Vehicle speed signal SUZUKI SWIFT 2008 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 226 of 1496

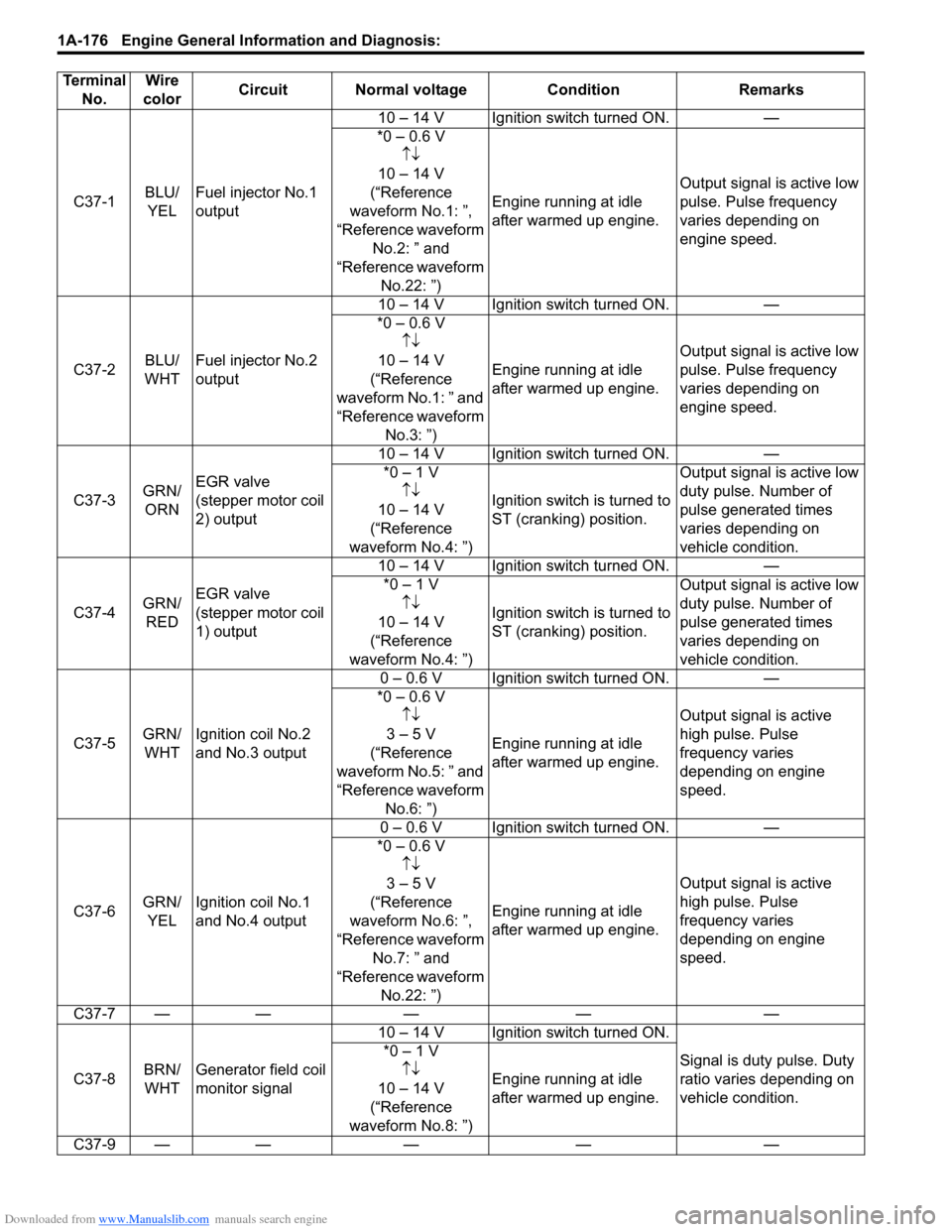

Downloaded from www.Manualslib.com manuals search engine 1A-176 Engine General Information and Diagnosis:

Terminal No. Wire

color Circuit Normal voltage Condition Remarks

C37-1 BLU/

YEL Fuel injector No.1

output 10 – 14 V Ignition switch turned ON. —

*0 – 0.6 V ↑↓

10 – 14 V

(“Reference

waveform No.1: ”,

“Reference waveform No.2: ” and

“Reference waveform No.22: ”) Engine running at idle

after warmed up engine.

Output signal is active low

pulse. Pulse frequency

varies depending on

engine speed.

C37-2 BLU/

WHT Fuel injector No.2

output 10 – 14 V Ignition switch turned ON. —

*0 – 0.6 V ↑↓

10 – 14 V

(“Reference

waveform No.1: ” and

“Reference waveform No.3: ”) Engine running at idle

after warmed up engine.

Output signal is active low

pulse. Pulse frequency

varies depending on

engine speed.

C37-3 GRN/

ORN EGR valve

(stepper motor coil

2) output 10 – 14 V Ignition switch turned ON. —

*0 – 1 V ↑↓

10 – 14 V

(“Reference

waveform No.4: ”) Ignition switch is turned to

ST (cranking) position. Output signal is active low

duty pulse. Number of

pulse generated times

varies depending on

vehicle condition.

C37-4 GRN/

RED EGR valve

(stepper motor coil

1) output 10 – 14 V Ignition switch turned ON. —

*0 – 1 V

↑↓

10 – 14 V

(“Reference

waveform No.4: ”) Ignition switch is turned to

ST (cranking) position. Output signal is active low

duty pulse. Number of

pulse generated times

varies depending on

vehicle condition.

C37-5 GRN/

WHT Ignition coil No.2

and No.3 output 0 – 0.6 V Ignition switch turned ON. —

*0 – 0.6 V ↑↓

3 – 5 V

(“Reference

waveform No.5: ” and

“Reference waveform No.6: ”) Engine running at idle

after warmed up engine.

Output signal is active

high pulse. Pulse

frequency varies

depending on engine

speed.

C37-6 GRN/

YEL Ignition coil No.1

and No.4 output 0 – 0.6 V Ignition switch turned ON. —

*0 – 0.6 V ↑↓

3 – 5 V

(“Reference

waveform No.6: ”,

“Reference waveform No.7: ” and

“Reference waveform No.22: ”

)Engine running at idle

after warmed up engine.

Output signal is active

high pulse. Pulse

frequency varies

depending on engine

speed.

C37-7 — —— — —

C37-8 BRN/

WHT Generator field coil

monitor signal 10 – 14 V Ignition switch turned ON.

Signal is duty pulse. Duty

ratio varies depending on

vehicle condition.

*0 – 1 V

↑↓

10 – 14 V

(“Reference

waveform No.8: ”) Engine running at idle

after warmed up engine.

C37-9 — —— — —

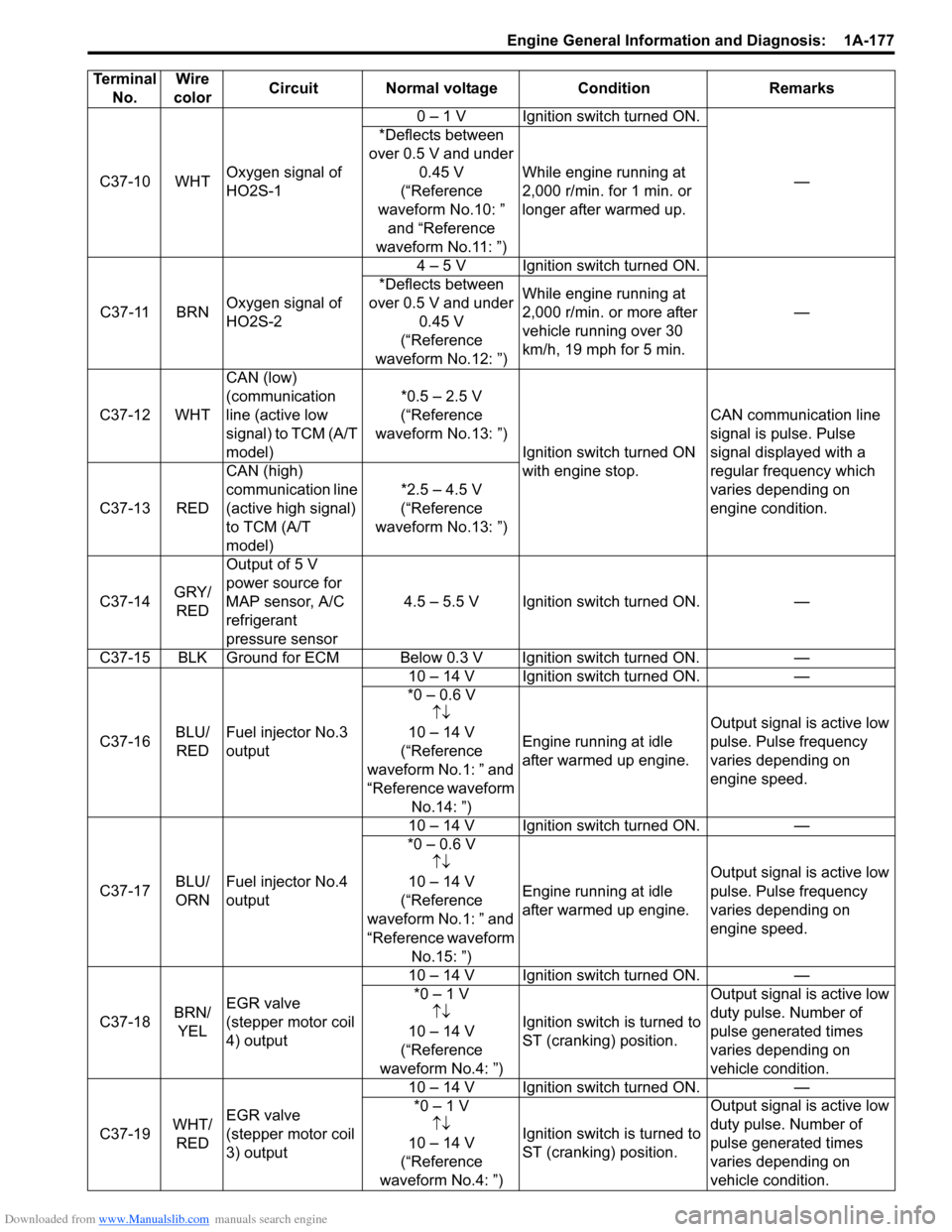

Page 227 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-177

C37-10 WHTOxygen signal of

HO2S-1 0 – 1 V Ignition switch turned ON.

—

*Deflects between

over 0.5 V and under 0.45 V

(“Reference

waveform No.10: ” and “Reference

waveform No.11: ”) While engine running at

2,000 r/min. for 1 min. or

longer after warmed up.

C37-11 BRN Oxygen signal of

HO2S-2 4 – 5 V Ignition switch turned ON.

—

*Deflects between

over 0.5 V and under 0.45 V

(“Reference

waveform No.12: ”) While engine running at

2,000 r/min. or more after

vehicle running over 30

km/h, 19 mph for 5 min.

C37-12 WHT CAN (low)

(communication

line (active low

signal) to TCM (A/T

model) *0.5 – 2.5 V

(“Reference

waveform No.13: ”) Ignition switch turned ON

with engine stop. CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency which

varies depending on

engine condition.

C37-13 RED CAN (high)

communication line

(active high signal)

to TCM (A/T

model) *2.5 – 4.5 V

(“Reference

waveform No.13: ”)

C37-14 GRY/

RED Output of 5 V

power source for

MAP sensor, A/C

refrigerant

pressure sensor

4.5 – 5.5 V Ignition switch turned ON. —

C37-15 BLK Ground for ECM Below 0.3 V Ignition switch turned ON. —

C37-16 BLU/

RED Fuel injector No.3

output 10 – 14 V Ignition switch turned ON. —

*0 – 0.6 V ↑↓

10 – 14 V

(“Reference

waveform No.1: ” and

“Reference waveform No.14: ”) Engine running at idle

after warmed up engine.

Output signal is active low

pulse. Pulse frequency

varies depending on

engine speed.

C37-17 BLU/

ORNFuel injector No.4

output 10 – 14 V Ignition switch turned ON. —

*0 – 0.6 V ↑↓

10 – 14 V

(“Reference

waveform No.1: ” and

“Reference waveform No.15: ”) Engine running at idle

after warmed up engine.

Output signal is active low

pulse. Pulse frequency

varies depending on

engine speed.

C37-18 BRN/

YEL EGR valve

(stepper motor coil

4) output 10 – 14 V Ignition switch turned ON. —

*0 – 1 V ↑↓

10 – 14 V

(“Reference

waveform No.4: ”) Ignition switch is turned to

ST (cranking) position. Output signal is active low

duty pulse. Number of

pulse generated times

varies depending on

vehicle condition.

C37-19 WHT/

RED EGR valve

(stepper motor coil

3) output 10 – 14 V Ignition switch turned ON. —

*0 – 1 V ↑↓

1

0 – 14 V

(“Reference

waveform No.4: ”) Ignition switch is turned to

ST (cranking) position. Output signal is active low

duty pulse. Number of

pulse generated times

varies depending on

vehicle condition.

Terminal

No. Wire

color Circuit Normal voltage

ConditionRemarks

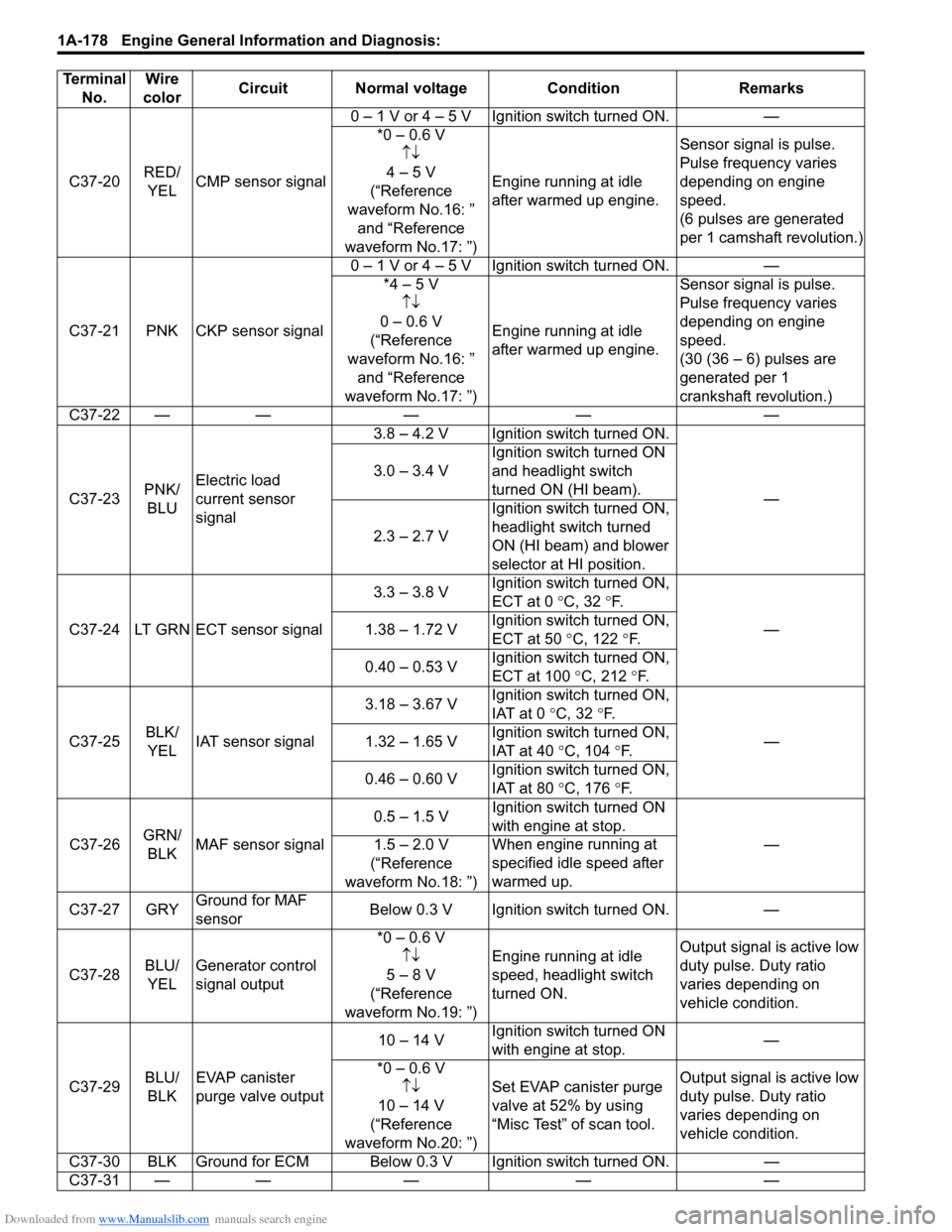

Page 228 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-178 Engine General Information and Diagnosis:

C37-20RED/

YEL CMP sensor signal 0 – 1 V or 4 – 5 V Ignition switch turned ON. —

*0 – 0.6 V↑↓

4 – 5 V

(“Reference

waveform No.16: ” and “Reference

waveform No.17: ”) Engine running at idle

after warmed up engine.

Sensor signal is pulse.

Pulse frequency varies

depending on engine

speed.

(6 pulses are generated

per 1 camshaft revolution.)

C37-21 PNK CKP sensor signal 0 – 1 V or 4 – 5 V Ignition switch turned ON. —

*4 – 5 V↑↓

0 – 0.6 V

(“Reference

waveform No.16: ” and “Reference

waveform No.17: ”) Engine running at idle

after warmed up engine. Sensor signal is pulse.

Pulse frequency varies

depending on engine

speed.

(30 (36 – 6) pulses are

generated per 1

crankshaft revolution.)

C37-22 — — — — —

C37-23 PNK/

BLU Electric load

current sensor

signal 3.8 – 4.2 V Ignition switch turned ON.

—

3.0 – 3.4 V

Ignition switch turned ON

and headlight switch

turned ON (HI beam).

2.3 – 2.7 V Ignition switch turned ON,

headlight switch turned

ON (HI beam) and blower

selector at HI position.

C37-24 LT GRN ECT sensor signal 3.3 – 3.8 V

Ignition switch turned ON,

ECT at 0

°C, 32 °F.

—

1.38 – 1.72 V Ignition switch turned ON,

ECT at 50

°C, 122 °F.

0.40 – 0.53 V Ignition switch turned ON,

ECT at 100

°C, 212 °F.

C37-25 BLK/

YEL IAT sensor signal 3.18 – 3.67 V

Ignition switch turned ON,

IAT at 0

°C, 32 °F.

—

1.32 – 1.65 V Ignition switch turned ON,

IAT at 40

°C, 104 °F.

0.46 – 0.60 V Ignition switch turned ON,

IAT at 80

°C, 176 °F.

C37-26 GRN/

BLK MAF sensor signal 0.5 – 1.5 V

Ignition switch turned ON

with engine at stop.

—

1.5 – 2.0 V

(“Reference

waveform No.18: ”) Wh

en engine running at

specified idle speed after

warmed up.

C37-27 GRY Ground for MAF

sensor Below 0.3 V Ignition switch turned ON.

—

C37-28 BLU/

YEL Generator control

signal output *0 – 0.6 V

↑↓

5 – 8 V

(“Reference

waveform No.19: ”) Engine running at idle

speed, headlight switch

turned ON.

Output signal is active low

duty pulse. Duty ratio

varies depending on

vehicle condition.

C37-29 BLU/

BLK EVAP canister

purge valve output 10 – 14 V

Ignition switch turned ON

with engine at stop. —

*0 – 0.6 V ↑↓

10 – 14 V

(“Reference

waveform No.20: ”) Set EVAP canister purge

valve at 52% by using

“Misc Test” of scan tool.

Output signal is active low

duty pulse. Duty ratio

varies depending on

vehicle condition.

C37-30 BLK Ground for ECM Below 0.3 V Ignition switch turned ON. —

C37-31 — —— — —

Terminal

No. Wire

color Circuit Normal voltage

ConditionRemarks

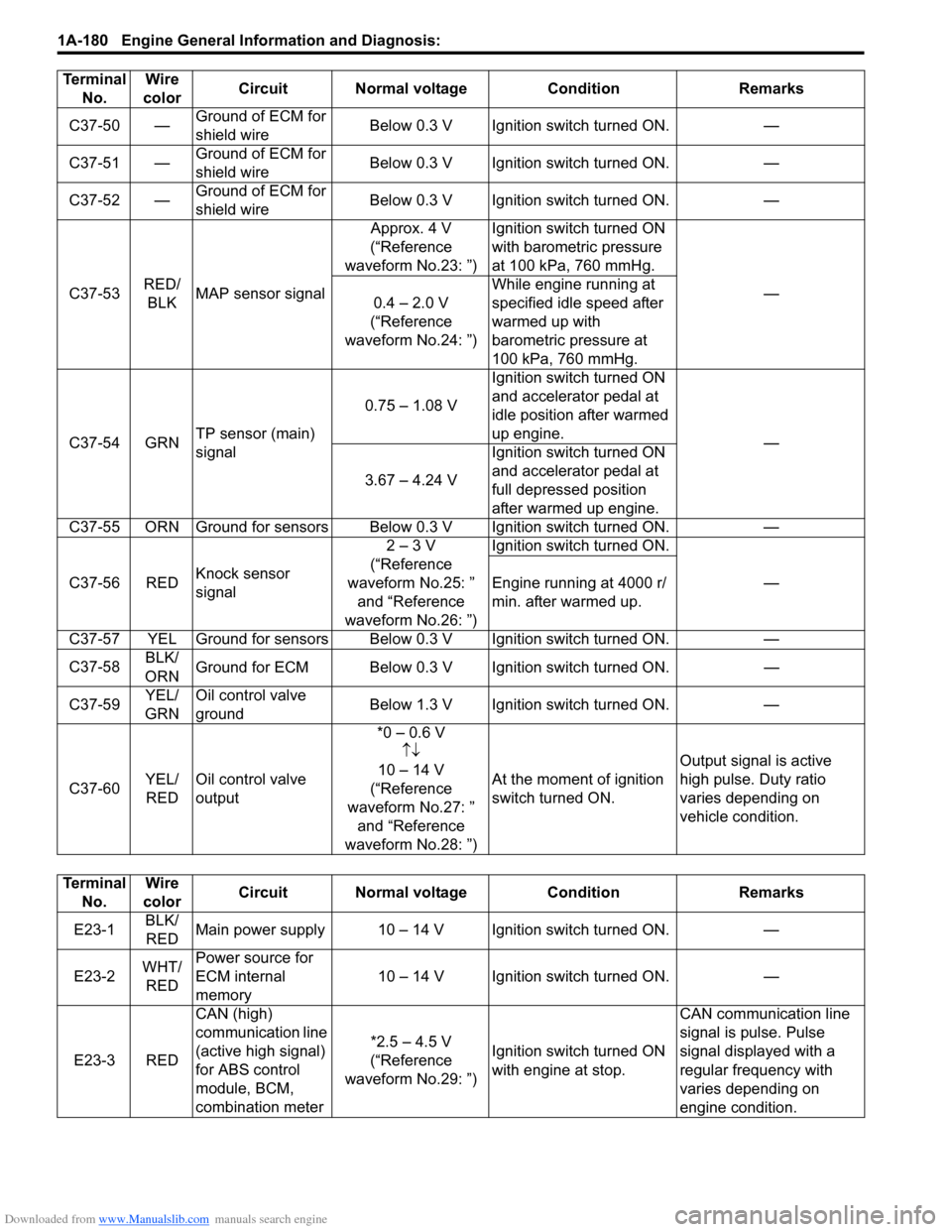

Page 230 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-180 Engine General Information and Diagnosis:

C37-50 —Ground of ECM for

shield wire Below 0.3 V Ignition switch turned ON. —

C37-51 — Ground of ECM for

shield wire Below 0.3 V Ignition switch turned ON. —

C37-52 — Ground of ECM for

shield wire Below 0.3 V Ignition switch turned ON. —

C37-53 RED/

BLK MAP sensor signal Approx. 4 V

(“Reference

waveform No.23: ”) Ignition switch turned ON

with barometric pressure

at 100 kPa, 760 mmHg.

—

0.4 – 2.0 V

(“Reference

waveform No.24: ”) While engine running at

specified idle speed after

warmed up with

barometric pressure at

100 kPa, 760 mmHg.

C37-54 GRN TP sensor (main)

signal 0.75 – 1.08 V

Ignition switch turned ON

and accelerator pedal at

idle position after warmed

up engine.

—

3.67 – 4.24 V Ignition switch turned ON

and accelerator pedal at

full depressed position

after warmed up engine.

C37-55 ORN Ground for sensors Below 0.3 V Ignition switch turned ON. —

C37-56 RED Knock sensor

signal 2 – 3 V

(“Reference

waveform No.25: ” and “Reference

waveform No.26: ”) Ignition switch turned ON.

—

Engine running at 4000 r/

min. after warmed up.

C37-57 YEL Ground for sensors Below 0.3 V Ignition switch turned ON. —

C37-58 BLK/

ORN Ground for ECM Below 0.3 V Ignition switch turned ON.

—

C37-59 YEL/

GRN Oil control valve

ground

Below 1.3 V Ignition switch turned ON.

—

C37-60 YEL/

RED Oil control valve

output *0 – 0.6 V

↑↓

10 – 14 V

(“Reference

waveform No.27: ” and “Reference

waveform No.28: ”) At the moment of ignition

switch turned ON.

Output signal is active

high pulse. Duty ratio

varies depending on

vehicle condition.

Terminal

No. Wire

color Circuit Normal voltage

ConditionRemarks

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

E23-1 BLK/

RED Main power supply 10 – 14 V Ignition switch turned ON. —

E23-2 WHT/

RED Power source for

ECM internal

memory

10 – 14 V Ignition switch turned ON. —

E23-3 RED CAN (high)

communication line

(active high signal)

for ABS control

module, BCM,

combination meter *2.5 – 4.5 V

(“Reference

waveform No.29: ”) Ignition switch turned ON

with engine at stop. CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency with

varies depending on

engine condition.

Page 232 of 1496

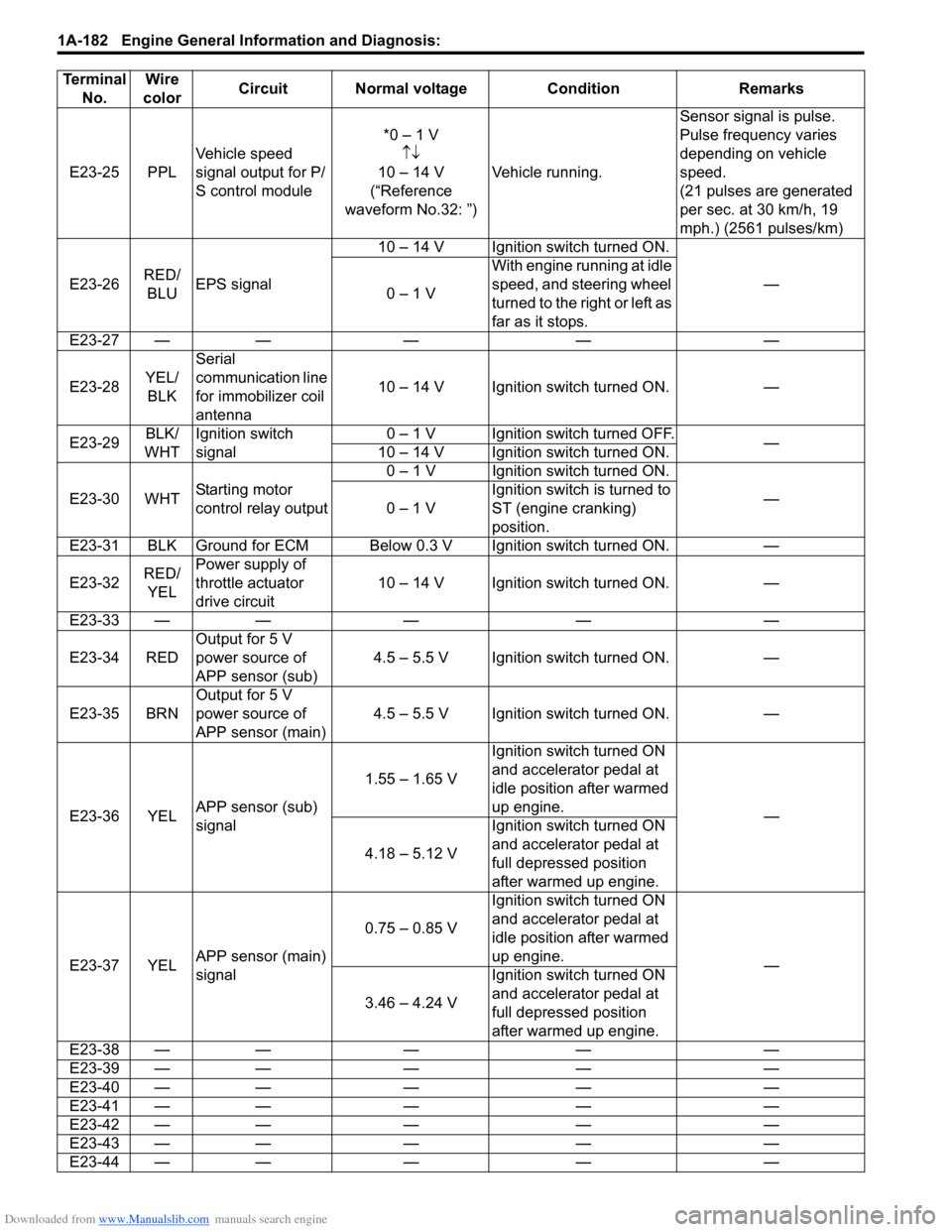

Downloaded from www.Manualslib.com manuals search engine 1A-182 Engine General Information and Diagnosis:

E23-25 PPLVehicle speed

signal output for P/

S control module *0 – 1 V

↑↓

10 – 14 V

(“Reference

waveform No.32: ”) Vehicle running. Sensor signal is pulse.

Pulse frequency varies

depending on vehicle

speed.

(21 pulses are generated

per sec. at 30 km/h, 19

mph.) (2561 pulses/km)

E23-26 RED/

BLU EPS signal 10 – 14 V Ignition switch turned ON.

—

0 – 1 V With engine running at idle

speed, and steering wheel

turned to the right or left as

far as it stops.

E23-27 — — — — —

E23-28 YEL/

BLK Serial

communication line

for immobilizer coil

antenna

10 – 14 V Ignition switch turned ON. —

E23-29 BLK/

WHT Ignition switch

signal 0 – 1 V Ignition switch turned OFF.

—

10 – 14 V Ignition switch turned ON.

E23-30 WHT Starting motor

control relay output 0 – 1 V Ignition switch turned ON.

—

0 – 1 V Ignition switch is turned to

ST (engine cranking)

position.

E23-31 BLK Ground for ECM Below 0.3 V Ignition switch turned ON. —

E23-32 RED/

YEL Power supply of

throttle actuator

drive circuit

10 – 14 V Ignition switch turned ON. —

E23-33 — — — — —

E23-34 RED Output for 5 V

power source of

APP sensor (sub) 4.5 – 5.5 V Ignition switch turned ON. —

E23-35 BRN Output for 5 V

power source of

APP sensor (main) 4.5 – 5.5 V Ignition switch turned ON. —

E23-36 YEL APP sensor (sub)

signal 1.55 – 1.65 V

Ignition switch turned ON

and accelerator pedal at

idle position after warmed

up engine.

—

4.18 – 5.12 V Ignition switch turned ON

and accelerator pedal at

full depressed position

after warmed up engine.

E23-37 YEL APP sensor (main)

signal 0.75 – 0.85 V

Ignition switch turned ON

and accelerator pedal at

idle position after warmed

up engine.

—

3.46 – 4.24 V Ignition switch turned ON

and accelerator pedal at

full depressed position

after warmed up engine.

E23-38 — — — — —

E23-39 — — — — —

E23-40 — — — — —

E23-41 — — — — —

E23-42 — — — — —

E23-43 — — — — —

E23-44 — — — — —

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

Page 237 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-187

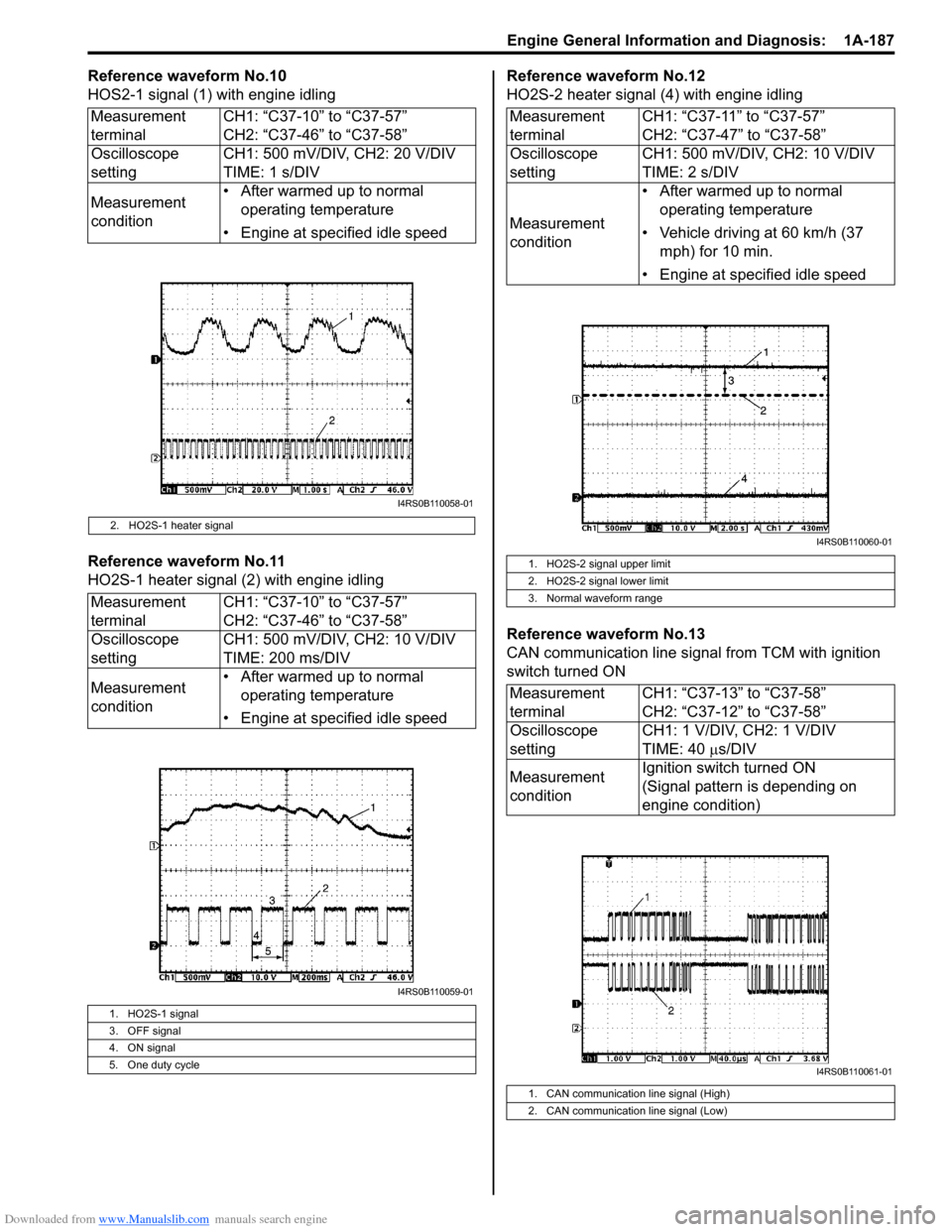

Reference waveform No.10

HOS2-1 signal (1) with engine idling

Reference waveform No.11

HO2S-1 heater signal (2) with engine idlingReference waveform No.12

HO2S-2 heater signal (4) with engine idling

Reference waveform No.13

CAN communication line signal from TCM with ignition

switch turned ON

Measurement

terminal

CH1: “C37-10” to “C37-57”

CH2: “C37-46” to “C37-58”

Oscilloscope

setting CH1: 500 mV/DIV, CH2: 20 V/DIV

TIME: 1 s/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

2. HO2S-1 heater signal

Measurement

terminal CH1: “C37-10” to “C37-57”

CH2: “C37-46” to “C37-58”

Oscilloscope

setting CH1: 500 mV/DIV, CH2: 10 V/DIV

TIME: 200 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

1. HO2S-1 signal

3. OFF signal

4. ON signal

5. One duty cycle

I4RS0B110058-01

I4RS0B110059-01

Measurement

terminal CH1: “C37-11” to “C37-57”

CH2: “C37-47” to “C37-58”

Oscilloscope

setting CH1: 500 mV/DIV, CH2: 10 V/DIV

TIME: 2 s/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Vehicle driving at 60 km/h (37 mph) for 10 min.

• Engine at specified idle speed

1. HO2S-2 signal upper limit

2. HO2S-2 signal lower limit

3. Normal waveform range

Measurement

terminal CH1: “C37-13” to “C37-58”

CH2: “C37-12” to “C37-58”

Oscilloscope

setting CH1: 1 V/DIV, CH2: 1 V/DIV

TIME: 40

µs/DIV

Measurement

condition Ignition switch turned ON

(Signal pattern is depending on

engine condition)

1. CAN communication line signal (High)

2. CAN communication line signal (Low)

I4RS0B110060-01

I4RS0B110061-01

Page 242 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-192 Engine General Information and Diagnosis:

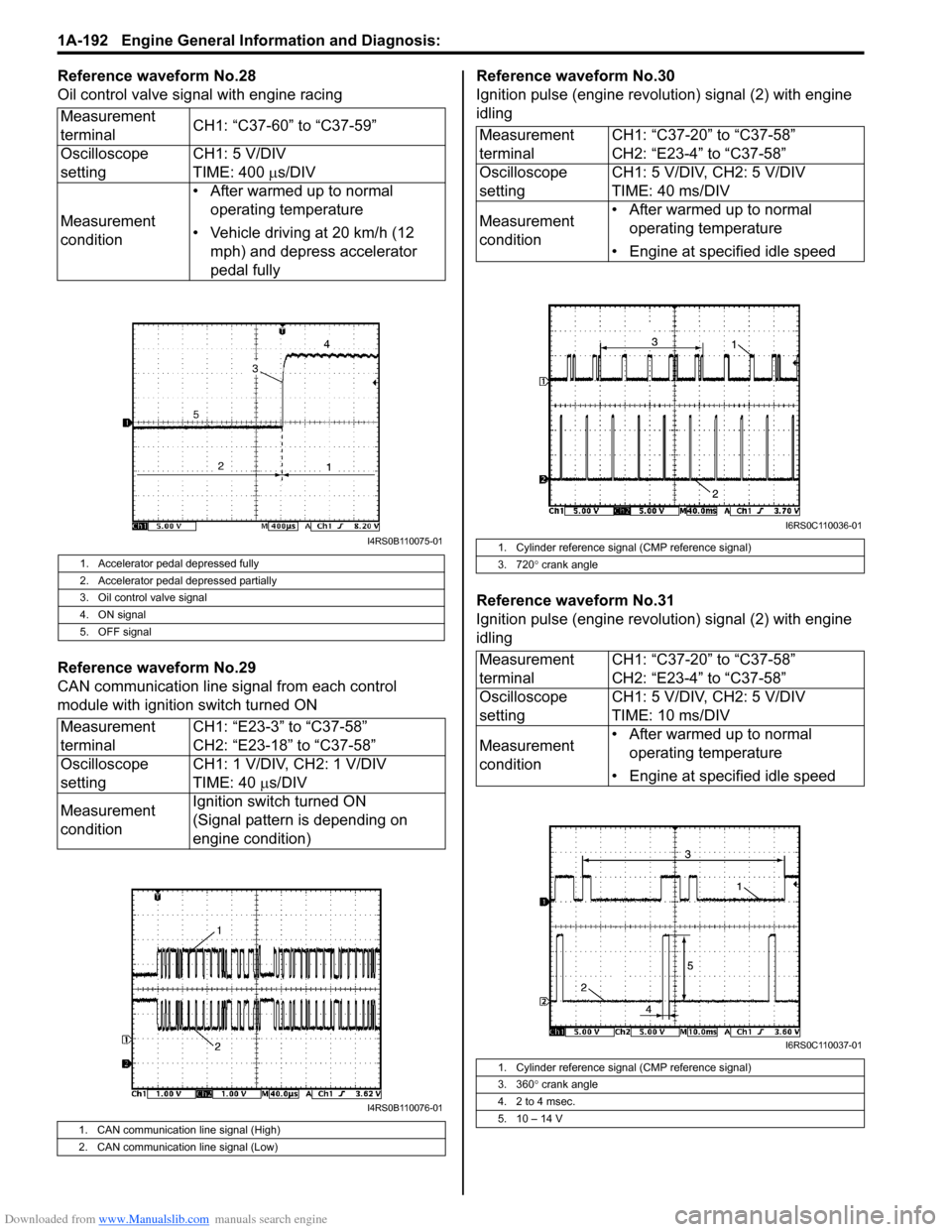

Reference waveform No.28

Oil control valve signal with engine racing

Reference waveform No.29

CAN communication line signal from each control

module with ignition switch turned ONReference waveform No.30

Ignition pulse (engine revolution) signal (2) with engine

idling

Reference waveform No.31

Ignition pulse (engine revolution) signal (2) with engine

idling

Measurement

terminal

CH1: “C37-60” to “C37-59”

Oscilloscope

setting CH1: 5 V/DIV

TIME: 400

µs/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Vehicle driving at 20 km/h (12 mph) and depress accelerator

pedal fully

1. Accelerator pedal depressed fully

2. Accelerator pedal depressed partially

3. Oil control valve signal

4. ON signal

5. OFF signal

Measurement

terminal CH1: “E23-3” to “C37-58”

CH2: “E23-18” to “C37-58”

Oscilloscope

setting CH1: 1 V/DIV, CH2: 1 V/DIV

TIME: 40

µs/DIV

Measurement

condition Ignition switch turned ON

(Signal pattern is depending on

engine condition)

1. CAN communication line signal (High)

2. CAN communication line signal (Low)

I4RS0B110075-01

I4RS0B110076-01

Measurement

terminal

CH1: “C37-20” to “C37-58”

CH2: “E23-4” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 40 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

1. Cylinder reference signal (CMP reference signal)

3. 720 ° crank angle

Measurement

terminal CH1: “C37-20” to “C37-58”

CH2: “E23-4” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 10 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

1. Cylinder reference signal (CMP reference signal)

3. 360 ° crank angle

4. 2 to 4 msec.

5. 10 – 14 V

I6RS0C110036-01

I6RS0C110037-01

Page 262 of 1496

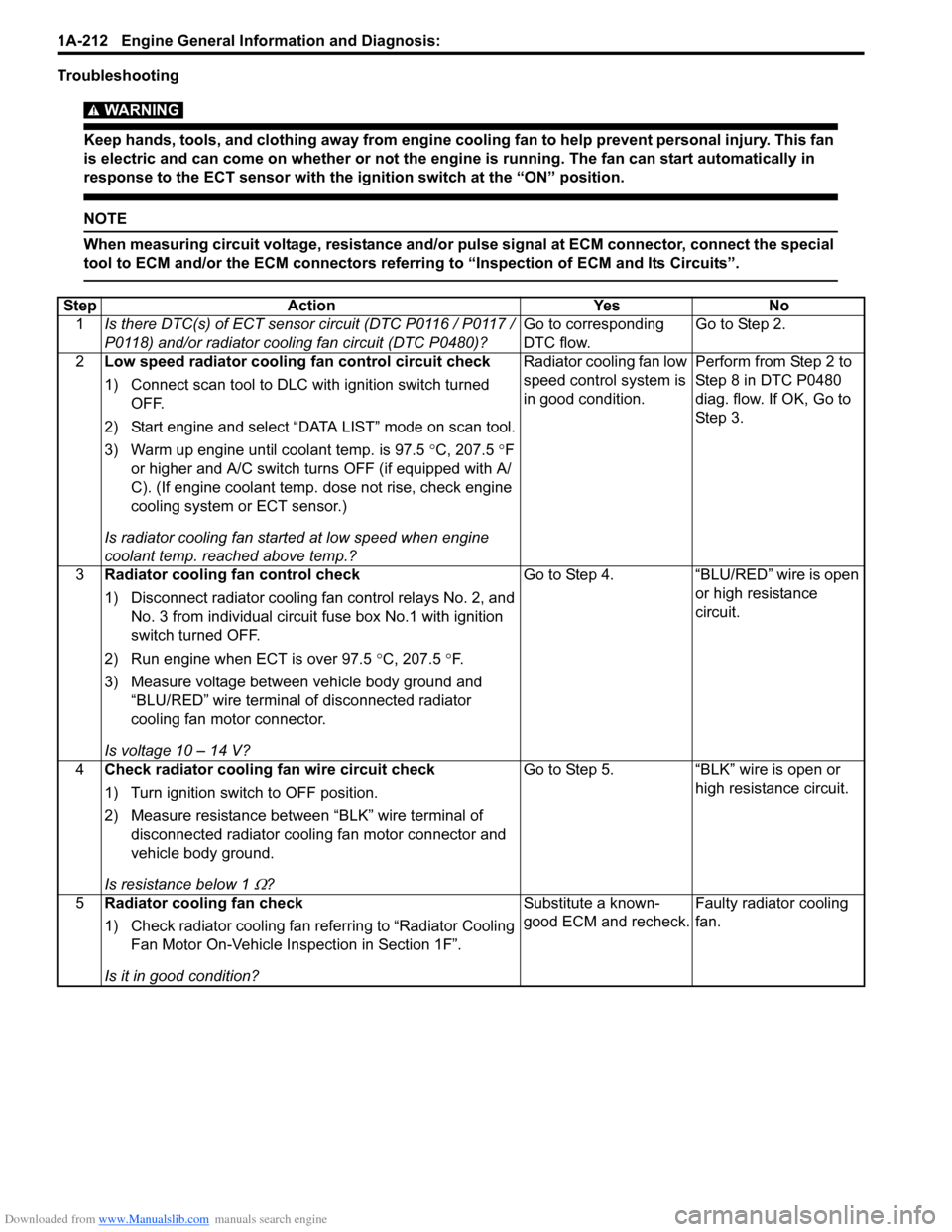

Downloaded from www.Manualslib.com manuals search engine 1A-212 Engine General Information and Diagnosis:

Troubleshooting

WARNING!

Keep hands, tools, and clothing away from engine cooling fan to help prevent personal injury. This fan

is electric and can come on whether or not the engi ne is running. The fan can start automatically in

response to the ECT sensor with the ig nition switch at the “ON” position.

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

StepAction YesNo

1 Is there DTC(s) of ECT sensor circuit (DTC P0116 / P0117 /

P0118) and/or radiator cooling fan circuit (DTC P0480)? Go to corresponding

DTC flow.Go to Step 2.

2 Low speed radiator cooling fan control circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Warm up engine until coolant temp. is 97.5 °C, 207.5 °F

or higher and A/C switch turns OFF (if equipped with A/

C). (If engine coolant temp. dose not rise, check engine

cooling system or ECT sensor.)

Is radiator cooling fan started at low speed when engine

coolant temp. reached above temp.? Radiator cooling fan low

speed control system is

in good condition.

Perform from Step 2 to

Step 8 in DTC P0480

diag. flow. If OK, Go to

Ste p 3.

3 Radiator cooling fan control check

1) Disconnect radiator cooling fan control relays No. 2, and

No. 3 from individual circuit fuse box No.1 with ignition

switch turned OFF.

2) Run engine when ECT is over 97.5 °C, 207.5 °F.

3) Measure voltage between vehicle body ground and “BLU/RED” wire terminal of disconnected radiator

cooling fan motor connector.

Is voltage 10 – 14 V? Go to Step 4.

“BLU/RED” wire is open

or high resistance

circuit.

4 Check radiator cooling fan wire circuit check

1) Turn ignition switch to OFF position.

2) Measure resistance between “BLK” wire terminal of

disconnected radiator coolin g fan motor connector and

vehicle body ground.

Is resistance below 1

Ω? Go to Step 5. “BLK” wire is open or

high resistance circuit.

5 Radiator cooling fan check

1) Check radiator cooling fan referring to “Radiator Cooling

Fan Motor On-Vehicle Inspection in Section 1F”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Faulty radiator cooling

fan.

Page 264 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-214 Engine General Information and Diagnosis:

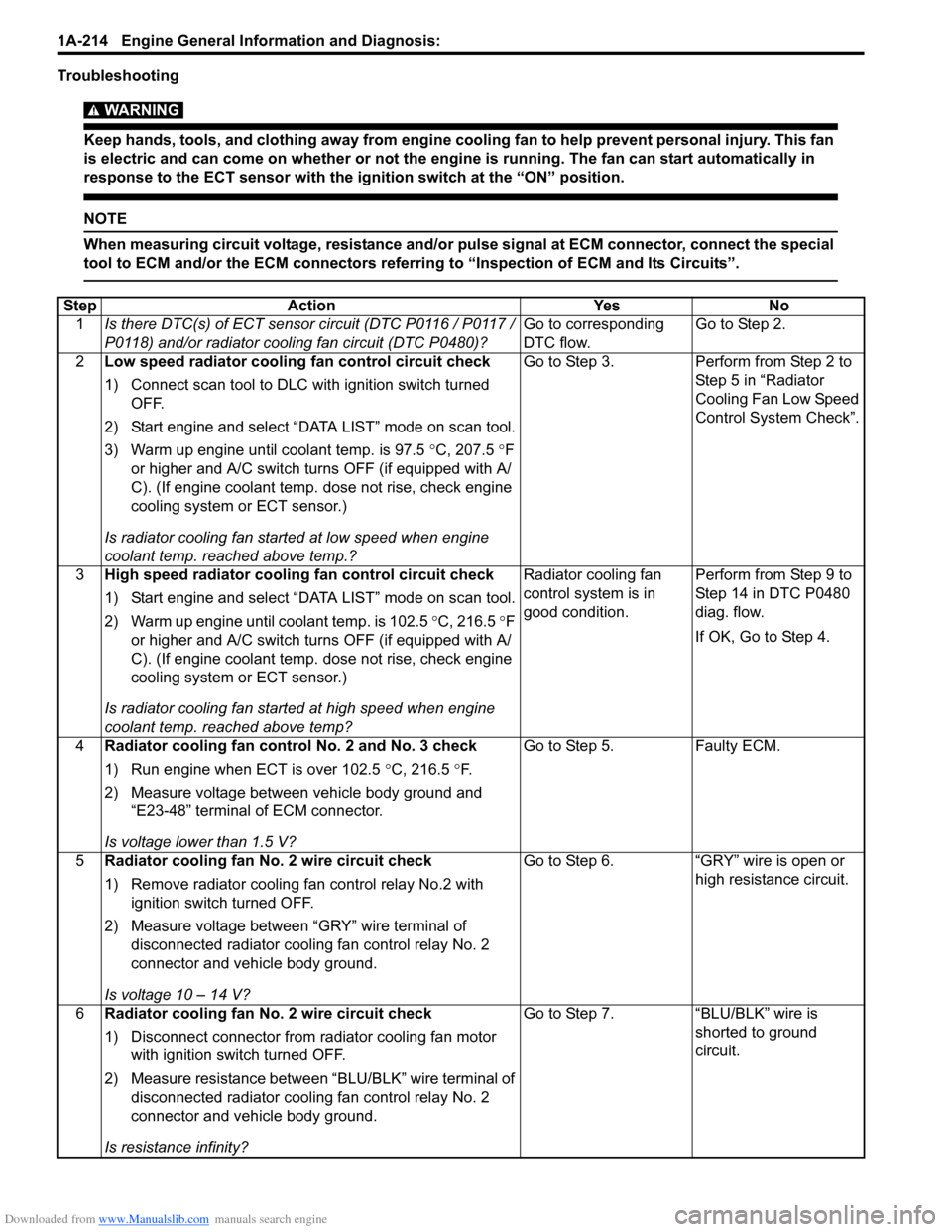

Troubleshooting

WARNING!

Keep hands, tools, and clothing away from engine cooling fan to help prevent personal injury. This fan

is electric and can come on whether or not the engi ne is running. The fan can start automatically in

response to the ECT sensor with the ig nition switch at the “ON” position.

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

StepAction YesNo

1 Is there DTC(s) of ECT sensor circuit (DTC P0116 / P0117 /

P0118) and/or radiator cooling fan circuit (DTC P0480)? Go to corresponding

DTC flow.Go to Step 2.

2 Low speed radiator cooling fan control circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Warm up engine until coolant temp. is 97.5 °C, 207.5 °F

or higher and A/C switch turns OFF (if equipped with A/

C). (If engine coolant temp. dose not rise, check engine

cooling system or ECT sensor.)

Is radiator cooling fan started at low speed when engine

coolant temp. reached above temp.? Go to Step 3.

Perform from Step 2 to

Step 5 in “Radiator

Cooling Fan Low Speed

Control System Check”.

3 High speed radiator cooling fan control circuit check

1) Start engine and select “DATA LIST” mode on scan tool.

2) Warm up engine until coolant temp. is 102.5 °C, 216.5 °F

or higher and A/C switch turns OFF (if equipped with A/

C). (If engine coolant temp. dose not rise, check engine

cooling system or ECT sensor.)

Is radiator cooling fan started at high speed when engine

coolant temp. reached above temp? Radiator cooling fan

control system is in

good condition.

Perform from Step 9 to

Step 14 in DTC P0480

diag. flow.

If OK, Go to Step 4.

4 Radiator cooling fan control No. 2 and No. 3 check

1) Run engine when ECT is over 102.5 °C, 216.5 °F.

2) Measure voltage between vehicle body ground and “E23-48” terminal of ECM connector.

Is voltage lower than 1.5 V? Go to Step 5.

Faulty ECM.

5 Radiator cooling fan No. 2 wire circuit check

1) Remove radiator cooling fan control relay No.2 with

ignition switch turned OFF.

2) Measure voltage between “GRY” wire terminal of disconnected radiator cooling fan control relay No. 2

connector and vehicle body ground.

Is voltage 10 – 14 V? Go to Step 6.

“GRY” wire is open or

high resistance circuit.

6 Radiator cooling fan No. 2 wire circuit check

1) Disconnect connector from radiator cooling fan motor

with ignition swit ch turned OFF.

2) Measure resistance between “BLU/BLK” wire terminal of disconnected radiator cooling fan control relay No. 2

connector and vehicle body ground.

Is resistance infinity? Go to Step 7.

“BLU/BLK” wire is

shorted to ground

circuit.

Page 283 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-11

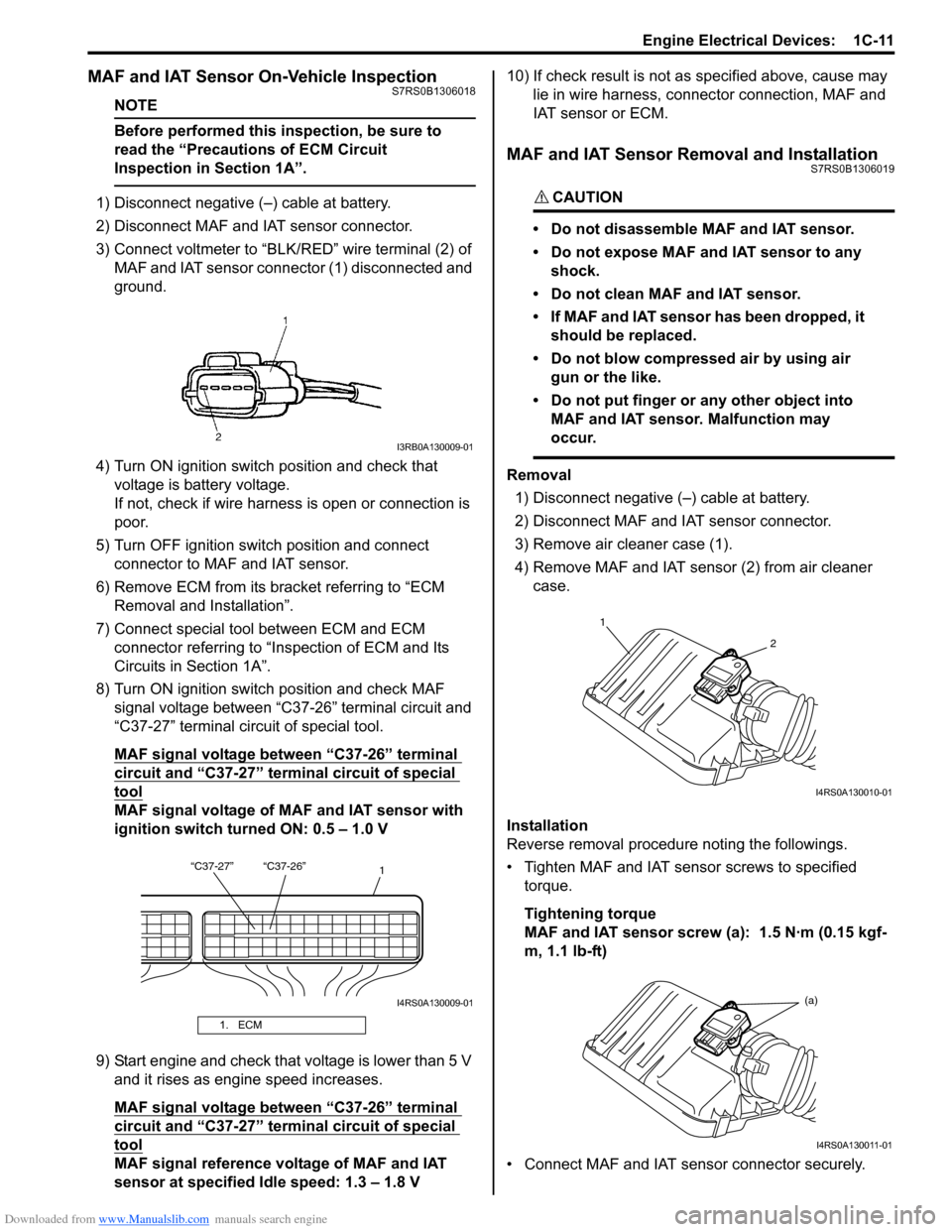

MAF and IAT Sensor On-Vehicle InspectionS7RS0B1306018

NOTE

Before performed this inspection, be sure to

read the “Precautions of ECM Circuit

Inspection in Section 1A”.

1) Disconnect negative (–) cable at battery.

2) Disconnect MAF and IAT sensor connector.

3) Connect voltmeter to “BLK/RED” wire terminal (2) of

MAF and IAT sensor connector (1) disconnected and

ground.

4) Turn ON ignition switch position and check that voltage is battery voltage.

If not, check if wire harness is open or connection is

poor.

5) Turn OFF ignition switch position and connect connector to MAF and IAT sensor.

6) Remove ECM from its bracket referring to “ECM Removal and Installation”.

7) Connect special tool between ECM and ECM connector referring to “Inspection of ECM and Its

Circuits in Section 1A”.

8) Turn ON ignition switch position and check MAF signal voltage between “C37-26” terminal circuit and

“C37-27” terminal circuit of special tool.

MAF signal voltage between “C37-26” terminal

circuit and “C37-27” termi nal circuit of special

tool

MAF signal voltage of MAF and IAT sensor with

ignition switch turned ON: 0.5 – 1.0 V

9) Start engine and check that voltage is lower than 5 V and it rises as engine speed increases.

MAF signal voltage between “C37-26” terminal

circuit and “C37-27” termi nal circuit of special

tool

MAF signal reference voltage of MAF and IAT

sensor at specified Idle speed: 1.3 – 1.8 V 10) If check result is not as

specified above, cause may

lie in wire harness, connec tor connection, MAF and

IAT sensor or ECM.

MAF and IAT Sensor Removal and InstallationS7RS0B1306019

CAUTION!

• Do not disassemble MAF and IAT sensor.

• Do not expose MAF and IAT sensor to any shock.

• Do not clean MAF and IAT sensor.

• If MAF and IAT sensor has been dropped, it should be replaced.

• Do not blow compressed air by using air gun or the like.

• Do not put finger or any other object into MAF and IAT sensor. Malfunction may

occur.

Removal

1) Disconnect negative (–) cable at battery.

2) Disconnect MAF and IAT sensor connector.

3) Remove air cleaner case (1).

4) Remove MAF and IAT sensor (2) from air cleaner case.

Installation

Reverse removal procedure noting the followings.

• Tighten MAF and IAT sensor screws to specified torque.

Tightening torque

MAF and IAT sensor screw (a): 1.5 N·m (0.15 kgf-

m, 1.1 lb-ft)

• Connect MAF and IAT sensor connector securely.

1. ECM

I3RB0A130009-01

“C37-27” “C37-26” 1

I4RS0A130009-01

1

2

I4RS0A130010-01

(a)

I4RS0A130011-01