MOUNT SUZUKI SWIFT 2008 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 438 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-5 Front Suspension:

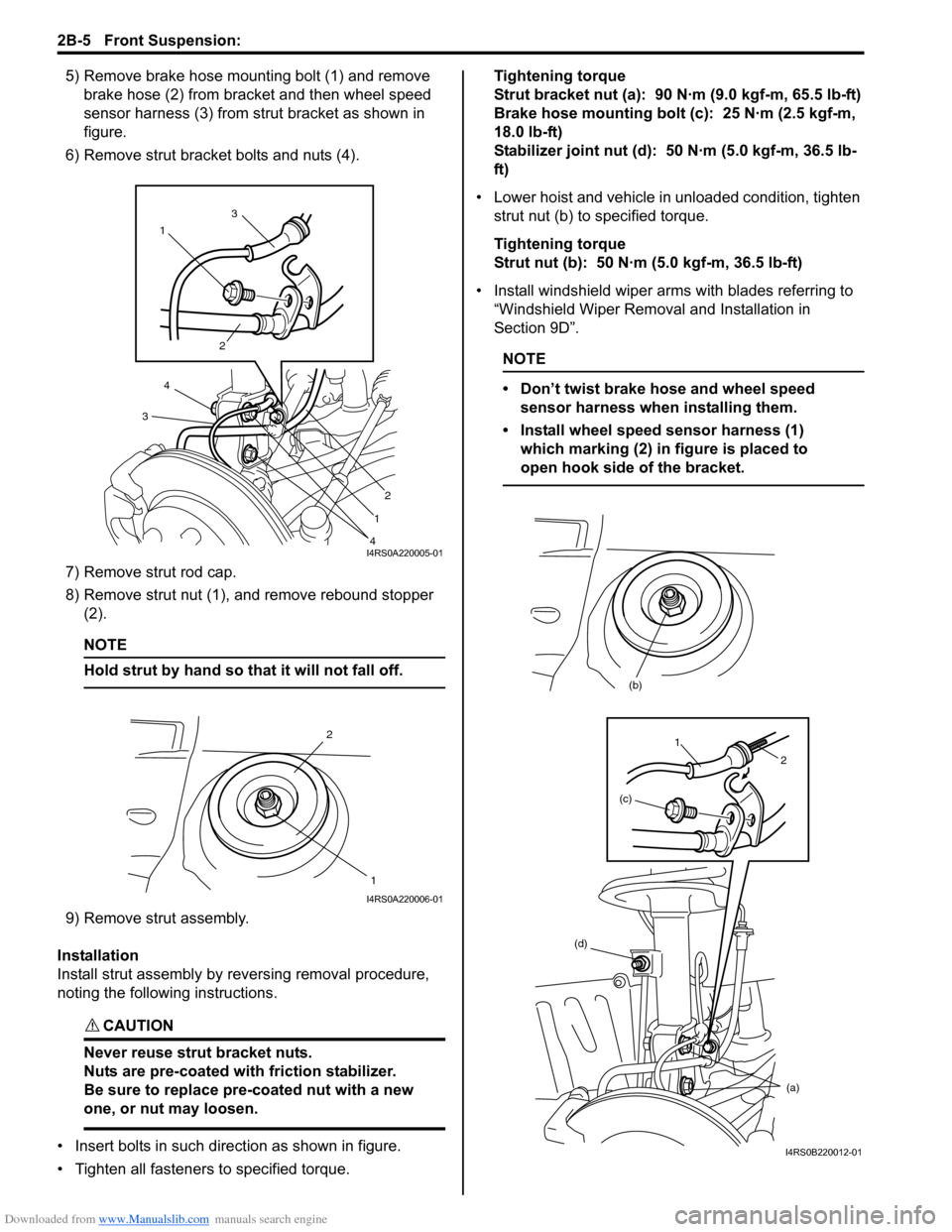

5) Remove brake hose mounting bolt (1) and remove brake hose (2) from bracket and then wheel speed

sensor harness (3) from strut bracket as shown in

figure.

6) Remove strut bracket bolts and nuts (4).

7) Remove strut rod cap.

8) Remove strut nut (1), and remove rebound stopper (2).

NOTE

Hold strut by hand so th at it will not fall off.

9) Remove strut assembly.

Installation

Install strut assembly by reversing removal procedure,

noting the following instructions.

CAUTION!

Never reuse strut bracket nuts.

Nuts are pre-coated with friction stabilizer.

Be sure to replace pre-coated nut with a new

one, or nut may loosen.

• Insert bolts in such direction as shown in figure.

• Tighten all fasteners to specified torque. Tightening torque

Strut bracket nut (a): 90 N·m (9.0 kgf-m, 65.5 lb-ft)

Brake hose mounting bolt (c): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

Stabilizer joint nut (d): 50 N·m (5.0 kgf-m, 36.5 lb-

ft)

• Lower hoist and vehicle in unloaded condition, tighten strut nut (b) to specified torque.

Tightening torque

Strut nut (b): 50 N·m (5.0 kgf-m, 36.5 lb-ft)

• Install windshield wiper arms with blades referring to

“Windshield Wiper Removal and Installation in

Section 9D”.

NOTE

• Don’t twist brake hose and wheel speed sensor harness when installing them.

• Install wheel speed sensor harness (1) which marking (2) in figure is placed to

open hook side of the bracket.

1 3

2

2

1

4

4

3

I4RS0A220005-01

2

1

I4RS0A220006-01

(d) (a)

(b)

(c)

1

2

I4RS0B220012-01

Page 440 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-7 Front Suspension:

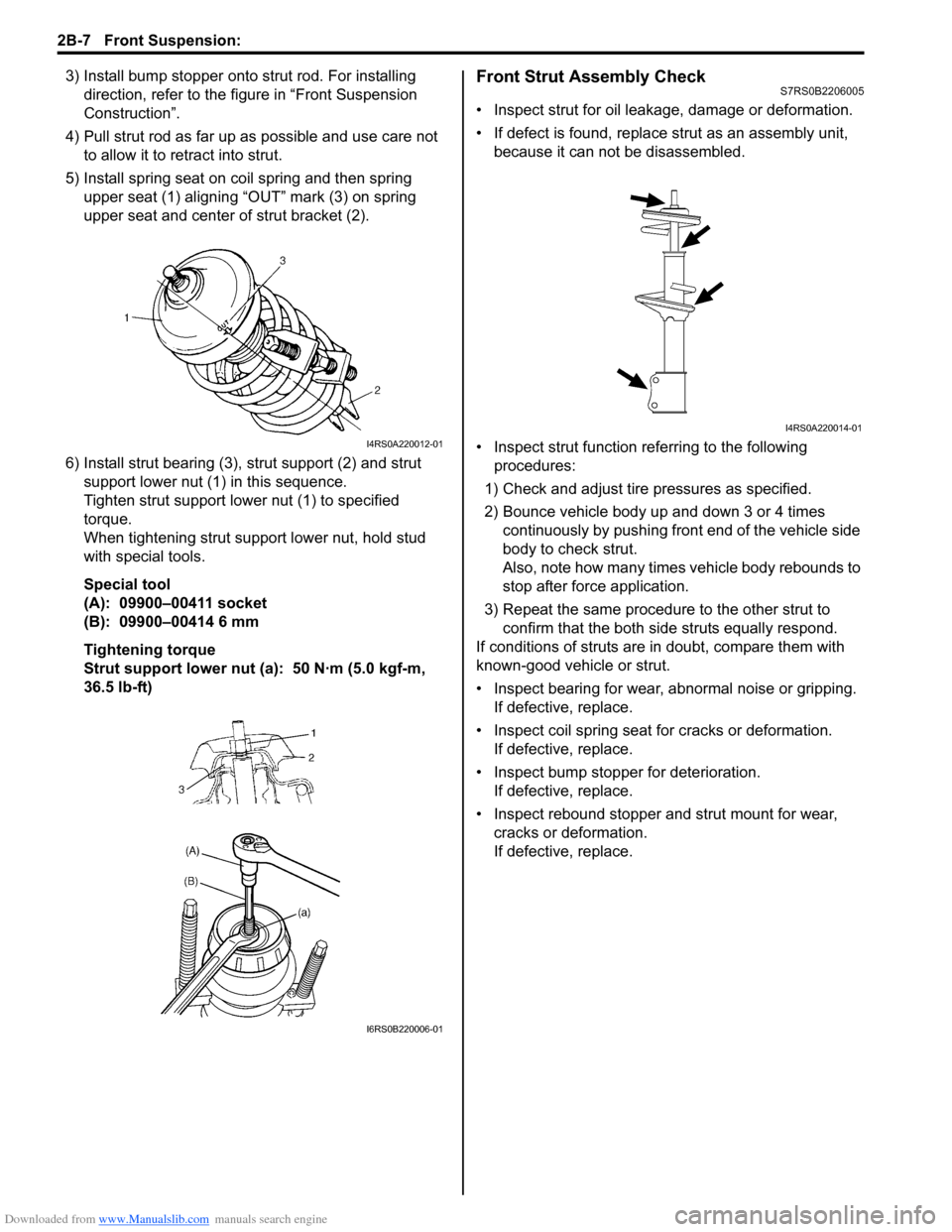

3) Install bump stopper onto strut rod. For installing

direction, refer to the figure in “Front Suspension

Construction”.

4) Pull strut rod as far up as possible and use care not to allow it to re tract into strut.

5) Install spring seat on coil spring and then spring upper seat (1) aligning “OUT” mark (3) on spring

upper seat and center of strut bracket (2).

6) Install strut bearing (3), strut support (2) and strut

support lower nut (1) in this sequence.

Tighten strut support lower nut (1) to specified

torque.

When tightening strut support lower nut, hold stud

with special tools.

Special tool

(A): 09900–00411 socket

(B): 09900–00414 6 mm

Tightening torque

Strut support lower nut (a): 50 N·m (5.0 kgf-m,

36.5 lb-ft)Front Strut Assembly CheckS7RS0B2206005

• Inspect strut for oil leakage, damage or deformation.

• If defect is found, replace strut as an assembly unit, because it can not be disassembled.

• Inspect strut function re ferring to the following

procedures:

1) Check and adjust tire pressures as specified.

2) Bounce vehicle body up and down 3 or 4 times continuously by pushing front end of the vehicle side

body to check strut.

Also, note how many times vehicle body rebounds to

stop after force application.

3) Repeat the same procedure to the other strut to confirm that the both side struts equally respond.

If conditions of struts are in doubt, compare them with

known-good vehicle or strut.

• Inspect bearing for wear, abnormal noise or gripping. If defective, replace.

• Inspect coil spring seat for cracks or deformation.

If defective, replace.

• Inspect bump stopper for deterioration. If defective, replace.

• Inspect rebound stopper and strut mount for wear, cracks or deformation.

If defective, replace.

I4RS0A220012-01

I6RS0B220006-01

I4RS0A220014-01

Page 444 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-11 Front Suspension:

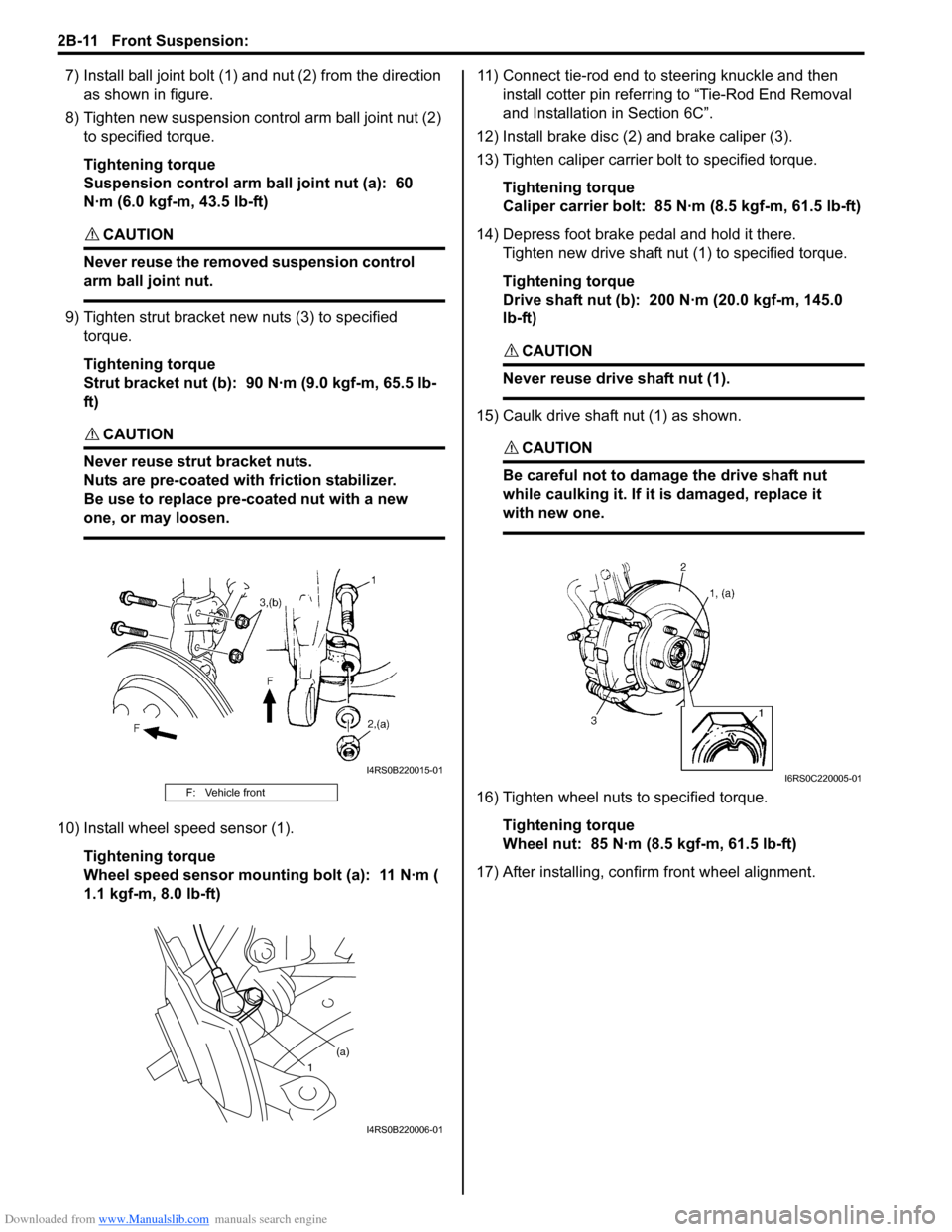

7) Install ball joint bolt (1) and nut (2) from the direction

as shown in figure.

8) Tighten new suspension co ntrol arm ball joint nut (2)

to specified torque.

Tightening torque

Suspension control arm ball joint nut (a): 60

N·m (6.0 kgf-m, 43.5 lb-ft)

CAUTION!

Never reuse the removed suspension control

arm ball joint nut.

9) Tighten strut bracket new nuts (3) to specified torque.

Tightening torque

Strut bracket nut (b): 90 N·m (9.0 kgf-m, 65.5 lb-

ft)

CAUTION!

Never reuse strut bracket nuts.

Nuts are pre-coated with friction stabilizer.

Be use to replace pre-coated nut with a new

one, or may loosen.

10) Install wheel speed sensor (1).

Tightening torque

Wheel speed sensor mounting bolt (a): 11 N·m (

1.1 kgf-m, 8.0 lb-ft) 11) Connect tie-rod end to steering knuckle and then

install cotter pin referrin g to “Tie-Rod End Removal

and Installation in Section 6C”.

12) Install brake disc (2) and brake caliper (3).

13) Tighten caliper carrier bolt to specified torque.

Tightening torque

Caliper carrier bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

14) Depress foot brake pedal and hold it there. Tighten new drive shaft nut (1) to specified torque.

Tightening torque

Drive shaft nut (b): 200 N·m (20.0 kgf-m, 145.0

lb-ft)

CAUTION!

Never reuse drive shaft nut (1).

15) Caulk drive shaft nut (1) as shown.

CAUTION!

Be careful not to damage the drive shaft nut

while caulking it. If it is damaged, replace it

with new one.

16) Tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

17) After installing, confirm front wheel alignment.F: Vehicle front

I4RS0B220015-01

1 (a)

I4RS0B220006-01

I6RS0C220005-01

Page 446 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-13 Front Suspension:

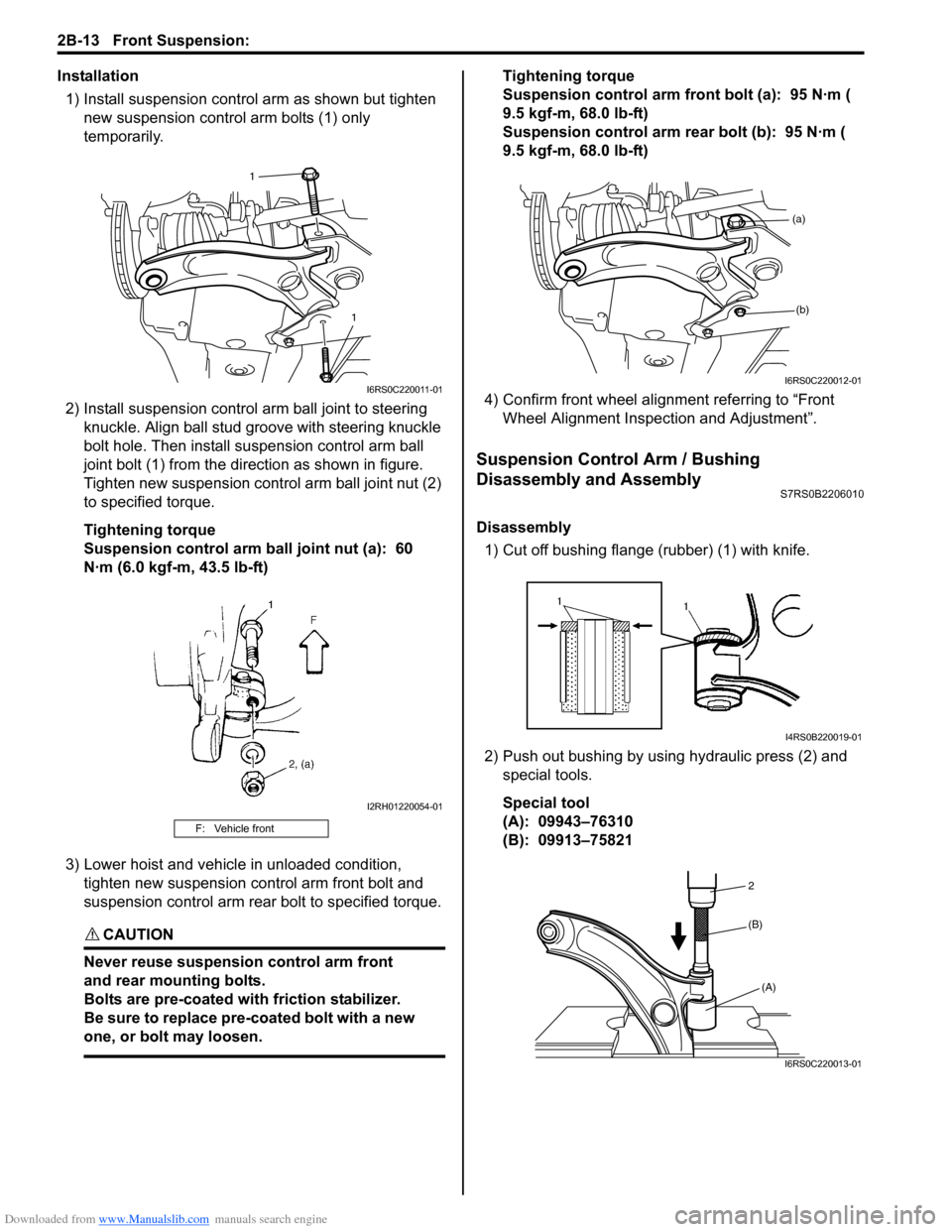

Installation1) Install suspension control arm as shown but tighten new suspension contro l arm bolts (1) only

temporarily.

2) Install suspensi on control arm ball joint to steering

knuckle. Align ball stud gr oove with steering knuckle

bolt hole. Then install su spension control arm ball

joint bolt (1) from the direction as shown in figure.

Tighten new suspension cont rol arm ball joint nut (2)

to specified torque.

Tightening torque

Suspension control arm ball joint nut (a): 60

N·m (6.0 kgf-m, 43.5 lb-ft)

3) Lower hoist and vehicle in unloaded condition, tighten new suspension control arm front bolt and

suspension control arm rear bolt to specified torque.

CAUTION!

Never reuse suspension control arm front

and rear mounting bolts.

Bolts are pre-coated with friction stabilizer.

Be sure to replace pre-coated bolt with a new

one, or bolt may loosen.

Tightening torque

Suspension control arm front bolt (a): 95 N·m (

9.5 kgf-m, 68.0 lb-ft)

Suspension control arm re ar bolt (b): 95 N·m (

9.5 kgf-m, 68.0 lb-ft)

4) Confirm front wheel alignment referring to “Front Wheel Alignment Inspection and Adjustment”.

Suspension Control Arm / Bushing

Disassembly and Assembly

S7RS0B2206010

Disassembly

1) Cut off bushing flange (rubber) (1) with knife.

2) Push out bushing by using hydraulic press (2) and special tools.

Special tool

(A): 09943–76310

(B): 09913–75821

F: Vehicle front

1

1

I6RS0C220011-01

I2RH01220054-01

(a)(b)

I6RS0C220012-01

I4RS0B220019-01

2

(A)

(B)

I6RS0C220013-01

Page 448 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-15 Front Suspension:

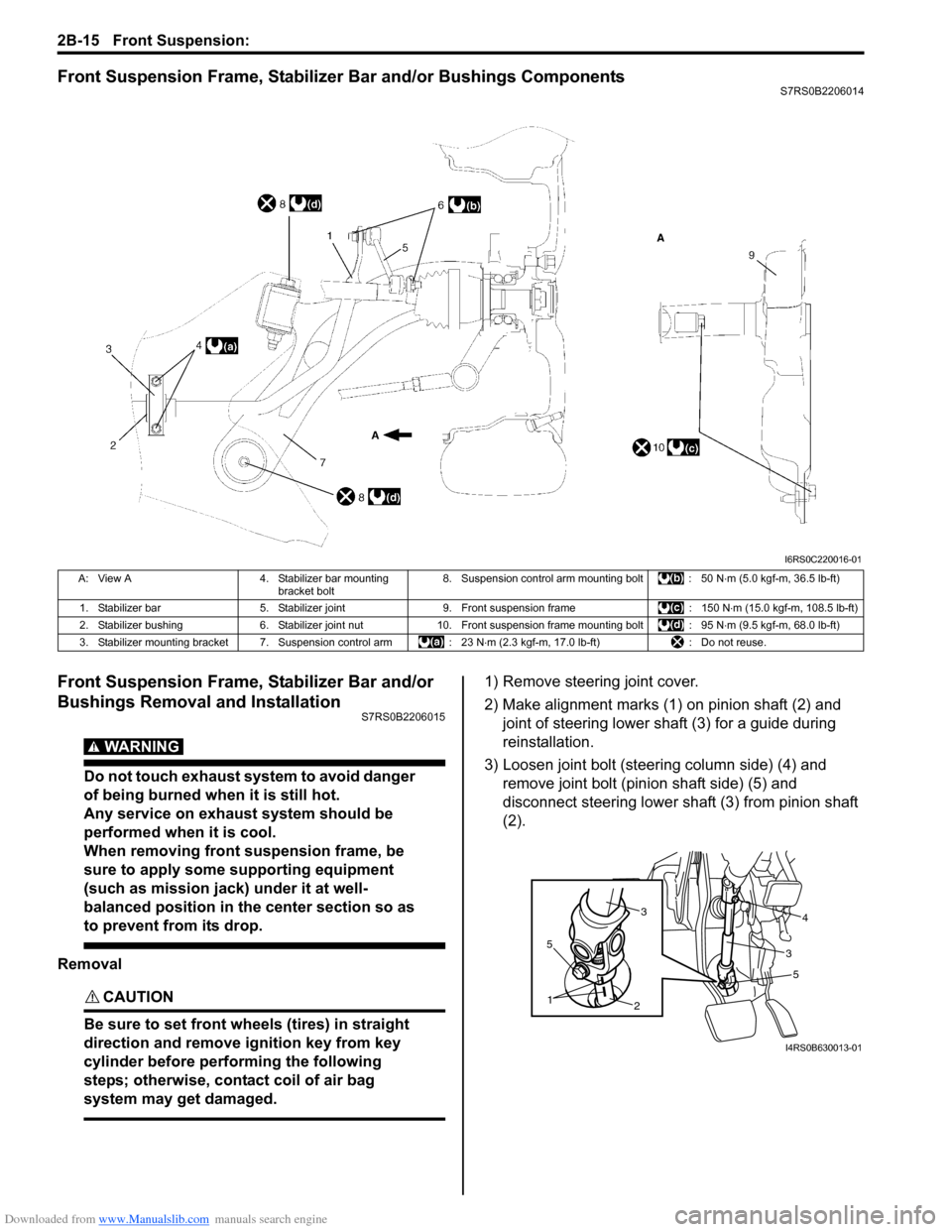

Front Suspension Frame, Stabilizer Bar and/or Bushings ComponentsS7RS0B2206014

Front Suspension Frame, Stabilizer Bar and/or

Bushings Removal and Installation

S7RS0B2206015

WARNING!

Do not touch exhaust system to avoid danger

of being burned when it is still hot.

Any service on exhaust system should be

performed when it is cool.

When removing front suspension frame, be

sure to apply some supporting equipment

(such as mission jack) under it at well-

balanced position in the center section so as

to prevent from its drop.

Removal

CAUTION!

Be sure to set front wheels (tires) in straight

direction and remove ignition key from key

cylinder before performing the following

steps; otherwise, contact coil of air bag

system may get damaged.

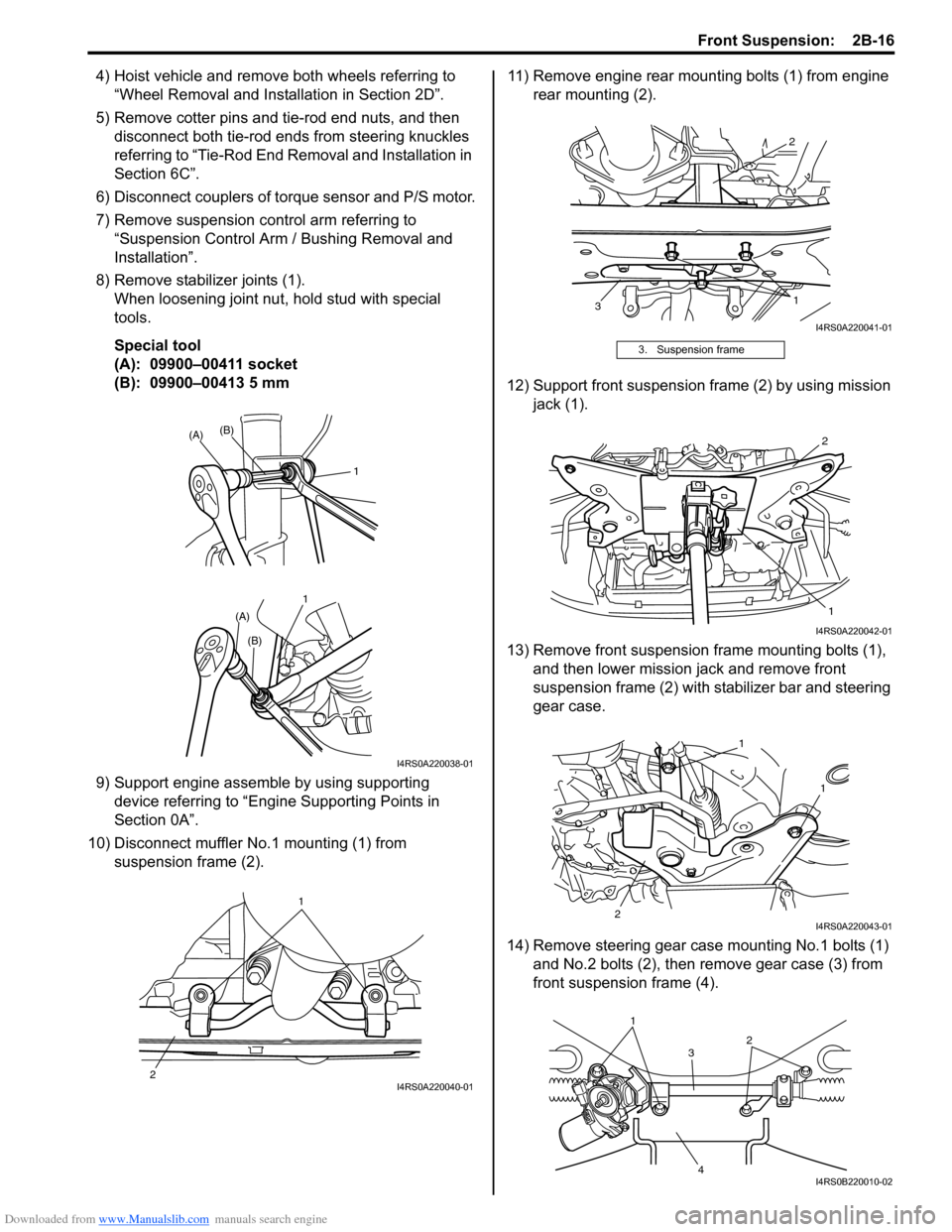

1) Remove steering joint cover.

2) Make alignment marks (1) on pinion shaft (2) and joint of steering lower shaft (3) for a guide during

reinstallation.

3) Loosen joint bolt (steering column side) (4) and remove joint bolt (pin ion shaft side) (5) and

disconnect steering lower shaft (3) from pinion shaft

(2).

I6RS0C220016-01

A: View A 4. Stabilizer bar mounting

bracket bolt 8. Suspension control arm mounting bolt : 50 N

⋅m (5.0 kgf-m, 36.5 lb-ft)

1. Stabilizer bar 5. Stabilizer joint 9. Front suspension frame : 150 N⋅m (15.0 kgf-m, 108.5 lb-ft)

2. Stabilizer bushing 6. Stabilizer joint nut10. Front suspension frame mounting bolt : 95 N ⋅m (9.5 kgf-m, 68.0 lb-ft)

3. Stabilizer mounting bracket 7. Suspension control arm : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft) : Do not reuse.

5

2

1

5

34

3

I4RS0B630013-01

Page 449 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-16

4) Hoist vehicle and remove both wheels referring to “Wheel Removal and Installation in Section 2D”.

5) Remove cotter pins and tie-rod end nuts, and then disconnect both tie-rod ends from steering knuckles

referring to “Tie-Rod End Re moval and Installation in

Section 6C”.

6) Disconnect couplers of torque sensor and P/S motor.

7) Remove suspension control arm referring to “Suspension Control Arm / Bushing Removal and

Installation”.

8) Remove stabilizer joints (1). When loosening joint nu t, hold stud with special

tools.

Special tool

(A): 09900–00411 socket

(B): 09900–00413 5 mm

9) Support engine assemble by using supporting device referring to “Engine Supporting Points in

Section 0A”.

10) Disconnect muffler No.1 mounting (1) from suspension frame (2). 11) Remove engine rear mounting bolts (1) from engine

rear mounting (2).

12) Support front suspension frame (2) by using mission jack (1).

13) Remove front suspension frame mounting bolts (1), and then lower mission jack and remove front

suspension frame (2) with st abilizer bar and steering

gear case.

14) Remove steering gear case mounting No.1 bolts (1) and No.2 bolts (2), then remove gear case (3) from

front suspensio n frame (4).

11

(A)

(A)

(B)

(B)

I4RS0A220038-01

1

2

I4RS0A220040-01

3. Suspension frame

2

3 1

I4RS0A220041-01

2

1

I4RS0A220042-01

1

2 1

I4RS0A220043-01

1

3

4 2

I4RS0B220010-02

Page 450 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-17 Front Suspension:

15) Remove stabilizer bar (1) and bushing from front

suspension frame (2).

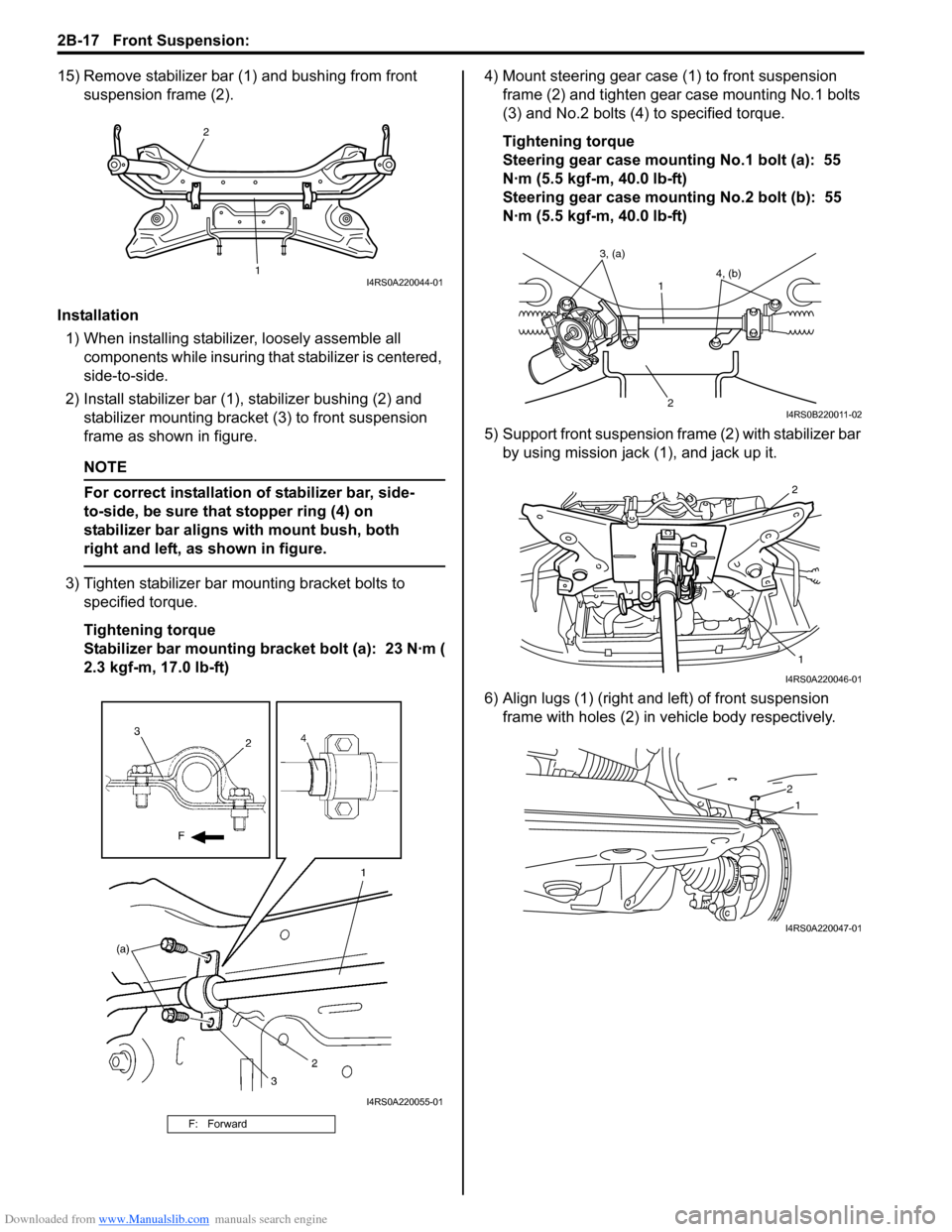

Installation 1) When installing stabilizer, loosely assemble all components while insuring that stabilizer is centered,

side-to-side.

2) Install stabilizer bar (1), stabilizer bushing (2) and

stabilizer mounting bracket (3) to front suspension

frame as shown in figure.

NOTE

For correct installation of stabilizer bar, side-

to-side, be sure that stopper ring (4) on

stabilizer bar aligns with mount bush, both

right and left, as shown in figure.

3) Tighten stabilizer bar mounting bracket bolts to specified torque.

Tightening torque

Stabilizer bar mounting bracket bolt (a): 23 N·m (

2.3 kgf-m, 17.0 lb-ft) 4) Mount steering gear case

(1) to front suspension

frame (2) and tighten gear case mounting No.1 bolts

(3) and No.2 bolts (4) to specified torque.

Tightening torque

Steering gear case mounting No.1 bolt (a): 55

N·m (5.5 kgf-m, 40.0 lb-ft)

Steering gear case mounting No.2 bolt (b): 55

N·m (5.5 kgf-m, 40.0 lb-ft)

5) Support front suspension frame (2) with stabilizer bar by using mission jack (1), and jack up it.

6) Align lugs (1) (right and left) of front suspension frame with holes (2) in vehicle body respectively.

F: Forward

1

2I4RS0A220044-01

I4RS0A220055-01

3, (a)

1

2 4, (b)

I4RS0B220011-02

2

1

I4RS0A220046-01

1

2

I4RS0A220047-01

Page 451 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-18

7) Tighten front suspension frame mounting bolts (a) to specified torque.

Tightening torque

Front suspension frame mounting bolt (a): 150

N·m (15.0 kgf-m, 108.5 lb-ft)

8) Lower mission jack.

9) Tighten engine rear mounting bolts (a) to specified torque.

Tightening torque

Engine rear mounting bolt (a): 55 N·m (5.5 kgf-

m, 40.0 lb-ft)

10) Connect muffler No.1 mounting (1) to front suspension frame (2). 11) Remove supporting device from engine.

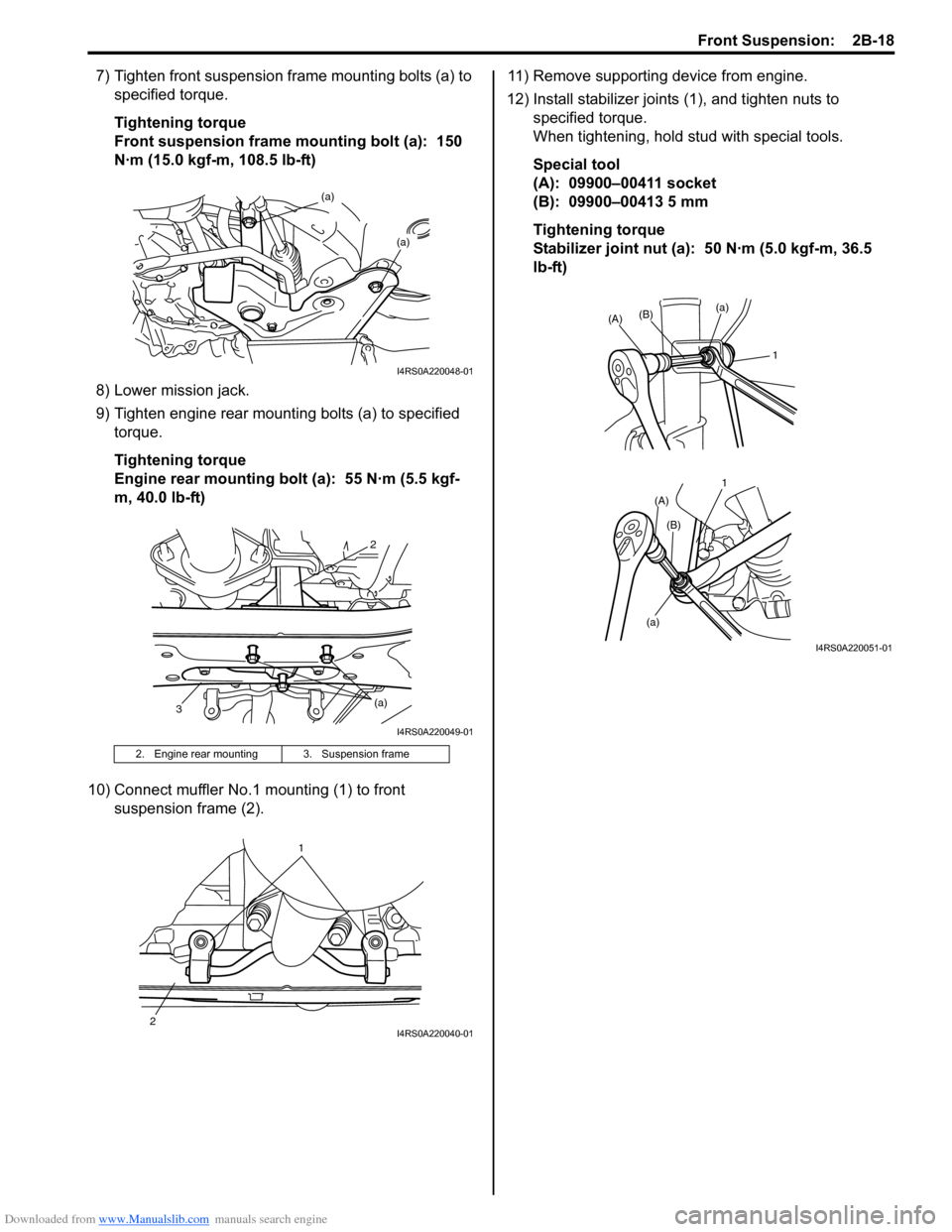

12) Install stabilizer joints (1), and tighten nuts to

specified torque.

When tightening, hold stud with special tools.

Special tool

(A): 09900–00411 socket

(B): 09900–00413 5 mm

Tightening torque

Stabilizer joint nut (a): 50 N·m (5.0 kgf-m, 36.5

lb-ft)

2. Engine rear mounting 3. Suspension frame

(a)

(a)

I4RS0A220048-01

2

3 (a)

I4RS0A220049-01

1

2

I4RS0A220040-01

1 1

(A)

(A)

(a) (a)

(B)

(B)

I4RS0A220051-01

Page 453 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-20

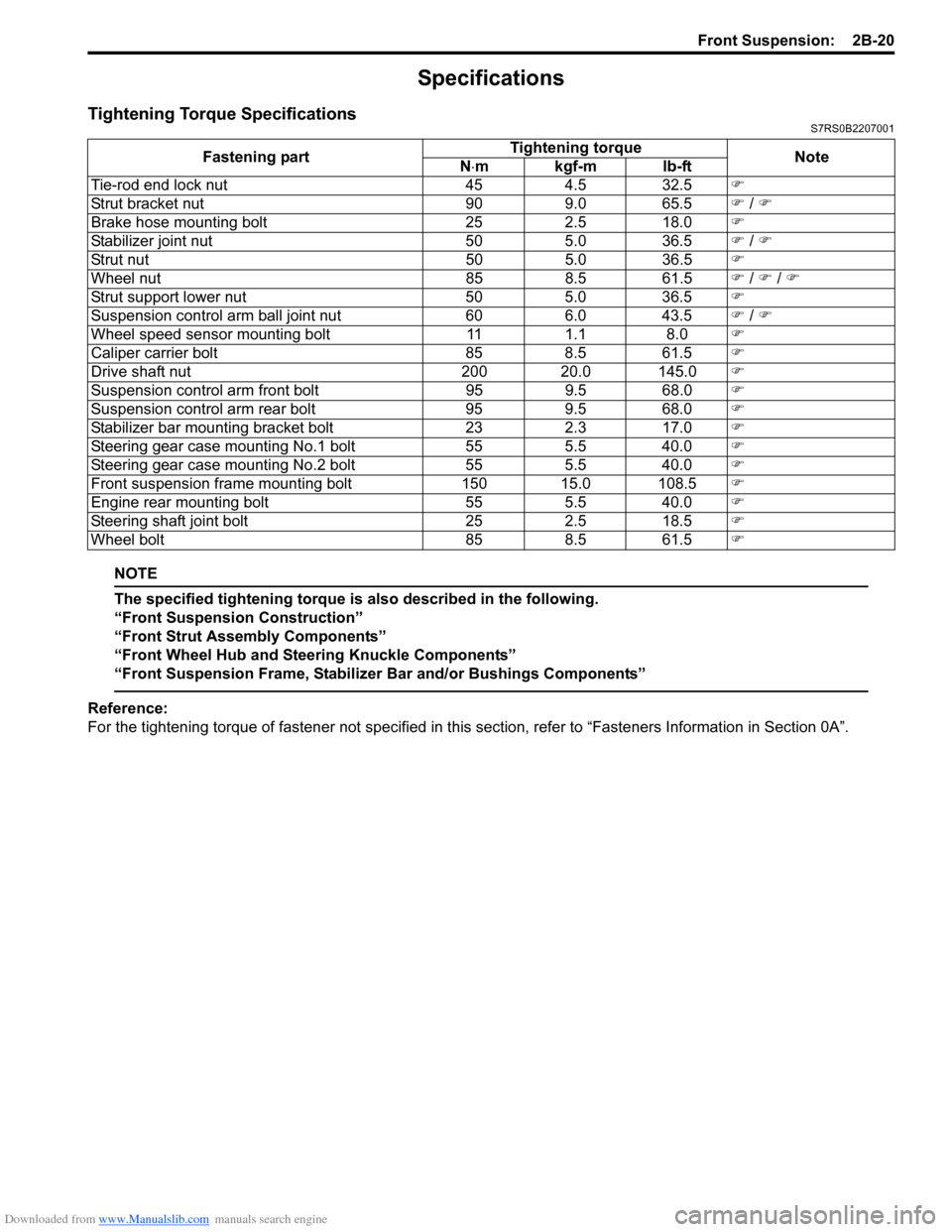

Specifications

Tightening Torque SpecificationsS7RS0B2207001

NOTE

The specified tightening torque is also described in the following.

“Front Suspension Construction”

“Front Strut Assembly Components”

“Front Wheel Hub and Steering Knuckle Components”

“Front Suspension Frame, Stabilizer Bar and/or Bushings Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Tie-rod end lock nut 454.5 32.5 �)

Strut bracket nut 909.0 65.5 �) / �)

Brake hose mounting bolt 252.5 18.0 �)

Stabilizer joint nut 505.0 36.5 �) / �)

Strut nut 505.0 36.5 �)

Wheel nut 858.5 61.5 �) / �) / �)

Strut support lower nut 505.0 36.5 �)

Suspension control arm ball joint nut 606.0 43.5 �) / �)

Wheel speed sensor mounting bolt 111.1 8.0 �)

Caliper carrier bolt 858.5 61.5 �)

Drive shaft nut 200 20.0 145.0�)

Suspension control arm front bolt 959.5 68.0 �)

Suspension control arm rear bolt 959.5 68.0 �)

Stabilizer bar mounting bracket bolt 232.3 17.0 �)

Steering gear case mounting No.1 bolt 555.5 40.0 �)

Steering gear case mounting No.2 bolt 555.5 40.0 �)

Front suspension frame mounting bolt 150 15.0 108.5�)

Engine rear mounting bolt 555.5 40.0 �)

Steering shaft joint bolt 252.5 18.5 �)

Wheel bolt 858.5 61.5 �)

Page 469 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-2

Lower than recommended pressure can cause:

• Tire squeal on turns

• Hard Steering

• Rapid and uneven wear on the edges of the tread

• Tire rim bruises and rupture

• Tire cord breakage

• High tire temperature

• Reduced handling

• High fuel consumption

Replacement Tires

When replacement is necessary, the original equipment

type tire should be used. Refer to the Tire Placard.

Replacement tires should be of the same size, load

range and construction as those originally on the vehicle.

Use of any other size or type tire may affect ride,

handling, speedometer / odometer calibration, vehicle

ground clearance and tire or snow chain clearance to the

body and chassis.

It is recommended that new tires be installed in pairs on

the same axle. If necessary to replace only one tire, it

should be paired with the tire having the most tread, to

equalize braking traction.

WARNING!

Do not mix different types of tires on the

same vehicle such as radial, bias and bias-

belted tires except in emergencies, because

handling may be seriously affected and may

result in loss of control.

The metric term for tire infl ation pressure is the kilo

pascal (kPa). Tire pressures is usually printed in both

kPa and kgf/cm

2 on the “Tire Placard”.

Metric tire gauges are available from tool suppliers.

The chart, shown the table, converts commonly used

inflation pressures from kPa to kgf/cm

2 and psi.

Wheels DescriptionS7RS0B2401002

Wheel Maintenance

Wheel repairs that use welding, heating, or peening are

not approved. All damaged wheels should be replaced.

Replacement Wheels

Wheels must be replaced if they are bent, dented, have

excessive lateral or radial runout, air leak through welds,

have elongated bolt holes, if lug wheel bolts won’t stay

tight, or if they are heavily rusted. Wheels with greater

runout than shown in the following may cause

objectional vibrations.

Replacement wheels must be equivalent to the original

equipment wheels in load capacity, diameter, rim with

offset and mounting configuration. A wheel of improper

size or type may affect wheel and bearing life, brake

cooling, speedometer / odometer calibration, vehicle

ground clearance and tire clearance to body and

chassis.

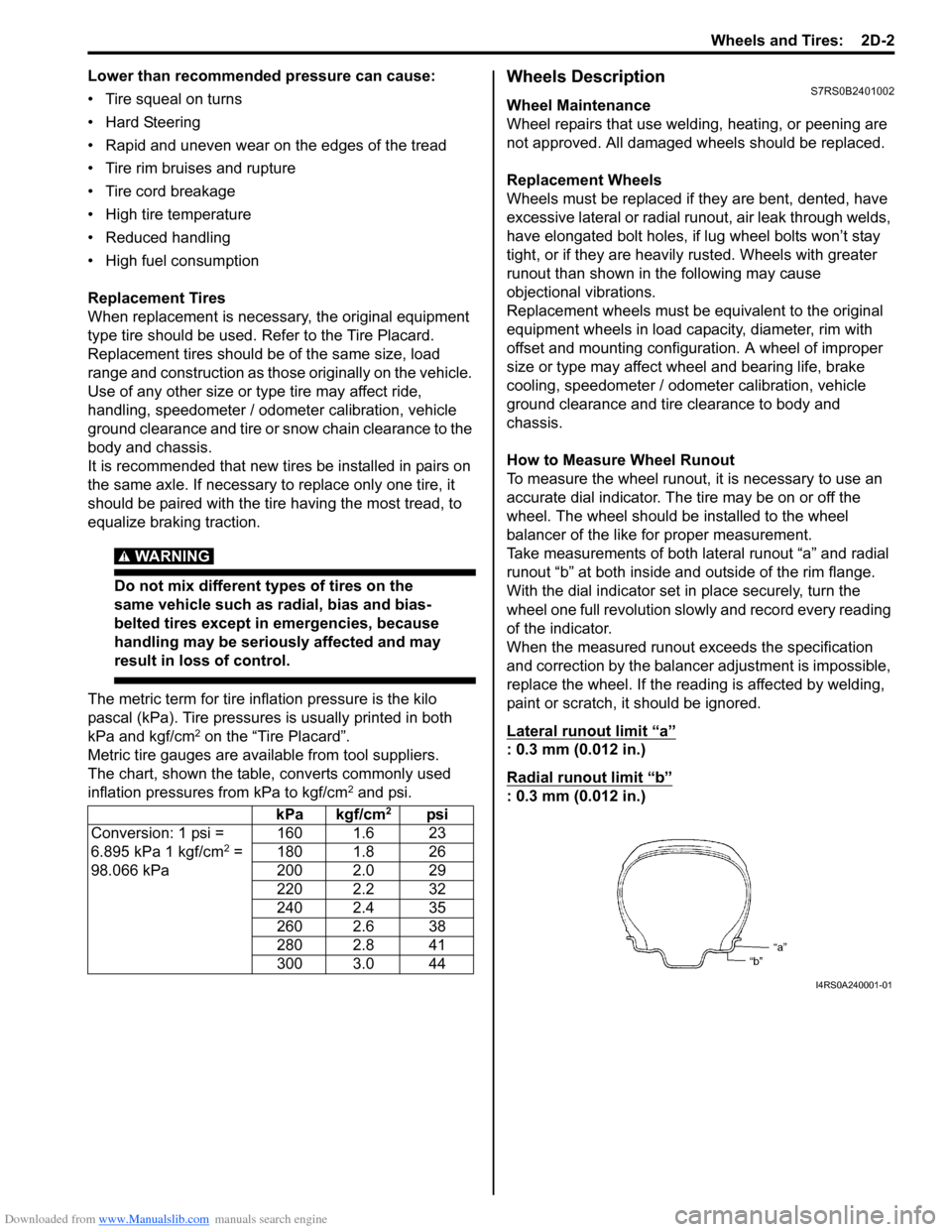

How to Measure Wheel Runout

To measure the wheel runout, it is necessary to use an

accurate dial indicator. The tire may be on or off the

wheel. The wheel should be installed to the wheel

balancer of the like for proper measurement.

Take measurements of both lateral runout “a” and radial

runout “b” at both inside an d outside of the rim flange.

With the dial indicator set in place securely, turn the

wheel one full revolution slowly and record every reading

of the indicator.

When the measured runout exceeds the specification

and correction by the balancer adjustment is impossible,

replace the wheel. If the reading is affected by welding,

paint or scratch, it should be ignored.

Lateral runout limit “a”

: 0.3 mm (0.012 in.)

Radial runout limit “b”

: 0.3 mm (0.012 in.)

kPa kgf/cm2psi

Conversion: 1 psi =

6.895 kPa 1 kgf/cm

2 =

98.066 kPa 160 1.6 23

180 1.8 26

200 2.0 29

220 2.2 32

240 2.4 35

260 2.6 38

280 2.8 41

300 3.0 44

I4RS0A240001-01