section 1 SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1016 of 1496

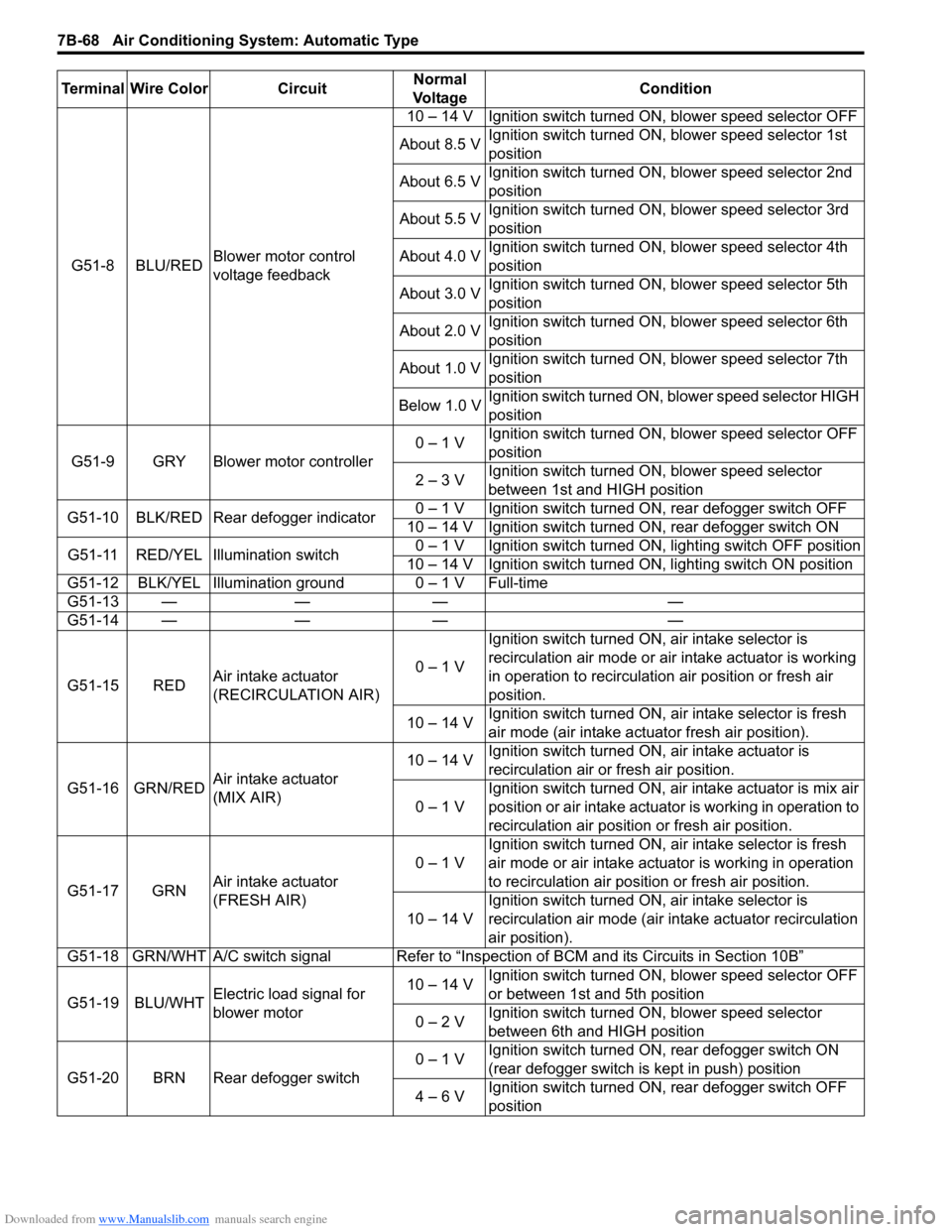

Downloaded from www.Manualslib.com manuals search engine 7B-68 Air Conditioning System: Automatic Type

G51-8 BLU/REDBlower motor control

voltage feedback 10 – 14 V Ignition switch turned ON, blower speed selector OFF

About 8.5 V Ignition switch turned ON, blower speed selector 1st

position

About 6.5 V Ignition switch turned ON, blower speed selector 2nd

position

About 5.5 V Ignition switch turned ON, blower speed selector 3rd

position

About 4.0 V Ignition switch turned ON, blower speed selector 4th

position

About 3.0 V Ignition switch turned ON, blower speed selector 5th

position

About 2.0 V Ignition switch turned ON, blower speed selector 6th

position

About 1.0 V Ignition switch turned ON, blower speed selector 7th

position

Below 1.0 V Ignition switch turned ON, blower speed selector HIGH

position

G51-9 GRY Blower motor controller 0 – 1 V

Ignition switch turned ON, blower speed selector OFF

position

2 – 3 V Ignition switch turned ON, blower speed selector

between 1st and HIGH position

G51-10 BLK/RED Rear defogger indicator 0 – 1 V Ignition switch turned ON, rear defogger switch OFF

10 – 14 V Ignition switch turned ON, rear defogger switch ON

G51-11 RED/YEL Illumination switch 0 – 1 V Ignition switch turned ON, lighting switch OFF position

10 – 14 V Ignition switch turned ON, lighting switch ON position

G51-12 BLK/YEL Illumination ground 0 – 1 V Full-time

G51-13 — — — —

G51-14 — — — —

G51-15 RED Air intake actuator

(RECIRCULATION AIR) 0 – 1 VIgnition switch turned ON, air intake selector is

recirculation air mode or air intake actuator is working

in operation to recirculation air position or fresh air

position.

10 – 14 V Ignition switch turned ON, ai

r intake selector is fresh

air mode (air intake actuator fresh air position).

G51-16 GRN/RED Air intake actuator

(MIX AIR) 10 – 14 V

Ignition switch turned ON, air intake actuator is

recirculation air or fresh air position.

0 – 1 V Ignition switch turned ON, air intake actuator is mix air

position or air intake actuator is working in operation to

recirculation air position or fresh air position.

G51-17 GRN Air intake actuator

(FRESH AIR) 0 – 1 V

Ignition switch turned ON, ai

r intake selector is fresh

air mode or air intake actuator is working in operation

to recirculation air position or fresh air position.

10 – 14 V Ignition switch turned ON, air intake selector is

recirculation air mode (air intake actuator recirculation

air position).

G51-18 GRN/WHT A/C switch signal Refer to “Inspe ction of BCM and its Circuits in Section 10B”

G51-19 BLU/WHT Electric load signal for

blower motor 10 – 14 V

Ignition switch turned ON, blower speed selector OFF

or between 1st and 5th position

0 – 2 V Ignition switch turned ON, blower speed selector

between 6th and HIGH position

G51-20 BRN Rear defogger switch 0 – 1 V

Ignition switch turned ON, rear defogger switch ON

(rear defogger switch is kept in push) position

4 – 6 V Ignition switch turned ON, rear defogger switch OFF

position

Terminal Wire Color Circuit

Normal

Vo l ta g e Condition

Page 1018 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-70 Air Conditioning System: Automatic Type

A/C System Performance InspectionS7RS0B7224027

Refer to “A/C System Performance Inspection”.

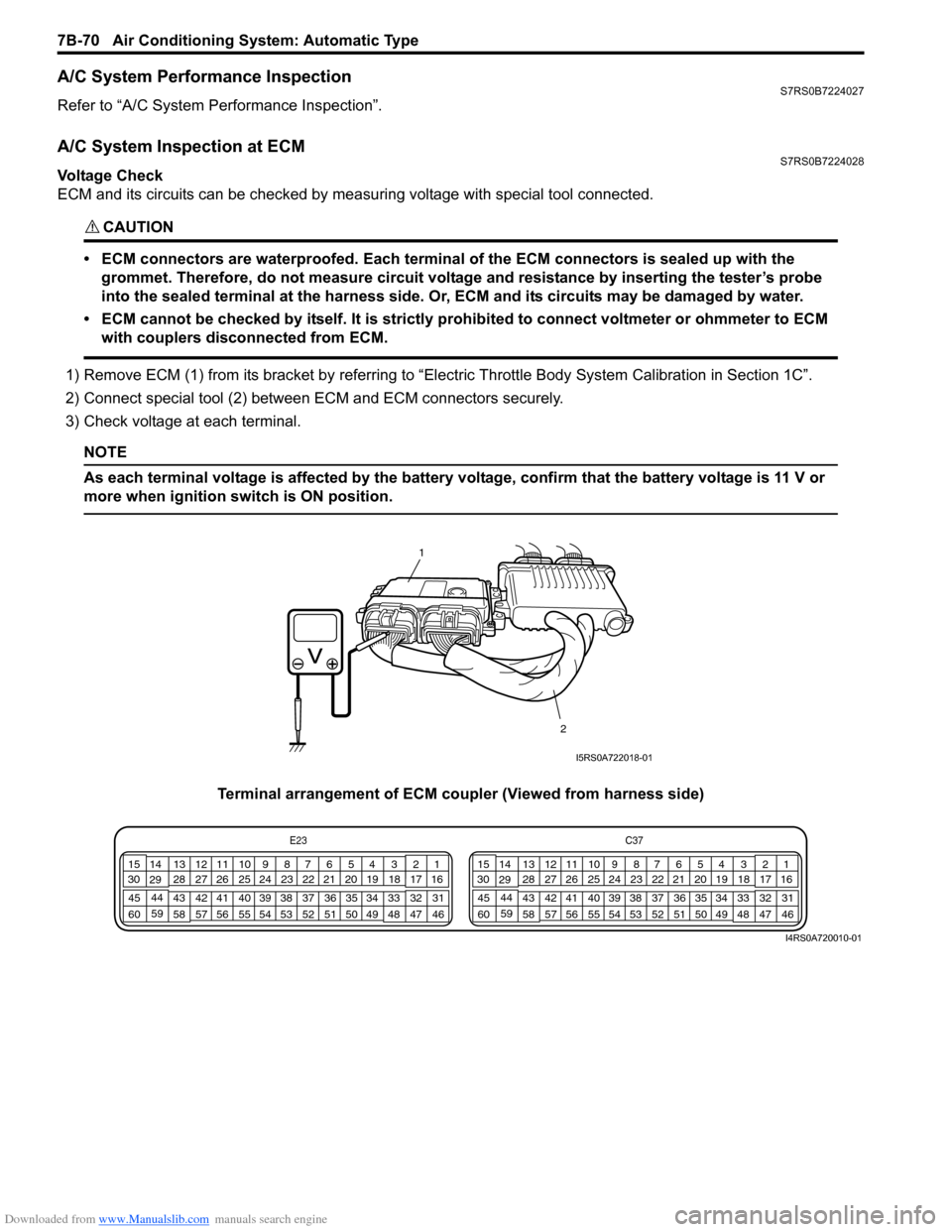

A/C System Inspection at ECMS7RS0B7224028

Voltage Check

ECM and its circuits can be checked by measuring voltage with special tool connected.

CAUTION!

• ECM connectors are waterproofed. Each terminal of the ECM connectors is sealed up with the

grommet. Therefore, do not measure circuit voltage and resistance by inserting the tester’s probe

into the sealed terminal at the harness side. Or, ECM and its circuits may be damaged by water.

• ECM cannot be checked by itself. It is strictly prohibited to connect voltmeter or ohmmeter to ECM with couplers disconnected from ECM.

1) Remove ECM (1) from its bracket by referring to “Electric Throttle Body System Calibration in Section 1C”.

2) Connect special tool (2) between ECM and ECM connectors securely.

3) Check voltage at each terminal.

NOTE

As each terminal voltage is affected by the battery voltage, confirm that the battery voltage is 11 V or

more when ignition sw itch is ON position.

Terminal arrangement of ECM coupler (Viewed from harness side)

1

2

I5RS0A722018-01

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

I4RS0A720010-01

Page 1019 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-71

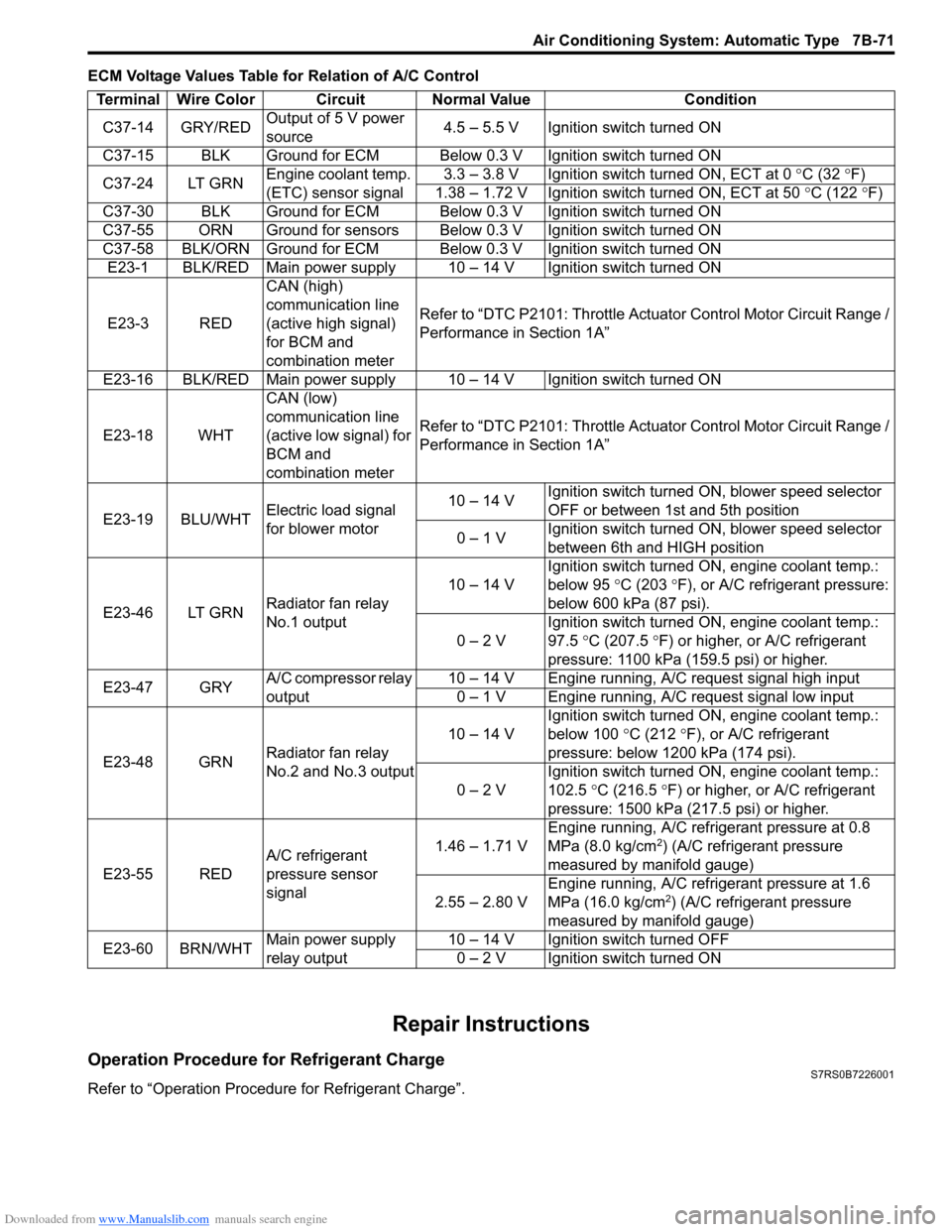

ECM Voltage Values Table for Relation of A/C Control

Repair Instructions

Operation Procedure for Refrigerant ChargeS7RS0B7226001

Refer to “Operation Procedure for Refrigerant Charge”.Terminal Wire Color Circuit Normal Value Condition

C37-14 GRY/RED Output of 5 V power

source 4.5 – 5.5 V Ignition switch turned ON

C37-15 BLK Ground for ECM Below 0.3 V Ignition switch turned ON

C37-24 LT GRN Engine coolant temp.

(ETC) sensor signal 3.3 – 3.8 V Ignition switch turned ON, ECT at 0

°C (32 ° F)

1.38 – 1.72 V Ignition switch turned ON, ECT at 50 °C (122 °F)

C37-30 BLK Ground for ECM Below 0.3 V Ignition switch turned ON

C37-55 ORN Ground for sensors Below 0.3 V Ignition switch turned ON

C37-58 BLK/ORN Ground for ECM Below 0.3 V Ignition switch turned ON E23-1 BLK/RED Main power supply 10 – 14 V Ignition switch turned ON

E23-3 RED CAN (high)

communication line

(active high signal)

for BCM and

combination meterRefer to “DTC P2101: Throttle Actu

ator Control Motor Circuit Range /

Performance in Section 1A”

E23-16 BLK/RED Main power supply 10 – 14 V Ignition switch turned ON

E23-18 WHT CAN (low)

communication line

(active low signal) for

BCM and

combination meterRefer to “DTC P2101: Throttle Actu

ator Control Motor Circuit Range /

Performance in Section 1A”

E23-19 BLU/WHT Electric load signal

for blower motor 10 – 14 V

Ignition switch turned ON, blower speed selector

OFF or between 1st and 5th position

0 – 1 V Ignition switch turned ON, blower speed selector

between 6th and HIGH position

E23-46 LT GRN Radiator fan relay

No.1 output 10 – 14 V

Ignition switch turned ON, engine coolant temp.:

below 95

°C (203 ° F), or A/C refrigerant pressure:

below 600 kPa (87 psi).

0 – 2 V Ignition switch turned ON, engine coolant temp.:

97.5

°C (207.5 °F) or higher, or A/C refrigerant

pressure: 1100 kPa (159.5 psi) or higher.

E23-47 GRY A/C compressor relay

output 10 – 14 V Engine running, A/C request signal high input

0 – 1 V Engine running, A/C request signal low input

E23-48 GRN Radiator fan relay

No.2 and No.3 output 10 – 14 V

Ignition switch turned ON, engine coolant temp.:

below 100

°C (212 °F), or A/C refrigerant

pressure: below 1200 kPa (174 psi).

0 – 2 V Ignition switch turned ON, engine coolant temp.:

102.5

°C (216.5 ° F) or higher, or A/C refrigerant

pressure: 1500 kPa (217.5 psi) or higher.

E23-55 RED A/C refrigerant

pressure sensor

signal 1.46 – 1.71 V

Engine running, A/C refrigerant pressure at 0.8

MPa (8.0 kg/cm

2) (A/C refrigerant pressure

measured by manifold gauge)

2.55 – 2.80 V Engine running, A/C refrigerant pressure at 1.6

MPa (16.0 kg/cm

2) (A/C refrigerant pressure

measured by manifold gauge)

E23-60 BRN/WHT Main power supply

relay output 10 – 14 V Ignition switch turned OFF

0 – 2 V Ignition switch turned ON

Page 1023 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-75

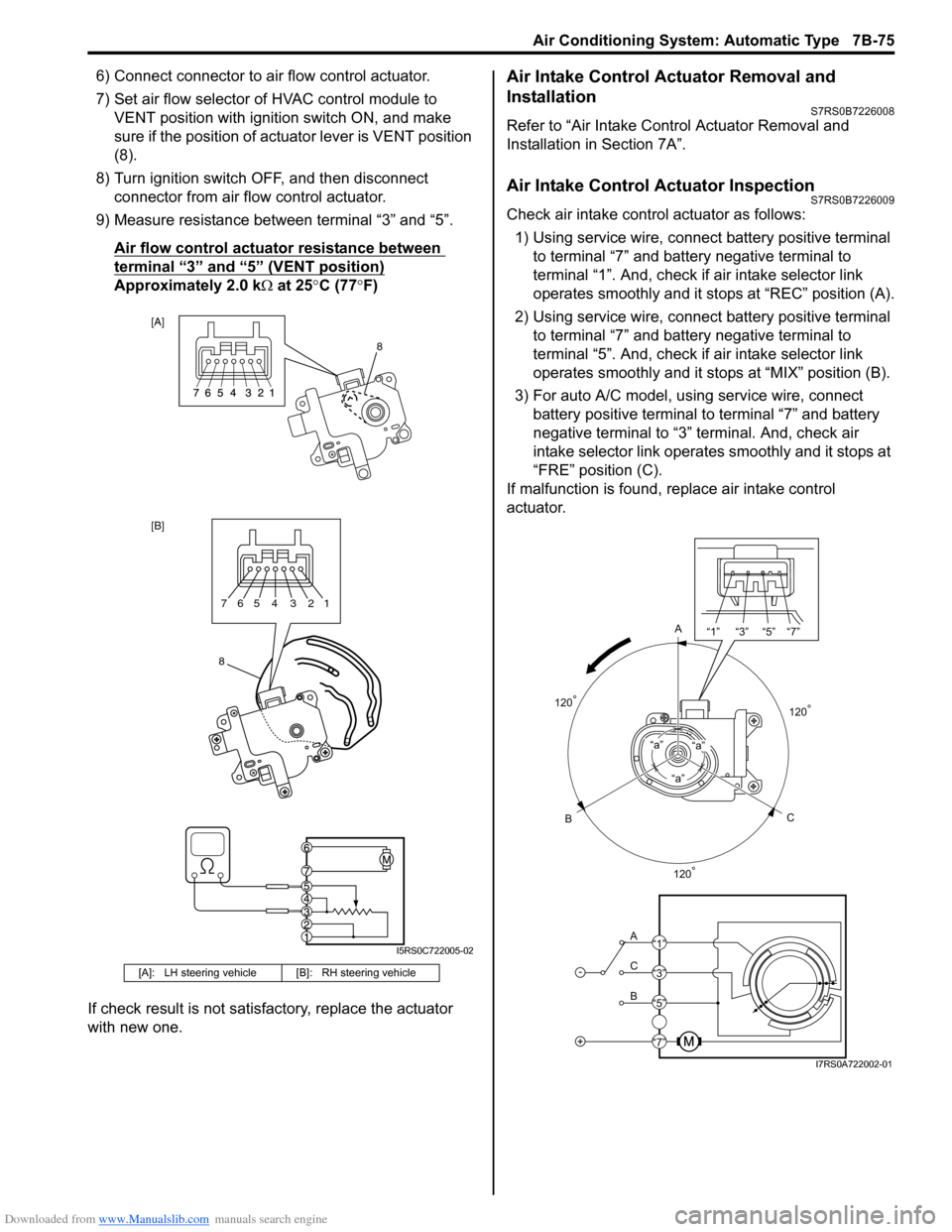

6) Connect connector to air flow control actuator.

7) Set air flow selector of HVAC control module to VENT position with ignition switch ON, and make

sure if the position of act uator lever is VENT position

(8).

8) Turn ignition switch OFF, and then disconnect connector from air flow control actuator.

9) Measure resistance between terminal “3” and “5”.

Air flow control actuator resistance between

terminal “3” and “5” (VENT position)

Approximately 2.0 k Ω at 25 °C (77 °F)

If check result is not satisfactory, replace the actuator

with new one.

Air Intake Control Actuator Removal and

Installation

S7RS0B7226008

Refer to “Air Intake Control Actuator Removal and

Installation in Section 7A”.

Air Intake Control Actuator InspectionS7RS0B7226009

Check air intake contro l actuator as follows:

1) Using service wire, connect battery positive terminal

to terminal “7” and battery negative terminal to

terminal “1”. And, check if air intake selector link

operates smoothly and it stops at “REC” position (A).

2) Using service wire, connect battery positive terminal

to terminal “7” and battery negative terminal to

terminal “5”. And, check if air intake selector link

operates smoothly and it stops at “MIX” position (B).

3) For auto A/C model, using service wire, connect battery positive terminal to terminal “7” and battery

negative terminal to “3” terminal. And, check air

intake selector link operates smoothly and it stops at

“FRE” position (C).

If malfunction is found, replace air intake control

actuator.

[A]: LH steering vehicl e [B]: RH steering vehicle

[A]

[B]

8

8765 4 3 21

I5RS0C722005-02

A

C

B“a”

“a”“a”

-

+

A

C

B “1” “3” “5” “7”

“1”

“3”

“5”

“7”

120

°

120° 120

°

I7RS0A722002-01

Page 1024 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-76 Air Conditioning System: Automatic Type

Actuator Linkage InspectionS7RS0B7226010

• Check if each actuator linkage operates smoothly.

• Check actuator rod for bend.

• Check each actuator linkage for breakage.

• Make sure if there is not any obstruction in operating range of actuator linkage.

If any malfunction is found, repair or replace faulty

part(s).

Blower Motor Controller Removal and

Installation

S7RS0B7226011

Refer to “Blower Motor Resistor Removal and

Installation in Section 7A”.

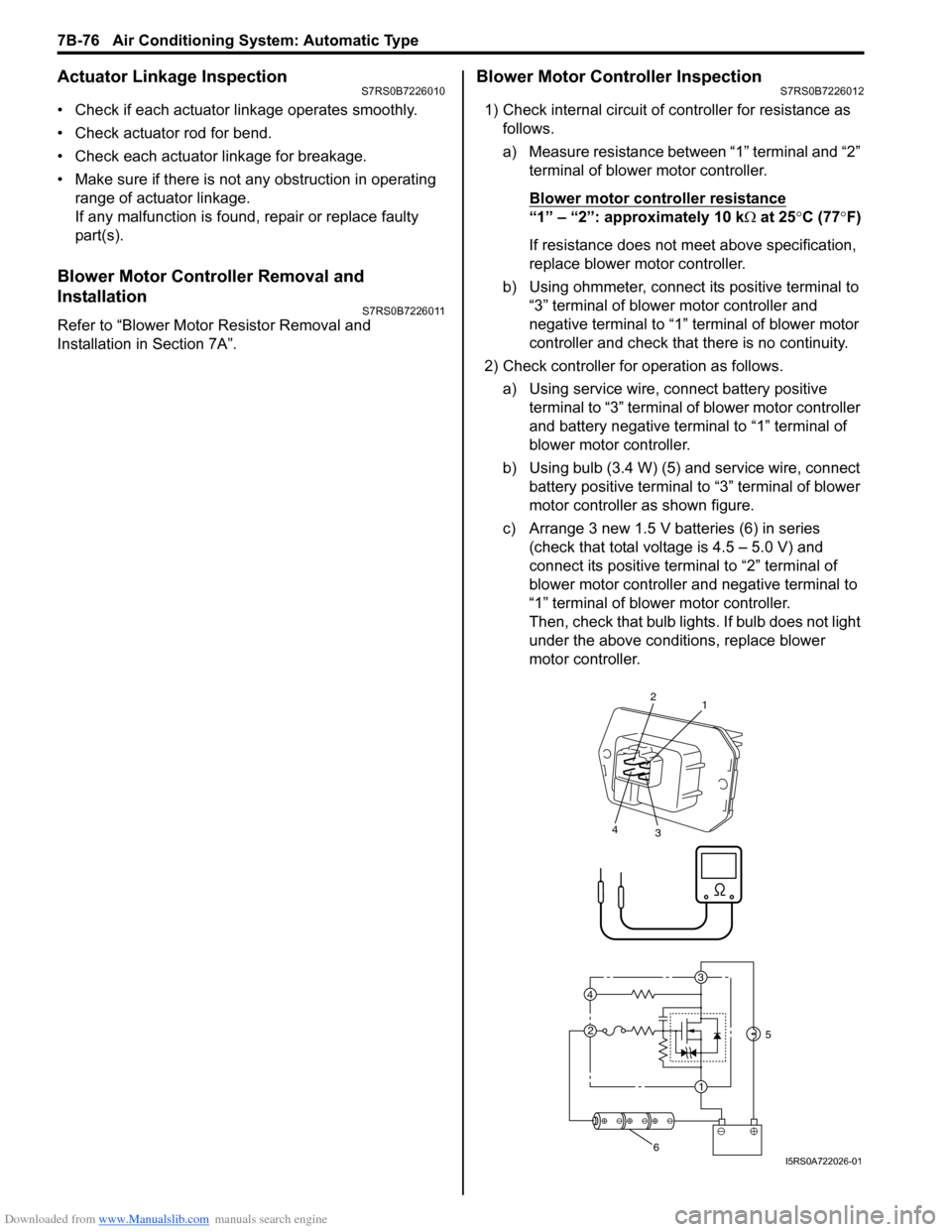

Blower Motor Controller InspectionS7RS0B7226012

1) Check internal circuit of controller for resistance as follows.

a) Measure resistance between “1” terminal and “2” terminal of blower motor controller.

Blower motor cont roller resistance

“1” – “2”: approximately 10 k Ω at 25 °C (77 °F)

If resistance does not meet above specification,

replace blower motor controller.

b) Using ohmmeter, connect its positive terminal to “3” terminal of blower motor controller and

negative terminal to “1” terminal of blower motor

controller and check that there is no continuity.

2) Check controller for operation as follows. a) Using service wire, connect battery positive terminal to “3” terminal of blower motor controller

and battery negative terminal to “1” terminal of

blower motor controller.

b) Using bulb (3.4 W) (5) and service wire, connect battery positive terminal to “3” terminal of blower

motor controller as shown figure.

c) Arrange 3 new 1.5 V batteries (6) in series (check that total voltage is 4.5 – 5.0 V) and

connect its positive term inal to “2” terminal of

blower motor controller and negative terminal to

“1” terminal of blower motor controller.

Then, check that bulb lights. If bulb does not light

under the above conditions, replace blower

motor controller.

3

1

2

4

2

1

3

4

5

6I5RS0A722026-01

Page 1025 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-77

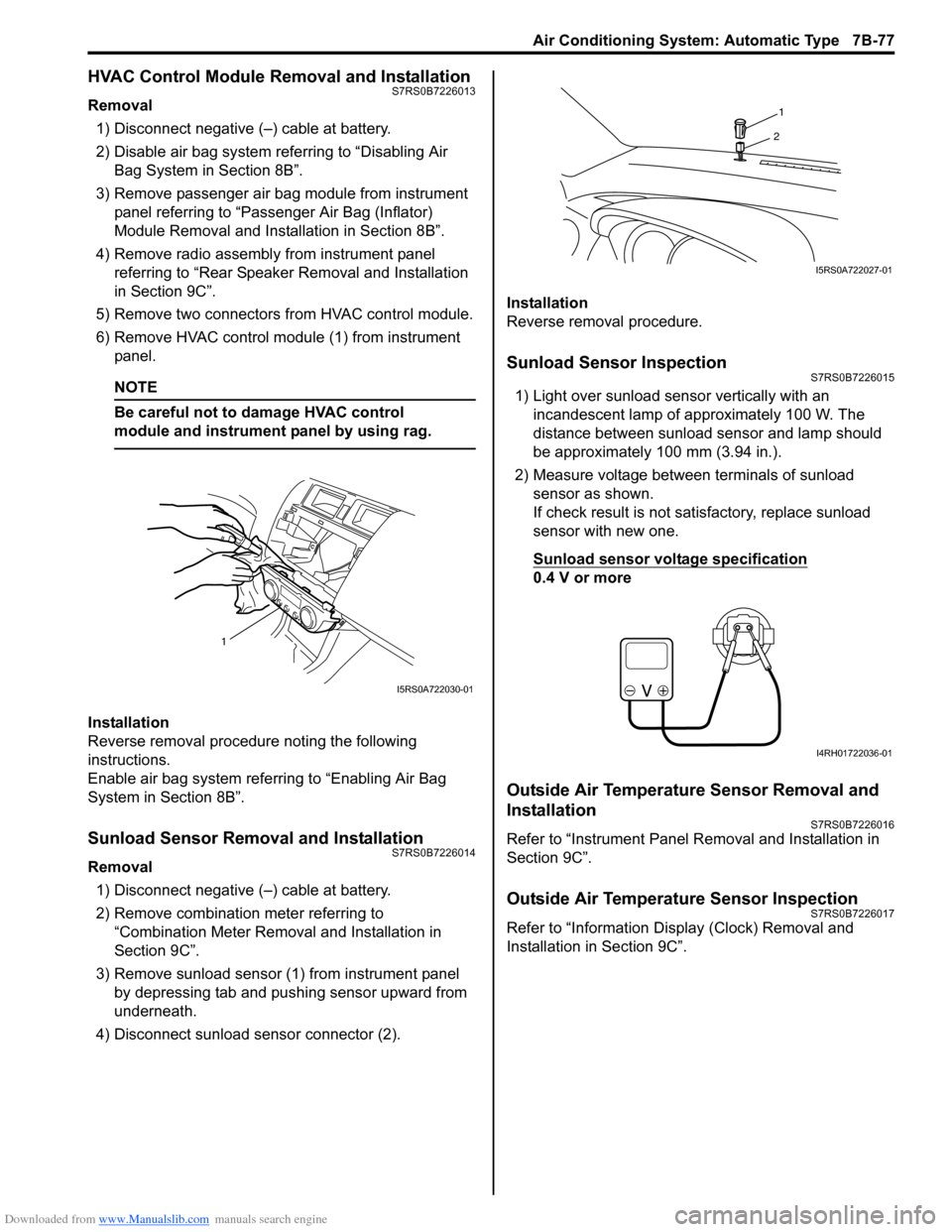

HVAC Control Module Removal and InstallationS7RS0B7226013

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Rear Speaker Removal and Installation

in Section 9C”.

5) Remove two connectors fr om HVAC control module.

6) Remove HVAC control modu le (1) from instrument

panel.

NOTE

Be careful not to damage HVAC control

module and instrument panel by using rag.

Installation

Reverse removal procedure noting the following

instructions.

Enable air bag system referring to “Enabling Air Bag

System in Section 8B”.

Sunload Sensor Removal and InstallationS7RS0B7226014

Removal

1) Disconnect negative (–) cable at battery.

2) Remove combination meter referring to “Combination Meter Removal and Installation in

Section 9C”.

3) Remove sunload sensor (1) from instrument panel by depressing tab and pushing sensor upward from

underneath.

4) Disconnect sunload sensor connector (2). Installation

Reverse removal procedure.

Sunload Sensor InspectionS7RS0B7226015

1) Light over sunload sensor vertically with an

incandescent lamp of approximately 100 W. The

distance between sunload sensor and lamp should

be approximately 100 mm (3.94 in.).

2) Measure voltage between terminals of sunload sensor as shown.

If check result is not satisfactory, replace sunload

sensor with new one.

Sunload sensor voltage specification

0.4 V or more

Outside Air Temperature Sensor Removal and

Installation

S7RS0B7226016

Refer to “Instrument Panel Re moval and Installation in

Section 9C”.

Outside Air Temperature Sensor InspectionS7RS0B7226017

Refer to “Information Display (Clock) Removal and

Installation in Section 9C”.

1

I5RS0A722030-01

1

2

I5RS0A722027-01

I4RH01722036-01

Page 1029 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 8- i

8

Section 8

CONTENTS

Restraint

Precautions ................................................. 8-1

Precautions............................................................. 8-1

Precautions on Restraint ....................................... 8-1

Seat Belts .......... ............................... ........ 8A-1

Precautions........................................................... 8A-1

Precautions on Service a nd Diagnosis of Seat

Belt .................................................................... 8A-1

General Description ............................................. 8A-1 Seat Belt Construction ........................................ 8A-1

Diagnostic Information and Procedures ............ 8A-2 Repair and Inspection Required after Accident ............................................................ 8A-2

Repair Instructions .............................................. 8A-3 Front Seat Belt Components ............................... 8A-3

Front Seat Belt Removal and Installation ............ 8A-4

Front Seat Belt Inspection ................................... 8A-4

Rear Seat Belt Components ............................... 8A-6

Rear Seat Belt Removal and Installation ............ 8A-7

Rear Seat Belt Inspection ................................... 8A-7

Specifications ....................................................... 8A-7

Tightening Torque Specifications ........................ 8A-7

Air Bag System ............... ......................... 8B-1

Precautions........................................................... 8B-1

Precautions on Service and Diagnosis of Air Bag System....................................................... 8B-1

Precautions on Handling and Storage of Air Bag System Components . ................................ 8B-2

Precautions on Disposal of Air Bag and Seat

Belt Pretensioner .............................................. 8B-5

General Description ............................................. 8B-5 Air Bag System Construction .............................. 8B-5

Air Bag System Input / Output Table .................. 8B-6

Schematic and Routing Diagram ........................ 8B-7 Air Bag System Wiring Circuit Diagram .............. 8B-7

Component Locatio n ........................................... 8B-9

Air Bag System Components, Wiring and Connectors Location ......................................... 8B-9

Diagnostic Information and Procedures .......... 8B-10 Air Bag Diagnostic System Check .................... 8B-10

Air Bag Diagnostic System Check Flow ............ 8B-10

DTC Table ......................................................... 8B-11

DTC Check ....................................................... 8B-12 DTC Clearance ................................................. 8B-12

Scan Tool Data ................................................. 8B-13

“AIR BAG” Warning Right Comes ON Steady .. 8B-13

“AIR BAG” Warning Right Does Not Come

ON ................................................................... 8B-15

“AIR BAG” Warning Right Flashes .................... 8B-16

DTC B1013: SDM fault...................................... 8B-17

DTC B1014: “AIR BAG” Warning Right Circuit Failure ............................................................. 8B-17

DTC B1016: Power Source Voltage High ......... 8B-18

DTC B1017: Power Source Voltage Low .......... 8B-20

DTC B1021: Front Air Bag Module Deployed ... 8B-22

DTC B1024 / B1025: Side-Air Bag (Driver / Passenger) Deployed...................................... 8B-22

DTC B1026: Pretensioner Activated ................. 8B-23

DTC B1027: Reusable Number Exceeded ....... 8B-24

DTC B1031: Driver Air Bag Initiator Circuit

Resistance High .............................................. 8B-24

DTC B1032: Driver Air Bag Initiator Circuit

Resistance Low ............................................... 8B-29

DTC B1033: Driver Air Bag Initiator Circuit

Short to Ground............................................... 8B-34

DTC B1034: Driver Air Bag Initiator Circuit

Short to Power Circuit .... ................................. 8B-39

DTC B1041: Passenger Air Bag Initiator Circuit Resistance High ................................... 8B-44

DTC B1042: Passenger Air Bag Initiator Circuit Resistance Low.................................... 8B-47

DTC B1043: Passenger Air Bag Initiator Circuit Short to Ground ................................... 8B-50

DTC B1044: Passenger Air Bag Initiator Circuit Short to Power Circ uit .......................... 8B-53

DTC B1051 / B1055: Driver / Passenger Pretensioner Initiator Circuit Resistance

High ................................................................. 8B-56

DTC B1052 / B1056: Driver / Passenger Pretensioner Initiator Circu it Resistance Low .. 8B-58

DTC B1053 / B1057: Driver / Passenger Pretensioner Initiator Circuit Short to Ground .. 8B-60

DTC B1054 / B1058: Driver / Passenger Pretensioner Initiator Circuit Short to Power

Circuit .............................................................. 8B-62

DTC B1061 / B1065: Driver / Passenger Side- Air Bag Initiator Circuit Resistance High ......... 8B-64

Page 1031 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 8-1

Restraint

Precautions

Precautions

Precautions on RestraintS7RS0B8000001

Air Bag System Service Warning

Refer to “Air Bag System Service Warning in Section 00”.

Fastener Caution

Refer to “Fastener Caution in Section 00”.

Precautions on Service and Diagnosis of Seat Belt

Refer to “Precautions on Service and Diagnosis of Seat Belt in Section 8A”.

Precautions on Service and Diagnosis of Air Bag System

Refer to “Precautions on Service and Diagnosis of Air Bag System in Section 8B”.

Precautions on Handling and Storage of Air Bag Components

Refer to “Precautions on Handling and Storage of Air Bag System Components in Section 8B”.

Precautions on Disposal of Air Bag and Seat Belt Pretensioner

Refer to “Precautions on Disposal of Air Bag and Seat Belt Pretensioner in Section 8B”.

Page 1033 of 1496

Downloaded from www.Manualslib.com manuals search engine Seat Belts: 8A-2

Seat Belt with ELR

The seat belt with emergency locking retractor (ELR) is

designed so that it locks immediately (to prevent the

webbing from being pulled out of the retractor any

further) when any of the following items is detected as

exceeding each set value;

• Speed at which the webbing is pulled out of the retractor.

• Acceleration or deceleration of the vehicle speed.

• Inclination.

Seat Belt with A-ELR

The automatic and emergency locking retractor (A-ELR)

works as an Emergency Locking Retractor (ELR) till its

webbing is pulled all the way out and then on as an

Automatic Locking Retractor (ALR ) till it is retracted fully.

ALR: Automatically locks when the webbing is pulled out

from the retractor and allowed to retract even a little.

Then the webbing can not be pulled out any further,

unless it is wound all the way back into the retractor,

which releases the lock and allows the webbing to be

pulled out.

Seat Belt with ELR and Pretensioner

The seat belt with ELR and a pretensioner has a

pretensioner mechanism whic h operates in linkage with

the air bag in addition to the described ELR.

The pretensioner is incorporated in retractor assembly

and controlled by SDM as one of air bag system

components. It will be activated at the same time as the

driver and passenger air bag module when an impact at

the front of vehicle exceeds the specified value.

When servicing seat belt (retractor assembly) with

pretensioner, be sure to observe all WARNINGS and

CAUTIONS and “Precautions on Service and Diagnosis

of Air Bag System in Section 8B”. CAUTION!

Do not reuse the seat belt pretensioner

(retractor assembly) that has activated.

Replace it with a new seat belt assembly and

buckle together as a set. For checking

procedure of its activation, refer to “Repair

and Inspection Required after Accident in

Section 8B”.

Seat Belt Remainder

When driver’s seat belt is unfastened (under the

following conditions), seat belt reminder light and

warning buzzer inform that driver’s seat belt is

unfastened. Seat belt reminder light located in

combination meter and warning buzzer located inside

BCM operate as follows:

• Seat belt reminder light comes on when driver’s seat belt is unfastened while igni tion key switch is at ON

position.

• If vehicle speed exceeds 15 km/h with seat belt unfastened, warning buzzer operates for

approximately 95 seconds and seat belt reminder light

flashes synchronously with buzzer. When warning

buzzer stops operating, seat belt reminder light is

turned on.

• If driver’s seat belt state is changed from “fastened” to “unfastened” while vehicle speed is above 15 km/h,

warning buzzer operates for approximately 95

seconds and seat belt reminder light flashes

synchronously with buzzer. When warning buzzer

stops operating, seat belt reminder light is turned on.

Diagnostic Information and Procedures

Repair and Inspection Required after AccidentS7RS0B8104001

After an accident, whether the seat belt pretensioner has been activated or not, be sure to perform checks and repairs

described on “Repair and Inspection Required after Accident in Section 8B”.

Page 1035 of 1496

Downloaded from www.Manualslib.com manuals search engine Seat Belts: 8A-4

Front Seat Belt Removal and InstallationS7RS0B8106002

WARNING!

• Never attempt to disassemble or repair the seat belt pretensioner (retractor

assembly). If any abnormality is found, be

sure to replace it with new one as an

assembly.

• Be sure to read “Precautions on Service and Diagnosis of Seat Belt” before starting

to work and observe every precaution

during work. Ne glecting them may result in

personal injury or una ctivation of the seat

belt pretensioner when necessary.

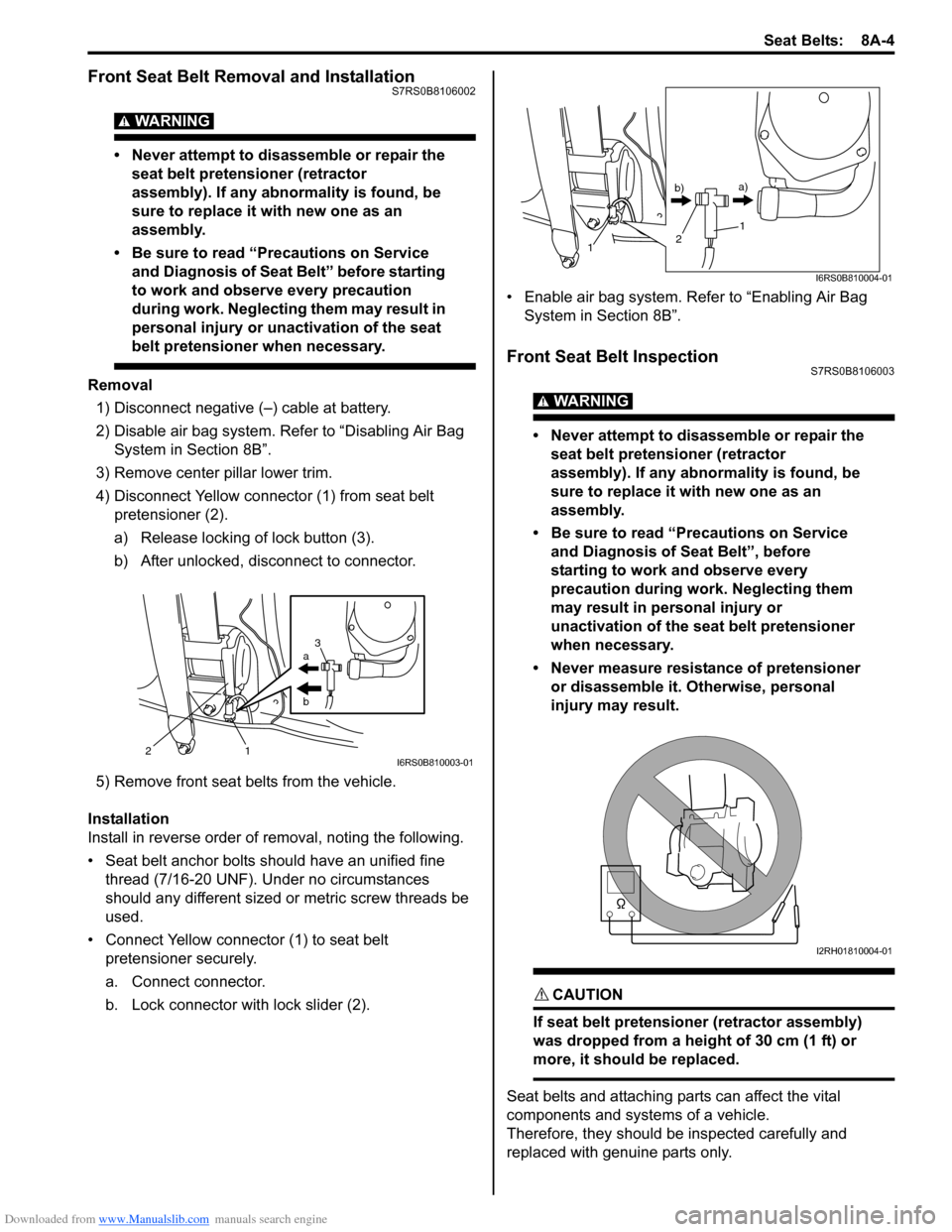

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Refer to “Disabling Air Bag System in Section 8B”.

3) Remove center pillar lower trim.

4) Disconnect Yellow connector (1) from seat belt pretensioner (2).

a) Release locking of lock button (3).

b) After unlocked, disconnect to connector.

5) Remove front seat belts from the vehicle.

Installation

Install in reverse order of removal, noting the following.

• Seat belt anchor bolts should have an unified fine thread (7/16-20 UNF). Under no circumstances

should any different sized or metric screw threads be

used.

• Connect Yellow connector (1) to seat belt pretensioner securely.

a. Connect connector.

b. Lock connector with lock slider (2). • Enable air bag system. Refer to “Enabling Air Bag

System in Section 8B”.

Front Seat Belt InspectionS7RS0B8106003

WARNING!

• Never attempt to disassemble or repair the seat belt pretensioner (retractor

assembly). If any abnormality is found, be

sure to replace it with new one as an

assembly.

• Be sure to read “Precautions on Service and Diagnosis of Seat Belt”, before

starting to work and observe every

precaution during work. Neglecting them

may result in personal injury or

unactivation of the seat belt pretensioner

when necessary.

• Never measure resistance of pretensioner or disassemble it. Otherwise, personal

injury may result.

CAUTION!

If seat belt pretensioner (retractor assembly)

was dropped from a height of 30 cm (1 ft) or

more, it should be replaced.

Seat belts and attaching parts can affect the vital

components and systems of a vehicle.

Therefore, they should be inspected carefully and

replaced with genuine parts only.

a

b

21 3I6RS0B810003-01

1

1

2

b)

a)

I6RS0B810004-01

I2RH01810004-01