section 1 SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 987 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-39

Diagnostic Information and Procedures

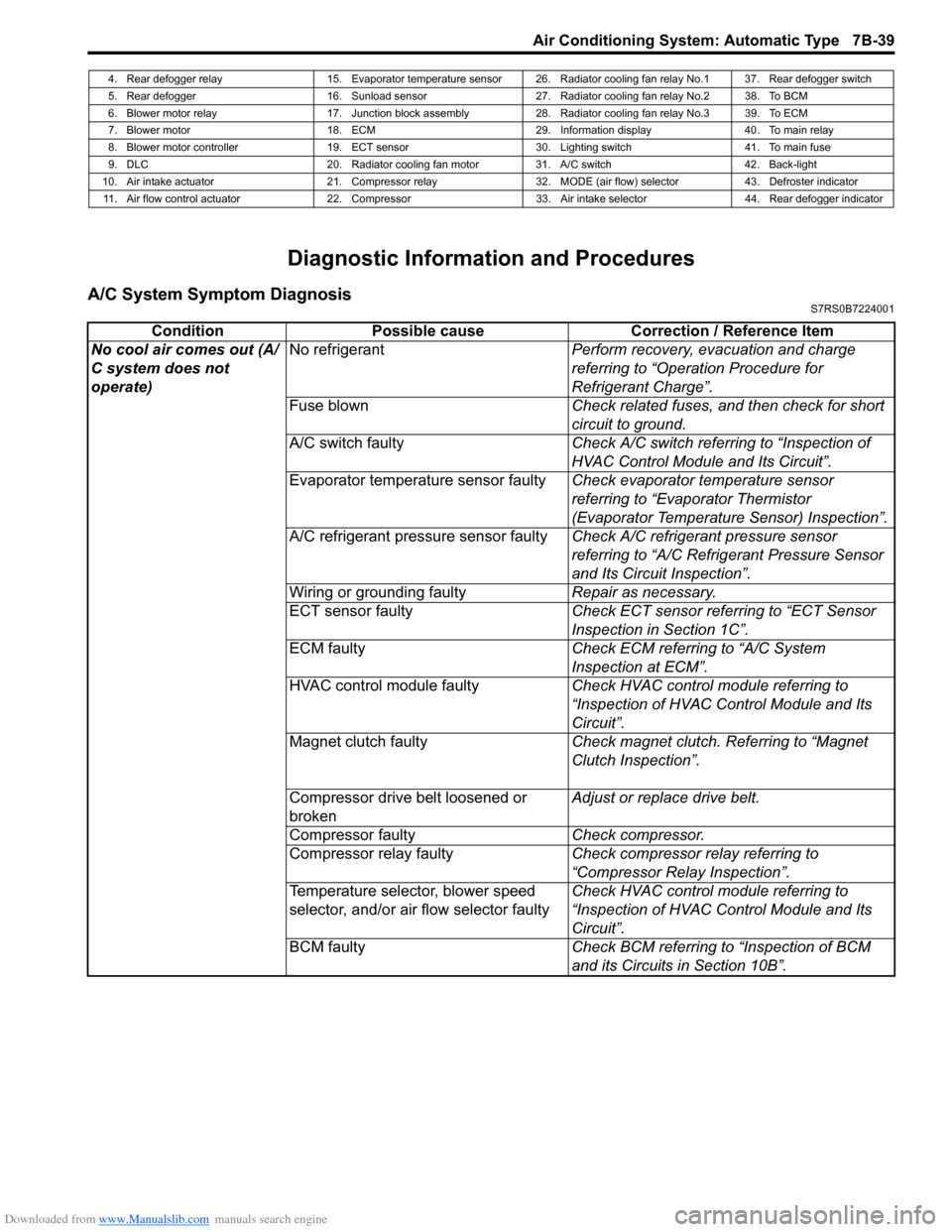

A/C System Symptom DiagnosisS7RS0B7224001

4. Rear defogger relay 15. Evaporator temperature sensor 26. Radiator cooling fan relay No.1 37. Rear defogger switch

5. Rear defogger 16. Sunload sensor 27. Radiator cooling fan relay No.2 38. To BCM

6. Blower motor relay 17. Junction block assembly 28. Radiator cooling fan relay No.3 39. To ECM

7. Blower motor 18. ECM 29. Information display 40. To main relay

8. Blower motor controller 19. ECT sensor 30. Lighting switch 41. To main fuse

9. DLC 20. Radiator cooling fan motor 31. A/C switch 42. Back-light

10. Air intake actuator 21. Compressor relay 32. MODE (air flow) selector 43. Defroster indicator 11. Air flow control actuator 22. Compressor 33. Air intake selector 44. Rear defogger indicator

Condition Possible cause Correction / Reference Item

No cool air comes out (A/

C system does not

operate) No refrigerant

Perform recovery, evacuation and charge

referring to “Operation Procedure for

Refrigerant Charge”.

Fuse blown Check related fuses, and then check for short

circuit to ground.

A/C switch faulty Check A/C switch referring to “Inspection of

HVAC Control Module and Its Circuit”.

Evaporator temperature sensor faulty Check evaporator temperature sensor

referring to “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

A/C refrigerant pressure sensor faulty Check A/C refrigerant pressure sensor

referring to “A/C Refrigerant Pressure Sensor

and Its Circuit Inspection”.

Wiring or grounding faulty Repair as necessary.

ECT sensor faulty Check ECT sensor referring to “ECT Sensor

Inspection in Section 1C”.

ECM faulty Check ECM referring to “A/C System

Inspection at ECM”.

HVAC control module faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

Magnet clutch faulty Check magnet clutch. Referring to “Magnet

Clutch Inspection”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Compressor relay faulty Check compressor relay referring to

“Compressor Relay Inspection”.

Temperature selector, blower speed

selector, and/or air flow selector faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

BCM faulty Check BCM referring to “Inspection of BCM

and its Circuits in Section 10B”.

Page 988 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-40 Air Conditioning System: Automatic Type

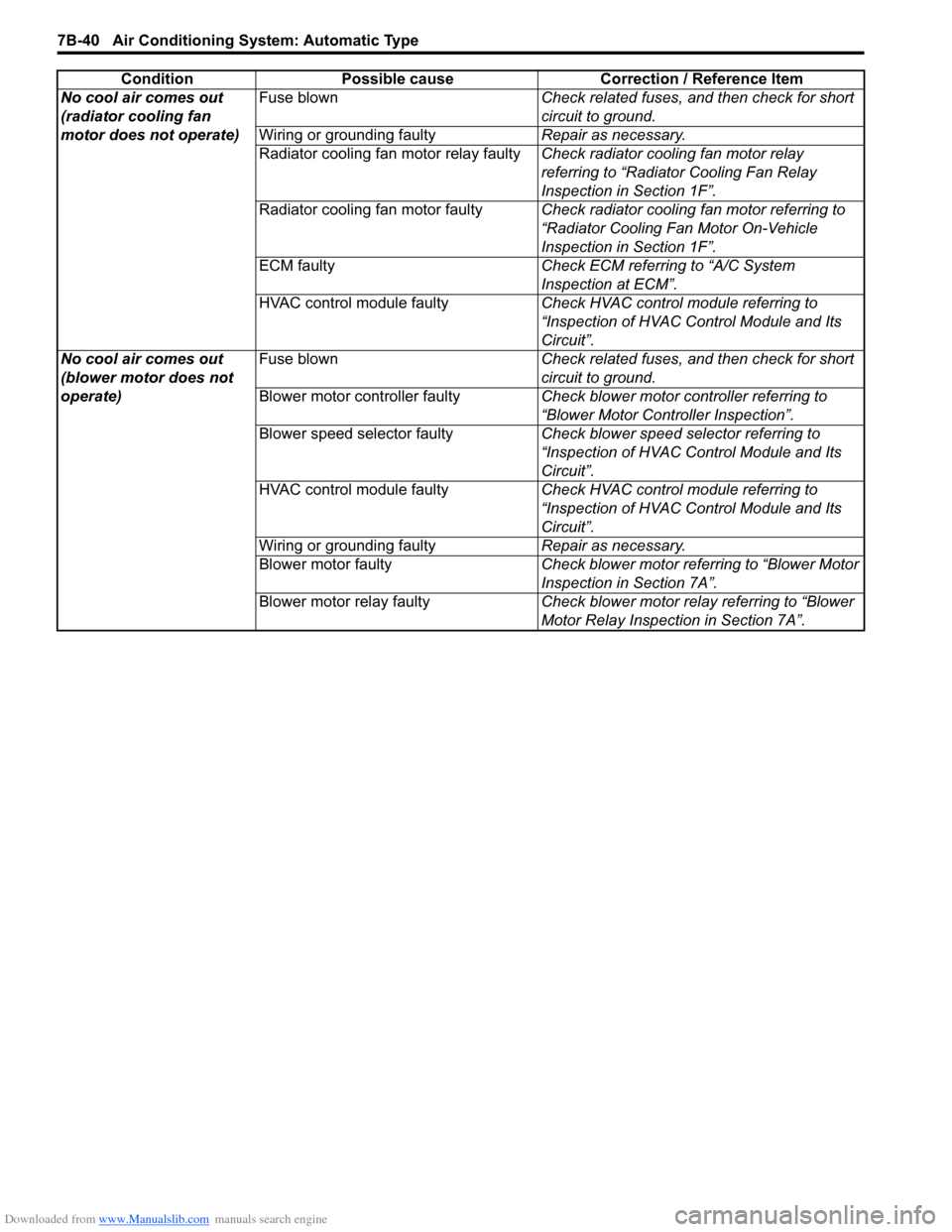

No cool air comes out

(radiator cooling fan

motor does not operate)Fuse blown

Check related fuses, and then check for short

circuit to ground.

Wiring or grounding faulty Repair as necessary.

Radiator cooling fan motor relay faulty Check radiator cooling fan motor relay

referring to “Radiator Cooling Fan Relay

Inspection in Section 1F”.

Radiator cooling fan motor faulty Check radiator cooling fan motor referring to

“Radiator Cooling Fan Motor On-Vehicle

Inspection in Section 1F”.

ECM faulty Check ECM referring to “A/C System

Inspection at ECM”.

HVAC control module faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

No cool air comes out

(blower motor does not

operate) Fuse blown

Check related fuses, and then check for short

circuit to ground.

Blower motor controller faulty Check blower motor controller referring to

“Blower Motor Controller Inspection”.

Blower speed selector faulty Check blower speed selector referring to

“Inspection of HVAC Control Module and Its

Circuit”.

HVAC control module faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

Wiring or grounding faulty Repair as necessary.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Blower motor relay faulty Check blower motor relay referring to “Blower

Motor Relay Inspection in Section 7A”.

Condition Possible cause Correction / Reference Item

Page 989 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-41

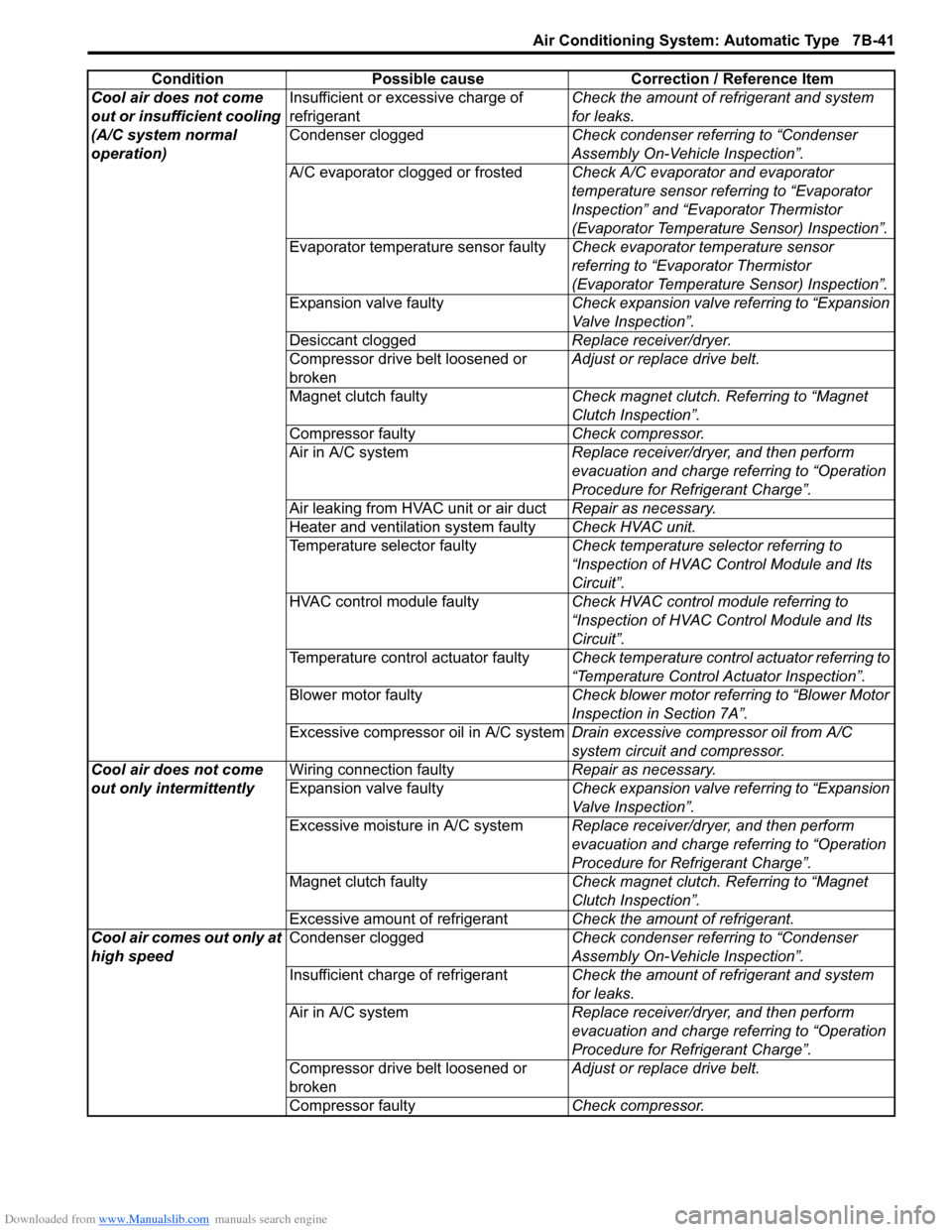

Cool air does not come

out or insufficient cooling

(A/C system normal

operation)Insufficient or excessive charge of

refrigerant

Check the amount of refrigerant and system

for leaks.

Condenser clogged Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

A/C evaporator clogged or frosted Check A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

Evaporator temperature sensor faulty Check evaporator temperature sensor

referring to “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Desiccant clogged Replace receiver/dryer.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Magnet clutch faulty Check magnet clutch. Referring to “Magnet

Clutch Inspection”.

Compressor faulty Check compressor.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Air leaking from HVAC unit or air duct Repair as necessary.

Heater and ventilation system faulty Check HVAC unit.

Temperature selector faulty Check temperature selector referring to

“Inspection of HVAC Control Module and Its

Circuit”.

HVAC control module faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

Temperature control actuator faulty Check temperature control actuator referring to

“Temperature Control Actuator Inspection”.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Excessive compressor oil in A/C system Drain excessive compressor oil from A/C

system circuit and compressor.

Cool air does not come

out only intermittently Wiring connection faulty

Repair as necessary.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Excessive moisture in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Magnet clutch faulty Check magnet clutch. Referring to “Magnet

Clutch Inspection”.

Excessive amount of refrigerant Check the amount of refrigerant.

Cool air comes out only at

high speed Condenser clogged

Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

Insufficient charge of refrigerant Check the amount of refrigerant and system

for leaks.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Condition Possible cause Correction / Reference Item

Page 990 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-42 Air Conditioning System: Automatic Type

Abnormal Noise Symptom Diagnosis of A/C

System

S7RS0B7224002

Refer to “Abnormal Noise Symptom Diagnosis of A/C

System”.

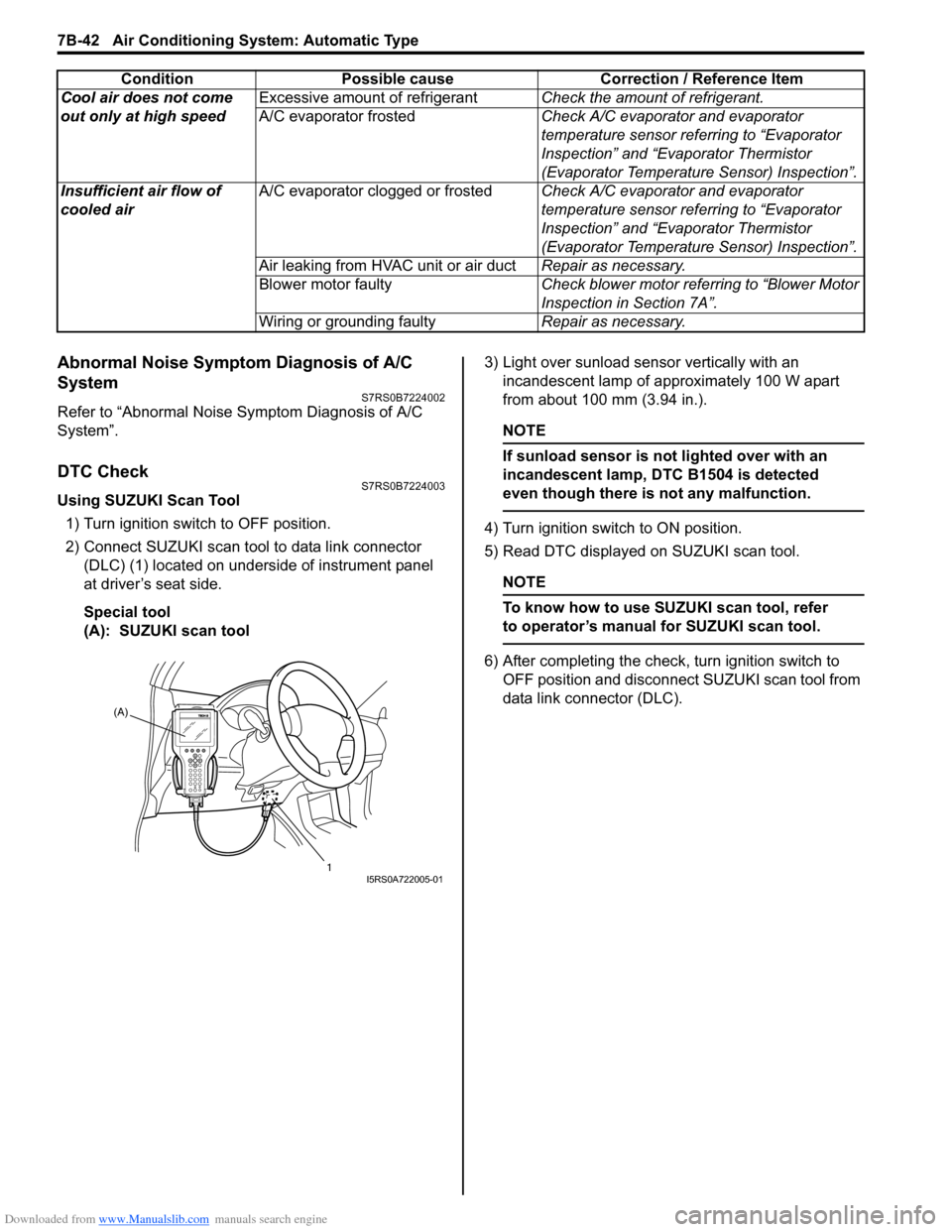

DTC CheckS7RS0B7224003

Using SUZUKI Scan Tool1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool 3) Light over sunload sensor vertically with an

incandescent lamp of approximately 100 W apart

from about 100 mm (3.94 in.).

NOTE

If sunload sensor is not lighted over with an

incandescent lamp, DTC B1504 is detected

even though there is not any malfunction.

4) Turn ignition switch to ON position.

5) Read DTC displayed on SUZUKI scan tool.

NOTE

To know how to use SUZUKI scan tool, refer

to operator’s manual for SUZUKI scan tool.

6) After completing the check, turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

data link connector (DLC).

Cool air does not come

out only at high speed

Excessive amount of refrigerant

Check the amount of refrigerant.

A/C evaporator frosted Check A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

Insufficient air flow of

cooled air A/C evaporator clogged or frosted

Check A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

Air leaking from HVAC unit or air duct Repair as necessary.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Wiring or grounding faulty Repair as necessary.

Condition Possible cause Correction / Reference Item

(A)

1

I5RS0A722005-01

Page 995 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-47

Scan Tool Data Definitions

TEMP CONT SWITCH (TEMPERATURE SELECTOR): Position of temperature control

selector of HVAC control module

CABIN TEMPERATURE: In-car temperature detected

by inside air temperature sensor installed in HVAC

control module

OUTSIDE AIR TEMP (OUTSIDE AIR TEMPERATURE): Outside air temperature

detected by outside air temperature sensor installed

in front bumper member

EVAPORATOR TEMP (EVAPORATOR TEMPERATURE): Temperature of air passed

through evaporator

COOLANT TEMP (ENGINE COOLANT TEMPERATURE): Engine coolant temperature

detected by engine coolant temperature sensor

SUN LOAD: Amount of sunlight detected by sunload

sensor installed on the driver side on the dashboard

MODE CONT SWITCH (MODE (AIR FLOW) SELECTOR): Position of air flow selector of HVAC

control module

FAN CONT SWITCH (BLOWER SPEED SELECTOR): Position of blower speed selector of HVAC control

module

FAN DESIRED VOLT: Voltage for blower motor AIR MIX POS SEN (TEMPERATURE CONTROL

ACTUATOR POSITI ON SENSOR): Input signal

from position sensor in temperature control actuator

MODE POS SENSOR (AIR FLOW CONTROL ACTUATOR POSITI ON SENSOR): Input signal

from position sensor in air flow control actuator

A/C CONT SIG (A/C SWITCH SIGNAL, ON or OFF): State of A/C switch

BLOWER LOAD SIG (BLO WER FAN LOAD SIGNAL,

ON or OFF): ON: Position of blower speed selector

is 1st position or more / OFF: Position of blower

speed selector is OFF position.

AIR INTAKE MODE (AUTO, FRE or REC): State of air

intake mode

REFRIGERANT PRESSURE (A/C REFRIGERANT ABSOLUTE PRESSURE): This parameter

indicates A/C refrigerant absolute pressure

calculated by ECM

A/C COMP CLUTCH (A/C COMPRESSOR MAGNET CLUTCH, ON or OFF): This parameter indicates

the state of the A/C switch

DFR INDICATOR (DEFROSTER INDICATOR LAMP, ON or OFF): State of defroster indicator lamp

VEHICLE SPEED: It is computed based on pulse

signals from vehicle speed sensor

Air Conditioning System CheckS7RS0B7224008

Step Action YesNo

1 Customer complaint analysis

1) Perform �)”Customer complaint analysis”.

Was customer complaint analysis performed? Go to Step 2.

Perform customer

complaint analysis.

2 Visual inspection

1) Perform �)“Visual inspection”.

Is there any faulty condition? Repair or replace

malfunction part.

Go to Step 3.

3 DTC check

1) Perform �)“DTC check”.

Is there any DTC code? Go to Step 4.

Go to Step 5.

4 Troubleshooting malfunction

1) Perform �) “Troubleshooting malfunction”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 5.

5 Perform A/C system symptom diagnosis

1) Inspect and repair referri ng to “A/C System Symptom

Diagnosis”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 6.

6 Check for intermittent problem

1) Check for intermittent troubles referring to “Intermittent

and Poor Connection Inspection in Section 00”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 7.

7 Final confirmation test

1) Perform �) “Final confirmation test”.

Is there any malfunction code? Go to Step 4.

End.

Page 1010 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-62 Air Conditioning System: Automatic Type

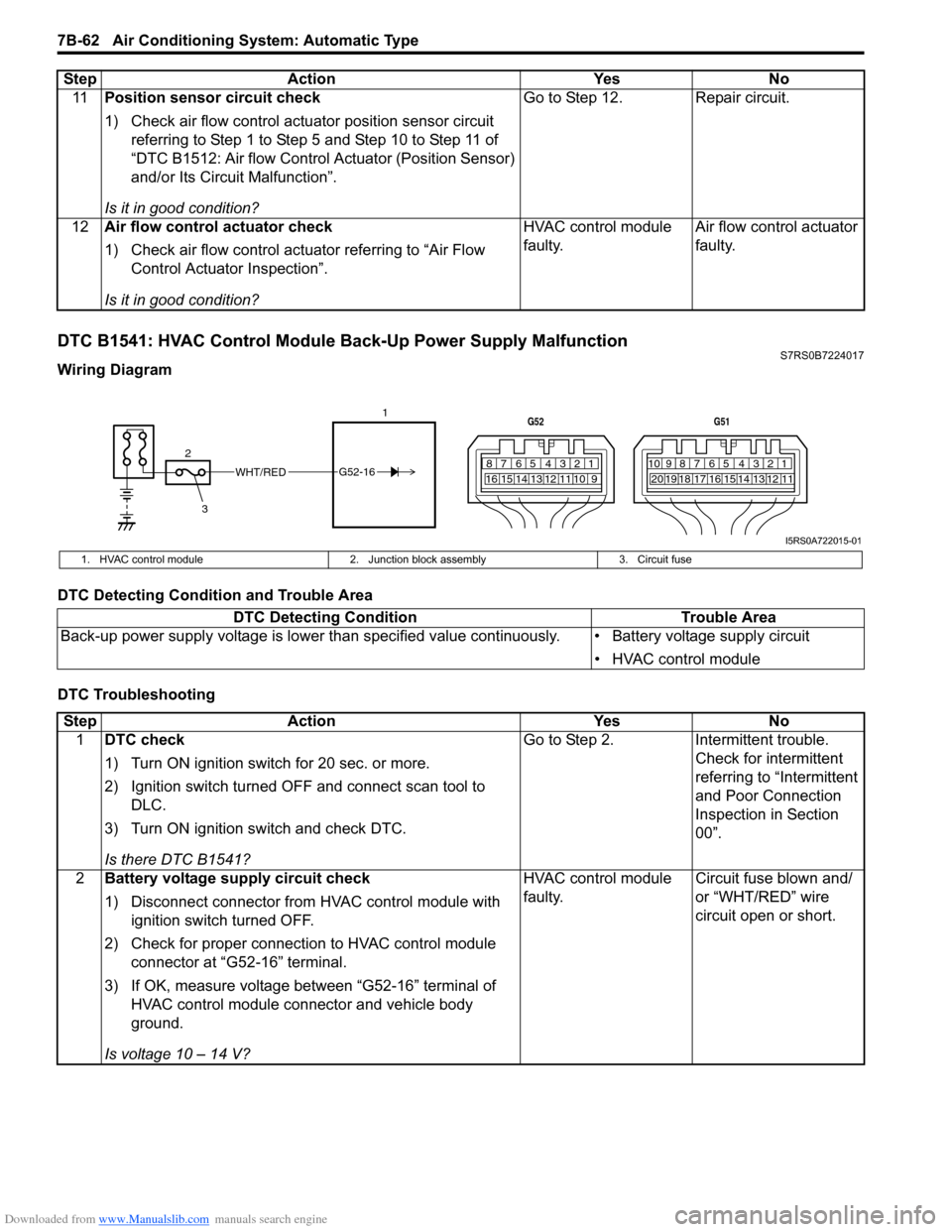

DTC B1541: HVAC Control Module Back-Up Power Supply MalfunctionS7RS0B7224017

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting11

Position sensor circuit check

1) Check air flow control actuator position sensor circuit

referring to Step 1 to Step 5 and Step 10 to Step 11 of

“DTC B1512: Air flow Control Actuator (Position Sensor)

and/or Its Circuit Malfunction”.

Is it in good condition? Go to Step 12. Repair circuit.

12 Air flow control actuator check

1) Check air flow control actuator referring to “Air Flow

Control Actuator Inspection”.

Is it in good condition? HVAC control module

faulty.

Air flow control actuator

faulty.

Step Action Yes No

WHT/RED

2 17812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

3

G52-16

I5RS0A722015-01

1. HVAC control module

2. Junction block assembly 3. Circuit fuse

DTC Detecting Condition Trouble Area

Back-up power supply voltage is lo wer than specified value continuously. • Battery voltage supply circuit

• HVAC control module

StepAction YesNo

1 DTC check

1) Turn ON ignition switch for 20 sec. or more.

2) Ignition switch turned OF F and connect scan tool to

DLC.

3) Turn ON ignition switch and check DTC.

Is there DTC B1541? Go to Step 2.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

2 Battery voltage supply circuit check

1) Disconnect connector from HVAC control module with

ignition switch turned OFF.

2) Check for proper connection to HVAC control module connector at “G52-16” terminal.

3) If OK, measure voltage between “G52-16” terminal of HVAC control module connector and vehicle body

ground.

Is voltage 10 – 14 V? HVAC control module

faulty.

Circuit fuse blown and/

or “WHT/RED” wire

circuit open or short.

Page 1011 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-63

DTC B1546: A/C Refrigerant Pressure MalfunctionS7RS0B7224018

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

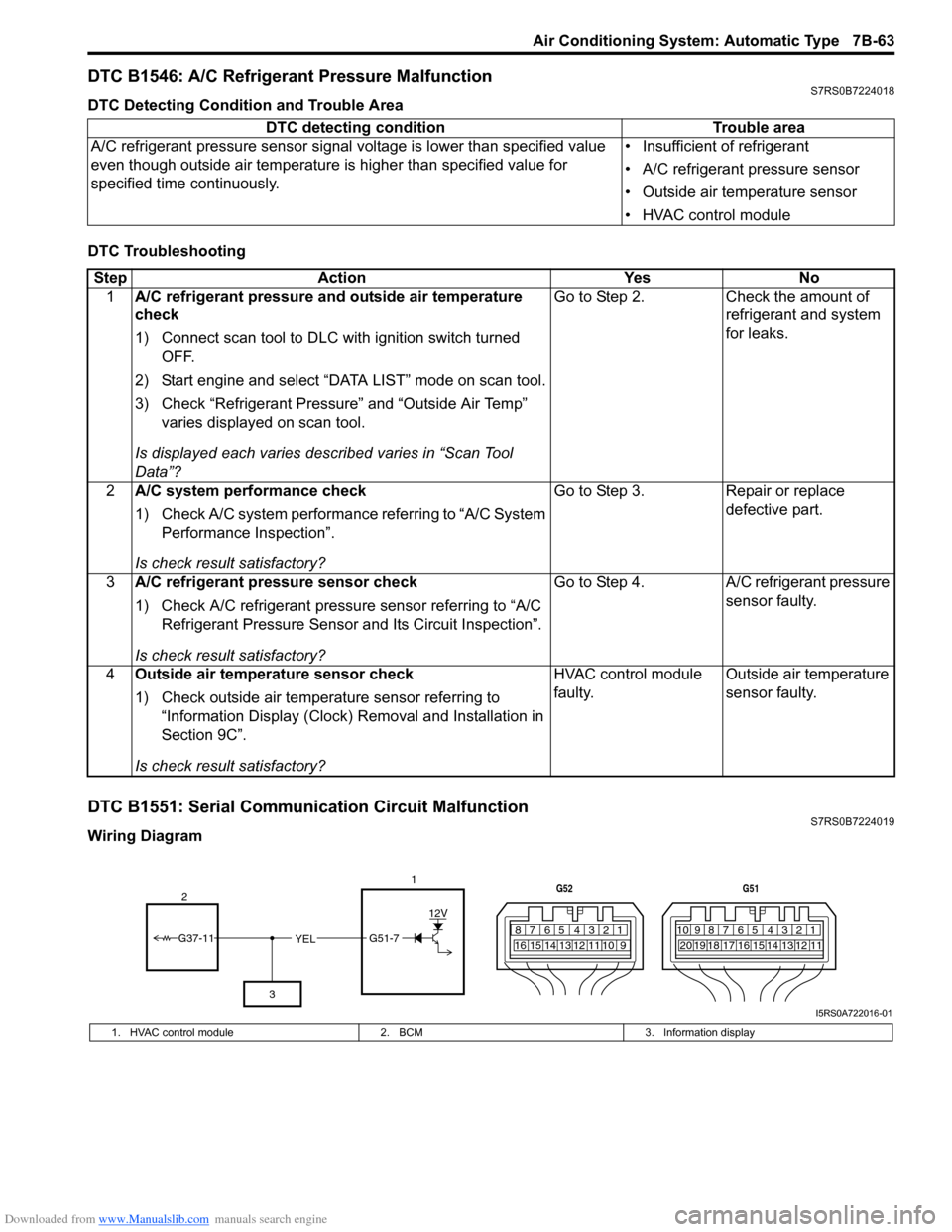

DTC B1551: Serial Communication Circuit MalfunctionS7RS0B7224019

Wiring DiagramDTC detecting condition Trouble area

A/C refrigerant pressure sensor signal voltage is lower t han specified value

even though outside air temperature is higher than specified value for

specified time continuously. • Insufficient of refrigerant

• A/C refrigerant pressure sensor

• Outside air temperature sensor

• HVAC control module

Step

Action YesNo

1 A/C refrigerant pressure and outside air temperature

check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Check “Refrigerant Pressure” and “Outside Air Temp” varies displayed on scan tool.

Is displayed each va ries described varies in “Scan Tool

Data”? Go to Step 2.

Check the amount of

refrigerant and system

for leaks.

2 A/C system performance check

1) Check A/C system performance referring to “A/C System

Performance Inspection”.

Is check result satisfactory? Go to Step 3.

Repair or replace

defective part.

3 A/C refrigerant pressure sensor check

1) Check A/C refrigerant pressure sensor referring to “A/C

Refrigerant Pressure Sensor and Its Circuit Inspection”.

Is check result satisfactory? Go to Step 4.

A/C refrigerant pressure

sensor faulty.

4 Outside air temperature sensor check

1) Check outside air temperature sensor referring to

“Information Display (Clock) Removal and Installation in

Section 9C”.

Is check result satisfactory? HVAC control module

faulty.

Outside air temperature

sensor faulty.

YEL17812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

G51-7

12V

2

3

G37-11

I5RS0A722016-01

1. HVAC control module 2. BCM3. Information display

Page 1012 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-64 Air Conditioning System: Automatic Type

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1552: Serial Communication Signal MalfunctionS7RS0B7224020

DTC Detecting Condition and Trouble AreaDTC detecting condition Trouble area

Serial communication signal is higher than or lower than specified value for

specified time continuously. • Serial communication line of BCM

• BCM (included in junction block

assembly)

• Information display

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Disconnect connector from information display.

3) Turn ignition switch ON and check DTC.

Is there DTC B1551? Go to Step 2.

Information display

faulty.

2 Wire harness check

1) Disconnect connectors from BCM and HVAC control

module.

2) Measure resistance between “G37-11” terminal of BCM connector and “G51-7” terminal of HVAC control module

connector.

Is resistance below 5

Ω? Go to Step 3. “YEL” wire open or high

resistance circuit.

3 Wire harness check

1) Measure resistance between “G51-7” terminal of HVAC

control module connector and vehicle body ground.

Is resistance infinity? Go to Step 4. “YEL” wire shorted to

ground circuit.

4 Wire harness check

1) Measure voltage between “G51-7” terminal of HVAC

control module connector and vehicle body ground with

ignition switch turned ON.

Is voltage 0 V? Go to Step 5. “YEL” wire shorted to

other circuit.

5 Serial communication signal check

1) Connect connectors to BCM and HVAC control module.

2) Using oscilloscope, check that serial communication

signal is outputted referring to “Reference waveform

No.8” of “Inspection of BCM and its Circuits in Section

10B”.

Is serial communication signal outputted at “G37-11”

terminal of BCM connector? HVAC control module

faulty.

BCM (included in

junction block

assembly) faulty.

DTC detecting condition

Trouble area

Data received by HVAC control module from BCM is erroneous continuously. • BCM (included in junction block assembly)

• HVAC control module

Page 1013 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-65

DTC Troubleshooting

DTC B1553: CAN Communication Signal MalfunctionS7RS0B7224021

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1557: Vehicle Speed Sensor Signal MalfunctionS7RS0B7224022

DTC Detecting Condition and Trouble Area

DTC TroubleshootingStep Action Yes No

1 Serial communication signal data check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Check “Refrigerant Pressure”, “Vehicle Speed”, “Coolant Temp” and “Outside Air Temp” varies displayed on scan

tool.

Is displayed each va ries described varies in “Scan Tool

Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 2.

2 Serial communication signal check

1) Connect connectors to BCM and HVAC control module.

2) Using oscilloscope, check that serial communication

signal is outputted referring to “Reference waveform

No.8” of “Inspection of BCM and its Circuits in Section

10B”.

Is serial communication signal outputted at “G37-11”

terminal of BCM connector? HVAC control module

faulty.

BCM (included in

junction block

assembly) faulty.

DTC detecting condition

Trouble area

HVAC control module receives error code fr om BCM continuously.• CAN communication circuit

• BCM (included in junction block assembly)

•ECM

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM and BCM for DTC.

Is there DTC(s)? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition

Trouble area

HVAC control module receives error code from BCM continuously. • VSS circuit

• VSS

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM for DTC.

Is there DTC P0500? Go to “DTC P0480: Fan

1 (Radiator Cooling

Fan) Control Circuit in

Section 1A”.

Substitute a known-

good HVAC control

module and recheck.

Page 1015 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-67

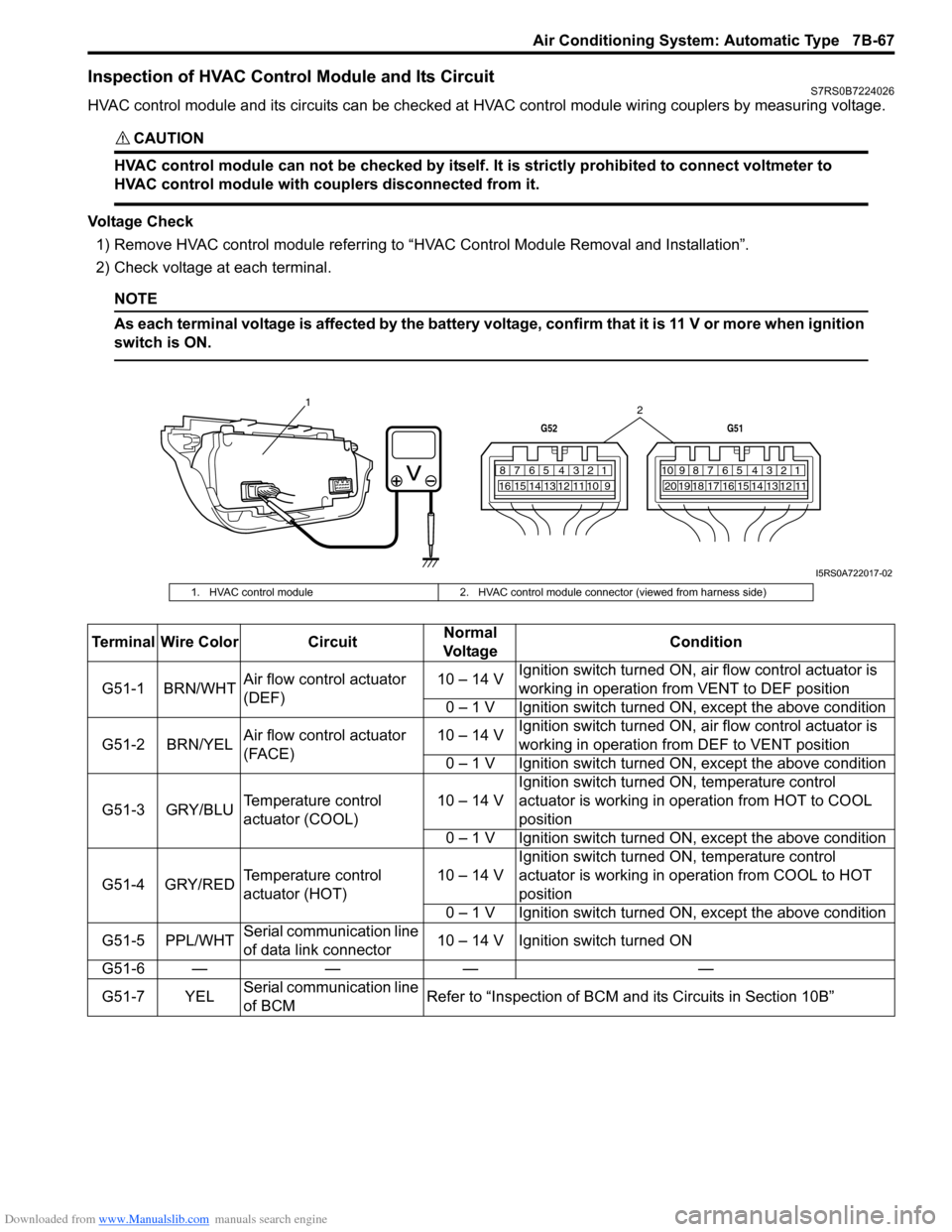

Inspection of HVAC Control Module and Its CircuitS7RS0B7224026

HVAC control module and its circuits can be checked at HVAC control module wiring couplers by measuring voltage.

CAUTION!

HVAC control module can not be checked by itself. It is strictly prohibited to connect voltmeter to

HVAC control module with couplers disconnected from it.

Voltage Check

1) Remove HVAC control module referring to “HVAC Control Module Removal and Installation”.

2) Check voltage at each terminal.

NOTE

As each terminal voltage is affected by the battery voltage, confirm that it is 11 V or more when ignition

switch is ON.

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

1

2

I5RS0A722017-02

1. HVAC control module2. HVAC control module connector (viewed from harness side)

Terminal Wire Color CircuitNormal

Vo l ta g e Condition

G51-1 BRN/WHT Air flow control actuator

(DEF) 10 – 14 V

Ignition switch turned ON, ai

r flow control actuator is

working in operation fr om VENT to DEF position

0 – 1 V Ignition switch turned ON, except the above condition

G51-2 BRN/YEL Air flow control actuator

(FACE) 10 – 14 V

Ignition switch turned ON, ai

r flow control actuator is

working in operation fr om DEF to VENT position

0 – 1 V Ignition switch turned ON, except the above condition

G51-3 GRY/BLU Temperature control

actuator (COOL) 10 – 14 VIgnition switch turned ON, temperature control

actuator is working in ope

ration from HOT to COOL

position

0 – 1 V Ignition switch turned ON, except the above condition

G51-4 GRY/RED Temperature control

actuator (HOT) 10 – 14 VIgnition switch turned ON, temperature control

actuator is working in operation from COOL to HOT

position

0 – 1 V Ignition switch turned ON, except the above condition

G51-5 PPL/WHT Serial communication line

of data link connector 10 – 14 V Ignition switch turned ON

G51-6 — — — —

G51-7 YEL Serial communication line

of BCM Refer to “Inspection of BCM a

nd its Circuits in Section 10B”