Wheel bolt SUZUKI SWIFT 2008 2.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 463 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-9

12) Fill reservoir with brake fluid and bleed brake system. For bleeding operation, see “Air Bleeding of

Brake System in Section 4A”.

13) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

14) Adjust parking brake cable. For adjustment, refer to “Parking Brake Inspection and Adjustment in Section

4D”.

15) Lower hoist and bounce vehicle up and down several times to stabilize suspension.

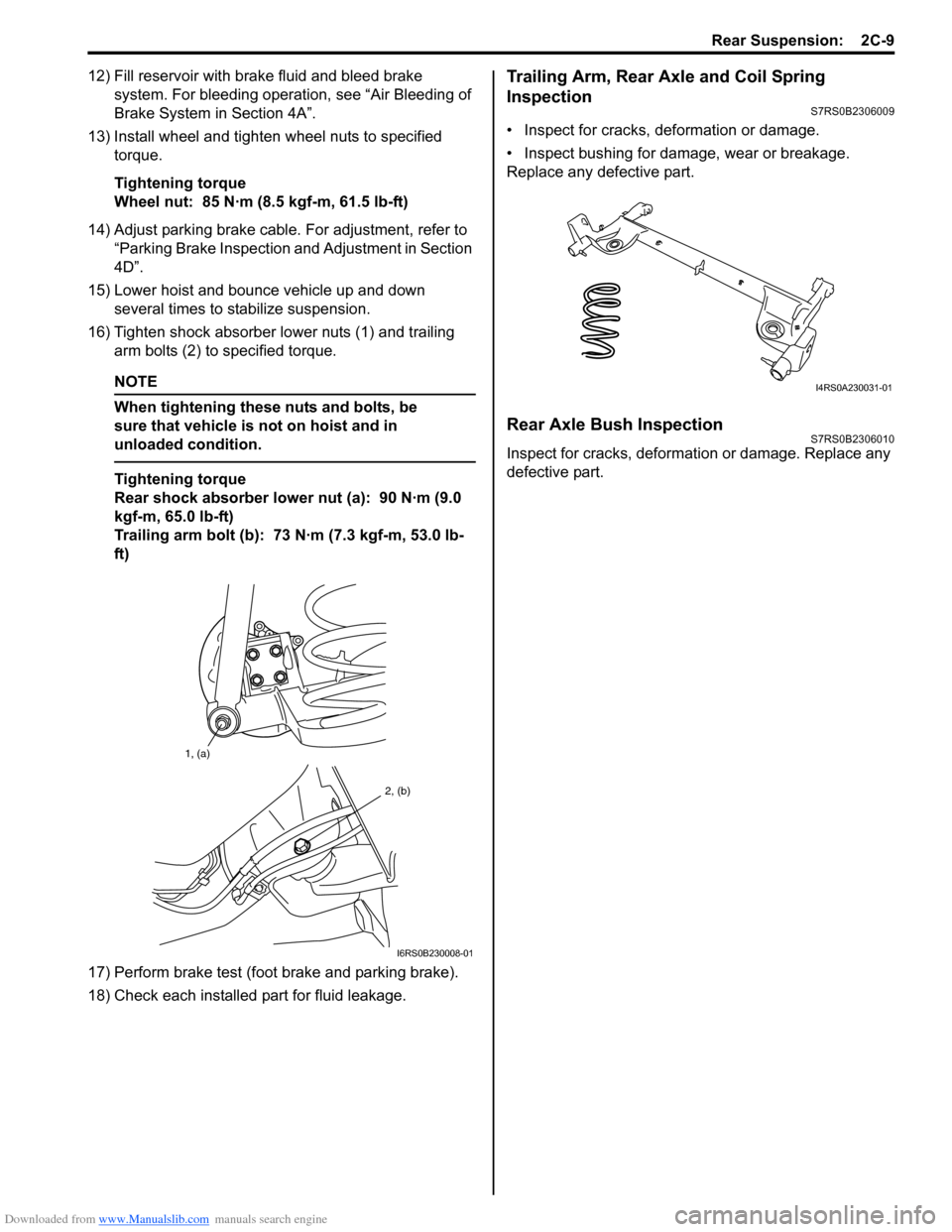

16) Tighten shock ab sorber lower nuts (1) and trailing

arm bolts (2) to specified torque.

NOTE

When tightening these nuts and bolts, be

sure that vehicle is not on hoist and in

unloaded condition.

Tightening torque

Rear shock absorber lower nut (a): 90 N·m (9.0

kgf-m, 65.0 lb-ft)

Trailing arm bolt (b): 73 N·m (7.3 kgf-m, 53.0 lb-

ft)

17) Perform brake test (foot brake and parking brake).

18) Check each installed part for fluid leakage.

Trailing Arm, Rear Axle and Coil Spring

Inspection

S7RS0B2306009

• Inspect for cracks, deformation or damage.

• Inspect bushing for damage, wear or breakage.

Replace any defective part.

Rear Axle Bush InspectionS7RS0B2306010

Inspect for cracks, deformation or damage. Replace any

defective part.

1, (a)

2, (b)

I6RS0B230008-01

I4RS0A230031-01

Page 464 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-10 Rear Suspension:

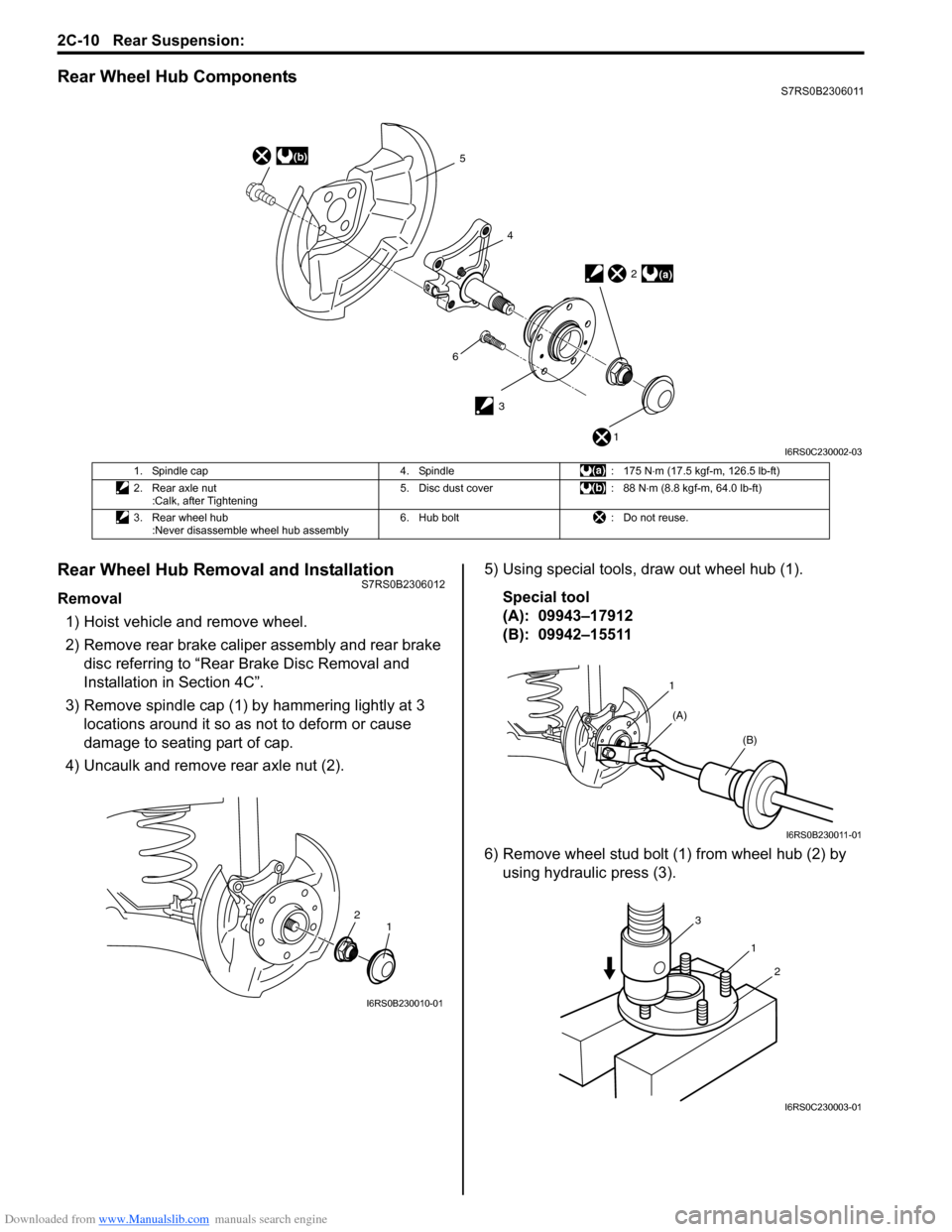

Rear Wheel Hub ComponentsS7RS0B2306011

Rear Wheel Hub Removal and InstallationS7RS0B2306012

Removal1) Hoist vehicle and remove wheel.

2) Remove rear brake caliper assembly and rear brake disc referring to “Rear Brake Disc Removal and

Installation in Section 4C”.

3) Remove spindle cap (1) by hammering lightly at 3 locations around it so as not to deform or cause

damage to seating part of cap.

4) Uncaulk and remove rear axle nut (2). 5) Using special tools, draw out wheel hub (1).

Special tool

(A): 09943–17912

(B): 09942–15511

6) Remove wheel stud bolt (1) from wheel hub (2) by using hydraulic press (3).

(b)5

4

3

(a)2

1

6

I6RS0C230002-03

1. Spindle cap 4. Spindle: 175 N⋅m (17.5 kgf-m, 126.5 lb-ft)

2. Rear axle nut :Calk, after Tightening 5. Disc dust cover

: 88 N⋅m (8.8 kgf-m, 64.0 lb-ft)

3. Rear wheel hub :Never disassemble wheel hub assembly 6. Hub bolt

: Do not reuse.

2

1

I6RS0B230010-01

1

(A) (B)

I6RS0B230011-01

1

3

2

I6RS0C230003-01

Page 465 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-11

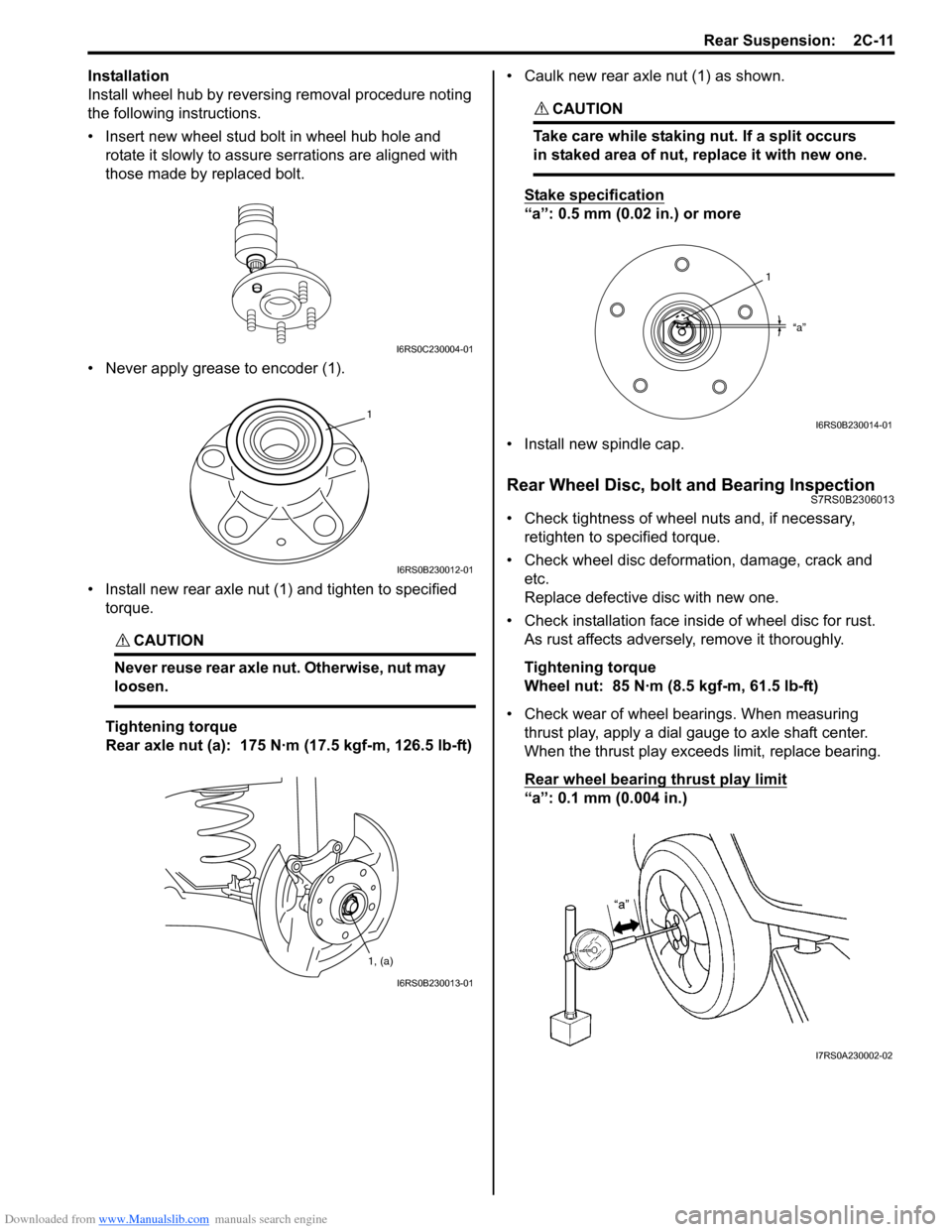

Installation

Install wheel hub by reversing removal procedure noting

the following instructions.

• Insert new wheel stud bolt in wheel hub hole and rotate it slowly to assure serrations are aligned with

those made by replaced bolt.

• Never apply grease to encoder (1).

• Install new rear axle nut (1) and tighten to specified torque.

CAUTION!

Never reuse rear axle nut. Otherwise, nut may

loosen.

Tightening torque

Rear axle nut (a): 175 N·m (17.5 kgf-m, 126.5 lb-ft) • Caulk new rear axle nut (1) as shown.

CAUTION!

Take care while staking nut. If a split occurs

in staked area of nut,

replace it with new one.

Stake specification

“a”: 0.5 mm (0.02 in.) or more

• Install new spindle cap.

Rear Wheel Disc, bolt and Bearing InspectionS7RS0B2306013

• Check tightness of wheel nuts and, if necessary, retighten to specified torque.

• Check wheel disc deformation, damage, crack and etc.

Replace defective disc with new one.

• Check installation face insi de of wheel disc for rust.

As rust affects adversely, remove it thoroughly.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

• Check wear of wheel bearings. When measuring thrust play, apply a dial gauge to axle shaft center.

When the thrust play exce eds limit, replace bearing.

Rear wheel bearing thrust play

limit

“a”: 0.1 mm (0.004 in.)

I6RS0C230004-01

1

I6RS0B230012-01

1, (a)

I6RS0B230013-01

1

“a”

I6RS0B230014-01

I7RS0A230002-02

Page 466 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-12 Rear Suspension:

• Check noise and smooth rotation of wheel by rotating wheel. If it is defect ive, replace bearing.

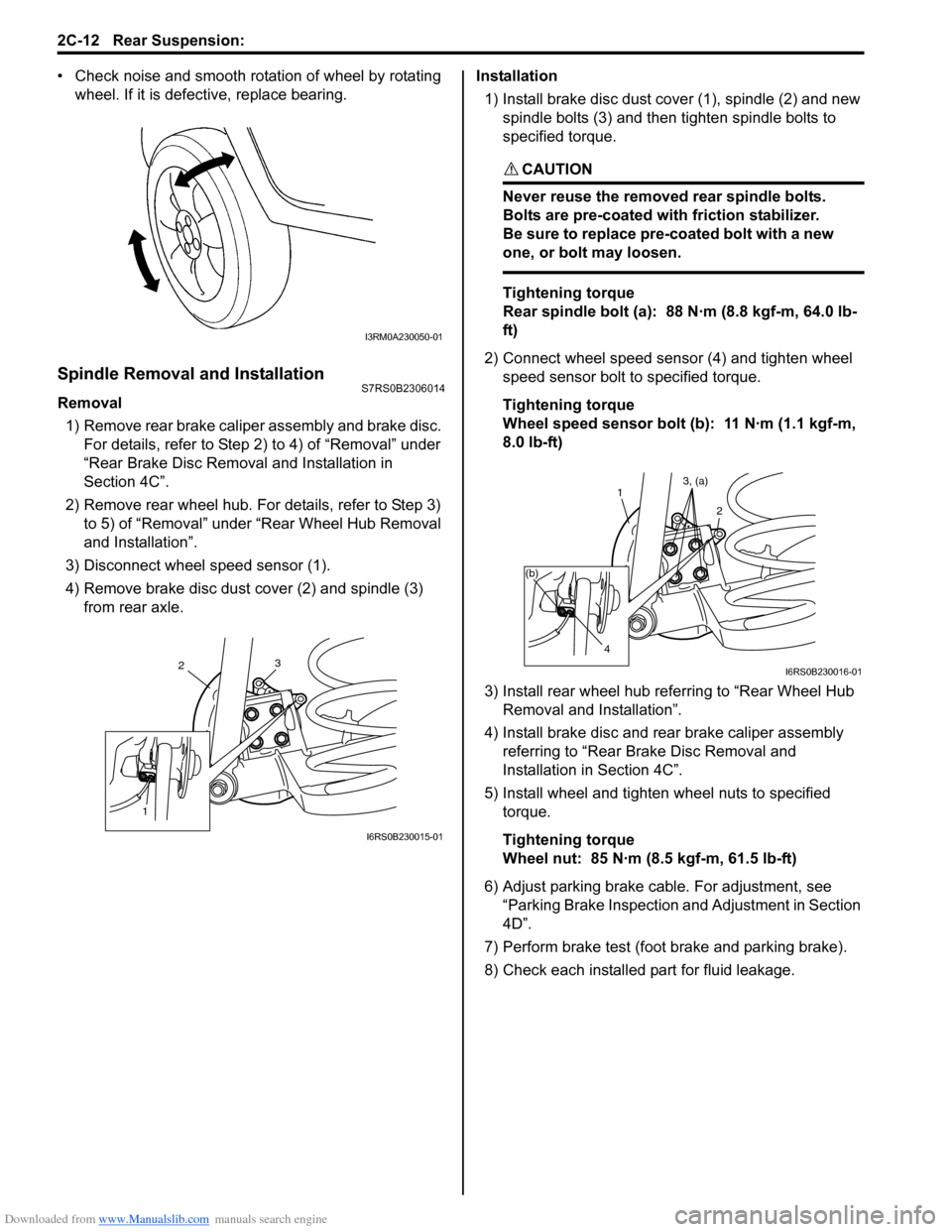

Spindle Removal and InstallationS7RS0B2306014

Removal

1) Remove rear brake caliper assembly and brake disc. For details, refer to Step 2) to 4) of “Removal” under

“Rear Brake Disc Removal and Installation in

Section 4C”.

2) Remove rear wheel hub. For details, refer to Step 3) to 5) of “Removal” under “Rear Wheel Hub Removal

and Installation”.

3) Disconnect wheel speed sensor (1).

4) Remove brake disc dust cover (2) and spindle (3) from rear axle. Installation

1) Install brake disc dust cover (1), spindle (2) and new spindle bolts (3) and then tighten spindle bolts to

specified torque.

CAUTION!

Never reuse the removed rear spindle bolts.

Bolts are pre-coated wi th friction stabilizer.

Be sure to replace pre-coated bolt with a new

one, or bolt may loosen.

Tightening torque

Rear spindle bolt (a): 88 N·m (8.8 kgf-m, 64.0 lb-

ft)

2) Connect wheel speed sensor (4) and tighten wheel speed sensor bolt to specified torque.

Tightening torque

Wheel speed sensor bolt (b): 11 N·m (1.1 kgf-m,

8.0 lb-ft)

3) Install rear wheel hub re ferring to “Rear Wheel Hub

Removal and Installation”.

4) Install brake disc and rear brake caliper assembly referring to “Rear Brake Disc Removal and

Installation in Section 4C”.

5) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

6) Adjust parking brake cable. For adjustment, see “Parking Brake Inspection and Adjustment in Section

4D”.

7) Perform brake test (foot brake and parking brake).

8) Check each installed part for fluid leakage.

I3RM0A230050-01

2

1 3

I6RS0B230015-01

1

(b)

4

2

3, (a)

I6RS0B230016-01

Page 467 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-13

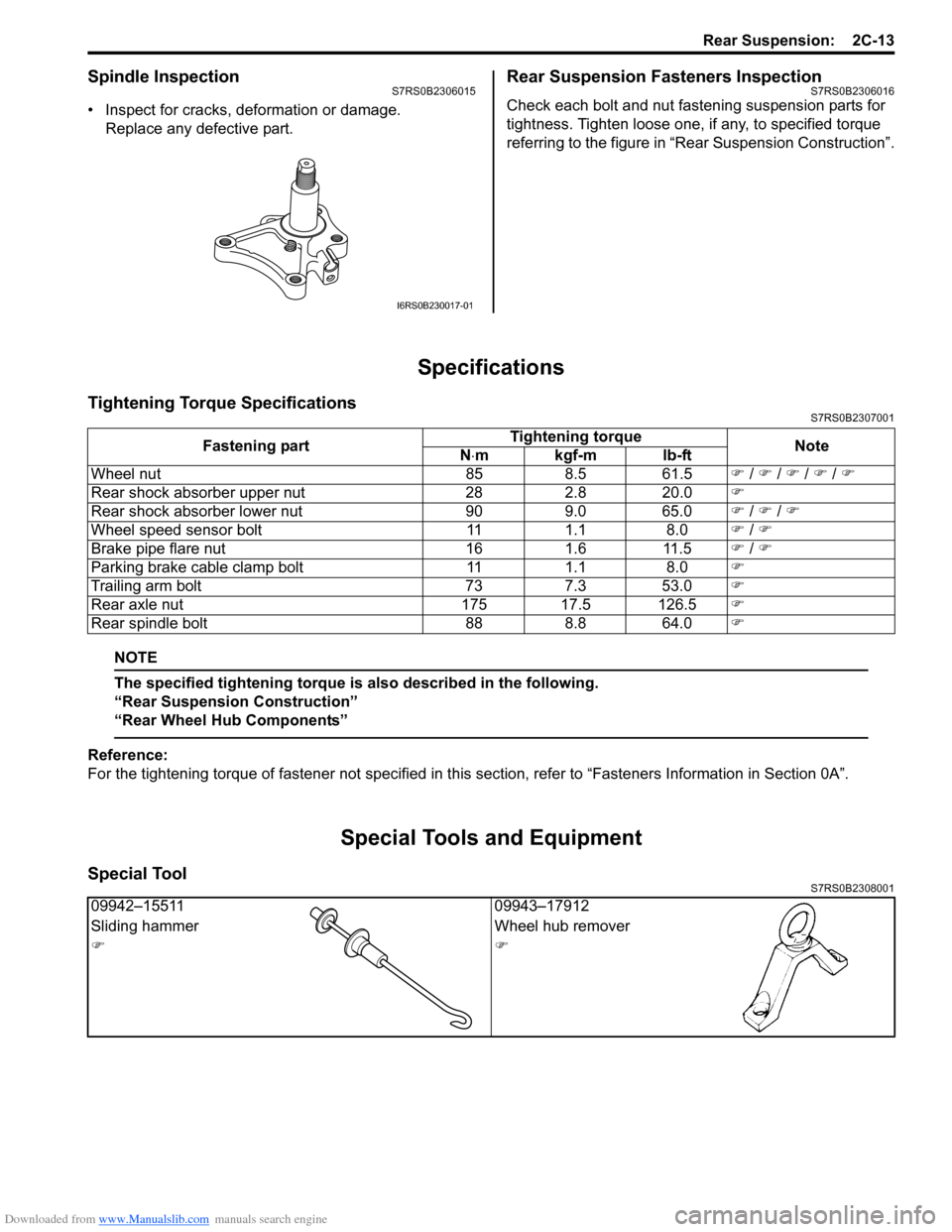

Spindle InspectionS7RS0B2306015

• Inspect for cracks, deformation or damage.Replace any defective part.

Rear Suspension Fasteners InspectionS7RS0B2306016

Check each bolt and nut fastening suspension parts for

tightness. Tighten loose one, if any, to specified torque

referring to the figure in “Rear Suspension Construction”.

Specifications

Tightening Torque SpecificationsS7RS0B2307001

NOTE

The specified tightening torque is also described in the following.

“Rear Suspension Construction”

“Rear Wheel Hub Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS7RS0B2308001

I6RS0B230017-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Wheel nut 85 8.5 61.5 �) / �) / �) / �) / �)

Rear shock absorber upper nut 28 2.8 20.0 �)

Rear shock absorber lower nut 90 9.0 65.0 �) / �) / �)

Wheel speed sensor bolt 11 1.1 8.0 �) / �)

Brake pipe flare nut 16 1.6 11.5 �) / �)

Parking brake cable clamp bolt 11 1.1 8.0 �)

Trailing arm bolt 73 7.3 53.0 �)

Rear axle nut 175 17.5 126.5 �)

Rear spindle bolt 88 8.8 64.0 �)

09942–1551109943–17912

Sliding hammer Wheel hub remover

�)�)

Page 469 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-2

Lower than recommended pressure can cause:

• Tire squeal on turns

• Hard Steering

• Rapid and uneven wear on the edges of the tread

• Tire rim bruises and rupture

• Tire cord breakage

• High tire temperature

• Reduced handling

• High fuel consumption

Replacement Tires

When replacement is necessary, the original equipment

type tire should be used. Refer to the Tire Placard.

Replacement tires should be of the same size, load

range and construction as those originally on the vehicle.

Use of any other size or type tire may affect ride,

handling, speedometer / odometer calibration, vehicle

ground clearance and tire or snow chain clearance to the

body and chassis.

It is recommended that new tires be installed in pairs on

the same axle. If necessary to replace only one tire, it

should be paired with the tire having the most tread, to

equalize braking traction.

WARNING!

Do not mix different types of tires on the

same vehicle such as radial, bias and bias-

belted tires except in emergencies, because

handling may be seriously affected and may

result in loss of control.

The metric term for tire infl ation pressure is the kilo

pascal (kPa). Tire pressures is usually printed in both

kPa and kgf/cm

2 on the “Tire Placard”.

Metric tire gauges are available from tool suppliers.

The chart, shown the table, converts commonly used

inflation pressures from kPa to kgf/cm

2 and psi.

Wheels DescriptionS7RS0B2401002

Wheel Maintenance

Wheel repairs that use welding, heating, or peening are

not approved. All damaged wheels should be replaced.

Replacement Wheels

Wheels must be replaced if they are bent, dented, have

excessive lateral or radial runout, air leak through welds,

have elongated bolt holes, if lug wheel bolts won’t stay

tight, or if they are heavily rusted. Wheels with greater

runout than shown in the following may cause

objectional vibrations.

Replacement wheels must be equivalent to the original

equipment wheels in load capacity, diameter, rim with

offset and mounting configuration. A wheel of improper

size or type may affect wheel and bearing life, brake

cooling, speedometer / odometer calibration, vehicle

ground clearance and tire clearance to body and

chassis.

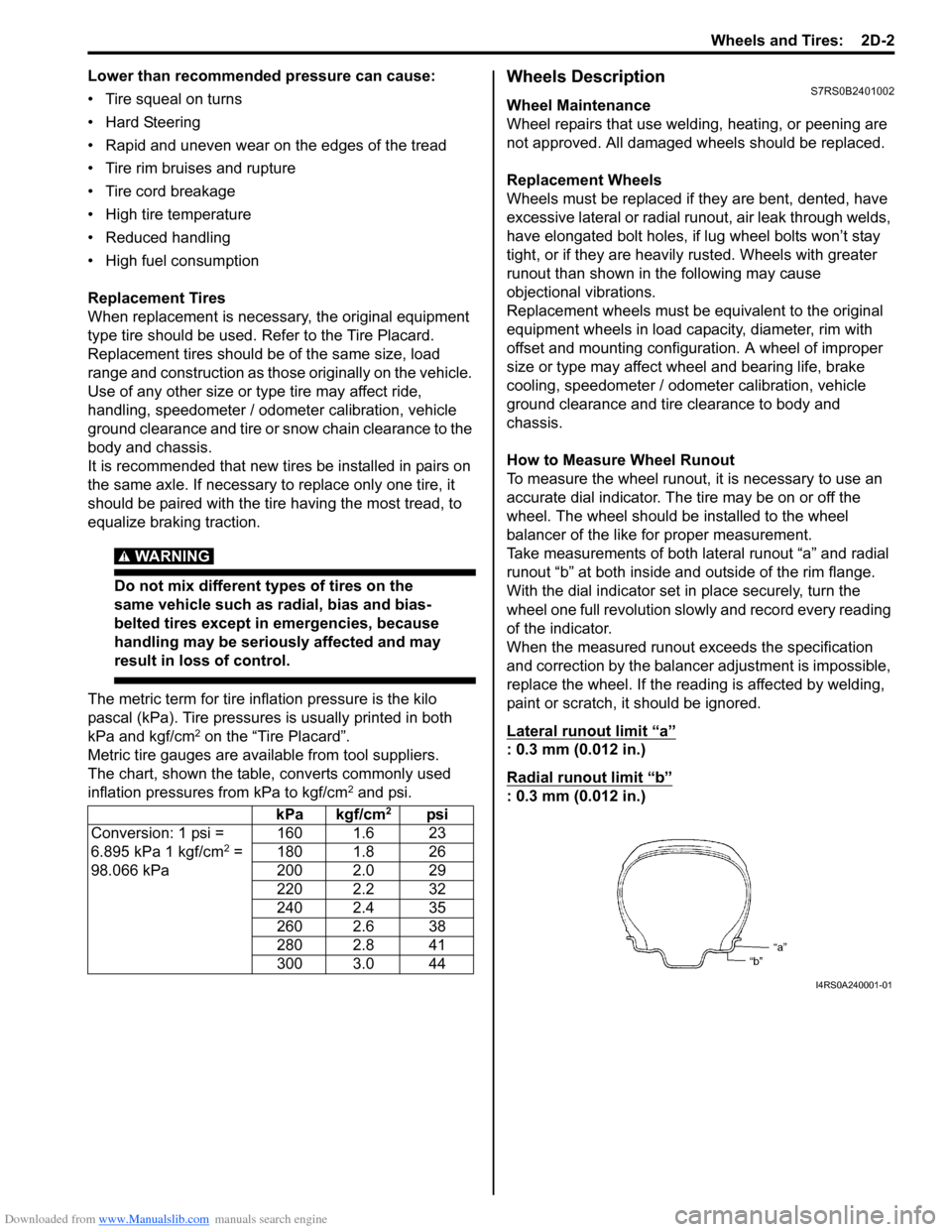

How to Measure Wheel Runout

To measure the wheel runout, it is necessary to use an

accurate dial indicator. The tire may be on or off the

wheel. The wheel should be installed to the wheel

balancer of the like for proper measurement.

Take measurements of both lateral runout “a” and radial

runout “b” at both inside an d outside of the rim flange.

With the dial indicator set in place securely, turn the

wheel one full revolution slowly and record every reading

of the indicator.

When the measured runout exceeds the specification

and correction by the balancer adjustment is impossible,

replace the wheel. If the reading is affected by welding,

paint or scratch, it should be ignored.

Lateral runout limit “a”

: 0.3 mm (0.012 in.)

Radial runout limit “b”

: 0.3 mm (0.012 in.)

kPa kgf/cm2psi

Conversion: 1 psi =

6.895 kPa 1 kgf/cm

2 =

98.066 kPa 160 1.6 23

180 1.8 26

200 2.0 29

220 2.2 32

240 2.4 35

260 2.6 38

280 2.8 41

300 3.0 44

I4RS0A240001-01

Page 479 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-1

Driveline / Axle

Drive Shaft / Axle

General Description

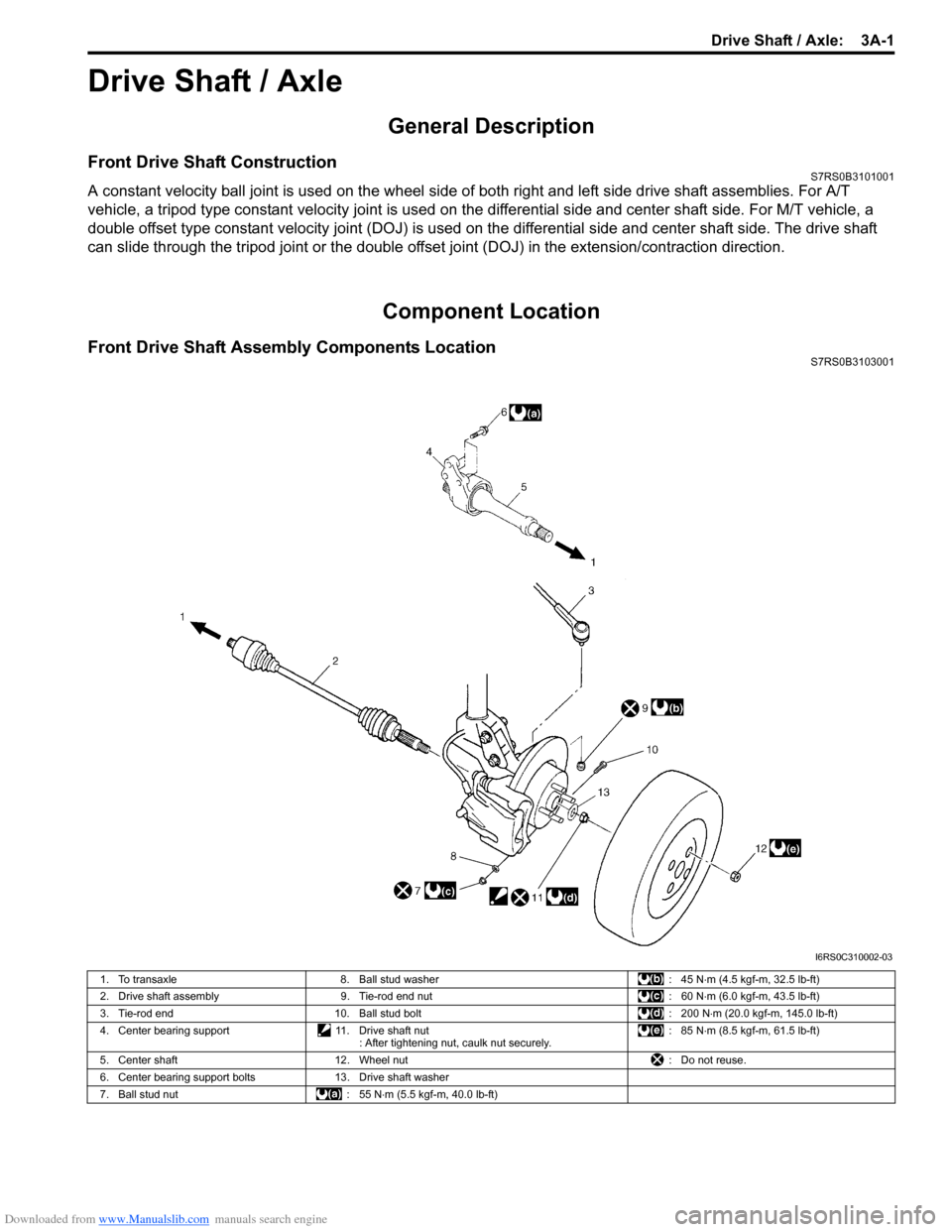

Front Drive Shaft ConstructionS7RS0B3101001

A constant velocity ball joint is used on the wheel side of both right and left side drive shaft assemblies. For A/T

vehicle, a tripod type constant velocity joint is used on the differential side and center shaft side. For M/T vehicle, a

double offset type constant velocity joint (DOJ) is used on the differential side and center shaft side. The drive shaft

can slide through the tripod joint or the double offset joint (DOJ) in the extension/contraction direction.

Component Location

Front Drive Shaft Assembly Components LocationS7RS0B3103001

I6RS0C310002-03

1. To transaxle 8. Ball stud washer : 45 N⋅m (4.5 kgf-m, 32.5 lb-ft)

2. Drive shaft assembly 9. Tie-rod end nut : 60 N⋅m (6.0 kgf-m, 43.5 lb-ft)

3. Tie-rod end 10. Ball stud bolt : 200 N⋅m (20.0 kgf-m, 145.0 lb-ft)

4. Center bearing support 11. Drive shaft nut

: After tightening nut, caulk nut securely. : 85 N

⋅m (8.5 kgf-m, 61.5 lb-ft)

5. Center shaft 12. Wheel nut : Do not reuse.

6. Center bearing support bolts 13. Drive shaft washer

7. Ball stud nut : 55 N⋅m (5.5 kgf-m, 40.0 lb-ft)

Page 482 of 1496

Downloaded from www.Manualslib.com manuals search engine 3A-4 Drive Shaft / Axle:

Front Drive Shaft Assembly On-Vehicle

Inspection

S7RS0B3106002

• Check boots for breakage or deterioration.

• Check wheel side joint for rattle or smooth rotation.

• Check differential side (or center shaft side) joint for smooth rotation.

If any abnormality is found, replace.

Front Drive Shaft Assembly Removal and

Installation

S7RS0B3106003

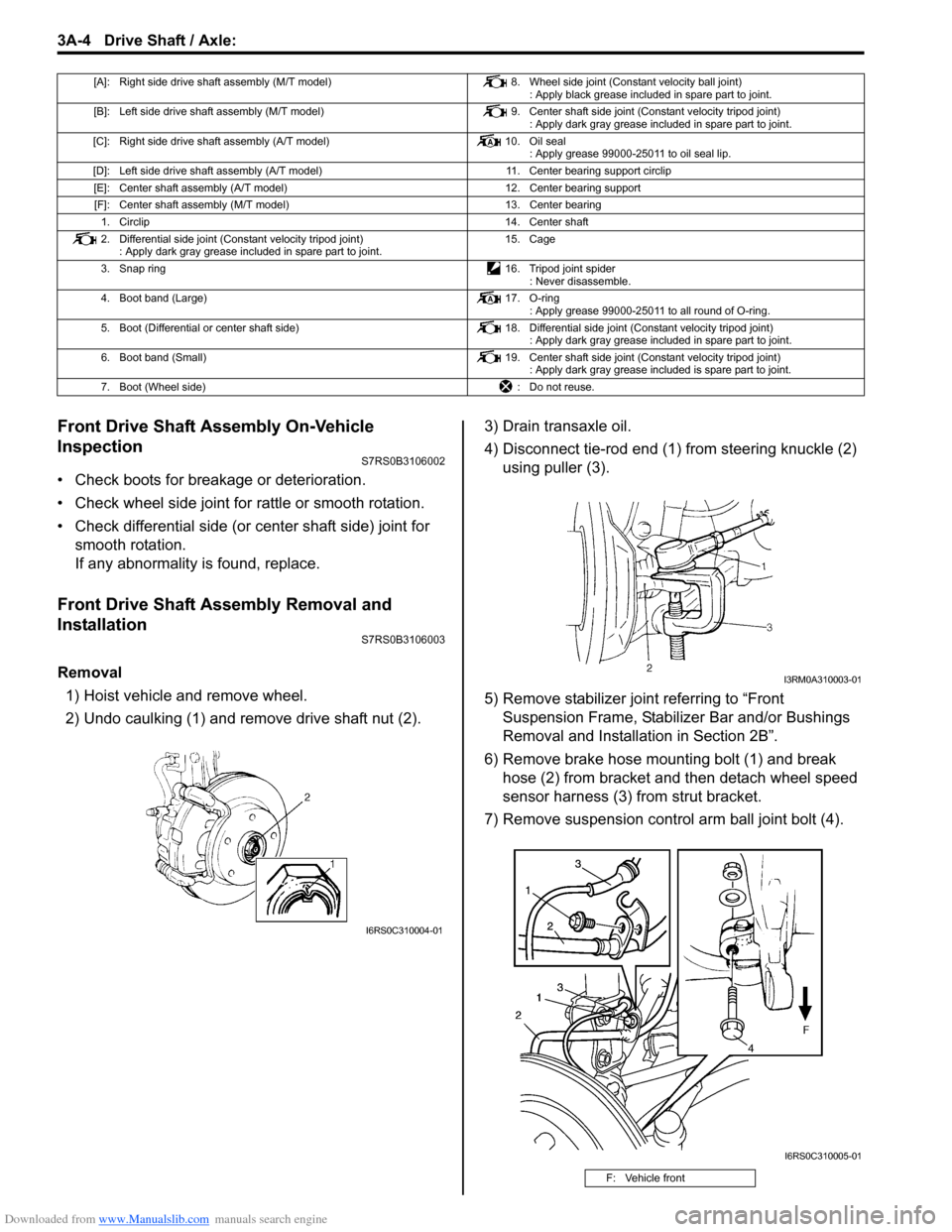

Removal

1) Hoist vehicle and remove wheel.

2) Undo caulking (1) and remove drive shaft nut (2). 3) Drain transaxle oil.

4) Disconnect tie-rod end (1) from steering knuckle (2)

using puller (3).

5) Remove stabilizer join t referring to “Front

Suspension Frame, Stabiliz er Bar and/or Bushings

Removal and Installati on in Section 2B”.

6) Remove brake hose mounting bolt (1) and break hose (2) from bracket and then detach wheel speed

sensor harness (3) from strut bracket.

7) Remove suspension contro l arm ball joint bolt (4).

[A]: Right side drive shaft assembly (M/T model) 8. Wheel side joint (Constant velocity ball joint)

: Apply black grease included in spare part to joint.

[B]: Left side drive shaft assembly (M/T model) 9. Center shaft side joint (Constant velocity tripod joint)

: Apply dark gray grease included in spare part to joint.

[C]: Right side drive shaft assembly (A/T model) 10. Oil seal

: Apply grease 99000-25011 to oil seal lip.

[D]: Left side drive shaft assembly (A/T model) 11. Center bearing support circlip

[E]: Center shaft assembly (A/T model) 12. Center bearing support

[F]: Center shaft assembly (M/T model) 13. Center bearing

1. Circlip 14. Center shaft

2. Differential side joint (Constant velocity tripod joint) : Apply dark gray grease included in spare part to joint. 15. Cage

3. Snap ring 16. Tripod joint spider

: Never disassemble.

4. Boot band (Large) 17. O-ring

: Apply grease 99000-25011 to all round of O-ring.

5. Boot (Differential or center shaft side) 18. Differential side joint (Constant velocity tripod joint)

: Apply dark gray grease included in spare part to joint.

6. Boot band (Small) 19. Center shaft side joint (Constant velocity tripod joint)

: Apply dark gray grease included is spare part to joint.

7. Boot (Wheel side) : Do not reuse.

I6RS0C310004-01

F: Vehicle front

I3RM0A310003-01

I6RS0C310005-01

Page 483 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-5

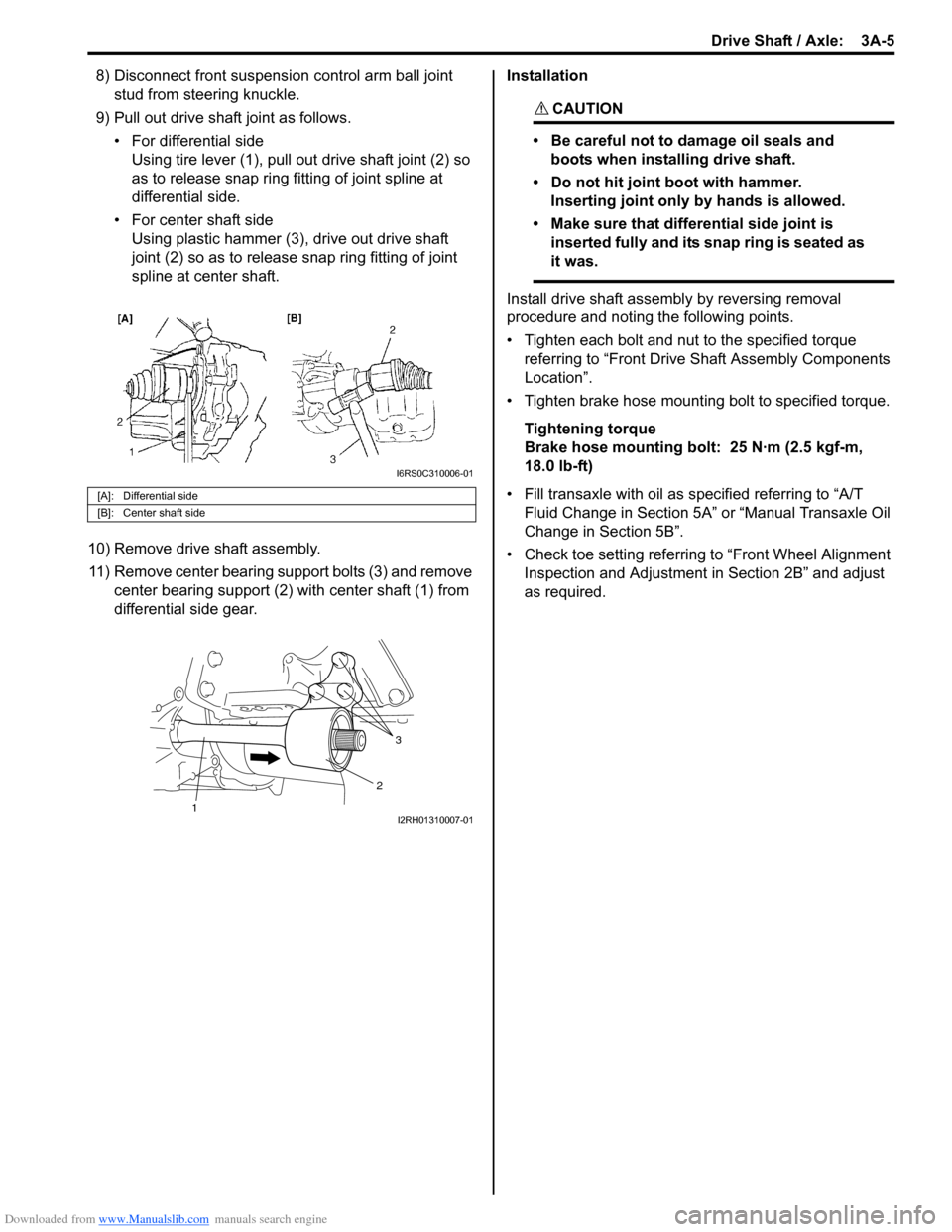

8) Disconnect front suspension control arm ball joint

stud from steering knuckle.

9) Pull out drive shaft joint as follows. • For differential sideUsing tire lever (1), pull out drive shaft joint (2) so

as to release snap ring fitting of joint spline at

differential side.

• For center shaft side Using plastic hammer (3), drive out drive shaft

joint (2) so as to release snap ring fitting of joint

spline at center shaft.

10) Remove drive shaft assembly. 11) Remove center bearing support bolts (3) and remove center bearing support (2) with center shaft (1) from

differential side gear. Installation

CAUTION!

• Be careful not to damage oil seals and

boots when installing drive shaft.

• Do not hit joint boot with hammer. Inserting joint only by hands is allowed.

• Make sure that differential side joint is inserted fully and its snap ring is seated as

it was.

Install drive shaft assemb ly by reversing removal

procedure and noting the following points.

• Tighten each bolt and nut to the specified torque referring to “Front Drive Shaft Assembly Components

Location”.

• Tighten brake hose mounting bolt to specified torque.

Tightening torque

Brake hose mounting bolt: 25 N·m (2.5 kgf-m,

18.0 lb-ft)

• Fill transaxle with oil as sp ecified referring to “A/T

Fluid Change in Section 5A” or “Manual Transaxle Oil

Change in Section 5B”.

• Check toe setting referring to “Front Wheel Alignment Inspection and Adjustment in Section 2B” and adjust

as required.

[A]: Differential side

[B]: Center shaft side

I6RS0C310006-01

3

2

1I2RH01310007-01

Page 502 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-4 Brake Control System and Diagnosis:

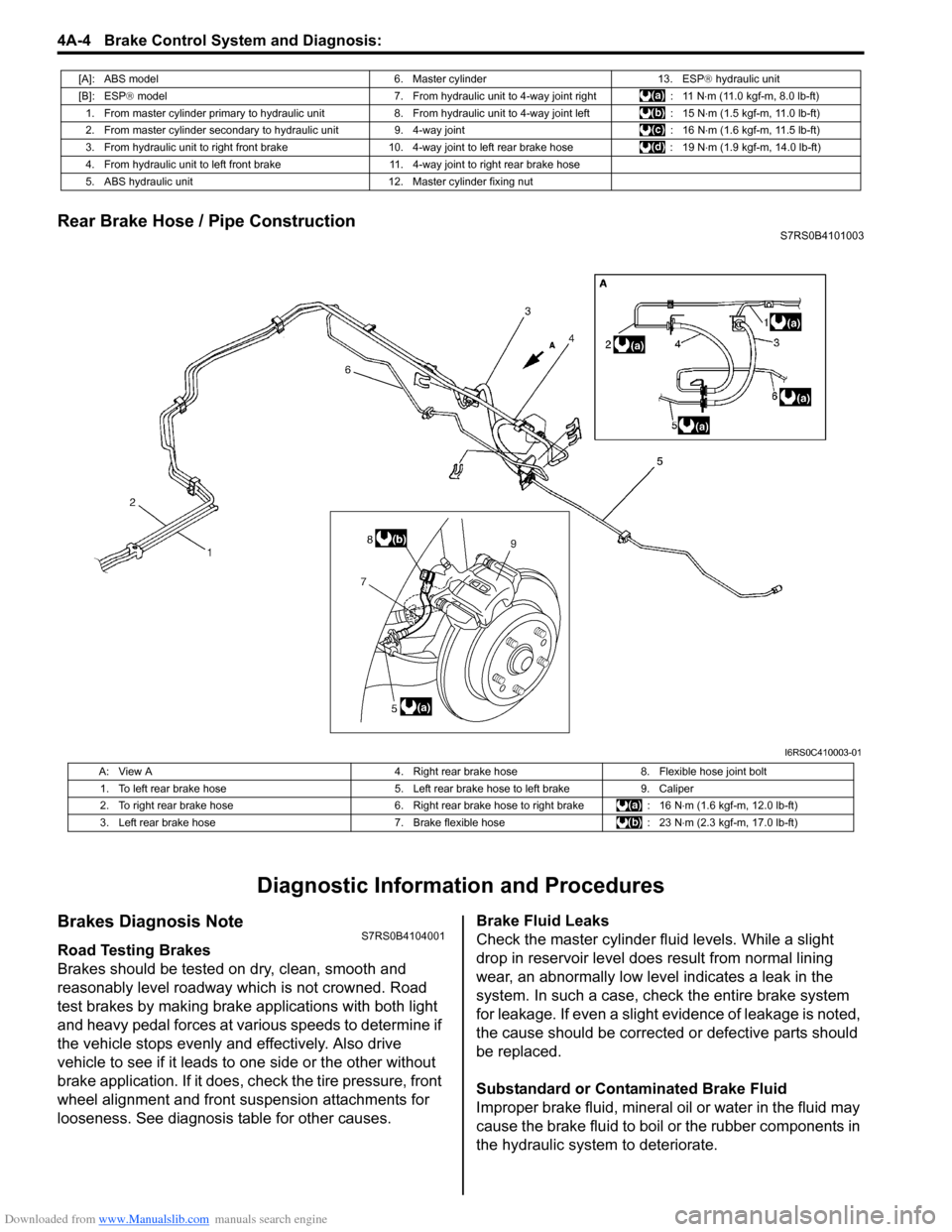

Rear Brake Hose / Pipe ConstructionS7RS0B4101003

Diagnostic Information and Procedures

Brakes Diagnosis NoteS7RS0B4104001

Road Testing Brakes

Brakes should be tested on dry, clean, smooth and

reasonably level roadway which is not crowned. Road

test brakes by making brake applications with both light

and heavy pedal forces at vari ous speeds to determine if

the vehicle stops evenly and effectively. Also drive

vehicle to see if it leads to one side or the other without

brake application. If it does, check the tire pressure, front

wheel alignment and front suspension attachments for

looseness. See diagnosis table for other causes. Brake Fluid Leaks

Check the master cylinder fl

uid levels. While a slight

drop in reservoir level does result from normal lining

wear, an abnormally low leve l indicates a leak in the

system. In such a case, chec k the entire brake system

for leakage. If even a slight ev idence of leakage is noted,

the cause should be corrected or defective parts should

be replaced.

Substandard or Contaminated Brake Fluid

Improper brake fluid, mineral oil or water in the fluid may

cause the brake fluid to boil or the rubber components in

the hydraulic system to deteriorate.

[A]: ABS model 6. Master cylinder13. ESP® hydraulic unit

[B]: ESP ® model 7. From hydraulic unit to 4-way joint right : 11 N⋅m (11.0 kgf-m, 8.0 lb-ft)

1. From master cylinder primary to hydraulic unit 8. From hydraulic unit to 4-way joint left: 15 N⋅m (1.5 kgf-m, 11.0 lb-ft)

2. From master cylinder secondary to hydraulic unit 9. 4-way joint: 16 N⋅m (1.6 kgf-m, 11.5 lb-ft)

3. From hydraulic unit to right front brake 10.4-way joint to left rear brake hose : 19 N⋅m (1.9 kgf-m, 14.0 lb-ft)

4. From hydraulic unit to left front brake 11. 4-way joint to right rear brake hose

5. ABS hydraulic unit 12. Master cylinder fixing nut

I6RS0C410003-01

A: View A4. Right rear brake hose8. Flexible hose joint bolt

1. To left rear brake hose 5. Left rear brake hose to left brake9. Caliper

2. To right rear brake hose 6. Right rear brake hose to right brake: 16 N⋅m (1.6 kgf-m, 12.0 lb-ft)

3. Left rear brake hose 7. Brake flexible hose: 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)