oil pan SUZUKI SWIFT 2008 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 364 of 1496

Downloaded from www.Manualslib.com manuals search engine 1F-1 Engine Cooling System:

Engine

Engine Cooling System

General Description

Cooling System DescriptionS7RS0B1601001

The cooling system consists of the radiator cap, radiator, coolant reservoir, hoses, water pump, cooling fan and

thermostat. The radiator is of tube-and-fin type.

Coolant DescriptionS7RS0B1601002

WARNING!

• Do not remove radiator cap to check engine coolant level; check coolant visually at the see-through coolant reservoir. Coolant should be added only to reservoir as necessary.

• As long as there is pressure in the cooling system, the temperature can be considerably higher than the boiling temperature of the solution in the radiator without causing the solution to boil. Removal

of the radiator cap while engine is hot and pressure is high will cause the solution to boil

instantaneously and possibly with explosive force, spewing the solution over engine, fenders and

person removing cap. If the solution contains flammable anti-freeze such as alcohol (not

recommended for use at any time), there is also the possibility of causing a serious fire.

• Check to make sure that engine coolant temperature is cold before removing any part of cooling system.

• Also be sure to disconnect negative cable from battery terminal before removing any part.

The coolant recovery system is standard. The coolant in the radiator expands with heat, and the coolant is overflowed

to the reservoir.

When the system cools down, the coolant is drawn back into the radiator.

The cooling system has be en filled with a quality coolant that is a 50/50 mixture of water and ethylene glycol

antifreeze.

This 50/50 mixture coolant solution provides freezing protection to –36 °C (–33 °F).

• Maintain cooling system freeze protection at –36 °C (–33 °F) to ensure protection against corrosion and loss of

coolant from boiling. This should be done even if freezing temperatures are not expected.

• Add ethylene glycol base coolant when coolant has to be added because of coolant loss or to provide added protection against freezing at temperature lower than –36 °C (–33 °F).

NOTE

• Alcohol or methanol base coolant or plain water alone should not be used in cooling system at any

time as damage to cooling system could occur.

• Coolant must be mixed with deminerated water or distilled water.

Anti-freeze proportioning table

For M/T model For A/T model

Freezing temperature °

C –36 –36

° F –33 –33

Anti-freeze / Anti-corrosion coolant concentration % 50 50

Ratio of compound to cooling water ltr. 3.10/3.10 3.05/3.05

US pt. 6.55/6.55 6.44/6.44

Imp pt. 5.46/5.46 5.37/5.37

Page 425 of 1496

Downloaded from www.Manualslib.com manuals search engine Exhaust System: 1K-2

Repair Instructions

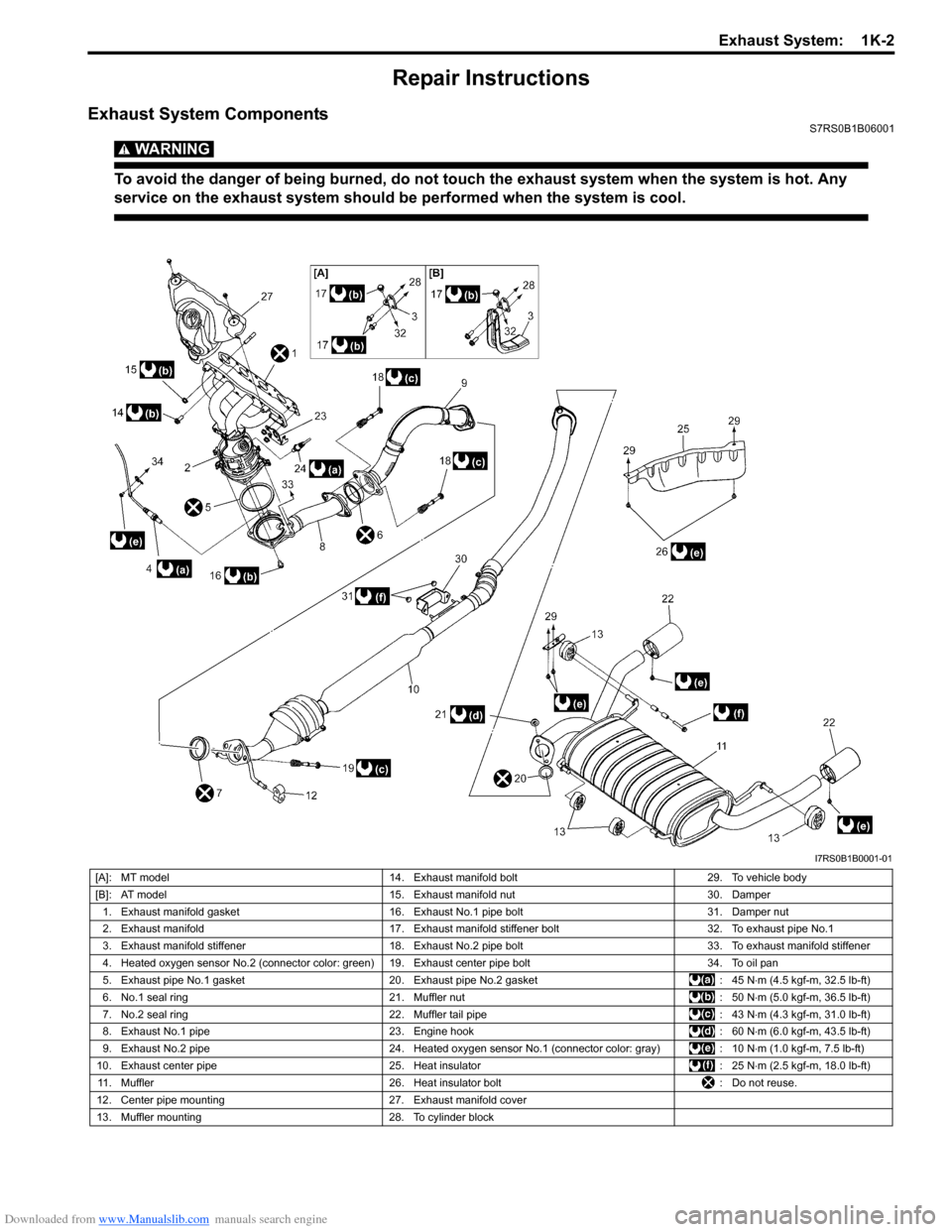

Exhaust System ComponentsS7RS0B1B06001

WARNING!

To avoid the danger of being burned, do not touch the exhaust system when the system is hot. Any

service on the exhaust system should be performed when the system is cool.

I7RS0B1B0001-01

[A]: MT model14. Exhaust manifold bolt 29. To vehicle body

[B]: AT model 15. Exhaust manifold nut 30. Damper

1. Exhaust manifold gasket 16. Exhaust No.1 pipe bolt 31. Damper nut

2. Exhaust manifold 17. Exhaust manifold stiffener bolt 32. To exhaust pipe No.1

3. Exhaust manifold stiffener 18. Exhaust No.2 pipe bolt 33. To exhaust manifold stiffener

4. Heated oxygen sensor No.2 (connector color: green) 19. Exhaust center pipe bolt 34. To oil pan

5. Exhaust pipe No.1 gasket 20. Exhaust pipe No.2 gasket : 45 N⋅m (4.5 kgf-m, 32.5 lb-ft)

6. No.1 seal ring 21. Muffler nut : 50 N⋅m (5.0 kgf-m, 36.5 lb-ft)

7. No.2 seal ring 22. Muffler tail pipe : 43 N⋅m (4.3 kgf-m, 31.0 lb-ft)

8. Exhaust No.1 pipe 23. Engine hook : 60 N⋅m (6.0 kgf-m, 43.5 lb-ft)

9. Exhaust No.2 pipe 24. Heated oxygen sensor No.1 (connector color: gray) : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

10. Exhaust center pipe 25. Heat insulator : 25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

11. Muffler 26. Heat insulator bolt : Do not reuse.

12. Center pipe mounting 27. Exhaust manifold cover

13. Muffler mounting 28. To cylinder block

Page 458 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-4 Rear Suspension:

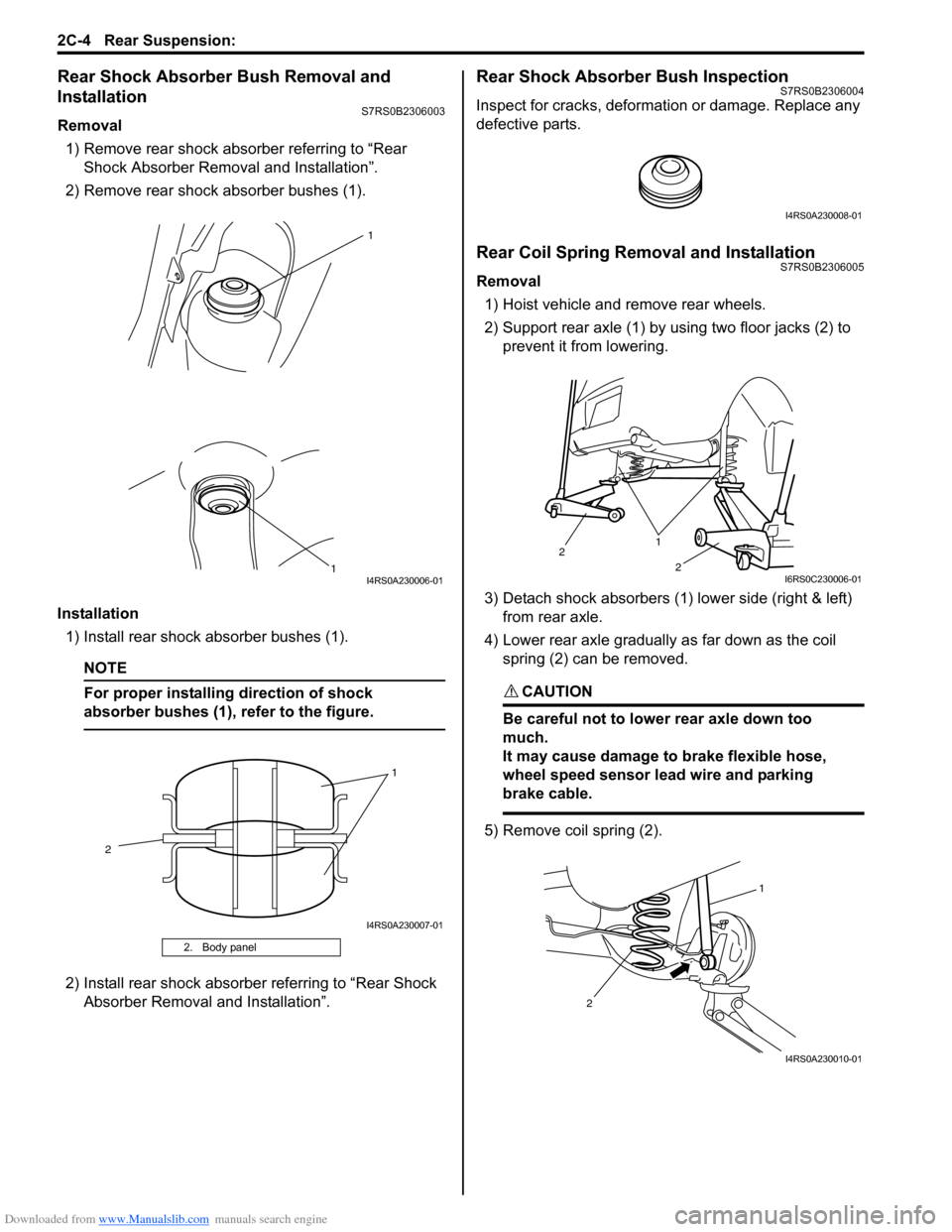

Rear Shock Absorber Bush Removal and

Installation

S7RS0B2306003

Removal1) Remove rear shock absorber referring to “Rear Shock Absorber Remova l and Installation”.

2) Remove rear shock absorber bushes (1).

Installation 1) Install rear shock absorber bushes (1).

NOTE

For proper installing direction of shock

absorber bushes (1), refer to the figure.

2) Install rear shock absorber referring to “Rear Shock Absorber Removal and Installation”.

Rear Shock Absorber Bush InspectionS7RS0B2306004

Inspect for cracks, deformation or damage. Replace any

defective parts.

Rear Coil Spring Removal and InstallationS7RS0B2306005

Removal

1) Hoist vehicle and remove rear wheels.

2) Support rear axle (1) by using two floor jacks (2) to prevent it from lowering.

3) Detach shock absorbers (1) lower side (right & left) from rear axle.

4) Lower rear axle gradually as far down as the coil spring (2) can be removed.

CAUTION!

Be careful not to lowe r rear axle down too

much.

It may cause damage to brake flexible hose,

wheel speed sensor lead wire and parking

brake cable.

5) Remove coil spring (2).

2. Body panel

1

1

I4RS0A230006-01

1

2

I4RS0A230007-01

I4RS0A230008-01

1

2

2

I6RS0C230006-01

1

2

I4RS0A230010-01

Page 500 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-2 Brake Control System and Diagnosis:

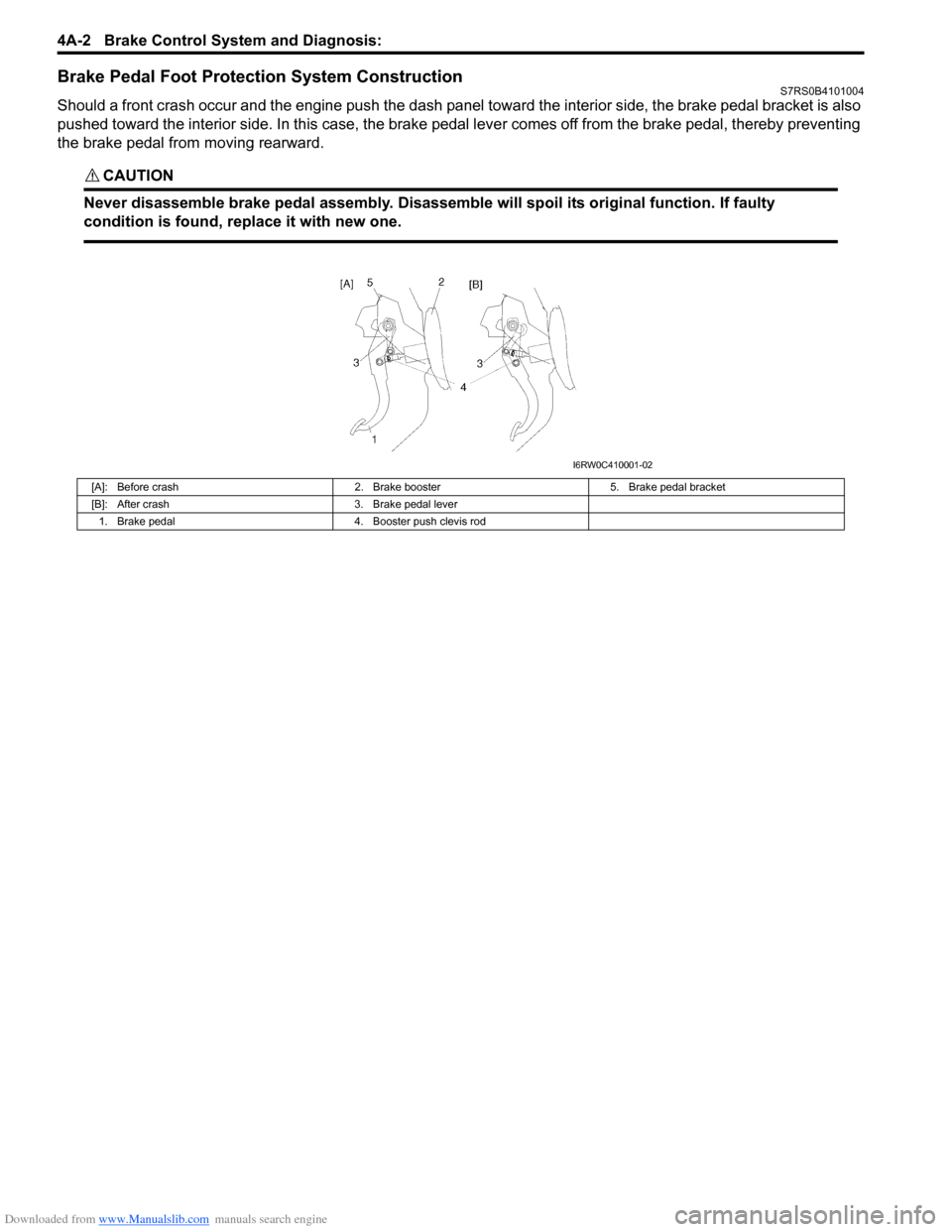

Brake Pedal Foot Protection System ConstructionS7RS0B4101004

Should a front crash occur and the engine push the dash panel toward the interior side, the brake pedal bracket is also

pushed toward the interior side. In this case, the brake pedal lever comes off from the brake pedal, thereby preventing

the brake pedal from moving rearward.

CAUTION!

Never disassemble brake pedal assembly. Disassemble will spoil its original function. If faulty

condition is found, replace it with new one.

[A]: Before crash2. Brake booster5. Brake pedal bracket

[B]: After crash 3. Brake pedal lever

1. Brake pedal 4. Booster push clevis rod

I6RW0C410001-02

Page 506 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-8 Brake Control System and Diagnosis:

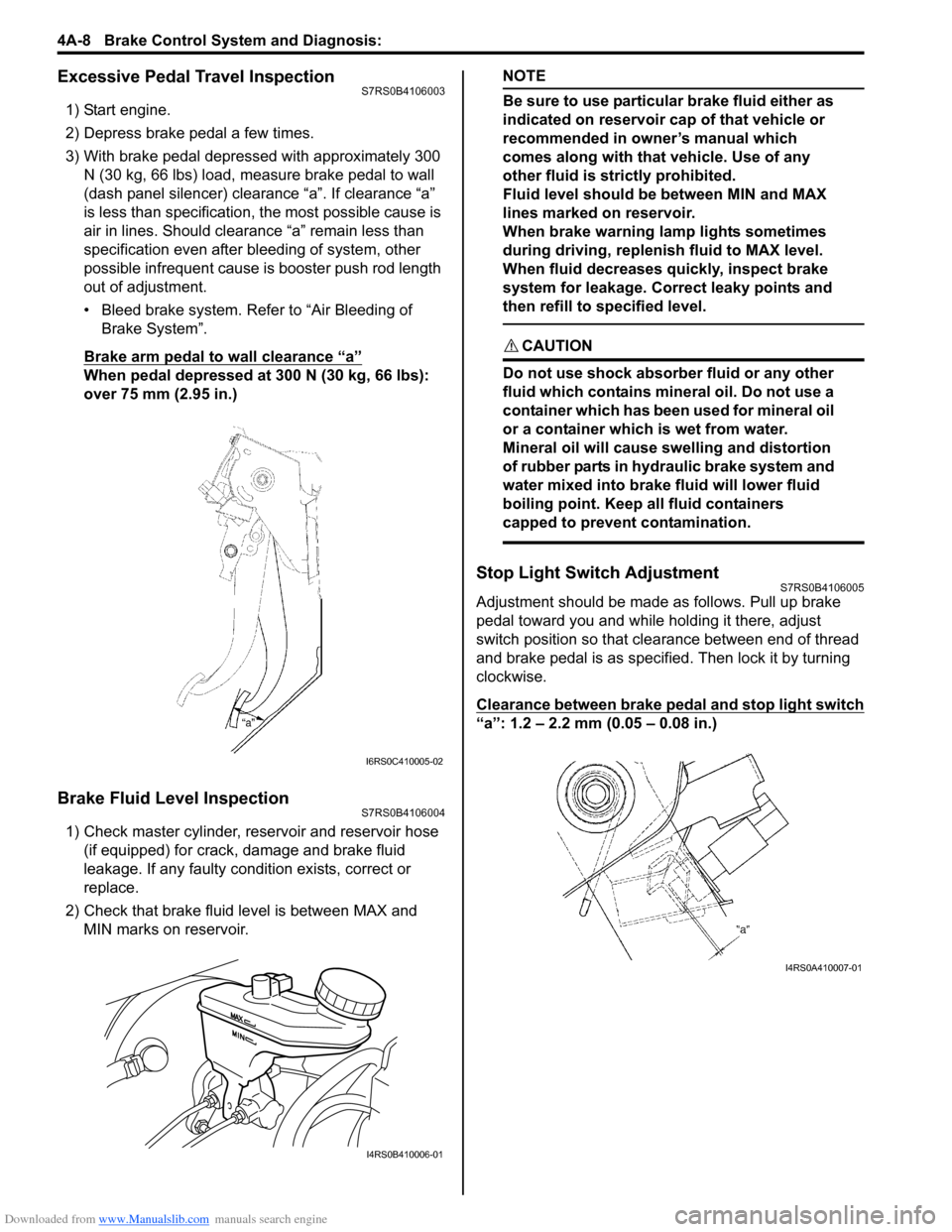

Excessive Pedal Travel InspectionS7RS0B4106003

1) Start engine.

2) Depress brake pedal a few times.

3) With brake pedal depressed with approximately 300 N (30 kg, 66 lbs) load, measure brake pedal to wall

(dash panel silencer) clearance “a”. If clearance “a”

is less than specification, the most possible cause is

air in lines. Should clearance “a” remain less than

specification even after bleeding of system, other

possible infrequent cause is booster push rod length

out of adjustment.

• Bleed brake system. Refer to “Air Bleeding of Brake System”.

Brake arm pedal to wall clearance “a”

When pedal depressed at 300 N (30 kg, 66 lbs):

over 75 mm (2.95 in.)

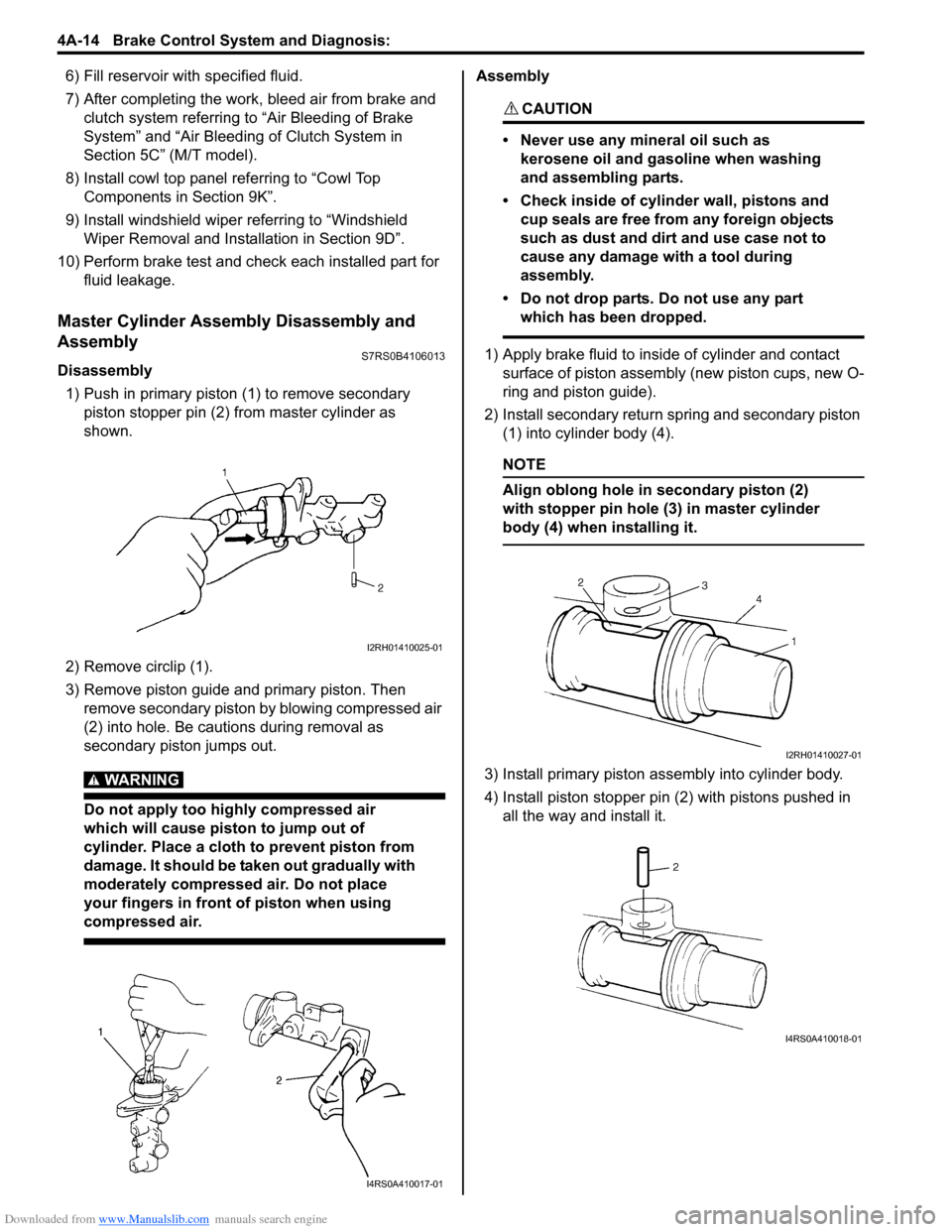

Brake Fluid Level InspectionS7RS0B4106004

1) Check master cylinder, reservoir and reservoir hose (if equipped) for crack, damage and brake fluid

leakage. If any faulty condition exists, correct or

replace.

2) Check that brake fluid level is between MAX and MIN marks on reservoir.

NOTE

Be sure to use particular brake fluid either as

indicated on reservoir cap of that vehicle or

recommended in owner’s manual which

comes along with that vehicle. Use of any

other fluid is strictly prohibited.

Fluid level should be between MIN and MAX

lines marked on reservoir.

When brake warning lamp lights sometimes

during driving, replenis h fluid to MAX level.

When fluid decreases quickly, inspect brake

system for leakage. Correct leaky points and

then refill to specified level.

CAUTION!

Do not use shock absorber fluid or any other

fluid which contains mineral oil. Do not use a

container which has been used for mineral oil

or a container which is wet from water.

Mineral oil will cause swelling and distortion

of rubber parts in hydraulic brake system and

water mixed into brake fluid will lower fluid

boiling point. Keep all fluid containers

capped to prevent contamination.

Stop Light Switch AdjustmentS7RS0B4106005

Adjustment should be made as follows. Pull up brake

pedal toward you and while holding it there, adjust

switch position so that clea rance between end of thread

and brake pedal is as specified. Then lock it by turning

clockwise.

Clearance between brake pedal and stop light switch

“a”: 1.2 – 2.2 mm (0.05 – 0.08 in.)

I6RS0C410005-02

I4RS0B410006-01

I4RS0A410007-01

Page 512 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-14 Brake Control System and Diagnosis:

6) Fill reservoir with specified fluid.

7) After completing the work, bleed air from brake and clutch system referring to “Air Bleeding of Brake

System” and “Air Bleeding of Clutch System in

Section 5C” (M/T model).

8) Install cowl top panel referring to “Cowl Top Components in Section 9K”.

9) Install windshield wiper referring to “Windshield

Wiper Removal and Insta llation in Section 9D”.

10) Perform brake test and check each installed part for fluid leakage.

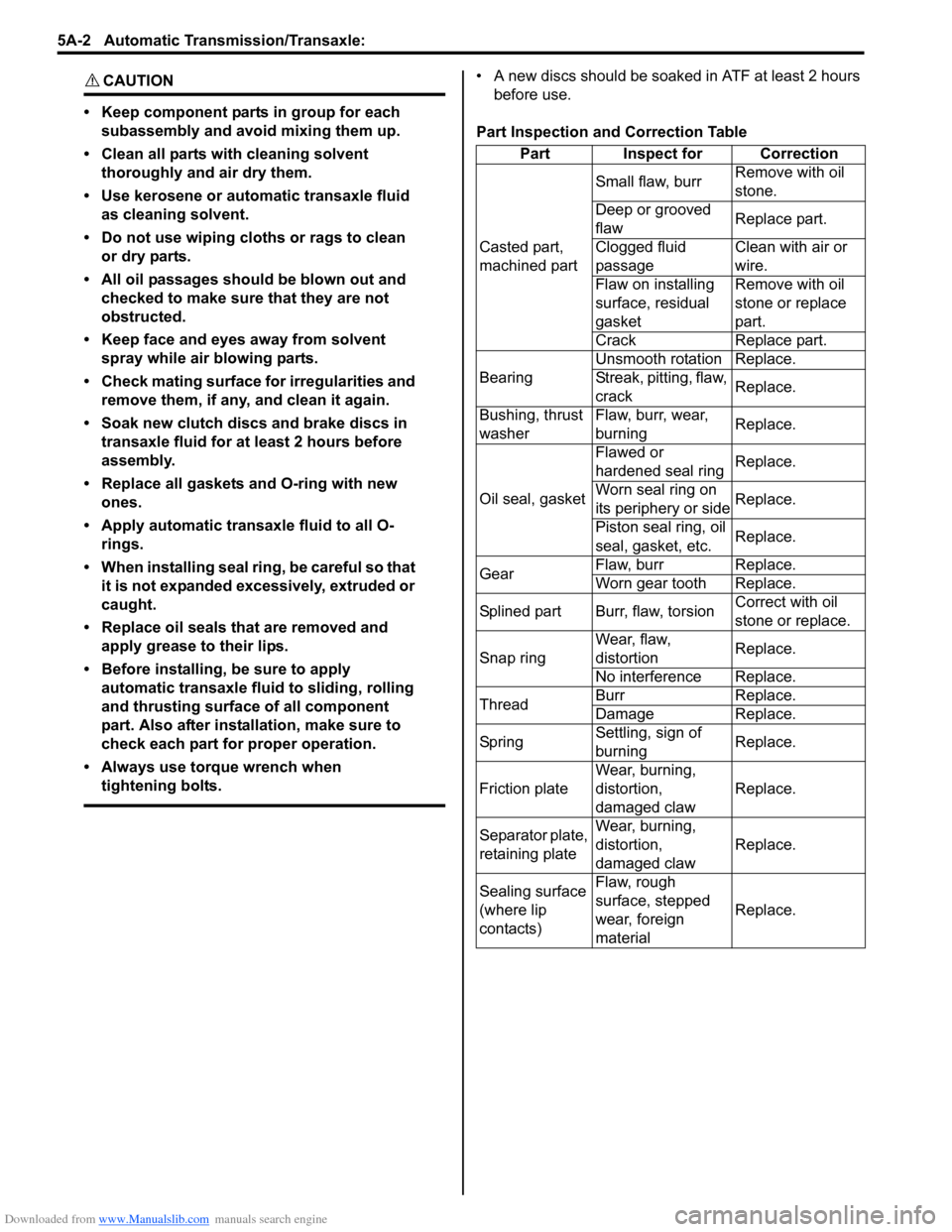

Master Cylinder Assembly Disassembly and

Assembly

S7RS0B4106013

Disassembly

1) Push in primary piston (1) to remove secondary

piston stopper pin (2) from master cylinder as

shown.

2) Remove circlip (1).

3) Remove piston guide and primary piston. Then remove secondary piston by blowing compressed air

(2) into hole. Be cautions during removal as

secondary piston jumps out.

WARNING!

Do not apply too highly compressed air

which will cause piston to jump out of

cylinder. Place a cloth to prevent piston from

damage. It should be taken out gradually with

moderately compressed air. Do not place

your fingers in front of piston when using

compressed air.

Assembly

CAUTION!

• Never use any mineral oil such as kerosene oil and gasoline when washing

and assembling parts.

• Check inside of cylinder wall, pistons and cup seals are free from any foreign objects

such as dust and dirt and use case not to

cause any damage with a tool during

assembly.

• Do not drop parts. Do not use any part which has been dropped.

1) Apply brake fluid to inside of cylinder and contact surface of piston assembly (new piston cups, new O-

ring and piston guide).

2) Install secondary return spring and secondary piston (1) into cylinder body (4).

NOTE

Align oblong hole in secondary piston (2)

with stopper pin hole (3) in master cylinder

body (4) when installing it.

3) Install primary piston assembly into cylinder body.

4) Install piston stopper pin (2) with pistons pushed in all the way and install it.

I2RH01410025-01

I4RS0A410017-01

I2RH01410027-01

I4RS0A410018-01

Page 646 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-2 Automatic Transmission/Transaxle:

CAUTION!

• Keep component parts in group for each subassembly and avoid mixing them up.

• Clean all parts with cleaning solvent thoroughly and air dry them.

• Use kerosene or automatic transaxle fluid as cleaning solvent.

• Do not use wiping cloths or rags to clean or dry parts.

• All oil passages should be blown out and checked to make sure that they are not

obstructed.

• Keep face and eyes away from solvent spray while air blowing parts.

• Check mating surface for irregularities and remove them, if any, and clean it again.

• Soak new clutch discs and brake discs in transaxle fluid for at least 2 hours before

assembly.

• Replace all gaskets and O-ring with new ones.

• Apply automatic transaxle fluid to all O- rings.

• When installing seal ring, be careful so that it is not expanded excessively, extruded or

caught.

• Replace oil seals that are removed and apply grease to their lips.

• Before installing, be sure to apply automatic transaxle fluid to sliding, rolling

and thrusting surface of all component

part. Also after installation, make sure to

check each part for proper operation.

• Always use torque wrench when tightening bolts.

• A new discs should be soaked in ATF at least 2 hours before use.

Part Inspection and Correction Table Part Inspect for Correction

Casted part,

machined part Small flaw, burr

Remove with oil

stone.

Deep or grooved

flaw Replace part.

Clogged fluid

passage Clean with air or

wire.

Flaw on installing

surface, residual

gasket Remove with oil

stone or replace

part.

Crack Replace part.

Bearing Unsmooth rotation Replace.

Streak, pitting, flaw,

crack

Replace.

Bushing, thrust

washer Flaw, burr, wear,

burning

Replace.

Oil seal, gasket Flawed or

hardened seal ring

Replace.

Worn seal ring on

its periphery or side Replace.

Piston seal ring, oil

seal, gasket, etc. Replace.

Gear Flaw, burr Replace.

Worn gear tooth Replace.

Splined part Burr, flaw, torsion Correct with oil

stone or replace.

Snap ring Wear, flaw,

distortion

Replace.

No interference Replace.

Thread Burr Replace.

Damage Replace.

Sp rin g Settling, sign of

burning Replace.

Friction plate Wear, burning,

distortion,

damaged claw Replace.

Separator plate,

retaining plate Wear, burning,

distortion,

damaged claw

Replace.

Sealing surface

(where lip

contacts) Flaw, rough

surface, stepped

wear, foreign

material

Replace.

Page 741 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-97

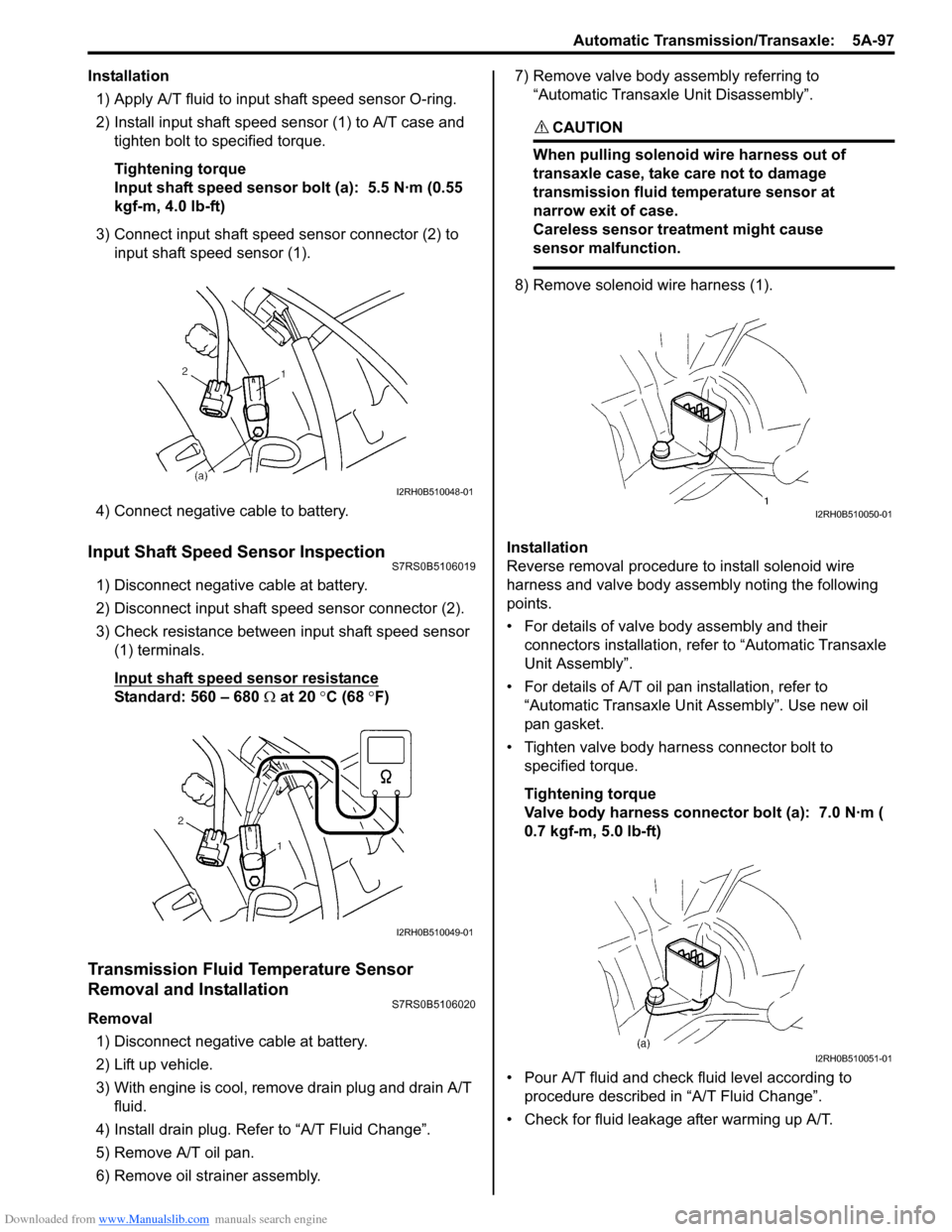

Installation1) Apply A/T fluid to input shaft speed sensor O-ring.

2) Install input shaft speed se nsor (1) to A/T case and

tighten bolt to specified torque.

Tightening torque

Input shaft speed sensor bolt (a): 5.5 N·m (0.55

kgf-m, 4.0 lb-ft)

3) Connect input shaft speed sensor connector (2) to input shaft speed sensor (1).

4) Connect negative cable to battery.

Input Shaft Speed Sensor InspectionS7RS0B5106019

1) Disconnect negative cable at battery.

2) Disconnect input shaft speed sensor connector (2).

3) Check resistance between input shaft speed sensor (1) terminals.

Input shaft speed sensor resistance

Standard: 560 – 680 Ω at 20 °C (68 °F)

Transmission Fluid Temperature Sensor

Removal and Installation

S7RS0B5106020

Removal

1) Disconnect negative cable at battery.

2) Lift up vehicle.

3) With engine is cool, remove drain plug and drain A/T fluid.

4) Install drain plug. Refer to “A/T Fluid Change”.

5) Remove A/T oil pan.

6) Remove oil stra iner assembly. 7) Remove valve body assembly referring to

“Automatic Transaxl e Unit Disassembly”.

CAUTION!

When pulling solenoid wire harness out of

transaxle case, take care not to damage

transmission fluid temperature sensor at

narrow exit of case.

Careless sensor treatment might cause

sensor malfunction.

8) Remove solenoid wire harness (1).

Installation

Reverse removal procedure to install solenoid wire

harness and valve body assembly noting the following

points.

• For details of valve body assembly and their connectors installation, refer to “Automatic Transaxle

Unit Assembly”.

• For details of A/T oil pa n installation, refer to

“Automatic Transaxle Unit Assembly”. Use new oil

pan gasket.

• Tighten valve body harness connector bolt to specified torque.

Tightening torque

Valve body harness connector bolt (a): 7.0 N·m (

0.7 kgf-m, 5.0 lb-ft)

• Pour A/T fluid and check fluid level according to procedure described in “A/T Fluid Change”.

• Check for fluid leakage after warming up A/T.

I2RH0B510048-01

I2RH0B510049-01

I2RH0B510050-01

I2RH0B510051-01

Page 742 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-98 Automatic Transmission/Transaxle:

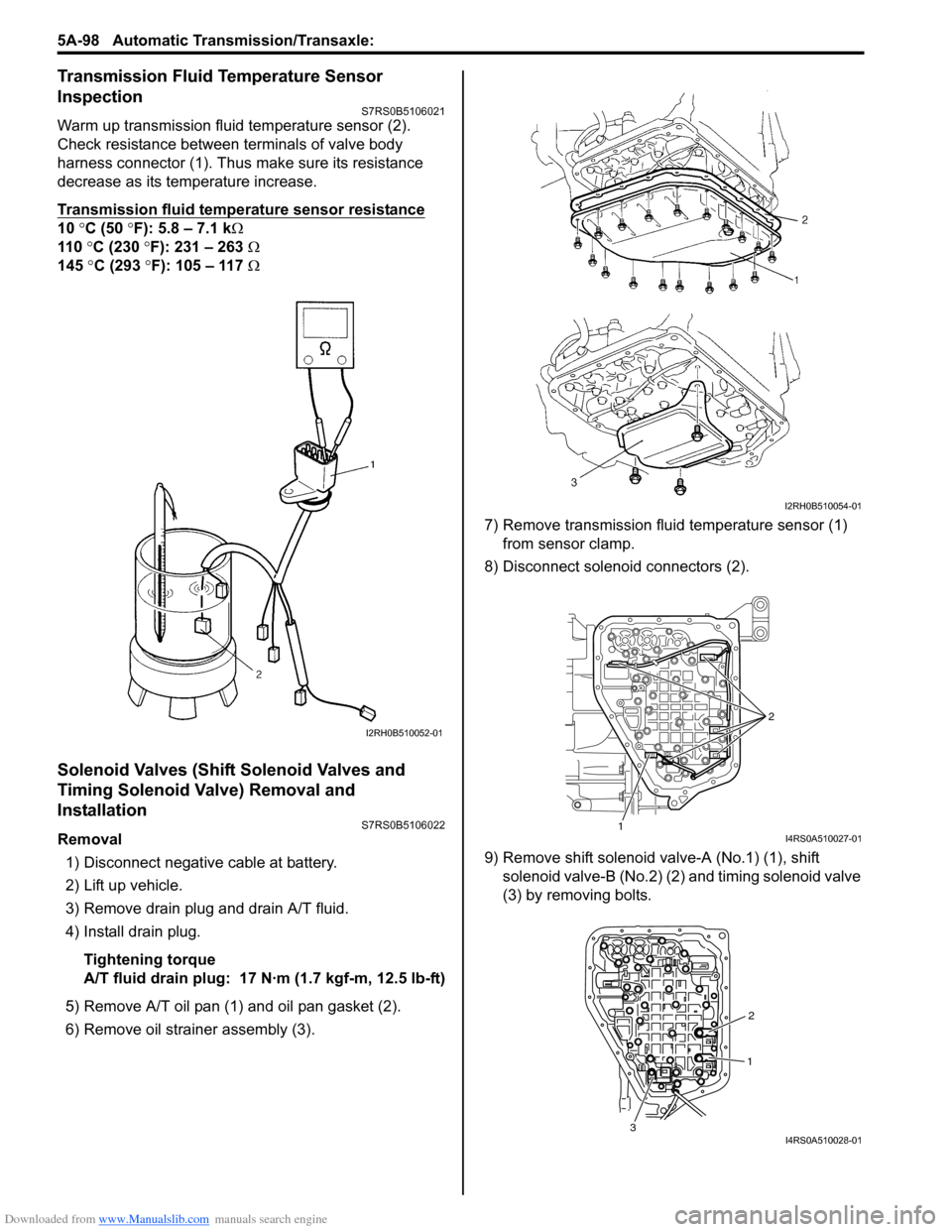

Transmission Fluid Temperature Sensor

Inspection

S7RS0B5106021

Warm up transmission fluid temperature sensor (2).

Check resistance between terminals of valve body

harness connector (1). Thus make sure its resistance

decrease as its temperature increase.

Transmission fluid temperature sensor resistance

10 °C (50 °F): 5.8 – 7.1 k Ω

110 °C (230 °F): 231 – 263 Ω

145 °C (293 °F): 105 – 117 Ω

Solenoid Valves (Shift Solenoid Valves and

Timing Solenoid Valve) Removal and

Installation

S7RS0B5106022

Removal

1) Disconnect negative cable at battery.

2) Lift up vehicle.

3) Remove drain plug and drain A/T fluid.

4) Install drain plug.

Tightening torque

A/T fluid drain plug: 17 N· m (1.7 kgf-m, 12.5 lb-ft)

5) Remove A/T oil pan (1) and oil pan gasket (2).

6) Remove oil strain er assembly (3). 7) Remove transmission fluid temperature sensor (1)

from sensor clamp.

8) Disconnect solenoid connectors (2).

9) Remove shift solenoid va lve-A (No.1) (1), shift

solenoid valve-B (No.2) (2) and timing solenoid valve

(3) by removing bolts.

I2RH0B510052-01

I2RH0B510054-01

1 2I4RS0A510027-01

1

2

3

I4RS0A510028-01

Page 743 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-99

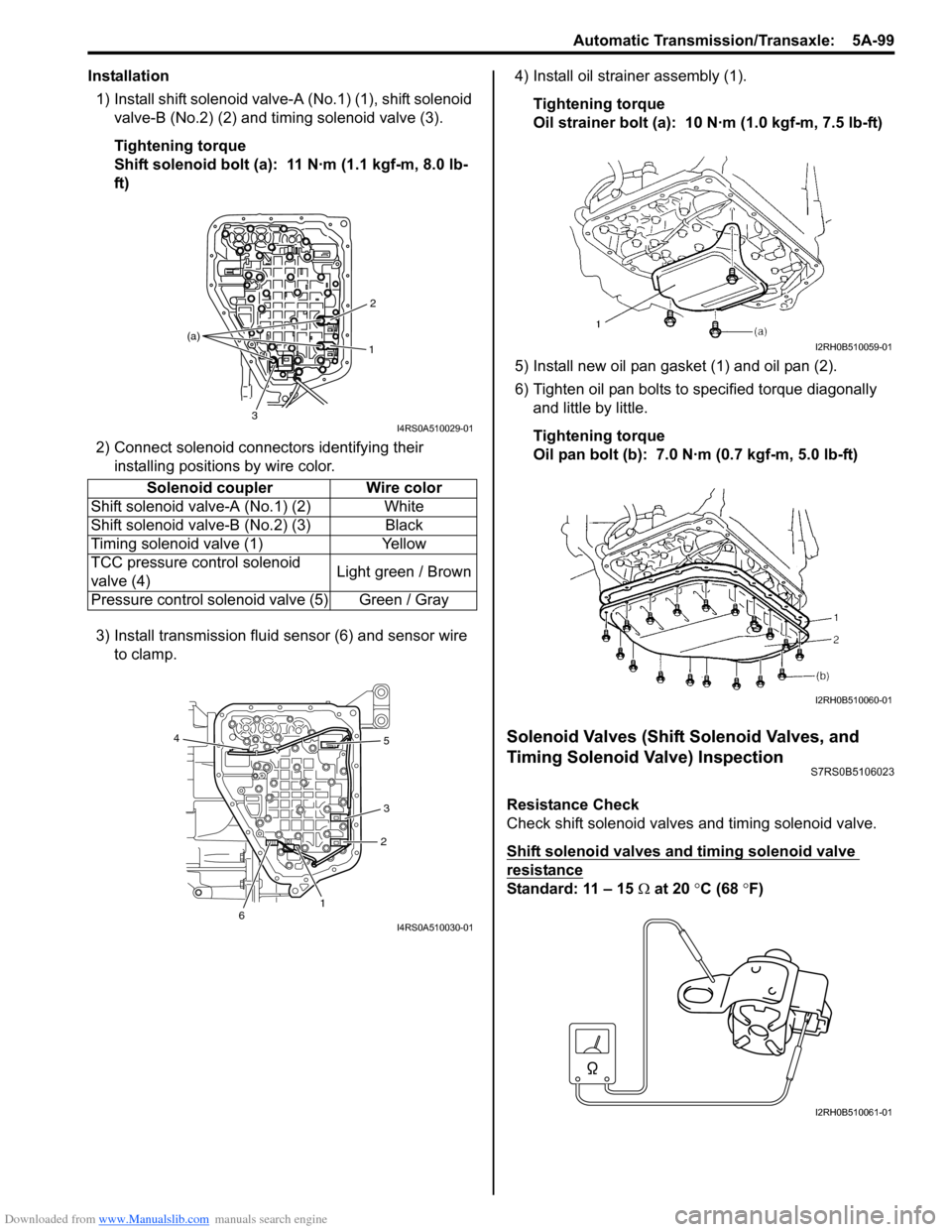

Installation1) Install shift solenoid valve- A (No.1) (1), shift solenoid

valve-B (No.2) (2) and timing solenoid valve (3).

Tightening torque

Shift solenoid bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-

ft)

2) Connect solenoid connectors identifying their installing positions by wire color.

3) Install transmission fluid sensor (6) and sensor wire to clamp. 4) Install oil strain

er assembly (1).

Tightening torque

Oil strainer bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

5) Install new oil pan gasket (1) and oil pan (2).

6) Tighten oil pan bolts to specified torque diagonally and little by little.

Tightening torque

Oil pan bolt (b): 7.0 N·m (0.7 kgf-m, 5.0 lb-ft)

Solenoid Valves (Shift Solenoid Valves, and

Timing Solenoid Valve) Inspection

S7RS0B5106023

Resistance Check

Check shift solenoid valves and timing solenoid valve.

Shift solenoid valves and timing solenoid valve

resistance

Standard: 11 – 15 Ω at 20 °C (68 ° F)

Solenoid coupler Wire color

Shift solenoid valv e-A (No.1) (2) White

Shift solenoid valv e-B (No.2) (3) Black

Timing solenoid valve (1) Yellow

TCC pressure control solenoid

valve (4) Light green / Brown

Pressure control solenoid valve (5) Green / Gray

1 2

3

(a)

I4RS0A510029-01

1

2

3 5

4

6

I4RS0A510030-01

I2RH0B510059-01

I2RH0B510060-01

I2RH0B510061-01