section 1 SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 955 of 1496

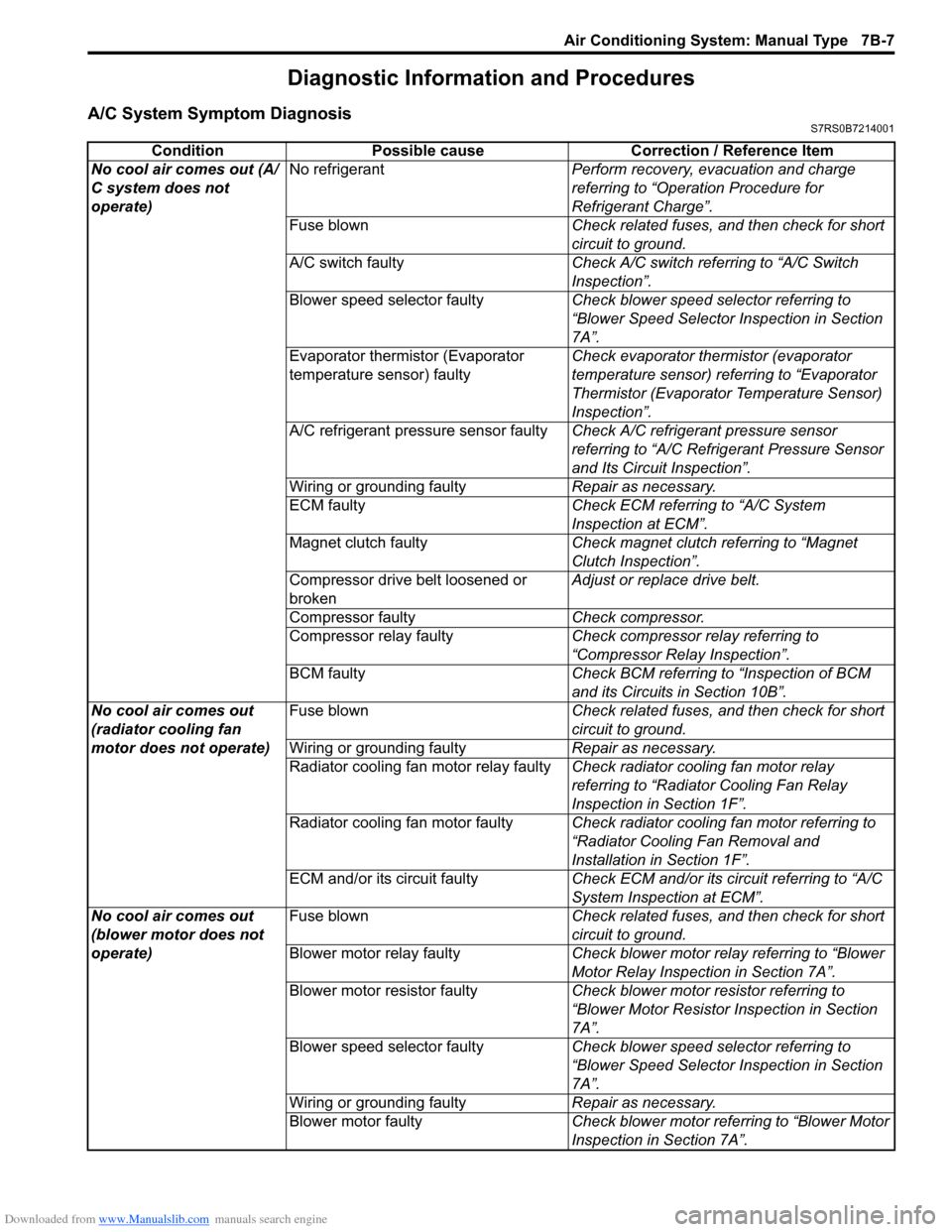

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-7

Diagnostic Information and Procedures

A/C System Symptom DiagnosisS7RS0B7214001

ConditionPossible cause Correction / Reference Item

No cool air comes out (A/

C system does not

operate) No refrigerant

Perform recovery, evacuation and charge

referring to “Operation Procedure for

Refrigerant Charge”.

Fuse blown Check related fuses, and then check for short

circuit to ground.

A/C switch faulty Check A/C switch referring to “A/C Switch

Inspection”.

Blower speed selector faulty Check blower speed selector referring to

“Blower Speed Selector Inspection in Section

7A”.

Evaporator thermistor (Evaporator

temperature sensor) faulty Check evaporator thermistor (evaporator

temperature sensor) referring to “Evaporator

Thermistor (Evaporator Temperature Sensor)

Inspection”.

A/C refrigerant pressure sensor faulty Check A/C refrigerant pressure sensor

referring to “A/C Refrigerant Pressure Sensor

and Its Circuit Inspection”.

Wiring or grounding faulty Repair as necessary.

ECM faulty Check ECM referring to “A/C System

Inspection at ECM”.

Magnet clutch faulty Check magnet clutch referring to “Magnet

Clutch Inspection”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Compressor relay faulty Check compressor relay referring to

“Compressor Relay Inspection”.

BCM faulty Check BCM referring to “Inspection of BCM

and its Circuits in Section 10B”.

No cool air comes out

(radiator cooling fan

motor does not operate) Fuse blown

Check related fuses, and then check for short

circuit to ground.

Wiring or grounding faulty Repair as necessary.

Radiator cooling fan motor relay faulty Check radiator cooling fan motor relay

referring to “Radiator Cooling Fan Relay

Inspection in Section 1F”.

Radiator cooling fan motor faulty Check radiator cooling fan motor referring to

“Radiator Cooling Fan Removal and

Installation in Section 1F”.

ECM and/or its circuit faulty Check ECM and/or its circuit referring to “A/C

System Inspection at ECM”.

No cool air comes out

(blower motor does not

operate) Fuse blown

Check related fuses, and then check for short

circuit to ground.

Blower motor relay faulty Check blower motor relay referring to “Blower

Motor Relay Inspection in Section 7A”.

Blower motor resistor faulty Check blower motor resistor referring to

“Blower Motor Resistor Inspection in Section

7A”.

Blower speed selector faulty Check blower speed selector referring to

“Blower Speed Selector Inspection in Section

7A”.

Wiring or grounding faulty Repair as necessary.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Page 956 of 1496

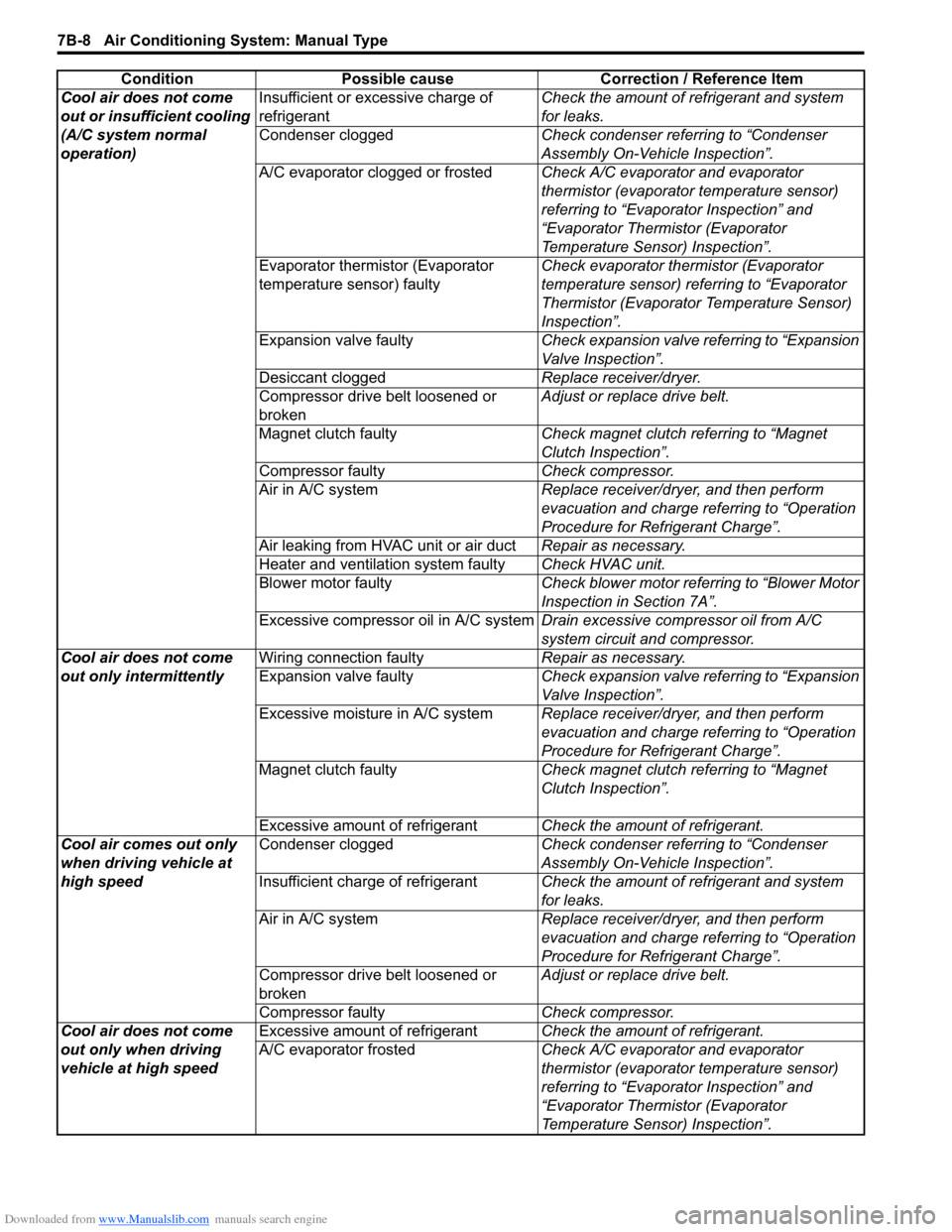

Downloaded from www.Manualslib.com manuals search engine 7B-8 Air Conditioning System: Manual Type

Cool air does not come

out or insufficient cooling

(A/C system normal

operation)Insufficient or excessive charge of

refrigerant

Check the amount of refrigerant and system

for leaks.

Condenser clogged Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

A/C evaporator clogged or frosted Check A/C evaporator and evaporator

thermistor (evaporator temperature sensor)

referring to “Evaporator Inspection” and

“Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Evaporator thermistor (Evaporator

temperature sensor) faulty Check evaporator thermistor (Evaporator

temperature sensor) referring to “Evaporator

Thermistor (Evaporator Temperature Sensor)

Inspection”.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Desiccant clogged Replace receiver/dryer.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Magnet clutch faulty Check magnet clutch referring to “Magnet

Clutch Inspection”.

Compressor faulty Check compressor.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Air leaking from HVAC unit or air duct Repair as necessary.

Heater and ventilation system faulty Check HVAC unit.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Excessive compressor oil in A/C system Drain excessive compressor oil from A/C

system circuit and compressor.

Cool air does not come

out only intermittently Wiring connection faulty

Repair as necessary.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Excessive moisture in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Magnet clutch faulty Check magnet clutch referring to “Magnet

Clutch Inspection”.

Excessive amount of refrigerant Check the amount of refrigerant.

Cool air comes out only

when driving vehicle at

high speed Condenser clogged

Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

Insufficient charge of refrigerant Check the amount of refrigerant and system

for leaks.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Cool air does not come

out only when driving

vehicle at high speed Excessive amount of refrigerant

Check the amount of refrigerant.

A/C evaporator frosted Check A/C evaporator and evaporator

thermistor (evaporator temperature sensor)

referring to “Evaporator Inspection” and

“Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Condition Possible cause Correction / Reference Item

Page 957 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-9

Abnormal Noise Symptom Diagnosis of A/C SystemS7RS0B7214002

Abnormal Noise from Compressor

Abnormal Noise from Magnetic Clutch

Abnormal Noise from Tubing

Abnormal Noise from Condenser Assembly

Abnormal Noise from Crankshaft PulleyInsufficient airflow of

cooled air

A/C evaporator clogged or frosted

Check A/C evaporator and evaporator

thermistor (evaporator temperature sensor)

referring to “Evaporator Inspection” and

“Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Air leaking from HVAC unit or air duct Repair as necessary.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Wiring or grounding faulty Repair as necessary.

Condition Possible cause Correction / Reference Item

Condition

Possible cause Correction / Reference Item

During compressor

operation, a rumbling

noise is heard

proportional to engine

revolutions Inadequate clearance in scroll area

Replace compressor.

A loud noise is heard at a

certain rpm,

disproportionately to

engine revolution Loose or faulty compressor drive belt

Adjust drive belt tension or replace drive belt.

Loose compressor mounting bolts Retighten mounting bolts.

A loud rattle is heard at

low engine rpm Loose compressor clutch plate bolt

Retighten clutch plate bolt.

Replace compressor if it was operated in this

condition for a long time.

Condition Possible cause Correction / Reference Item

A rumbling noise is heard

when compressor is not

in operation Worn or damaged bearings

Replace magnet clutch assembly.

A chattering noise is

heard when compressor

is in operation Faulty magnet clutch clearance

(excessive clearance)

Adjust magnet clutch clearance.

Worn magnet clutch friction surface Replace magnet clutch assembly.

Compressor oil leaked from shaft seal,

contaminating the friction surface Replace compressor body assembly.

Condition

Possible cause Correction / Reference Item

A droning noise is heard

from inside of the vehicle,

but not particularly

noticeable in engine

compartment Faulty tubing clamps

Reposition clamps or increase the number of

clamps.

Resonance caused by pulsation from

variations in re frigerant pressure Attach a silencer to tubing, or modify its

position and length.

Condition

Possible cause Correction / Reference Item

Considerable vibration in

condenser assembly Resonance from condenser assembly

bracket and body Firmly insert a silenc

er between condenser

assembly bracket and body.

Condition Possible cause Correction / Reference Item

A large rattling noise is

heard at idle or sudden

acceleration Loosen crankshaft pulley bolt

Retighten bolt.

Page 960 of 1496

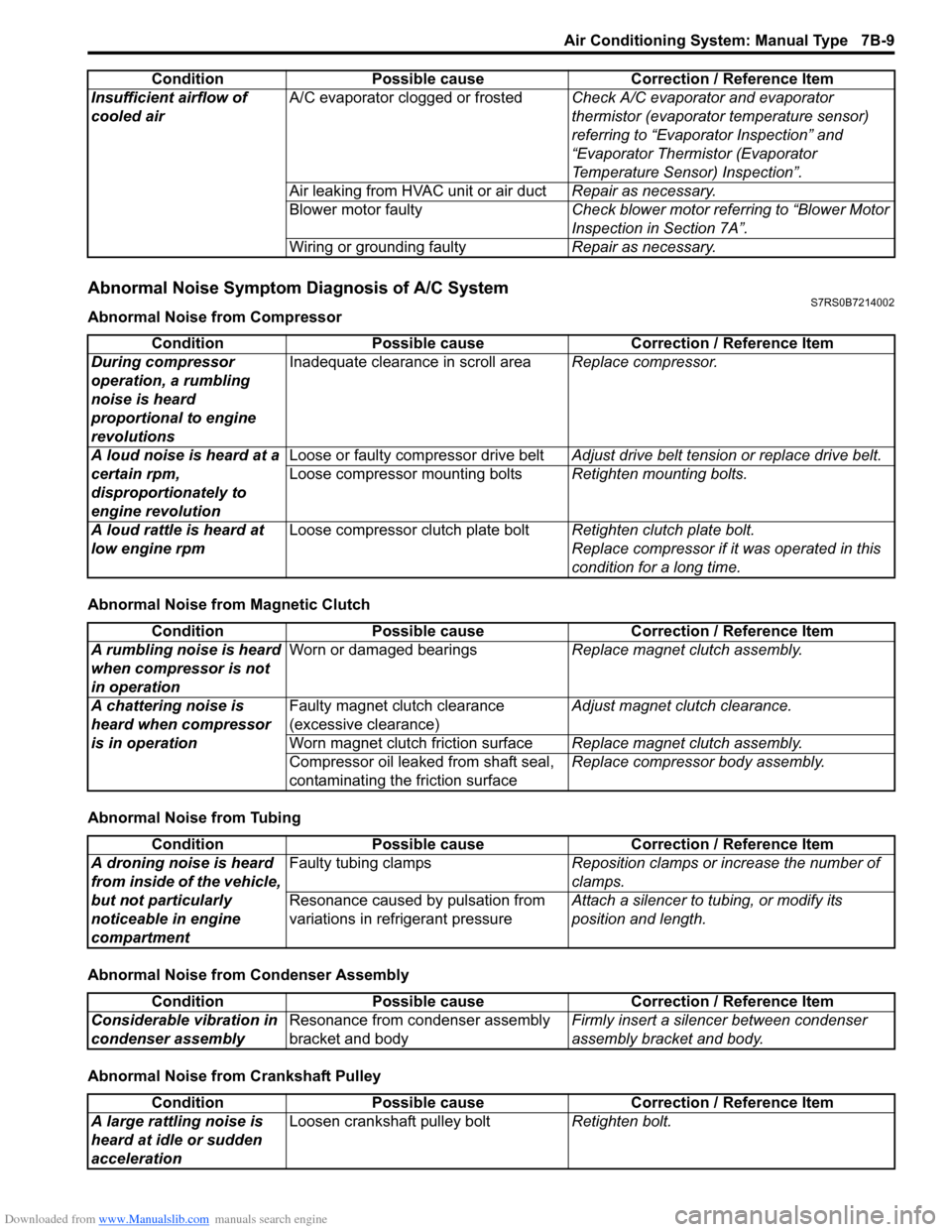

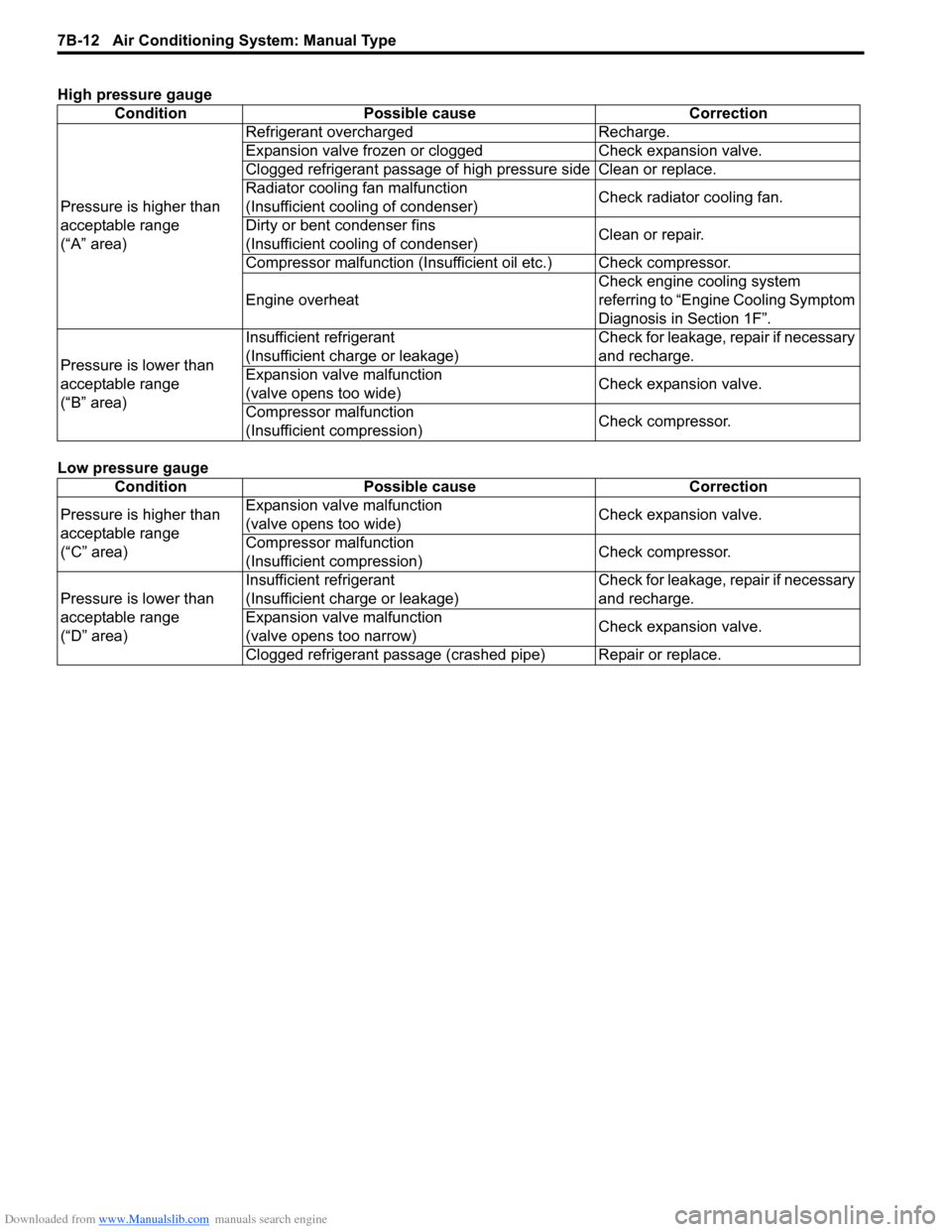

Downloaded from www.Manualslib.com manuals search engine 7B-12 Air Conditioning System: Manual Type

High pressure gauge

Low pressure gaugeCondition Possible cause Correction

Pressure is higher than

acceptable range

(“A” area) Refrigerant overcharged Recharge.

Expansion valve frozen or clogged Check expansion valve.

Clogged refrigerant passage of high pressure side Clean or replace.

Radiator cooling fan malfunction

(Insufficient cooling of condenser)

Check radiator cooling fan.

Dirty or bent condenser fins

(Insufficient cooling of condenser) Clean or repair.

Compressor malfunction (Insuffi cient oil etc.) Check compressor.

Engine overheat Check engine cooling system

referring to “Engin

e Cooling Symptom

Diagnosis in Section 1F”.

Pressure is lower than

acceptable range

(“B” area) Insufficient refrigerant

(Insufficient charge or leakage)

Check for leakage, repair if necessary

and recharge.

Expansion valve malfunction

(valve opens too wide) Check expansion valve.

Compressor malfunction

(Insufficient compression) Check compressor.

Condition Possible cause Correction

Pressure is higher than

acceptable range

(“C” area) Expansion valve malfunction

(valve opens too wide)

Check expansion valve.

Compressor malfunction

(Insufficient compression) Check compressor.

Pressure is lower than

acceptable range

(“D” area) Insufficient refrigerant

(Insufficient charge or leakage)

Check for leakage, repair if necessary

and recharge.

Expansion valve malfunction

(valve opens too narrow) Check expansion valve.

Clogged refrigerant passage (crashed pipe) Repair or replace.

Page 963 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-15

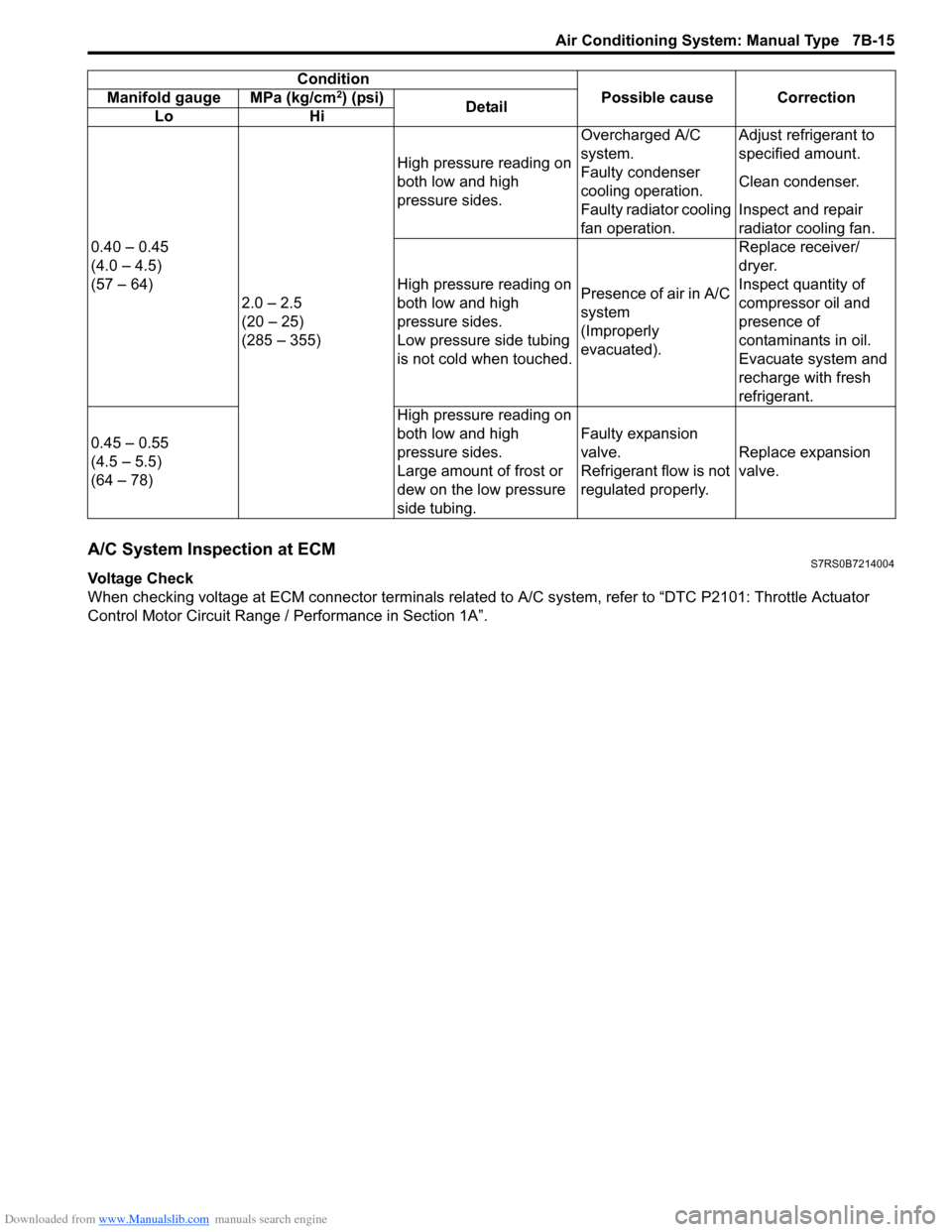

A/C System Inspection at ECMS7RS0B7214004

Voltage Check

When checking voltage at ECM connector terminals related to A/C system, refer to “DTC P2101: Throttle Actuator

Control Motor Circuit Range / Performance in Section 1A”.

0.40 – 0.45

(4.0 – 4.5)

(57 – 64)

2.0 – 2.5

(20 – 25)

(285 – 355) High pressure reading on

both low and high

pressure sides.

Overcharged A/C

system.

Adjust refrigerant to

specified amount.

Faulty condenser

cooling operation. Clean condenser.

Faulty radiator cooling

fan operation. Inspect and repair

radiator cooling fan.

High pressure reading on

both low and high

pressure sides.

Low pressure side tubing

is not cold when touched. Presence of air in A/C

system

(Improperly

evacuated).Replace receiver/

dryer.

Inspect quantity of

compressor oil and

presence of

contaminants in oil.

Evacuate system and

recharge with fresh

refrigerant.

0.45 – 0.55

(4.5 – 5.5)

(64 – 78) High pressure reading on

both low and high

pressure sides.

Large amount of frost or

dew on the low pressure

side tubing.Faulty expansion

valve.

Refrigerant flow is not

regulated properly.

Replace expansion

valve.

Condition

Possible cause Correction

Manifold gauge MPa (kg/cm

2) (psi)

Detail

Lo Hi

Page 969 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-21

Removal of Manifold Gauge Set

WARNING!

High pressure side is under high pressure.

Therefore, be careful not to get injured

especially on your eyes and skin.

For the A/C system charged with the specified amount of

refrigerant, remove manifold gauge set as follows:

1) Close low pressure side valve of manifold gauge set. (The high pressure side valve is closed continuously

during the process of charging.)

2) Close refrigerant container valve.

3) Stop engine.

4) Using shop rag, remove charging hoses from service valves. This operation must be performed quickly.

5) Put caps on service valves.

Check A/C System for Refrigerant Leaks

Whenever a refrigerant leak is suspected in the system

or any service operation has been performed which may

result in malfunction of lines and connections, it is

advisable to check for leaks.

Common sense should be used during refrigerant leak

test, since the need and extent of any such test will, in

general, depend upon the nature of a complaint and the

type of a service performed on the system.

Liquid leak detector

WARNING!

• To prevent explosions and fires, make sure that there are no flammables in the vicinity.

• When the refrigerant exposed to fire, it turns into a poisonous gas (phosgene). Do

not inhale this gas.

There is a number of fittings and places throughout the

A/C system where a liquid leak detector solution may be

used to pinpoint refrigerant leaks.

By merely applying the solution to the area in question

with a swab, such as attached to the cap of a vial,

bubbles will form within seconds if there is a leak.

For confined areas, such as sections of the evaporator

and condenser, an electronic (refrigerant) leak detector

is more practical fo r determining leaks.

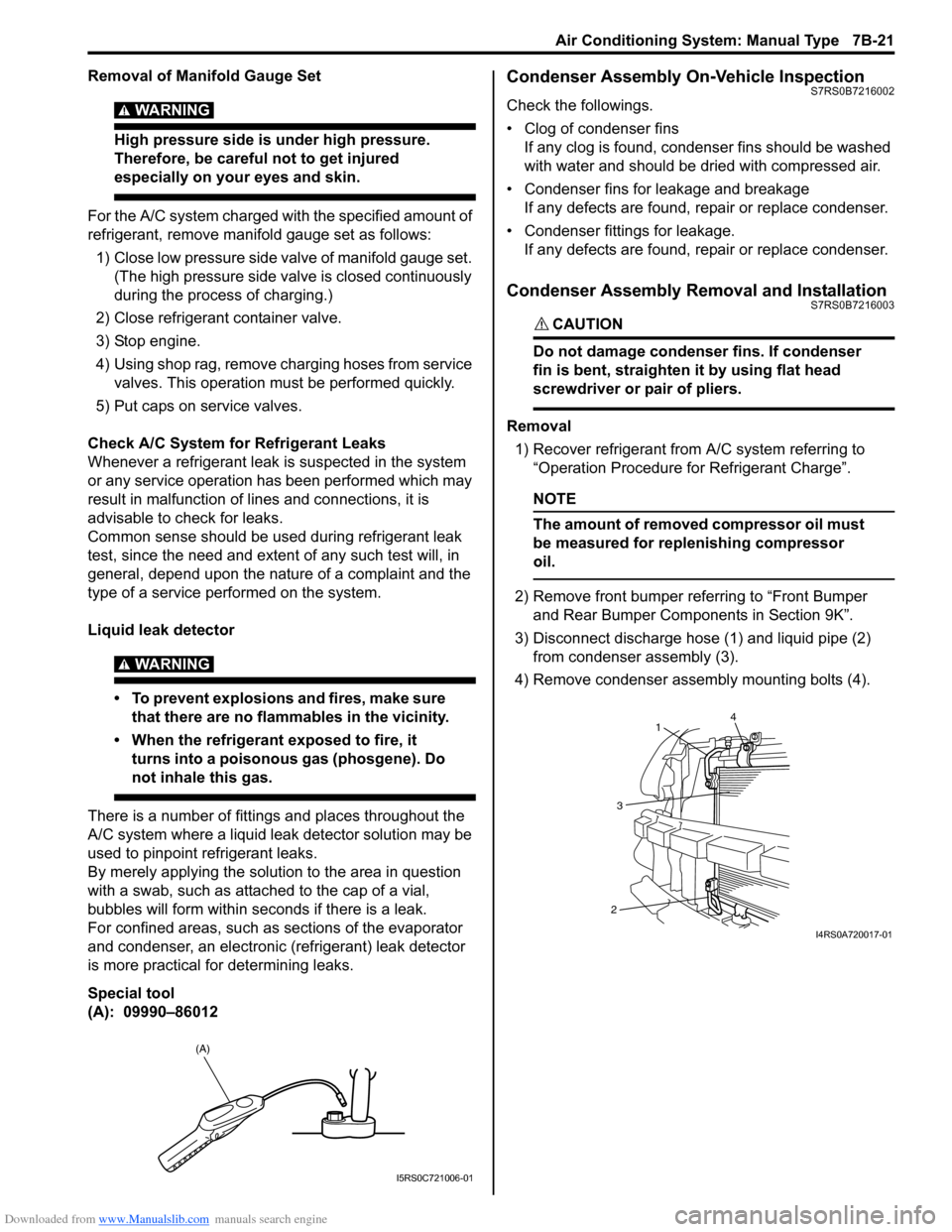

Special tool

(A): 09990–86012

Condenser Assembly On-Vehicle InspectionS7RS0B7216002

Check the followings.

• Clog of condenser fins If any clog is found, cond enser fins should be washed

with water and should be dried with compressed air.

• Condenser fins for leakage and breakage If any defects are found, repair or replace condenser.

• Condenser fittings for leakage. If any defects are found, repair or replace condenser.

Condenser Assembly Removal and InstallationS7RS0B7216003

CAUTION!

Do not damage condenser fins. If condenser

fin is bent, straighten it by using flat head

screwdriver or pair of pliers.

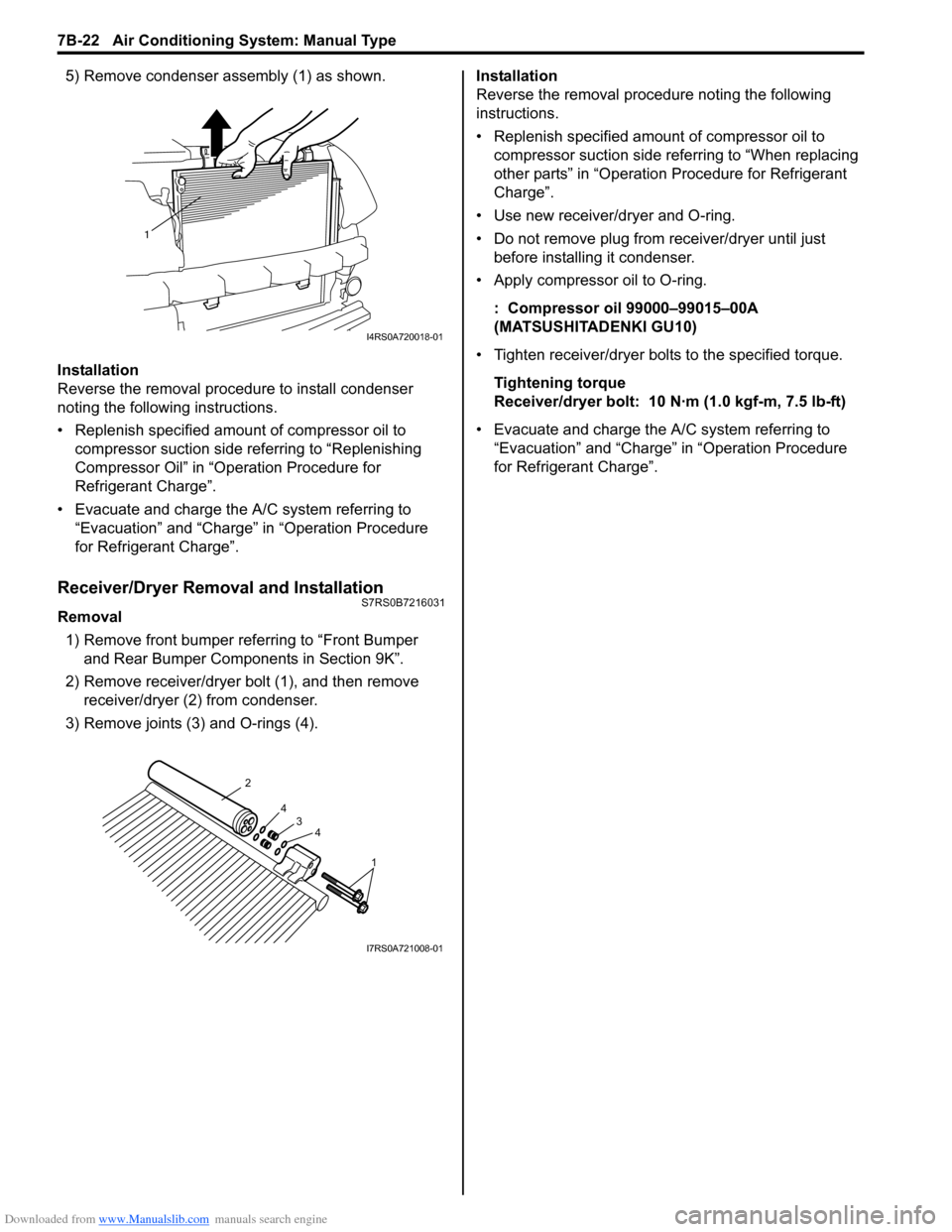

Removal

1) Recover refrigerant from A/C system referring to “Operation Procedure for Refrigerant Charge”.

NOTE

The amount of removed compressor oil must

be measured for replenishing compressor

oil.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect discharge hose (1) and liquid pipe (2) from condenser assembly (3).

4) Remove condenser assembly mounting bolts (4).

(A)

I5RS0C721006-01

4

1

3

2

I4RS0A720017-01

Page 970 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-22 Air Conditioning System: Manual Type

5) Remove condenser assembly (1) as shown.

Installation

Reverse the removal procedure to install condenser

noting the following instructions.

• Replenish specified amount of compressor oil to compressor suction side referring to “Replenishing

Compressor Oil” in “Operation Procedure for

Refrigerant Charge”.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

Receiver/Dryer Removal and InstallationS7RS0B7216031

Removal

1) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

2) Remove receiver/dryer bolt (1), and then remove receiver/dryer (2) from condenser.

3) Remove joints (3) and O-rings (4). Installation

Reverse the removal procedure noting the following

instructions.

• Replenish specified amount of compressor oil to

compressor suction side referring to “When replacing

other parts” in “Operation Procedure for Refrigerant

Charge”.

• Use new receiver/dryer and O-ring.

• Do not remove plug from receiver/dryer until just before installin g it condenser.

• Apply compressor oil to O-ring.

: Compressor oil 99000–99015–00A

(MATSUSHITADENKI GU10)

• Tighten receiver/dryer bolts to the specified torque. Tightening torque

Receiver/dryer bolt: 10 N· m (1.0 kgf-m, 7.5 lb-ft)

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

1

I4RS0A720018-01

1

4

4

3

2

I7RS0A721008-01

Page 972 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-24 Air Conditioning System: Manual Type

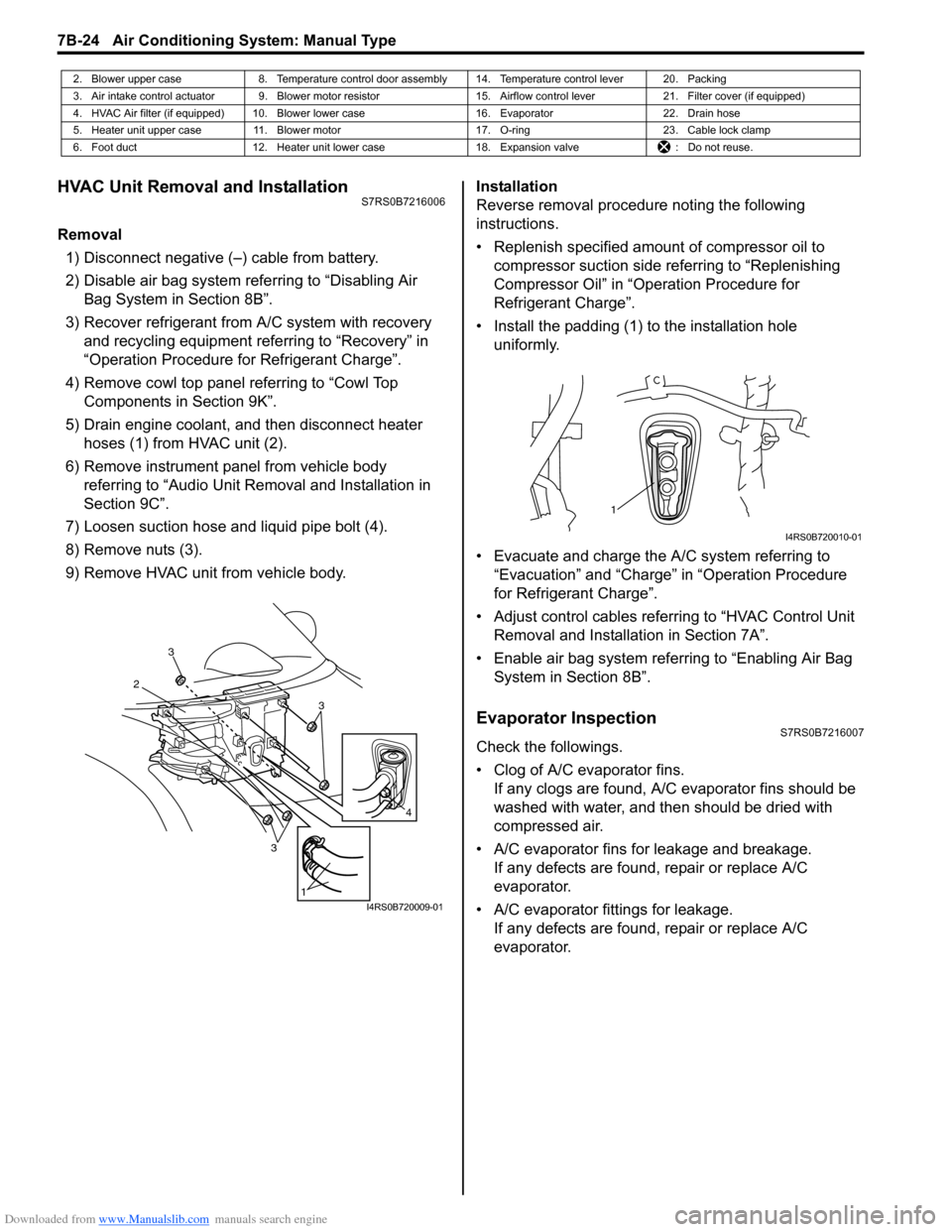

HVAC Unit Removal and InstallationS7RS0B7216006

Removal1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Recover refrigerant from A/C system with recovery and recycling equipment referring to “Recovery” in

“Operation Procedure for Refrigerant Charge”.

4) Remove cowl top panel referring to “Cowl Top Components in Section 9K”.

5) Drain engine coolant, and then disconnect heater hoses (1) from HVAC unit (2).

6) Remove instrument panel from vehicle body referring to “Audio Unit Re moval and Installation in

Section 9C”.

7) Loosen suction hose and liquid pipe bolt (4).

8) Remove nuts (3).

9) Remove HVAC unit from vehicle body. Installation

Reverse removal procedure noting the following

instructions.

• Replenish specified amount of compressor oil to

compressor suction side referring to “Replenishing

Compressor Oil” in “Operation Procedure for

Refrigerant Charge”.

• Install the padding (1) to the installation hole uniformly.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

• Adjust control cables referr ing to “HVAC Control Unit

Removal and Installati on in Section 7A”.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Evaporator InspectionS7RS0B7216007

Check the followings.

• Clog of A/C evaporator fins.If any clogs are found, A/C evaporator fins should be

washed with water, and then should be dried with

compressed air.

• A/C evaporator fins for leakage and breakage. If any defects are found, repair or replace A/C

evaporator.

• A/C evaporator fittings for leakage. If any defects are found, repair or replace A/C

evaporator.

2. Blower upper case 8. Temperature control door assembly 14. Temperature control lever 20. Packing

3. Air intake control actuator 9. Blower motor resistor 15. Airflow control lever21. Filter cover (if equipped)

4. HVAC Air filter (if equipped) 10. Blower lower case 16. Evaporator22. Drain hose

5. Heater unit upper case 11. Blower motor 17. O-ring23. Cable lock clamp

6. Foot duct 12. Heater unit lower case 18. Expansion valve: Do not reuse.

3

2

3

3

1

4

I4RS0B720009-01

1

I4RS0B720010-01

Page 980 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-32 Air Conditioning System: Manual Type

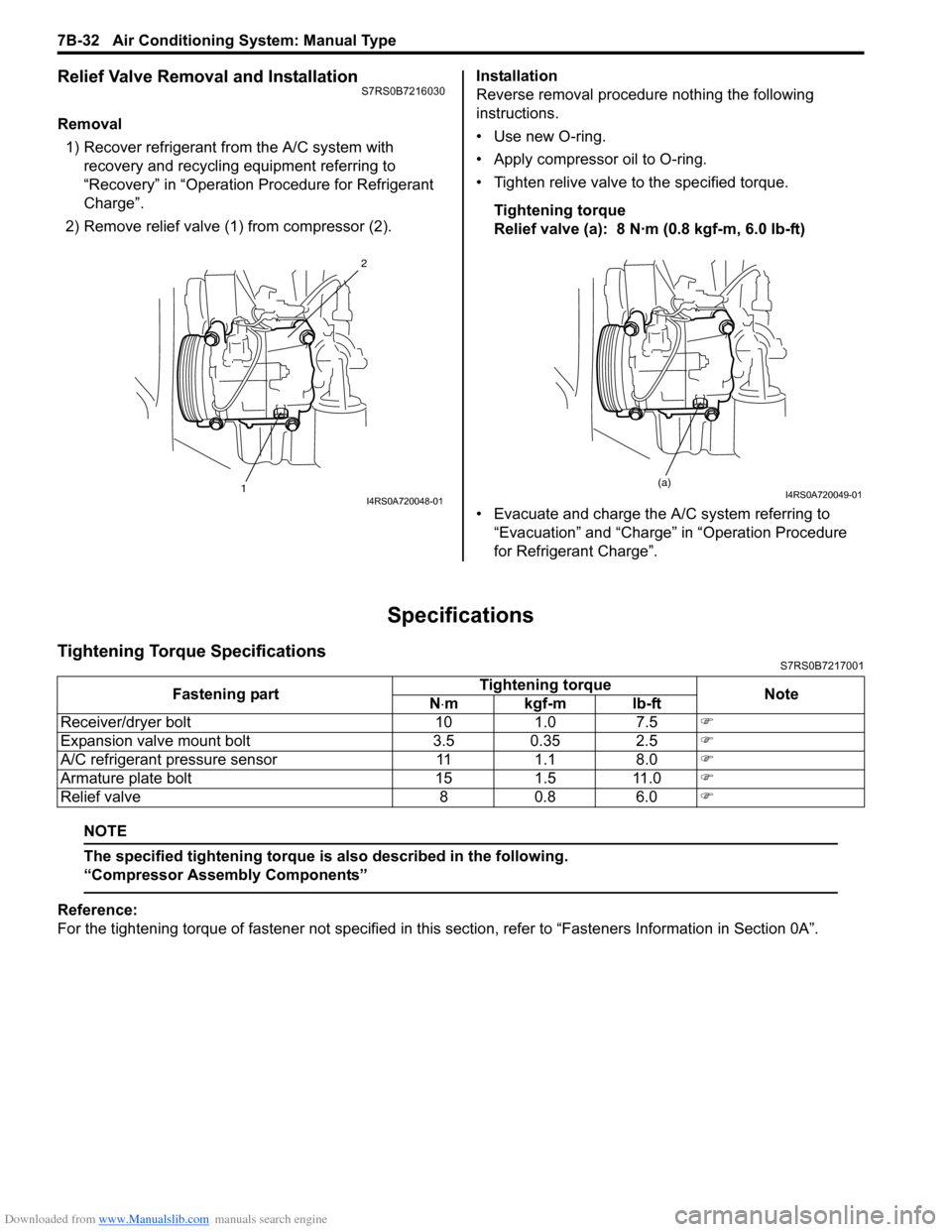

Relief Valve Removal and InstallationS7RS0B7216030

Removal1) Recover refrigerant fr om the A/C system with

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Remove relief valve (1) from compressor (2). Installation

Reverse removal procedure nothing the following

instructions.

• Use new O-ring.

• Apply compressor oil to O-ring.

• Tighten relive valve to the specified torque.

Tightening torque

Relief valve (a): 8 N·m (0.8 kgf-m, 6.0 lb-ft)

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

Specifications

Tightening Torque SpecificationsS7RS0B7217001

NOTE

The specified tightening torque is also described in the following.

“Compressor Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

12I4RS0A720048-01

(a)I4RS0A720049-01

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Receiver/dryer bolt 10 1.0 7.5 �)

Expansion valve mount bolt 3.5 0.35 2.5 �)

A/C refrigerant pressure sensor 11 1.1 8.0 �)

Armature plate bolt 15 1.5 11.0 �)

Relief valve 8 0.8 6.0 �)

Page 982 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-34 Air Conditioning System: Automatic Type

Automatic Type

Precautions

A/C System CautionS7RS0B7220001

Refer to “A/C System Caution”.

Precautions in Diagnosing TroubleS7RS0B7220002

• Do not disconnect couplers from HVAC control module, battery cable from battery, HVAC control module ground

wire harness from body or main fuse before confirming diagnostic information (diagnostic trouble code) stored in

HVAC control module memory.

• Diagnostic information (diagnostic trouble code) stored in HVAC control module can be checked by display of HVAC

control module. Also, it can be checked by using SU ZUKI scan tool. Before checking diagnostic information

(diagnostic trouble code), read this manual and operator's manual for SUZUKI scan tool to know how to read

diagnostic information (diagnostic trouble code).

• When trouble is diagnosed using diagnostic information (diagnostic trouble code) on display of HVAC control

module, keep in your mind that each diagnostic inform ation (diagnostic trouble code) has priority, and only

diagnostic information (diagnostic troub le code) which has the highest priority is indicated. Therefore, after

troubleshooting the malfunction, make sure if there exists any other diagnostic information (diagnostic trouble

code).

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” before inspection.

Precautions on Servicing A/C SystemS7RS0B7220003

Refer to “Precautions on Servicing A/C System”.

General Description

Auto A/C System DescriptionS7RS0B7221001

The automatic type air conditioning system (auto A/C) is pr ovided with the function to automatically control the inside

air temperature, fan speed, air flow outl et direction and air intake position by HVAC control module in addition to

functions of the manual type air conditioning system (manua l A/C). Once the inside air temperature is set using the

temperature selector, HVAC control module automatically controls the inside air temperature at the constant level at all

times based on the inside air temperature, outside ai r temperature, amount of sunlight and engine coolant

temperature detected respectively by the inside air te mperature sensor, outside air temperature sensor, sunload

sensor and ECT sensor. At this time, “FULL AUTO A/ C” appears on the display of HVAC control module.

With the air intake selector pushed in the above state, it is possible to select any position of the air intake actuator.

Then, “FULL AUTO A/C” on the display changes to “AUTO A/C”.