oil pan SUZUKI SWIFT 2008 2.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 745 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-101

Pressure Control Solenoid Valves (Pressure

Control Solenoid and TCC Pressure Control

Solenoid) Removal and Installation

S7RS0B5106024

Removal1) Disconnect negative cable at battery.

2) Lift up vehicle.

3) Remove drain plug and drain A/T fluid.

4) Install drain plug.

Tightening torque

A/T fluid drain plug: 17 N·m (1.7 kgf-m, 12.5 lb-ft)

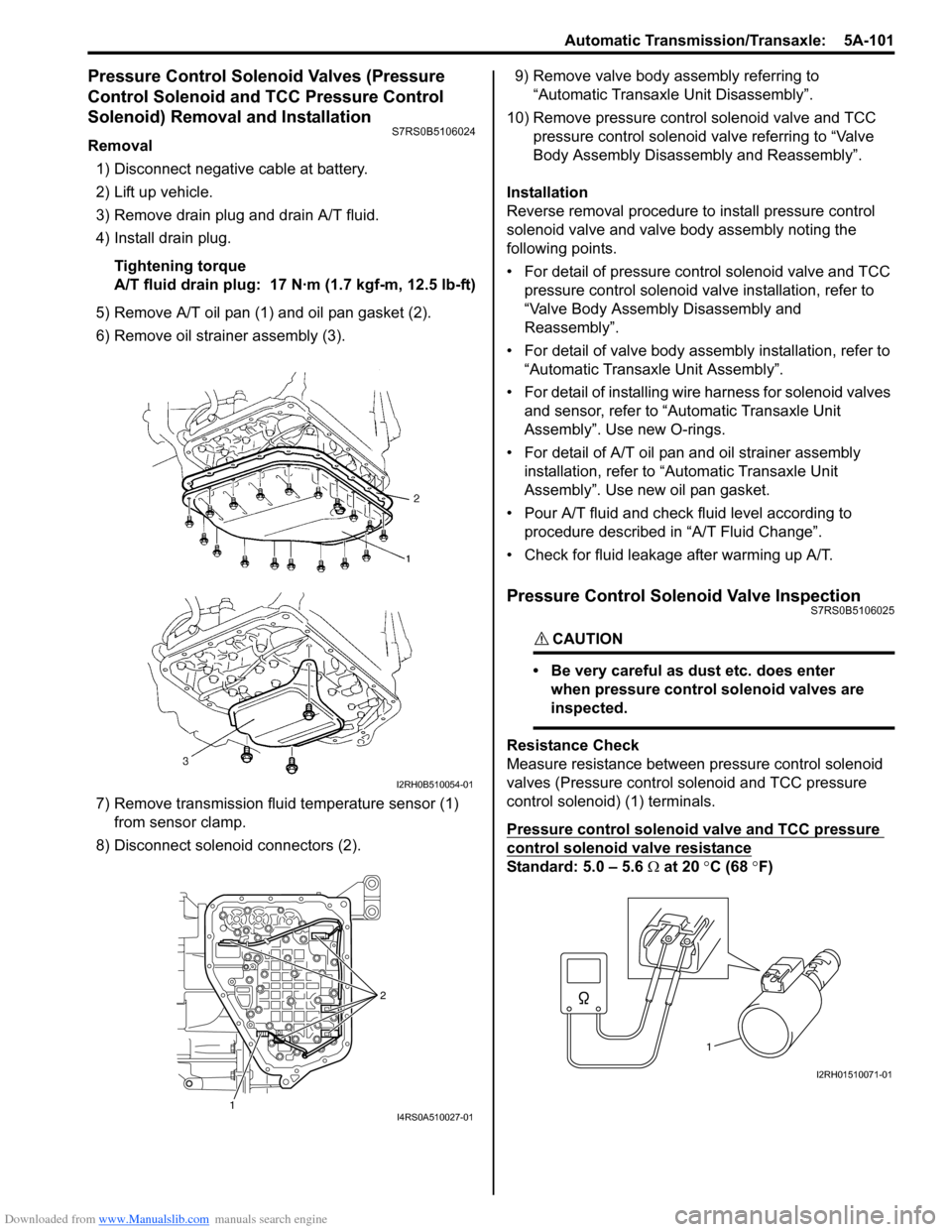

5) Remove A/T oil pan (1) and oil pan gasket (2).

6) Remove oil strain er assembly (3).

7) Remove transmission fluid temperature sensor (1) from sensor clamp.

8) Disconnect solenoid connectors (2). 9) Remove valve body assembly referring to

“Automatic Transaxl e Unit Disassembly”.

10) Remove pressure control solenoid valve and TCC pressure control solenoid valve referring to “Valve

Body Assembly Disassembly and Reassembly”.

Installation

Reverse removal procedure to install pressure control

solenoid valve and valve body assembly noting the

following points.

• For detail of pressure control solenoid valve and TCC pressure control solenoid va lve installation, refer to

“Valve Body Assembly Disassembly and

Reassembly”.

• For detail of valve body asse mbly installation, refer to

“Automatic Transaxle Unit Assembly”.

• For detail of installing wire harness for solenoid valves and sensor, refer to “Automatic Transaxle Unit

Assembly”. Use new O-rings.

• For detail of A/T oil pan and oil strainer assembly

installation, refer to “A utomatic Transaxle Unit

Assembly”. Use new oil pan gasket.

• Pour A/T fluid and check fluid level according to procedure described in “A/T Fluid Change”.

• Check for fluid leakage after warming up A/T.

Pressure Control Solenoid Valve InspectionS7RS0B5106025

CAUTION!

• Be very careful as dust etc. does enter when pressure control solenoid valves are

inspected.

Resistance Check

Measure resistance between pressure control solenoid

valves (Pressure control solenoid and TCC pressure

control solenoid) (1) terminals.

Pressure control solenoid valve and TCC pressure

control solenoid valve resistance

Standard: 5.0 – 5.6 Ω at 20 °C (68 °F)

I2RH0B510054-01

1 2I4RS0A510027-01

1

I2RH01510071-01

Page 751 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-107

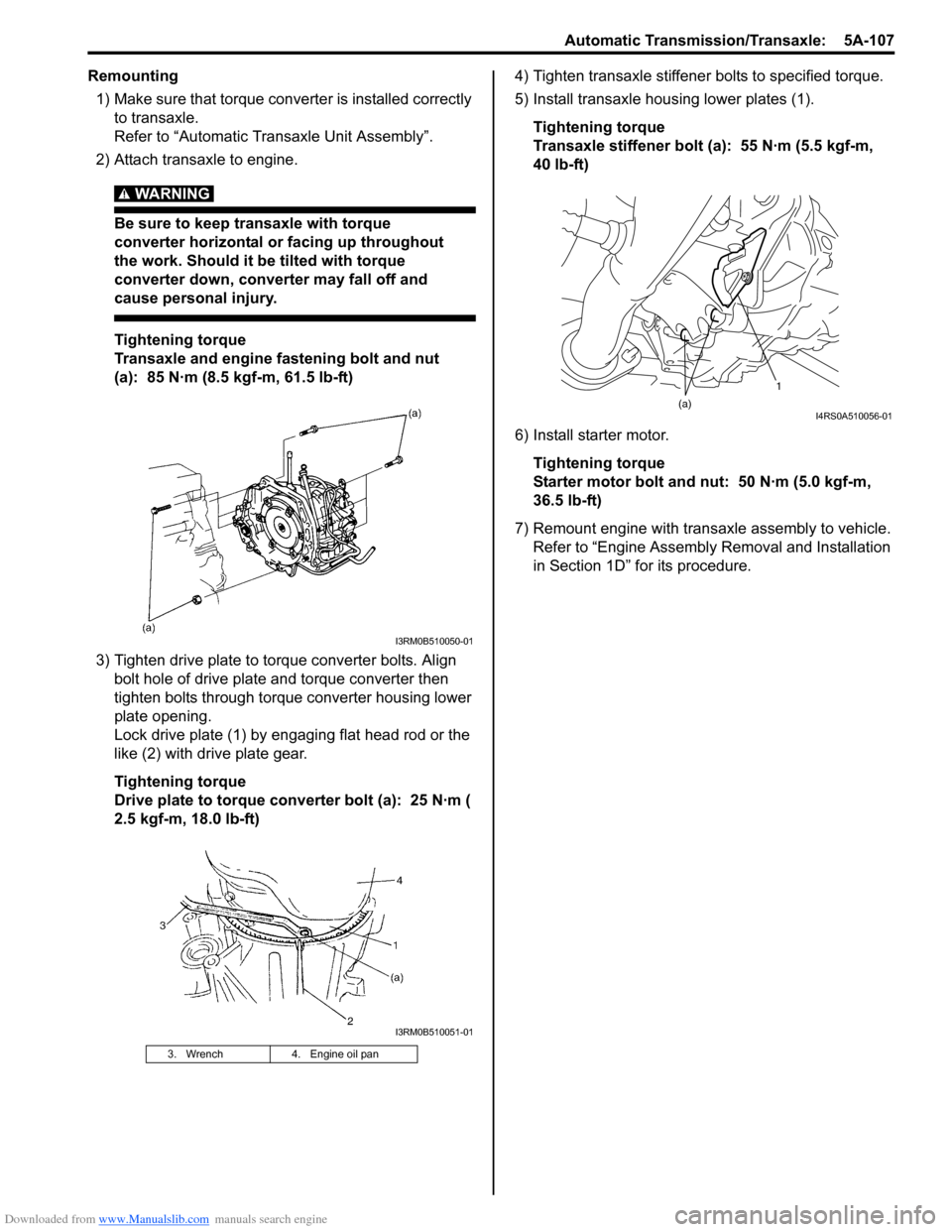

Remounting1) Make sure that torque converter is installed correctly to transaxle.

Refer to “Automatic Transaxle Unit Assembly”.

2) Attach transaxle to engine.

WARNING!

Be sure to keep transaxle with torque

converter horizontal or facing up throughout

the work. Should it be tilted with torque

converter down, converter may fall off and

cause personal injury.

Tightening torque

Transaxle and engine fastening bolt and nut

(a): 85 N·m (8.5 kgf-m, 61.5 lb-ft)

3) Tighten drive plate to torque converter bolts. Align bolt hole of drive plate and torque converter then

tighten bolts through torque converter housing lower

plate opening.

Lock drive plate (1) by engaging flat head rod or the

like (2) with drive plate gear.

Tightening torque

Drive plate to torque converter bolt (a): 25 N·m (

2.5 kgf-m, 18.0 lb-ft) 4) Tighten transaxle stiffener bolts to specified torque.

5) Install transaxle housing lower plates (1).

Tightening torque

Transaxle stiffener bolt (a): 55 N·m (5.5 kgf-m,

40 lb-ft)

6) Install starter motor. Tightening torque

Starter motor bolt and nut: 50 N·m (5.0 kgf-m,

36.5 lb-ft)

7) Remount engine with transaxle assembly to vehicle. Refer to “Engine Assembly Removal and Installation

in Section 1D” for its procedure.

3. Wrench 4. Engine oil pan

I3RM0B510050-01

I3RM0B510051-01

1

(a)

I4RS0A510056-01

Page 753 of 1496

Downloaded from www.Manualslib.com manuals search engine A u to m a tic Tra n s m is s io n /Tra n s a x le : 5 A -1 0 9

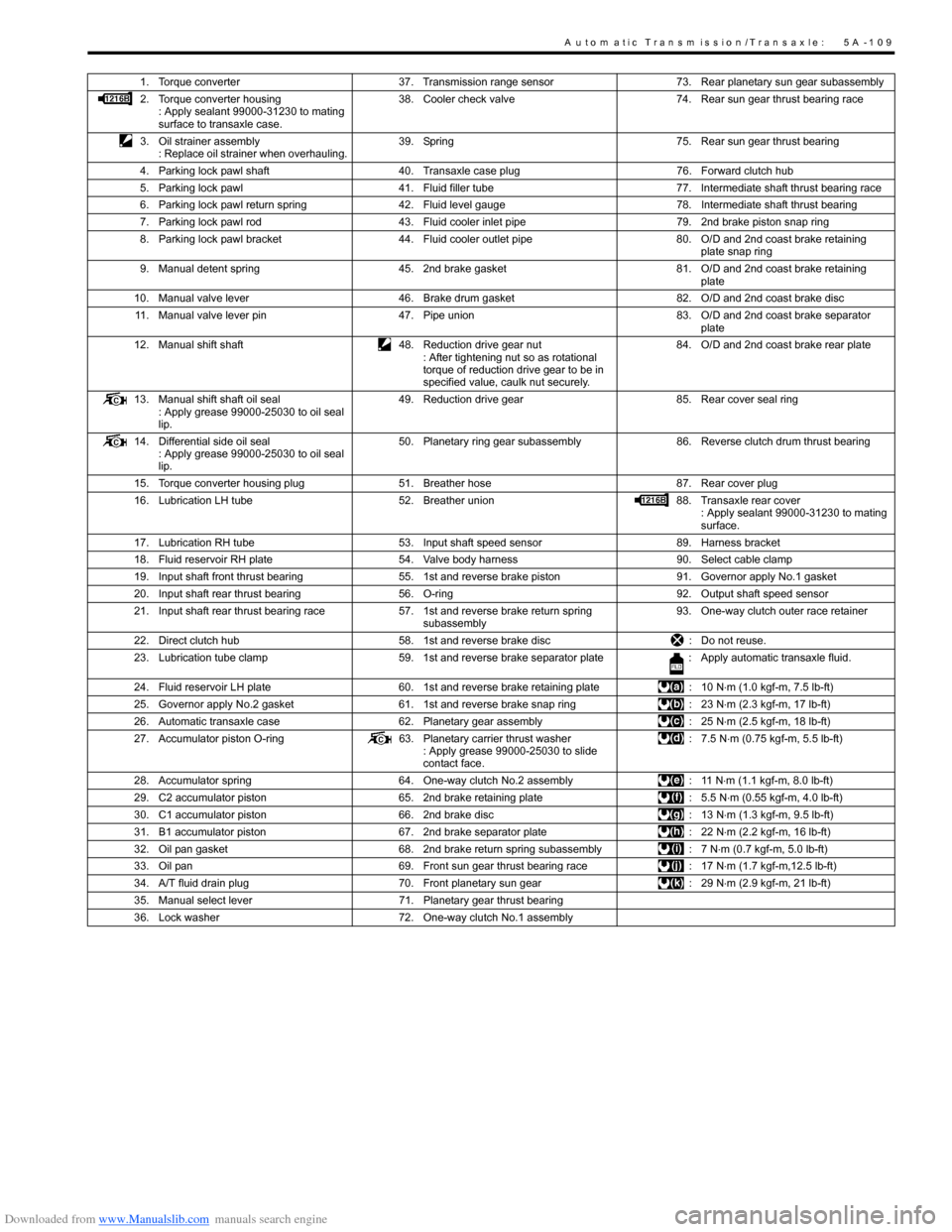

1. Torque converter37. Transmission range sensor 73. Rear planetary sun gear subassembly

2. Torque converter housing : Apply sealant 99000-31230 to mating

surface to transaxle case. 38. Cooler check valve

74. Rear sun gear thrust bearing race

3. Oil strainer assembly : Replace oil strainer when overhauling. 39. Spring

75. Rear sun gear thrust bearing

4. Parking lock pawl shaft 40. Transaxle case plug 76. Forward clutch hub

5. Parking lock pawl 41. Fluid filler tube 77. Intermediate shaft thrust bearing race

6. Parking lock pawl return spring 42. Fluid level gauge 78. Intermediate shaft thrust bearing

7. Parking lock pawl rod 43. Fluid cooler inlet pipe 79. 2nd brake piston snap ring

8. Parking lock pawl bracket 44. Fluid cooler outlet pipe 80. O/D and 2nd coast brake retaining

plate snap ring

9. Manual detent spring 45. 2nd brake gasket 81. O/D and 2nd coast brake retaining

plate

10. Manual valve lever 46. Brake drum gasket 82. O/D and 2nd coast brake disc

11. Manual valve lever pin 47. Pipe union 83. O/D and 2nd coast brake separator

plate

12. Manual shift shaft 48. Reduction drive gear nut

: After tightening nut so as rotational

torque of reduction drive gear to be in

specified value, caulk nut securely. 84. O/D and 2nd coast brake rear plate

13. Manual shift shaft oil seal : Apply grease 99000-25030 to oil seal

lip. 49. Reduction drive gear

85. Rear cover seal ring

14. Differential side oil seal : Apply grease 99000-25030 to oil seal

lip. 50. Planetary ring gear subassembly

86. Reverse clutch drum thrust bearing

15. Torque converter housing plug 51. Breather hose 87. Rear cover plug

16. Lubrication LH tube 52. Breather union 88. Transaxle rear cover

: Apply sealant 99000-31230 to mating

surface.

17. Lubrication RH tube 53. Input shaft speed sensor 89. Harness bracket

18. Fluid reservoir RH plate 54. Valve body harness 90. Select cable clamp

19. Input shaft front thrust bearing 55. 1st and reverse brake piston 91. Governor apply No.1 gasket

20. Input shaft rear thrust bearing 56. O-ring 92. Output shaft speed sensor

21. Input shaft rear thrust bearing race 57. 1st and reverse brake return spring

subassembly 93. One-way clutch outer race retainer

22. Direct clutch hub 58. 1st and reverse brake disc : Do not reuse.

23. Lubrication tube clamp 59. 1st and reverse brake separator plate : Apply automatic transaxle fluid.

24. Fluid reservoir LH plate 60. 1st and reverse brake retaining plate : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

25. Governor apply No.2 gasket 61. 1st and reverse brake snap ring : 23 N⋅m (2.3 kgf-m, 17 lb-ft)

26. Automatic transaxle case 62. Planetary gear assembly : 25 N⋅m (2.5 kgf-m, 18 lb-ft)

27. Accumulator piston O-ring 63. Planetary carrier thrust washer

: Apply grease 99000-25030 to slide

contact face. : 7.5 N

⋅m (0.75 kgf-m, 5.5 lb-ft)

28. Accumulator spring 64. One-way clutch No.2 assembly : 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

29. C2 accumulator piston 65. 2nd brake retaining plate : 5.5 N⋅m (0.55 kgf-m, 4.0 lb-ft)

30. C1 accumulator piston 66. 2nd brake disc : 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

31. B1 accumulator piston 67. 2nd brake separator plate : 22 N⋅m (2.2 kgf-m, 16 lb-ft)

32. Oil pan gasket 68. 2nd brake return spring subassembly : 7 N⋅m (0.7 kgf-m, 5.0 lb-ft)

33. Oil pan 69. Front sun gear thrust bearing race : 17 N⋅m (1.7 kgf-m,12.5 lb-ft)

34. A/T fluid drain plug 70. Front planetary sun gear : 29 N⋅m (2.9 kgf-m, 21 lb-ft)

35. Manual select lever 71. Planetary gear thrust bearing

36. Lock washer 72. One-way clutch No.1 assembly

Page 755 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-111

8) Remove fluid cooler pipes (1) and pipe union (2).

9) Remove fluid level gauge (3) and fluid filler tube (4).

10) Remove oil pan (1) and oil pan gasket (2).

NOTE

• For removal of oil pan, do not turn transaxle over as this will contaminate

valve body with foreign materials in

bottom of oil pan.

• When removing oil pan, tap around it lightly with plastic ha mmer. Do not force it

off by using screwdriver or the like.

11) Remove oil strain er assembly (1). 12) Disconnect connectors (2) from solenoid valves and

transmission fluid temperature sensor (1).

13) Remove valve body assembly bolts.

CAUTION!

Be careful not to let manual valve fall off

when removing valve body assembly.

NOTE

There are five kinds of bolts (bolts A (1), B (2),

C (3), D (4) and E (5)) fixing valve body

assembly.

14) Remove manual valve rod (1) from manual valve lever (2), then remove valve body assembly (3).

1 2

4

3

I3RM0B510059-01

I2RH0B510086-01

I2RH0B510087-01

1 2I4RS0A510027-01

I2RH0B510089-01

I2RH0B510090-01

Page 808 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-164 Automatic Transmission/Transaxle:

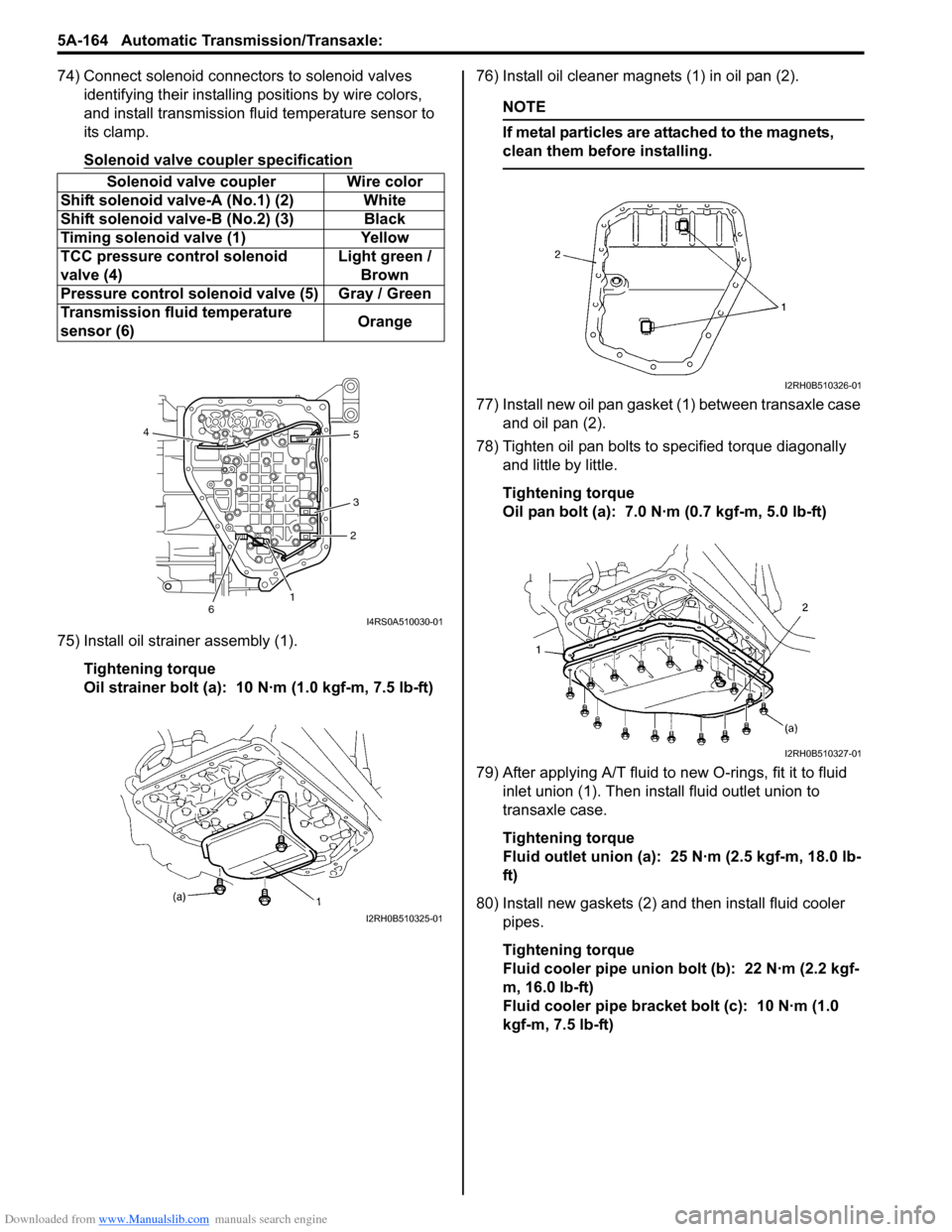

74) Connect solenoid connectors to solenoid valves identifying their installing positions by wire colors,

and install transmission fluid temperature sensor to

its clamp.

Solenoid valve coupler specification

75) Install oil strainer assembly (1).

Tightening torque

Oil strainer bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft) 76) Install oil cleaner magnets (1) in oil pan (2).

NOTE

If metal particles are attached to the magnets,

clean them before installing.

77) Install new oil pan gasket (1) between transaxle case

and oil pan (2).

78) Tighten oil pan bolts to specified torque diagonally and little by little.

Tightening torque

Oil pan bolt (a): 7.0 N·m (0.7 kgf-m, 5.0 lb-ft)

79) After applying A/T fluid to new O-rings, fit it to fluid inlet union (1). Then inst all fluid outlet union to

transaxle case.

Tightening torque

Fluid outlet union (a): 25 N·m (2.5 kgf-m, 18.0 lb-

ft)

80) Install new gaskets (2) and then install fluid cooler pipes.

Tightening torque

Fluid cooler pipe union bolt (b): 22 N·m (2.2 kgf-

m, 16.0 lb-ft)

Fluid cooler pipe bracket bolt (c): 10 N·m (1.0

kgf-m, 7.5 lb-ft)

Solenoid valve coupler Wire color

Shift solenoid valve-A (No.1) (2) White

Shift solenoid val ve-B (No.2) (3) Black

Timing solenoid valve (1) Yellow

TCC pressure control solenoid

valve (4) Light green /

Brown

Pressure control solenoid valve (5) Gray / Green

Transmission fluid temperature

sensor (6) Orange

12

3 5

4

6

I4RS0A510030-01

I2RH0B510325-01

I2RH0B510326-01

I2RH0B510327-01

Page 811 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-167

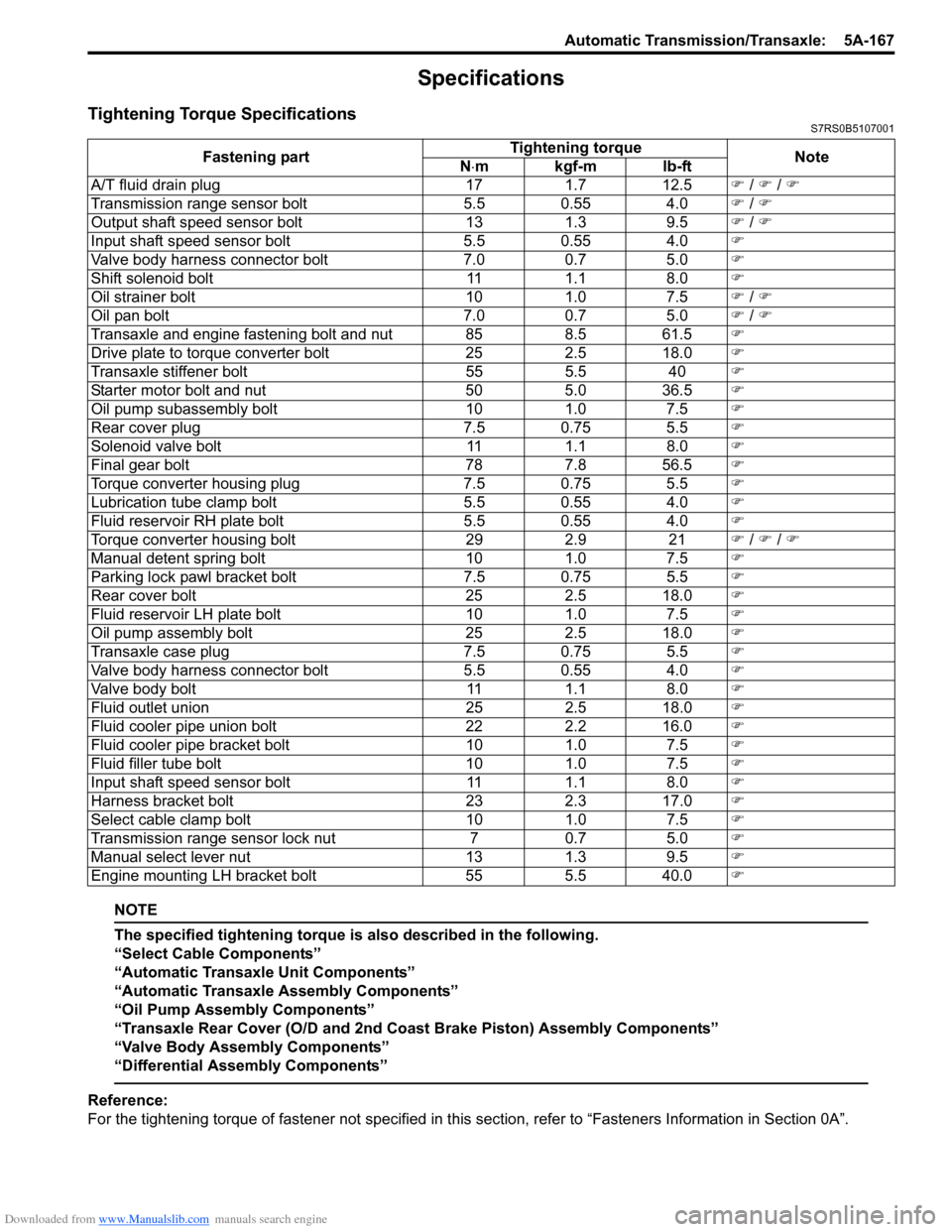

Specifications

Tightening Torque SpecificationsS7RS0B5107001

NOTE

The specified tightening torque is also described in the following.

“Select Cable Components”

“Automatic Transaxle Unit Components”

“Automatic Transaxle Assembly Components”

“Oil Pump Assembly Components”

“Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Components”

“Valve Body Assembly Components”

“Differential Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

A/T fluid drain plug 171.7 12.5 �) / �) / �)

Transmission range sensor bolt 5.5 0.55 4.0�) / �)

Output shaft speed sensor bolt 131.3 9.5 �) / �)

Input shaft speed sensor bolt 5.5 0.55 4.0�)

Valve body harness connector bolt 7.00.7 5.0 �)

Shift solenoid bolt 111.1 8.0 �)

Oil strainer bolt 101.0 7.5 �) / �)

Oil pan bolt 7.00.7 5.0 �) / �)

Transaxle and engine fastening bolt and nut 85 8.5 61.5�)

Drive plate to torque converter bolt 252.5 18.0 �)

Transaxle stiffener bolt 555.5 40�)

Starter motor bolt and nut 505.0 36.5 �)

Oil pump subassembly bolt 101.0 7.5 �)

Rear cover plug 7.5 0.75 5.5�)

Solenoid valve bolt 111.1 8.0 �)

Final gear bolt 787.8 56.5 �)

Torque converter housing plug 7.5 0.75 5.5�)

Lubrication tube clamp bolt 5.5 0.55 4.0�)

Fluid reservoir RH plate bolt 5.5 0.55 4.0�)

Torque converter housing bolt 292.9 21�) / �) / �)

Manual detent spring bolt 101.0 7.5 �)

Parking lock pawl bracket bolt 7.5 0.75 5.5�)

Rear cover bolt 252.5 18.0 �)

Fluid reservoir LH plate bolt 101.0 7.5 �)

Oil pump assembly bolt 252.5 18.0 �)

Transaxle case plug 7.5 0.75 5.5�)

Valve body harness connector bolt 5.5 0.55 4.0�)

Valve body bolt 111.1 8.0 �)

Fluid outlet union 252.5 18.0 �)

Fluid cooler pipe union bolt 222.2 16.0 �)

Fluid cooler pipe bracket bolt 101.0 7.5 �)

Fluid filler tube bolt 101.0 7.5 �)

Input shaft speed sensor bolt 111.1 8.0 �)

Harness bracket bolt 232.3 17.0 �)

Select cable clamp bolt 101.0 7.5 �)

Transmission range sensor lock nut 70.7 5.0 �)

Manual select lever nut 131.3 9.5 �)

Engine mounting LH bracket bolt 555.5 40.0

�)

Page 878 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-7 Steering Wheel and Column:

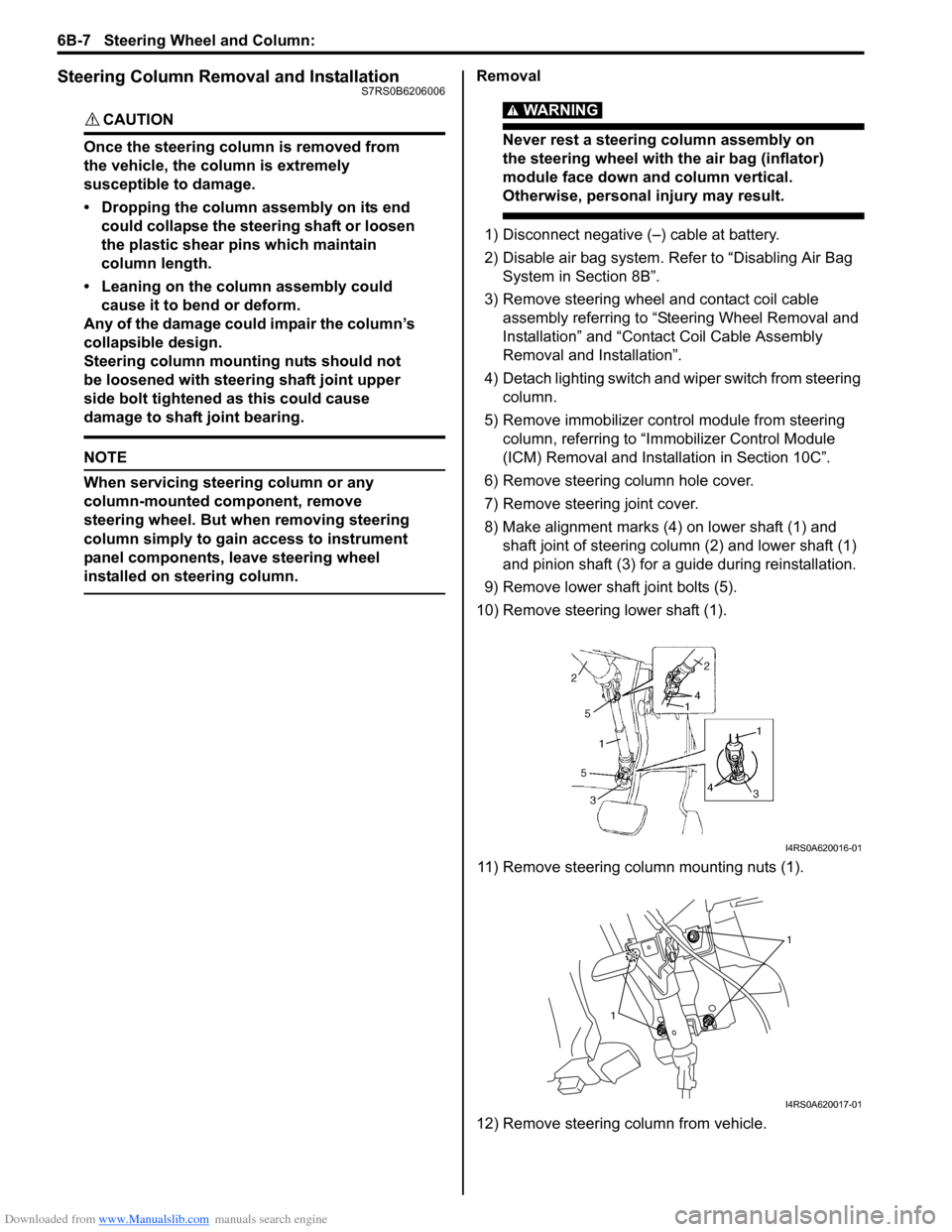

Steering Column Removal and InstallationS7RS0B6206006

CAUTION!

Once the steering column is removed from

the vehicle, the column is extremely

susceptible to damage.

• Dropping the column assembly on its end could collapse the steering shaft or loosen

the plastic shear pins which maintain

column length.

• Leaning on the column assembly could cause it to bend or deform.

Any of the damage could impair the column’s

collapsible design.

Steering column mounting nuts should not

be loosened with steering shaft joint upper

side bolt tightened as this could cause

damage to shaft joint bearing.

NOTE

When servicing steering column or any

column-mounted component, remove

steering wheel. But when removing steering

column simply to gain access to instrument

panel components, leave steering wheel

installed on steering column.

Removal

WARNING!

Never rest a steering column assembly on

the steering wheel with the air bag (inflator)

module face down and column vertical.

Otherwise, personal injury may result.

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Re fer to “Disabling Air Bag

System in Section 8B”.

3) Remove steering wheel and contact coil cable assembly referring to “S teering Wheel Removal and

Installation” and “Contact Coil Cable Assembly

Removal and Installation”.

4) Detach lighting switch and wiper switch from steering column.

5) Remove immobilizer cont rol module from steering

column, referring to “Immo bilizer Control Module

(ICM) Removal and Installation in Section 10C”.

6) Remove steering column hole cover.

7) Remove steering joint cover.

8) Make alignment marks (4) on lower shaft (1) and shaft joint of steering column (2) and lower shaft (1)

and pinion shaft (3) for a guide during reinstallation.

9) Remove lower shaf t joint bolts (5).

10) Remove steering lower shaft (1).

11) Remove steering column mounting nuts (1).

12) Remove steering column from vehicle.

I4RS0A620016-01

1

1

I4RS0A620017-01

Page 948 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-12 Heater and Ventilation:

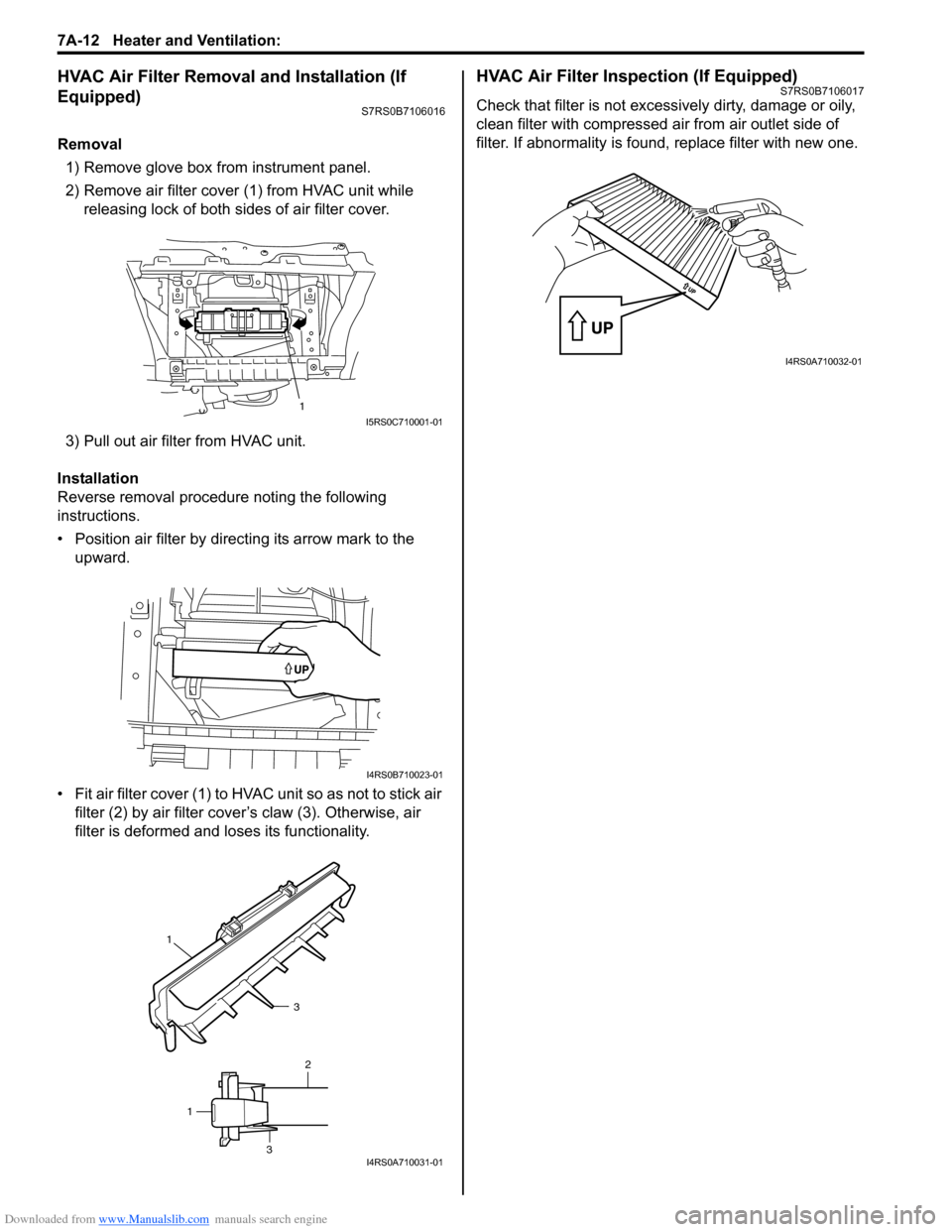

HVAC Air Filter Removal and Installation (If

Equipped)

S7RS0B7106016

Removal1) Remove glove box from instrument panel.

2) Remove air filter cover (1) from HVAC unit while

releasing lock of both sides of air filter cover.

3) Pull out air filter from HVAC unit.

Installation

Reverse removal procedure noting the following

instructions.

• Position air filter by directing its arrow mark to the upward.

• Fit air filter cover (1) to HVAC unit so as not to stick air

filter (2) by air filter cove r’s claw (3). Otherwise, air

filter is deformed and loses its functionality.

HVAC Air Filter Inspection (If Equipped)S7RS0B7106017

Check that filter is not excessively dirty, damage or oily,

clean filter with compressed air from air outlet side of

filter. If abnormality is found, replace filter with new one.

1I5RS0C710001-01

I4RS0B710023-01

1

3

2

1

3I4RS0A710031-01

I4RS0A710032-01

Page 950 of 1496

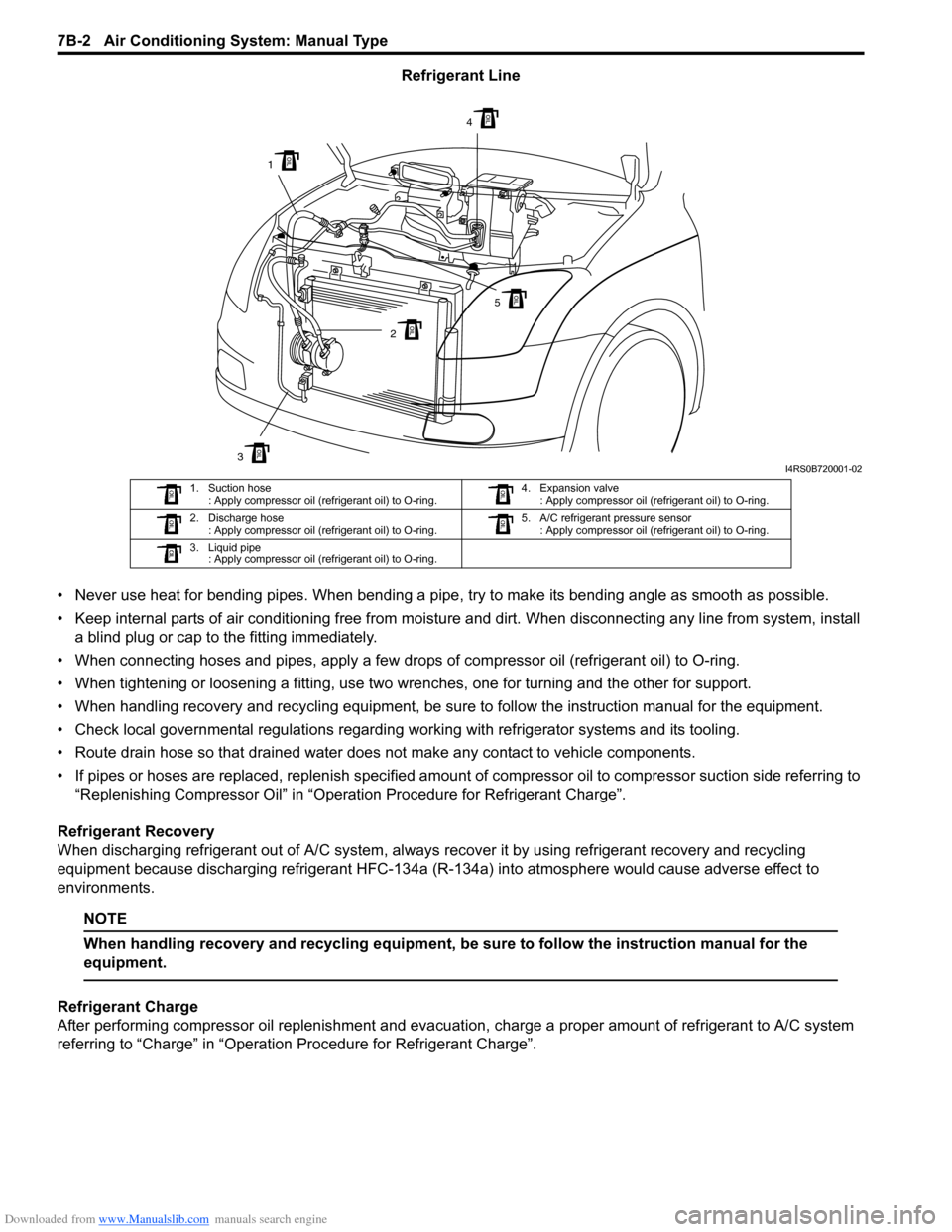

Downloaded from www.Manualslib.com manuals search engine 7B-2 Air Conditioning System: Manual Type

Refrigerant Line

• Never use heat for bending pipes. When bending a pipe , try to make its bending angle as smooth as possible.

• Keep internal parts of air conditioning free from moistu re and dirt. When disconnecting any line from system, install

a blind plug or cap to the fitting immediately.

• When connecting hoses and pipes, apply a few drops of compressor oil (refrigerant oil) to O-ring.

• When tightening or loosening a fitting, use two wrenches, one for turning and the other for support.

• When handling recovery and recycling equipment, be sure to follow the instruction manual for the equipment.

• Check local governmental regulations regarding working with refrigerator systems and its tooling.

• Route drain hose so that drained water does not make any contact to vehicle components.

• If pipes or hoses are replaced, replenish specified amount of compressor oil to compre ssor suction side referring to

“Replenishing Compressor Oil” in “Operation Procedure for Refrigerant Charge”.

Refrigerant Recovery

When discharging refrigerant out of A/C system, always recover it by using refrigerant recovery and recycling

equipment because discharging refrigerant HFC-134a (R-1 34a) into atmosphere would cause adverse effect to

environments.

NOTE

When handling recovery and recycling equipment, be sure to follow the instruction manual for the

equipment.

Refrigerant Charge

After performing compressor oil replenishment and evacuat ion, charge a proper amount of refrigerant to A/C system

referring to “Charge” in “Operation Procedure for Refrigerant Charge”.

3

1

2

4

5

I4RS0B720001-02

1. Suction hose : Apply compressor oil (refrigerant oil) to O-ring. 4. Expansion valve

: Apply compressor oil (refrigerant oil) to O-ring.

2. Discharge hose : Apply compressor oil (refrigerant oil) to O-ring. 5. A/C refrigerant pressure sensor

: Apply compressor oil (refrigerant oil) to O-ring.

3. Liquid pipe : Apply compressor oil (refrigerant oil) to O-ring.

Page 956 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-8 Air Conditioning System: Manual Type

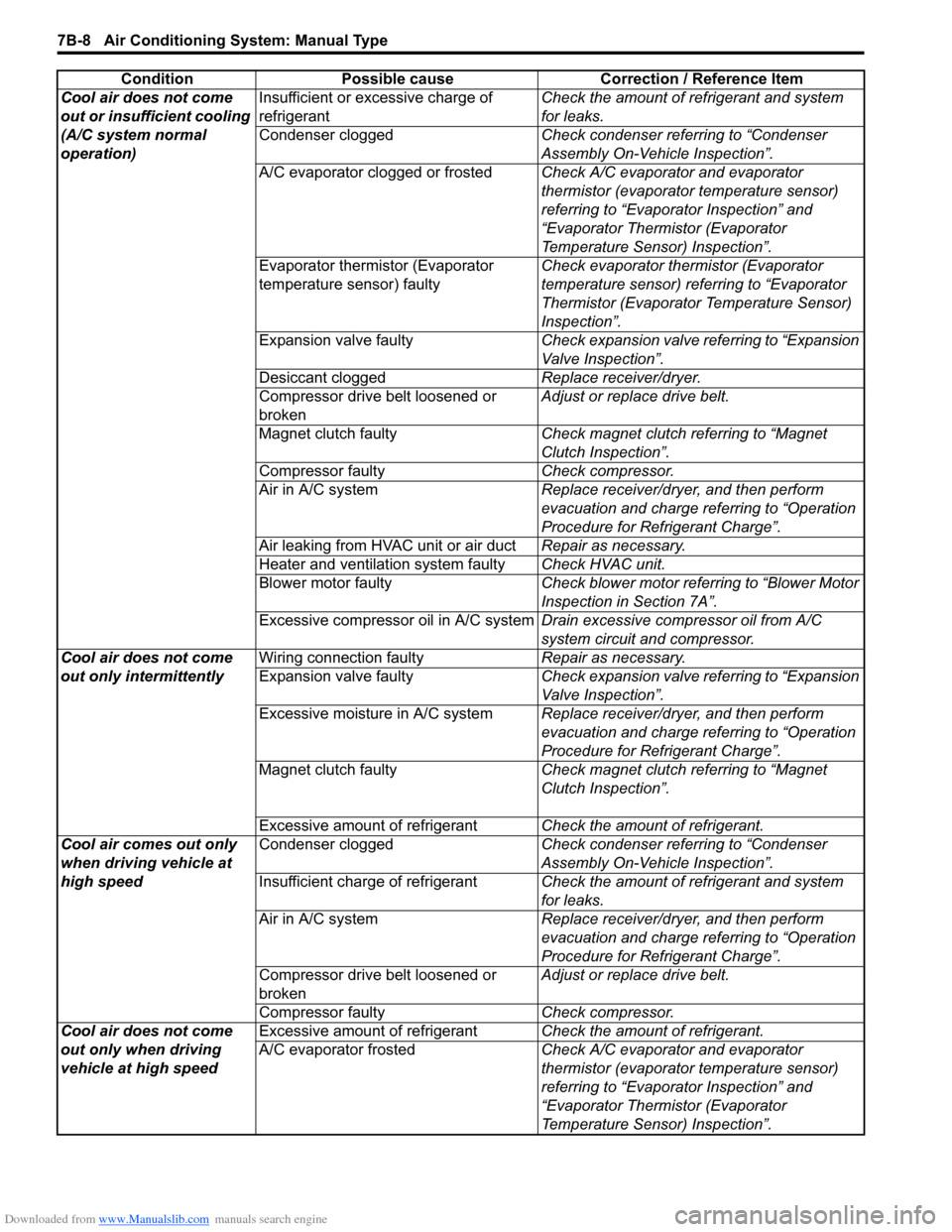

Cool air does not come

out or insufficient cooling

(A/C system normal

operation)Insufficient or excessive charge of

refrigerant

Check the amount of refrigerant and system

for leaks.

Condenser clogged Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

A/C evaporator clogged or frosted Check A/C evaporator and evaporator

thermistor (evaporator temperature sensor)

referring to “Evaporator Inspection” and

“Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Evaporator thermistor (Evaporator

temperature sensor) faulty Check evaporator thermistor (Evaporator

temperature sensor) referring to “Evaporator

Thermistor (Evaporator Temperature Sensor)

Inspection”.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Desiccant clogged Replace receiver/dryer.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Magnet clutch faulty Check magnet clutch referring to “Magnet

Clutch Inspection”.

Compressor faulty Check compressor.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Air leaking from HVAC unit or air duct Repair as necessary.

Heater and ventilation system faulty Check HVAC unit.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Excessive compressor oil in A/C system Drain excessive compressor oil from A/C

system circuit and compressor.

Cool air does not come

out only intermittently Wiring connection faulty

Repair as necessary.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Excessive moisture in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Magnet clutch faulty Check magnet clutch referring to “Magnet

Clutch Inspection”.

Excessive amount of refrigerant Check the amount of refrigerant.

Cool air comes out only

when driving vehicle at

high speed Condenser clogged

Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

Insufficient charge of refrigerant Check the amount of refrigerant and system

for leaks.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Cool air does not come

out only when driving

vehicle at high speed Excessive amount of refrigerant

Check the amount of refrigerant.

A/C evaporator frosted Check A/C evaporator and evaporator

thermistor (evaporator temperature sensor)

referring to “Evaporator Inspection” and

“Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Condition Possible cause Correction / Reference Item