battery type SUZUKI SWIFT 2008 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 940 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-4 Heater and Ventilation:

Repair Instructions

HVAC Unit ComponentsS7RS0B7106001

For manual type A/C, refer to “HVAC Unit Components

in Section 7B”.

For automatic type A/C, refer to “HVAC Unit

Components in Section 7B”.

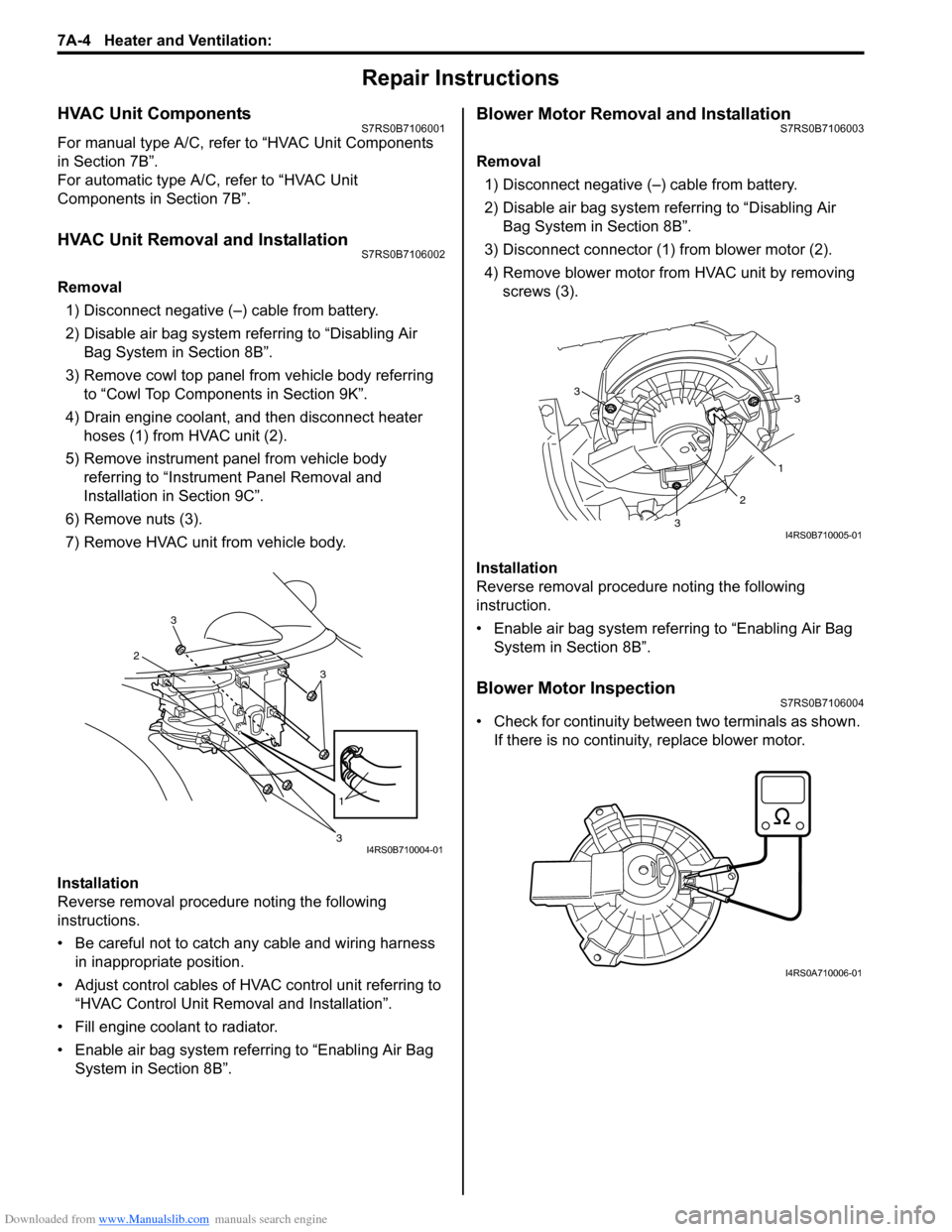

HVAC Unit Removal and InstallationS7RS0B7106002

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove cowl top panel from vehicle body referring to “Cowl Top Components in Section 9K”.

4) Drain engine coolant, and then disconnect heater hoses (1) from HVAC unit (2).

5) Remove instrument panel from vehicle body referring to “Instrument Panel Removal and

Installation in Section 9C”.

6) Remove nuts (3).

7) Remove HVAC unit from vehicle body.

Installation

Reverse removal procedure noting the following

instructions.

• Be careful not to catch any cable and wiring harness in inappropriate position.

• Adjust control cables of HVAC control unit referring to “HVAC Control Unit Remo val and Installation”.

• Fill engine coolant to radiator.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

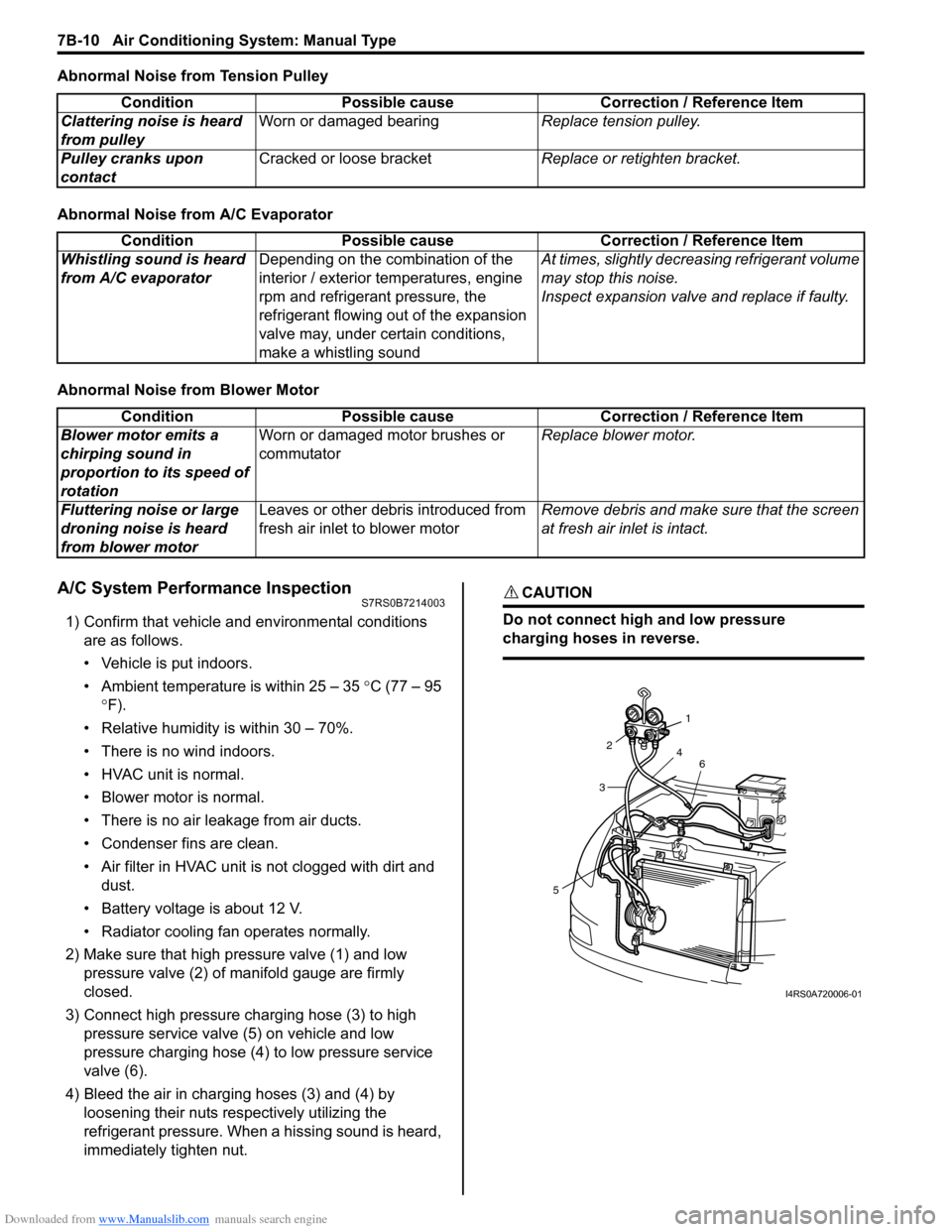

Blower Motor Removal and InstallationS7RS0B7106003

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Disconnect connector (1) from blower motor (2).

4) Remove blower motor from HVAC unit by removing screws (3).

Installation

Reverse removal procedure noting the following

instruction.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Blower Motor InspectionS7RS0B7106004

• Check for continuity between two terminals as shown. If there is no continuity, replace blower motor.

3

2

3

1

3I4RS0B710004-01

3

1

2

3

3

I4RS0B710005-01

I4RS0A710006-01

Page 958 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-10 Air Conditioning System: Manual Type

Abnormal Noise from Tension Pulley

Abnormal Noise from A/C Evaporator

Abnormal Noise from Blower Motor

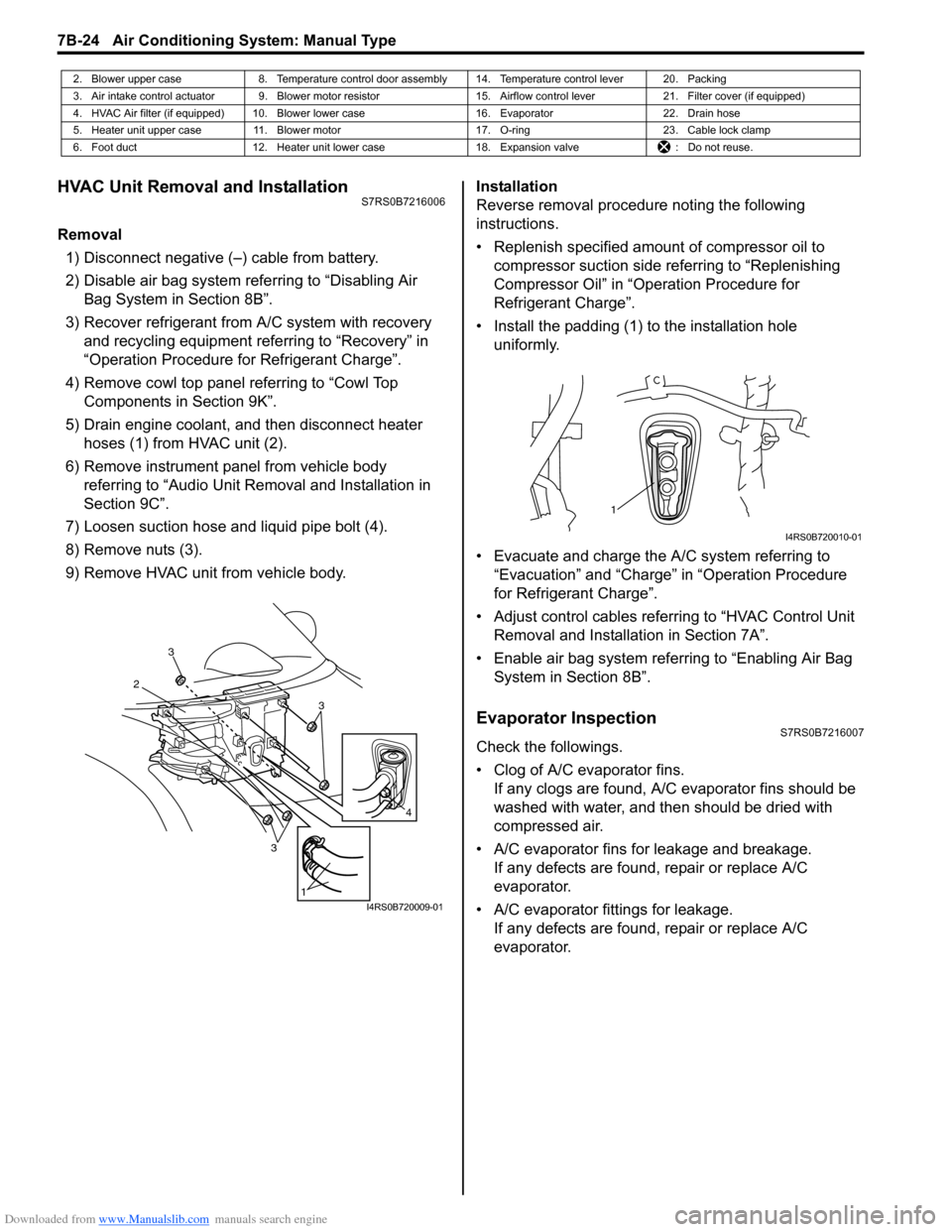

A/C System Performance InspectionS7RS0B7214003

1) Confirm that vehicle and environmental conditions are as follows.

• Vehicle is put indoors.

• Ambient temperature is within 25 – 35 °C (77 – 95

° F).

• Relative humidity is within 30 – 70%.

• There is no wind indoors.

• HVAC unit is normal.

• Blower motor is normal.

• There is no air leakage from air ducts.

• Condenser fins are clean.

• Air filter in HVAC unit is not clogged with dirt and

dust.

• Battery voltage is about 12 V.

• Radiator cooling fan operates normally.

2) Make sure that high pressure valve (1) and low pressure valve (2) of manifold gauge are firmly

closed.

3) Connect high pressure charging hose (3) to high pressure service valve (5) on vehicle and low

pressure charging hose (4) to low pressure service

valve (6).

4) Bleed the air in charging hoses (3) and (4) by loosening their nuts respectively utilizing the

refrigerant pressure. When a hissing sound is heard,

immediately tighten nut.

CAUTION!

Do not connect high and low pressure

charging hoses in reverse.

Condition Possible cause Correction / Reference Item

Clattering noise is heard

from pulley Worn or damaged bearing

Replace tension pulley.

Pulley cranks upon

contact Cracked or loose bracket

Replace or retighten bracket.

ConditionPossible cause Correction / Reference Item

Whistling sound is heard

from A/C evaporator Depending on the combination of the

interior / exterior temperatures, engine

rpm and refrigerant pressure, the

refrigerant flowing out of the expansion

valve may, under certain conditions,

make a whistling sound At times, slightly decrea

sing refrigerant volume

may stop this noise.

Inspect expansion valve and replace if faulty.

Condition Possible cause Correction / Reference Item

Blower motor emits a

chirping sound in

proportion to its speed of

rotation Worn or damaged motor brushes or

commutator

Replace blower motor.

Fluttering noise or large

droning noise is heard

from blower motor Leaves or other debris introduced from

fresh air inlet to blower motor

Remove debris and make sure that the screen

at fresh air inlet is intact.

53

2

1

4 6

I4RS0A720006-01

Page 972 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-24 Air Conditioning System: Manual Type

HVAC Unit Removal and InstallationS7RS0B7216006

Removal1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Recover refrigerant from A/C system with recovery and recycling equipment referring to “Recovery” in

“Operation Procedure for Refrigerant Charge”.

4) Remove cowl top panel referring to “Cowl Top Components in Section 9K”.

5) Drain engine coolant, and then disconnect heater hoses (1) from HVAC unit (2).

6) Remove instrument panel from vehicle body referring to “Audio Unit Re moval and Installation in

Section 9C”.

7) Loosen suction hose and liquid pipe bolt (4).

8) Remove nuts (3).

9) Remove HVAC unit from vehicle body. Installation

Reverse removal procedure noting the following

instructions.

• Replenish specified amount of compressor oil to

compressor suction side referring to “Replenishing

Compressor Oil” in “Operation Procedure for

Refrigerant Charge”.

• Install the padding (1) to the installation hole uniformly.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

• Adjust control cables referr ing to “HVAC Control Unit

Removal and Installati on in Section 7A”.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Evaporator InspectionS7RS0B7216007

Check the followings.

• Clog of A/C evaporator fins.If any clogs are found, A/C evaporator fins should be

washed with water, and then should be dried with

compressed air.

• A/C evaporator fins for leakage and breakage. If any defects are found, repair or replace A/C

evaporator.

• A/C evaporator fittings for leakage. If any defects are found, repair or replace A/C

evaporator.

2. Blower upper case 8. Temperature control door assembly 14. Temperature control lever 20. Packing

3. Air intake control actuator 9. Blower motor resistor 15. Airflow control lever21. Filter cover (if equipped)

4. HVAC Air filter (if equipped) 10. Blower lower case 16. Evaporator22. Drain hose

5. Heater unit upper case 11. Blower motor 17. O-ring23. Cable lock clamp

6. Foot duct 12. Heater unit lower case 18. Expansion valve: Do not reuse.

3

2

3

3

1

4

I4RS0B720009-01

1

I4RS0B720010-01

Page 973 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-25

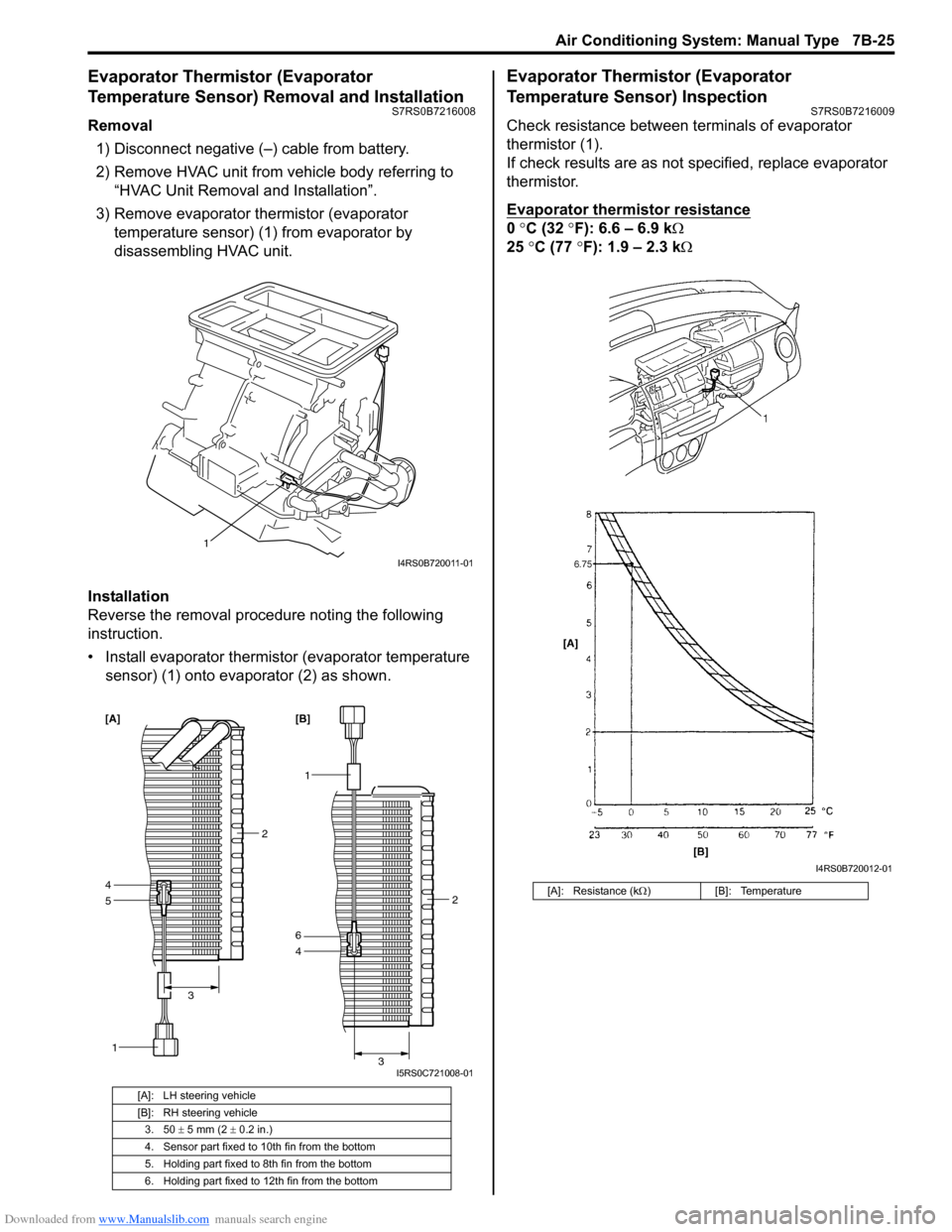

Evaporator Thermistor (Evaporator

Temperature Sensor) Removal and Installation

S7RS0B7216008

Removal1) Disconnect negative (–) cable from battery.

2) Remove HVAC unit from vehicle body referring to “HVAC Unit Removal and Installation”.

3) Remove evaporator thermistor (evaporator temperature sensor) (1) from evaporator by

disassembling HVAC unit.

Installation

Reverse the removal procedure noting the following

instruction.

• Install evaporator thermistor (evaporator temperature sensor) (1) onto evaporator (2) as shown.

Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection

S7RS0B7216009

Check resistance between terminals of evaporator

thermistor (1).

If check results are as not specified, replace evaporator

thermistor.

Evaporator thermistor resistance

0 °C (32 °F): 6.6 – 6.9 k Ω

25 °C (77 °F): 1.9 – 2.3 kΩ

[A]: LH steering vehicle

[B]: RH steering vehicle

3. 50 ± 5 mm (2 ± 0.2 in.)

4. Sensor part fixed to 10th fin from the bottom

5. Holding part fixed to 8th fin from the bottom

6. Holding part fixed to 12th fin from the bottom

1

I4RS0B720011-01

5

1

4

2

3

[A]

1

4 2

3

6 [B]

I5RS0C721008-01

[A]: Resistance (k Ω) [B]: Temperature

I4RS0B720012-01

Page 974 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-26 Air Conditioning System: Manual Type

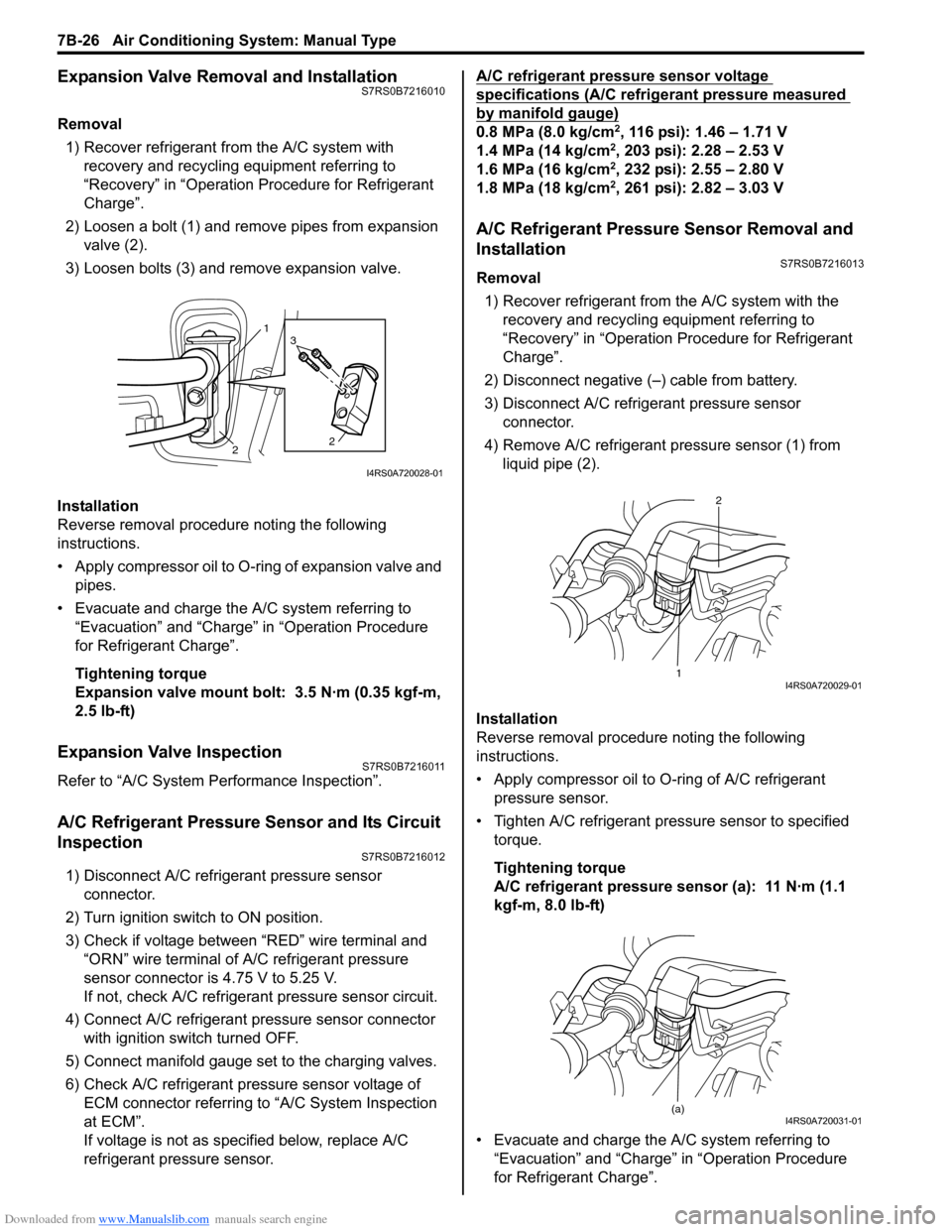

Expansion Valve Removal and InstallationS7RS0B7216010

Removal1) Recover refrigerant fr om the A/C system with

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Loosen a bolt (1) and remove pipes from expansion valve (2).

3) Loosen bolts (3) and remove expansion valve.

Installation

Reverse removal procedure noting the following

instructions.

• Apply compressor oil to O-ring of expansion valve and pipes.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

Tightening torque

Expansion valve mount bolt: 3.5 N·m (0.35 kgf-m,

2.5 lb-ft)

Expansion Valve InspectionS7RS0B7216011

Refer to “A/C System Performance Inspection”.

A/C Refrigerant Pressure Sensor and Its Circuit

Inspection

S7RS0B7216012

1) Disconnect A/C refrigerant pressure sensor connector.

2) Turn ignition switch to ON position.

3) Check if voltage between “RED” wire terminal and “ORN” wire terminal of A/C refrigerant pressure

sensor connector is 4.75 V to 5.25 V.

If not, check A/C refrigerant pressure sensor circuit.

4) Connect A/C refrigerant pressure sensor connector with ignition switch turned OFF.

5) Connect manifold gauge set to the charging valves.

6) Check A/C refrigerant pressure sensor voltage of ECM connector referring to “A/C System Inspection

at ECM”.

If voltage is not as specified below, replace A/C

refrigerant pressure sensor. A/C refrigerant pressure sensor voltage

specifications (A/C refrigerant pressure measured

by manifold gauge)

0.8 MPa (8.0 kg/cm2, 116 psi): 1.46 – 1.71 V

1.4 MPa (14 kg/cm2, 203 psi): 2.28 – 2.53 V

1.6 MPa (16 kg/cm2, 232 psi): 2.55 – 2.80 V

1.8 MPa (18 kg/cm2, 261 psi): 2.82 – 3.03 V

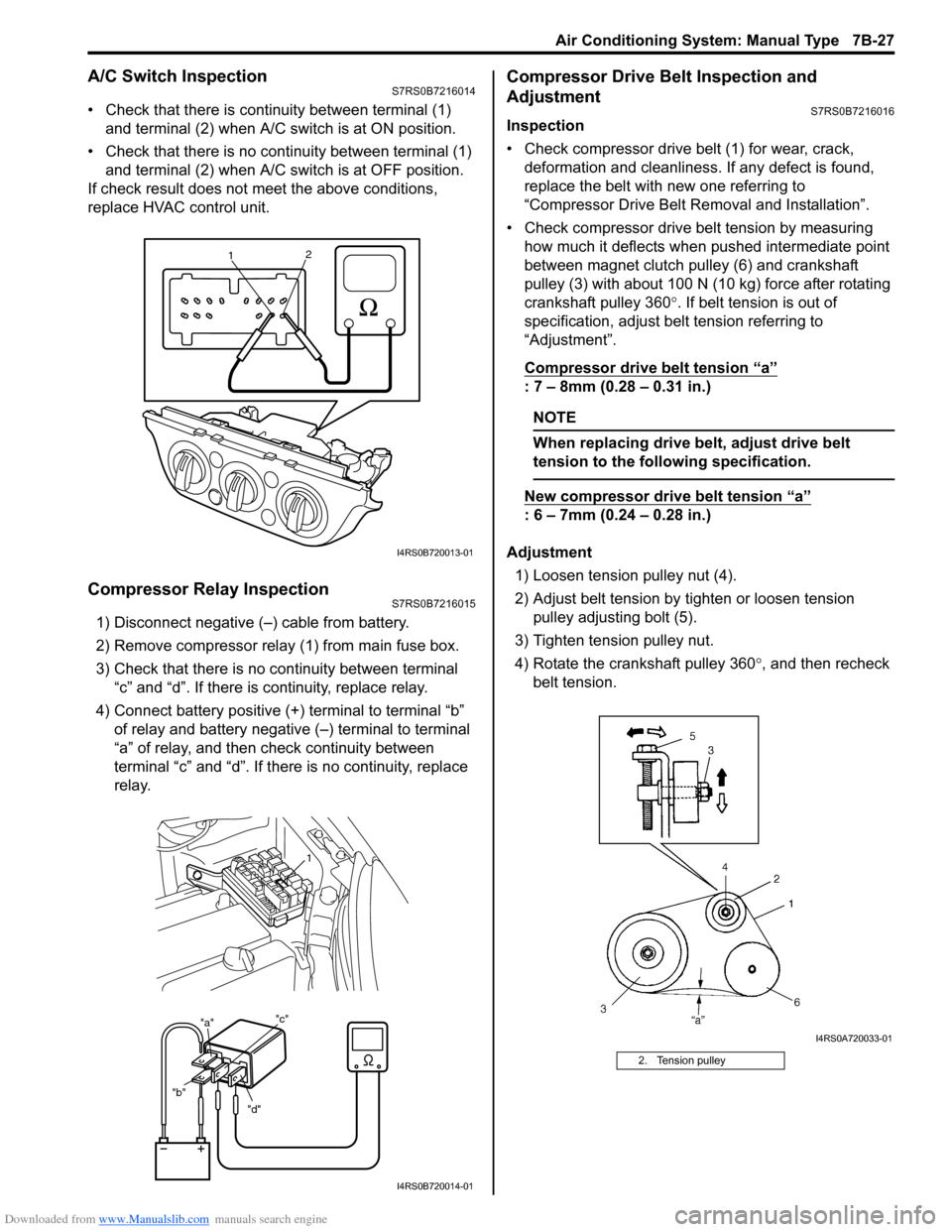

A/C Refrigerant Pressure Sensor Removal and

Installation

S7RS0B7216013

Removal

1) Recover refrigerant from the A/C system with the recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Disconnect negative (–) cable from battery.

3) Disconnect A/C refrigerant pressure sensor connector.

4) Remove A/C refrigerant pressure sensor (1) from liquid pipe (2).

Installation

Reverse removal procedure noting the following

instructions.

• Apply compressor oil to O-ring of A/C refrigerant

pressure sensor.

• Tighten A/C refrigerant pressure sensor to specified torque.

Tightening torque

A/C refrigerant pressure sensor (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

1

2 2

3

I4RS0A720028-01

1 2I4RS0A720029-01

(a)I4RS0A720031-01

Page 975 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-27

A/C Switch InspectionS7RS0B7216014

• Check that there is continuity between terminal (1) and terminal (2) when A/C s witch is at ON position.

• Check that there is no continuity between terminal (1) and terminal (2) when A/C s witch is at OFF position.

If check result does not meet the above conditions,

replace HVAC control unit.

Compressor Relay InspectionS7RS0B7216015

1) Disconnect negative (–) cable from battery.

2) Remove compressor relay (1) from main fuse box.

3) Check that there is no continuity between terminal “c” and “d”. If there is continuity, replace relay.

4) Connect battery positive (+ ) terminal to terminal “b”

of relay and battery negative (–) terminal to terminal

“a” of relay, and then check continuity between

terminal “c” and “d”. If there is no continuity, replace

relay.

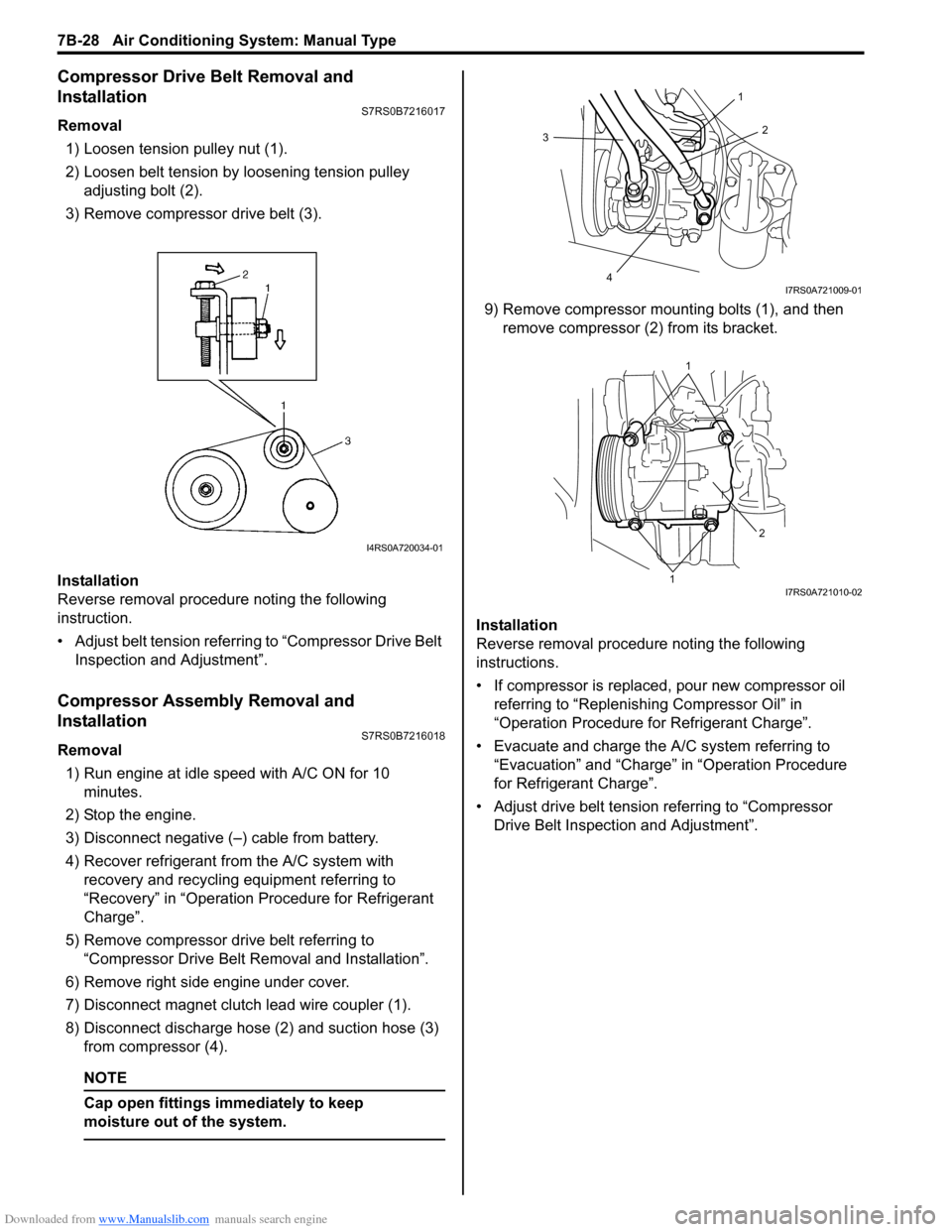

Compressor Drive Belt Inspection and

Adjustment

S7RS0B7216016

Inspection

• Check compressor drive belt (1) for wear, crack, deformation and cleanliness. If any defect is found,

replace the belt with new one referring to

“Compressor Drive Belt Re moval and Installation”.

• Check compressor drive belt tension by measuring how much it deflects when pushed intermediate point

between magnet clutch pulley (6) and crankshaft

pulley (3) with about 100 N (10 kg) force after rotating

crankshaft pulley 360 °. If belt tension is out of

specification, adjust belt tension referring to

“Adjustment”.

Compressor drive belt tension

“a”

: 7 – 8mm (0.28 – 0.31 in.)

NOTE

When replacing drive belt, adjust drive belt

tension to the following specification.

New compressor dr ive belt tension “a”

: 6 – 7mm (0.24 – 0.28 in.)

Adjustment 1) Loosen tension pulley nut (4).

2) Adjust belt tension by ti ghten or loosen tension

pulley adjusting bolt (5).

3) Tighten tension pulley nut.

4) Rotate the crankshaft pulley 360 °, and then recheck

belt tension.

1 2

I4RS0B720013-01

"d"

"b" "a"

"c"

1

I4RS0B720014-01

2. Tension pulley

I4RS0A720033-01

Page 976 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-28 Air Conditioning System: Manual Type

Compressor Drive Belt Removal and

Installation

S7RS0B7216017

Removal1) Loosen tension pulley nut (1).

2) Loosen belt tension by loosening tension pulley adjusting bolt (2).

3) Remove compressor drive belt (3).

Installation

Reverse removal procedure noting the following

instruction.

• Adjust belt tension referring to “Compressor Drive Belt Inspection and Adjustment”.

Compressor Assembly Removal and

Installation

S7RS0B7216018

Removal

1) Run engine at idle speed with A/C ON for 10 minutes.

2) Stop the engine.

3) Disconnect negative (–) cable from battery.

4) Recover refrigerant fr om the A/C system with

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

5) Remove compressor drive belt referring to “Compressor Drive Belt Re moval and Installation”.

6) Remove right side engine under cover.

7) Disconnect magnet clutch lead wire coupler (1).

8) Disconnect discharge hose (2) and suction hose (3) from compressor (4).

NOTE

Cap open fittings immediately to keep

moisture out of the system.

9) Remove compressor mounting bolts (1), and then remove compressor (2 ) from its bracket.

Installation

Reverse removal procedure noting the following

instructions.

• If compressor is replaced, pour new compressor oil referring to “Replenishi ng Compressor Oil” in

“Operation Procedure for Refrigerant Charge”.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

• Adjust drive belt tension referring to “Compressor Drive Belt Inspecti on and Adjustment”.

I4RS0A720034-01

3

4 2

1

I7RS0A721009-01

1

1 2

I7RS0A721010-02

Page 979 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-31

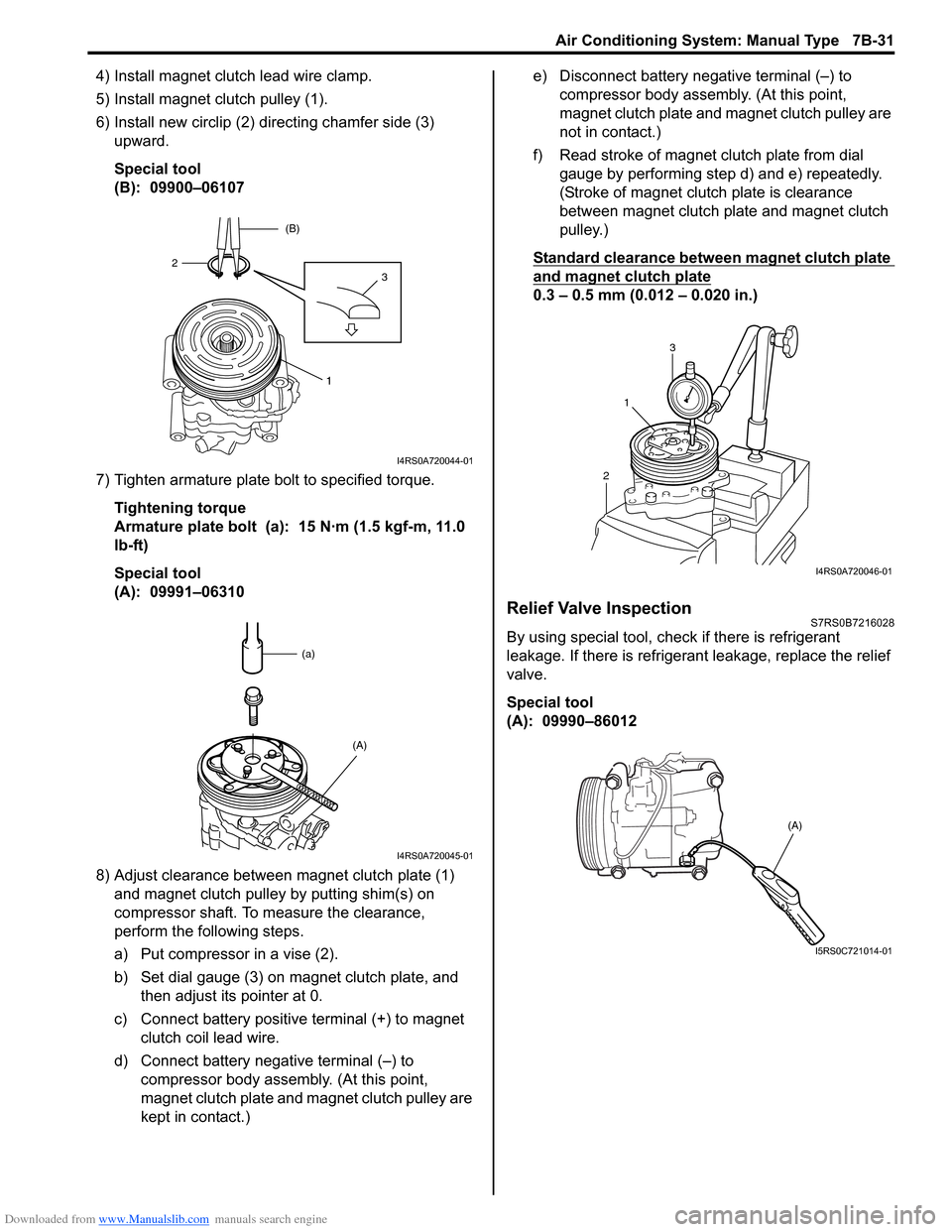

4) Install magnet clutch lead wire clamp.

5) Install magnet clutch pulley (1).

6) Install new circlip (2) directing chamfer side (3) upward.

Special tool

(B): 09900–06107

7) Tighten armature plate bolt to specified torque. Tightening torque

Armature plate bolt (a): 15 N·m (1.5 kgf-m, 11.0

lb-ft)

Special tool

(A): 09991–06310

8) Adjust clearance between magnet clutch plate (1) and magnet clutch pulley by putting shim(s) on

compressor shaft. To measure the clearance,

perform the following steps.

a) Put compressor in a vise (2).

b) Set dial gauge (3) on magnet clutch plate, and then adjust its pointer at 0.

c) Connect battery positive terminal (+) to magnet clutch coil lead wire.

d) Connect battery negative terminal (–) to compressor body assemb ly. (At this point,

magnet clutch plate and magnet clutch pulley are

kept in contact.) e) Disconnect battery negative terminal (–) to

compressor body assembly. (At this point,

magnet clutch plate and magnet clutch pulley are

not in contact.)

f) Read stroke of magnet clutch plate from dial gauge by performing step d) and e) repeatedly.

(Stroke of magnet clutch plate is clearance

between magnet clutch plate and magnet clutch

pulley.)

Standard clearance between magnet clutch plate

and magnet clutch plate

0.3 – 0.5 mm (0.012 – 0.020 in.)

Relief Valve InspectionS7RS0B7216028

By using special tool, chec k if there is refrigerant

leakage. If there is refrigerant leakage, replace the relief

valve.

Special tool

(A): 09990–86012

1

32 (B)

I4RS0A720044-01

(a)

(A)

I4RS0A720045-01

21

3

I4RS0A720046-01

(A)

I5RS0C721014-01

Page 981 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-33

Special Tools and Equipment

Recommended Service MaterialS7RS0B7218001

NOTE

Required service material is also described in the following.

“Precautions on Servicing A/C System”

Special ToolS7RS0B7218002

Material SUZUKI recommended product or Specification Note

Compressor oil MATSUSHITADEN KI GU10 P/No.: 99000–99015–

00A �)

/ �)

Silicon sealant SUZUKI SILICON SEALANT KE-

347W (100g) P/No.: 99000–34220

�)

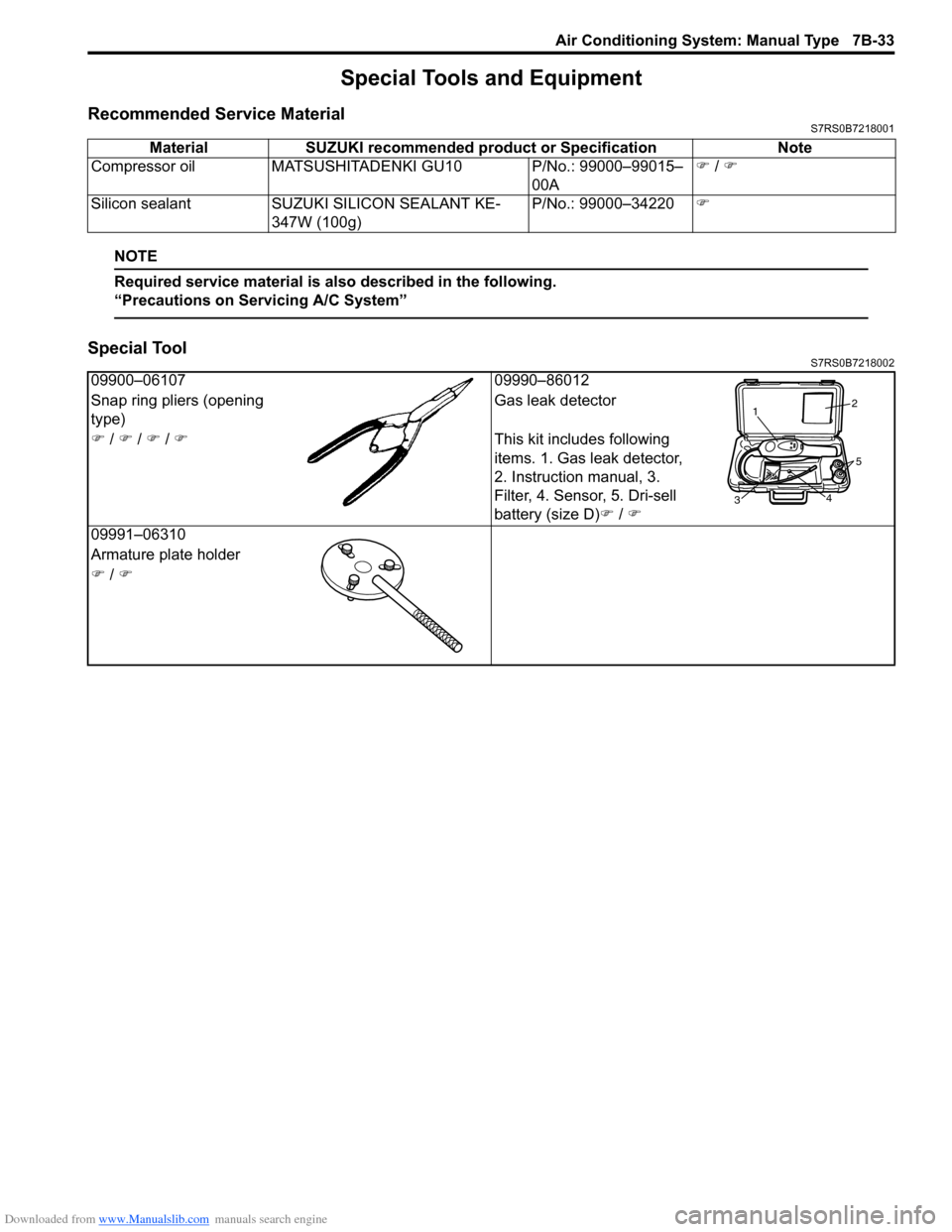

09900–06107 09990–86012

Snap ring pliers (opening

type) Gas leak detector

�) / �) / �) / �) This kit includes following

items. 1. Gas leak detector,

2. Instruction manual, 3.

Filter, 4. Sensor, 5. Dri-sell

battery (size D)�) / �)

09991–06310

Armature plate holder

�) / �)

1 2

3 4

5

Page 982 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-34 Air Conditioning System: Automatic Type

Automatic Type

Precautions

A/C System CautionS7RS0B7220001

Refer to “A/C System Caution”.

Precautions in Diagnosing TroubleS7RS0B7220002

• Do not disconnect couplers from HVAC control module, battery cable from battery, HVAC control module ground

wire harness from body or main fuse before confirming diagnostic information (diagnostic trouble code) stored in

HVAC control module memory.

• Diagnostic information (diagnostic trouble code) stored in HVAC control module can be checked by display of HVAC

control module. Also, it can be checked by using SU ZUKI scan tool. Before checking diagnostic information

(diagnostic trouble code), read this manual and operator's manual for SUZUKI scan tool to know how to read

diagnostic information (diagnostic trouble code).

• When trouble is diagnosed using diagnostic information (diagnostic trouble code) on display of HVAC control

module, keep in your mind that each diagnostic inform ation (diagnostic trouble code) has priority, and only

diagnostic information (diagnostic troub le code) which has the highest priority is indicated. Therefore, after

troubleshooting the malfunction, make sure if there exists any other diagnostic information (diagnostic trouble

code).

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” before inspection.

Precautions on Servicing A/C SystemS7RS0B7220003

Refer to “Precautions on Servicing A/C System”.

General Description

Auto A/C System DescriptionS7RS0B7221001

The automatic type air conditioning system (auto A/C) is pr ovided with the function to automatically control the inside

air temperature, fan speed, air flow outl et direction and air intake position by HVAC control module in addition to

functions of the manual type air conditioning system (manua l A/C). Once the inside air temperature is set using the

temperature selector, HVAC control module automatically controls the inside air temperature at the constant level at all

times based on the inside air temperature, outside ai r temperature, amount of sunlight and engine coolant

temperature detected respectively by the inside air te mperature sensor, outside air temperature sensor, sunload

sensor and ECT sensor. At this time, “FULL AUTO A/ C” appears on the display of HVAC control module.

With the air intake selector pushed in the above state, it is possible to select any position of the air intake actuator.

Then, “FULL AUTO A/C” on the display changes to “AUTO A/C”.