MOUNT SUZUKI SWIFT 2008 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 413 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-3

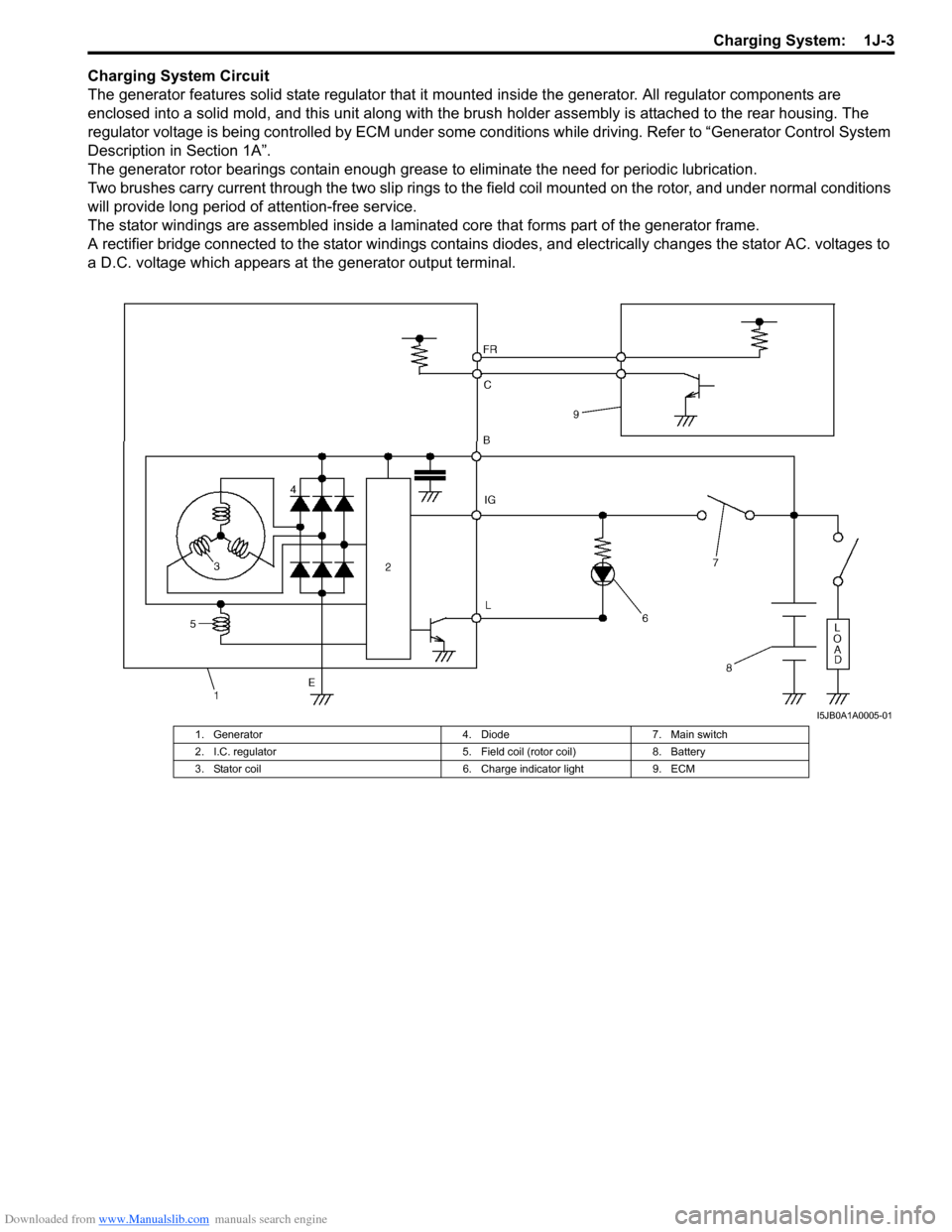

Charging System Circuit

The generator features solid state regulator that it mounted inside the generator. All regulator components are

enclosed into a solid mold, and this unit along with the brus h holder assembly is attached to the rear housing. The

regulator voltage is being controlled by ECM under some cond itions while driving. Refer to “Generator Control System

Description in Section 1A”.

The generator rotor bearings contain enough grease to eliminate the need for periodic lubrication.

Two brushes carry current through the two slip rings to the field coil mounted on the rotor, and under normal conditions

will provide long period of attention-free service.

The stator windings are assembled inside a laminate d core that forms part of the generator frame.

A rectifier bridge connected to the stator windings contains diodes, and electrically changes the stator AC. voltages to

a D.C. voltage which appears at the generator output terminal.

I5JB0A1A0005-01

1. Generator 4. Diode7. Main switch

2. I.C. regulator 5. Field coil (rotor coil)8. Battery

3. Stator coil 6. Charge indicator light9. ECM

Page 414 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-4 Charging System:

Diagnostic Information and Procedures

Battery InspectionS7RS0B1A04001

Common Causes of Failure

A battery is not designed to last indefinitely; however, with proper care, it will provide many years of service. If the

battery performs satisfactorily during te st but fails to operate properly for no apparent reason, the following are some

factors that may point to the cause of trouble:

• Accessories left on overnight or for an extended period without the generator operating.

• Slow average driving speeds for short periods.

• Electrical load exceeding generator output partic ularly with addition of aftermarket equipment.

• Defects in charging system such as high resistance, s lipping drive belt, loose generator output terminal, faulty

generator or voltage regulator, Refer to “Generator Symptom Diagnosis”.

• Battery abuse, including failure to keep battery cable terminals clean and tight or loose battery hold down.

• Mechanical problems in electrical sys tem such as shorted or pinched wires.

Visual Inspection

Check for obvious damage, such as cracked or broken case or cover, that could permit loss of electrolyte. If obvious

damage is noted, replace battery. Determine cause of damage and correct as needed.

Generator Symptom DiagnosisS7RS0B1A04002

CAUTION!

• Do not mistake polarities of “IG” terminal and “L” terminal.

• Do not create short circuit between “IG” and “L” terminals. Always connect these terminals through a lamp.

• Do not connect any load between “L” and “E” terminals.

• When connecting charger or booster battery to vehicle battery, refer to “Jump Starting in Case of Emergency”.

Trouble in charging system will show up as one or more of the following conditions:

1) Faulty indicator lamp operation.

2) An undercharged battery as evidenced by slow cranking or indicator dark.

3) An overcharged battery as evidenced by ex cessive spewing of electrolyte from vents.

Condition Possible cause Correction / Reference Item

Noisy generator Loose drive belt Adjust or replace drive belt.

Loose drive belt pulley Tighten by specified torque.

Loose mounting bolts Tighten by specified torque.

Worn or dirty bearings Replace.

Defective diode or stator Replace.

Charge light does not

light with ignition ON and

engine off Fuse blown

Replace fuse and check for shorted circuit.

Indicator lamp (LED) faulty Replace combination meter.

Wiring connection loose Tighten loose connection.

IC regulator or field coil faulty Replace.

Poor contact between brush and slip

ring Repair or replace.

Charge light does not go

out with engine running

(battery requires frequent

recharging) Drive belt loose or worn

Adjust or replace drive belt.

IC regulator or generator faulty Replace.

Wiring faulty Repair wiring.

Page 417 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-7

With Charging Equipment

CAUTION!

When jump starting engine with charging

equipment, be sure equipment used is 12-

volt and negative ground. Do not use 24-volt

charging equipment. Using such equipment

can cause serious damage to electrical

system or electronic parts.

Battery Dismounting and RemountingS7RS0B1A06002

WARNING!

When handling battery, following safety

precautions should be followed:

• Hydrogen gas is produced by battery. A flame or spark near battery may cause the

gas to ignite.

• Battery fluid is highly acidic. Avoid spilling on clothing or other fabric. Any spilled

electrolyte should be flushed with large

quantity of water and cleaned immediately.

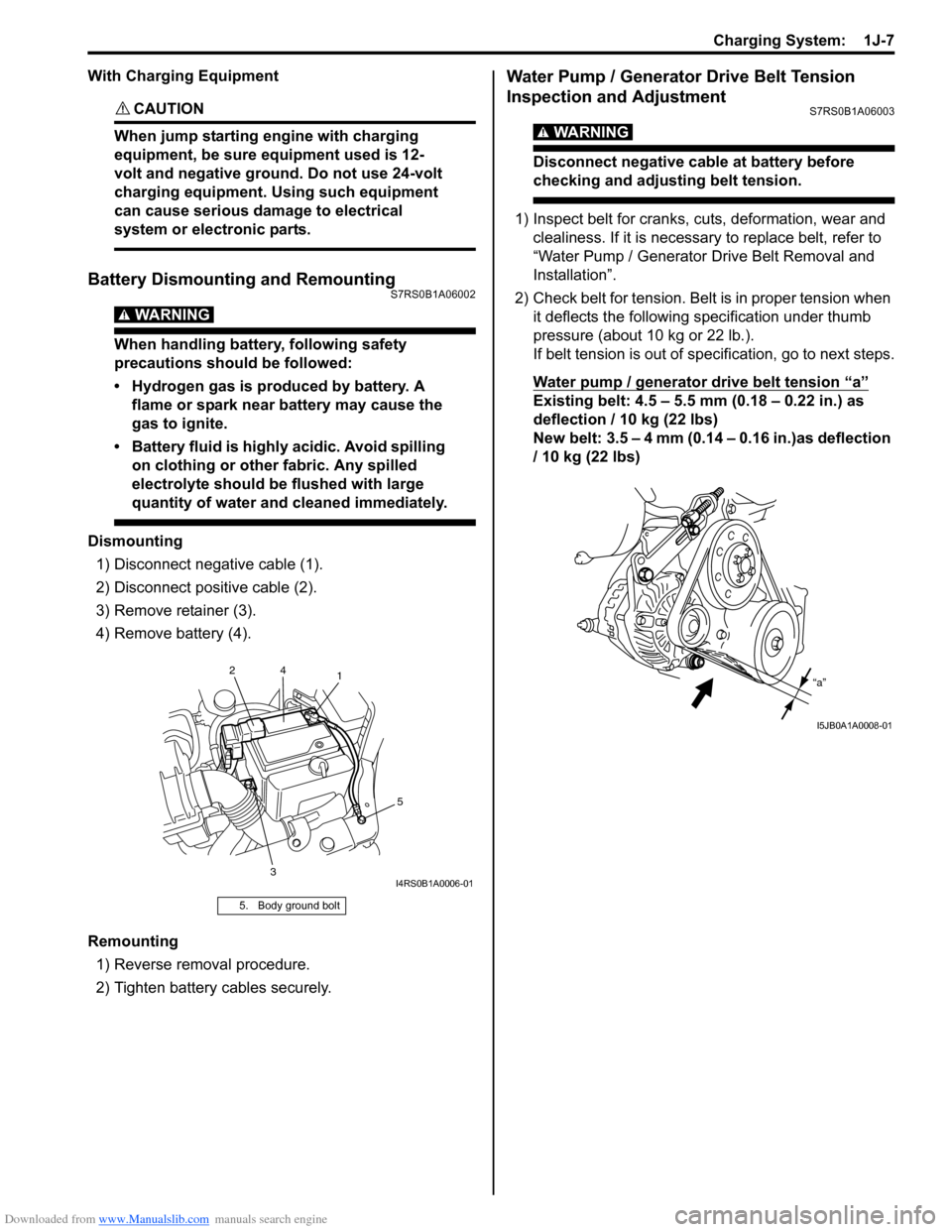

Dismounting

1) Disconnect negative cable (1).

2) Disconnect positive cable (2).

3) Remove retainer (3).

4) Remove battery (4).

Remounting 1) Reverse removal procedure.

2) Tighten battery cables securely.

Water Pump / Generator Drive Belt Tension

Inspection and Adjustment

S7RS0B1A06003

WARNING!

Disconnect negative cable at battery before

checking and adjusting belt tension.

1) Inspect belt for cranks, cuts, deformation, wear and clealiness. If it is necessary to replace belt, refer to

“Water Pump / Generator Drive Belt Removal and

Installation”.

2) Check belt for tension. Belt is in proper tension when it deflects the following specification under thumb

pressure (about 10 kg or 22 lb.).

If belt tension is out of spec ification, go to next steps.

Water pump / generator drive belt tension

“a”

Existing belt: 4.5 – 5.5 mm (0.18 – 0.22 in.) as

deflection / 10 kg (22 lbs)

New belt: 3.5 – 4 mm (0.14 – 0.16 in.)as deflection

/ 10 kg (22 lbs)

5. Body ground bolt

1

3 5

2

4

I4RS0B1A0006-01

“a”

I5JB0A1A0008-01

Page 419 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-9

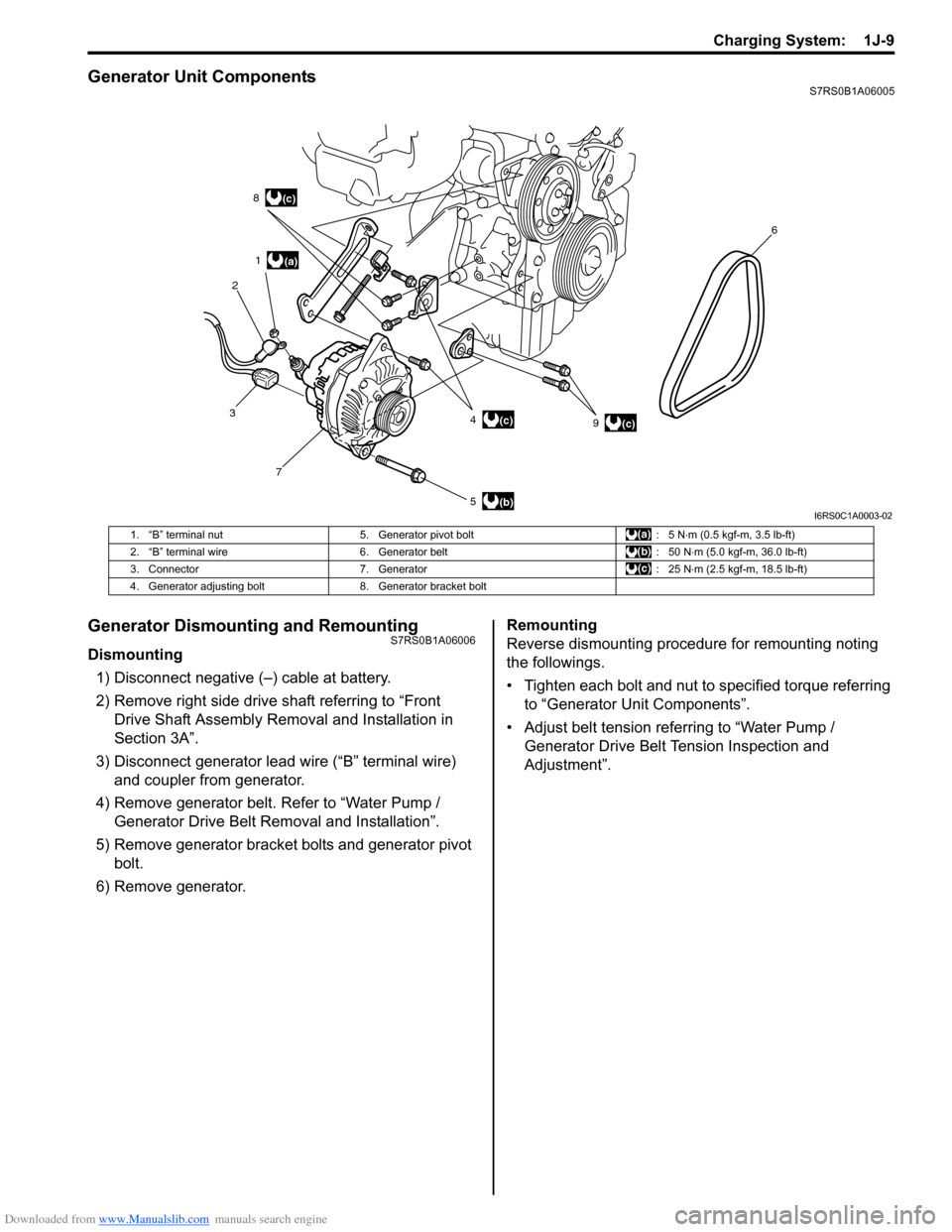

Generator Unit ComponentsS7RS0B1A06005

Generator Dismounting and RemountingS7RS0B1A06006

Dismounting1) Disconnect negative (–) cable at battery.

2) Remove right side drive shaft referring to “Front Drive Shaft Assembly Removal and Installation in

Section 3A”.

3) Disconnect generator lead wire (“B” terminal wire) and coupler from generator.

4) Remove generator belt. Refer to “Water Pump / Generator Drive Belt Re moval and Installation”.

5) Remove generator bracket bolts and generator pivot bolt.

6) Remove generator. Remounting

Reverse dismounting procedure for remounting noting

the followings.

• Tighten each bolt and nut to specified torque referring

to “Generator Unit Components”.

• Adjust belt tension referring to “Water Pump / Generator Drive Belt Tension Inspection and

Adjustment”.

(a)

(b)

(c)

1

2 8

3 7 5 49 6(c)

(c)

I6RS0C1A0003-02

1. “B” terminal nut

5. Generator pivot bolt : 5 N⋅m (0.5 kgf-m, 3.5 lb-ft)

2. “B” terminal wire 6. Generator belt : 50 N⋅m (5.0 kgf-m, 36.0 lb-ft)

3. Connector 7. Generator : 25 N⋅m (2.5 kgf-m, 18.5 lb-ft)

4. Generator adjusting bolt 8. Generator bracket bolt

Page 424 of 1496

Downloaded from www.Manualslib.com manuals search engine 1K-1 Exhaust System:

Engine

Exhaust System

General Description

Exhaust System DescriptionS7RS0B1B01001

The exhaust system consists of an exhaust manifold, three-way catalytic converter (TWC) in catalyst case, exhaust

pipes, a muffler and seals, gasket and etc.

The three-way catalytic converter is an emission control device added to the exhaust system to lower the levels of

Hydrocarbon (HC), Carbon Monoxide (CO), and Oxides of Nitrogen (NOx) pollutants in the exhaust gas.

Diagnostic Information and Procedures

Exhaust System CheckS7RS0B1B04001

WARNING!

To avoid the danger of being burned, do not touch the exhaust system when the system is hot. Any

service on the exhaust system should be performed when the system is cool.

At every interval of periodic maintenance service, and when vehicle is raised for other service, check exhaust system

as follows:

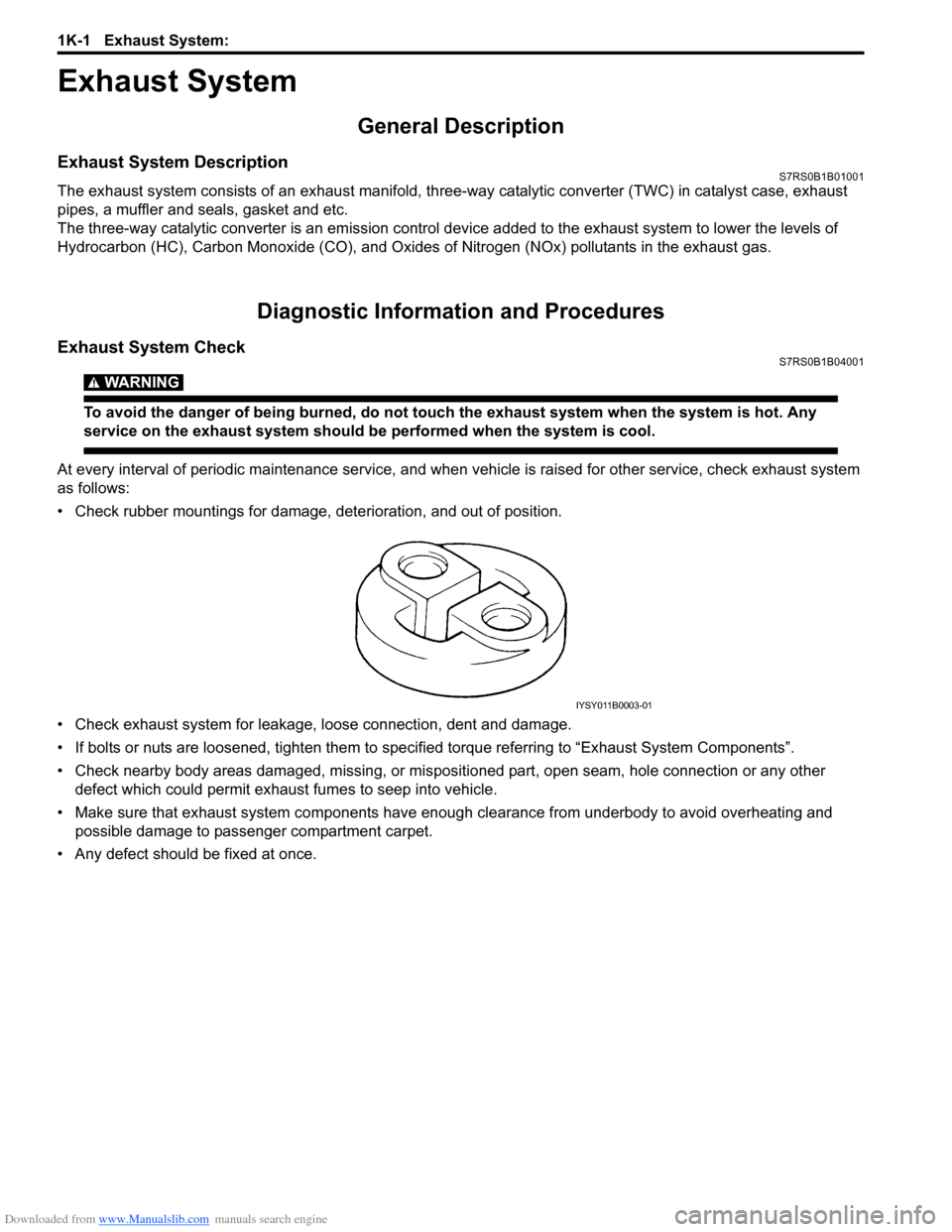

• Check rubber mountings for damage, deterioration, and out of position.

• Check exhaust system for leakage, loose connection, dent and damage.

• If bolts or nuts are loosened, tighten them to specified torque referring to “Exhaust System Components”.

• Check nearby body areas damaged, missing, or mispositio ned part, open seam, hole connection or any other

defect which could permit exhaust fumes to seep into vehicle.

• Make sure that exhaust system components have enough clearance from underbody to avoid overheating and

possible damage to passenger compartment carpet.

• Any defect should be fixed at once.

IYSY011B0003-01

Page 425 of 1496

Downloaded from www.Manualslib.com manuals search engine Exhaust System: 1K-2

Repair Instructions

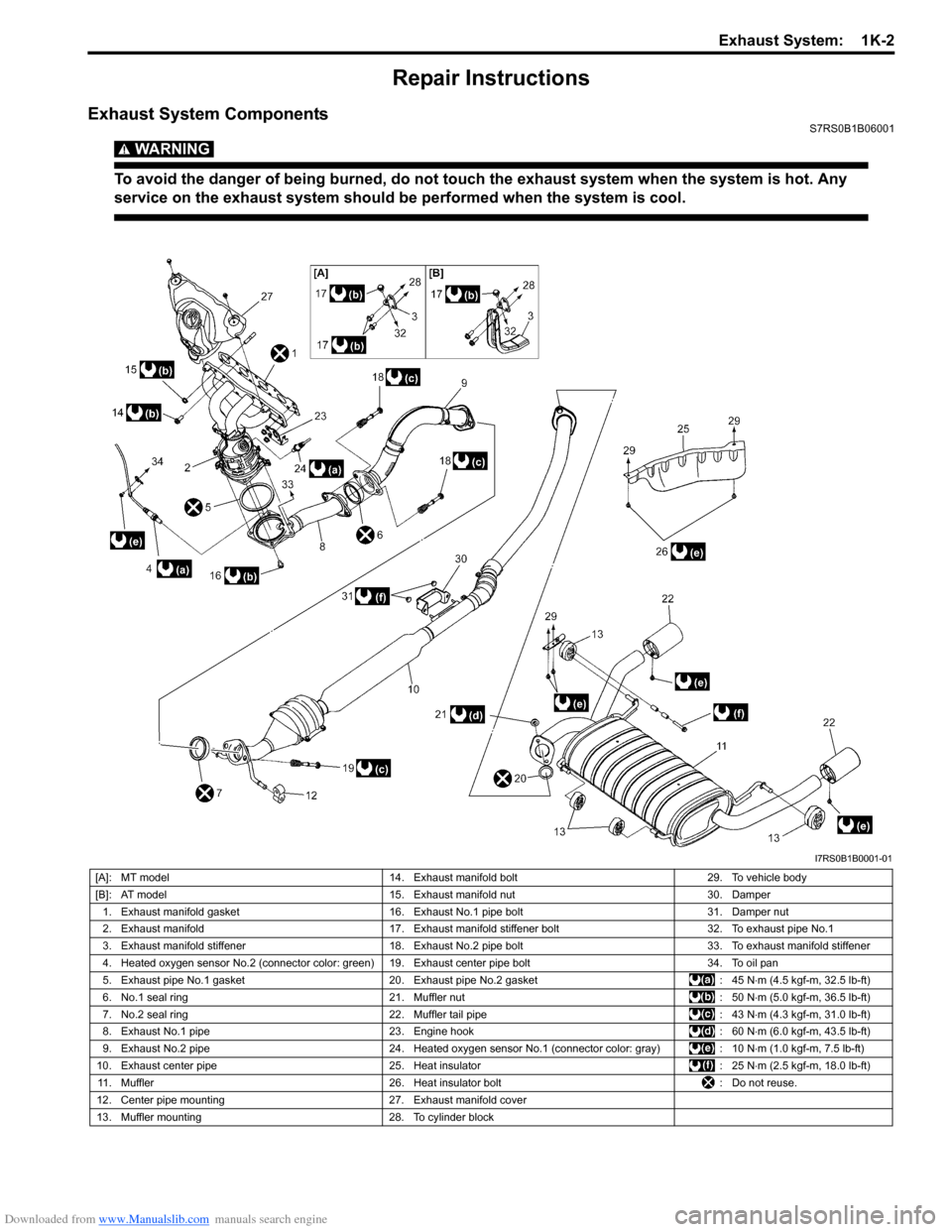

Exhaust System ComponentsS7RS0B1B06001

WARNING!

To avoid the danger of being burned, do not touch the exhaust system when the system is hot. Any

service on the exhaust system should be performed when the system is cool.

I7RS0B1B0001-01

[A]: MT model14. Exhaust manifold bolt 29. To vehicle body

[B]: AT model 15. Exhaust manifold nut 30. Damper

1. Exhaust manifold gasket 16. Exhaust No.1 pipe bolt 31. Damper nut

2. Exhaust manifold 17. Exhaust manifold stiffener bolt 32. To exhaust pipe No.1

3. Exhaust manifold stiffener 18. Exhaust No.2 pipe bolt 33. To exhaust manifold stiffener

4. Heated oxygen sensor No.2 (connector color: green) 19. Exhaust center pipe bolt 34. To oil pan

5. Exhaust pipe No.1 gasket 20. Exhaust pipe No.2 gasket : 45 N⋅m (4.5 kgf-m, 32.5 lb-ft)

6. No.1 seal ring 21. Muffler nut : 50 N⋅m (5.0 kgf-m, 36.5 lb-ft)

7. No.2 seal ring 22. Muffler tail pipe : 43 N⋅m (4.3 kgf-m, 31.0 lb-ft)

8. Exhaust No.1 pipe 23. Engine hook : 60 N⋅m (6.0 kgf-m, 43.5 lb-ft)

9. Exhaust No.2 pipe 24. Heated oxygen sensor No.1 (connector color: gray) : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

10. Exhaust center pipe 25. Heat insulator : 25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

11. Muffler 26. Heat insulator bolt : Do not reuse.

12. Center pipe mounting 27. Exhaust manifold cover

13. Muffler mounting 28. To cylinder block

Page 430 of 1496

Downloaded from www.Manualslib.com manuals search engine 2-ii Table of Contents

Balancing Wheels Description ............................ 2D-5

Repair Instructions ..............................................2D-6 General Balance Procedures ..............................2D-6

Tire Rotation........................................................2D-6

Wheel Removal and Installation..........................2D-7

Tire Mounting and Dismounting ..........................2D-8 Tire Repair ..........................................................2D-8

Tire Repair for Emergency Repaired-Tire with

Sealant ..............................................................2D-8

Specifications ..................... ..................................2D-9

Wheels and Tires Specifications .........................2D-9

Tightening Torque Specifications ........................2D-9

Page 432 of 1496

Downloaded from www.Manualslib.com manuals search engine 2A-1 Suspension General Diagnosis:

Suspension

Suspension General Diagnosis

Diagnostic Information and Procedures

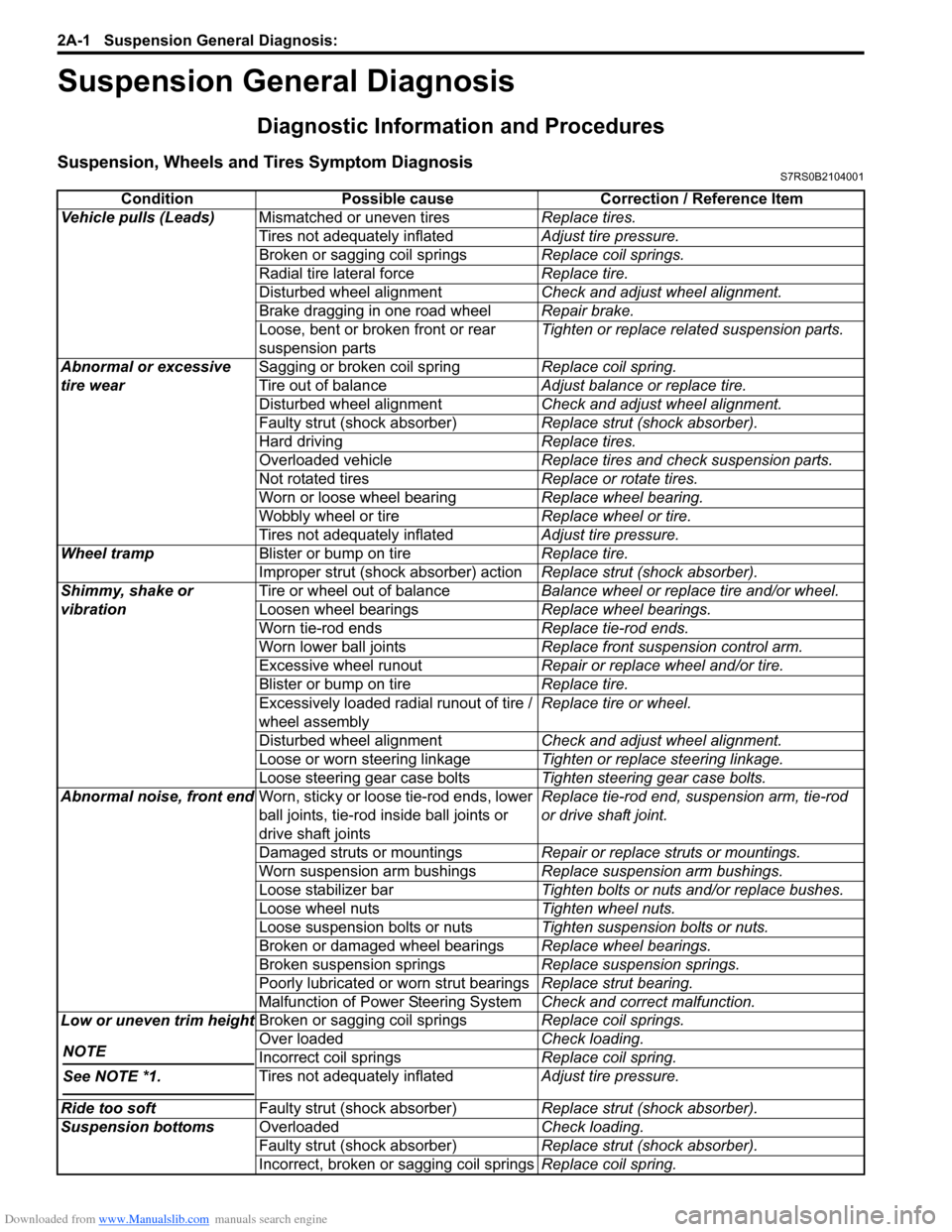

Suspension, Wheels and Tires Symptom DiagnosisS7RS0B2104001

ConditionPossible cause Correction / Reference Item

Vehicle pulls (Leads) Mismatched or uneven tires Replace tires.

Tires not adequately inflated Adjust tire pressure.

Broken or sagging coil springs Replace coil springs.

Radial tire lateral force Replace tire.

Disturbed wheel alignment Check and adjust wheel alignment.

Brake dragging in one road wheel Repair brake.

Loose, bent or broken front or rear

suspension parts Tighten or replace related suspension parts.

Abnormal or excessive

tire wear Sagging or broken coil spring

Replace coil spring.

Tire out of balance Adjust balance or replace tire.

Disturbed wheel alignment Check and adjust wheel alignment.

Faulty strut (shock absorber) Replace strut (shock absorber).

Hard driving Replace tires.

Overloaded vehicle Replace tires and check suspension parts.

Not rotated tires Replace or rotate tires.

Worn or loose wheel bearing Replace wheel bearing.

Wobbly wheel or tire Replace wheel or tire.

Tires not adequately inflated Adjust tire pressure.

Wheel tramp Blister or bump on tire Replace tire.

Improper strut (shock absorber) action Replace strut (shock absorber).

Shimmy, shake or

vibration Tire or wheel out of balance

Balance wheel or replace tire and/or wheel.

Loosen wheel bearings Replace wheel bearings.

Worn tie-rod ends Replace tie-rod ends.

Worn lower ball joints Replace front suspension control arm.

Excessive wheel runout Repair or replace wheel and/or tire.

Blister or bump on tire Replace tire.

Excessively loaded radial runout of tire /

wheel assembly Replace tire or wheel.

Disturbed wheel alignment Check and adjust wheel alignment.

Loose or worn steering linkage Tighten or replace steering linkage.

Loose steering gear case bolts Tighten steering gear case bolts.

Abnormal noise, front end Worn, sticky or loose tie-rod ends, lower

ball joints, tie-rod in side ball joints or

drive shaft joints Replace tie-rod end, su

spension arm, tie-rod

or drive shaft joint.

Damaged struts or mountings Repair or replace struts or mountings.

Worn suspension arm bushings Replace suspension arm bushings.

Loose stabilizer bar Tighten bolts or nuts and/or replace bushes.

Loose wheel nuts Tighten wheel nuts.

Loose suspension bolts or nuts Tighten suspension bolts or nuts.

Broken or damaged wheel bearings Replace wheel bearings.

Broken suspension springs Replace suspension springs.

Poorly lubricated or worn strut bearings Replace strut bearing.

Malfunction of Power Steering System Check and correct malfunction.

Low or uneven trim height

NOTE

See NOTE *1.

Broken or sagging coil springs Replace coil springs.

Over loaded Check loading.

Incorrect coil springs Replace coil spring.

Tires not adequately inflated Adjust tire pressure.

Ride too soft Faulty strut (shock absorber) Replace strut (shock absorber).

Suspension bottoms Overloaded Check loading.

Faulty strut (shock absorber) Replace strut (shock absorber).

Incorrect, broken or sagging coil springs Replace coil spring.

Page 433 of 1496

Downloaded from www.Manualslib.com manuals search engine Suspension General Diagnosis: 2A-2

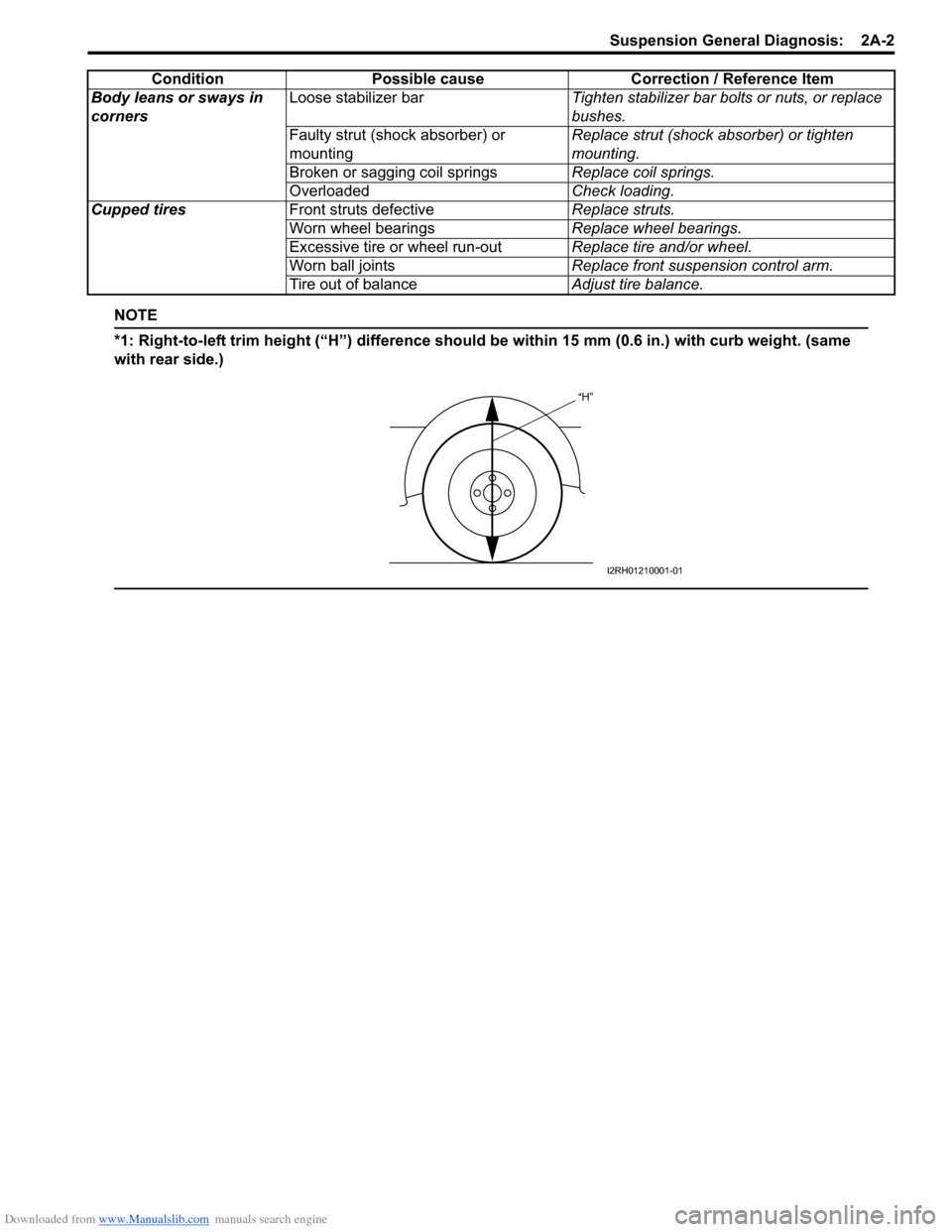

NOTE

*1: Right-to-left trim height (“H”) difference should be within 15 mm (0.6 in.) with curb weight. (same

with rear side.)

Body leans or sways in

corners Loose stabilizer bar

Tighten stabilizer bar bolts or nuts, or replace

bushes.

Faulty strut (shock absorber) or

mounting Replace strut (shock absorber) or tighten

mounting.

Broken or sagging coil springs Replace coil springs.

Overloaded Check loading.

Cupped tires Front struts defective Replace struts.

Worn wheel bearings Replace wheel bearings.

Excessive tire or wheel run-out Replace tire and/or wheel.

Worn ball joints Replace front suspension control arm.

Tire out of balance Adjust tire balance.

Condition Possible cause Correction / Reference Item

“H”

I2RH01210001-01

Page 436 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-3 Front Suspension:

Adjustment1) Loosen right and left tie-rod end lock nuts (1) first.

2) Rotate right and left tie-rods (2) by the same amount to align toe to specification. In this adjustment, the

lengths “A” of both right and left tie-rod should be

equal.

NOTE

Before rotating tie-rods (2), apply grease

between tie-rods and rack boots so that

boots won’t be twisted.

3) After adjustment, tighten lock nuts (1) to specified torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5 lb-

ft)

NOTE

Make sure that rack boots are not twisted.

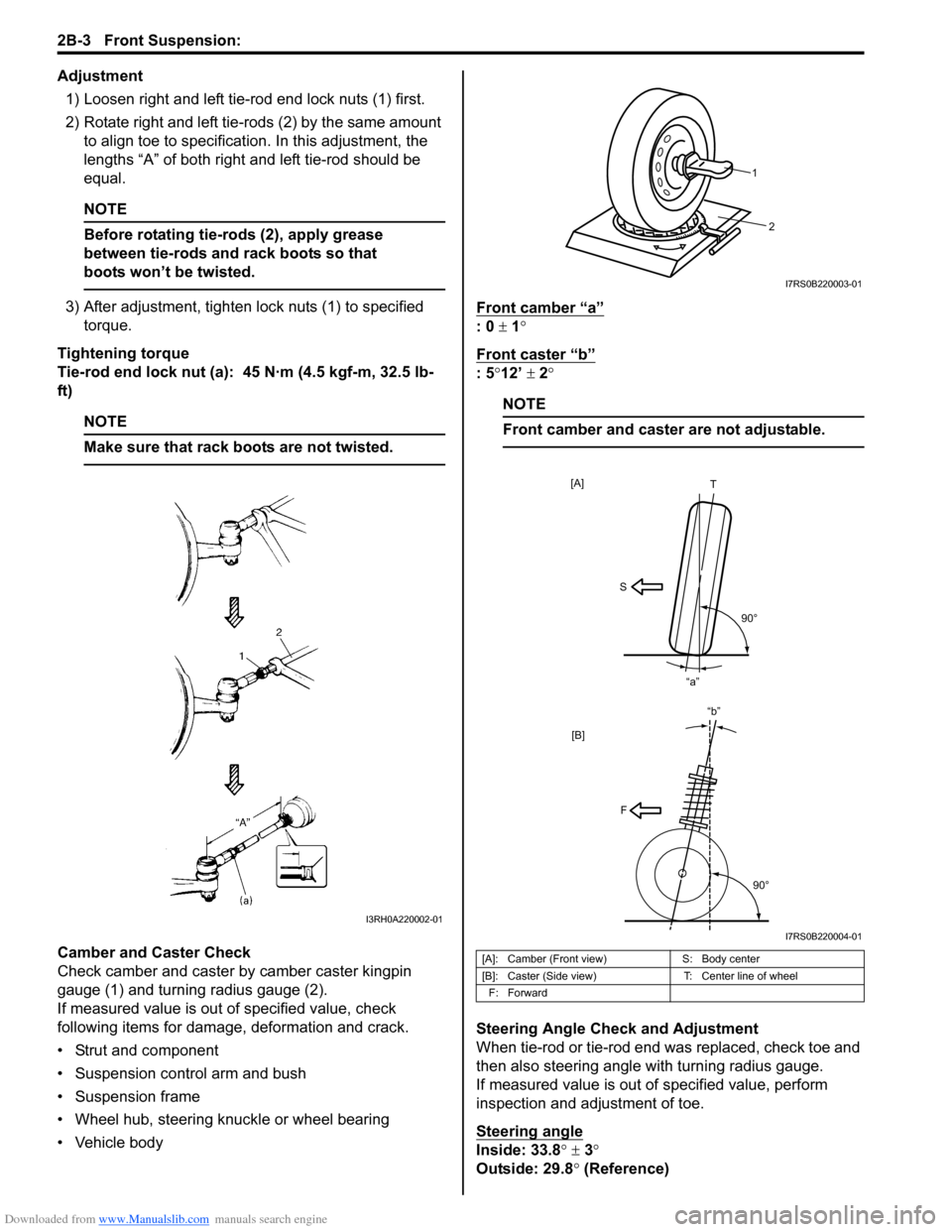

Camber and Caster Check

Check camber and caster by camber caster kingpin

gauge (1) and turning radius gauge (2).

If measured value is out of specified value, check

following items for damage, deformation and crack.

• Strut and component

• Suspension control arm and bush

• Suspension frame

• Wheel hub, steering knuckle or wheel bearing

• Vehicle body Front camber “a”

: 0

± 1°

Front caster “b”

: 5 °12’ ± 2°

NOTE

Front camber and caster are not adjustable.

Steering Angle Check and Adjustment

When tie-rod or tie-rod end was replaced, check toe and

then also steering angle with turning radius gauge.

If measured value is out of specified value, perform

inspection and adjustment of toe.

Steering angle

Inside: 33.8 ° ± 3 °

Outside: 29.8 ° (Reference)

I3RH0A220002-01

[A]: Camber (Front view) S: Body center

[B]: Caster (Side view) T: Center line of wheel

F: Forward

2

1

I7RS0B220003-01

[B]

S T

90°

“a”

[A]

F

90°

“b”

I7RS0B220004-01