AIR CON SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 946 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-10 Heater and Ventilation:

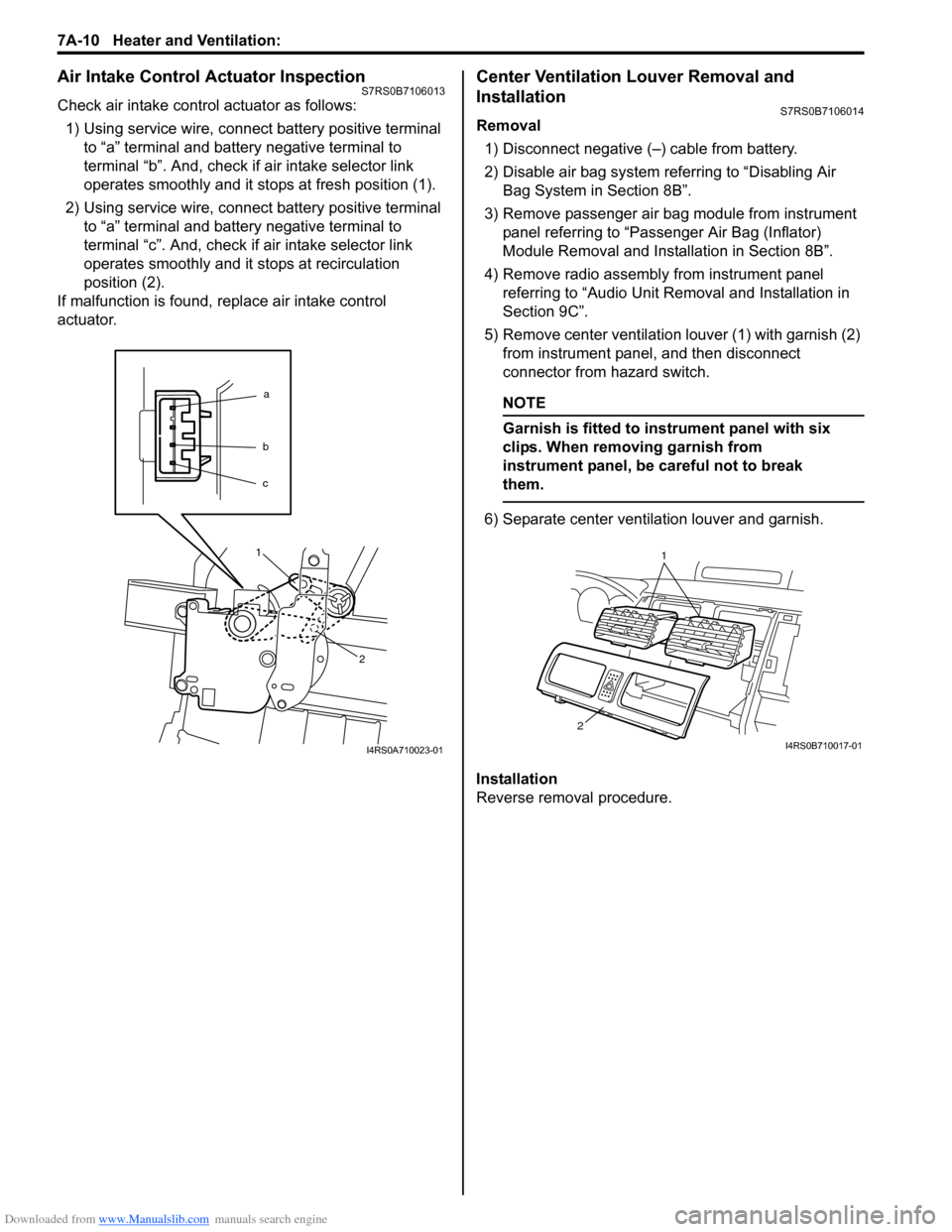

Air Intake Control Actuator InspectionS7RS0B7106013

Check air intake control actuator as follows:1) Using service wire, connect battery positive terminal to “a” terminal and battery negative terminal to

terminal “b”. And, check if air intake selector link

operates smoothly and it st ops at fresh position (1).

2) Using service wire, connect battery positive terminal to “a” terminal and battery negative terminal to

terminal “c”. And, check if air intake selector link

operates smoothly and it stops at recirculation

position (2).

If malfunction is found, replace air intake control

actuator.

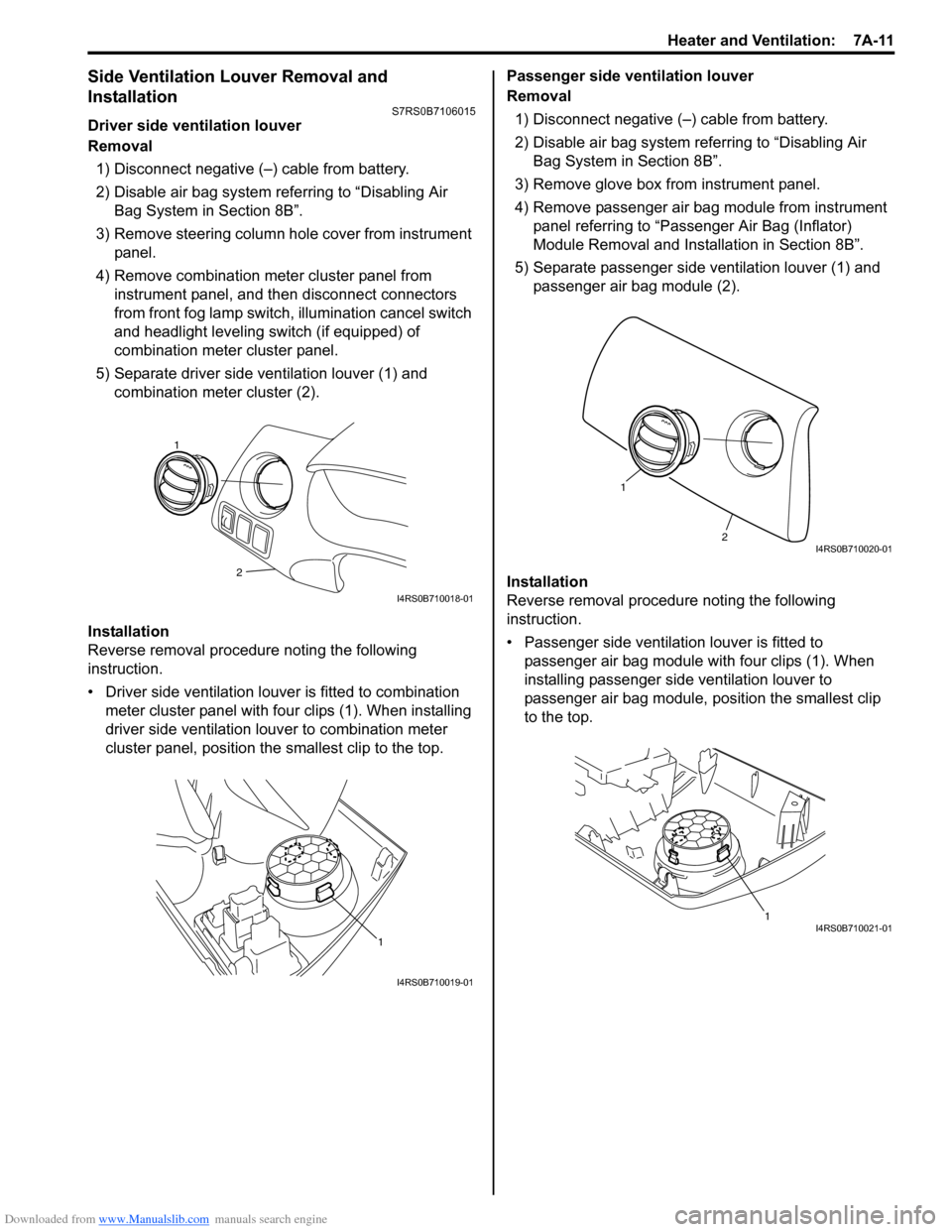

Center Ventilation Louver Removal and

Installation

S7RS0B7106014

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Audio Unit Re moval and Installation in

Section 9C”.

5) Remove center ventilation louver (1) with garnish (2) from instrument panel, and then disconnect

connector from hazard switch.

NOTE

Garnish is fitted to in strument panel with six

clips. When removing garnish from

instrument panel, be careful not to break

them.

6) Separate center ventilation louver and garnish.

Installation

Reverse removal procedure.

a

b

c

1

2

I4RS0A710023-01

1

2

I4RS0B710017-01

Page 947 of 1496

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-11

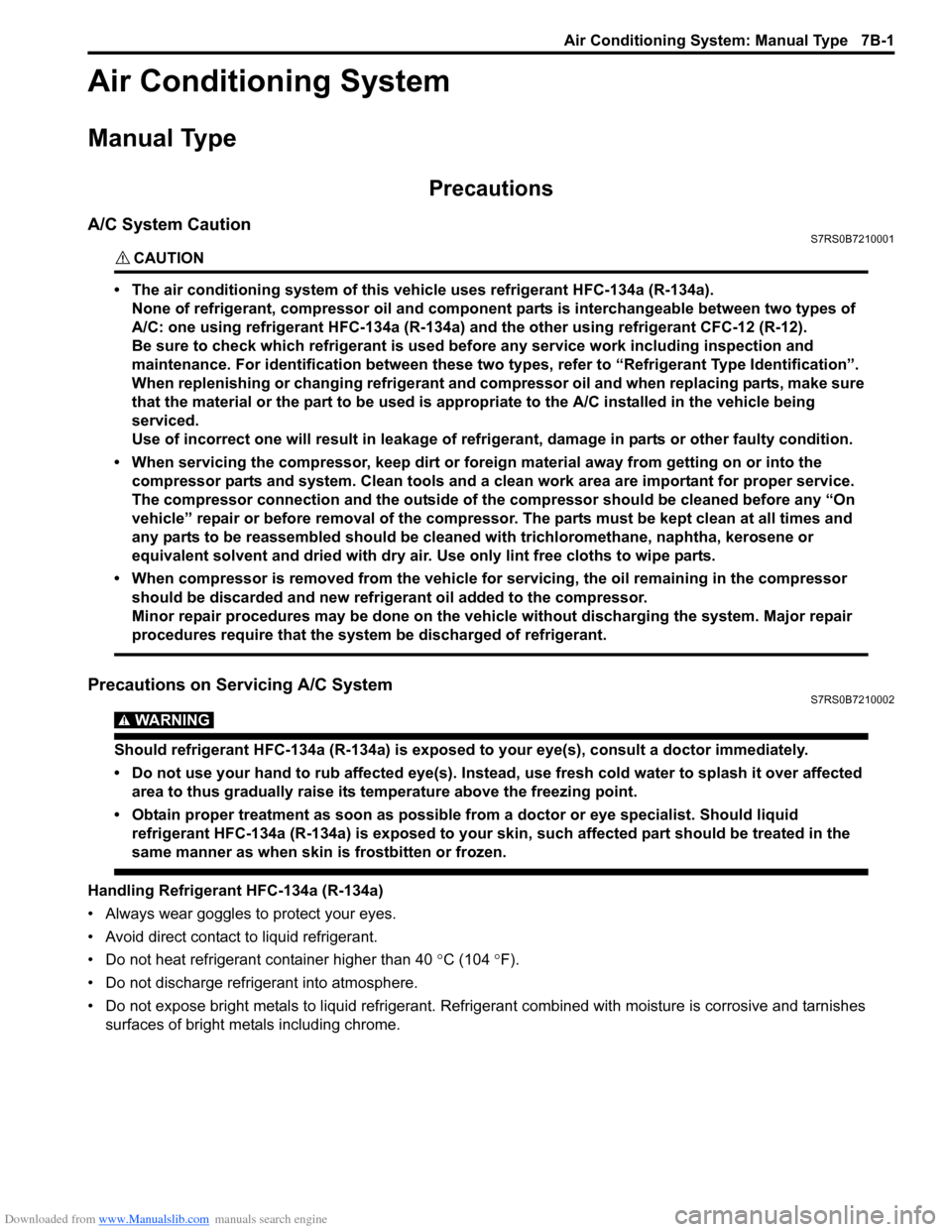

Side Ventilation Louver Removal and

Installation

S7RS0B7106015

Driver side ventilation louver

Removal1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove steering column hol e cover from instrument

panel.

4) Remove combination meter cluster panel from instrument panel, and then disconnect connectors

from front fog lamp switch, illumination cancel switch

and headlight leveling switch (if equipped) of

combination meter cluster panel.

5) Separate driver side ventilation louver (1) and combination meter cluster (2).

Installation

Reverse removal procedure noting the following

instruction.

• Driver side ventilation louver is fitted to combination meter cluster panel with four clips (1). When installing

driver side ventilation louv er to combination meter

cluster panel, position the smallest clip to the top. Passenger side ventilation louver

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove glove box from instrument panel.

4) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

5) Separate passenger side ventilation louver (1) and passenger air bag module (2).

Installation

Reverse removal procedure noting the following

instruction.

• Passenger side ventilation louver is fitted to passenger air bag module with four clips (1). When

installing passenger side ventilation louver to

passenger air bag module, position the smallest clip

to the top.

2

1

I4RS0B710018-01

1

I4RS0B710019-01

2

1

I4RS0B710020-01

1I4RS0B710021-01

Page 949 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-1

HVAC

Air Conditioning System

Manual Type

Precautions

A/C System CautionS7RS0B7210001

CAUTION!

• The air conditioning system of this vehicle uses refrigerant HFC-134a (R-134a).

None of refrigerant, compressor oil and component parts is interchangeable between two types of

A/C: one using refrigerant HFC-134a (R-134a) and the other using refrigerant CFC-12 (R-12).

Be sure to check which refrigerant is used be fore any service work including inspection and

maintenance. For identification between these two types, refer to “Refrigerant Type Identification”.

When replenishing or changing refrigerant and comp ressor oil and when replacing parts, make sure

that the material or the part to be used is appropriate to the A/C installed in the vehicle being

serviced.

Use of incorrect one will result in leakage of refrigerant, damage in parts or other faulty condition.

• When servicing the compressor, keep dirt or foreign material away from getting on or into the compressor parts and system. Clean tools and a clean work area are important for proper service.

The compressor connection and the outside of the compressor should be cleaned before any “On

vehicle” repair or before removal of the compressor. The parts must be kept clean at all times and

any parts to be reassembled should be cleaned with trichloromethane, naphtha, kerosene or

equivalent solvent and dried with dry air. Use only lint free cloths to wipe parts.

• When compressor is removed from the vehicle for servicing, the oil remaining in the compressor

should be discarded and new refrigerant oil added to the compressor.

Minor repair procedures may be done on the vehicle without discharging the system. Major repair

procedures require that the system be discharged of refrigerant.

Precautions on Servicing A/C SystemS7RS0B7210002

WARNING!

Should refrigerant HFC-134a (R-134a) is exposed to your eye(s), consult a doctor immediately.

• Do not use your hand to rub affected eye(s). Instead, use fresh cold water to splash it over affected area to thus gradually raise its temperature above the freezing point.

• Obtain proper treatment as soon as possible from a doctor or eye specialist. Should liquid refrigerant HFC-134a (R-134a) is exposed to your skin, such affected part should be treated in the

same manner as when skin is frostbitten or frozen.

Handling Refrigerant HFC-134a (R-134a)

• Always wear goggles to protect your eyes.

• Avoid direct contact to liquid refrigerant.

• Do not heat refrigerant container higher than 40 °C (104 ° F).

• Do not discharge refrigerant into atmosphere.

• Do not expose bright metals to liquid refrigerant. Refrig erant combined with moisture is corrosive and tarnishes

surfaces of bright metals including chrome.

Page 950 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-2 Air Conditioning System: Manual Type

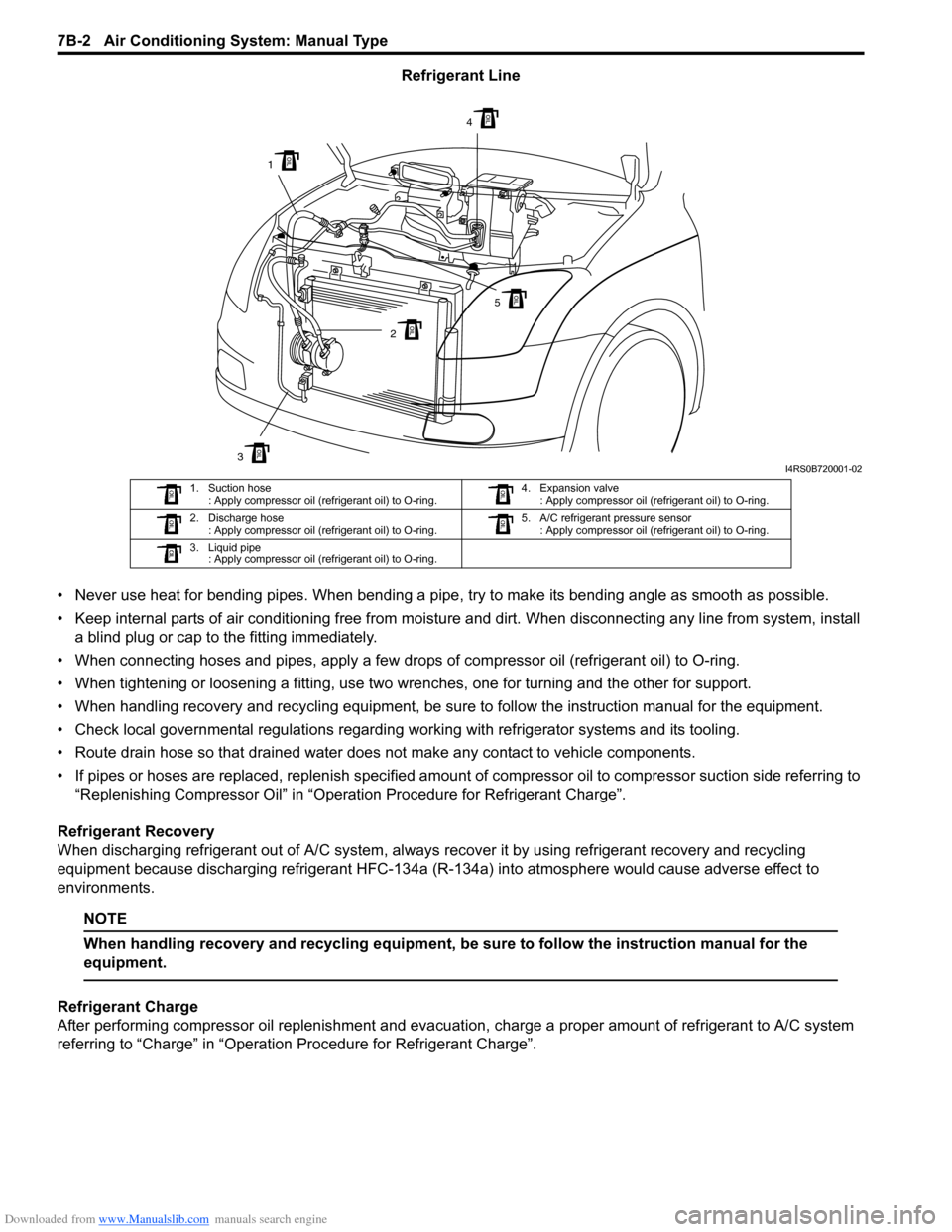

Refrigerant Line

• Never use heat for bending pipes. When bending a pipe , try to make its bending angle as smooth as possible.

• Keep internal parts of air conditioning free from moistu re and dirt. When disconnecting any line from system, install

a blind plug or cap to the fitting immediately.

• When connecting hoses and pipes, apply a few drops of compressor oil (refrigerant oil) to O-ring.

• When tightening or loosening a fitting, use two wrenches, one for turning and the other for support.

• When handling recovery and recycling equipment, be sure to follow the instruction manual for the equipment.

• Check local governmental regulations regarding working with refrigerator systems and its tooling.

• Route drain hose so that drained water does not make any contact to vehicle components.

• If pipes or hoses are replaced, replenish specified amount of compressor oil to compre ssor suction side referring to

“Replenishing Compressor Oil” in “Operation Procedure for Refrigerant Charge”.

Refrigerant Recovery

When discharging refrigerant out of A/C system, always recover it by using refrigerant recovery and recycling

equipment because discharging refrigerant HFC-134a (R-1 34a) into atmosphere would cause adverse effect to

environments.

NOTE

When handling recovery and recycling equipment, be sure to follow the instruction manual for the

equipment.

Refrigerant Charge

After performing compressor oil replenishment and evacuat ion, charge a proper amount of refrigerant to A/C system

referring to “Charge” in “Operation Procedure for Refrigerant Charge”.

3

1

2

4

5

I4RS0B720001-02

1. Suction hose : Apply compressor oil (refrigerant oil) to O-ring. 4. Expansion valve

: Apply compressor oil (refrigerant oil) to O-ring.

2. Discharge hose : Apply compressor oil (refrigerant oil) to O-ring. 5. A/C refrigerant pressure sensor

: Apply compressor oil (refrigerant oil) to O-ring.

3. Liquid pipe : Apply compressor oil (refrigerant oil) to O-ring.

Page 951 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-3

General Description

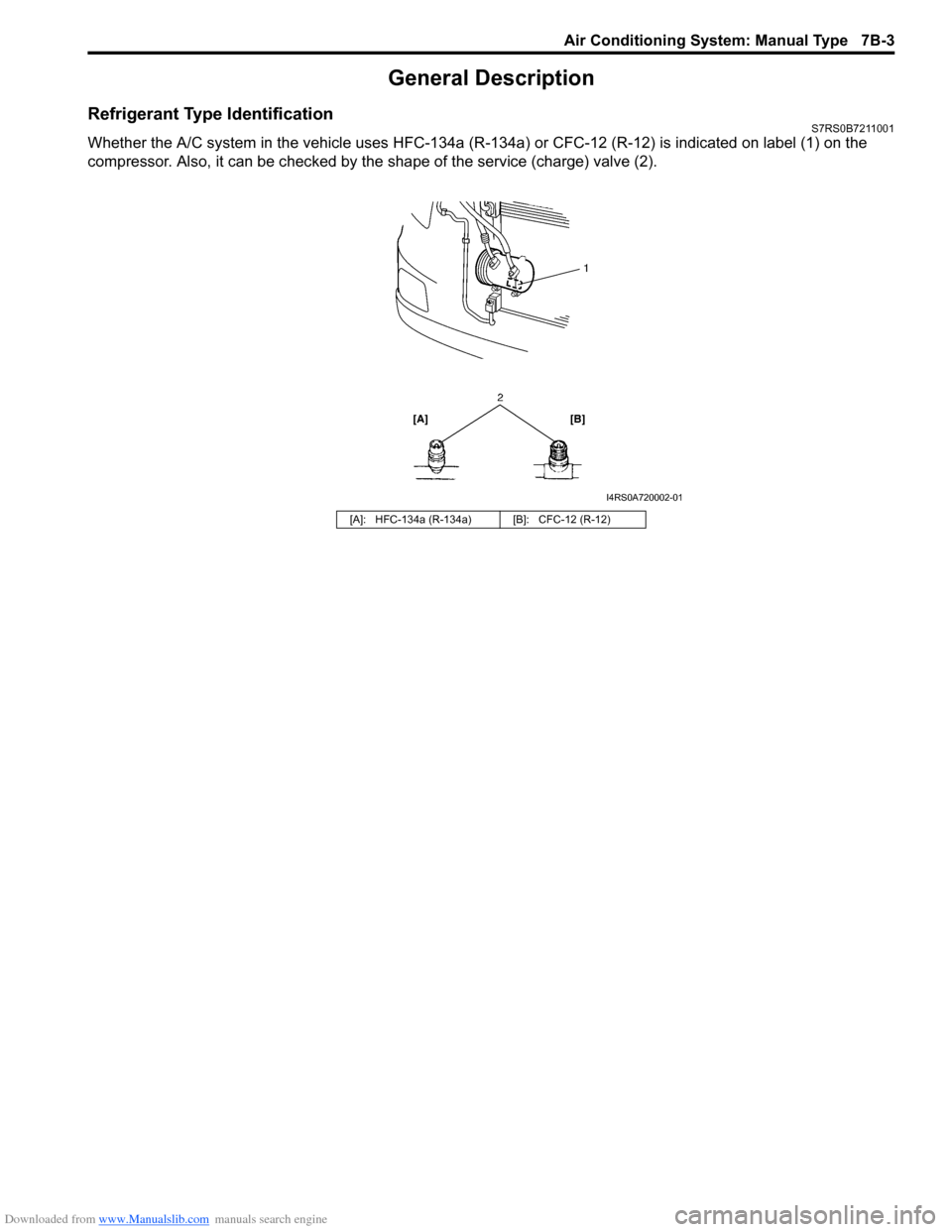

Refrigerant Type IdentificationS7RS0B7211001

Whether the A/C system in the vehicle uses HFC-134a (R-134a) or CFC-12 (R-12) is indicated on label (1) on the

compressor. Also, it can be checked by th e shape of the service (charge) valve (2).

[A]: HFC-134a (R-134a) [B]: CFC-12 (R-12)

I4RS0A720002-01

Page 952 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-4 Air Conditioning System: Manual Type

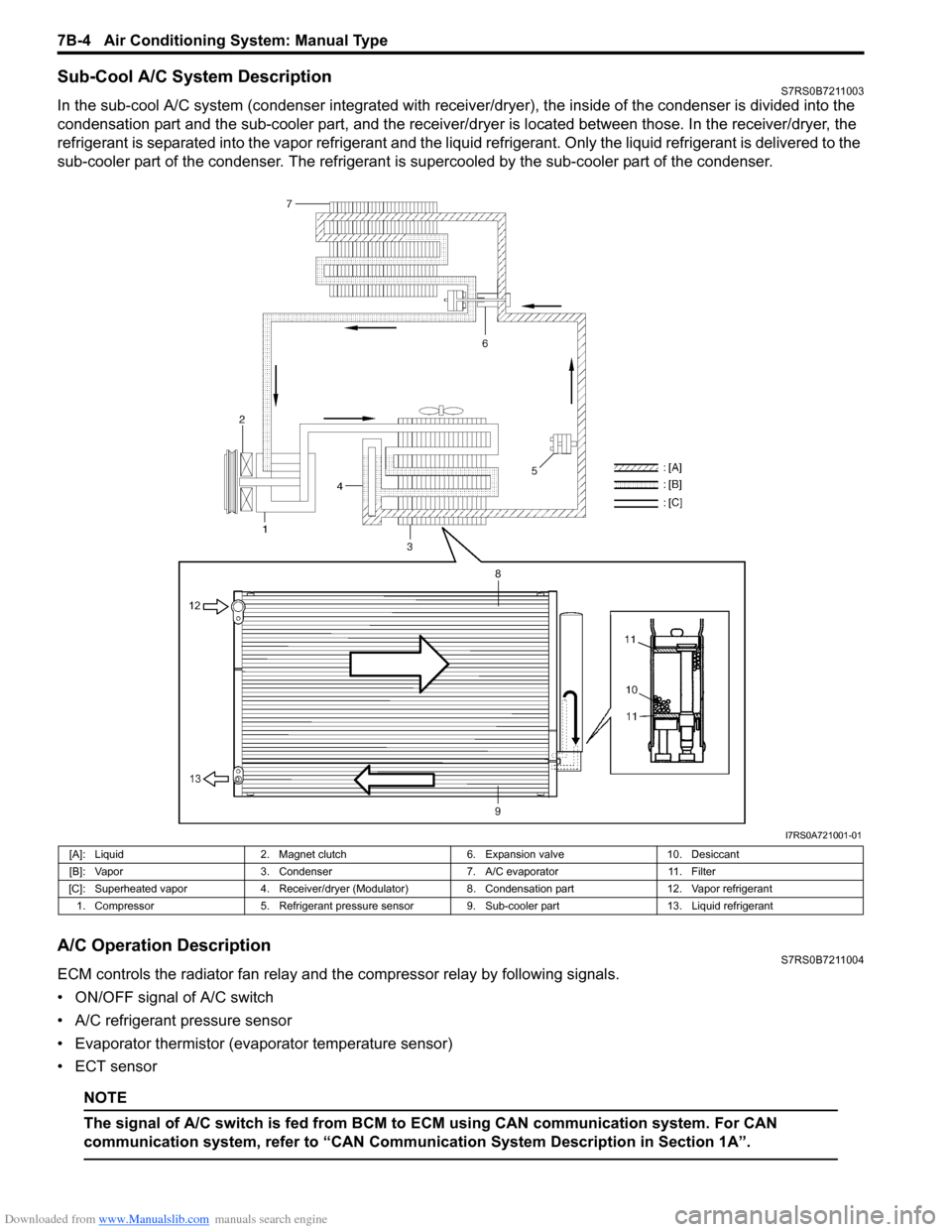

Sub-Cool A/C System DescriptionS7RS0B7211003

In the sub-cool A/C system (condenser integrated with receiver/dryer), the inside of the condenser is divided into the

condensation part and the sub-cooler part, and the receiver/dryer is located between those. In the receiver/dryer, the

refrigerant is separated into the vapor refrigerant and the liqui d refrigerant. Only the liquid refrigerant is delivered to the

sub-cooler part of the condenser. The refrigerant is supercooled by the sub-cooler part of the condenser.

A/C Operation DescriptionS7RS0B7211004

ECM controls the radiator fan relay and the compressor relay by following signals.

• ON/OFF signal of A/C switch

• A/C refrigerant pressure sensor

• Evaporator thermistor (evaporator temperature sensor)

• ECT sensor

NOTE

The signal of A/C swit ch is fed from BCM to ECM usin g CAN communication system. For CAN

communication system, refer to “CAN Communication System Description in Section 1A”.

I7RS0A721001-01

[A]: Liquid 2. Magnet clutch 6. Expansion valve10. Desiccant

[B]: Vapor 3. Condenser 7. A/C evaporator11. Filter

[C]: Superheated vapor 4. Receiver/dryer (Modulator) 8. Condensation part12. Vapor refrigerant

1. Compressor 5. Refrigerant pressure sensor 9. Sub-cooler part 13. Liquid refrigerant

Page 953 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-5

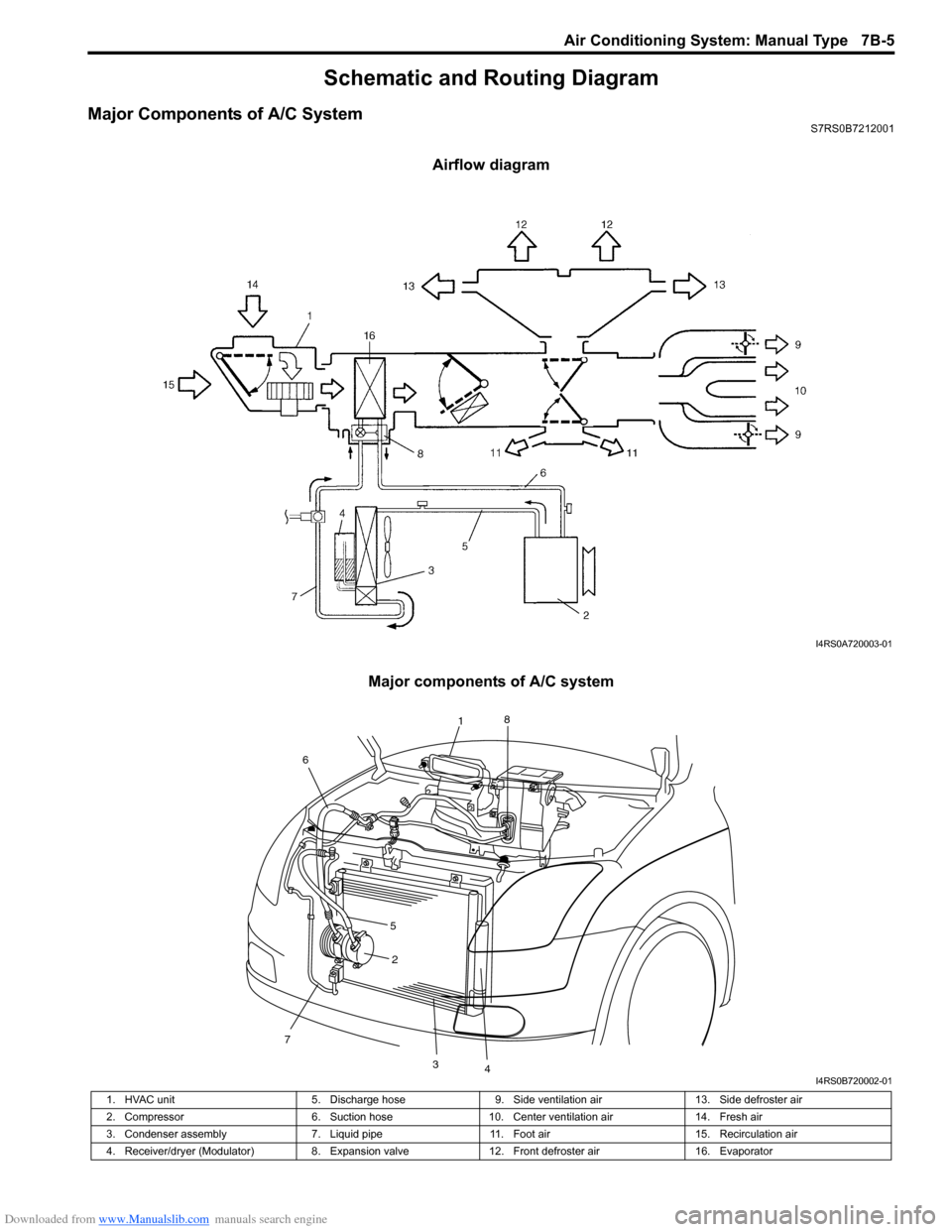

Schematic and Routing Diagram

Major Components of A/C SystemS7RS0B7212001

Airflow diagram

Major components of A/C system

I4RS0A720003-01

7

2

34

1 8

6

5

I4RS0B720002-01

1. HVAC unit 5. Discharge hose9. Side ventilation air 13. Side defroster air

2. Compressor 6. Suction hose10. Center ventilation air 14. Fresh air

3. Condenser assembly 7. Liquid pipe11. Foot air 15. Recirculation air

4. Receiver/dryer (Modulator) 8. Expansion valve12. Front defroster air 16. Evaporator

Page 954 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-6 Air Conditioning System: Manual Type

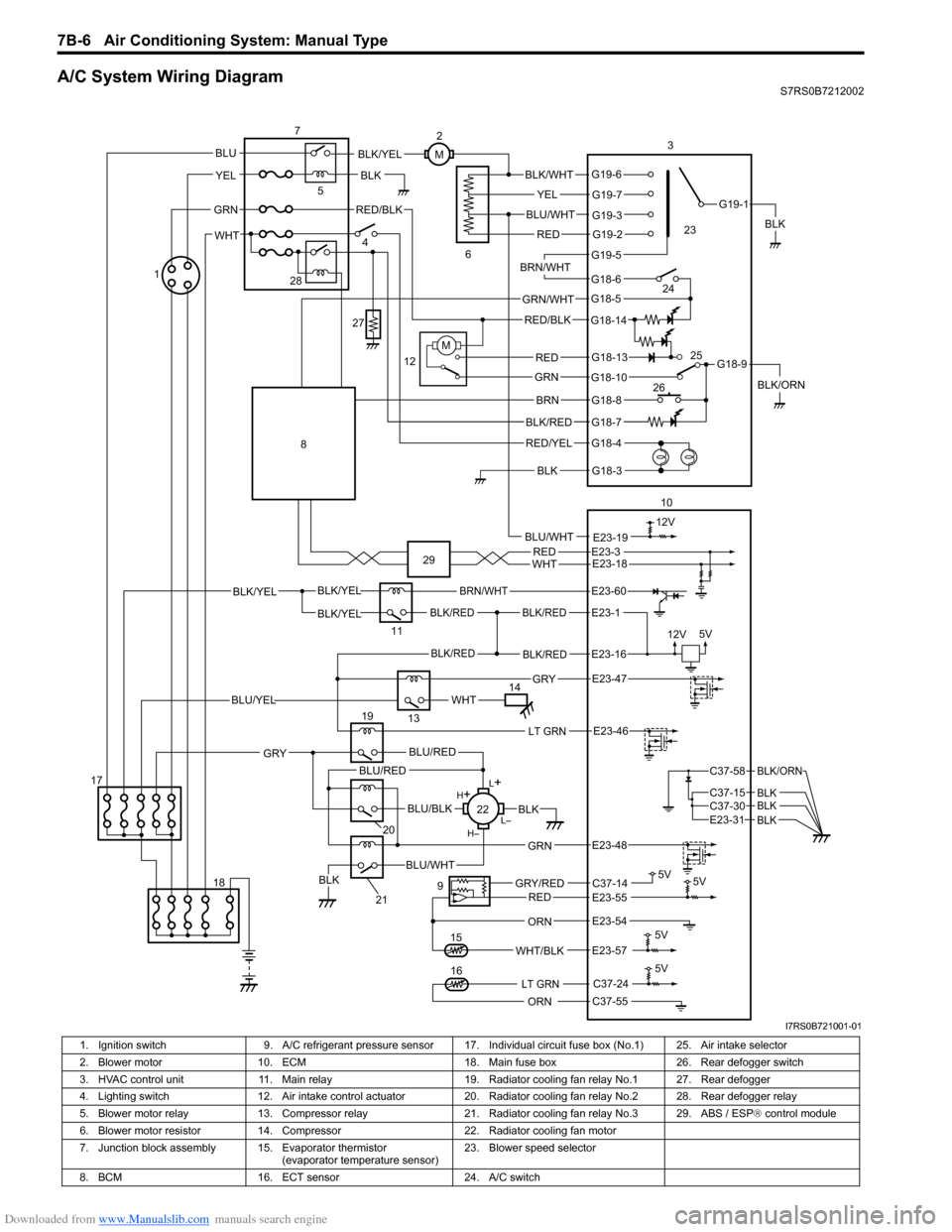

A/C System Wiring DiagramS7RS0B7212002

BLK/REDBLK/RED

BLK/YELBLK/YEL

BLK/YEL

BRN/WHT

12V5V

5V 5V

5V11

E23-1

E23-60

BLK/REDBLK/REDE23-16

E23-57WHT/BLK

9

13

E23-55C37-14GRY/REDRED

BLK

ORN

E23-47 GRY

WHTBLU/YEL

RED/BLK

14 3

1

15

5

7

BLK

2

M

12VBLU/WHTE23-19

C37-24

C37-55ORN

5V

LT GRN16

G18-3

G18-4

G18-7

G18-8

G18-10

G18-13

G18-5

G18-6

G19-5

G19-2

G19-3

G19-7

G19-6

G19-1

G18-9

G18-14

BLK/WHT

YEL

BLU/WHT

RED

BRN/WHT

GRN/WHT

RED/BLK

RED

GRN

BRN

BLK/RED

RED/YEL

BLK

BLK/YEL

BLK/ORN

4

6

12

10

M

E23-54

REDWHTE23-3E23-18

17 18

LT GRNE23-46

L+

L–

H–

H

+

BLU/RED

BLK

BLU/WHTBLK

BLU/BLK

20

GRN

GRY

E23-48

19

21

22

BLU/REDC37-58

C37-15 C37-30

BLK/ORN

BLKBLKE23-31 BLK

BLU

YEL

GRN

WHT

23

24

26 25

28

27

8

29

I7RS0B721001-01

1. Ignition switch

9. A/C refrigerant pressure sensor 17. I ndividual circuit fuse box (No.1) 25. Air intake selector

2. Blower motor 10. ECM 18. Main fuse box 26. Rear defogger switch

3. HVAC control unit 11. Main relay 19. Radiator cooling fan relay No.1 27. Rear defogger

4. Lighting switch 12. Air intake control actuator 20. Radiator cooling fan relay No.2 28. Rear defogger relay

5. Blower motor relay 13. Compressor relay 21. Radiator cooling fan relay No.3 29. ABS / ESP ® control module

6. Blower motor resistor 14. Compressor 22. Radiator cooling fan motor

7. Junction block assembly 15. Evaporator thermistor (evaporator temperature sensor)23. Blower speed selector

8. BCM 16. ECT sensor 24. A/C switch

Page 955 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-7

Diagnostic Information and Procedures

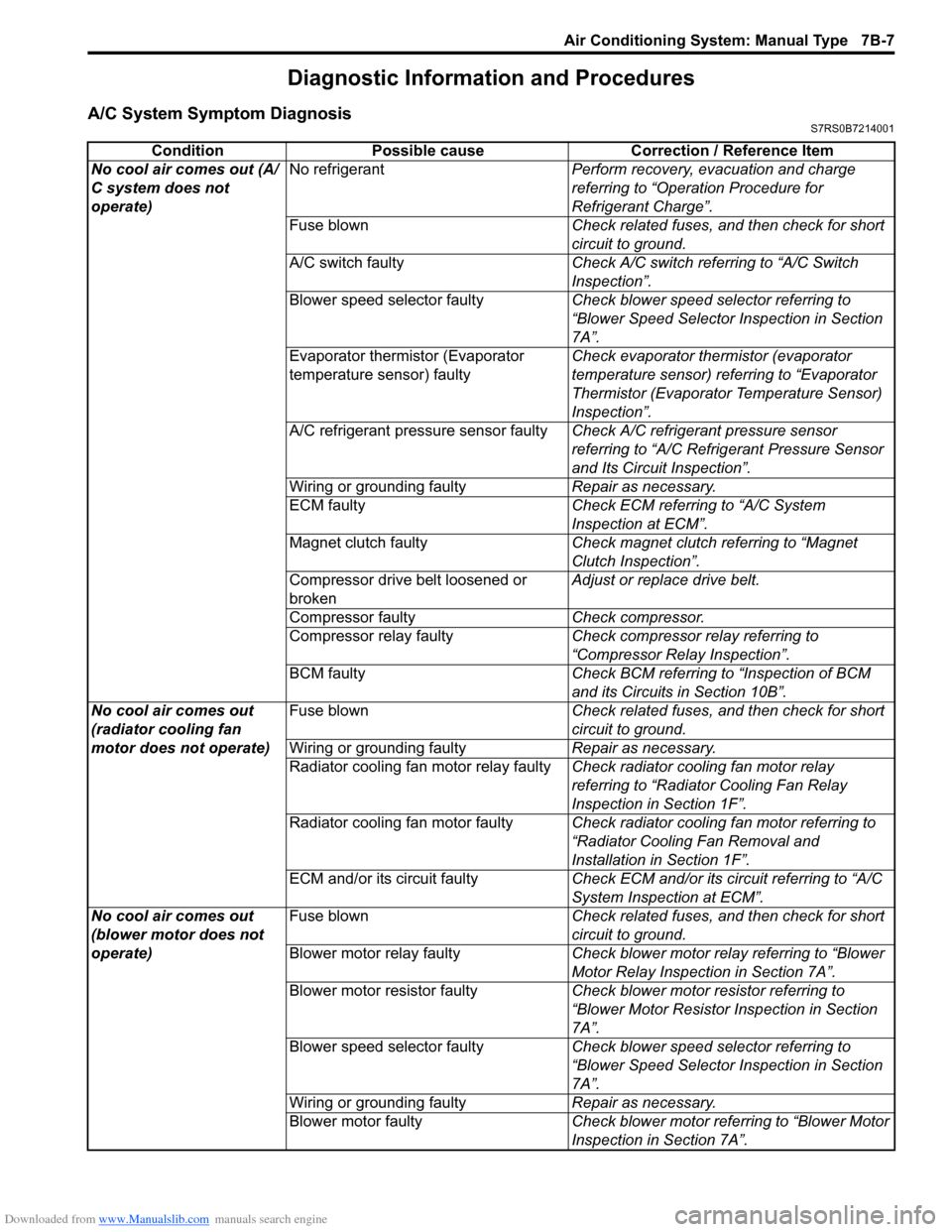

A/C System Symptom DiagnosisS7RS0B7214001

ConditionPossible cause Correction / Reference Item

No cool air comes out (A/

C system does not

operate) No refrigerant

Perform recovery, evacuation and charge

referring to “Operation Procedure for

Refrigerant Charge”.

Fuse blown Check related fuses, and then check for short

circuit to ground.

A/C switch faulty Check A/C switch referring to “A/C Switch

Inspection”.

Blower speed selector faulty Check blower speed selector referring to

“Blower Speed Selector Inspection in Section

7A”.

Evaporator thermistor (Evaporator

temperature sensor) faulty Check evaporator thermistor (evaporator

temperature sensor) referring to “Evaporator

Thermistor (Evaporator Temperature Sensor)

Inspection”.

A/C refrigerant pressure sensor faulty Check A/C refrigerant pressure sensor

referring to “A/C Refrigerant Pressure Sensor

and Its Circuit Inspection”.

Wiring or grounding faulty Repair as necessary.

ECM faulty Check ECM referring to “A/C System

Inspection at ECM”.

Magnet clutch faulty Check magnet clutch referring to “Magnet

Clutch Inspection”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Compressor relay faulty Check compressor relay referring to

“Compressor Relay Inspection”.

BCM faulty Check BCM referring to “Inspection of BCM

and its Circuits in Section 10B”.

No cool air comes out

(radiator cooling fan

motor does not operate) Fuse blown

Check related fuses, and then check for short

circuit to ground.

Wiring or grounding faulty Repair as necessary.

Radiator cooling fan motor relay faulty Check radiator cooling fan motor relay

referring to “Radiator Cooling Fan Relay

Inspection in Section 1F”.

Radiator cooling fan motor faulty Check radiator cooling fan motor referring to

“Radiator Cooling Fan Removal and

Installation in Section 1F”.

ECM and/or its circuit faulty Check ECM and/or its circuit referring to “A/C

System Inspection at ECM”.

No cool air comes out

(blower motor does not

operate) Fuse blown

Check related fuses, and then check for short

circuit to ground.

Blower motor relay faulty Check blower motor relay referring to “Blower

Motor Relay Inspection in Section 7A”.

Blower motor resistor faulty Check blower motor resistor referring to

“Blower Motor Resistor Inspection in Section

7A”.

Blower speed selector faulty Check blower speed selector referring to

“Blower Speed Selector Inspection in Section

7A”.

Wiring or grounding faulty Repair as necessary.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Page 956 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-8 Air Conditioning System: Manual Type

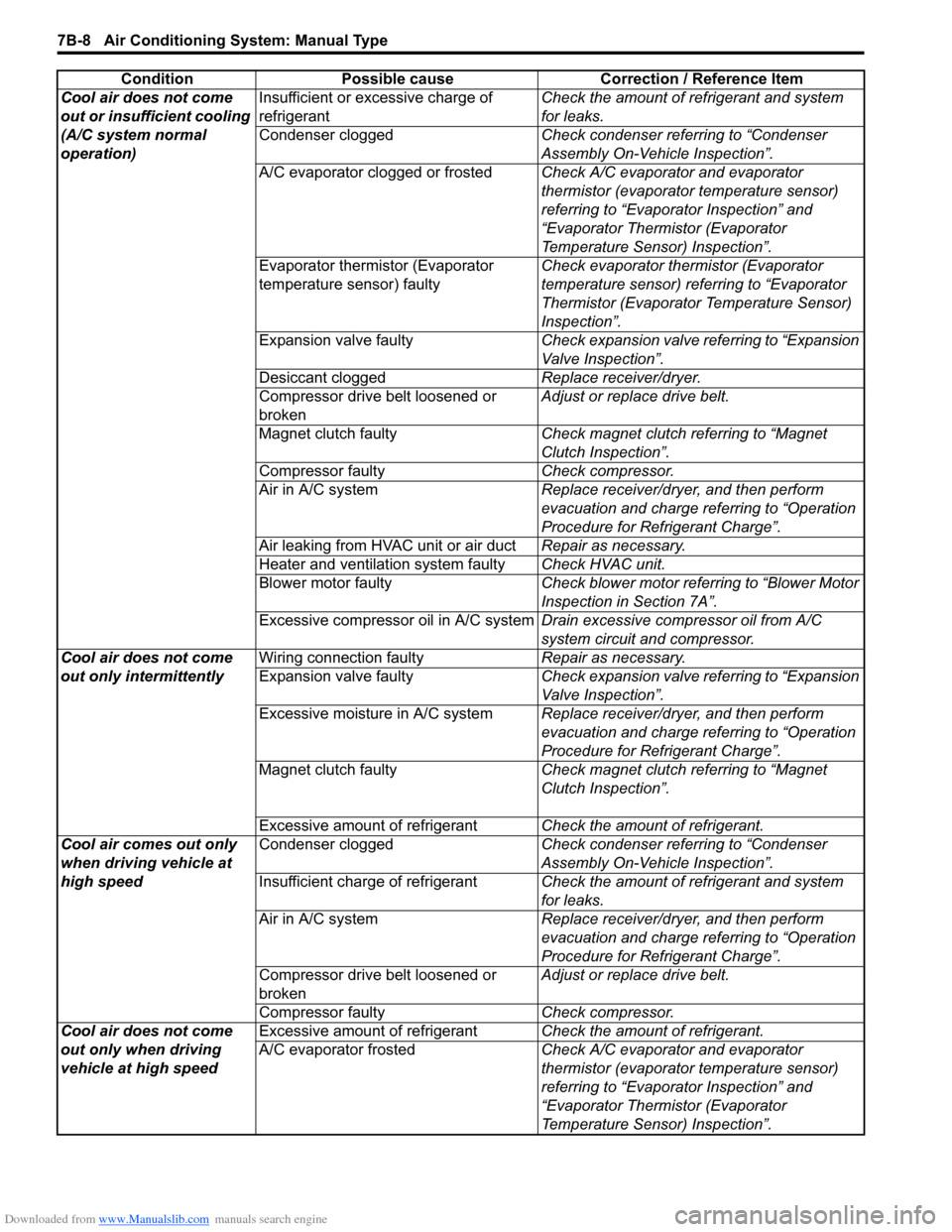

Cool air does not come

out or insufficient cooling

(A/C system normal

operation)Insufficient or excessive charge of

refrigerant

Check the amount of refrigerant and system

for leaks.

Condenser clogged Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

A/C evaporator clogged or frosted Check A/C evaporator and evaporator

thermistor (evaporator temperature sensor)

referring to “Evaporator Inspection” and

“Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Evaporator thermistor (Evaporator

temperature sensor) faulty Check evaporator thermistor (Evaporator

temperature sensor) referring to “Evaporator

Thermistor (Evaporator Temperature Sensor)

Inspection”.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Desiccant clogged Replace receiver/dryer.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Magnet clutch faulty Check magnet clutch referring to “Magnet

Clutch Inspection”.

Compressor faulty Check compressor.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Air leaking from HVAC unit or air duct Repair as necessary.

Heater and ventilation system faulty Check HVAC unit.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Excessive compressor oil in A/C system Drain excessive compressor oil from A/C

system circuit and compressor.

Cool air does not come

out only intermittently Wiring connection faulty

Repair as necessary.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Excessive moisture in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Magnet clutch faulty Check magnet clutch referring to “Magnet

Clutch Inspection”.

Excessive amount of refrigerant Check the amount of refrigerant.

Cool air comes out only

when driving vehicle at

high speed Condenser clogged

Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

Insufficient charge of refrigerant Check the amount of refrigerant and system

for leaks.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Cool air does not come

out only when driving

vehicle at high speed Excessive amount of refrigerant

Check the amount of refrigerant.

A/C evaporator frosted Check A/C evaporator and evaporator

thermistor (evaporator temperature sensor)

referring to “Evaporator Inspection” and

“Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Condition Possible cause Correction / Reference Item