Wheel bolt SUZUKI SWIFT 2008 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 350 of 1496

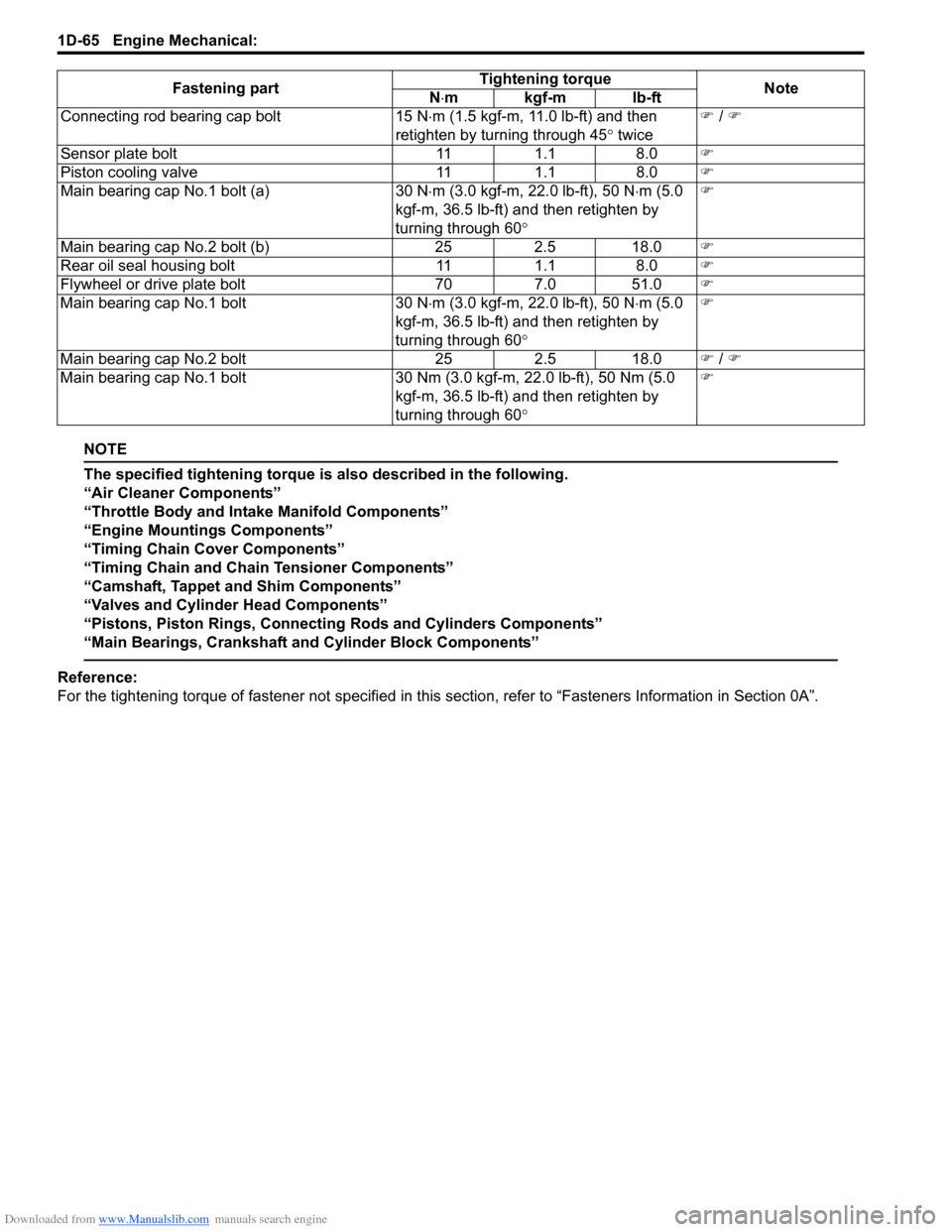

Downloaded from www.Manualslib.com manuals search engine 1D-65 Engine Mechanical:

NOTE

The specified tightening torque is also described in the following.

“Air Cleaner Components”

“Throttle Body and Intake Manifold Components”

“Engine Mountings Components”

“Timing Chain Cover Components”

“Timing Chain and Chain Tensioner Components”

“Camshaft, Tappet and Shim Components”

“Valves and Cylinder Head Components”

“Pistons, Piston Rings, Connecting Rods and Cylinders Components”

“Main Bearings, Crankshaft and Cylinder Block Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Connecting rod bearing cap bolt

15 N⋅m (1.5 kgf-m, 11.0 lb-ft) and then

retighten by turning through 45 ° twice �)

/ �)

Sensor plate bolt 111.1 8.0 �)

Piston cooling valve 111.1 8.0 �)

Main bearing cap No.1 bolt (a) 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N ⋅m (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Main bearing cap No.2 bolt (b) 252.5 18.0 �)

Rear oil seal housing bolt 111.1 8.0 �)

Flywheel or drive plate bolt 707.0 51.0 �)

Main bearing cap No.1 bolt 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N ⋅m (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Main bearing cap No.2 bolt 252.5 18.0 �) / �)

Main bearing cap No.1 bolt 30 Nm (3.0 kgf-m, 22.0 lb-ft), 50 Nm (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Page 355 of 1496

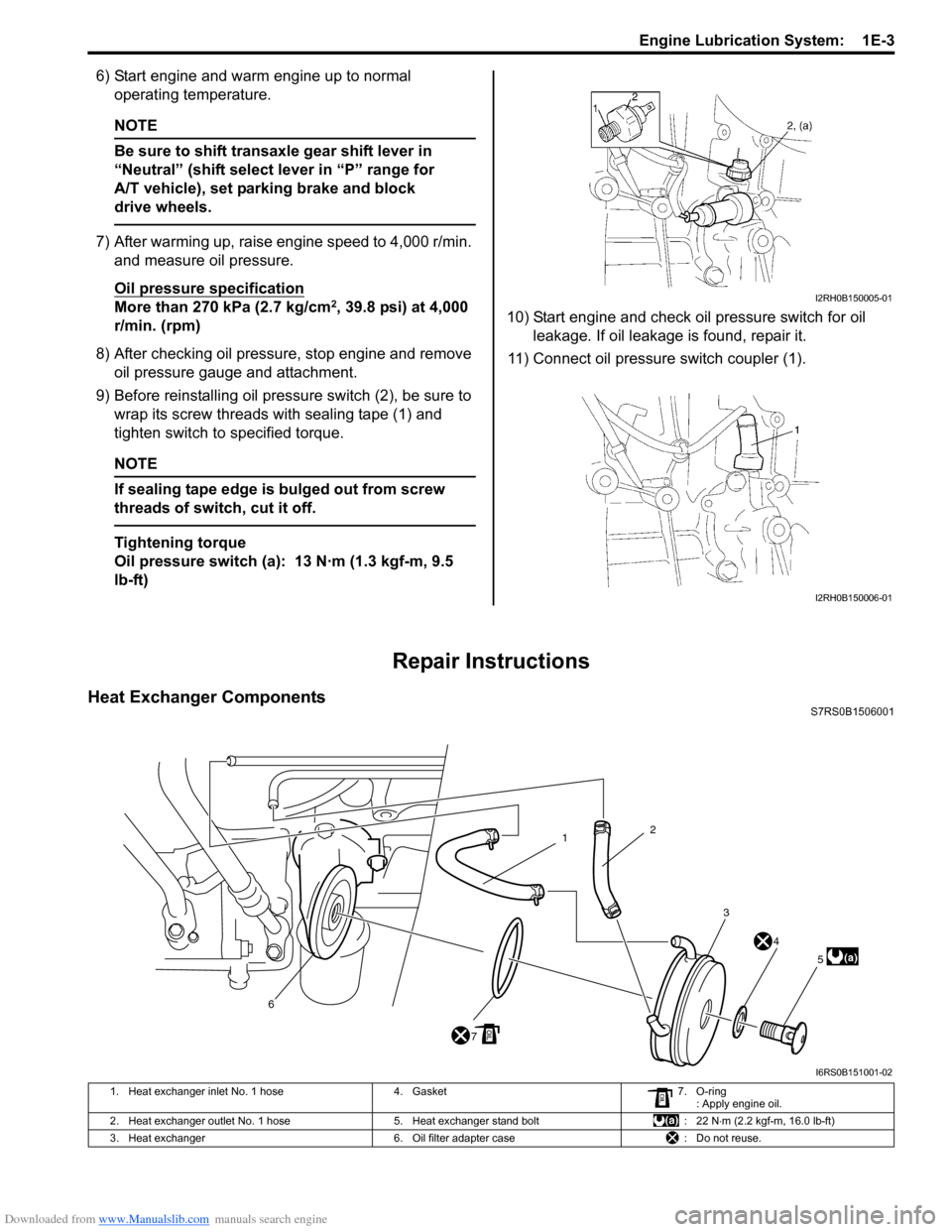

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-3

6) Start engine and warm engine up to normal operating temperature.

NOTE

Be sure to shift transaxle gear shift lever in

“Neutral” (shift select lever in “P” range for

A/T vehicle), set parking brake and block

drive wheels.

7) After warming up, raise engine speed to 4,000 r/min. and measure oil pressure.

Oil pressure specification

More than 270 kPa (2.7 kg/cm2, 39.8 psi) at 4,000

r/min. (rpm)

8) After checking oil pressure, stop engine and remove oil pressure gauge and attachment.

9) Before reinstalling oil pressure switch (2), be sure to

wrap its screw threads with sealing tape (1) and

tighten switch to specified torque.

NOTE

If sealing tape edge is bulged out from screw

threads of switch, cut it off.

Tightening torque

Oil pressure switch (a): 13 N·m (1.3 kgf-m, 9.5

lb-ft) 10) Start engine and check oil pressure switch for oil

leakage. If oil leakage is found, repair it.

11) Connect oil pressure switch coupler (1).

Repair Instructions

Heat Exchanger ComponentsS7RS0B1506001

I2RH0B150005-01

I2RH0B150006-01

3

4

5

7

6

(a)

2

1

I6RS0B151001-02

1. Heat exchanger inlet No. 1 hose 4. Gasket7. O-ring

: Apply engine oil.

2. Heat exchanger outlet No. 1 hose 5. Heat exchanger stand bolt : 22 N⋅m (2.2 kgf-m, 16.0 lb-ft)

3. Heat exchanger 6. Oil filter adapter case : Do not reuse.

Page 429 of 1496

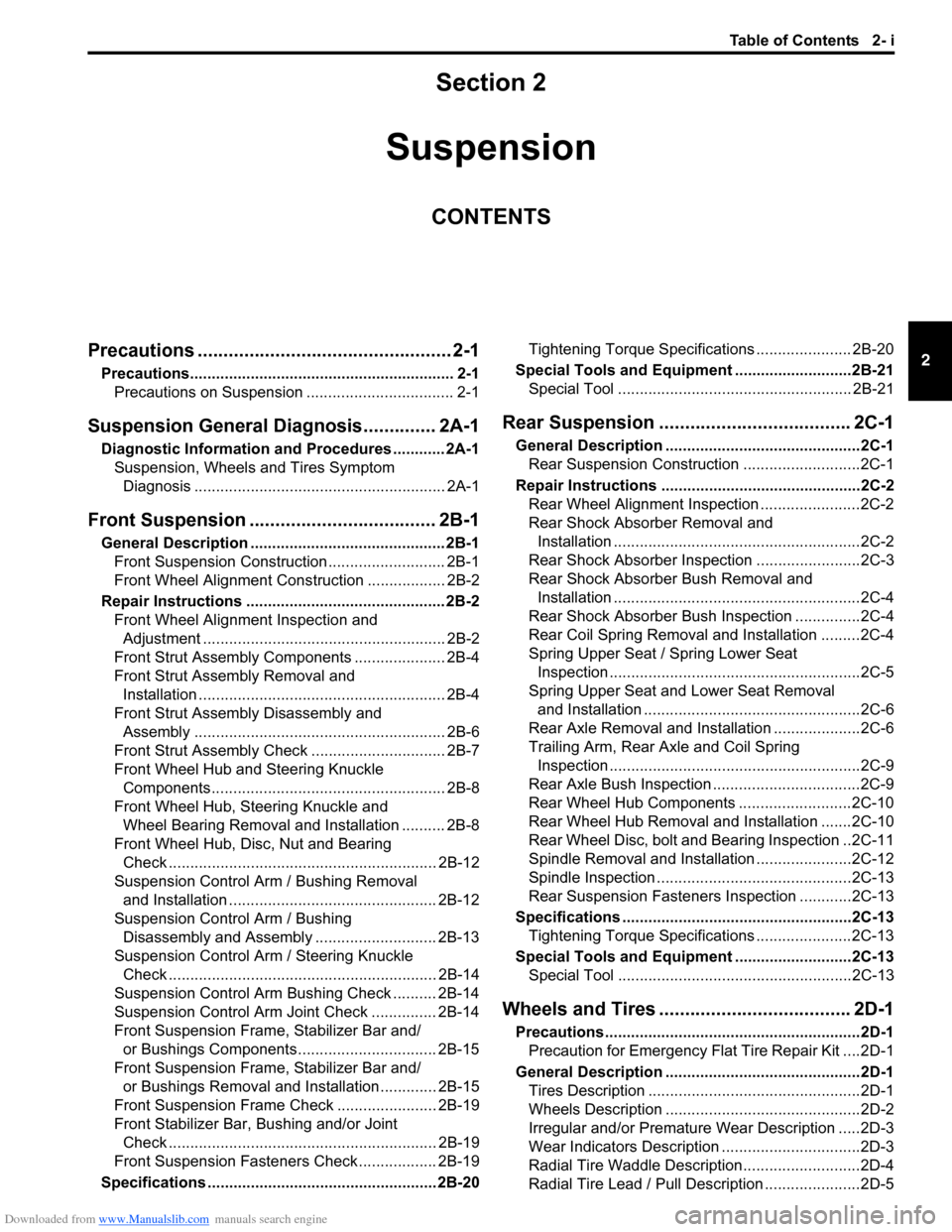

Downloaded from www.Manualslib.com manuals search engine Table of Contents 2- i

2

Section 2

CONTENTS

Suspension

Precautions ................................................. 2-1

Precautions............................................................. 2-1

Precautions on Suspension .................................. 2-1

Suspension General Dia gnosis.............. 2A-1

Diagnostic Information and Procedures ............ 2A-1

Suspension, Wheels and Tires Symptom Diagnosis .......................................................... 2A-1

Front Suspension ........... ......................... 2B-1

General Description ............................................. 2B-1

Front Suspension Construction ........................... 2B-1

Front Wheel Alignment Cons truction .................. 2B-2

Repair Instructions .............................................. 2B-2 Front Wheel Alignment Inspection and Adjustment ........................................................ 2B-2

Front Strut Assembly Comp onents ..................... 2B-4

Front Strut Assembly Removal and Installation ......................................................... 2B-4

Front Strut Assembly Disassembly and Assembly .......................................................... 2B-6

Front Strut Assembly Chec k ............................... 2B-7

Front Wheel Hub and Steering Knuckle Components...................................................... 2B-8

Front Wheel Hub, Steering Knuckle and Wheel Bearing Removal and Installation .......... 2B-8

Front Wheel Hub, Disc, Nut and Bearing Check .............................................................. 2B-12

Suspension Control Arm / Bushing Removal and Installation ................................................ 2B-12

Suspension Control Arm / Bushing Disassembly and Assembly ............................ 2B-13

Suspension Control Arm / Steering Knuckle Check .............................................................. 2B-14

Suspension Control Arm Bushing Check .......... 2B-14

Suspension Control Arm Joint Check ............... 2B-14

Front Suspension Fram e, Stabilizer Bar and/

or Bushings Components................................ 2B-15

Front Suspension Fram e, Stabilizer Bar and/

or Bushings Removal and Installation ............. 2B-15

Front Suspension Frame Ch eck ....................... 2B-19

Front Stabilizer Bar, Bushing and/or Joint Check .............................................................. 2B-19

Front Suspension Fastener s Check .................. 2B-19

Specifications ..................................................... 2B-20 Tightening Torque Specifications ...................... 2B-20

Special Tools and Equipmen t ...........................2B-21

Special Tool ...................................................... 2B-21

Rear Suspension ............ ......................... 2C-1

General Description .............................................2C-1

Rear Suspension Construction ...........................2C-1

Repair Instructions ........... ...................................2C-2

Rear Wheel Alignment Inspection .......................2C-2

Rear Shock Absorber Removal and Installation .........................................................2C-2

Rear Shock Absorber Ins pection ........................2C-3

Rear Shock Absorber Bush Removal and Installation .........................................................2C-4

Rear Shock Absorber Bush Inspection ...............2C-4

Rear Coil Spring Removal and Installation .........2C-4

Spring Upper Seat / Spring Lower Seat Inspection ..........................................................2C-5

Spring Upper Seat and Lower Seat Removal and Installation ..................................................2C-6

Rear Axle Removal and Inst allation ....................2C-6

Trailing Arm, Rear Axle and Coil Spring Inspection ..........................................................2C-9

Rear Axle Bush Inspection ..................................2C-9

Rear Wheel Hub Components ..........................2C-10

Rear Wheel Hub Removal an d Installation .......2C-10

Rear Wheel Disc, bolt and Bearing Inspection ..2C-11

Spindle Removal and Installation ......................2C-12

Spindle Inspection .............................................2C-13

Rear Suspension Fasteners Inspection ............2C-13

Specifications .................... .................................2C-13

Tightening Torque Specifications ......................2C-13

Special Tools and Equipmen t ...........................2C-13

Special Tool ......................................................2C-13

Wheels and Tires ............ ......................... 2D-1

Precautions...........................................................2D-1

Precaution for Emergency Flat Tire Repair Kit ....2D-1

General Description .............................................2D-1 Tires Description .................................................2D-1

Wheels Description .............................................2D-2

Irregular and/or Premature Wear Description .....2D-3

Wear Indicators Description ................................2D-3

Radial Tire Waddle Description...........................2D-4

Radial Tire Lead / Pull Description ......................2D-5

Page 432 of 1496

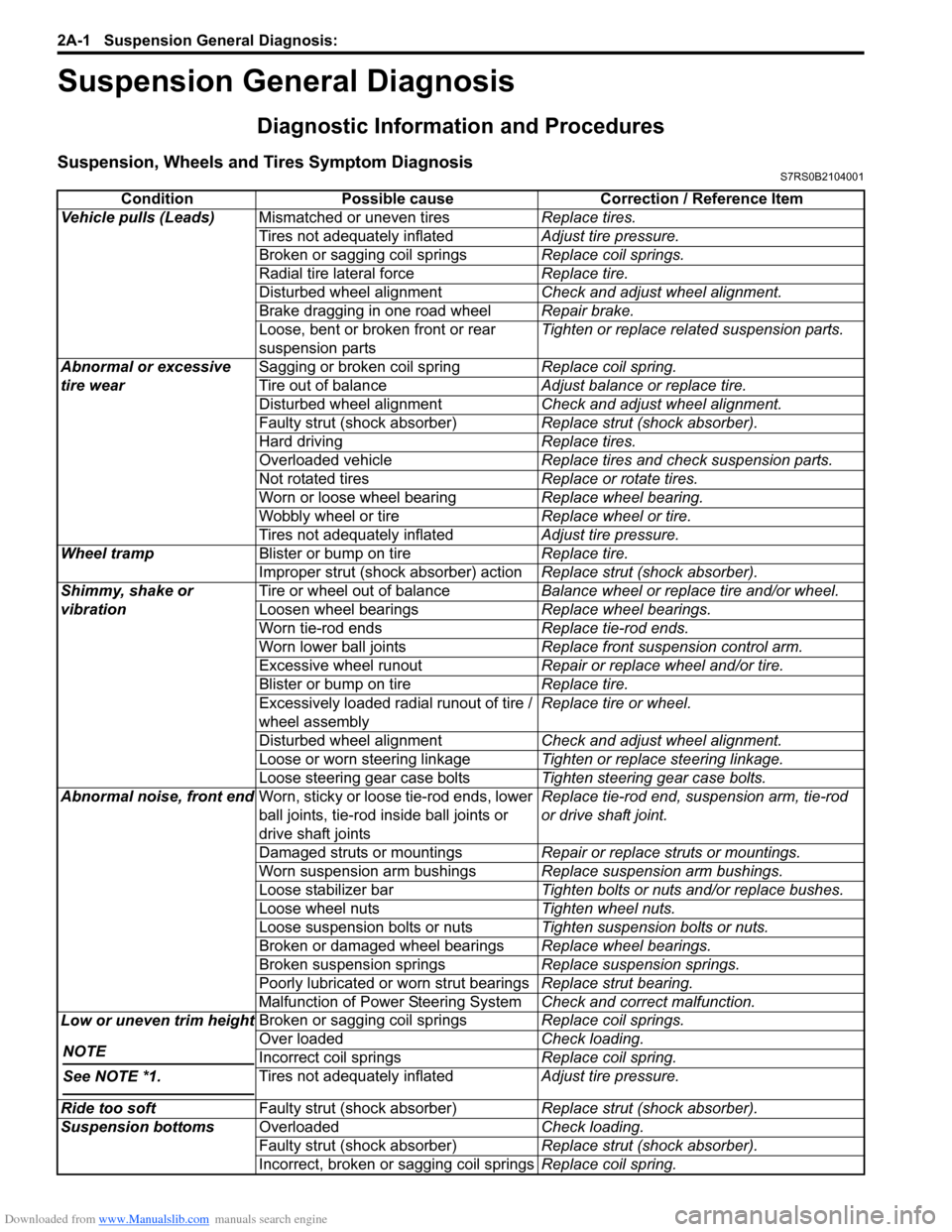

Downloaded from www.Manualslib.com manuals search engine 2A-1 Suspension General Diagnosis:

Suspension

Suspension General Diagnosis

Diagnostic Information and Procedures

Suspension, Wheels and Tires Symptom DiagnosisS7RS0B2104001

ConditionPossible cause Correction / Reference Item

Vehicle pulls (Leads) Mismatched or uneven tires Replace tires.

Tires not adequately inflated Adjust tire pressure.

Broken or sagging coil springs Replace coil springs.

Radial tire lateral force Replace tire.

Disturbed wheel alignment Check and adjust wheel alignment.

Brake dragging in one road wheel Repair brake.

Loose, bent or broken front or rear

suspension parts Tighten or replace related suspension parts.

Abnormal or excessive

tire wear Sagging or broken coil spring

Replace coil spring.

Tire out of balance Adjust balance or replace tire.

Disturbed wheel alignment Check and adjust wheel alignment.

Faulty strut (shock absorber) Replace strut (shock absorber).

Hard driving Replace tires.

Overloaded vehicle Replace tires and check suspension parts.

Not rotated tires Replace or rotate tires.

Worn or loose wheel bearing Replace wheel bearing.

Wobbly wheel or tire Replace wheel or tire.

Tires not adequately inflated Adjust tire pressure.

Wheel tramp Blister or bump on tire Replace tire.

Improper strut (shock absorber) action Replace strut (shock absorber).

Shimmy, shake or

vibration Tire or wheel out of balance

Balance wheel or replace tire and/or wheel.

Loosen wheel bearings Replace wheel bearings.

Worn tie-rod ends Replace tie-rod ends.

Worn lower ball joints Replace front suspension control arm.

Excessive wheel runout Repair or replace wheel and/or tire.

Blister or bump on tire Replace tire.

Excessively loaded radial runout of tire /

wheel assembly Replace tire or wheel.

Disturbed wheel alignment Check and adjust wheel alignment.

Loose or worn steering linkage Tighten or replace steering linkage.

Loose steering gear case bolts Tighten steering gear case bolts.

Abnormal noise, front end Worn, sticky or loose tie-rod ends, lower

ball joints, tie-rod in side ball joints or

drive shaft joints Replace tie-rod end, su

spension arm, tie-rod

or drive shaft joint.

Damaged struts or mountings Repair or replace struts or mountings.

Worn suspension arm bushings Replace suspension arm bushings.

Loose stabilizer bar Tighten bolts or nuts and/or replace bushes.

Loose wheel nuts Tighten wheel nuts.

Loose suspension bolts or nuts Tighten suspension bolts or nuts.

Broken or damaged wheel bearings Replace wheel bearings.

Broken suspension springs Replace suspension springs.

Poorly lubricated or worn strut bearings Replace strut bearing.

Malfunction of Power Steering System Check and correct malfunction.

Low or uneven trim height

NOTE

See NOTE *1.

Broken or sagging coil springs Replace coil springs.

Over loaded Check loading.

Incorrect coil springs Replace coil spring.

Tires not adequately inflated Adjust tire pressure.

Ride too soft Faulty strut (shock absorber) Replace strut (shock absorber).

Suspension bottoms Overloaded Check loading.

Faulty strut (shock absorber) Replace strut (shock absorber).

Incorrect, broken or sagging coil springs Replace coil spring.

Page 433 of 1496

Downloaded from www.Manualslib.com manuals search engine Suspension General Diagnosis: 2A-2

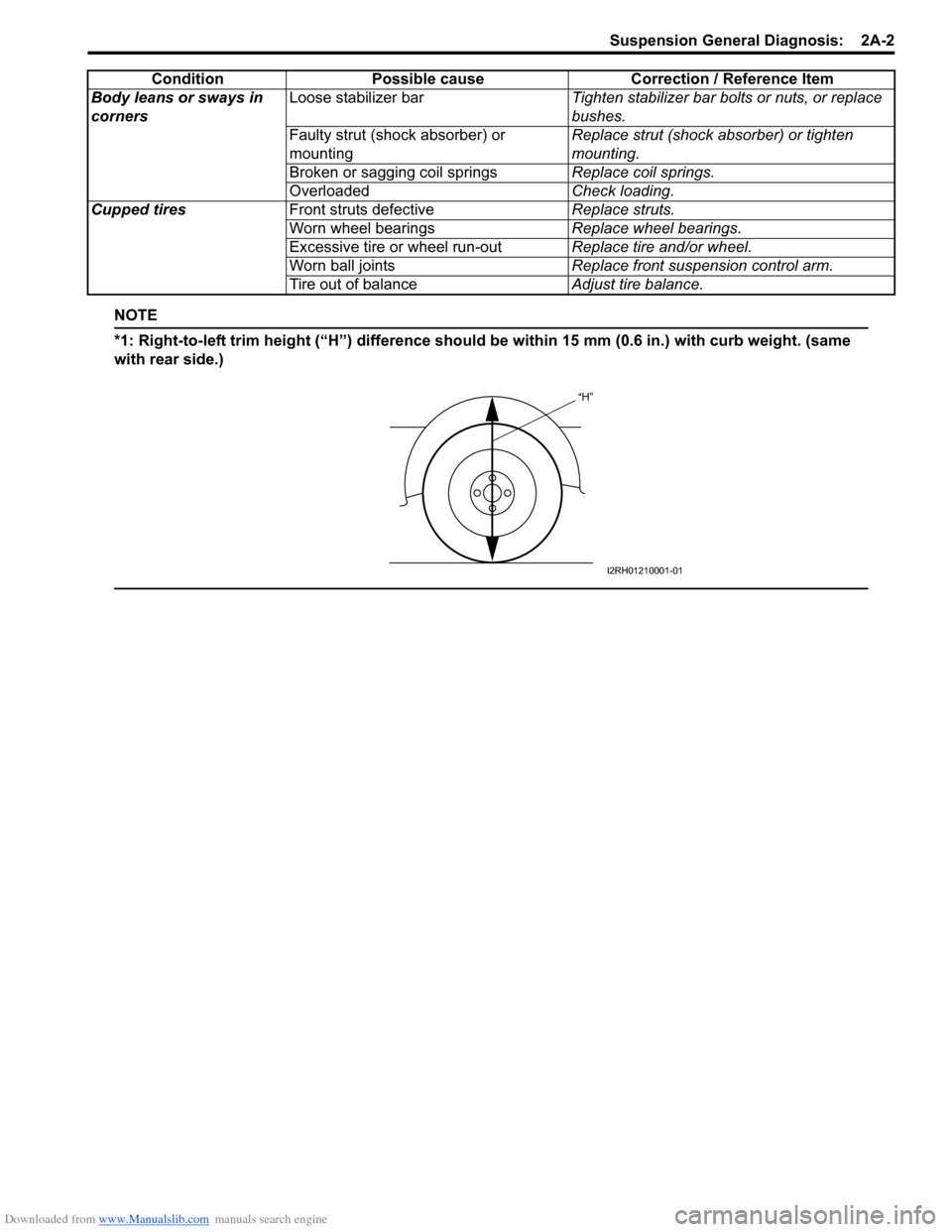

NOTE

*1: Right-to-left trim height (“H”) difference should be within 15 mm (0.6 in.) with curb weight. (same

with rear side.)

Body leans or sways in

corners Loose stabilizer bar

Tighten stabilizer bar bolts or nuts, or replace

bushes.

Faulty strut (shock absorber) or

mounting Replace strut (shock absorber) or tighten

mounting.

Broken or sagging coil springs Replace coil springs.

Overloaded Check loading.

Cupped tires Front struts defective Replace struts.

Worn wheel bearings Replace wheel bearings.

Excessive tire or wheel run-out Replace tire and/or wheel.

Worn ball joints Replace front suspension control arm.

Tire out of balance Adjust tire balance.

Condition Possible cause Correction / Reference Item

“H”

I2RH01210001-01

Page 437 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-4

Reference Information

Side slip

When checked with side slip tester, side slip should

satisfy following specification.Side slip

0 to IN 3.0 mm/m (0 to IN 0.118 in/3.3 ft)

If side slip is greatly di

fferent, toe or front wheel

alignment may not be correct.

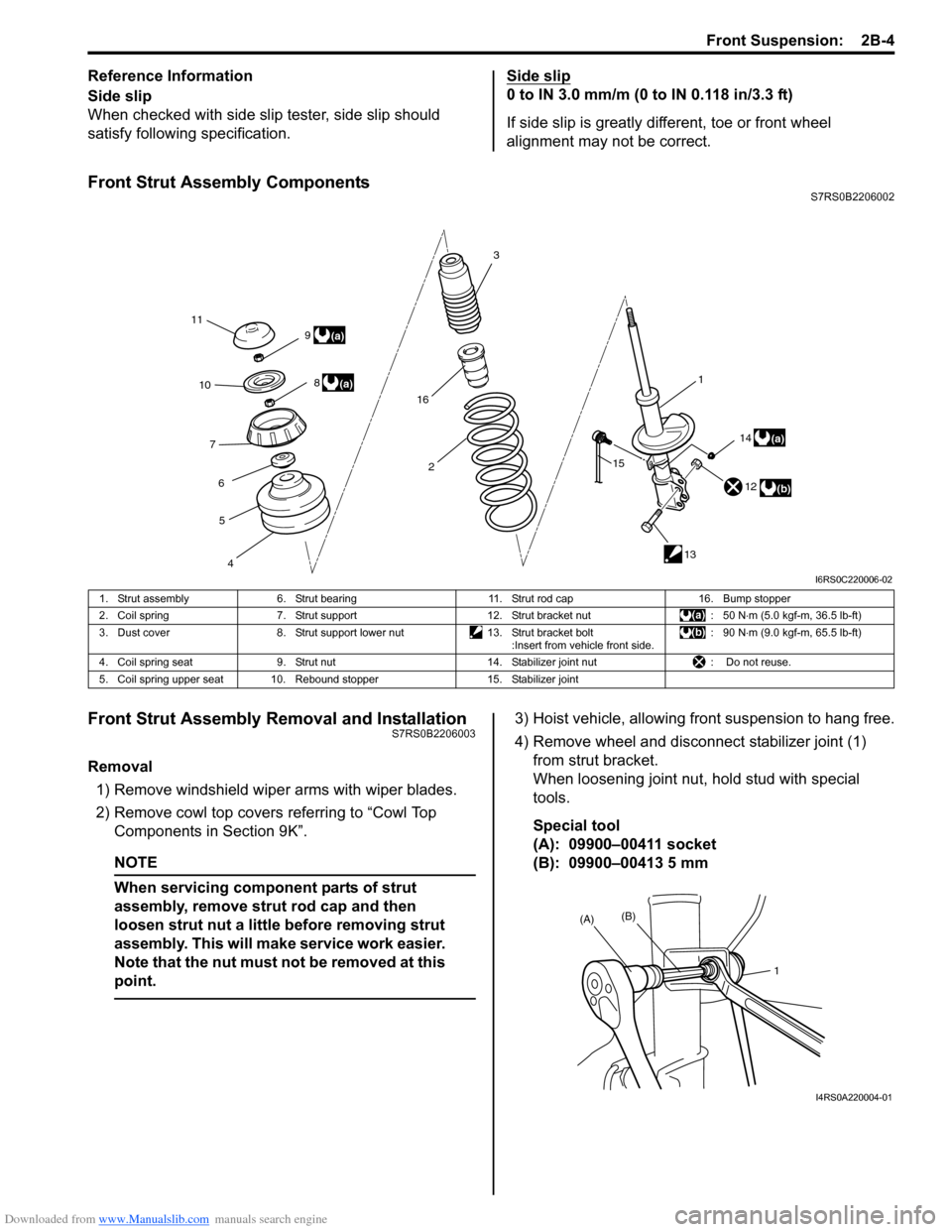

Front Strut Assembly ComponentsS7RS0B2206002

Front Strut Assembly Removal and InstallationS7RS0B2206003

Removal

1) Remove windshield wipe r arms with wiper blades.

2) Remove cowl top covers referring to “Cowl Top

Components in Section 9K”.

NOTE

When servicing component parts of strut

assembly, remove stru t rod cap and then

loosen strut nut a little before removing strut

assembly. This will make service work easier.

Note that the nut must not be removed at this

point.

3) Hoist vehicle, allowing front suspension to hang free.

4) Remove wheel and disconn ect stabilizer joint (1)

from strut bracket.

When loosening joint nu t, hold stud with special

tools.

Special tool

(A): 09900–00411 socket

(B): 09900–00413 5 mm

11 3

2 1

12

13

4

5

6

7

10

8(a)

(b)

9

(a)

14

15(a)

16

I6RS0C220006-02

1. Strut assembly

6. Strut bearing 11. Strut rod cap16. Bump stopper

2. Coil spring 7. Strut support 12. Strut bracket nut : 50 N⋅m (5.0 kgf-m, 36.5 lb-ft)

3. Dust cover 8. Strut support lower nut 13. Strut bracket bolt

:Insert from vehicle front side. : 90 N

⋅m (9.0 kgf-m, 65.5 lb-ft)

4. Coil spring seat 9. Strut nut 14. Stabilizer joint nut : Do not reuse.

5. Coil spring upper seat 10. Rebound stopper 15. Stabilizer joint

1

(A)

(B)

I4RS0A220004-01

Page 438 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-5 Front Suspension:

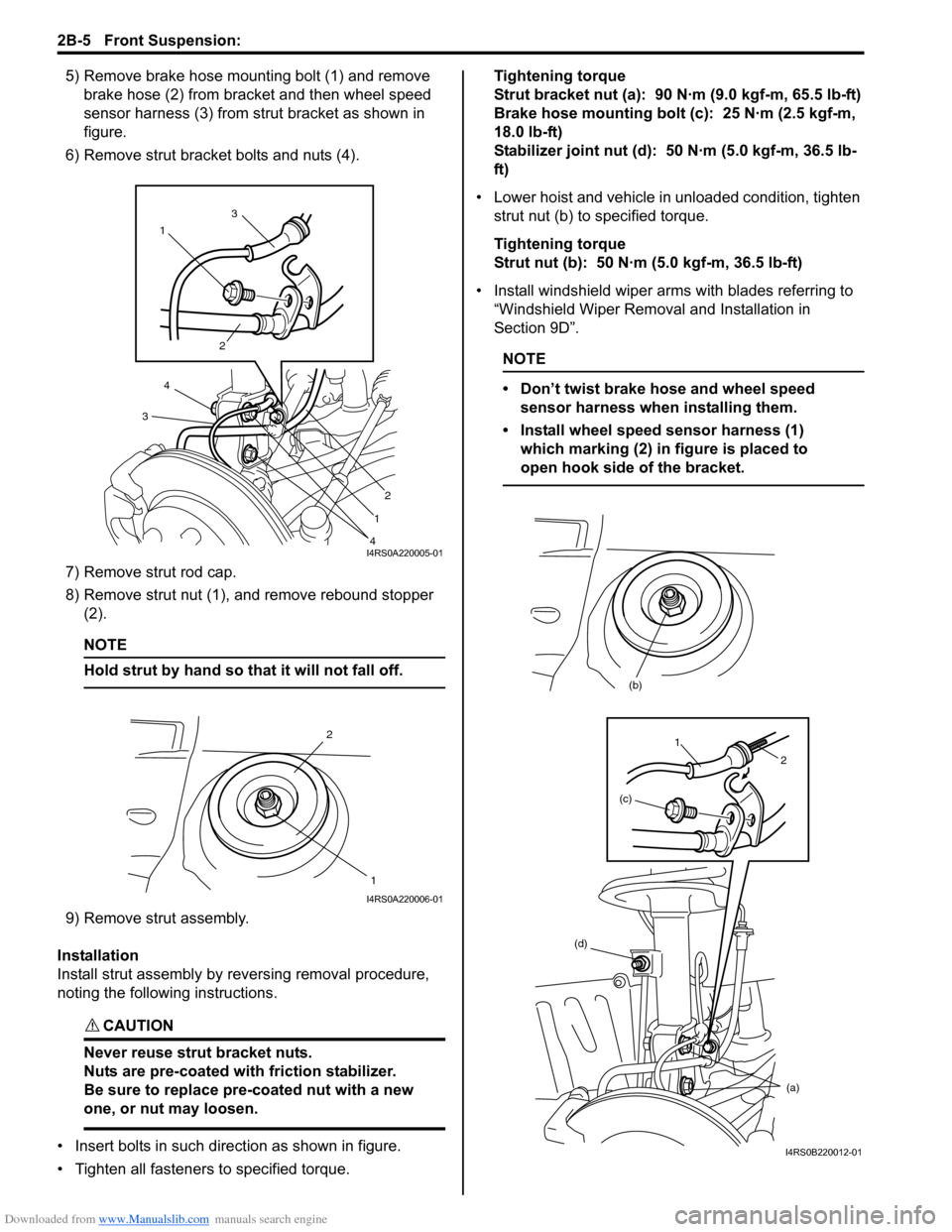

5) Remove brake hose mounting bolt (1) and remove brake hose (2) from bracket and then wheel speed

sensor harness (3) from strut bracket as shown in

figure.

6) Remove strut bracket bolts and nuts (4).

7) Remove strut rod cap.

8) Remove strut nut (1), and remove rebound stopper (2).

NOTE

Hold strut by hand so th at it will not fall off.

9) Remove strut assembly.

Installation

Install strut assembly by reversing removal procedure,

noting the following instructions.

CAUTION!

Never reuse strut bracket nuts.

Nuts are pre-coated with friction stabilizer.

Be sure to replace pre-coated nut with a new

one, or nut may loosen.

• Insert bolts in such direction as shown in figure.

• Tighten all fasteners to specified torque. Tightening torque

Strut bracket nut (a): 90 N·m (9.0 kgf-m, 65.5 lb-ft)

Brake hose mounting bolt (c): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

Stabilizer joint nut (d): 50 N·m (5.0 kgf-m, 36.5 lb-

ft)

• Lower hoist and vehicle in unloaded condition, tighten strut nut (b) to specified torque.

Tightening torque

Strut nut (b): 50 N·m (5.0 kgf-m, 36.5 lb-ft)

• Install windshield wiper arms with blades referring to

“Windshield Wiper Removal and Installation in

Section 9D”.

NOTE

• Don’t twist brake hose and wheel speed sensor harness when installing them.

• Install wheel speed sensor harness (1) which marking (2) in figure is placed to

open hook side of the bracket.

1 3

2

2

1

4

4

3

I4RS0A220005-01

2

1

I4RS0A220006-01

(d) (a)

(b)

(c)

1

2

I4RS0B220012-01

Page 439 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-6

• Tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

• After installation, confirm front wheel alignment.

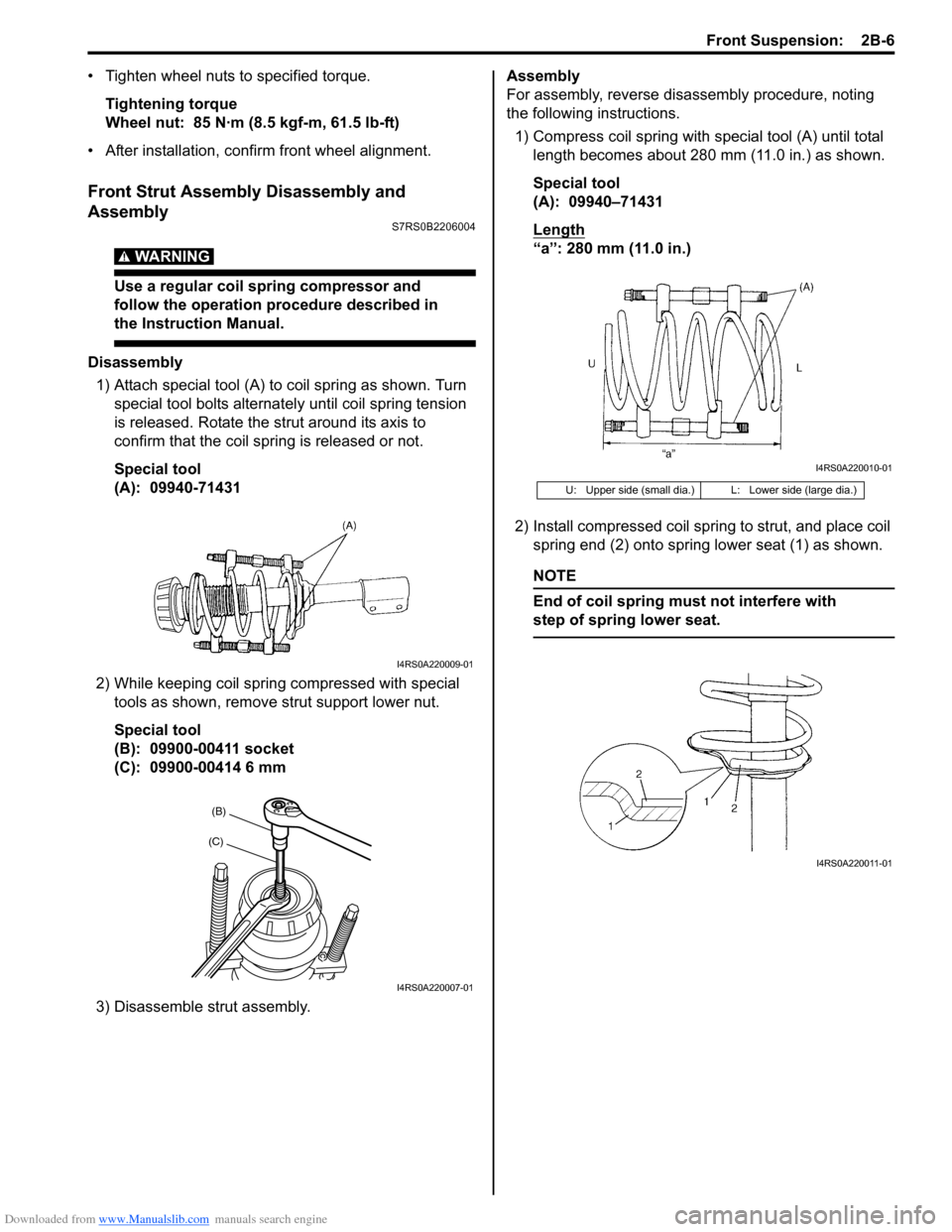

Front Strut Assembly Disassembly and

Assembly

S7RS0B2206004

WARNING!

Use a regular coil spring compressor and

follow the operation procedure described in

the Instruction Manual.

Disassembly 1) Attach special tool (A) to coil spring as shown. Turn special tool bolts alternat ely until coil spring tension

is released. Rotate the strut around its axis to

confirm that the coil spring is released or not.

Special tool

(A): 09940-71431

2) While keeping coil spring compressed with special

tools as shown, remove strut support lower nut.

Special tool

(B): 09900-00411 socket

(C): 09900-00414 6 mm

3) Disassemble strut assembly. Assembly

For assembly, reverse disassembly procedure, noting

the following instructions.

1) Compress coil spring with special tool (A) until total

length becomes about 280 mm (11.0 in.) as shown.

Special tool

(A): 09940–71431

Length

“a”: 280 mm (11.0 in.)

2) Install compressed coil spring to strut, and place coil

spring end (2) onto spring lower seat (1) as shown.

NOTE

End of coil spring must not interfere with

step of spring lower seat.

I4RS0A220009-01

(B)

(C)

I4RS0A220007-01

U: Upper side (small dia.) L: Lower side (large dia.)

I4RS0A220010-01

I4RS0A220011-01

Page 441 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-8

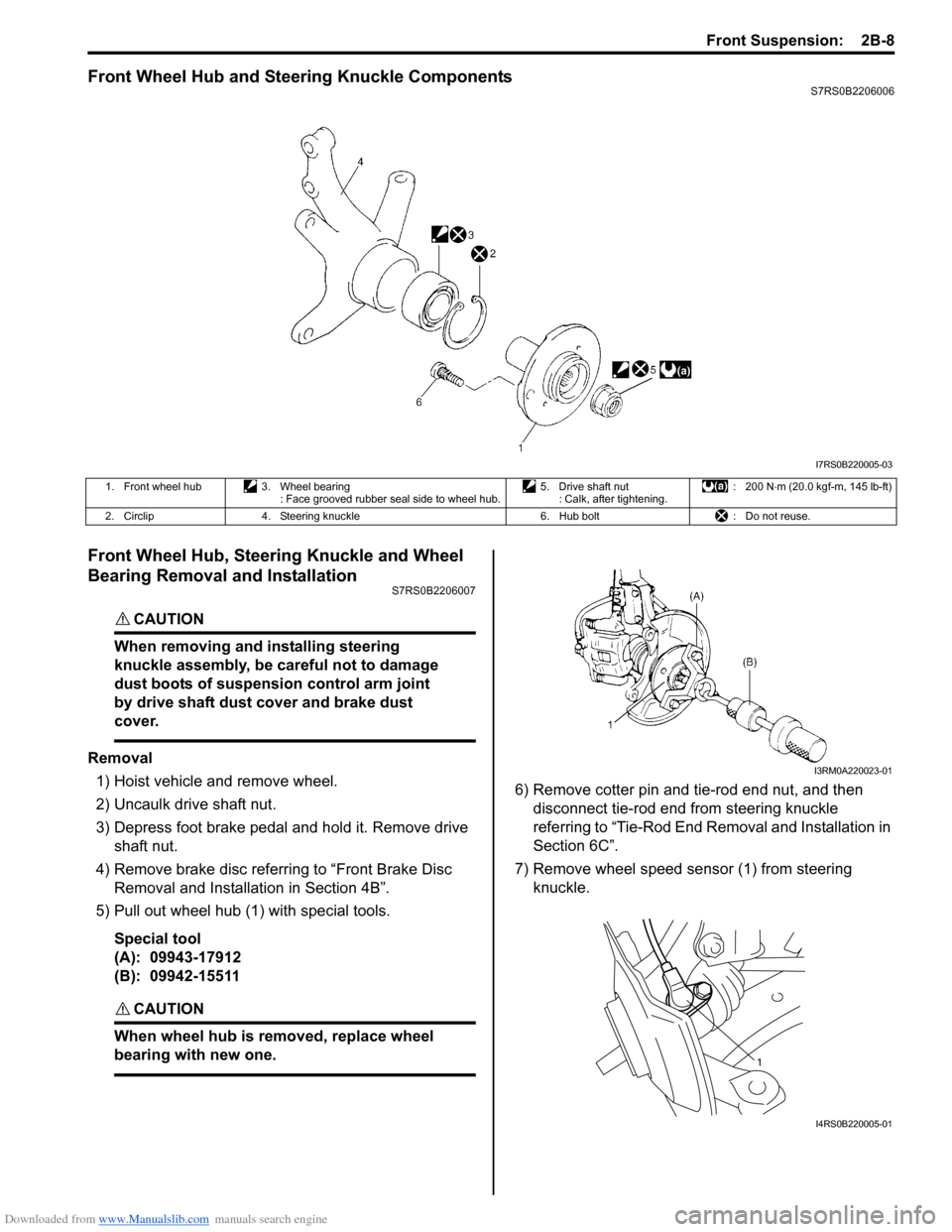

Front Wheel Hub and Steering Knuckle ComponentsS7RS0B2206006

Front Wheel Hub, Steering Knuckle and Wheel

Bearing Removal and Installation

S7RS0B2206007

CAUTION!

When removing and installing steering

knuckle assembly, be careful not to damage

dust boots of suspension control arm joint

by drive shaft dust cover and brake dust

cover.

Removal1) Hoist vehicle and remove wheel.

2) Uncaulk drive shaft nut.

3) Depress foot brake pedal and hold it. Remove drive shaft nut.

4) Remove brake disc referring to “Front Brake Disc Removal and Installa tion in Section 4B”.

5) Pull out wheel hub (1) with special tools.

Special tool

(A): 09943-17912

(B): 09942-15511

CAUTION!

When wheel hub is removed, replace wheel

bearing with new one.

6) Remove cotter pin and tie-rod end nut, and then disconnect tie-rod end from steering knuckle

referring to “Tie-Rod End Removal and Installation in

Section 6C”.

7) Remove wheel speed sensor (1) from steering knuckle.

I7RS0B220005-03

1. Front wheel hub 3. Wheel bearing

: Face grooved rubber seal side to wheel hub. 5. Drive shaft nut

: Calk, after tightening. : 200 N

⋅m (20.0 kgf-m, 145 lb-ft)

2. Circlip 4. Steering knuckle 6. Hub bolt: Do not reuse.

I3RM0A220023-01

1

I4RS0B220005-01

Page 442 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-9 Front Suspension:

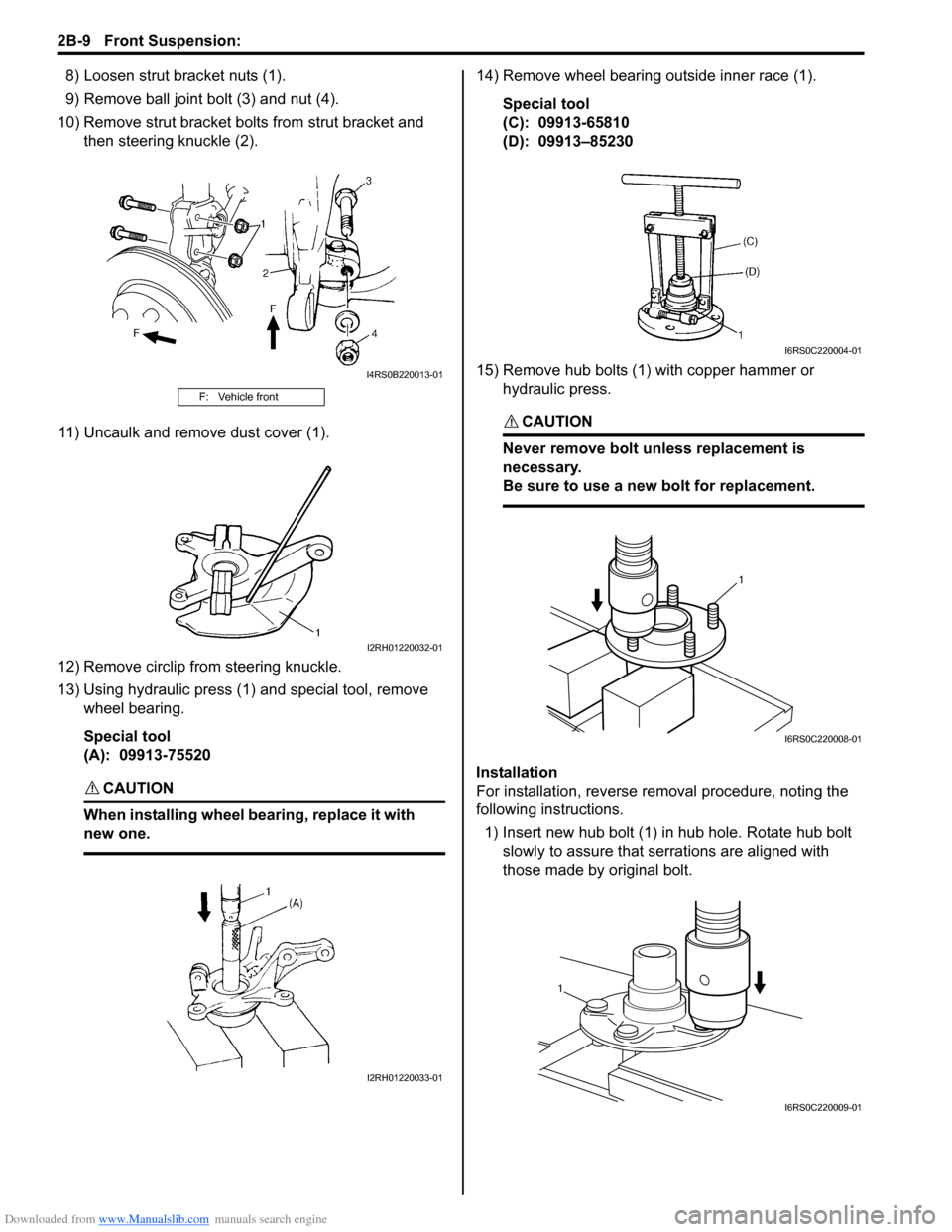

8) Loosen strut bracket nuts (1).

9) Remove ball joint bolt (3) and nut (4).

10) Remove strut bracket bolt s from strut bracket and

then steering knuckle (2).

11) Uncaulk and remove dust cover (1).

12) Remove circlip from steering knuckle.

13) Using hydraulic press (1) and special tool, remove wheel bearing.

Special tool

(A): 09913-75520

CAUTION!

When installing wheel bearing, replace it with

new one.

14) Remove wheel bearing outside inner race (1).

Special tool

(C): 09913-65810

(D): 09913–85230

15) Remove hub bolts (1) with copper hammer or hydraulic press.

CAUTION!

Never remove bolt unle ss replacement is

necessary.

Be sure to use a new bolt for replacement.

Installation

For installation, reverse removal procedure, noting the

following instructions.

1) Insert new hub bolt (1) in hub hole. Rotate hub bolt slowly to assure that serrations are aligned with

those made by original bolt.

F: Vehicle front

I4RS0B220013-01

I2RH01220032-01

I2RH01220033-01

I6RS0C220004-01

1

I6RS0C220008-01

1

I6RS0C220009-01