AIR CON SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 872 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-1 Steering Wheel and Column:

Steeri ng

Steering Wheel and Column

Precautions

Service Precautions of Steering Wheel and

Column

S7RS0B6200001

For service precautions, refer to “Precautions on Service

and Diagnosis of Air Bag System in Section 8B”.

Service and Diagnosis

For diagnosis and servicing, refer to “Precautions on

Service and Diagnosis of Air Bag System in Section 8B”.

Disabling Air Bag System

For disabling air bag system, refer to “Disabling Air Bag

System in Section 8B”. Enabling Air Bag System

For enabling air bag system, refer to “Enabling Air Bag

System in Section 8B”.

Handling and Storage

For handling and storage, refer to “Precautions on

Handling and Storage of Air Bag System Components in

Section 8B”.

Disposal

For disposal, refer to “Prec

autions on Disposal of Air

Bag and Seat Belt Pretensioner in Section 8B”.

General Description

Steering Wheel and Column ConstructionS7RS0B6201001

This double tube type steering column has the following three important features in addition to the steering function:

• The column is energy absorbing, desig ned to compress in a front-end collision.

• The ignition switch and lock are mounted conveniently on this column.

• With the column mounted lock, the ignition and steering op erations can be locked to inhibit theft of the vehicle.

To insure the energy absorbing action, it is important th at only the specified screws, bolts and nuts be used as

designated, and that they are tightened to the specified torque. When the column assembly is removed from the

vehicle, special care must be taken in handling it. Use of a steering wheel puller or a sharp blow on the end of the

steering shaft, leaning on the assembly, or dropping the a ssembly could shear the plastic shear pins which maintain

column length and position.

The driver air bag (inflator) module is one of the supplemental restraint (air bag) system components and is mounted

to the center of the steering wheel. During certain frontal crashes, the air bag system supplements the restraint of the

driver’s and passenger’s seat belts by deploying the air b ags. The air bag (inflator) module should be handled with

care to prevent accidental deployment. When servicing, be sure to observe “Precautions on Service and Diagnosis of

Air Bag System in Section 8B”.

Page 874 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-3 Steering Wheel and Column:

Repair Instructions

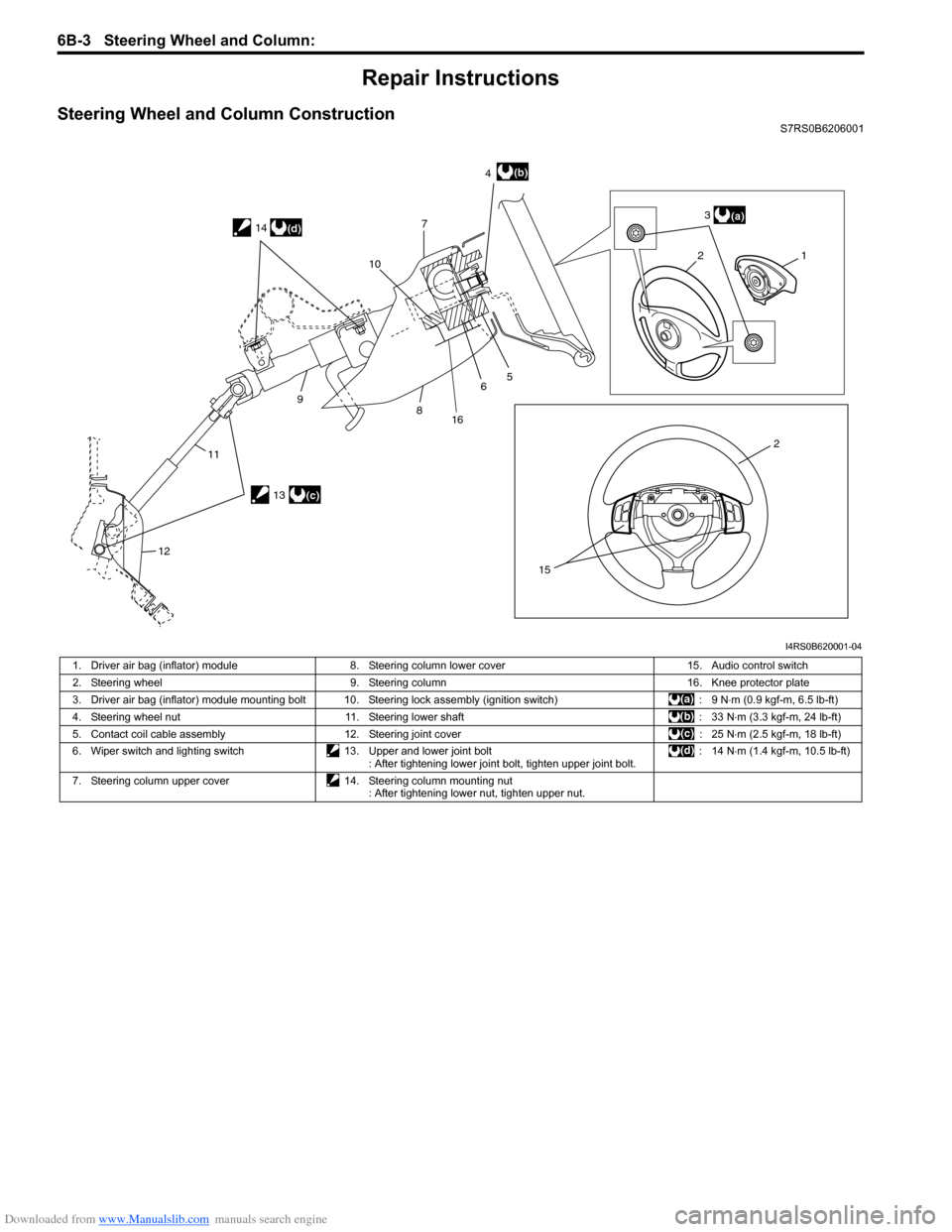

Steering Wheel and Column ConstructionS7RS0B6206001

21

2 3

4

7

5

6

8

9

11

12 10

15

(a)

(b)

13(c)

14

(d)

16

I4RS0B620001-04

1. Driver air bag (inflator) module

8. Steering column lower cover 15. Audio control switch

2. Steering wheel 9. Steering column 16. Knee protector plate

3. Driver air bag (inflator) module mounting bolt 10. Steering lock assembly (ignition switch) : 9 N⋅m (0.9 kgf-m, 6.5 lb-ft)

4. Steering wheel nut 11. Steering lower shaft : 33 N⋅m (3.3 kgf-m, 24 lb-ft)

5. Contact coil cable assembly 12. Steering joint cover : 25 N⋅m (2.5 kgf-m, 18 lb-ft)

6. Wiper switch and lighting switch 13. Upper and lower joint bolt

: After tightening lower joint bolt, tighten upper joint bolt. : 14 N

⋅m (1.4 kgf-m, 10.5 lb-ft)

7. Steering column upper cover 14. Steering column mounting nut

: After tightening lower nut, tighten upper nut.

Page 875 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-4

Steering Wheel Removal and InstallationS7RS0B6206002

CAUTION!

Do not turn the contact coil more than

allowable number of turns (about two and a

half turns from the center position clockwise

or counterclockwise respectively) with

steering wheel removed, or coil will break.

Removal

CAUTION!

Do not hammer the end of the shaft.

Hammering it will loosen the plastic shear

pins which maintain the column length and

impair the collapsible design of the column.

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air

Bag System in Section 8B”.

3) Remove driver air bag (inflator) module from steering wheel. Refer to “Driver Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Disconnect horn connector and audio control switch connector, if equipped.

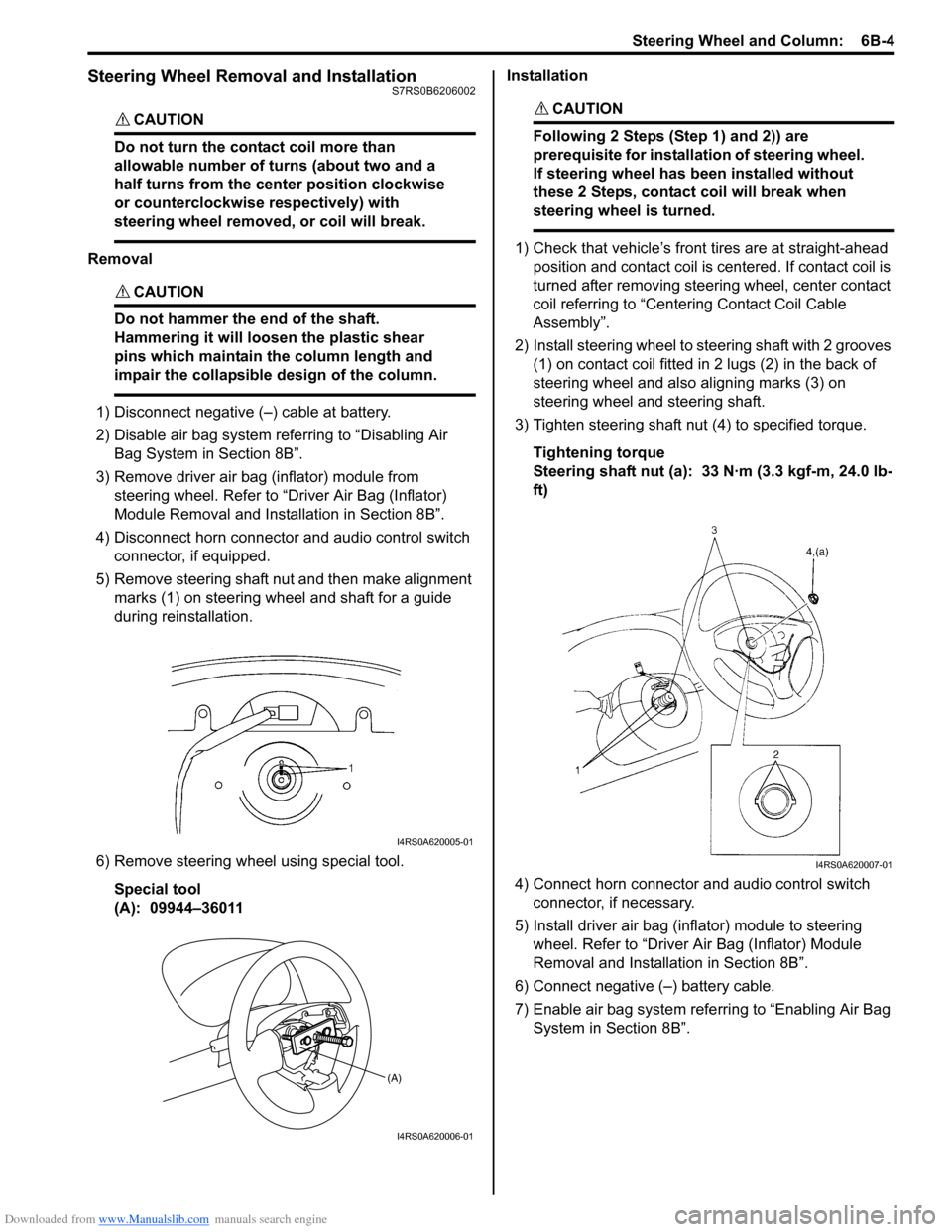

5) Remove steering shaft nut and then make alignment marks (1) on steering wheel and shaft for a guide

during reinstallation.

6) Remove steering wheel using special tool. Special tool

(A): 09944–36011 Installation

CAUTION!

Following 2 Steps (Step 1) and 2)) are

prerequisite for installation of steering wheel.

If steering wheel has

been installed without

these 2 Steps, contact coil will break when

steering wheel is turned.

1) Check that vehicle’s front tires are at straight-ahead position and contact coil is centered. If contact coil is

turned after removing steering wheel, center contact

coil referring to “Centering Contact Coil Cable

Assembly”.

2) Install steering wheel to steering shaft with 2 grooves (1) on contact coil fitted in 2 lugs (2) in the back of

steering wheel and also aligning marks (3) on

steering wheel and steering shaft.

3) Tighten steering shaft nut (4) to specified torque.

Tightening torque

Steering shaft nut (a): 33 N·m (3.3 kgf-m, 24.0 lb-

ft)

4) Connect horn connector and audio control switch connector, if necessary.

5) Install driver air bag (inflator) module to steering wheel. Refer to “Driver Air Bag (Inflator) Module

Removal and Installati on in Section 8B”.

6) Connect negative (–) battery cable.

7) Enable air bag system refe rring to “Enabling Air Bag

System in Section 8B”.

I4RS0A620005-01

(A)

I4RS0A620006-01

I4RS0A620007-01

Page 876 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-5 Steering Wheel and Column:

Contact Coil Cable Assembly Removal and

Installation

S7RS0B6206003

CAUTION!

Do not turn contact coil more than allowable

number of turns (about two and a half turns

from the center position clockwise or

counterclockwise respectively), or coil will

break.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove steering wheel from steering column referring to “Steering Wheel Removal and

Installation”.

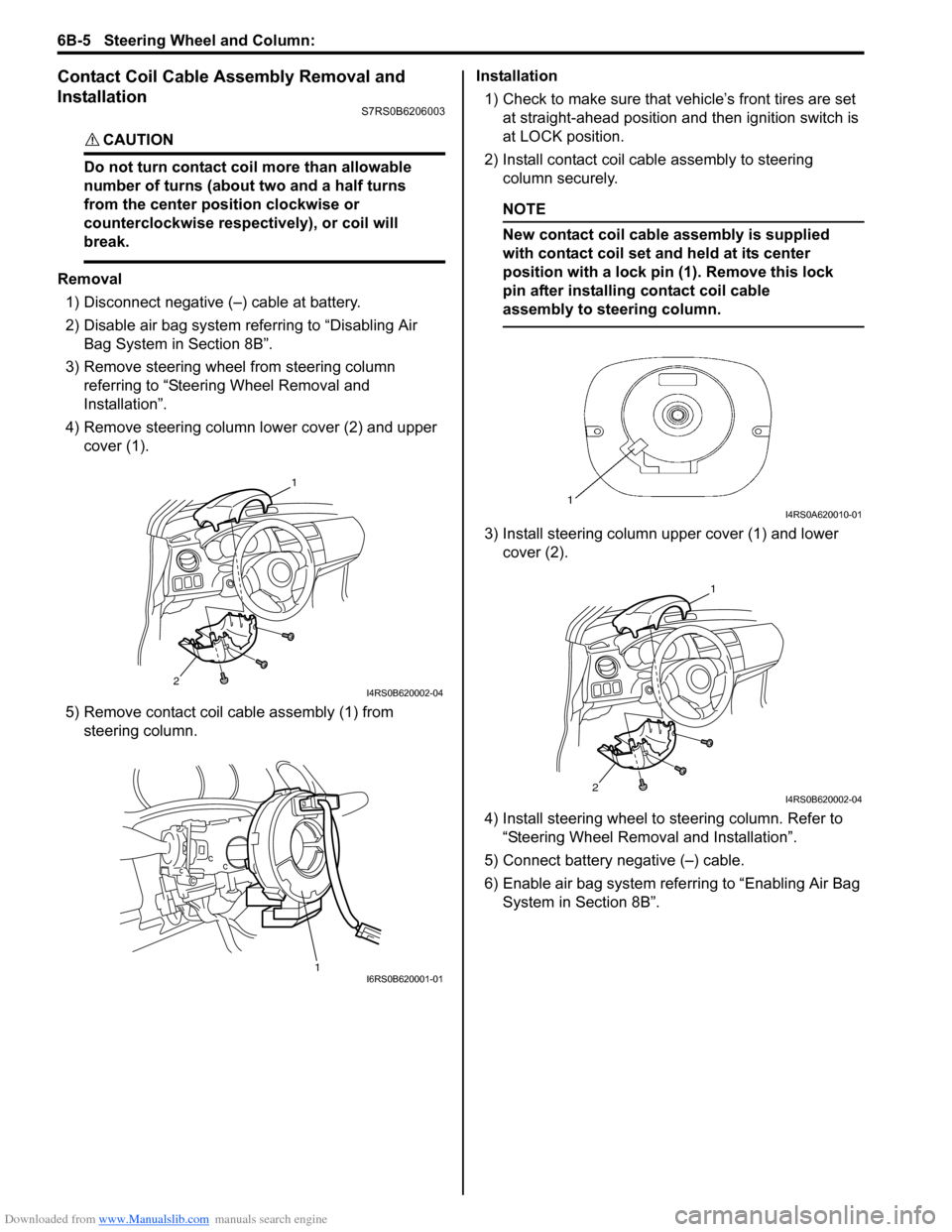

4) Remove steering column lower cover (2) and upper cover (1).

5) Remove contact coil cable assembly (1) from steering column. Installation

1) Check to make sure that vehicle’s front tires are set

at straight-ahead position and then ignition switch is

at LOCK position.

2) Install contact coil cable assembly to steering column securely.

NOTE

New contact coil cable assembly is supplied

with contact coil set and held at its center

position with a lock pin (1). Remove this lock

pin after installing contact coil cable

assembly to steering column.

3) Install steering column upper cover (1) and lower cover (2).

4) Install steering wheel to steering column. Refer to

“Steering Wheel Removal and Installation”.

5) Connect battery negative (–) cable.

6) Enable air bag system refe rring to “Enabling Air Bag

System in Section 8B”.

2

1

I4RS0B620002-04

1I6RS0B620001-01

I4RS0A620010-01

2

1

I4RS0B620002-04

Page 878 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-7 Steering Wheel and Column:

Steering Column Removal and InstallationS7RS0B6206006

CAUTION!

Once the steering column is removed from

the vehicle, the column is extremely

susceptible to damage.

• Dropping the column assembly on its end could collapse the steering shaft or loosen

the plastic shear pins which maintain

column length.

• Leaning on the column assembly could cause it to bend or deform.

Any of the damage could impair the column’s

collapsible design.

Steering column mounting nuts should not

be loosened with steering shaft joint upper

side bolt tightened as this could cause

damage to shaft joint bearing.

NOTE

When servicing steering column or any

column-mounted component, remove

steering wheel. But when removing steering

column simply to gain access to instrument

panel components, leave steering wheel

installed on steering column.

Removal

WARNING!

Never rest a steering column assembly on

the steering wheel with the air bag (inflator)

module face down and column vertical.

Otherwise, personal injury may result.

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Re fer to “Disabling Air Bag

System in Section 8B”.

3) Remove steering wheel and contact coil cable assembly referring to “S teering Wheel Removal and

Installation” and “Contact Coil Cable Assembly

Removal and Installation”.

4) Detach lighting switch and wiper switch from steering column.

5) Remove immobilizer cont rol module from steering

column, referring to “Immo bilizer Control Module

(ICM) Removal and Installation in Section 10C”.

6) Remove steering column hole cover.

7) Remove steering joint cover.

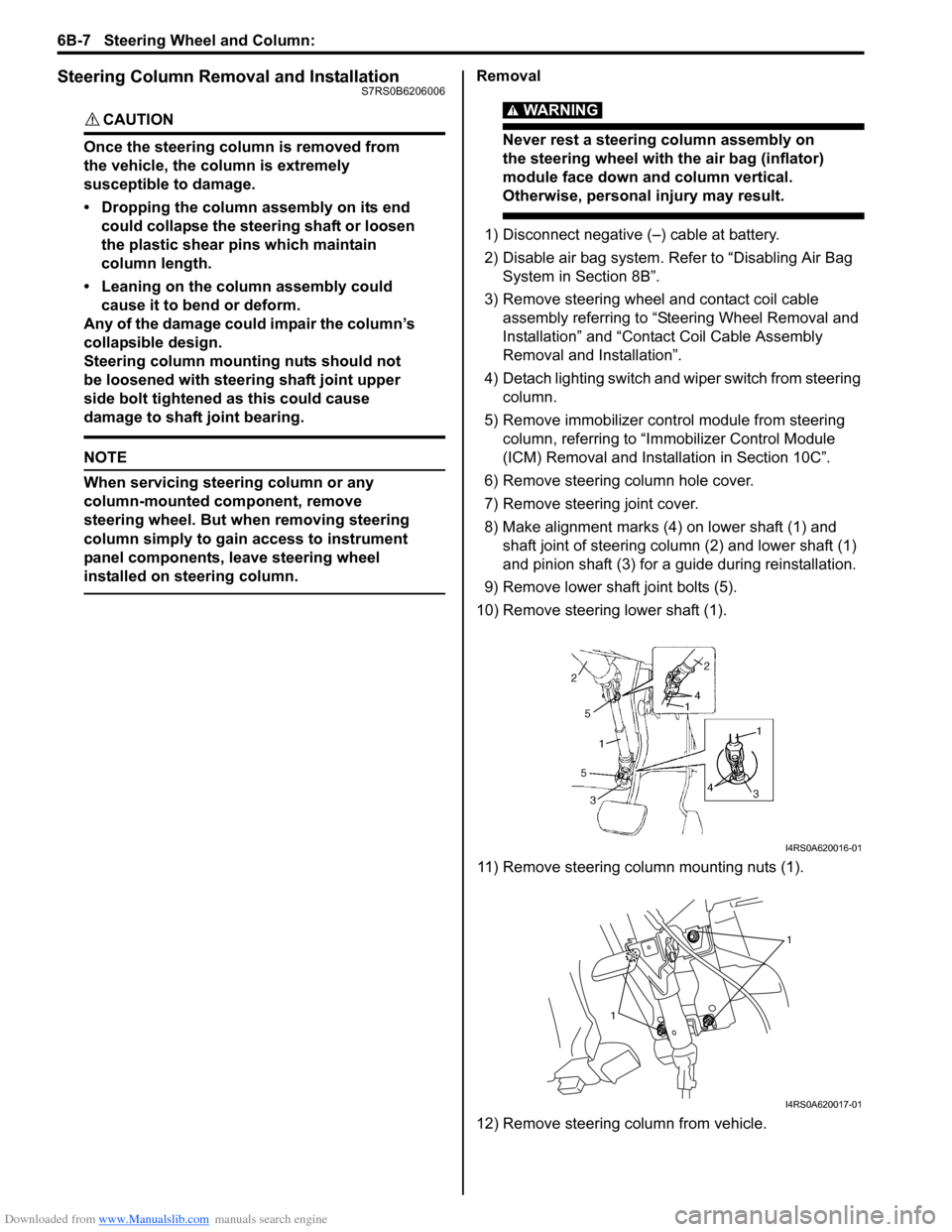

8) Make alignment marks (4) on lower shaft (1) and shaft joint of steering column (2) and lower shaft (1)

and pinion shaft (3) for a guide during reinstallation.

9) Remove lower shaf t joint bolts (5).

10) Remove steering lower shaft (1).

11) Remove steering column mounting nuts (1).

12) Remove steering column from vehicle.

I4RS0A620016-01

1

1

I4RS0A620017-01

Page 879 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-8

Installation

CAUTION!

After tightening steering column mounting

nuts, shaft joint bolts should be tightened.

Wrong tightening order could cause a

damage to shaft joint.

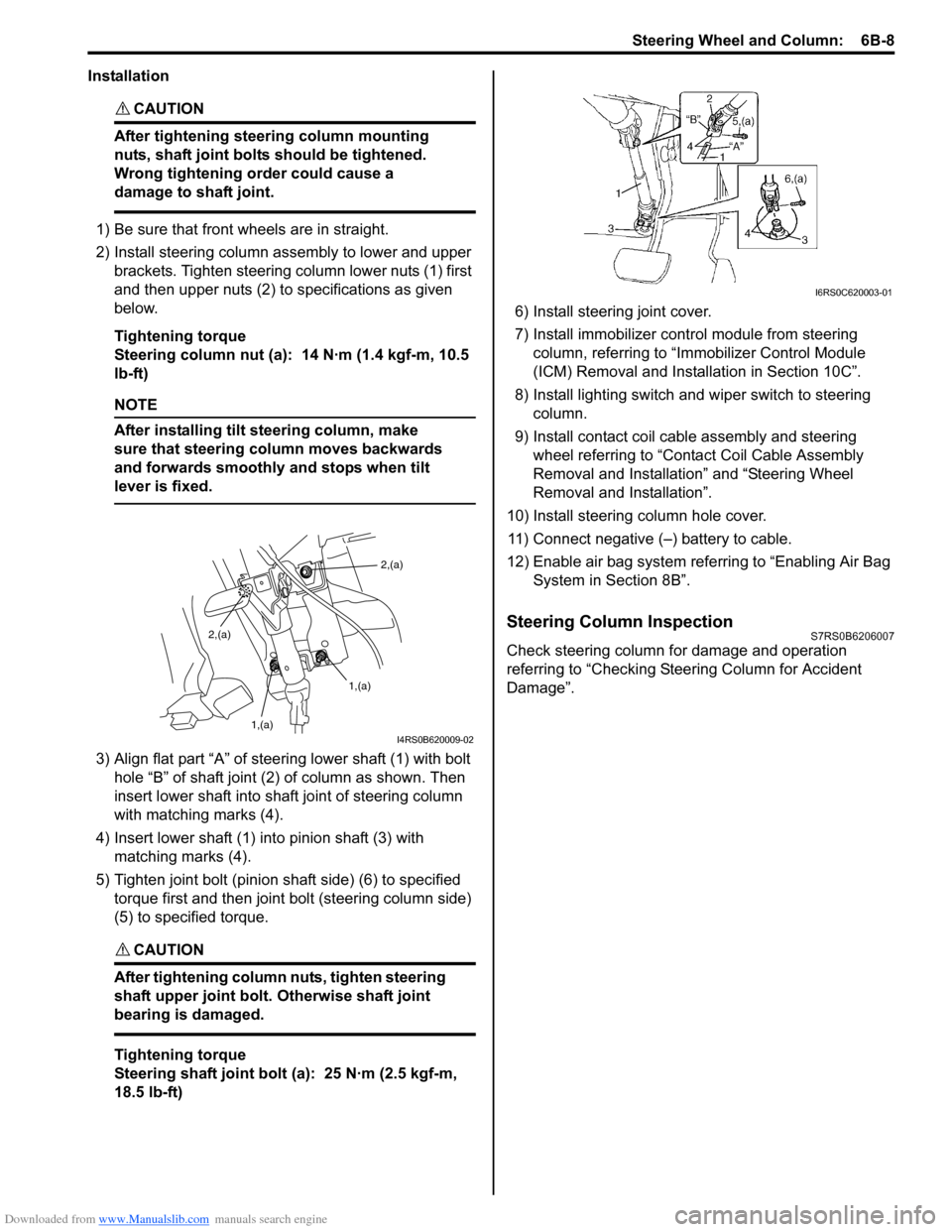

1) Be sure that front wheels are in straight.

2) Install steering column assembly to lower and upper brackets. Tighten steering column lower nuts (1) first

and then upper nuts (2) to specifications as given

below.

Tightening torque

Steering column nut (a): 14 N·m (1.4 kgf-m, 10.5

lb-ft)

NOTE

After installing tilt steering column, make

sure that steering column moves backwards

and forwards smoothly and stops when tilt

lever is fixed.

3) Align flat part “A” of stee ring lower shaft (1) with bolt

hole “B” of shaft joint (2) of column as shown. Then

insert lower shaft into shaf t joint of steering column

with matching marks (4).

4) Insert lower shaft (1) into pinion shaft (3) with matching marks (4).

5) Tighten joint bolt (pinion shaft side) (6) to specified torque first and then joint bolt (steering column side)

(5) to specified torque.

CAUTION!

After tightening column nuts, tighten steering

shaft upper joint bolt. Otherwise shaft joint

bearing is damaged.

Tightening torque

Steering shaft joint bolt (a): 25 N·m (2.5 kgf-m,

18.5 lb-ft) 6) Install steering joint cover.

7) Install immobilizer cont

rol module from steering

column, referring to “Immo bilizer Control Module

(ICM) Removal and Installation in Section 10C”.

8) Install lighting switch and wiper switch to steering column.

9) Install contact coil cable assembly and steering wheel referring to “Conta ct Coil Cable Assembly

Removal and Installation” and “Steering Wheel

Removal and Installation”.

10) Install steering column hole cover. 11) Connect negative (–) battery to cable.

12) Enable air bag system refe rring to “Enabling Air Bag

System in Section 8B”.

Steering Column InspectionS7RS0B6206007

Check steering column for damage and operation

referring to “Checking Steering Column for Accident

Damage”.

2,(a)

1,(a)

1,(a)

2,(a)

I4RS0B620009-02

I6RS0C620003-01

Page 880 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-9 Steering Wheel and Column:

Ignition Switch Cylinder Assembly Removal

and Installation (Non- Keyless Start Model)

S7RS0B6206008

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove steering column upper and lower covers.

4) Remove immobilizer co ntrol module referring to

“Immobilizer Control Modu le (ICM) Removal and

Installation in Section 10C”.

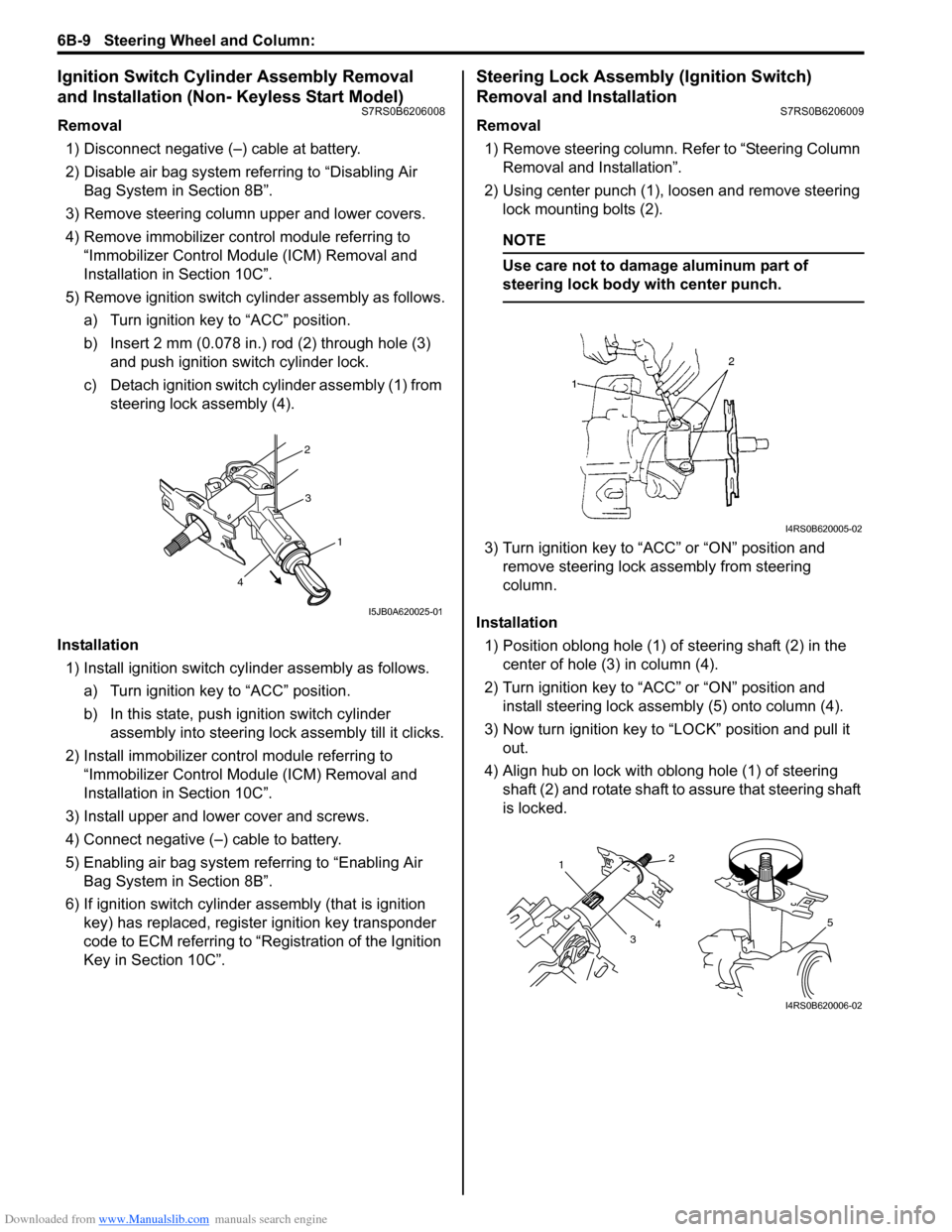

5) Remove ignition switch cy linder assembly as follows.

a) Turn ignition key to “ACC” position.

b) Insert 2 mm (0.078 in.) rod (2) through hole (3) and push ignition switch cylinder lock.

c) Detach ignition switch cylinder assembly (1) from steering lock assembly (4).

Installation 1) Install ignition switch cy linder assembly as follows.

a) Turn ignition key to “ACC” position.

b) In this state, push ignition switch cylinder assembly into steering lock assembly till it clicks.

2) Install immobilizer cont rol module referring to

“Immobilizer Control Modu le (ICM) Removal and

Installation in Section 10C”.

3) Install upper and lower cover and screws.

4) Connect negative (–) cable to battery.

5) Enabling air bag system referring to “Enabling Air Bag System in Section 8B”.

6) If ignition switch cylinder assembly (that is ignition

key) has replaced, register ignition key transponder

code to ECM referring to “R egistration of the Ignition

Key in Section 10C”.

Steering Lock Assembly (Ignition Switch)

Removal and Installation

S7RS0B6206009

Removal

1) Remove steering column. Refer to “Steering Column

Removal and Installation”.

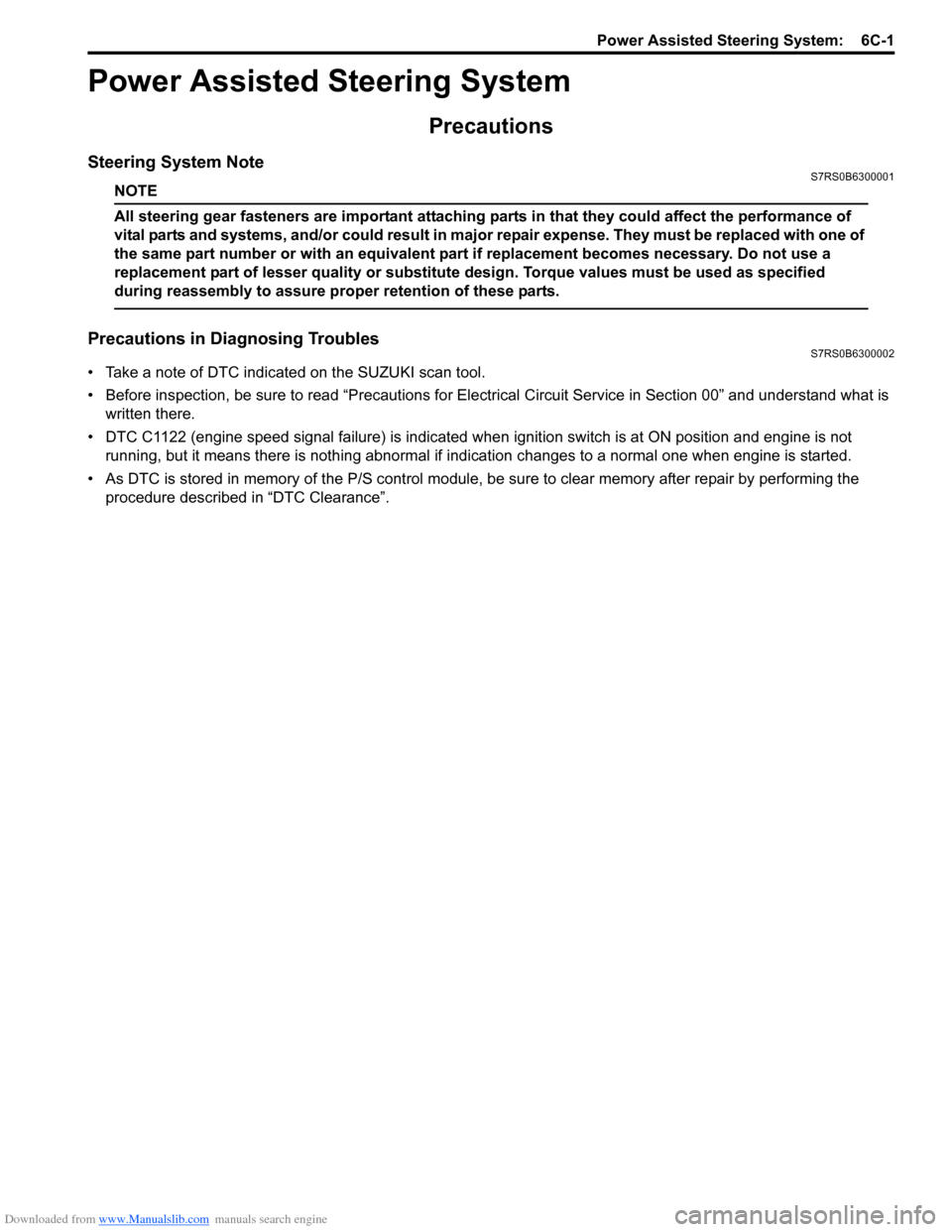

2) Using center punch (1), loosen and remove steering lock mounting bolts (2).

NOTE

Use care not to damage aluminum part of

steering lock body with center punch.

3) Turn ignition key to “ACC” or “ON” position and remove steering lock a ssembly from steering

column.

Installation 1) Position oblong hole (1) of steering shaft (2) in the center of hole (3) in column (4).

2) Turn ignition key to “ACC” or “ON” position and install steering lock assemb ly (5) onto column (4).

3) Now turn ignition key to “LOCK” position and pull it out.

4) Align hub on lock with oblong hole (1) of steering shaft (2) and rotate shaft to assure that steering shaft

is locked.

2

3

1

4

I5JB0A620025-01

I4RS0B620005-02

1

32

4

5

I4RS0B620006-02

Page 883 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-1

Steeri ng

Power Assisted Steering System

Precautions

Steering System NoteS7RS0B6300001

NOTE

All steering gear fasteners are important attaching parts in that they could affect the performance of

vital parts and systems, and/or could result in major repair expense. They must be replaced with one of

the same part number or with an equivalent part if replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. Torque values must be used as specified

during reassembly to assure proper retention of these parts.

Precautions in Diagnosing TroublesS7RS0B6300002

• Take a note of DTC indicated on the SUZUKI scan tool.

• Before inspection, be sure to read “Pre cautions for Electrical Circuit Service in Section 00” and understand what is

written there.

• DTC C1122 (engine speed signal failure) is indicated when ignition switch is at ON position and engine is not

running, but it means there is nothing abnormal if indica tion changes to a normal one when engine is started.

• As DTC is stored in memory of the P/S control module, be sure to clear memory after repair by performing the

procedure described in “DTC Clearance”.

Page 886 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

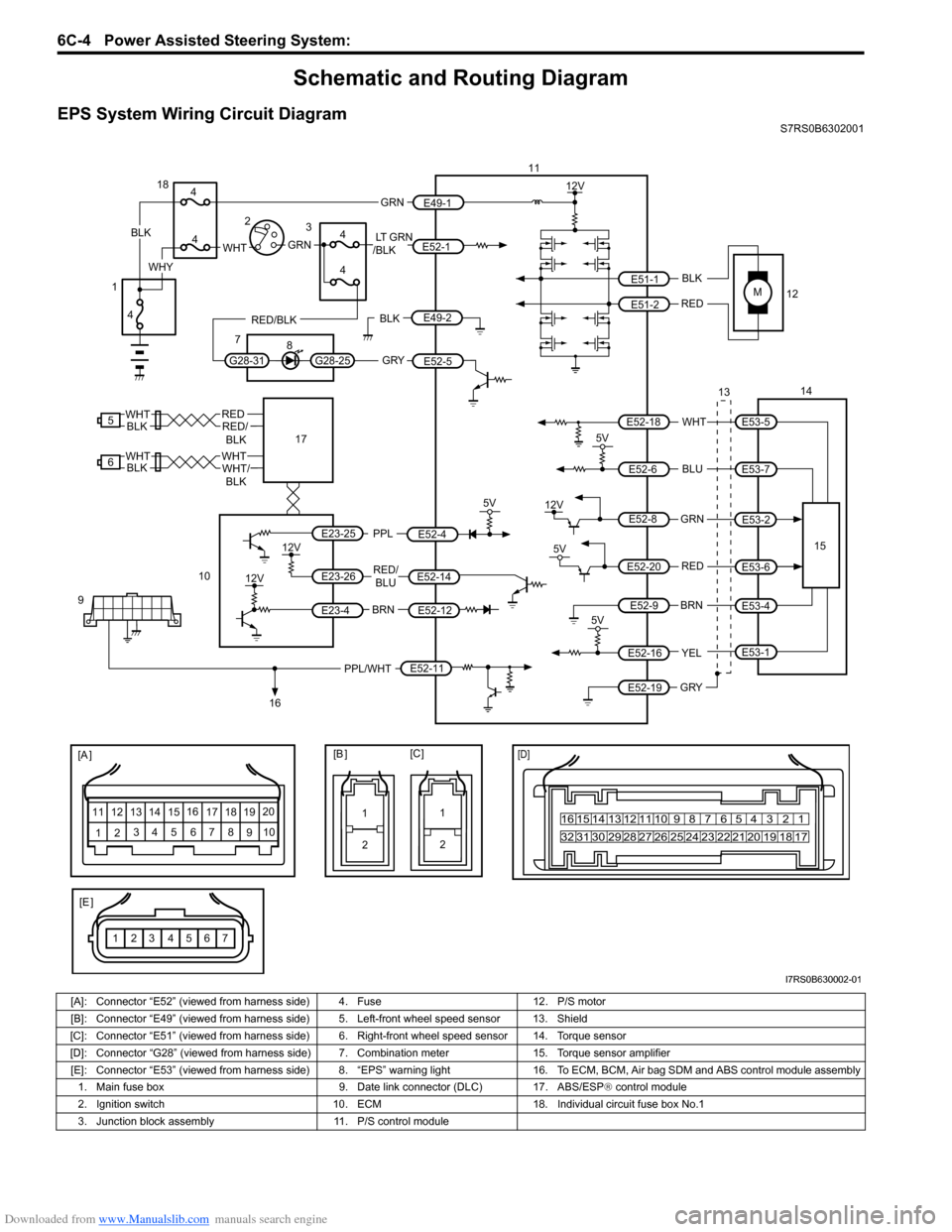

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS7RS0B6302001

M

5V

BRNRED/

BLU

BLK

RED

WHT

BLU

GRN

BRN YEL

E52-11

E52-14E52-12

E23-4

E23-26

E23-25 E51-1

E51-2

E52-18

E53-5

E53-7

E52-6

E52-8

E53-2

E52-9

E52-16

E52-19

GRY

PPL/WHT

[A ]

[E ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

1

2

[B ][C ]

1210 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[D]

5V

PPL

E52-4

11

12

13 14

15

10

9

16

12V

5V

5V

12V

REDE52-20E53-6

E53-4

E53-1

7654321

5

REDRED/

BLKWHT

6WHTWHT/BLKWHTBLK

12V

12V

17BLK

GRY

LT GRN

/BLK

E52-1

E52-5

E49-1

GRNGRNWHTBLK

WHY

G28-25G28-31

RED/BLK

18

3

4

4

7 8

4

4

1 2

4

E49-2BLK

I7RS0B630002-01

[A]: Connector “E52” (viewed from harness side) 4. Fuse 12. P/S motor

[B]: Connector “E49” (viewed from harness side ) 5. Left-front wheel speed sensor 13. Shield

[C]: Connector “E51” (viewed from harness side) 6 . Right-front wheel speed sensor 14. Torque sensor

[D]: Connector “G28” (viewed from harness side) 7. Combination meter 15. Torque sensor amplifier

[E]: Connector “E53” (viewed from harness side) 8. “EPS” warning light16. To ECM, BCM, Air bag SDM and ABS control module assembly

1. Main fuse box 9. Date link connector (DLC) 17. ABS/ESP ® control module

2. Ignition switch 10. ECM18. Individual circuit fuse box No.1

3. Junction block assembly 11. P/S control module

Page 887 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-5

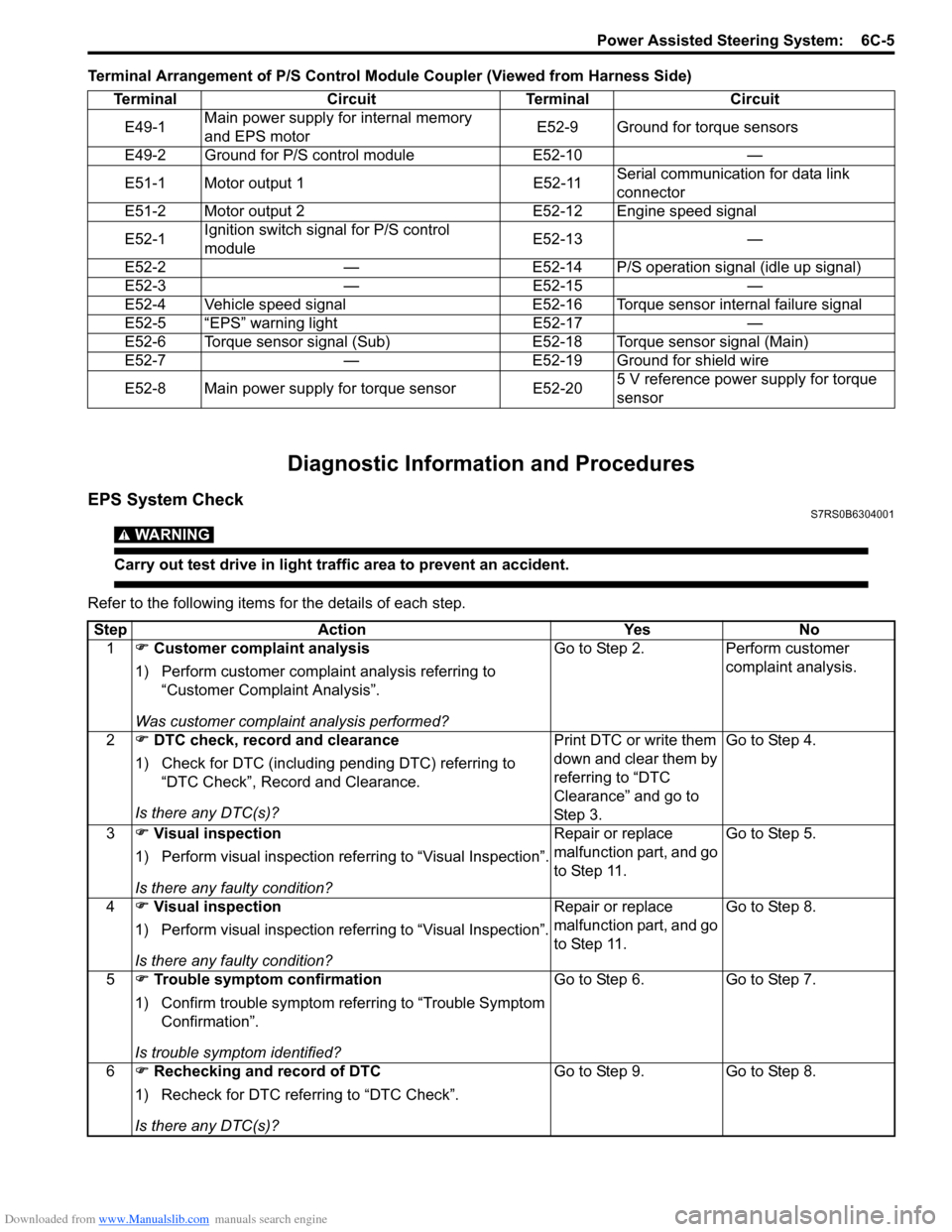

Terminal Arrangement of P/S Control Module Coupler (Viewed from Harness Side)

Diagnostic Information and Procedures

EPS System CheckS7RS0B6304001

WARNING!

Carry out test drive in light traffic area to prevent an accident.

Refer to the following items for the details of each step.Terminal Circuit Terminal Circuit

E49-1 Main power supply for internal memory

and EPS motor E52-9 Ground for torque sensors

E49-2 Ground for P/S control module E52-10 —

E51-1 Motor output 1 E52-11 Serial communication for data link

connector

E51-2 Motor output 2 E52-12 Engine speed signal

E52-1 Ignition switch signal for P/S control

module E52-13 —

E52-2 — E52-14 P/S operation signal (idle up signal)

E52-3 — E52-15 —

E52-4 Vehicle speed signal E52-16 Torque sensor internal failure signal

E52-5 “EPS” warning light E52-17 —

E52-6 Torque sensor signal (Sub) E52-18 Torque sensor signal (Main)

E52-7 — E52-19 Ground for shield wire

E52-8 Main power supply for torque sensor E52-20 5 V reference power supply for torque

sensor

Step

Action YesNo

1 �) Customer complaint analysis

1) Perform customer complaint analysis referring to “Customer Complaint Analysis”.

Was customer complaint analysis performed? Go to Step 2.

Perform customer

complaint analysis.

2 �) DTC check, record and clearance

1) Check for DTC (including pending DTC) referring to “DTC Check”, Record and Clearance.

Is there any DTC(s)? Print DTC or write them

down and clear them by

referring to “DTC

Clearance” and go to

St ep 3 .Go to Step 4.

3 �) Visual inspection

1) Perform visual inspection referring to “Visual Inspection”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 11.

Go to Step 5.

4 �) Visual inspection

1) Perform visual inspection referring to “Visual Inspection”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 11.

Go to Step 8.

5 �) Trouble symptom confirmation

1) Confirm trouble symptom referring to “Trouble Symptom Confirmation”.

Is trouble symptom identified? Go to Step 6.

Go to Step 7.

6 �) Rechecking and record of DTC

1) Recheck for DTC referring to “DTC Check”.

Is there any DTC(s)? Go to Step 9.

Go to Step 8.