battery type SUZUKI SWIFT 2008 2.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1027 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-79

Compressor Drive Belt Removal and

Installation

S7RS0B7226032

Refer to “Compressor Drive Belt Removal and

Installation”.

Compressor Assembly Removal and

Installation

S7RS0B7226033

Refer to “Compressor Assembly Removal and

Installation”.

Compressor Assembly ComponentsS7RS0B7226034

Refer to “Compressor Assembly Components”.

Magnet Clutch Removal and InstallationS7RS0B7226035

Refer to “Magnet Clutch Removal and Installation”.

Magnet Clutch InspectionS7RS0B7226036

Refer to “Magnet Clutch Inspection”.

Relief Valve InspectionS7RS0B7226039

Refer to “Relief Valve Inspection”.

Special Tools and Equipment

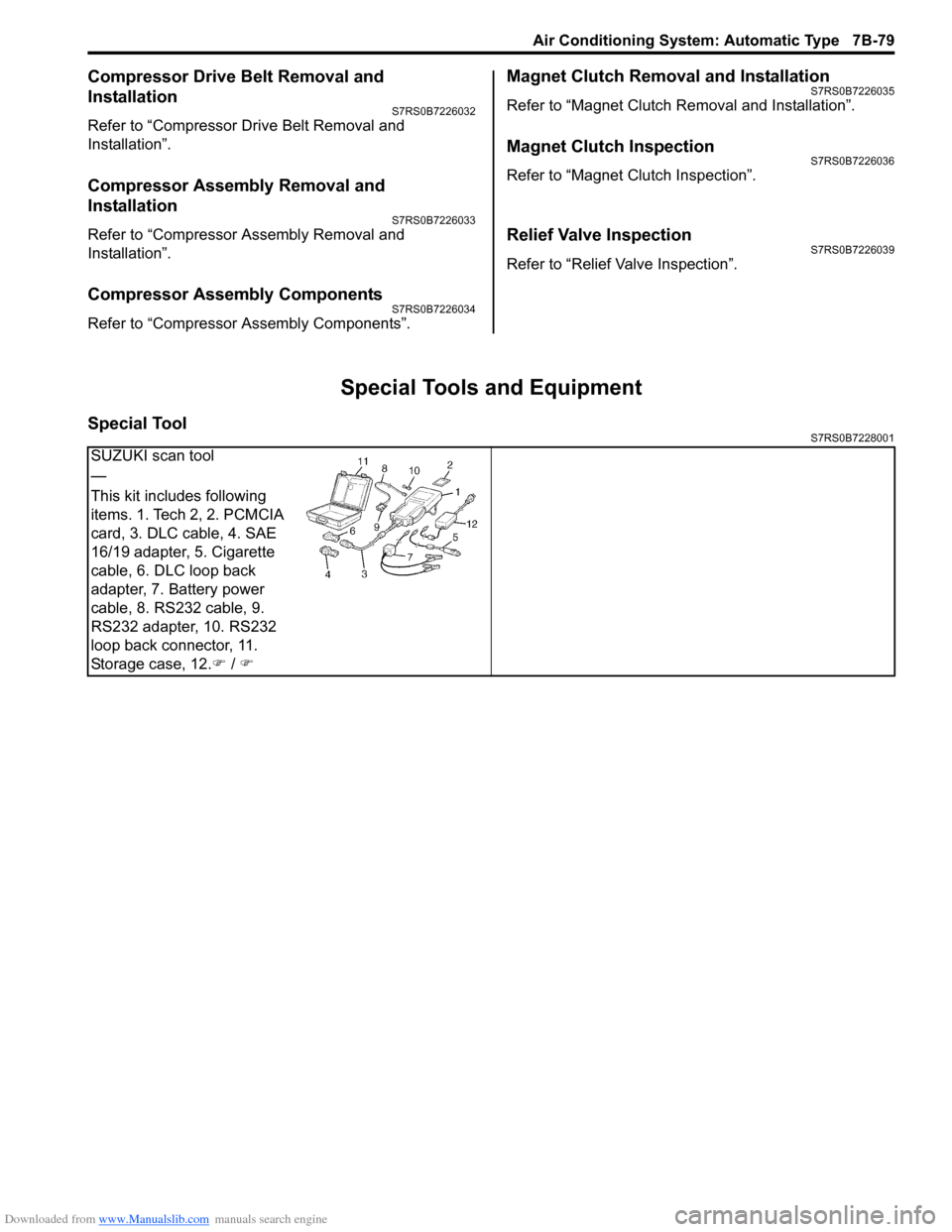

Special ToolS7RS0B7228001

SUZUKI scan tool

—

This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12.�) / �)

Page 1048 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-10 Air Bag System:

Diagnostic Information and Procedures

Air Bag Diagnostic System CheckS7RS0B8204001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified in this manual. Do not use a non-

powered probe type tester.

Instructions in this manual must be followed

carefully, otherwise personal injury may

result.

CAUTION!

The order in which DTCs are diagnosed is

very important. Failure to diagnose the DTCs

in the order specified may result in extended

diagnostic time, incorrect diagnosis and

incorrect parts replacement.

The diagnostic procedures used are designed to find

and repair air bag system malfunctions.

To get the best results, it is important to use the

diagnostic flow and follow the sequence in the following.1) Perform the “Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” must

be the starting point of any air bag system diagnosis.

The “Air Bag Diagnostic System Check Flow” checks

for proper “AIR BAG” warning right operation

through “AIR BAG” warning right and whether air

bag DTCs exist.)

2) Refer to the proper diagnost ic flow as directed by the

“Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” will

lead you to the correct flow to diagnose any air bag

system malfunctions. Bypassing these procedures

may result in extended diagnostic time, incorrect

diagnosis and incorrect parts replacement.)

3) Repeat the “Air Bag Diagnostic System Check Flow” after any repair or diagnostic procedures have been

performed.

(Performing the “Air Bag Diagnostic System Check

Flow” after all repair or diagnostic procedures will

ensure that the repair has been made correctly and

that no other malfunctions exist.)

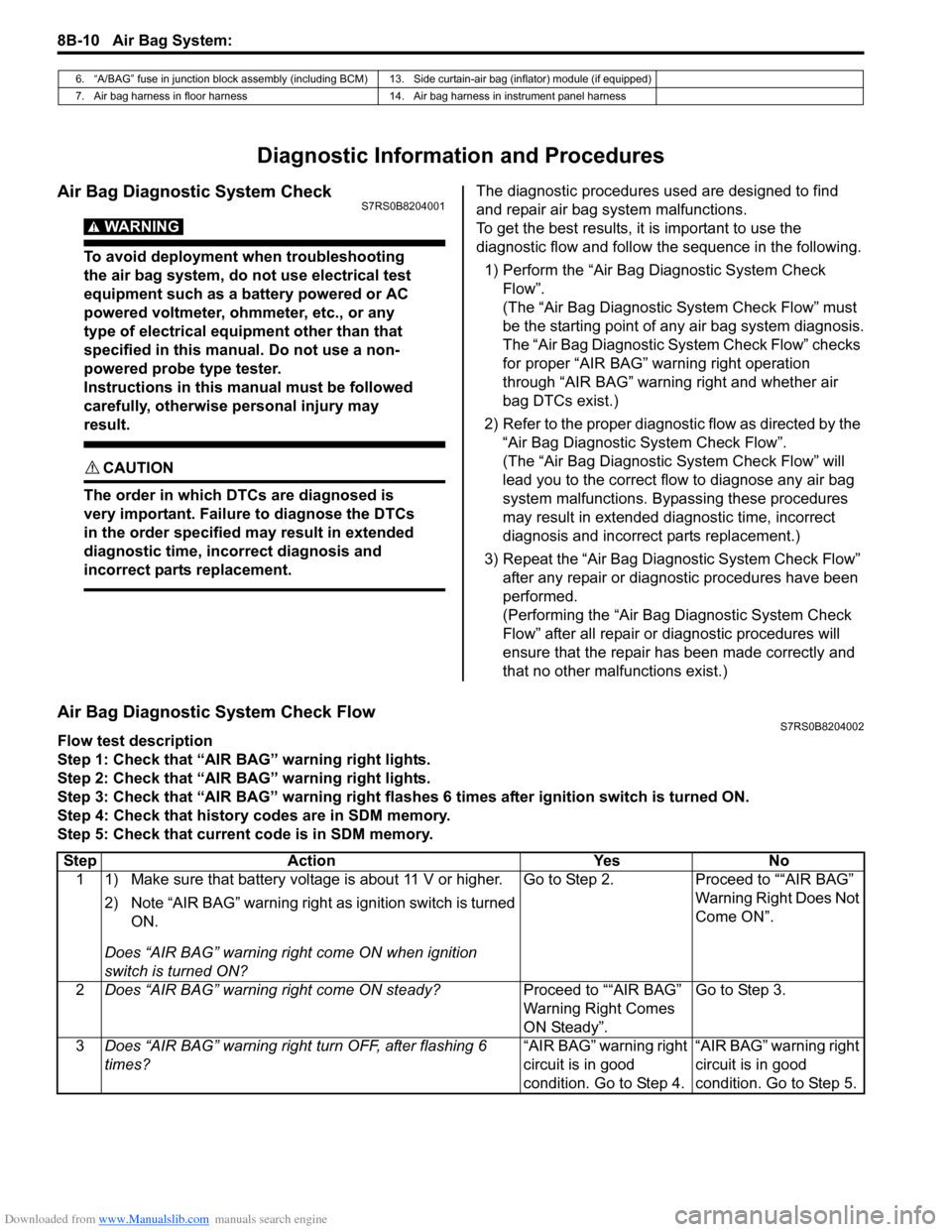

Air Bag Diagnostic System Check FlowS7RS0B8204002

Flow test description

Step 1: Check that “AIR BAG” warning right lights.

Step 2: Check that “AIR BAG” warning right lights.

Step 3: Check that “AIR BAG” warning right flas hes 6 times after ignition switch is turned ON.

Step 4: Check that history codes are in SDM memory.

Step 5: Check that current code is in SDM memory.

6. “A/BAG” fuse in junction block assembly (including BCM) 13. Side curtain-air bag (inflator) module (if equipped)

7. Air bag harness in floor harness 14. Air bag harness in instrument panel harness

Step Action YesNo

1 1) Make sure that battery voltage is about 11 V or higher.

2) Note “AIR BAG” warning right as ignition switch is turned

ON.

Does “AIR BAG” warning ri ght come ON when ignition

switch is turned ON? Go to Step 2.

Proceed to ““AIR BAG”

Warning Right Does Not

Come ON”.

2 Does “AIR BAG” warning right come ON steady? Proceed to ““AIR BAG”

Warning Right Comes

ON Steady”.Go to Step 3.

3 Does “AIR BAG” warning right turn OFF, after flashing 6

times? “AIR BAG” warning right

circuit is in good

condition. Go to Step 4.“AIR BAG” warning right

circuit is in good

condition. Go to Step 5.

Page 1139 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-101

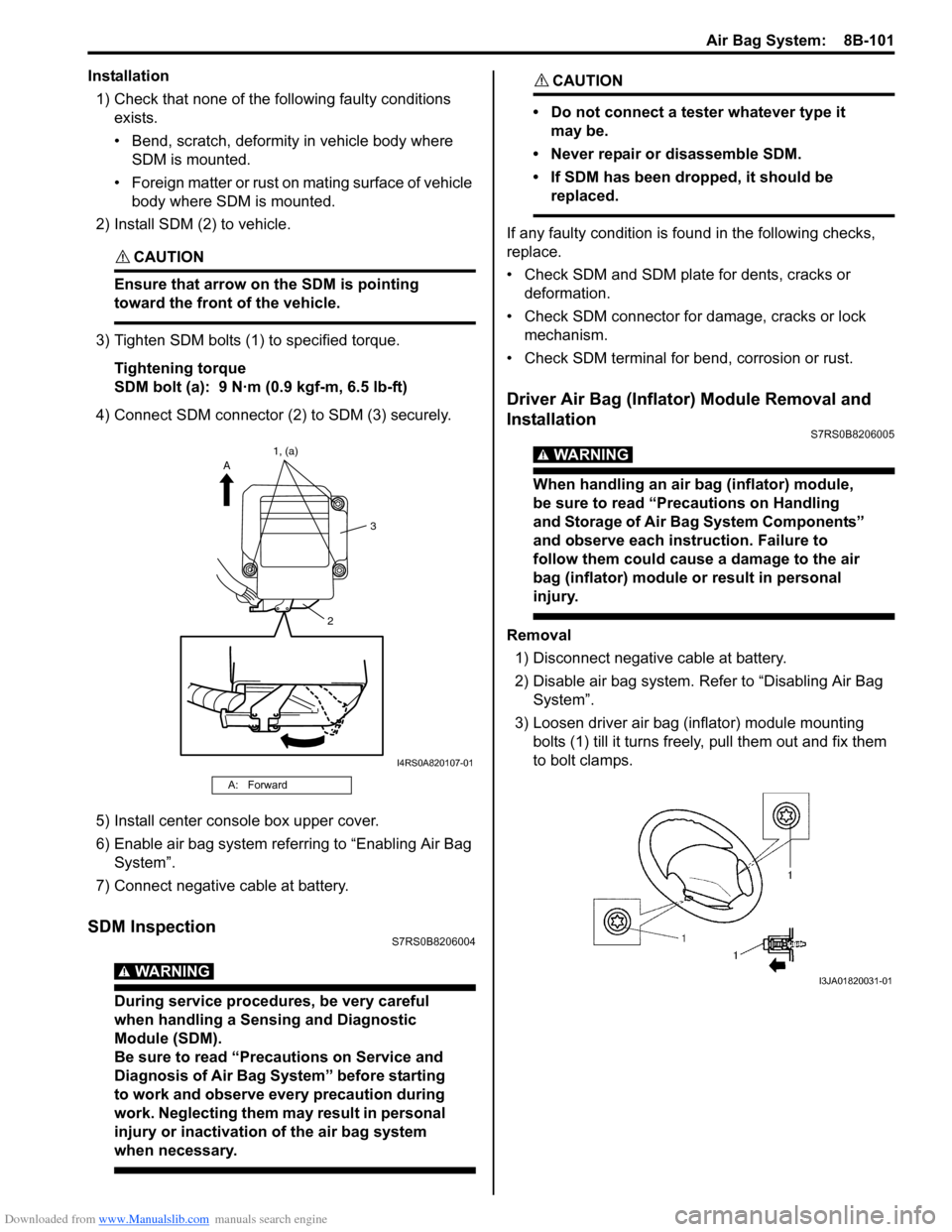

Installation1) Check that none of the following faulty conditions exists.

• Bend, scratch, deformity in vehicle body where SDM is mounted.

• Foreign matter or rust on mating surface of vehicle body where SDM is mounted.

2) Install SDM (2) to vehicle.

CAUTION!

Ensure that arrow on the SDM is pointing

toward the front of the vehicle.

3) Tighten SDM bolts (1) to specified torque.

Tightening torque

SDM bolt (a): 9 N·m (0.9 kgf-m, 6.5 lb-ft)

4) Connect SDM connector (2) to SDM (3) securely.

5) Install center console box upper cover.

6) Enable air bag system referring to “Enabling Air Bag System”.

7) Connect negative cable at battery.

SDM InspectionS7RS0B8206004

WARNING!

During service procedures, be very careful

when handling a Sensing and Diagnostic

Module (SDM).

Be sure to read “Precautions on Service and

Diagnosis of Air Bag System” before starting

to work and observe every precaution during

work. Neglecting them ma y result in personal

injury or inactivation of the air bag system

when necessary.

CAUTION!

• Do not connect a tester whatever type it may be.

• Never repair or disassemble SDM.

• If SDM has been dropped, it should be replaced.

If any faulty condition is fo und in the following checks,

replace.

• Check SDM and SDM plate for dents, cracks or deformation.

• Check SDM connector for damage, cracks or lock mechanism.

• Check SDM terminal for bend, corrosion or rust.

Driver Air Bag (Inflator) Module Removal and

Installation

S7RS0B8206005

WARNING!

When handling an air bag (inflator) module,

be sure to read “Precautions on Handling

and Storage of Air Bag System Components”

and observe each instruction. Failure to

follow them could cause a damage to the air

bag (inflator) module or result in personal

injury.

Removal 1) Disconnect negative cable at battery.

2) Disable air bag system. Re fer to “Disabling Air Bag

System”.

3) Loosen driver air bag (inflator) module mounting bolts (1) till it turns freely, pull them out and fix them

to bolt clamps.

A: Forward

2 3

A

1, (a)

I4RS0A820107-01

I3JA01820031-01

Page 1163 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-125

Specifications

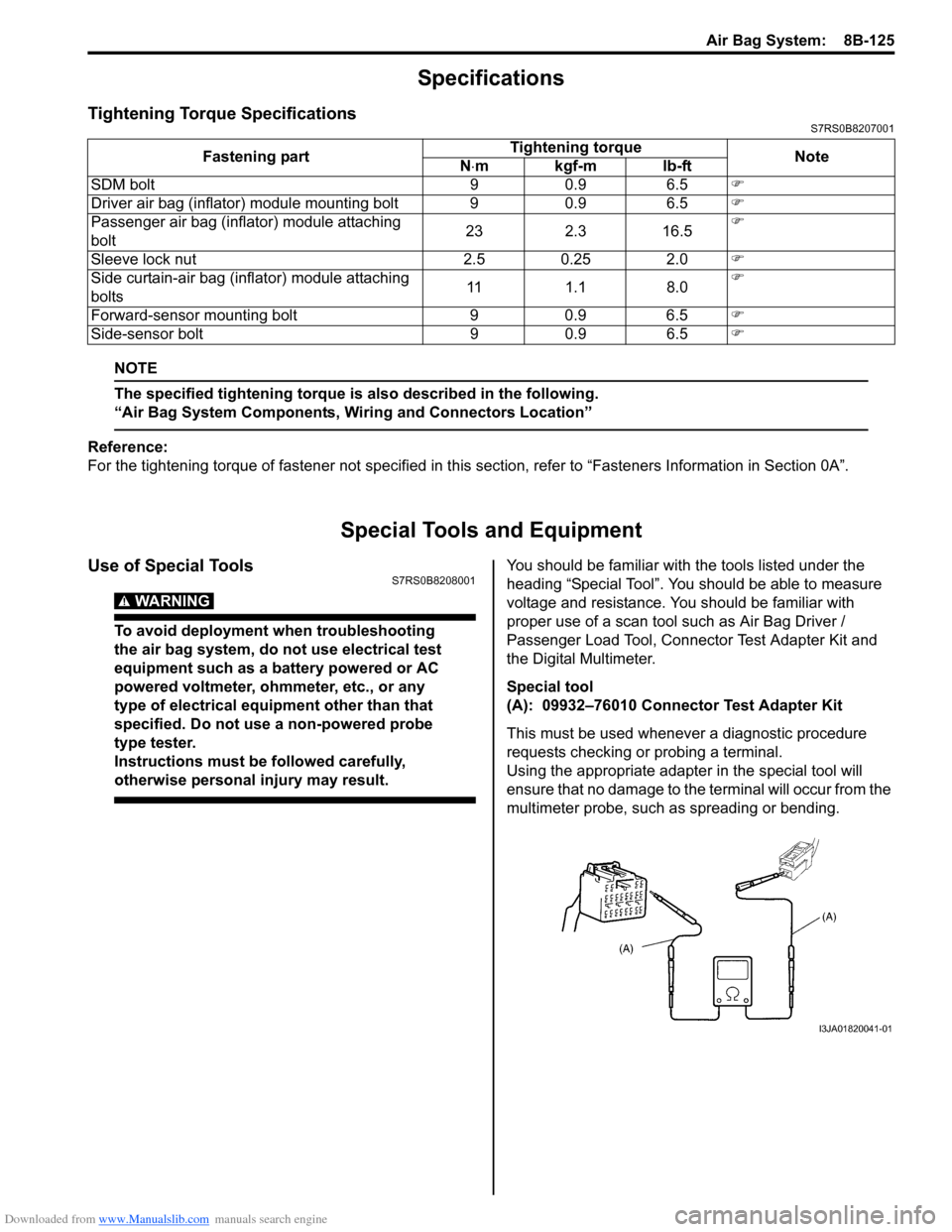

Tightening Torque SpecificationsS7RS0B8207001

NOTE

The specified tightening torque is also described in the following.

“Air Bag System Components, Wiring and Connectors Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Use of Special ToolsS7RS0B8208001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified. Do not use a non-powered probe

type tester.

Instructions must be followed carefully,

otherwise personal injury may result.

You should be familiar with the tools listed under the

heading “Special Tool”. You should be able to measure

voltage and resistance. You should be familiar with

proper use of a scan tool such as Air Bag Driver /

Passenger Load Tool, Connector Test Adapter Kit and

the Digital Multimeter.

Special tool

(A): 09932–76010 Connector Test Adapter Kit

This must be used whenever a diagnostic procedure

requests checking or probing a terminal.

Using the appropriate adapter in the special tool will

ensure that no damage to the terminal will occur from the

multimeter probe, such as spreading or bending.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

SDM bolt 9 0.9 6.5 �)

Driver air bag (inflator) module mounting bolt 9 0.9 6.5 �)

Passenger air bag (inflator) module attaching

bolt 23 2.3 16.5�)

Sleeve lock nut 2.5 0.25 2.0 �)

Side curtain-air bag (inflator) module attaching

bolts 11 1.1 8.0�)

Forward-sensor mounting bolt 9 0.9 6.5 �)

Side-sensor bolt 9 0.9 6.5 �)

I3JA01820041-01

Page 1359 of 1496

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-13

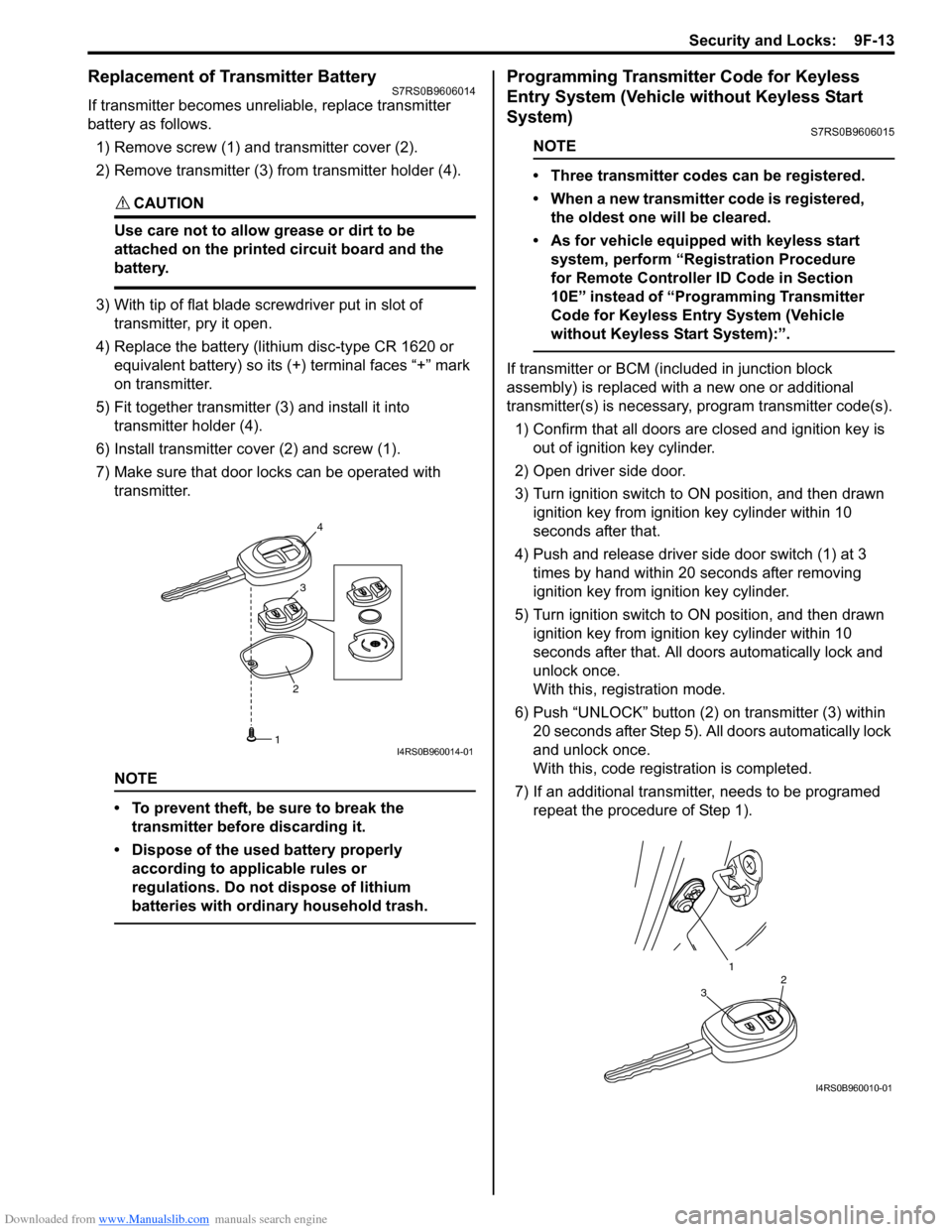

Replacement of Transmitter Battery S7RS0B9606014

If transmitter becomes unreliable, replace transmitter

battery as follows.

1) Remove screw (1) and transmitter cover (2).

2) Remove transmitter (3) from transmitter holder (4).

CAUTION!

Use care not to allow grease or dirt to be

attached on the printed circuit board and the

battery.

3) With tip of flat blade screwdriver put in slot of transmitter, pry it open.

4) Replace the battery (lithium disc-type CR 1620 or equivalent battery) so its (+) terminal faces “+” mark

on transmitter.

5) Fit together transmitter (3) and install it into

transmitter holder (4).

6) Install transmitter co ver (2) and screw (1).

7) Make sure that door locks can be operated with transmitter.

NOTE

• To prevent theft, be sure to break the transmitter before discarding it.

• Dispose of the used battery properly according to applicable rules or

regulations. Do not dispose of lithium

batteries with ordinary household trash.

Programming Transmitter Code for Keyless

Entry System (Vehicle without Keyless Start

System)

S7RS0B9606015

NOTE

• Three transmitter codes can be registered.

• When a new transmitter code is registered, the oldest one will be cleared.

• As for vehicle equipped with keyless start system, perform “Registration Procedure

for Remote Controller ID Code in Section

10E” instead of “Programming Transmitter

Code for Keyless Entry System (Vehicle

without Keyless Start System):”.

If transmitter or BCM (included in junction block

assembly) is replaced with a new one or additional

transmitter(s) is necessary, program transmitter code(s).

1) Confirm that all doors are closed and ignition key is

out of ignition key cylinder.

2) Open driver side door.

3) Turn ignition switch to ON position, and then drawn ignition key from igniti on key cylinder within 10

seconds after that.

4) Push and release driver side door switch (1) at 3 times by hand within 20 seconds after removing

ignition key from ig nition key cylinder.

5) Turn ignition switch to ON position, and then drawn ignition key from igniti on key cylinder within 10

seconds after that. All d oors automatically lock and

unlock once.

With this, registration mode.

6) Push “UNLOCK” button (2) on transmitter (3) within

20 seconds after Step 5). All doors automatically lock

and unlock once.

With this, code registration is completed.

7) If an additional transmitter, needs to be programed repeat the procedure of Step 1).

23

4

1I4RS0B960014-01

1

32

I4RS0B960010-01

Page 1444 of 1496

Downloaded from www.Manualslib.com manuals search engine 10C-1 Immobilizer Control System:

Control Systems

Immobilizer Control System

Precautions

Precautions in Diagnosing TroublesS7RS0BA300001

• Before confirming the diagnostic trouble code (DTC),

do not disconnect connector from ECM, battery cable

from battery, ground wire harness, or main fuse. Such

disconnection will erase DTC stored in ECM.

• DTC stored in ECM memory can be checked as well as cleared by using SUZUKI scan tool. Before using

SUZUKI scan tool, read its operator’s manual

carefully to know how to use it and what functions are

available.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” before inspection.

• Communication of ECM, BCM, keyless start control module (if equipped), ABS / ESP ® control module,

steering angle sensor (ESP ® model), combination

meter and TCM (A/T model) is established by CAN

(Controller Area Network). Therefore, handle CAN

communication lines with care referring to “Precaution

for CAN Communication System in Section 00”. For

CAN communication system, refer to description on

“CAN Communication System Description in Section

1A”.

Precaution in Replacing ECMS7RS0BA300002

• If ECM is replaced with new or used one without immobilizer control function , the engine will not be

started. In case of the above, check if the newly

installed ECM has immobilizer control function.

• After ECM is replaced with new one or used one, the transponder code in the transponder built in the

ignition key has to be registered with ECM. Or, the

engine cannot be started up. For the registration

procedure, refer to “Procedure after ECM

Replacement”.

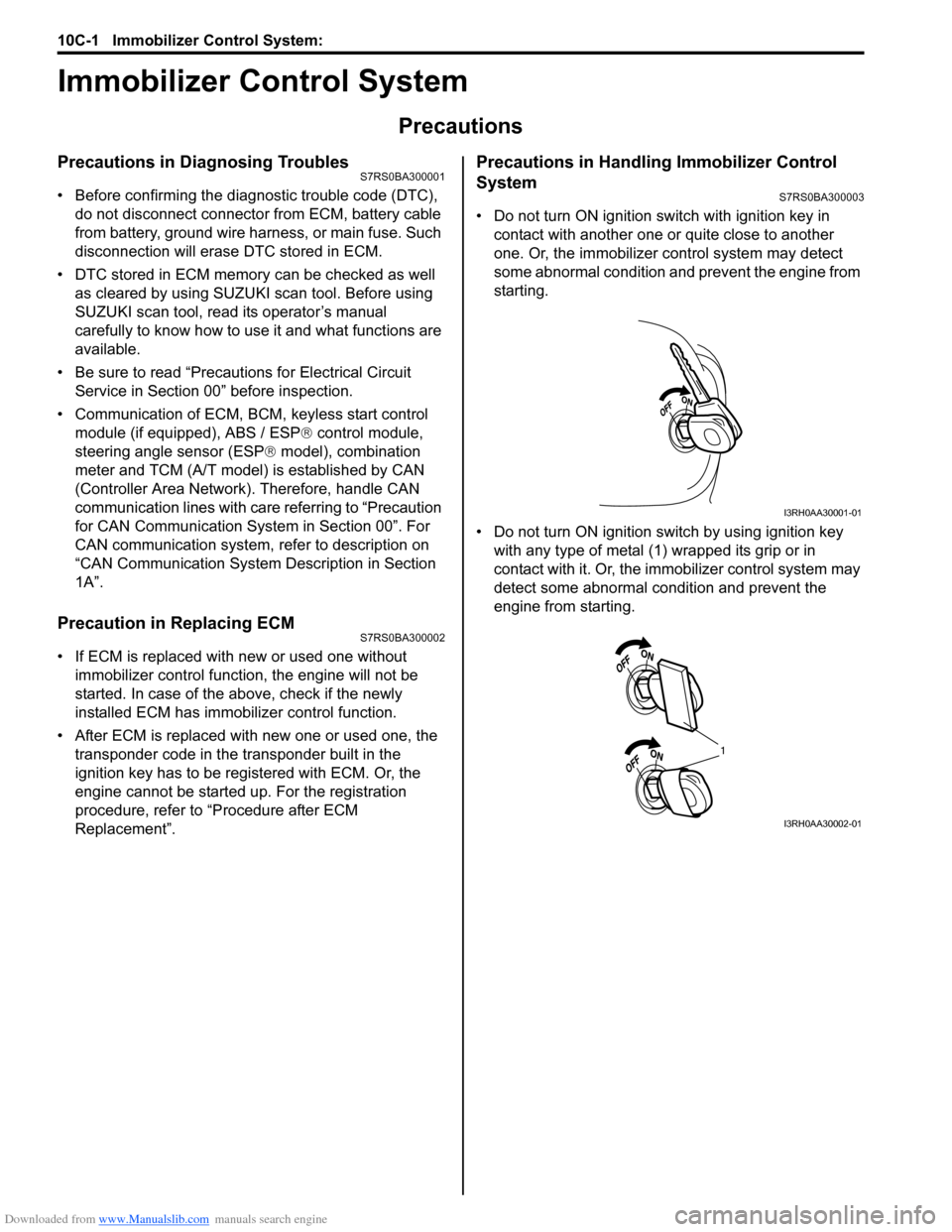

Precautions in Handling Immobilizer Control

System

S7RS0BA300003

• Do not turn ON ignition sw itch with ignition key in

contact with another one or quite close to another

one. Or, the immobilizer co ntrol system may detect

some abnormal condition and prevent the engine from

starting.

• Do not turn ON ignition switch by using ignition key with any type of metal (1) wrapped its grip or in

contact with it. Or, the i mmobilizer control system may

detect some abnormal condition and prevent the

engine from starting.

I3RH0AA30001-01

1

I3RH0AA30002-01

Page 1495 of 1496

Downloaded from www.Manualslib.com manuals search engine Keyless Start System: 10E-33

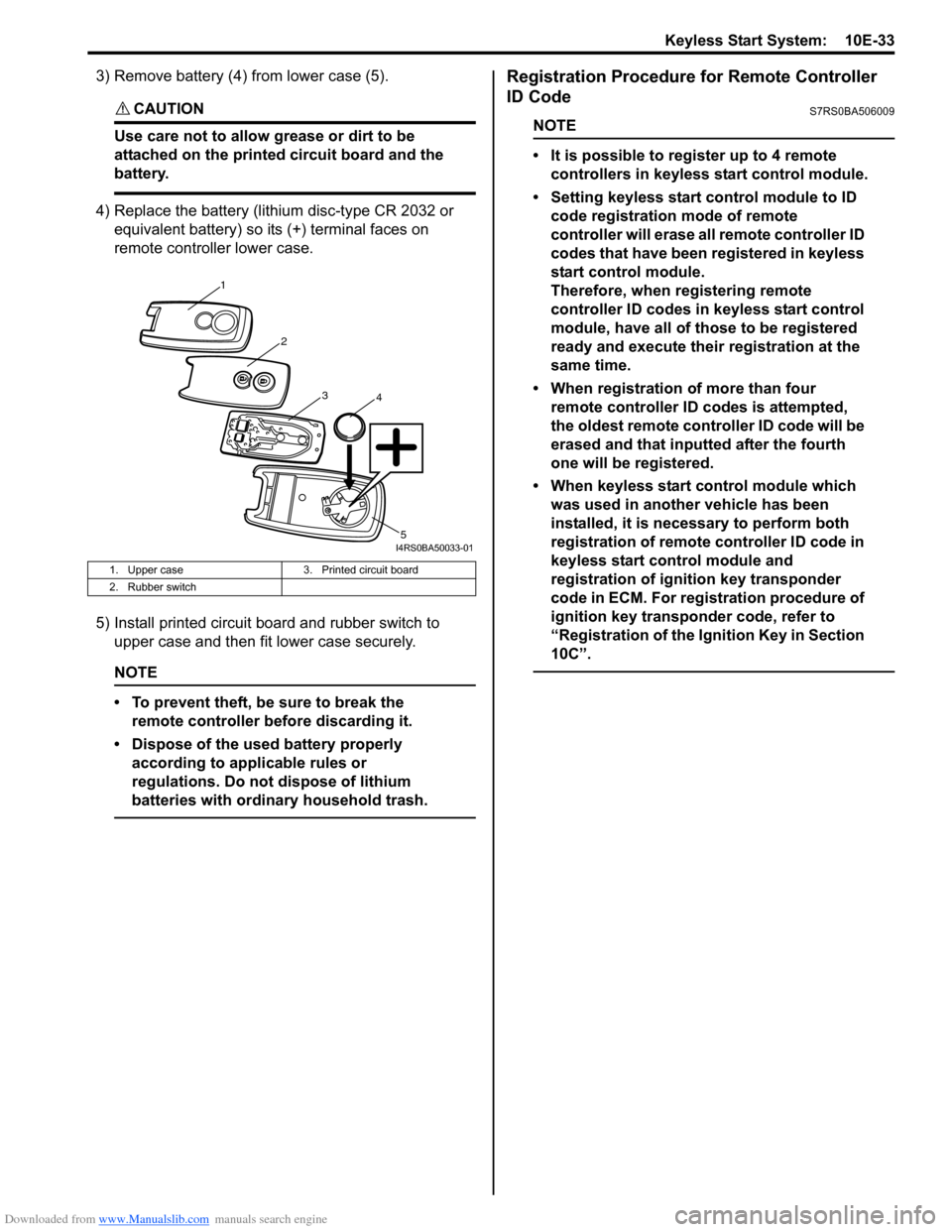

3) Remove battery (4) from lower case (5).

CAUTION!

Use care not to allow grease or dirt to be

attached on the printed circuit board and the

battery.

4) Replace the battery (lithium disc-type CR 2032 or equivalent battery) so its (+) terminal faces on

remote controller lower case.

5) Install printed circuit board and rubber switch to upper case and then fit lower case securely.

NOTE

• To prevent theft, be sure to break the remote controller be fore discarding it.

• Dispose of the used battery properly according to applicable rules or

regulations. Do not dispose of lithium

batteries with ordinary household trash.

Registration Procedure for Remote Controller

ID Code

S7RS0BA506009

NOTE

• It is possible to register up to 4 remote controllers in keyless start control module.

• Setting keyless start control module to ID code registration mode of remote

controller will erase all remote controller ID

codes that have been registered in keyless

start control module.

Therefore, when re gistering remote

controller ID codes in keyless start control

module, have all of those to be registered

ready and execute their registration at the

same time.

• When registration of more than four remote controller ID codes is attempted,

the oldest remote cont roller ID code will be

erased and that inputted after the fourth

one will be registered.

• When keyless start control module which was used in another vehicle has been

installed, it is nece ssary to perform both

registration of remote controller ID code in

keyless start control module and

registration of ignition key transponder

code in ECM. For registration procedure of

ignition key transponder code, refer to

“Registration of the Ignition Key in Section

10C”.

1. Upper case 3. Printed circuit board

2. Rubber switch

1

2

34

5I4RS0BA50033-01