ect sensor SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 956 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-8 Air Conditioning System: Manual Type

Cool air does not come

out or insufficient cooling

(A/C system normal

operation)Insufficient or excessive charge of

refrigerant

Check the amount of refrigerant and system

for leaks.

Condenser clogged Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

A/C evaporator clogged or frosted Check A/C evaporator and evaporator

thermistor (evaporator temperature sensor)

referring to “Evaporator Inspection” and

“Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Evaporator thermistor (Evaporator

temperature sensor) faulty Check evaporator thermistor (Evaporator

temperature sensor) referring to “Evaporator

Thermistor (Evaporator Temperature Sensor)

Inspection”.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Desiccant clogged Replace receiver/dryer.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Magnet clutch faulty Check magnet clutch referring to “Magnet

Clutch Inspection”.

Compressor faulty Check compressor.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Air leaking from HVAC unit or air duct Repair as necessary.

Heater and ventilation system faulty Check HVAC unit.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Excessive compressor oil in A/C system Drain excessive compressor oil from A/C

system circuit and compressor.

Cool air does not come

out only intermittently Wiring connection faulty

Repair as necessary.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Excessive moisture in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Magnet clutch faulty Check magnet clutch referring to “Magnet

Clutch Inspection”.

Excessive amount of refrigerant Check the amount of refrigerant.

Cool air comes out only

when driving vehicle at

high speed Condenser clogged

Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

Insufficient charge of refrigerant Check the amount of refrigerant and system

for leaks.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Cool air does not come

out only when driving

vehicle at high speed Excessive amount of refrigerant

Check the amount of refrigerant.

A/C evaporator frosted Check A/C evaporator and evaporator

thermistor (evaporator temperature sensor)

referring to “Evaporator Inspection” and

“Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Condition Possible cause Correction / Reference Item

Page 957 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-9

Abnormal Noise Symptom Diagnosis of A/C SystemS7RS0B7214002

Abnormal Noise from Compressor

Abnormal Noise from Magnetic Clutch

Abnormal Noise from Tubing

Abnormal Noise from Condenser Assembly

Abnormal Noise from Crankshaft PulleyInsufficient airflow of

cooled air

A/C evaporator clogged or frosted

Check A/C evaporator and evaporator

thermistor (evaporator temperature sensor)

referring to “Evaporator Inspection” and

“Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Air leaking from HVAC unit or air duct Repair as necessary.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Wiring or grounding faulty Repair as necessary.

Condition Possible cause Correction / Reference Item

Condition

Possible cause Correction / Reference Item

During compressor

operation, a rumbling

noise is heard

proportional to engine

revolutions Inadequate clearance in scroll area

Replace compressor.

A loud noise is heard at a

certain rpm,

disproportionately to

engine revolution Loose or faulty compressor drive belt

Adjust drive belt tension or replace drive belt.

Loose compressor mounting bolts Retighten mounting bolts.

A loud rattle is heard at

low engine rpm Loose compressor clutch plate bolt

Retighten clutch plate bolt.

Replace compressor if it was operated in this

condition for a long time.

Condition Possible cause Correction / Reference Item

A rumbling noise is heard

when compressor is not

in operation Worn or damaged bearings

Replace magnet clutch assembly.

A chattering noise is

heard when compressor

is in operation Faulty magnet clutch clearance

(excessive clearance)

Adjust magnet clutch clearance.

Worn magnet clutch friction surface Replace magnet clutch assembly.

Compressor oil leaked from shaft seal,

contaminating the friction surface Replace compressor body assembly.

Condition

Possible cause Correction / Reference Item

A droning noise is heard

from inside of the vehicle,

but not particularly

noticeable in engine

compartment Faulty tubing clamps

Reposition clamps or increase the number of

clamps.

Resonance caused by pulsation from

variations in re frigerant pressure Attach a silencer to tubing, or modify its

position and length.

Condition

Possible cause Correction / Reference Item

Considerable vibration in

condenser assembly Resonance from condenser assembly

bracket and body Firmly insert a silenc

er between condenser

assembly bracket and body.

Condition Possible cause Correction / Reference Item

A large rattling noise is

heard at idle or sudden

acceleration Loosen crankshaft pulley bolt

Retighten bolt.

Page 973 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-25

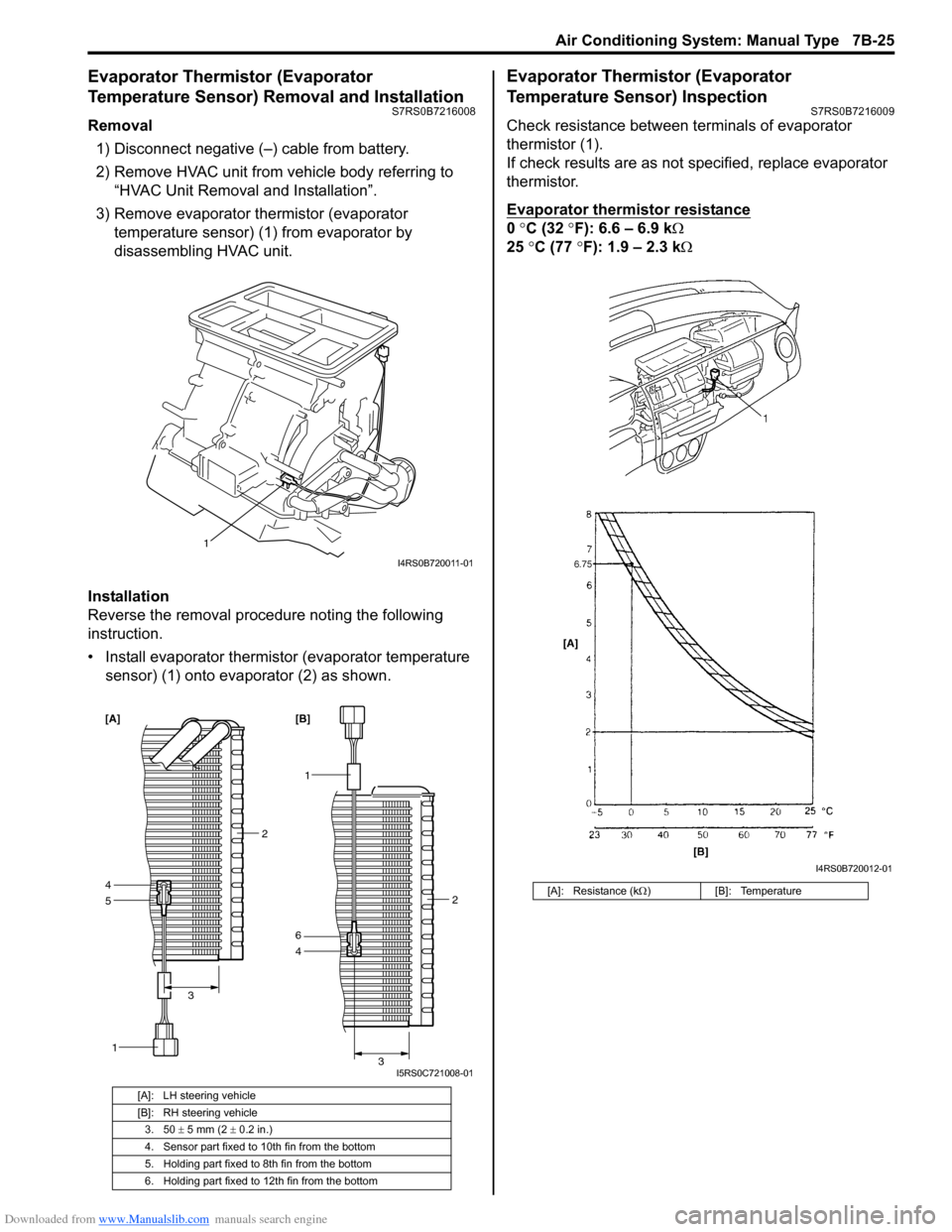

Evaporator Thermistor (Evaporator

Temperature Sensor) Removal and Installation

S7RS0B7216008

Removal1) Disconnect negative (–) cable from battery.

2) Remove HVAC unit from vehicle body referring to “HVAC Unit Removal and Installation”.

3) Remove evaporator thermistor (evaporator temperature sensor) (1) from evaporator by

disassembling HVAC unit.

Installation

Reverse the removal procedure noting the following

instruction.

• Install evaporator thermistor (evaporator temperature sensor) (1) onto evaporator (2) as shown.

Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection

S7RS0B7216009

Check resistance between terminals of evaporator

thermistor (1).

If check results are as not specified, replace evaporator

thermistor.

Evaporator thermistor resistance

0 °C (32 °F): 6.6 – 6.9 k Ω

25 °C (77 °F): 1.9 – 2.3 kΩ

[A]: LH steering vehicle

[B]: RH steering vehicle

3. 50 ± 5 mm (2 ± 0.2 in.)

4. Sensor part fixed to 10th fin from the bottom

5. Holding part fixed to 8th fin from the bottom

6. Holding part fixed to 12th fin from the bottom

1

I4RS0B720011-01

5

1

4

2

3

[A]

1

4 2

3

6 [B]

I5RS0C721008-01

[A]: Resistance (k Ω) [B]: Temperature

I4RS0B720012-01

Page 974 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-26 Air Conditioning System: Manual Type

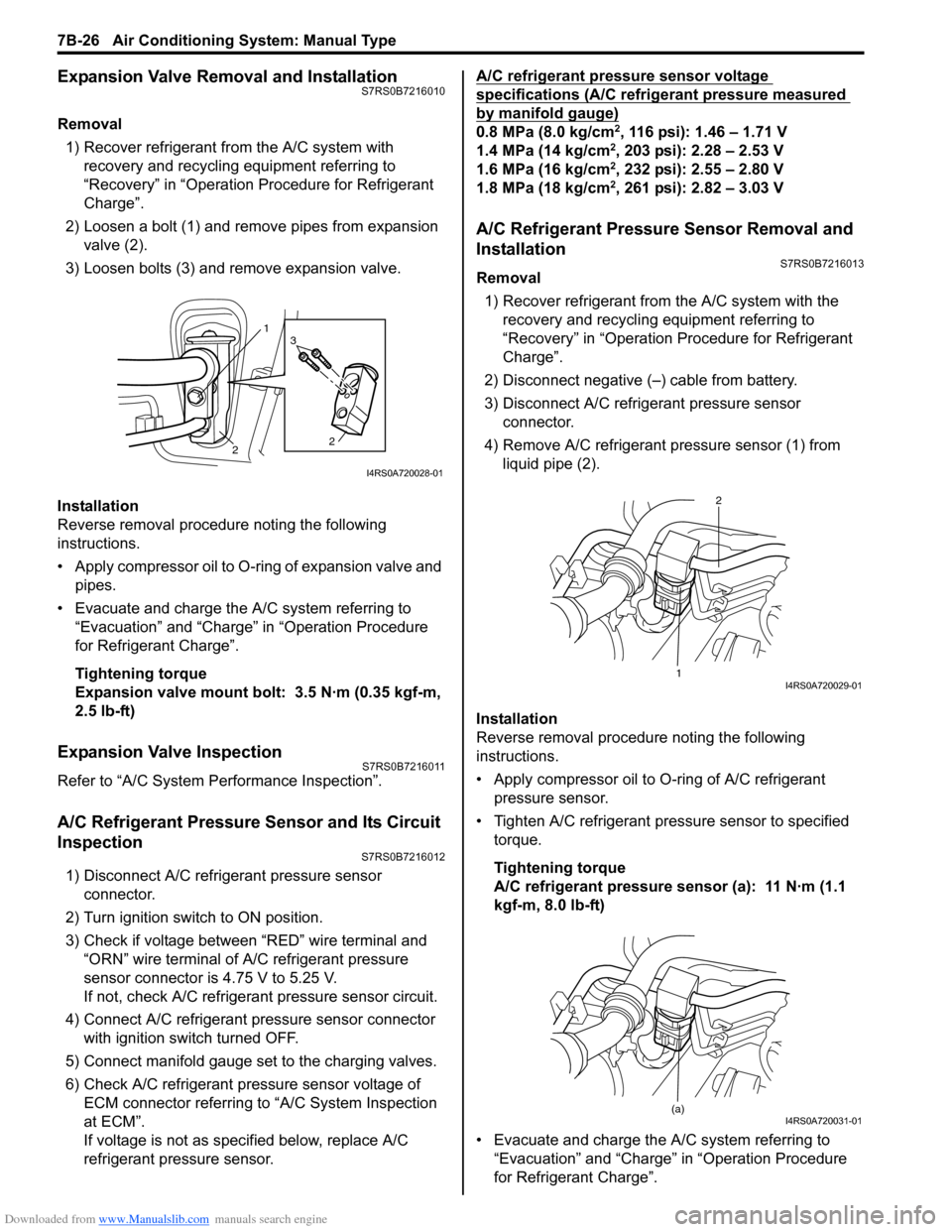

Expansion Valve Removal and InstallationS7RS0B7216010

Removal1) Recover refrigerant fr om the A/C system with

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Loosen a bolt (1) and remove pipes from expansion valve (2).

3) Loosen bolts (3) and remove expansion valve.

Installation

Reverse removal procedure noting the following

instructions.

• Apply compressor oil to O-ring of expansion valve and pipes.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

Tightening torque

Expansion valve mount bolt: 3.5 N·m (0.35 kgf-m,

2.5 lb-ft)

Expansion Valve InspectionS7RS0B7216011

Refer to “A/C System Performance Inspection”.

A/C Refrigerant Pressure Sensor and Its Circuit

Inspection

S7RS0B7216012

1) Disconnect A/C refrigerant pressure sensor connector.

2) Turn ignition switch to ON position.

3) Check if voltage between “RED” wire terminal and “ORN” wire terminal of A/C refrigerant pressure

sensor connector is 4.75 V to 5.25 V.

If not, check A/C refrigerant pressure sensor circuit.

4) Connect A/C refrigerant pressure sensor connector with ignition switch turned OFF.

5) Connect manifold gauge set to the charging valves.

6) Check A/C refrigerant pressure sensor voltage of ECM connector referring to “A/C System Inspection

at ECM”.

If voltage is not as specified below, replace A/C

refrigerant pressure sensor. A/C refrigerant pressure sensor voltage

specifications (A/C refrigerant pressure measured

by manifold gauge)

0.8 MPa (8.0 kg/cm2, 116 psi): 1.46 – 1.71 V

1.4 MPa (14 kg/cm2, 203 psi): 2.28 – 2.53 V

1.6 MPa (16 kg/cm2, 232 psi): 2.55 – 2.80 V

1.8 MPa (18 kg/cm2, 261 psi): 2.82 – 3.03 V

A/C Refrigerant Pressure Sensor Removal and

Installation

S7RS0B7216013

Removal

1) Recover refrigerant from the A/C system with the recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Disconnect negative (–) cable from battery.

3) Disconnect A/C refrigerant pressure sensor connector.

4) Remove A/C refrigerant pressure sensor (1) from liquid pipe (2).

Installation

Reverse removal procedure noting the following

instructions.

• Apply compressor oil to O-ring of A/C refrigerant

pressure sensor.

• Tighten A/C refrigerant pressure sensor to specified torque.

Tightening torque

A/C refrigerant pressure sensor (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

1

2 2

3

I4RS0A720028-01

1 2I4RS0A720029-01

(a)I4RS0A720031-01

Page 980 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-32 Air Conditioning System: Manual Type

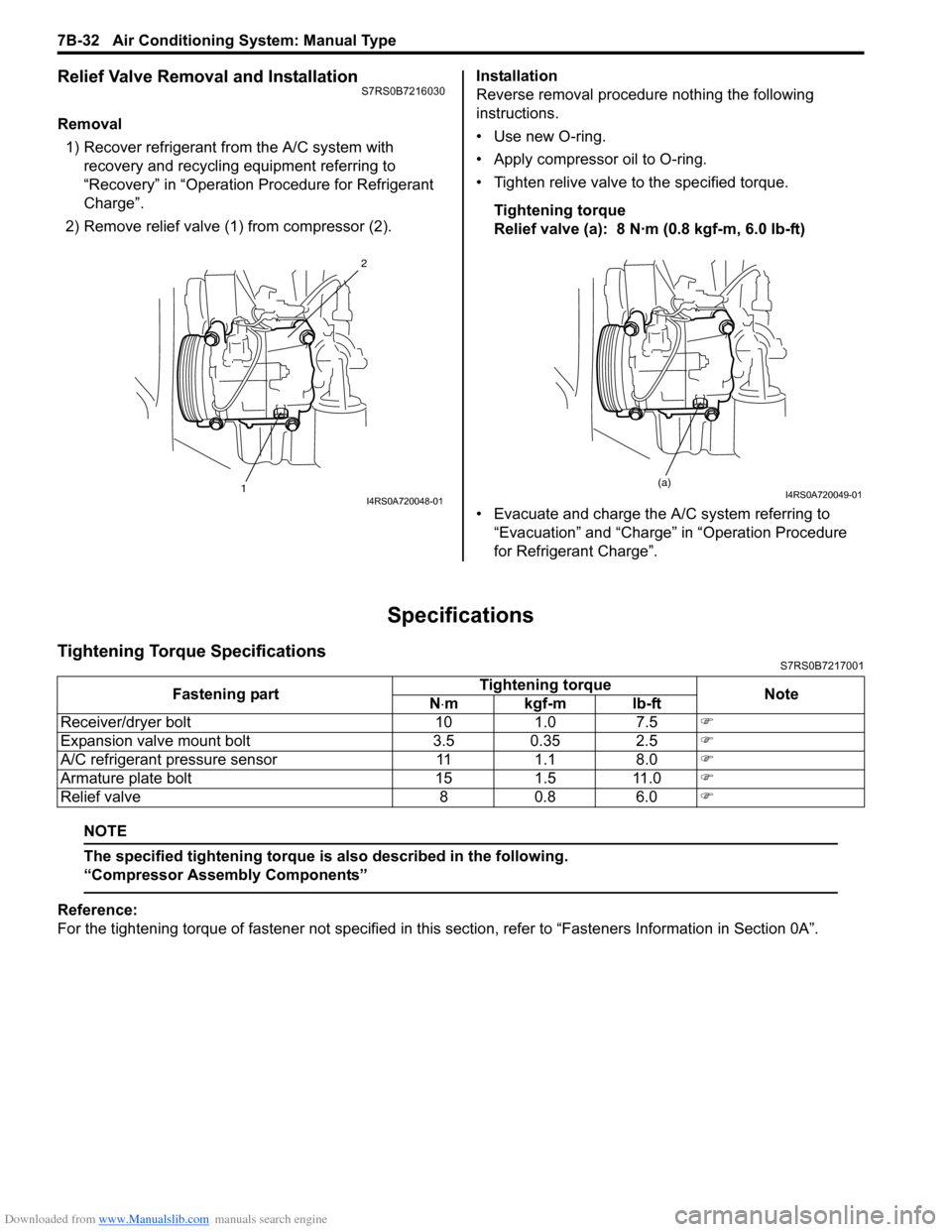

Relief Valve Removal and InstallationS7RS0B7216030

Removal1) Recover refrigerant fr om the A/C system with

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Remove relief valve (1) from compressor (2). Installation

Reverse removal procedure nothing the following

instructions.

• Use new O-ring.

• Apply compressor oil to O-ring.

• Tighten relive valve to the specified torque.

Tightening torque

Relief valve (a): 8 N·m (0.8 kgf-m, 6.0 lb-ft)

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

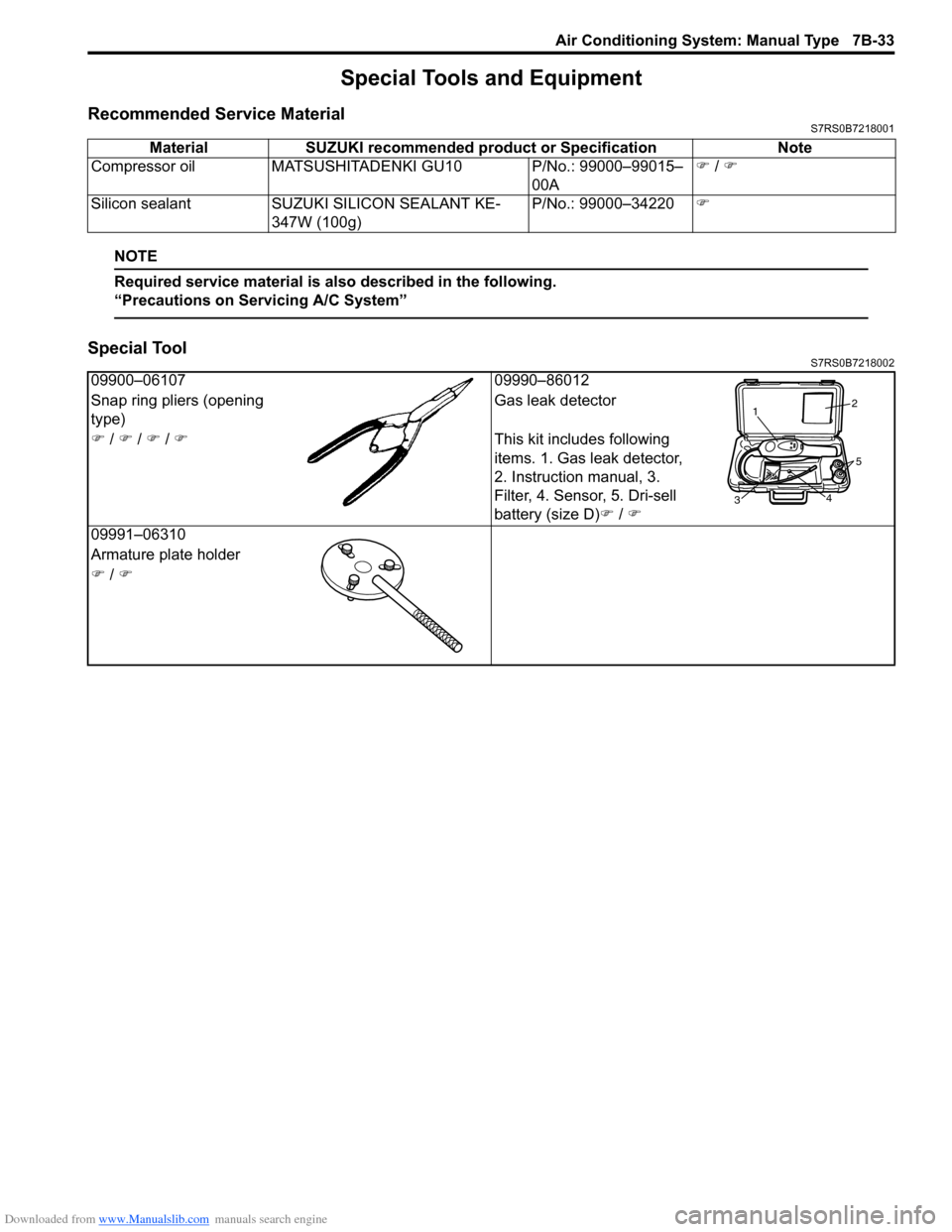

Specifications

Tightening Torque SpecificationsS7RS0B7217001

NOTE

The specified tightening torque is also described in the following.

“Compressor Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

12I4RS0A720048-01

(a)I4RS0A720049-01

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Receiver/dryer bolt 10 1.0 7.5 �)

Expansion valve mount bolt 3.5 0.35 2.5 �)

A/C refrigerant pressure sensor 11 1.1 8.0 �)

Armature plate bolt 15 1.5 11.0 �)

Relief valve 8 0.8 6.0 �)

Page 981 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-33

Special Tools and Equipment

Recommended Service MaterialS7RS0B7218001

NOTE

Required service material is also described in the following.

“Precautions on Servicing A/C System”

Special ToolS7RS0B7218002

Material SUZUKI recommended product or Specification Note

Compressor oil MATSUSHITADEN KI GU10 P/No.: 99000–99015–

00A �)

/ �)

Silicon sealant SUZUKI SILICON SEALANT KE-

347W (100g) P/No.: 99000–34220

�)

09900–06107 09990–86012

Snap ring pliers (opening

type) Gas leak detector

�) / �) / �) / �) This kit includes following

items. 1. Gas leak detector,

2. Instruction manual, 3.

Filter, 4. Sensor, 5. Dri-sell

battery (size D)�) / �)

09991–06310

Armature plate holder

�) / �)

1 2

3 4

5

Page 982 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-34 Air Conditioning System: Automatic Type

Automatic Type

Precautions

A/C System CautionS7RS0B7220001

Refer to “A/C System Caution”.

Precautions in Diagnosing TroubleS7RS0B7220002

• Do not disconnect couplers from HVAC control module, battery cable from battery, HVAC control module ground

wire harness from body or main fuse before confirming diagnostic information (diagnostic trouble code) stored in

HVAC control module memory.

• Diagnostic information (diagnostic trouble code) stored in HVAC control module can be checked by display of HVAC

control module. Also, it can be checked by using SU ZUKI scan tool. Before checking diagnostic information

(diagnostic trouble code), read this manual and operator's manual for SUZUKI scan tool to know how to read

diagnostic information (diagnostic trouble code).

• When trouble is diagnosed using diagnostic information (diagnostic trouble code) on display of HVAC control

module, keep in your mind that each diagnostic inform ation (diagnostic trouble code) has priority, and only

diagnostic information (diagnostic troub le code) which has the highest priority is indicated. Therefore, after

troubleshooting the malfunction, make sure if there exists any other diagnostic information (diagnostic trouble

code).

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” before inspection.

Precautions on Servicing A/C SystemS7RS0B7220003

Refer to “Precautions on Servicing A/C System”.

General Description

Auto A/C System DescriptionS7RS0B7221001

The automatic type air conditioning system (auto A/C) is pr ovided with the function to automatically control the inside

air temperature, fan speed, air flow outl et direction and air intake position by HVAC control module in addition to

functions of the manual type air conditioning system (manua l A/C). Once the inside air temperature is set using the

temperature selector, HVAC control module automatically controls the inside air temperature at the constant level at all

times based on the inside air temperature, outside ai r temperature, amount of sunlight and engine coolant

temperature detected respectively by the inside air te mperature sensor, outside air temperature sensor, sunload

sensor and ECT sensor. At this time, “FULL AUTO A/ C” appears on the display of HVAC control module.

With the air intake selector pushed in the above state, it is possible to select any position of the air intake actuator.

Then, “FULL AUTO A/C” on the display changes to “AUTO A/C”.

Page 983 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-35

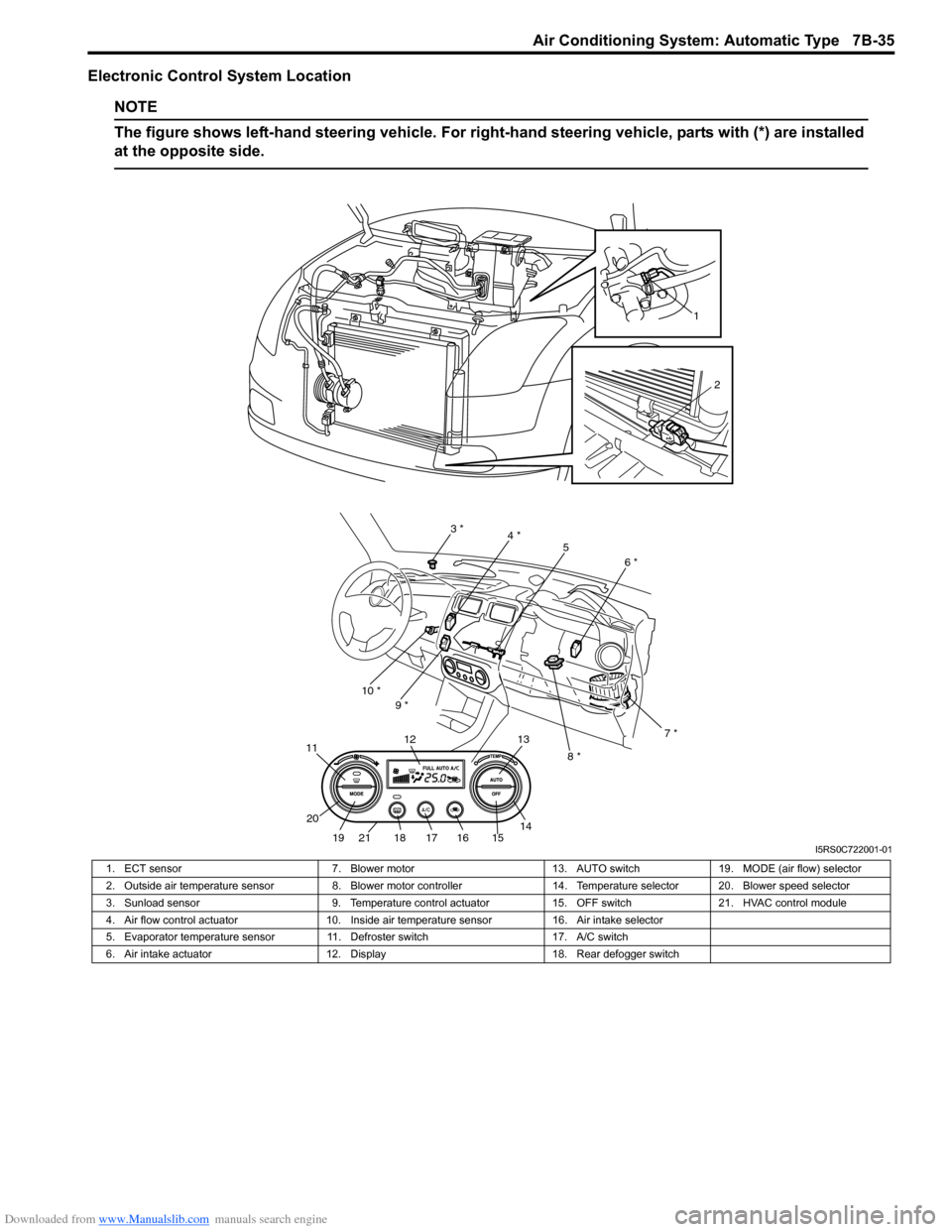

Electronic Control System Location

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

1

2

3 * 4 *

5

6 *

7 *

8 *

9 *

10 *

21

11

12 13

14

15161718

19

20

I5RS0C722001-01

1. ECT sensor

7. Blower motor13. AUTO switch19. MODE (air flow) selector

2. Outside air temperature sensor 8. Blower motor controller 14. Temperature selector 20. Blower speed selector

3. Sunload sensor 9. Temperature control actuator15. OFF switch21. HVAC control module

4. Air flow control actuator 10. Inside air temperature sensor 16. Air intake selector

5. Evaporator temperature sensor 11. Defroster switch 17. A/C switch

6. Air intake actuator 12. Display 18. Rear defogger switch

Page 984 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-36 Air Conditioning System: Automatic Type

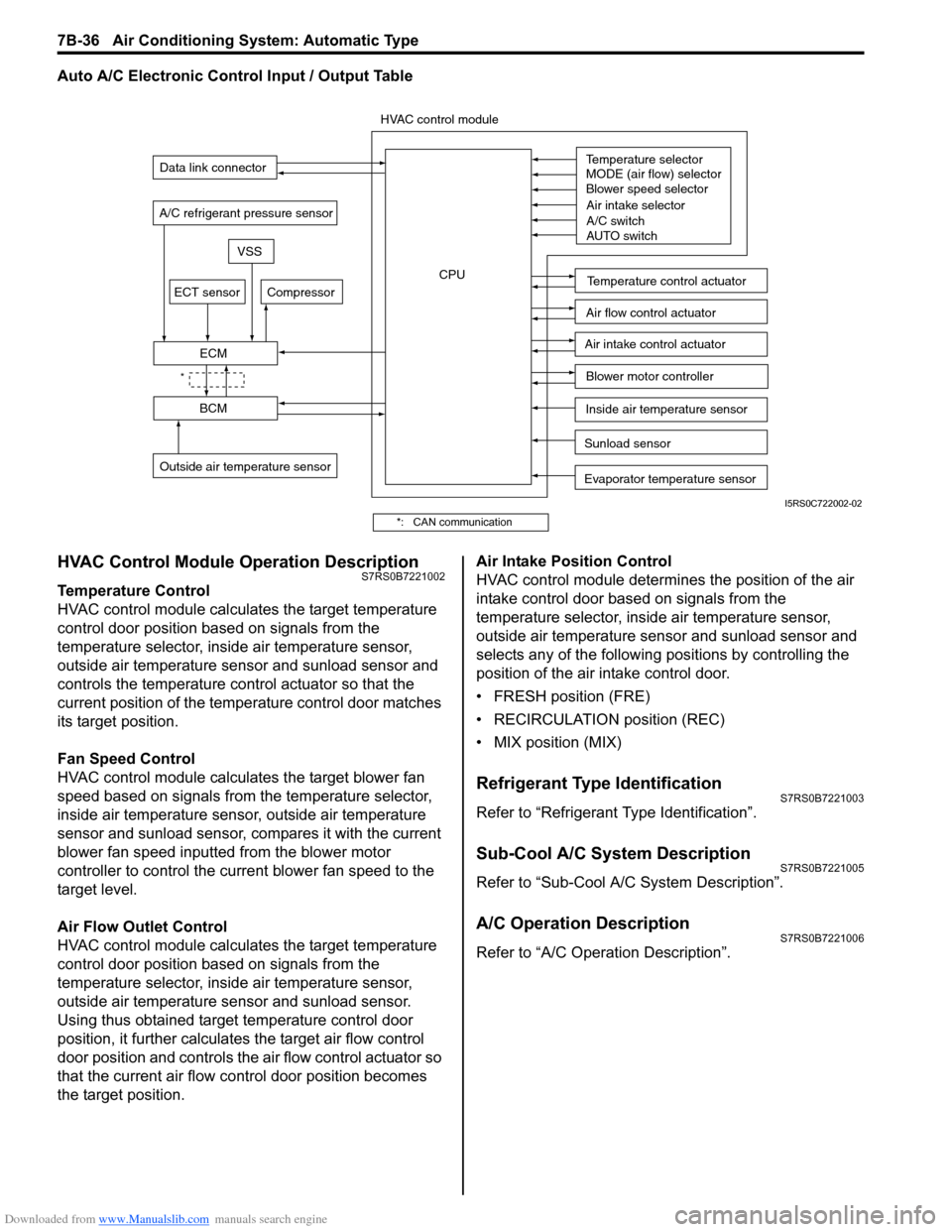

Auto A/C Electronic Control Input / Output Table

HVAC Control Module Operation DescriptionS7RS0B7221002

Temperature Control

HVAC control module calculates the target temperature

control door position based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor and

controls the temperature control actuator so that the

current position of the temperature control door matches

its target position.

Fan Speed Control

HVAC control module calculates the target blower fan

speed based on signals from the temperature selector,

inside air temperature sensor, outside air temperature

sensor and sunload sensor, compares it with the current

blower fan speed inputted from the blower motor

controller to control the current blower fan speed to the

target level.

Air Flow Outlet Control

HVAC control module calculates the target temperature

control door position based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor.

Using thus obtained target temperature control door

position, it further calculates the target air flow control

door position and controls the ai r flow control actuator so

that the current air flow c ontrol door position becomes

the target position. Air Intake Position Control

HVAC control module determines the position of the air

intake control door based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor and

selects any of the following positions by controlling the

position of the air intake control door.

• FRESH position (FRE)

• RECIRCULATION position (REC)

• MIX position (MIX)

Refrigerant Type IdentificationS7RS0B7221003

Refer to “Refrigerant Type Identification”.

Sub-Cool A/C System DescriptionS7RS0B7221005

Refer to “Sub-Cool A/C System Description”.

A/C Operation DescriptionS7RS0B7221006

Refer to “A/C Operation Description”.

Sunload sensor

Outside air temperature sensor Evaporator temperature sensor

A/C refrigerant pressure sensor

Temperature selector

MODE (air flow) selector

Blower speed selector

Air intake selector

AUTO switch

A/C switch

Compressor

Blower motor controller

Temperature control actuator

Air flow control actuator

Air intake control actuator

BCM

ECM

Data link connector

HVAC control module

CPU

ECT sensor

Inside air temperature sensor

VSS

*

I5RS0C722002-02

*: CAN communication

Page 985 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-37

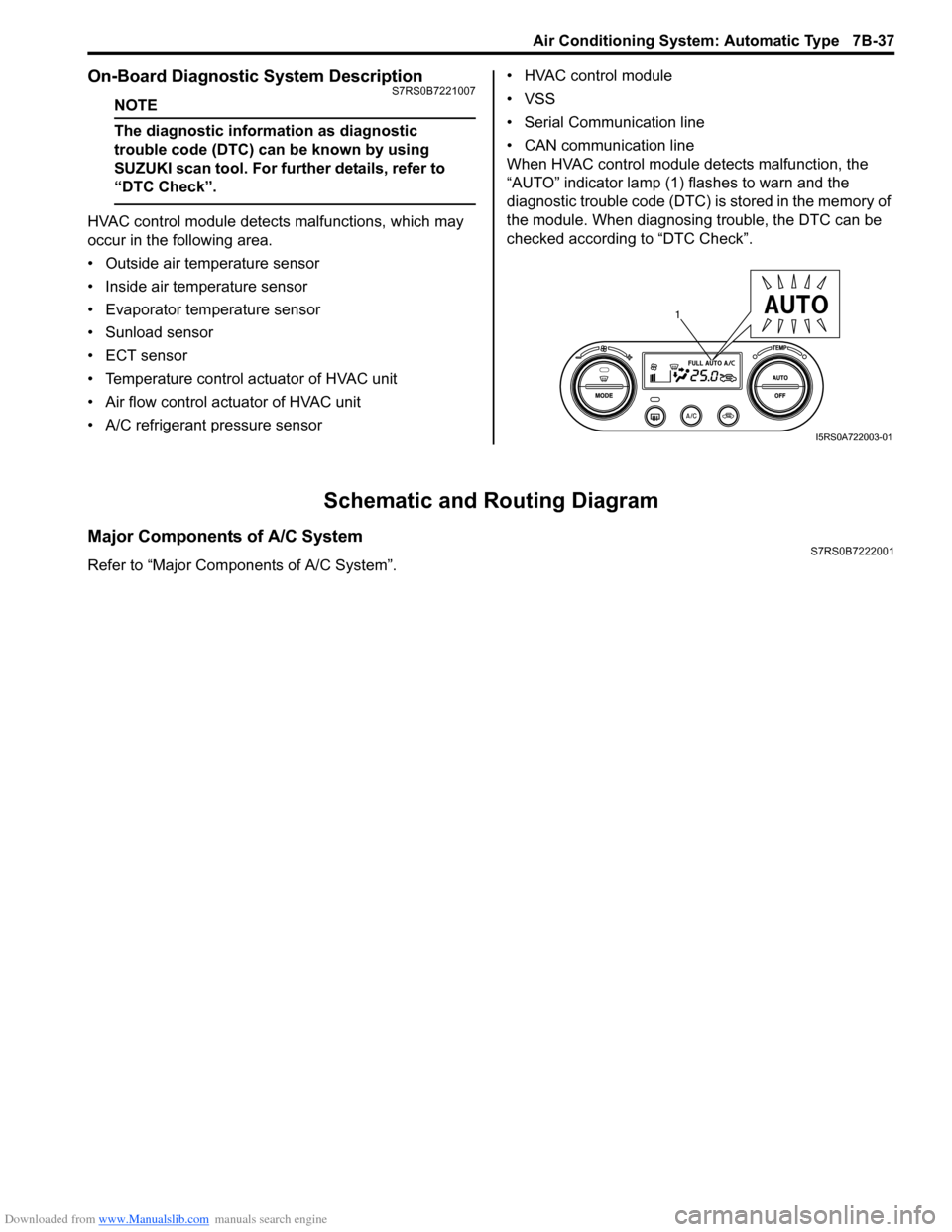

On-Board Diagnostic System DescriptionS7RS0B7221007

NOTE

The diagnostic information as diagnostic

trouble code (DTC) can be known by using

SUZUKI scan tool. For further details, refer to

“DTC Check”.

HVAC control module detect s malfunctions, which may

occur in the following area.

• Outside air temperature sensor

• Inside air temperature sensor

• Evaporator temperature sensor

• Sunload sensor

• ECT sensor

• Temperature control actuator of HVAC unit

• Air flow control actuator of HVAC unit

• A/C refrigerant pressure sensor • HVAC control module

• VSS

• Serial Communication line

• CAN communication line

When HVAC control module detects malfunction, the

“AUTO” indicator lamp (1) flashes to warn and the

diagnostic trouble code (DTC) is stored in the memory of

the module. When diagnosing trouble, the DTC can be

checked according to “DTC Check”.

Schematic and Routing Diagram

Major Components of A/C SystemS7RS0B7222001

Refer to “Major Components of A/C System”.

1

I5RS0A722003-01