dtc check SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1402 of 1496

Downloaded from www.Manualslib.com manuals search engine 10-ii Table of Contents

DTC P1615: ID Code Does Not Registered (Vehicle equipped with keyless start system

only) ................................................................10C-9

DTC P1616: Different Registration ID Codes (Vehicle equipped with keyless start system

only) ..............................................................10C-10

DTC P1618: CAN Communication Error (Reception Error for Keyless Start Control

Module) (Vehicle equipped with keyless

start system only) ..........................................10C-11

DTC P1621: Immobilizer Communication Line Error ......................................................10C-12

DTC P1622: EEPROM Reading / Writing Error ..............................................................10C-13

DTC P1623: Unregistered Transponder .........10C-13

DTC P1625: Immobilizer An tenna Error..........10C-14

DTC P1636: Immobilizer Information Registration Failure .......................................10C-14

DTC P1638: Immobilizer Information Mismatched ...................................................10C-15

Inspection of Immobilizer Control Module (ICM) and Its Circuit ....... ...............................10C-16

Repair Instructions ........... ...............................10C-18

Immobilizer Control Mo dule (ICM) Removal

and Installation ..............................................10C-18

Registration of the Ignition Key .......................10C-18

Procedure after ECM Replacement ................10C-18

Special Tools and Equipmen t .........................10C-19

Special Tool ....................................................10C-19

Keyless Start System ....... ......................10E-1

General Description ........................................... 10E-1

Keyless Start System Description ..................... 10E-1

Parts and Functions .......................................... 10E-2

Keyless Engine Start Function .......................... 10E-3

Door Lock Function of Keyless Start System .... 10E-4

Operation Area of Remote Controller................ 10E-5

Alarm Function .................................................. 10E-6

CAN Communication System Description......... 10E-6

Schematic and Routing Diagram ...................... 10E-7 Keyless Start System El ectric Wiring Circuit

Diagram .......................................................... 10E-7

Diagnostic Information and Procedures .......... 10E-8 Precautions in Diagnosing Troubles ................. 10E-8

Self-Diagnosis Function .................................... 10E-8

Keyless Start System Diagn osis Introduction ... 10E-8 Keyless Start System Chec

k ............................. 10E-8

Customer Questionnaire (E xample) .................. 10E-9

Key Indicator Lamp Check .............................. 10E-10

DTC Check...................................................... 10E-10

DTC Table ....................................................... 10E-11

DTC Clearance ............................................... 10E-12

Keyless Start System Symp tom Diagnosis ..... 10E-12

Keyless Start System Operation Inspection .... 10E-13

Door Lock Operation (Keyless Start System) . 10E-14

Inspection of Keyless Start Control Module and Its Circuits .............................................. 10E-14

No DTC Detection After Performing DTC Check ............................................................ 10E-18

Key Indicator Lamp Circuit Check (Key indicator lamp doesn’t light when ignition

knob switch is pushed.) ................................. 10E-20

Keyless Start Control Module Power and Ground Circuit Check .................................... 10E-22

DTC No. 11: Communi cation Error with

Steering Lock Unit ......................................... 10E-23

DTC No. 13 / No. 14: Release Signal Error from Steering Lock Unit / Steering Lock Unit

Malfunction .................................................... 10E-24

DTC No. 21 / No. 22: Internal Error of Keyless Start Control Module (EEPROM reading

error) / (EEPROM writing error) ............ ........ 10E-24

DTC No. 31: Lost Commun ication with BCM .. 10E-25

DTC No. 33: Control Module Communication

Bus Off .......................................................... 10E-27

DTC No. 51 / No. 52 / No. 53: Driver Side / Passenger Side / Rear End Door Request

Switch Failure................................................ 10E-28

Repair Instructions ............ .............................. 10E-30

Antennas and Request Switches Removal and Installation .............................................. 10E-30

Front Door (Driver and Passenger Side), Rear End Door Request Switch Inspection............ 10E-31

Steering Lock Unit Removal and Installation .. 10E-31

Steering Lock Unit Inspection ......................... 10E-31

Front Door Lock Switch In spection ................. 10E-31

Keyless Start Control Module Removal and Installation ..................................................... 10E-32

Remote Controller Inspection.......................... 10E-32

Replacement of Remote Controller Battery .... 10E-32

Registration Procedure for Remote Controller

ID Code ......................................................... 10E-33

Page 1406 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-3 Body Electrical Control System:

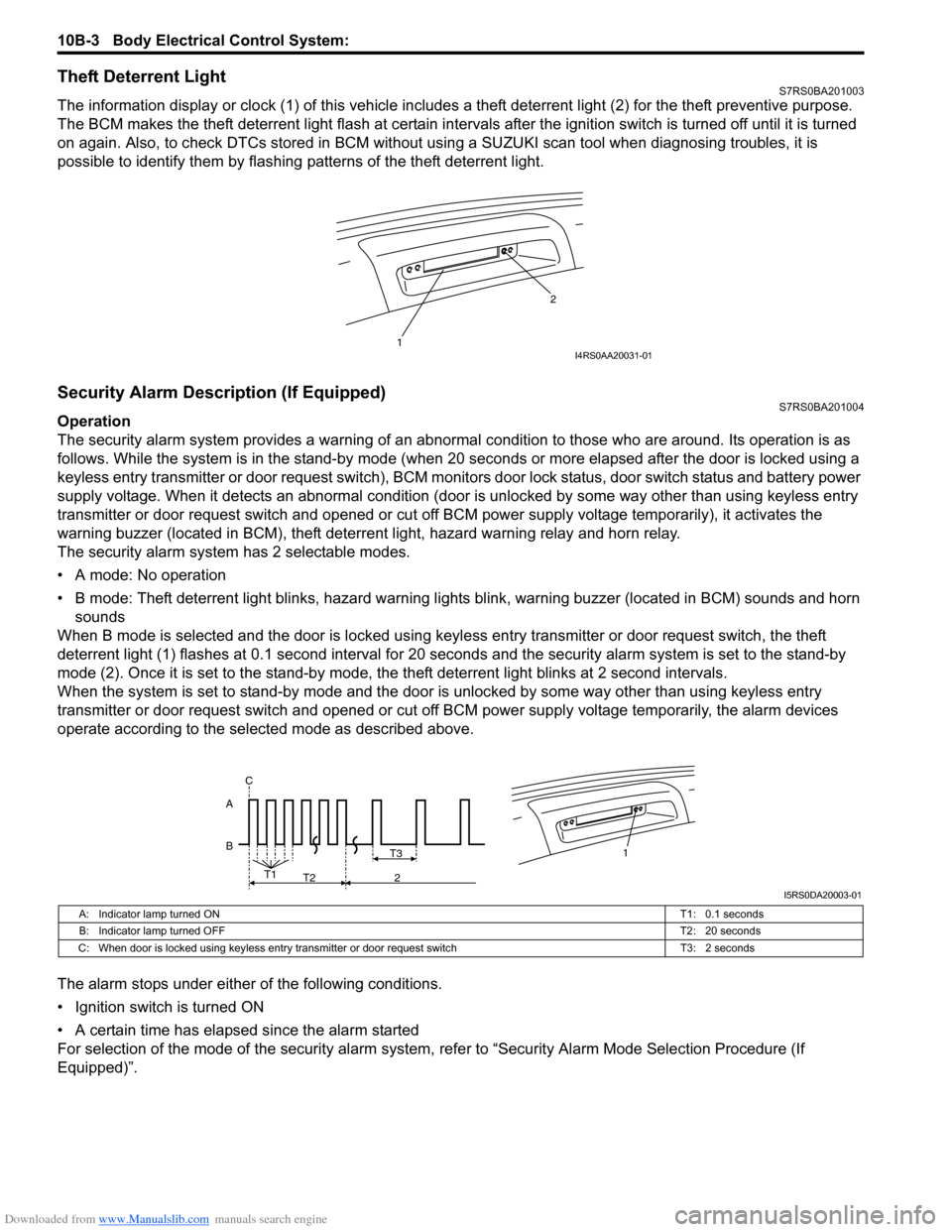

Theft Deterrent LightS7RS0BA201003

The information display or clock (1) of this vehicle includes a theft deterrent light (2) for the theft preventive purpose.

The BCM makes the theft deterrent light flash at certain interval s after the ignition switch is turned off until it is turned

on again. Also, to check DTCs stored in BCM without usin g a SUZUKI scan tool when diagnosing troubles, it is

possible to identify them by flashing patterns of the theft deterrent light.

Security Alarm Description (If Equipped)S7RS0BA201004

Operation

The security alarm system provides a warning of an abnormal condition to those who are around. Its operation is as

follows. While the system is in the stand- by mode (when 20 seconds or more elapsed after the door is locked using a

keyless entry transmitter or door request switch), BCM monitors door lock status, door switch status and battery power

supply voltage. When it detects an abnormal condition (door is unlocked by some way other than using keyless entry

transmitter or door request switch and opened or cut off BCM power supply voltage temporarily), it activates the

warning buzzer (located in BCM), theft deterr ent light, hazard warning relay and horn relay.

The security alarm system has 2 selectable modes.

• A mode: No operation

• B mode: Theft deterrent light blinks, hazard warning lights blink, warning buzzer (located in BCM) sounds and horn

sounds

When B mode is selected and the door is locked using keyl ess entry transmitter or door request switch, the theft

deterrent light (1) flashes at 0.1 second interval for 20 seconds and the se curity alarm system is set to the stand-by

mode (2). Once it is se t to the stand-by mode, the theft deterrent light blinks at 2 second intervals.

When the system is set to stand-by mode and the door is unlocked by some way other than using keyless entry

transmitter or door request switch and opened or cut off BCM power supply voltage temporarily, the alarm devices

operate according to the selected mode as described above.

The alarm stops under either of the following conditions.

• Ignition switch is turned ON

• A certain time has elapsed since the alarm started

For selection of the mode of the security alarm system , refer to “Security Alarm Mode Selection Procedure (If

Equipped)”.

1 2I4RS0AA20031-01

B A1T3

T1

T2 2

C

I5RS0DA20003-01

A: Indicator lamp turned ON

T1: 0.1 seconds

B: Indicator lamp turned OFF T2: 20 seconds

C: When door is locked using keyless entry tr ansmitter or door request switch T3: 2 seconds

Page 1412 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-9 Body Electrical Control System:

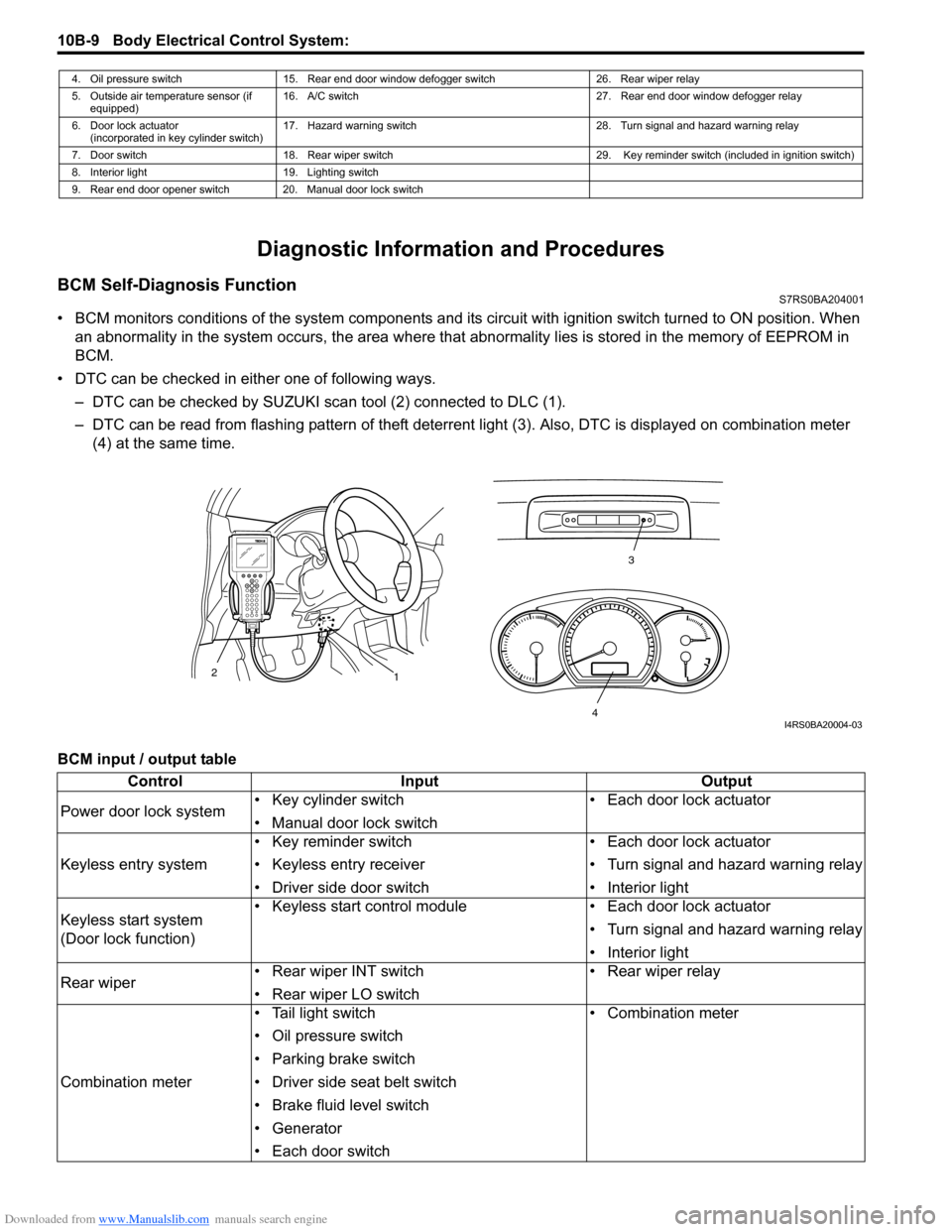

Diagnostic Information and Procedures

BCM Self-Diagnosis FunctionS7RS0BA204001

• BCM monitors conditions of the system components and its circuit with ignition switch turned to ON position. When

an abnormality in the system oc curs, the area where that abnormality lies is stored in the memory of EEPROM in

BCM.

• DTC can be checked in either one of following ways. – DTC can be checked by SUZUKI scan tool (2) connected to DLC (1).

– DTC can be read from flashing pattern of theft deterrent light (3). Also, DTC is displayed on combination meter

(4) at the same time.

BCM input / output table

4. Oil pressure switch 15. Rear end door window defogger switch 26. Rear wiper relay

5. Outside air temperature sensor (if equipped) 16. A/C switch

27. Rear end door window defogger relay

6. Door lock actuator (incorporated in key cylinder switch) 17. Hazard warning switch

28. Turn signal and hazard warning relay

7. Door switch 18. Rear wiper switch 29. Key reminder switch (included in ignition switch)

8. Interior light 19. Lighting switch

9. Rear end door opener switch 20. Manual door lock switch

3

1

2

4I4RS0BA20004-03

Control

Input Output

Power door lock system • Key cylinder switch

• Manual door lock switch • Each door lock actuator

Keyless entry system • Key reminder switch

• Keyless entry receiver

• Driver side door switch • Each door lock actuator

• Turn signal and hazard warning relay

• Interior light

Keyless start system

(Door lock function) • Keyless start control module

• Each door lock actuator

• Turn signal and hazard warning relay

• Interior light

Rear wiper • Rear wiper INT switch

• Rear wiper LO switch • Rear wiper relay

Combination meter • Tail light switch

• Oil pressure switch

• Parking brake switch

• Driver side seat belt switch

• Brake fluid level switch

• Generator

• Each door switch • Combination meter

Page 1413 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-10

Body Electrical Control System CheckS7RS0BA204002

Interior light• Each door switch

• Key reminder switch • Interior light

Warning buzzer • Key reminder switch

• Tail light switch

• Driver side door switch

• TCM (reverse signal) (if equipped)

• ECM (vehicle speed signal)

• Keyless start control module (if equipped) • Warning buzzer (located in BCM)

Rear end door window

defogger • Rear end door window defogger switch

• Generator • Rear end door window defogger

relay

Rear end door opener • Manual door lock switch (unlock signal)

• Key cylinder switch (unlock signal)

• Keyless entry transmitter (unlock signal) (if

equipped)

• Rear end door opener switch • Rear end door opener relay

Theft deterrent light • Key reminder switch • Theft deterrent light (located in

information display or clock)

Control Input Output

Step

Action YesNo

1 �) Customer complaint analysis

1) Perform customer complaint analysis.

Was customer complaint analysis performed? Go to Step 2.

Perform customer

complaint analysis.

2 �) Problem symptom confirmation

1) Perform problem symptom confirmation.

Does trouble recur? Go to Step 3.

Go to Step 7.

3 �) DTC check

1) Check DTC.

Is it malfunction code? Go to Step 4.

Go to Step 5.

4 �) Troubleshooting for DTC

1) Check and repair according to DTC diag. flow.

Are check and repair completed? Go to Step 7.

Check and repair

malfunction part(s).

5 �) Body electrical control system symptom diagnosis

1) Perform check and repair referring to “Symptom Diagnosis” of system having a trouble.

Is there faulty condition? Repair or replace

malfunction part(s).

Go to Step 6.

6 �) Check for intermittent problem

1) Check for interm ittent problem.

Is there faulty condition? Repair or replace

malfunction part(s).

Go to Step 7.

7 �) Final confirmation test

1) Clear DTC referring to “DTC Clearance”.

2) Check DTC referring to “DTC Check”.

Is there any DTC? Go to Step 4.

End.

Page 1414 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-11 Body Electrical Control System:

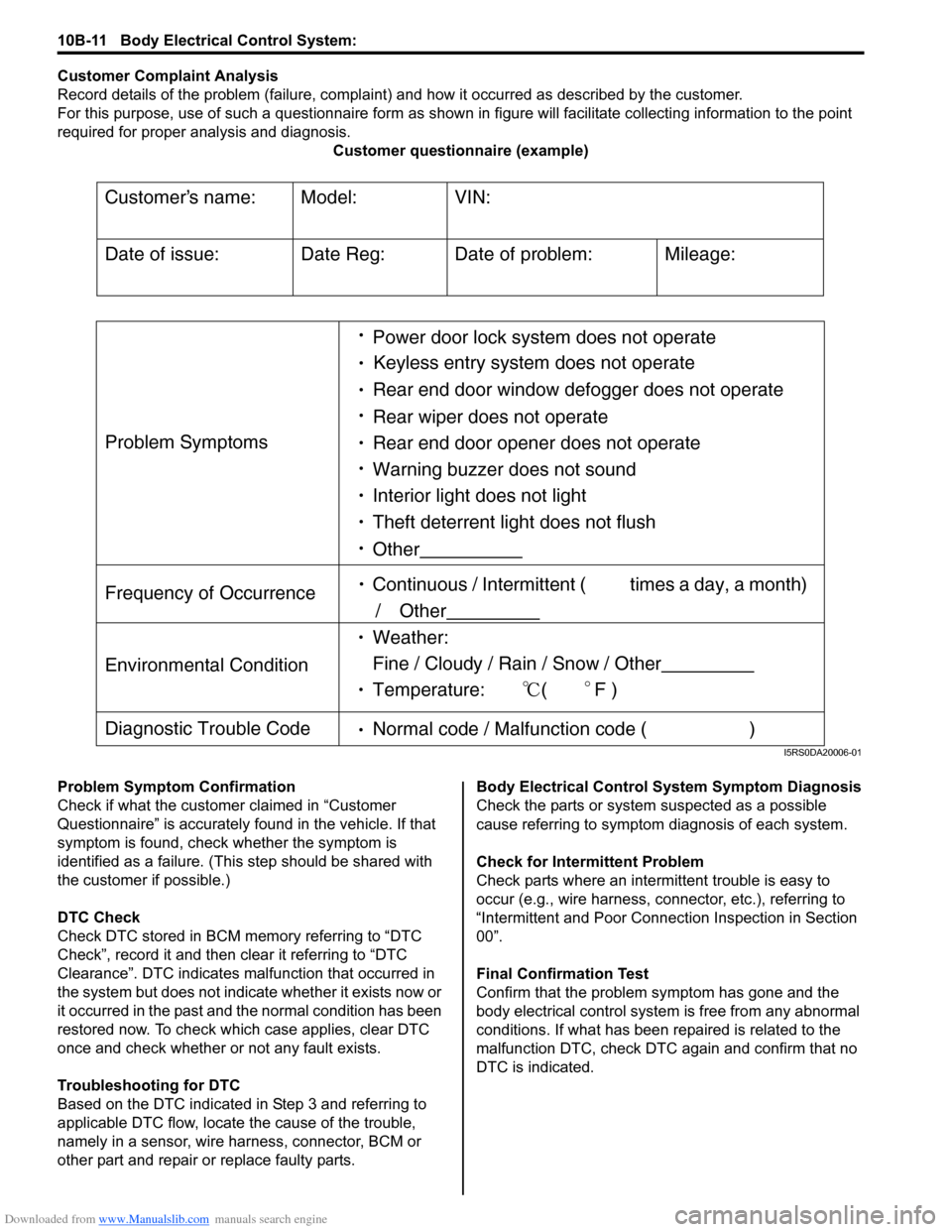

Customer Complaint Analysis

Record details of the problem (failure, complaint) and how it occurred as described by the customer.

For this purpose, use of such a questionnaire form as shown in figure will facilitate collectin g information to the point

required for proper analysis and diagnosis. Customer questionnaire (example)

Problem Symptom Confirmation

Check if what the custom er claimed in “Customer

Questionnaire” is accurately f ound in the vehicle. If that

symptom is found, check whether the symptom is

identified as a failure. (This step should be shared with

the customer if possible.)

DTC Check

Check DTC stored in BCM me mory referring to “DTC

Check”, record it and then clear it referring to “DTC

Clearance”. DTC indicates malfunction that occurred in

the system but does not indicate whether it exists now or

it occurred in the past and the normal condition has been

restored now. To check which case applies, clear DTC

once and check whether or not any fault exists.

Troubleshooting for DTC

Based on the DTC indicated in Step 3 and referring to

applicable DTC flow, locate the cause of the trouble,

namely in a sensor, wire harness, connector, BCM or

other part and repair or replace faulty parts. Body Electrical Control System Symptom Diagnosis

Check the parts or system

suspected as a possible

cause referring to symptom diagnosis of each system.

Check for Intermi ttent Problem

Check parts where an intermit tent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connec tion Inspection in Section

00”.

Final Confirmation Test

Confirm that the problem symptom has gone and the

body electrical control system is free from any abnormal

conditions. If what has been repaired is related to the

malfunction DTC, check DTC again and confirm that no

DTC is indicated.

Customers name:

Model:

VIN:

Date of issue:

Date Reg:

Date of problem:

Mileage:

Problem Symptoms

Power door lock system does not operate

Keyless entry system does not operate

Rear end door window defogger does not operate

Rear wiper does not operate

Rear end door opener does not operate

Other

Frequency of Occurrence

Continuous / Intermittent ( times a day, a month)

/ Other

Environmental Condition

Weather:

Fine / Cloudy / Rain / Snow / Other

Temperature: (F )

Diagnostic Trouble Code Normal code / Malfunction code ( )

Warning buzzer does not sound

Interior light does not light

Theft deterrent light does not flush

I5RS0DA20006-01

Page 1417 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-14

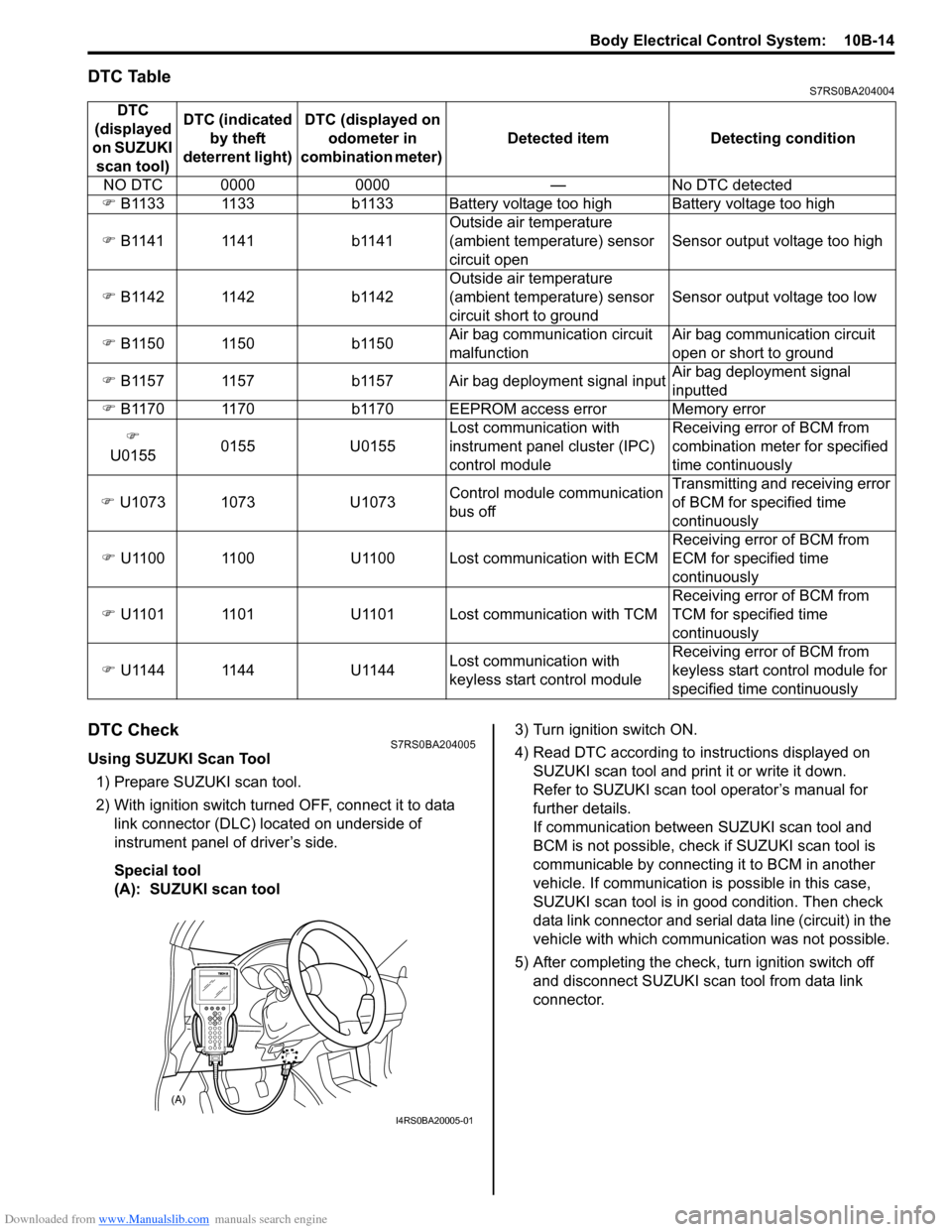

DTC TableS7RS0BA204004

DTC CheckS7RS0BA204005

Using SUZUKI Scan Tool1) Prepare SUZUKI scan tool.

2) With ignition switch turned OFF, connect it to data link connector (DLC) located on underside of

instrument panel of driver’s side.

Special tool

(A): SUZUKI scan tool 3) Turn ignition switch ON.

4) Read DTC according to

instructions displayed on

SUZUKI scan tool and print it or write it down.

Refer to SUZUKI scan tool operator’s manual for

further details.

If communication between SUZUKI scan tool and

BCM is not possible, check if SUZUKI scan tool is

communicable by connecting it to BCM in another

vehicle. If communication is possible in this case,

SUZUKI scan tool is in good condition. Then check

data link connector and serial data line (circuit) in the

vehicle with which communica tion was not possible.

5) After completing the check, turn ignition switch off and disconnect SUZUKI scan tool from data link

connector.

DTC

(displayed

on SUZUKI scan tool) DTC (indicated

by theft

deterrent light) DTC (displayed on

odometer in

combination meter) Detected item Detecting condition

NO DTC 0000 0000 — No DTC detected

�) B1133 1133 b1133 Battery voltage too high Battery voltage too high

�) B1141 1141 b1141 Outside air temperature

(ambient temperature) sensor

circuit openSensor output voltage too high

�) B1142 1142 b1142 Outside air temperature

(ambient temperature) sensor

circuit short to groundSensor output voltage too low

�) B1150 1150 b1150 Air bag communication circuit

malfunctionAir bag communication circuit

open or short to ground

�) B1157 1157 b1157 Air bag deployment signal input Air bag deployment signal

inputted

�) B1170 1170 b1170 EEPROM access error Memory error

�)

U0155 0155 U0155 Lost communication with

instrument panel cluster (IPC)

control moduleReceiving error of BCM from

combination mete

r for specified

time continuously

�) U1073 1073 U1073 Control module communication

bus offTransmitting and receiving error

of BCM for specified time

continuously

�) U1100 1100 U1100 Lost communication with ECM Receiving error of BCM from

ECM for specified time

continuously

�) U1101 1101 U1101 Lost communication with TCM Receiving error of BCM from

TCM for specified time

continuously

�) U1144 1144 U1144 Lost communication with

keyless start control moduleReceiving error of BCM from

keyless start control module for

specified time continuously

(A)

I4RS0BA20005-01

Page 1418 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-15 Body Electrical Control System:

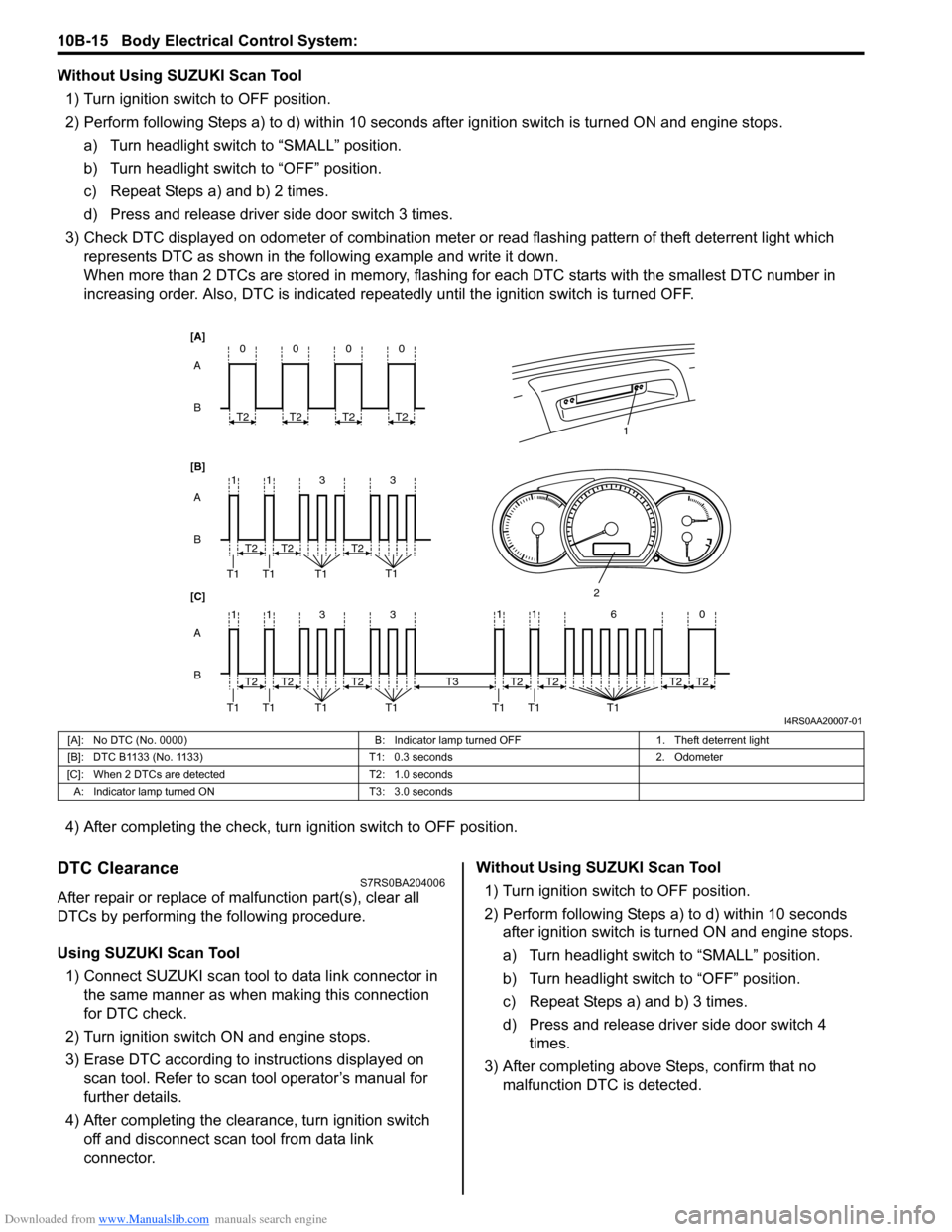

Without Using SUZUKI Scan Tool1) Turn ignition switch to OFF position.

2) Perform following Steps a) to d) within 10 seconds af ter ignition switch is turned ON and engine stops.

a) Turn headlight switch to “SMALL” position.

b) Turn headlight switch to “OFF” position.

c) Repeat Steps a) and b) 2 times.

d) Press and release driver side door switch 3 times.

3) Check DTC displayed on odometer of combination meter or read flashing pattern of theft deterrent light which

represents DTC as shown in the following example and write it down.

When more than 2 DTCs are stored in memory, flashing for each DTC starts with the smallest DTC number in

increasing order. Also, DTC is indicated repeatedly until the ignition switch is turned OFF.

4) After completing the check, turn ignition switch to OFF position.

DTC ClearanceS7RS0BA204006

After repair or replace of malfunction part(s), clear all

DTCs by performing the following procedure.

Using SUZUKI Scan Tool 1) Connect SUZUKI scan tool to data link connector in the same manner as when making this connection

for DTC check.

2) Turn ignition switch ON and engine stops.

3) Erase DTC according to instructions displayed on scan tool. Refer to scan tool operator’s manual for

further details.

4) After completing the clear ance, turn ignition switch

off and disconnect scan tool from data link

connector. Without Using SUZUKI Scan Tool

1) Turn ignition switch to OFF position.

2) Perform following Steps a) to d) within 10 seconds after ignition switch is turned ON and engine stops.

a) Turn headlight switch to “SMALL” position.

b) Turn headlight switch to “OFF” position.

c) Repeat Steps a) and b) 3 times.

d) Press and release driver side door switch 4 times.

3) After completing above Steps, confirm that no malfunction DTC is detected.

B A

[B] [A]

[C]

B A B A

3

113

3

113

T2

T1 T1 T1 T1

1

2

T2T2

T2

T1 T1 T1 T1T2T2

0

T2

0

T2

0

T2

0

T2

11 6 0

T1 T1 T1

T2

T3T2T2T2

I4RS0AA20007-01

[A]: No DTC (No. 0000) B: Indicator lamp turned OFF1. Theft deterrent light

[B]: DTC B1133 (No. 1133) T1: 0.3 seconds2. Odometer

[C]: When 2 DTCs are detected T2: 1.0 seconds

A: Indicator lamp tur ned ON T3: 3.0 seconds

Page 1420 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-17 Body Electrical Control System:

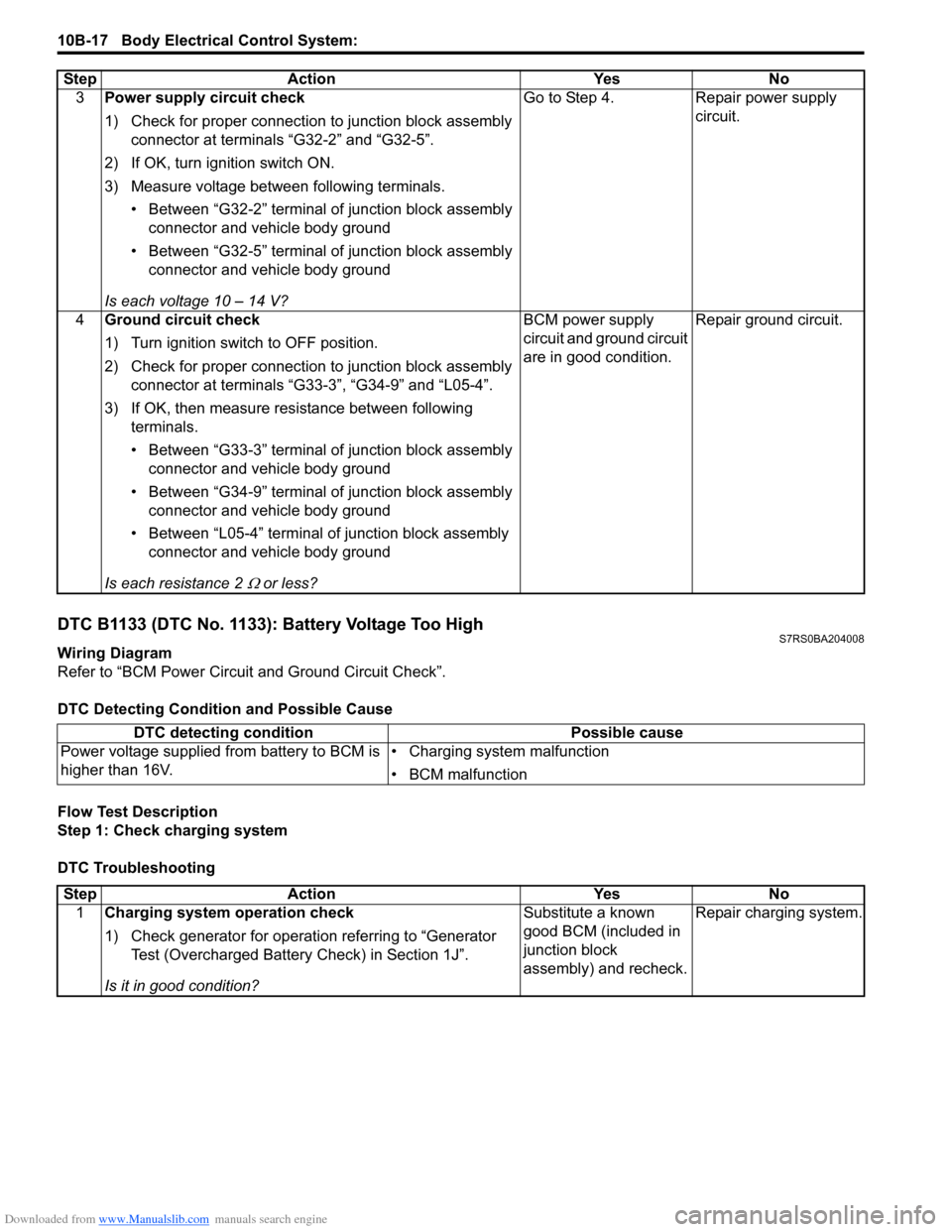

DTC B1133 (DTC No. 1133): Battery Voltage Too HighS7RS0BA204008

Wiring Diagram

Refer to “BCM Power Circuit and Ground Circuit Check”.

DTC Detecting Conditi on and Possible Cause

Flow Test Description

Step 1: Check charging system

DTC Troubleshooting 3

Power supply circuit check

1) Check for proper connection to junction block assembly

connector at terminals “G32-2” and “G32-5”.

2) If OK, turn ignition switch ON.

3) Measure voltage between following terminals. • Between “G32-2” terminal of junction block assembly connector and vehicle body ground

• Between “G32-5” terminal of junction block assembly connector and vehicle body ground

Is each voltage 10 – 14 V? Go to Step 4. Repair power supply

circuit.

4 Ground circuit check

1) Turn ignition switch to OFF position.

2) Check for proper connection to junction block assembly

connector at terminals “G33-3”, “G34-9” and “L05-4”.

3) If OK, then measure resistance between following terminals.

• Between “G33-3” terminal of junction block assembly connector and vehicle body ground

• Between “G34-9” terminal of junction block assembly connector and vehicle body ground

• Between “L05-4” terminal of junction block assembly connector and vehicle body ground

Is each resistance 2

Ω or less? BCM power supply

circuit and ground circuit

are in good condition.

Repair ground circuit.

Step Action Yes No

DTC detecting condition

Possible cause

Power voltage supplied from battery to BCM is

higher than 16V. • Charging system malfunction

• BCM malfunction

Step

Action YesNo

1 Charging system operation check

1) Check generator for operation referring to “Generator

Test (Overcharged Battery Check) in Section 1J”.

Is it in good condition? Substitute a known

good BCM (included in

junction block

assembly) and recheck.

Repair charging system.

Page 1421 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-18

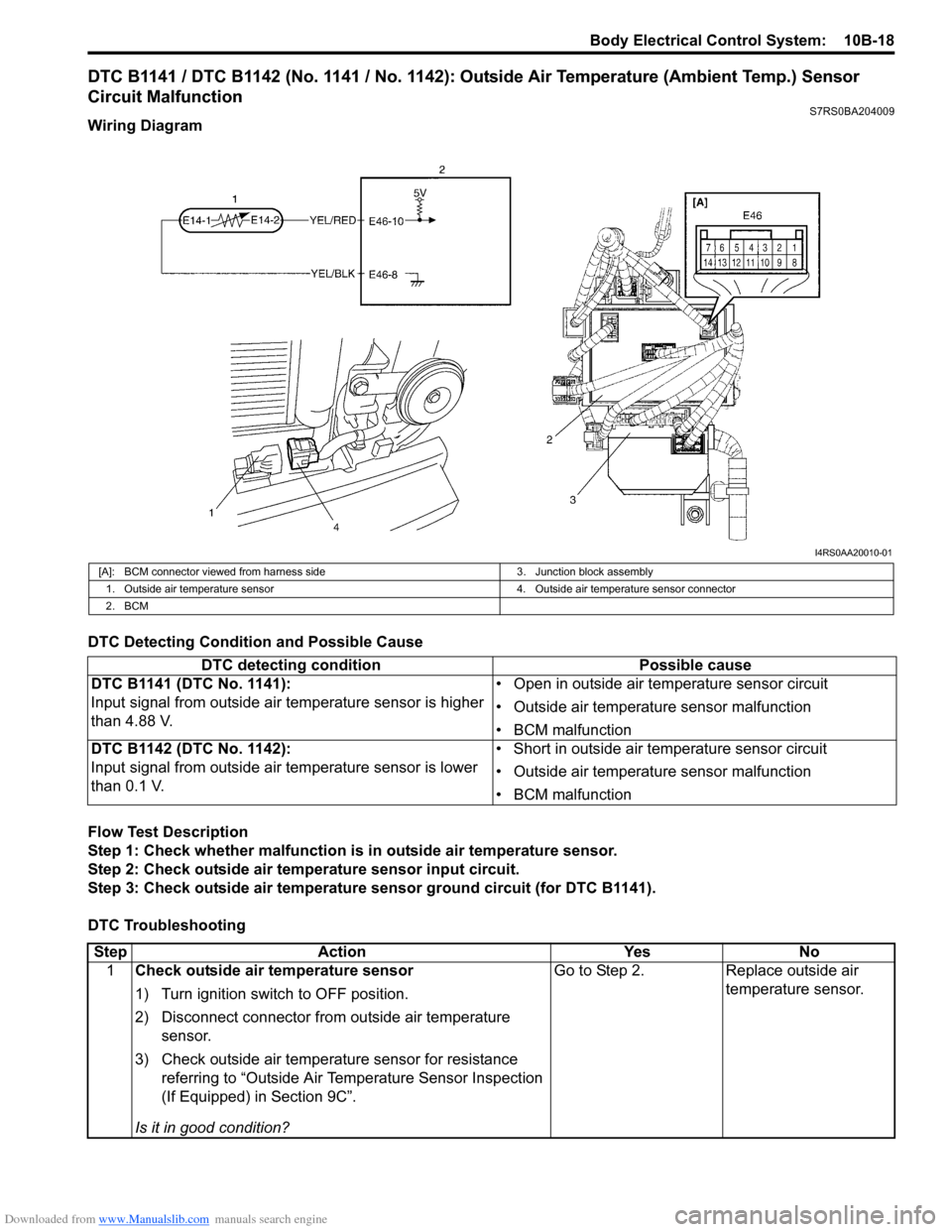

DTC B1141 / DTC B1142 (No. 1141 / No. 1142): Outside Air Temperature (Ambient Temp.) Sensor

Circuit Malfunction

S7RS0BA204009

Wiring Diagram

DTC Detecting Condition and Possible Cause

Flow Test Description

Step 1: Check whether malfunction is in outside air temperature sensor.

Step 2: Check outside air temperature sensor input circuit.

Step 3: Check outside air temperature sensor ground circuit (for DTC B1141).

DTC Troubleshooting

I4RS0AA20010-01

[A]: BCM connector viewed from harness side 3. Junction block assembly

1. Outside air temperature sensor 4. Outside air temperature sensor connector

2. BCM

DTC detecting condition Possible cause

DTC B1141 (DTC No. 1141):

Input signal from outside air temperature sensor is higher

than 4.88 V. • Open in outside air temperature sensor circuit

• Outside air temperature sensor malfunction

• BCM malfunction

DTC B1142 (DTC No. 1142):

Input signal from outside air temperature sensor is lower

than 0.1 V. • Short in outside air temperature sensor circuit

• Outside air temperature sensor malfunction

• BCM malfunction

Step

Action YesNo

1 Check outside air temperature sensor

1) Turn ignition switch to OFF position.

2) Disconnect connector from outside air temperature

sensor.

3) Check outside air temperature sensor for resistance referring to “Outside Air Temperature Sensor Inspection

(If Equipped) in Section 9C”.

Is it in good condition? Go to Step 2.

Replace outside air

temperature sensor.

Page 1422 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-19 Body Electrical Control System:

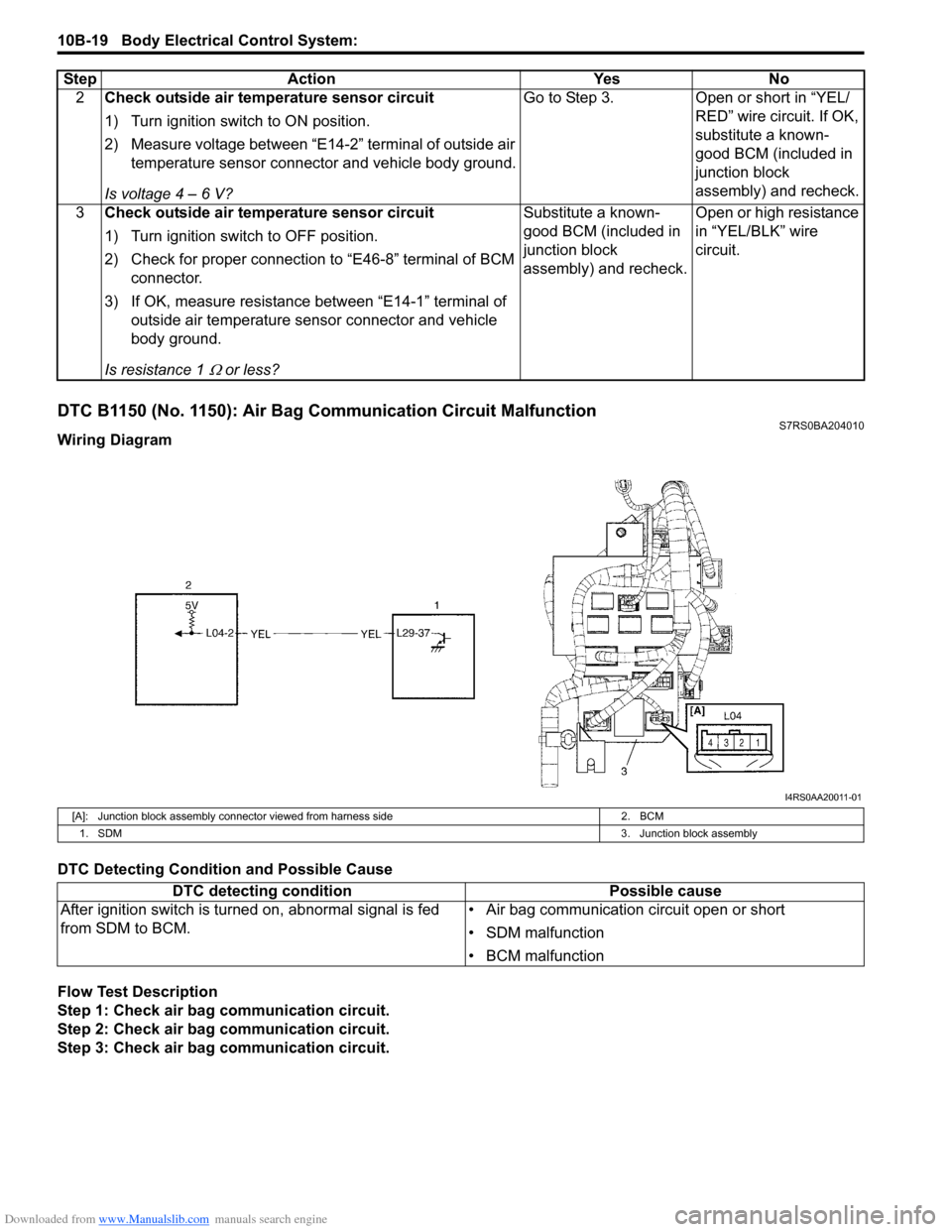

DTC B1150 (No. 1150): Air Bag Communication Circuit MalfunctionS7RS0BA204010

Wiring Diagram

DTC Detecting Condition and Possible Cause

Flow Test Description

Step 1: Check air bag communication circuit.

Step 2: Check air bag communication circuit.

Step 3: Check air bag communication circuit. 2

Check outside air temperature sensor circuit

1) Turn ignition switch to ON position.

2) Measure voltage between “E14-2” terminal of outside air

temperature sensor connector and vehicle body ground.

Is voltage 4 – 6 V? Go to Step 3. Open or short in “YEL/

RED” wire circuit. If OK,

substitute a known-

good BCM (included in

junction block

assembly) and recheck.

3 Check outside air temperature sensor circuit

1) Turn ignition switch to OFF position.

2) Check for proper connection to “E46-8” terminal of BCM

connector.

3) If OK, measure resistance between “E14-1” terminal of outside air temperature sens or connector and vehicle

body ground.

Is resistance 1

Ω or less? Substitute a known-

good BCM (included in

junction block

assembly) and recheck.

Open or high resistance

in “YEL/BLK” wire

circuit.

Step Action Yes No

I4RS0AA20011-01

[A]: Junction block assembly connect

or viewed from harness side 2. BCM

1. SDM 3. Junction block assembly

DTC detecting conditionPossible cause

After ignition switch is turned on, abnormal signal is fed

from SDM to BCM. • Air bag communication circuit open or short

• SDM malfunction

• BCM malfunction