dtc check SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1126 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-88 Air Bag System:

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components, ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC B1363 / B1367: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Short to GroundS7RS0B8204045

Wiring Diagram2 1) With ignition switch OFF, disconnect SDM connector

“L29”.

2) Check proper connection to SDM at terminals “L29-19” and “L29-20” or “L29-21” and “L29-22”.

3) If OK, release shorting bar in SDM connector inserting

release tool (1) included in special tool (A).

4) Measure resistance between “L29-19” and “L29-20” terminals (for DTC B1362) or “L29-21” and “L29-22”

terminals (for DTC B1366) with connected special tools

(A), (B) and (C).

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

Is resistance 1.8

Ω or more? Substitute a known-

good SDM and recheck.

DTC B1362: Repair

short from “YEL/GRN”

wire circuit to “YEL/

BLU” wire circuit or from

“YEL/GRN” or “YEL/

BLU” wire circuit to

other wire circuit.

DTC B1366: Repair

short from “BLK/YEL”

wire circuit to “BRN/

YEL” wire circuit or from

“BLK/YEL” or “BRN/

YEL” wire circuit to

other wire circuit.

Step Action Yes No

(A)

"L29-20""L29-21""L29-22"

"L29-19"

STEERING WHEEL(B)

(C)

(A)

"L18", "L41"

I7RS0A820033-02

1

2

3

GRN

RED

8

BLK

L29-27

L29-28 IG

E1

4

“L29”

“L04”

“G32”

“L29”

L29-20

DC+

L29-19

DC-YEL/BLU

YEL/GRN

56

“L18”

L29-21

PC+

L29-22

PC-BRN/YEL BLK/YEL7

“L41”[A]

I7RS0A820031-04

[A]: Shorting bar 3. “A/BAG” fuse 6. Driver side curtain-air bag (inflator) module

1. From main fuse 4. Junction block assembly 7. Passenger side curtain-air bag (inflator) module

2. Ignition switch 5. SDM 8. Ground for air bag system

Page 1127 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-89

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The voltage measured at side curtain-air bag (driver or passenger) initiator circuit is below a specified value for

specified time.

Flow Test Description

Step 1: Check whether malfunction is in side curtain-air bag (inflator) module.

Step 2: Check side curtain-air bag initiator circuit.

DTC Troubleshooting

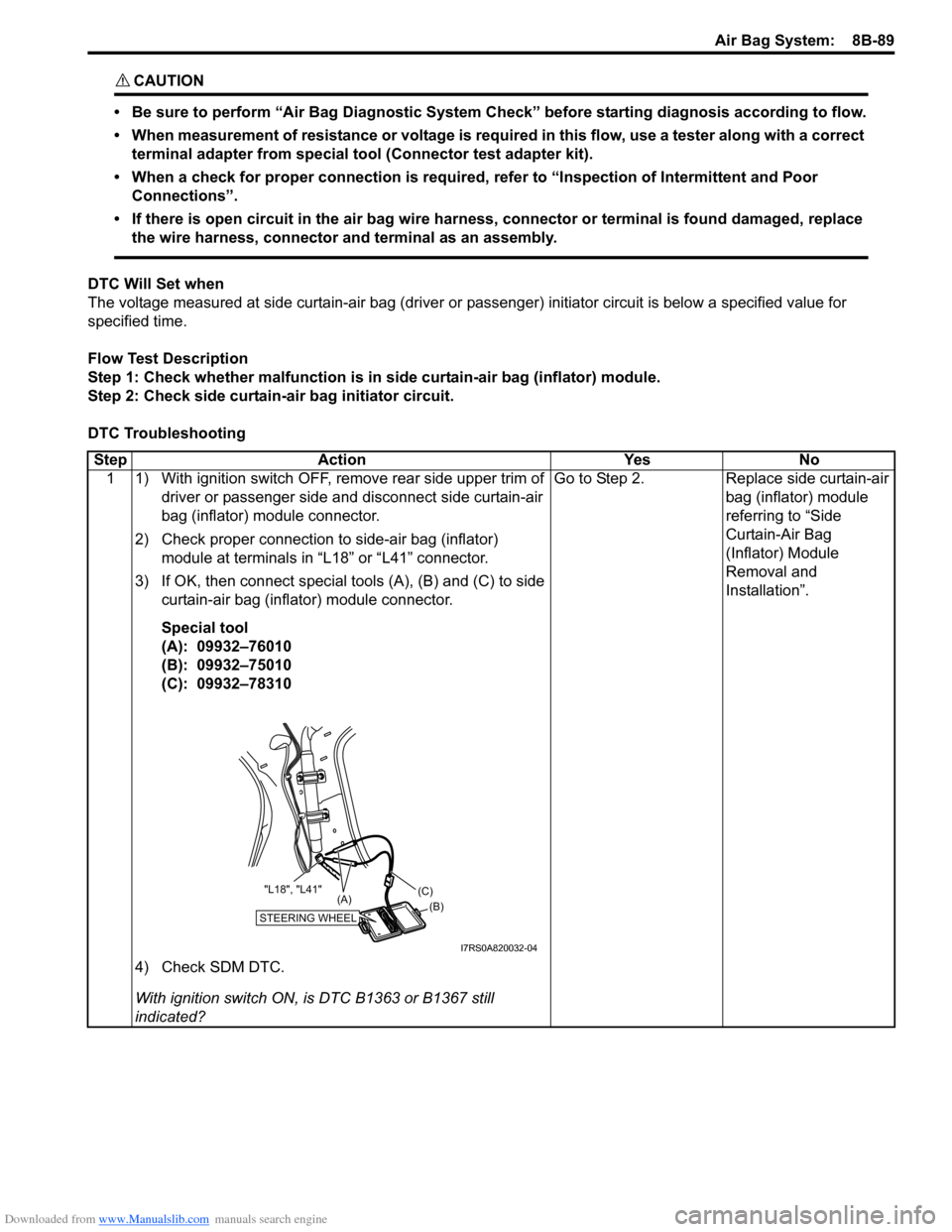

Step Action YesNo

1 1) With ignition switch OFF, remove rear side upper trim of driver or passenger side and disconnect side curtain-air

bag (inflator) module connector.

2) Check proper connection to side-air bag (inflator) module at terminals in “L18” or “L41” connector.

3) If OK, then connect special tools (A), (B) and (C) to side curtain-air bag (inflator) module connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM DTC.

With ignition switch ON, is DTC B1363 or B1367 still

indicated? Go to Step 2.

Replace side curtain-air

bag (inflator) module

referring to “Side

Curtain-Air Bag

(Inflator) Module

Removal and

Installation”.

STEERING WHEEL(B)

(C)

(A)

"L18", "L41"

I7RS0A820032-04

Page 1128 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-90 Air Bag System:

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components, ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC B1364 / B1368: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Short to Power CircuitS7RS0B8204046

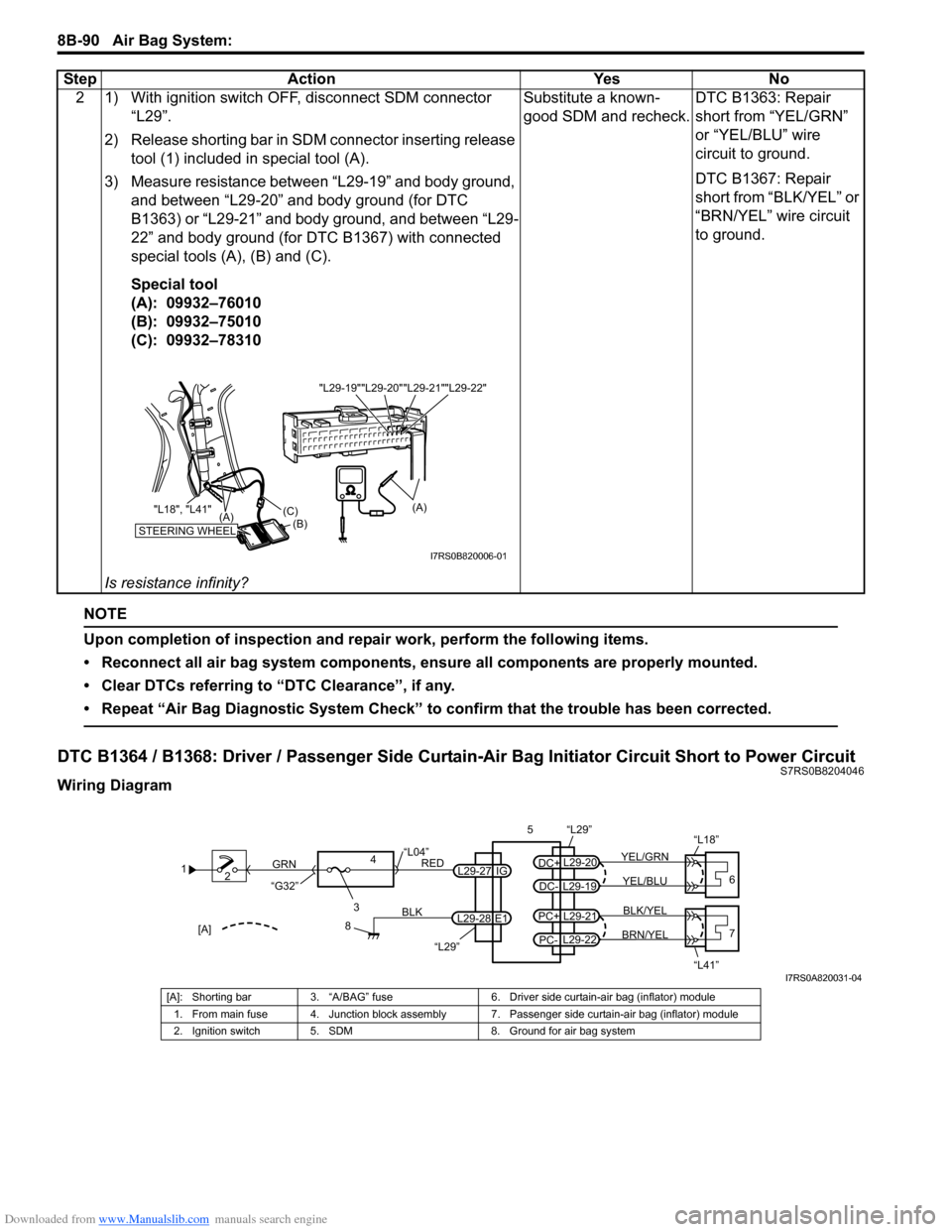

Wiring Diagram2 1) With ignition switch OFF, disconnect SDM connector

“L29”.

2) Release shorting bar in SDM connector inserting release tool (1) included in special tool (A).

3) Measure resistance between “L29-19” and body ground, and between “L29-20” and body ground (for DTC

B1363) or “L29-21” and body ground, and between “L29-

22” and body ground (for DTC B1367) with connected

special tools (A), (B) and (C).

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

Is resistance infinity? Substitute a known-

good SDM and recheck.

DTC B1363: Repair

short from “YEL/GRN”

or “YEL/BLU” wire

circuit to ground.

DTC B1367: Repair

short from “BLK/YEL” or

“BRN/YEL” wire circuit

to ground.

Step Action Yes No

"L29-20""L29-21""L29-22"

"L29-19"

STEERING WHEEL(B)

(C)

(A)

"L18", "L41"

(A)

I7RS0B820006-01

1

2

3

GRN

RED

8

BLK

L29-27

L29-28 IG

E1

4

“L29”

“L04”

“G32”

“L29”

L29-20

DC+

L29-19

DC-YEL/BLU

YEL/GRN

56

“L18”

L29-21

PC+

L29-22

PC-BRN/YEL BLK/YEL7

“L41”[A]

I7RS0A820031-04

[A]: Shorting bar 3. “A/BAG” fuse 6. Driver side curtain-air bag (inflator) module

1. From main fuse 4. Junction block assembly 7. Passenger side curtain-air bag (inflator) module

2. Ignition switch 5. SDM 8. Ground for air bag system

Page 1129 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-91

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

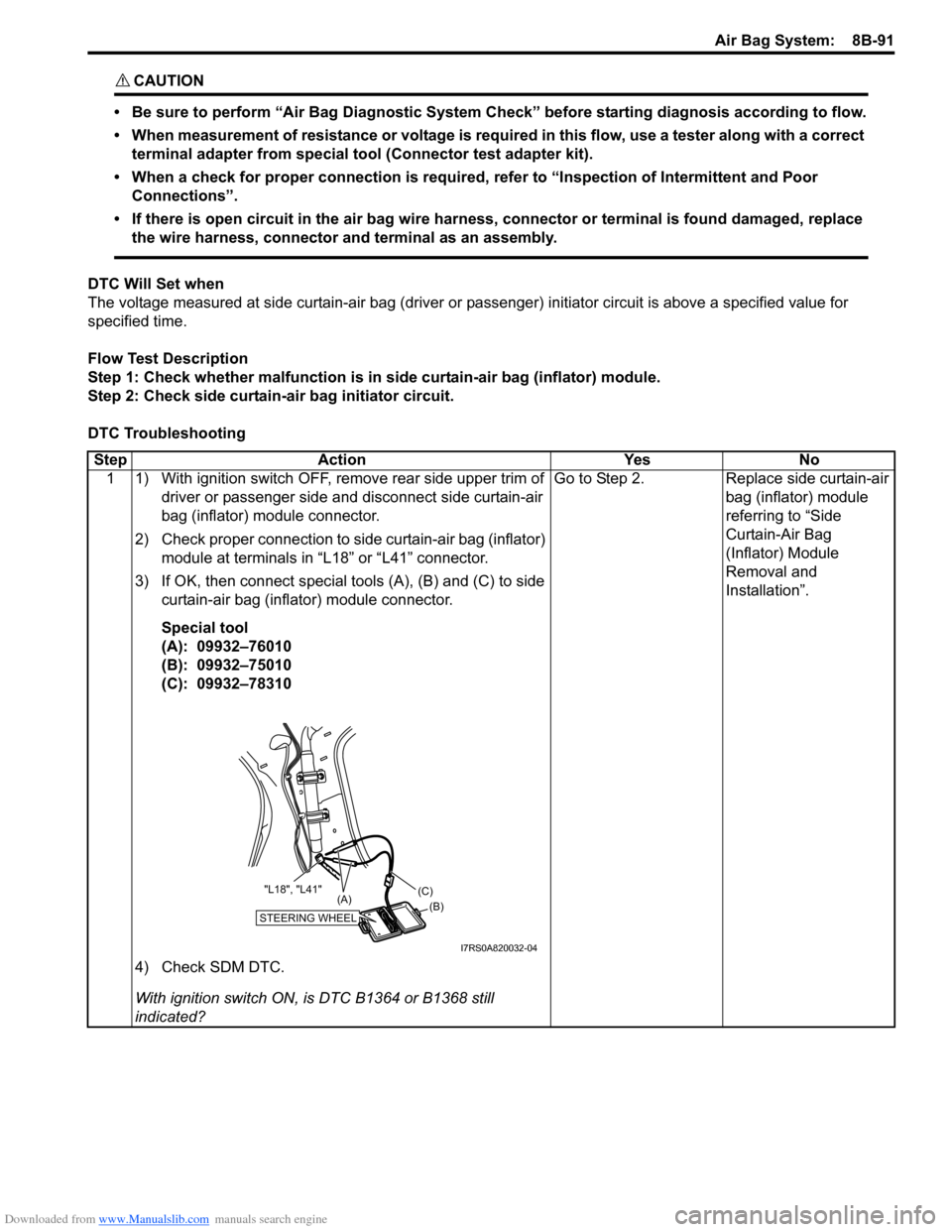

DTC Will Set when

The voltage measured at side curtain-air bag (driver or passenger) initiator circuit is above a specified value for

specified time.

Flow Test Description

Step 1: Check whether malfunction is in side curtain-air bag (inflator) module.

Step 2: Check side curtain-air bag initiator circuit.

DTC Troubleshooting

Step Action YesNo

1 1) With ignition switch OFF, remove rear side upper trim of driver or passenger side and disconnect side curtain-air

bag (inflator) module connector.

2) Check proper connection to side curtain-air bag (inflator) module at terminals in “L18” or “L41” connector.

3) If OK, then connect special tools (A), (B) and (C) to side curtain-air bag (inflator) module connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM DTC.

With ignition switch ON, is DTC B1364 or B1368 still

indicated? Go to Step 2.

Replace side curtain-air

bag (inflator) module

referring to “Side

Curtain-Air Bag

(Inflator) Module

Removal and

Installation”.

STEERING WHEEL(B)

(C)

(A)

"L18", "L41"

I7RS0A820032-04

Page 1130 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-92 Air Bag System:

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components, ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

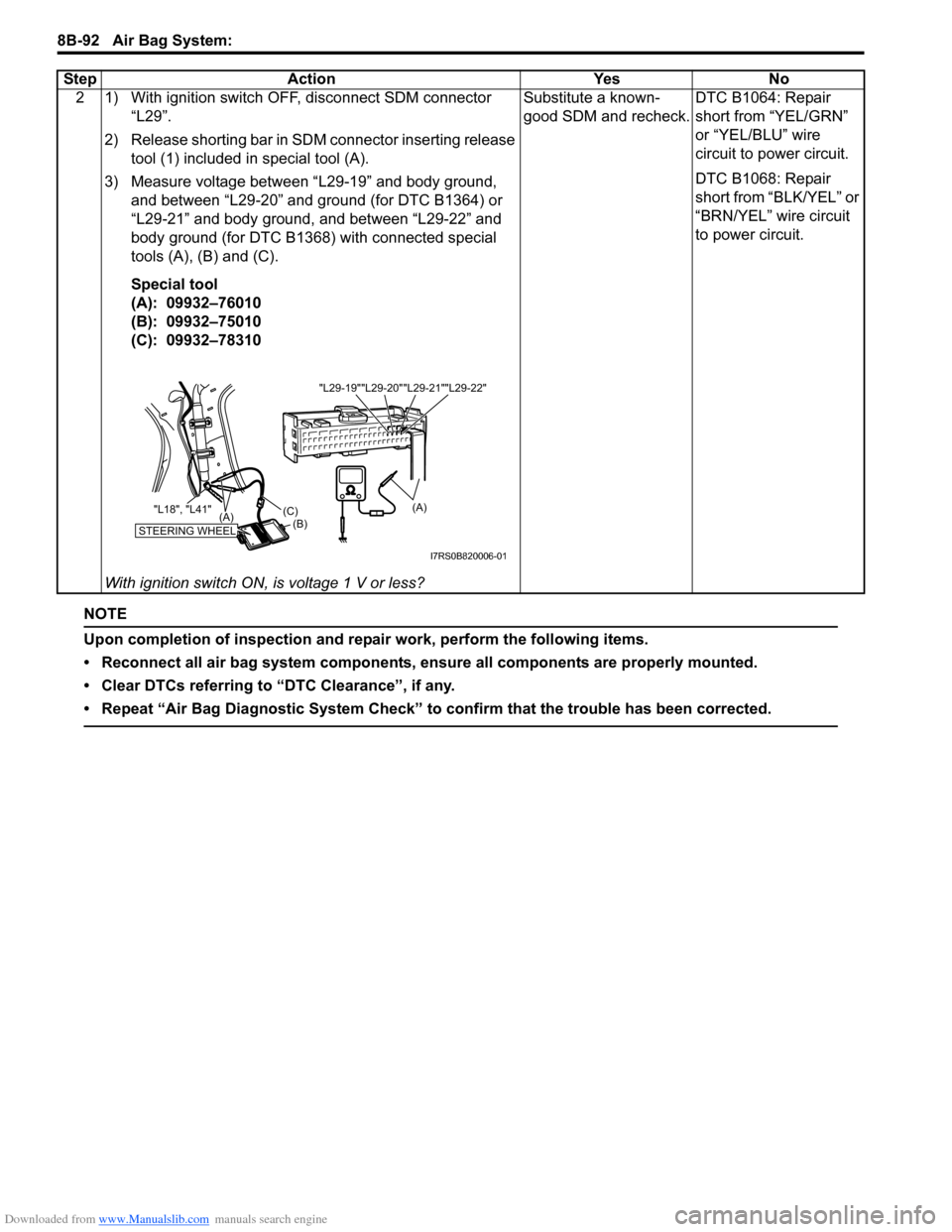

2 1) With ignition switch OFF, disconnect SDM connector “L29”.

2) Release shorting bar in SDM connector inserting release tool (1) included in special tool (A).

3) Measure voltage between “L29-19” and body ground, and between “L29-20” and ground (for DTC B1364) or

“L29-21” and body ground, and between “L29-22” and

body ground (for DTC B1368) with connected special

tools (A), (B) and (C).

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

With ignition switch ON, is voltage 1 V or less? Substitute a known-

good SDM and recheck.

DTC B1064: Repair

short from “YEL/GRN”

or “YEL/BLU” wire

circuit to power circuit.

DTC B1068: Repair

short from “BLK/YEL” or

“BRN/YEL” wire circuit

to power circuit.

Step Action Yes No

"L29-20""L29-21""L29-22"

"L29-19"

STEERING WHEEL(B)

(C)

(A)

"L18", "L41"

(A)

I7RS0B820006-01

Page 1135 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-97

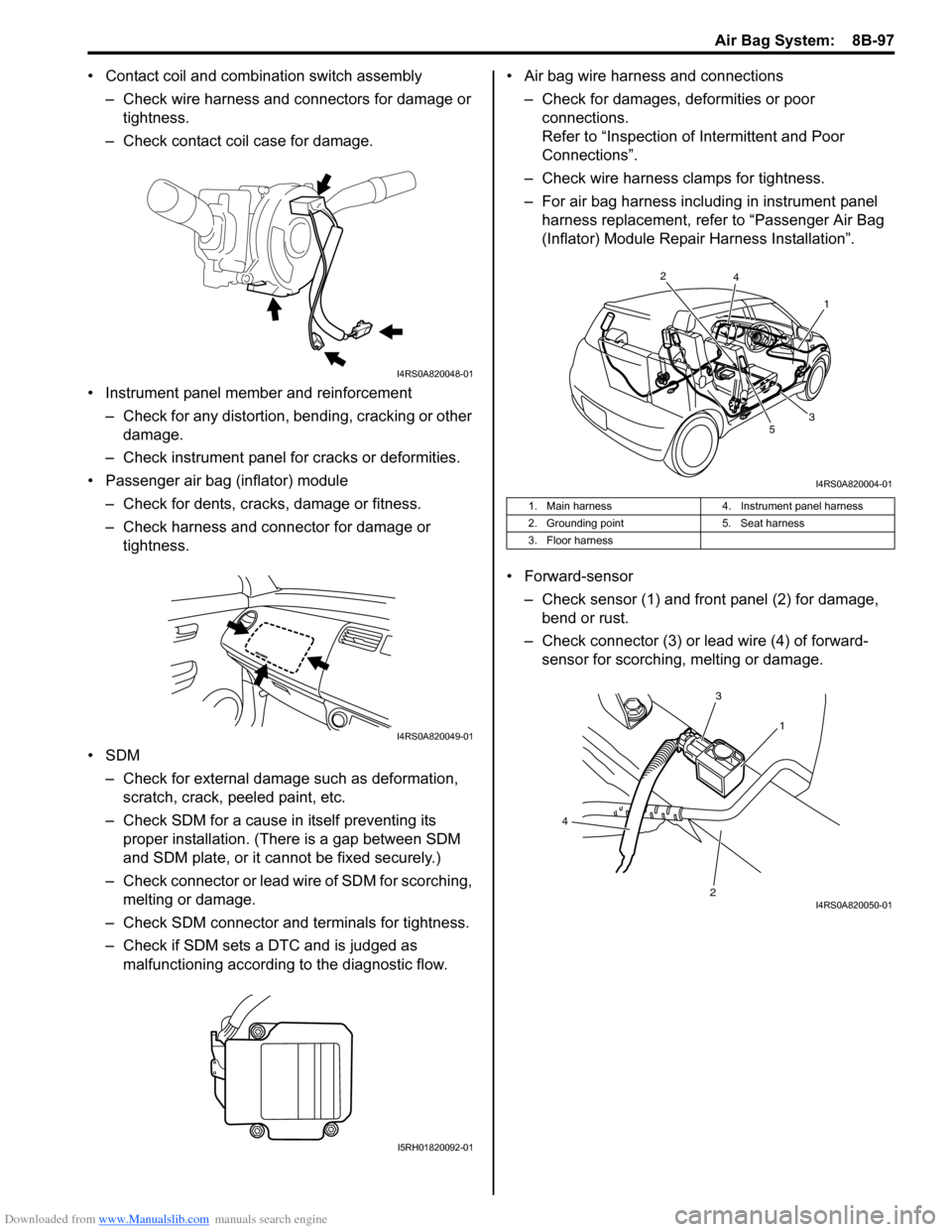

• Contact coil and combination switch assembly

– Check wire harness and connectors for damage or tightness.

– Check contact coil case for damage.

• Instrument panel member and reinforcement – Check for any distortion, bending, cracking or other damage.

– Check instrument panel fo r cracks or deformities.

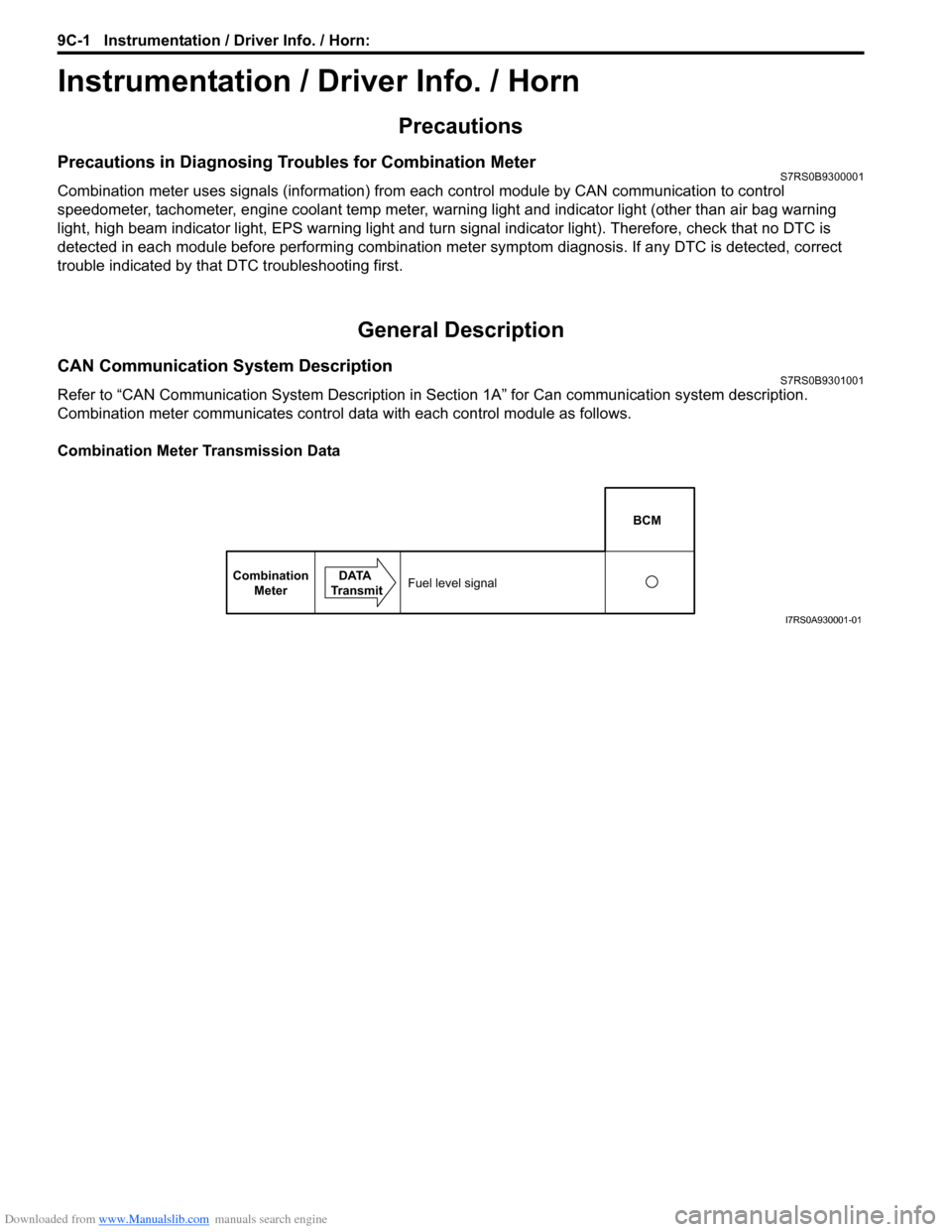

• Passenger air bag (inflator) module

– Check for dents, cracks, damage or fitness.

– Check harness and connector for damage or tightness.

•SDM – Check for external damage such as deformation, scratch, crack, peeled paint, etc.

– Check SDM for a cause in itself preventing its proper installation. (There is a gap between SDM

and SDM plate, or it cannot be fixed securely.)

– Check connector or lead wire of SDM for scorching, melting or damage.

– Check SDM connector and terminals for tightness.

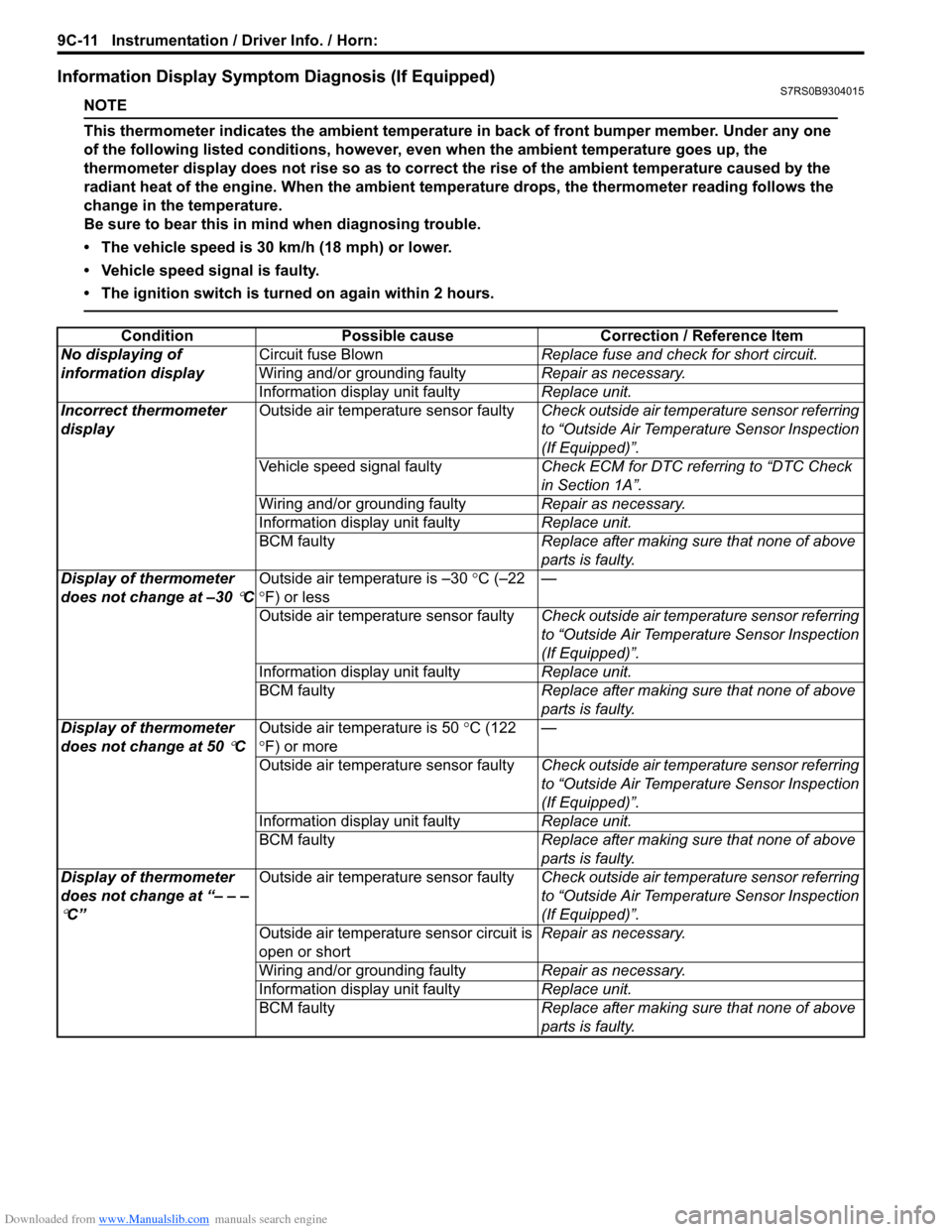

– Check if SDM sets a DTC and is judged as malfunctioning according to the diagnostic flow. • Air bag wire harness and connections

– Check for damages, deformities or poor connections.

Refer to “Inspection of Intermittent and Poor

Connections”.

– Check wire harness clamps for tightness.

– For air bag harness including in instrument panel harness replacement, refer to “Passenger Air Bag

(Inflator) Module Repair Harness Installation”.

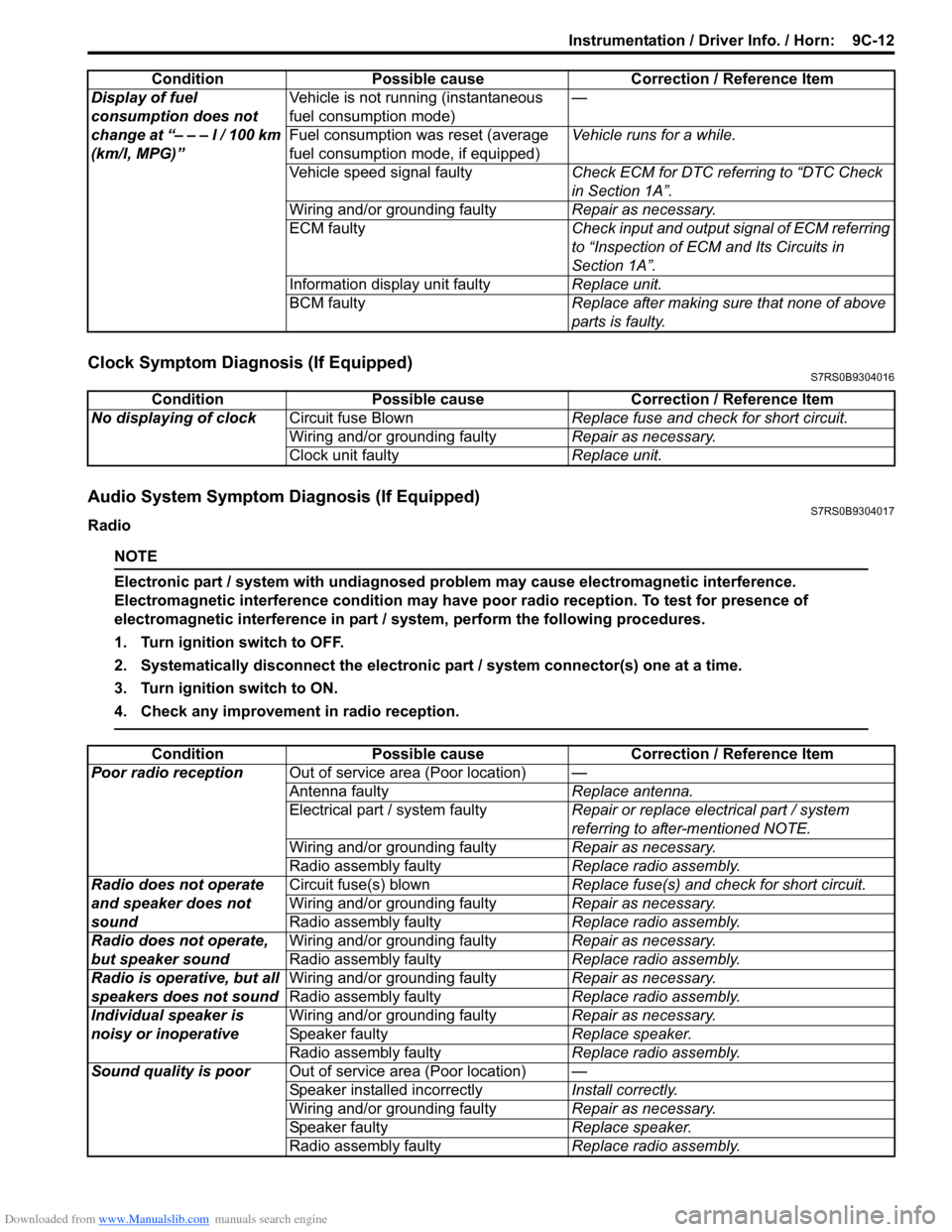

• Forward-sensor – Check sensor (1) and front panel (2) for damage, bend or rust.

– Check connector (3) or lead wire (4) of forward- sensor for scorching, melting or damage.

I4RS0A820048-01

I4RS0A820049-01

I5RH01820092-01

1. Main harness 4. Instrument panel harness

2. Grounding point 5. Seat harness

3. Floor harness

1

2

3

4

5

I4RS0A820004-01

1

3

2

4

I4RS0A820050-01

Page 1296 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-1 Instrumentation / Driver Info. / Horn:

Body, Cab and Accessories

Instrumentation / Driver Info. / Horn

Precautions

Precautions in Diagnosing Troubles for Combination MeterS7RS0B9300001

Combination meter uses signals (information) from each control module by CAN communication to control

speedometer, tachometer, engine coolant temp meter, warning light and indicator light (other than air bag warning

light, high beam indicator light, EPS warn ing light and turn signal indicator light). Therefore, check that no DTC is

detected in each module before performing combination me ter symptom diagnosis. If any DTC is detected, correct

trouble indicated by that DTC troubleshooting first.

General Description

CAN Communication System DescriptionS7RS0B9301001

Refer to “CAN Communication System Description in Section 1A” for Can communication system description.

Combination meter communicates control data with each control module as follows.

Combination Meter Transmission Data

BCM

Combination Meter DATA

TransmitFuel level signal

I7RS0A930001-01

Page 1306 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-11 Instrumentation / Driver Info. / Horn:

Information Display Symptom Diagnosis (If Equipped)S7RS0B9304015

NOTE

This thermometer indicates the ambient temperature in back of front bumper member. Under any one

of the following listed conditions, however, even when the ambient temperature goes up, the

thermometer display does not rise so as to correct the rise of the ambient temperature caused by the

radiant heat of the engine. When the ambient temperature drops, the thermometer reading follows the

change in the temperature.

Be sure to bear this in mind when diagnosing trouble.

• The vehicle speed is 30 km/h (18 mph) or lower.

• Vehicle speed signal is faulty.

• The ignition switch is turned on again within 2 hours.

ConditionPossible cause Correction / Reference Item

No displaying of

information display Circuit fuse Blown

Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Information display unit faulty Replace unit.

Incorrect thermometer

display Outside air temperature sensor faulty

Check outside air temperature sensor referring

to “Outside Air Temperature Sensor Inspection

(If Equipped)”.

Vehicle speed signal faulty Check ECM for DTC referring to “DTC Check

in Section 1A”.

Wiring and/or grounding faulty Repair as necessary.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Display of thermometer

does not change at –30

°C Outside air temperature is –30

°C (–22

° F) or less —

Outside air temperature sensor faulty Check outside air temperature sensor referring

to “Outside Air Temperature Sensor Inspection

(If Equipped)”.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Display of thermometer

does not change at 50

°C Outside air temperature is 50

°C (122

° F) or more —

Outside air temperature sensor faulty Check outside air temperature sensor referring

to “Outside Air Temperature Sensor Inspection

(If Equipped)”.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Display of thermometer

does not change at “– – –

°C” Outside air temperature sensor faulty

Check outside air temperature sensor referring

to “Outside Air Temperature Sensor Inspection

(If Equipped)”.

Outside air temperature sensor circuit is

open or short Repair as necessary.

Wiring and/or grounding faulty Repair as necessary.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Page 1307 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-12

Clock Symptom Diagnosis (If Equipped)S7RS0B9304016

Audio System Symptom Diagnosis (If Equipped)S7RS0B9304017

Radio

NOTE

Electronic part / system with undiagnosed pr oblem may cause electromagnetic interference.

Electromagnetic interference condition may have poor radio reception. To test for presence of

electromagnetic interference in part / system, perform the following procedures.

1. Turn ignition switch to OFF.

2. Systematically disconnect the electronic part / system connector(s) one at a time.

3. Turn ignition switch to ON.

4. Check any improvement in radio reception.

Display of fuel

consumption does not

change at “– – – l / 100 km

(km/l, MPG)” Vehicle is not running (instantaneous

fuel consumption mode)

—

Fuel consumption was reset (average

fuel consumption mo de, if equipped)Vehicle runs for a while.

Vehicle speed signal faulty Check ECM for DTC referring to “DTC Check

in Section 1A”.

Wiring and/or grounding faulty Repair as necessary.

ECM faulty Check input and output signal of ECM referring

to “Inspection of ECM and Its Circuits in

Section 1A”.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

Condition

Possible cause Correction / Reference Item

No displaying of clock Circuit fuse Blown Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Clock unit faulty Replace unit.

ConditionPossible cause Correction / Reference Item

Poor radio reception Out of service area (Poor location) —

Antenna faulty Replace antenna.

Electrical part / system faulty Repair or replace electrical part / system

referring to after-mentioned NOTE.

Wiring and/or grounding faulty Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio does not operate

and speaker does not

sound Circuit fuse(s) blown

Replace fuse(s) and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio does not operate,

but speaker sound Wiring and/or grounding faulty

Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio is operative, but all

speakers does not sound Wiring and/or grounding faulty

Repair as necessary.

Radio assembly faulty Replace radio assembly.

Individual speaker is

noisy or inoperative Wiring and/or grounding faulty

Repair as necessary.

Speaker faulty Replace speaker.

Radio assembly faulty Replace radio assembly.

Sound quality is poor Out of service area (Poor location) —

Speaker installed incorrectly Install correctly.

Wiring and/or grounding faulty Repair as necessary.

Speaker faulty Replace speaker.

Radio assembly faulty Replace radio assembly.

Page 1401 of 1496

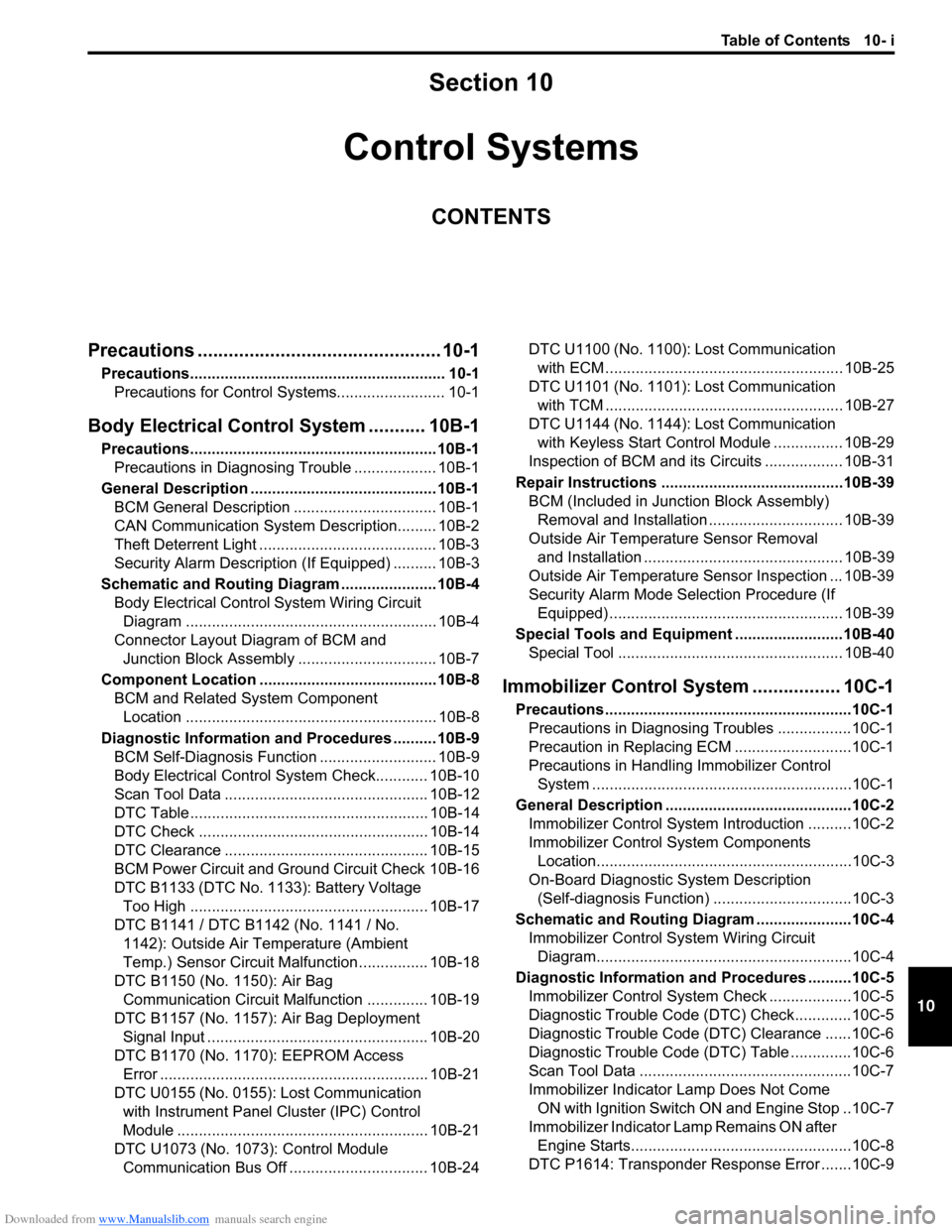

Downloaded from www.Manualslib.com manuals search engine Table of Contents 10- i

10

Section 10

CONTENTS

Control Systems

Precautions ............................................... 10-1

Precautions........................................................... 10-1

Precautions for Control Systems......................... 10-1

Body Electrical Contro l System ........... 10B-1

Precautions......................................................... 10B-1

Precautions in Diagnosing Trouble ................... 10B-1

General Description ........................................... 10B-1 BCM General Description ................................. 10B-1

CAN Communication System Description......... 10B-2

Theft Deterrent Light ......................................... 10B-3

Security Alarm Description (If Equipped) .......... 10B-3

Schematic and Routing Diagram ...................... 10B-4 Body Electrical Control System Wiring Circuit Diagram .......................................................... 10B-4

Connector Layout Diagram of BCM and Junction Block Assembly ................................ 10B-7

Component Locatio n ......................................... 10B-8

BCM and Related System Component Location .......................................................... 10B-8

Diagnostic Information an d Procedures .......... 10B-9

BCM Self-Diagnosis Function ........................... 10B-9

Body Electrical Control System Check............ 10B-10

Scan Tool Data ............................................... 10B-12

DTC Table ....................................................... 10B-14

DTC Check ..................................................... 10B-14

DTC Clearance ............................................... 10B-15

BCM Power Circuit and Ground Circuit Check 10B-16

DTC B1133 (DTC No. 1133): Battery Voltage Too High ....................................................... 10B-17

DTC B1141 / DTC B1142 (No. 1141 / No. 1142): Outside Air Temperature (Ambient

Temp.) Sensor Circuit Ma lfunction ................ 10B-18

DTC B1150 (No. 1150): Air Bag Communication Circuit Malfunction .............. 10B-19

DTC B1157 (No. 1157): Air Bag Deployment Signal Input ................................................... 10B-20

DTC B1170 (No. 1170 ): EEPROM Access

Error .............................................................. 10B-21

DTC U0155 (No. 0155): Lost Communication with Instrument Panel Cluster (IPC) Control

Module .......................................................... 10B-21

DTC U1073 (No. 1073): Control Module Communication Bus Off ................................ 10B-24 DTC U1100 (No. 1100): Lost Communication

with ECM ....................................................... 10B-25

DTC U1101 (No. 1101): Lost Communication with TCM ....................................................... 10B-27

DTC U1144 (No. 1144): Lost Communication with Keyless Start Control Module ................ 10B-29

Inspection of BCM and its Circuits .................. 10B-31

Repair Instructions ........... ...............................10B-39

BCM (Included in Junction Block Assembly) Removal and Installation ............................... 10B-39

Outside Air Temperature Sensor Removal and Installation .............................................. 10B-39

Outside Air Temperature Sensor Inspection ... 10B-39

Security Alarm Mode Selection Procedure (If Equipped) ...................................................... 10B-39

Special Tools and Equipmen t .........................10B-40

Special Tool .................................................... 10B-40

Immobilizer Control Syst em ................. 10C-1

Precautions.........................................................10C-1

Precautions in Diagnosing Troubles .................10C-1

Precaution in Replacing ECM ...........................10C-1

Precautions in Handli ng Immobilizer Control

System ............................................................10C-1

General Description ...........................................10C-2 Immobilizer Control System Introduction ..........10C-2

Immobilizer Control System Components Location...........................................................10C-3

On-Board Diagnostic System Description (Self-diagnosis Function) ................................10C-3

Schematic and Routing Diag ram ......................10C-4

Immobilizer Control System Wiring Circuit Diagram...........................................................10C-4

Diagnostic Information an d Procedures ..........10C-5

Immobilizer Control System Check ...................10C-5

Diagnostic Trouble Code (DTC) Check.............10C-5

Diagnostic Trouble Code (DTC) Clearance ......10C-6

Diagnostic Trouble Code (DTC) Table ..............10C-6

Scan Tool Data .................................................10C-7

Immobilizer Indicator Lamp Does Not Come ON with Ignition Switch ON and Engine Stop ..10C-7

Immobilizer Indicator Lamp Remains ON after Engine Starts...................................................10C-8

DTC P1614: Transponder Re sponse Error .......10C-9