data Link Circuit Check .......................... 4F-26

DTC C1016: Stop Lamp Swit ch Circuit Failure .. 4F-28

DTC C1017 / C1023: Yaw Rate / G Sensor Assembly Failure ............................................ 4F-29

DTC C1018: Brake Fluid Le vel Switch Failure .. 4F-30

DTC 1020: Master Cylinder Pressure Sensor Power Supply Failure ...................................... 4F-31

DTC C1021, C1022 / C1025, C1026 / C1031, C1032 / C1035, C1036: Wheel Speed

Sensor Circuit or Encode r Failure ................... 4F-32

DTC C1024: Steering Angle Sensor Circuit

Failure ............................................................. 4F-34

DTC C1027: ESP ® OFF Switch Circuit

Failure ............................................................. 4F-34

DTC C1028: Master Cylinder Pressure Sensor Circuit Failure ....... .............................. 4F-35

DTC C1034: Yaw Rate / G Sensor Assembly Power Supply Failure ...................................... 4F-36

DTC C1037: Steering Angle Sensor Power Supply Failure ................................................. 4F-37

DTC C1038: Steering Angle Sensor Detect Rolling Counter Fa ilure from ESP® Control

Module ............................................................ 4F-38

DTC C1039: Yaw Rate / G Sensor Assembly Internal Failure .............. .................................. 4F-39

DTC C1040: Stability Control System Function Failure .............................................. 4F-39

DTC C1041 / C1042 / C1043 / C1044 / C1045 / C1046 / C1051 / C1052 / C1053 / C1054 /

C1055 / C1056: Solenoid Circuit Failure ......... 4F-40

DTC C1057: ESP ® Control Module Power

Supply Circuit Failure .... .................................. 4F-41

DTC C1061: Pump Motor and/or Motor Driver Circuit Failure .................................................. 4F-42

DTC C1063: Solenoid Valve Power Supply Driver Circuit Failure ....................................... 4F-43

DTC 1071: ESP ® Control Module Internal

Defect.............................................................. 4F-44 DTC C1073: Lost Communication With Yaw

Rate / G Sensor Assembly .............................. 4F-45

DTC C1075 / 1076 / 1078: Sensor Calibration Incomplete.......................... ............................. 4F-46

DTC C1090: Invalid Communication with

ECM ................................................................ 4F-47

DTC C1091 / C1094: ECM Data in CAN Line Failure / Invalid Torque Control

Communication with ECM .. ............................. 4F-48

DTC U1073: Control Module Communication Bus Off ............................................................ 4F-49

DTC U1100: Lost Communication with ECM (Reception Error)............................................. 4F-50

DTC U1126: Lost Communication with Steering Angle Sensor (Reception Error)........ 4F-51

DTC U1140: Lost Communication with BCM (Reception Error)............................................. 4F-52

Repair Instructions ........... ................................. 4F-54

ESP® Hydraulic Unit Operation Check ............. 4F-54

Sensor Calibration............................................. 4F-54

ESP® Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4F-55

ESP ® Hydraulic

Unit / Control Module

Assembly Removal and Inst allation ................ 4F-56

Front / Rear Wheel Speed Sensor On-Vehicle Inspection ........................................................ 4F-57

Front Wheel Speed Sensor Removal and Installation ....................................................... 4F-58

Front Wheel Speed Sensor Inspection ............. 4F-59

Rear Wheel Speed Sensor Removal and Installation ....................................................... 4F-59

Rear Wheel Speed Sensor Inspection .............. 4F-60

Front Wheel Encode r On-Vehicle Inspection .... 4F-61

Front Wheel Encoder Removal and Installation ....................................................... 4F-61

Rear Wheel Encoder On-Veh icle Inspection..... 4F-61

Rear Wheel Encoder Removal and Installation ....................................................... 4F-61

Master Cylinder Pressure Sensor On-Vehicle

Inspection ........................................................ 4F-61

Yaw Rate / G Sensor Assembly On-Vehicle Inspection ........................................................ 4F-62

Yaw Rate / G Sensor Assembly Removal and Installation ....................................................... 4F-63

Yaw Rate / G Sensor Inspection ....................... 4F-64

Steering Angle Sensor On-Vehicle Inspection .. 4F-64

Steering Angle Sensor Removal and Installation ....................................................... 4F-65

Steering Angle Sensor Inspection ..................... 4F-65

ESP® OFF Switch Removal an d Installation .... 4F-65

ESP® OFF Switch Inspection ........................... 4F-65

Specifications .................... ................................. 4F-66

Tightening Torque Specifications ...................... 4F-66

Special Tools and Equipmen t ........................... 4F-66

Special Tool ...................................................... 4F-66

Page 498 of 1496

Downloaded from www.Manualslib.com manuals search engine 4-1 Precautions:

Brakes

Precautions

Precautions

Precautions for BrakesS7RS0B4000001

Suspension Caution

Refer to “Suspension Caution in Section 00”.

Wheels and Tires Caution

Refer to “Wheels and Tires Caution in Section 00”.

Brake Caution

Refer to “Brake Caution in Section 00”.

ESP® System Precautions

Refer to “Precaution for Vehicle Equipped with ESP ® System in Section 00”.

General Precautions

Refer to “General Precautions in Section 00”.

Vehicle Lifting Points

Refer to “Vehicle Liftin g Points in Section 0A”.

Fastener Caution

Refer to “Fastener Caution in Section 00”.

Fastener Information

Refer to “Fasteners Information in Section 0A”.

Page 499 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-1

Brakes

Brake Control System and Diagnosis

Precautions

Precautions on BrakeS7RS0B4100001

Air Bag Warning

Refer to “Air Bag System Service Warning in Section 00”.

Brakes Diagnosis Note

Refer to “Brakes Diagnosis Note”.

General Description

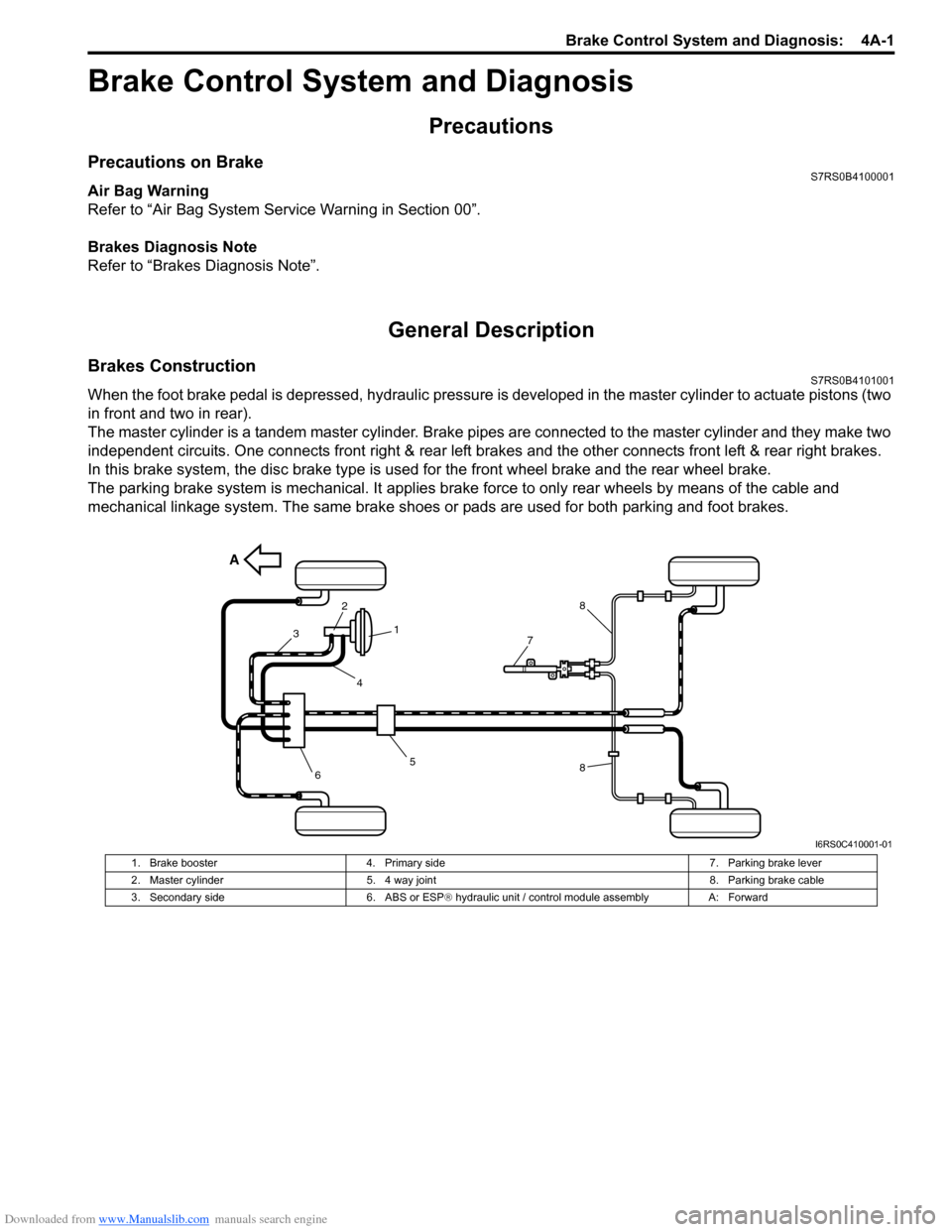

Brakes ConstructionS7RS0B4101001

When the foot brake pedal is depressed, hydraulic pressure is developed in the master cylinder to actuate pistons (two

in front and two in rear).

The master cylinder is a tandem master cylinder. Brake pipes are connected to the master cylinder and they make two

independent circuits. One connects front right & rear left brakes and the other connects front left & rear right brakes.

In this brake system, the disc brake type is used for the front wheel brake and the rear wheel brake.

The parking brake system is mechanical. It applies brake force to only rear wheels by means of the cable and

mechanical linkage system. The same brake shoes or pads are used for both parking and foot brakes.

A

5

3

2

1

4

8

8

6

7

I6RS0C410001-01

1. Brake booster 4. Primary side 7. Parking brake lever

2. Master cylinder 5. 4 way joint 8. Parking brake cable

3. Secondary side 6. ABS or ESP® hydraulic unit / control module assembly A: Forward

Page 500 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-2 Brake Control System and Diagnosis:

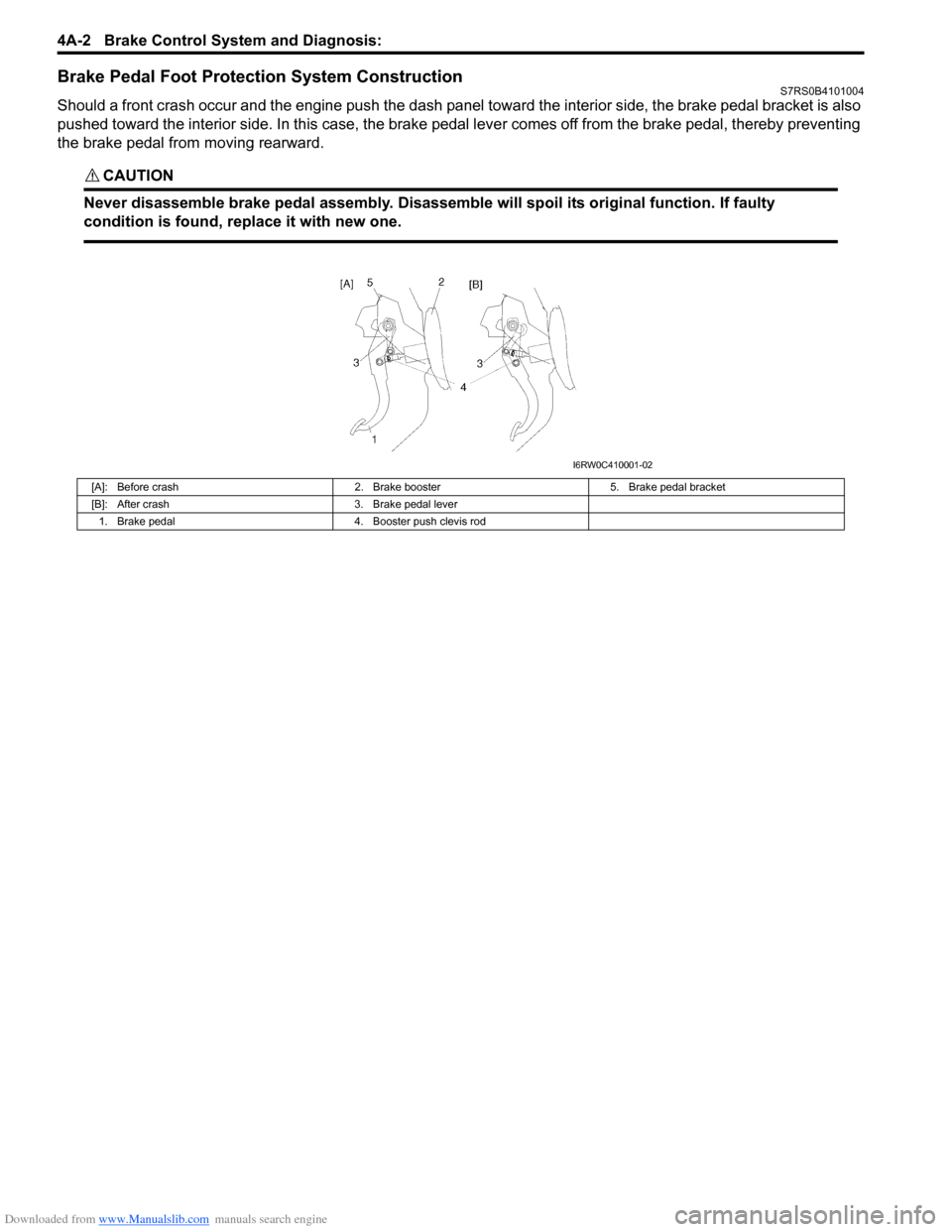

Brake Pedal Foot Protection System ConstructionS7RS0B4101004

Should a front crash occur and the engine push the dash panel toward the interior side, the brake pedal bracket is also

pushed toward the interior side. In this case, the brake pedal lever comes off from the brake pedal, thereby preventing

the brake pedal from moving rearward.

CAUTION!

Never disassemble brake pedal assembly. Disassemble will spoil its original function. If faulty

condition is found, replace it with new one.

[A]: Before crash2. Brake booster5. Brake pedal bracket

[B]: After crash 3. Brake pedal lever

1. Brake pedal 4. Booster push clevis rod

I6RW0C410001-02

Page 501 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-3

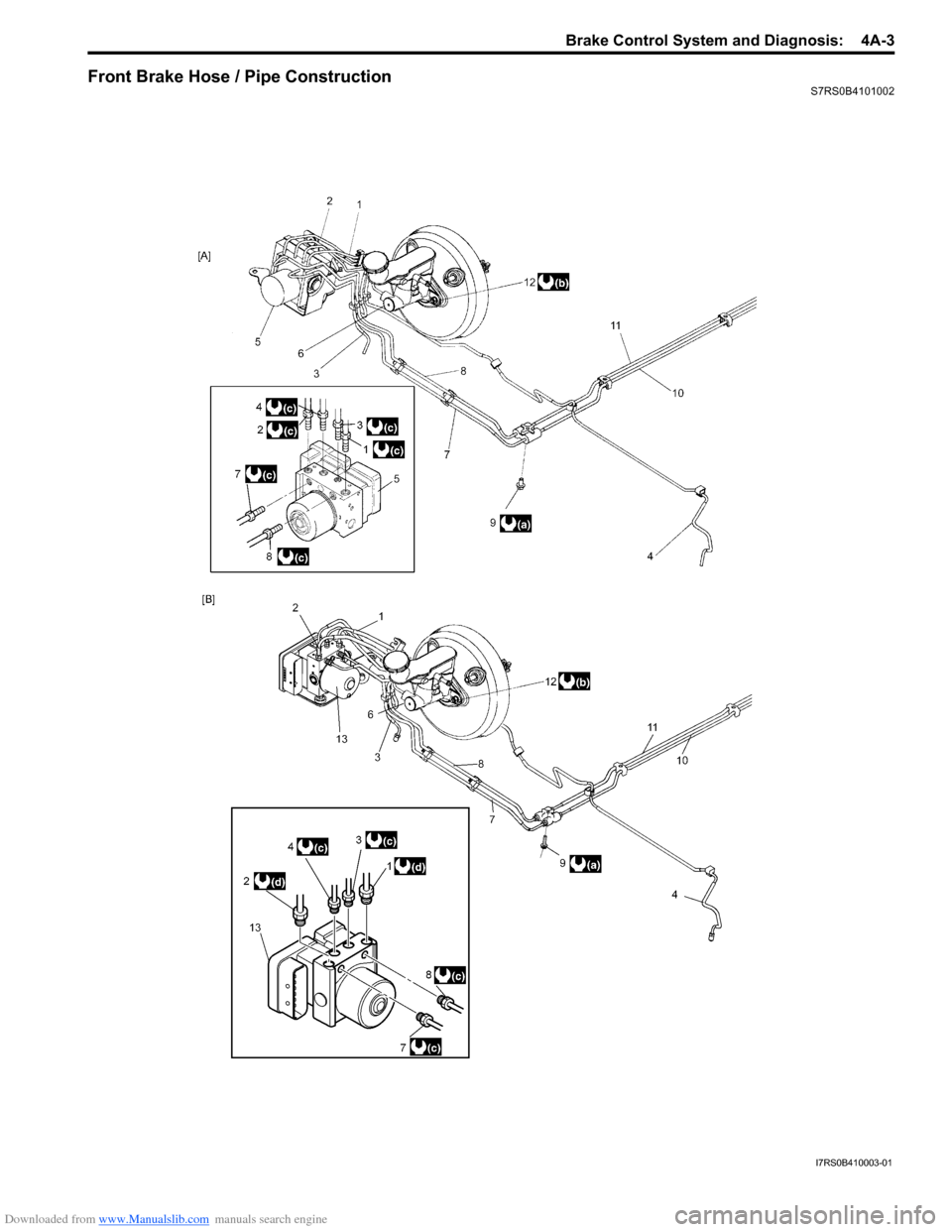

Front Brake Hose / Pipe ConstructionS7RS0B4101002

I7RS0B410003-01

Page 502 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-4 Brake Control System and Diagnosis:

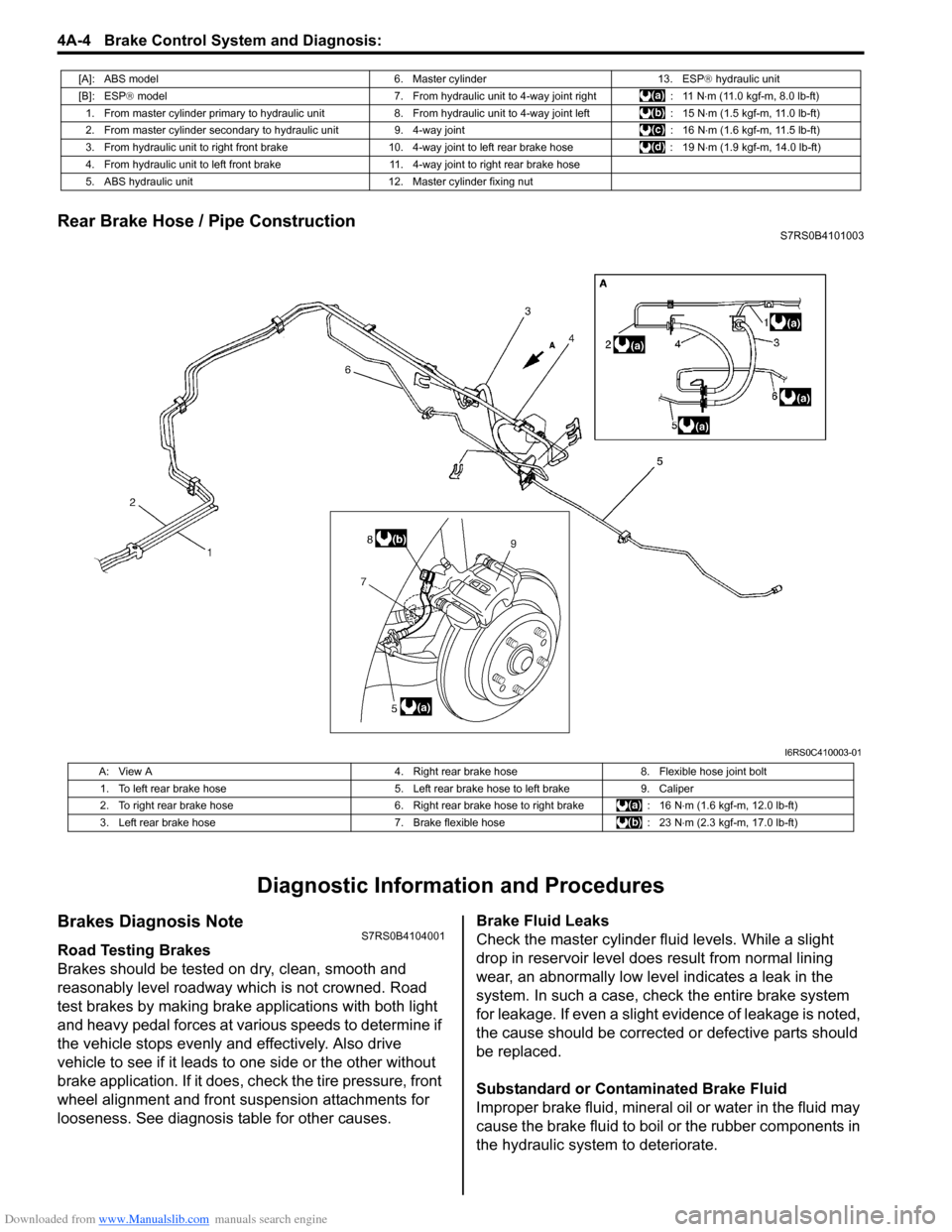

Rear Brake Hose / Pipe ConstructionS7RS0B4101003

Diagnostic Information and Procedures

Brakes Diagnosis NoteS7RS0B4104001

Road Testing Brakes

Brakes should be tested on dry, clean, smooth and

reasonably level roadway which is not crowned. Road

test brakes by making brake applications with both light

and heavy pedal forces at vari ous speeds to determine if

the vehicle stops evenly and effectively. Also drive

vehicle to see if it leads to one side or the other without

brake application. If it does, check the tire pressure, front

wheel alignment and front suspension attachments for

looseness. See diagnosis table for other causes. Brake Fluid Leaks

Check the master cylinder fl

uid levels. While a slight

drop in reservoir level does result from normal lining

wear, an abnormally low leve l indicates a leak in the

system. In such a case, chec k the entire brake system

for leakage. If even a slight ev idence of leakage is noted,

the cause should be corrected or defective parts should

be replaced.

Substandard or Contaminated Brake Fluid

Improper brake fluid, mineral oil or water in the fluid may

cause the brake fluid to boil or the rubber components in

the hydraulic system to deteriorate.

[A]: ABS model 6. Master cylinder13. ESP® hydraulic unit

[B]: ESP ® model 7. From hydraulic unit to 4-way joint right : 11 N⋅m (11.0 kgf-m, 8.0 lb-ft)

1. From master cylinder primary to hydraulic unit 8. From hydraulic unit to 4-way joint left: 15 N⋅m (1.5 kgf-m, 11.0 lb-ft)

2. From master cylinder secondary to hydraulic unit 9. 4-way joint: 16 N⋅m (1.6 kgf-m, 11.5 lb-ft)

3. From hydraulic unit to right front brake 10.4-way joint to left rear brake hose : 19 N⋅m (1.9 kgf-m, 14.0 lb-ft)

4. From hydraulic unit to left front brake 11. 4-way joint to right rear brake hose

5. ABS hydraulic unit 12. Master cylinder fixing nut

I6RS0C410003-01

A: View A4. Right rear brake hose8. Flexible hose joint bolt

1. To left rear brake hose 5. Left rear brake hose to left brake9. Caliper

2. To right rear brake hose 6. Right rear brake hose to right brake: 16 N⋅m (1.6 kgf-m, 12.0 lb-ft)

3. Left rear brake hose 7. Brake flexible hose: 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)