coolant system SUZUKI SWIFT 2008 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 374 of 1496

Downloaded from www.Manualslib.com manuals search engine 1F-11 Engine Cooling System:

Water Pump Removal and InstallationS7RS0B1606014

Removal1) Disconnect negative cable at battery.

2) Drain coolant.

3) Remove water pump / generator drive belt referring to “Water Pump / Generator Drive Belt Removal and

Installation in Section 1J”.

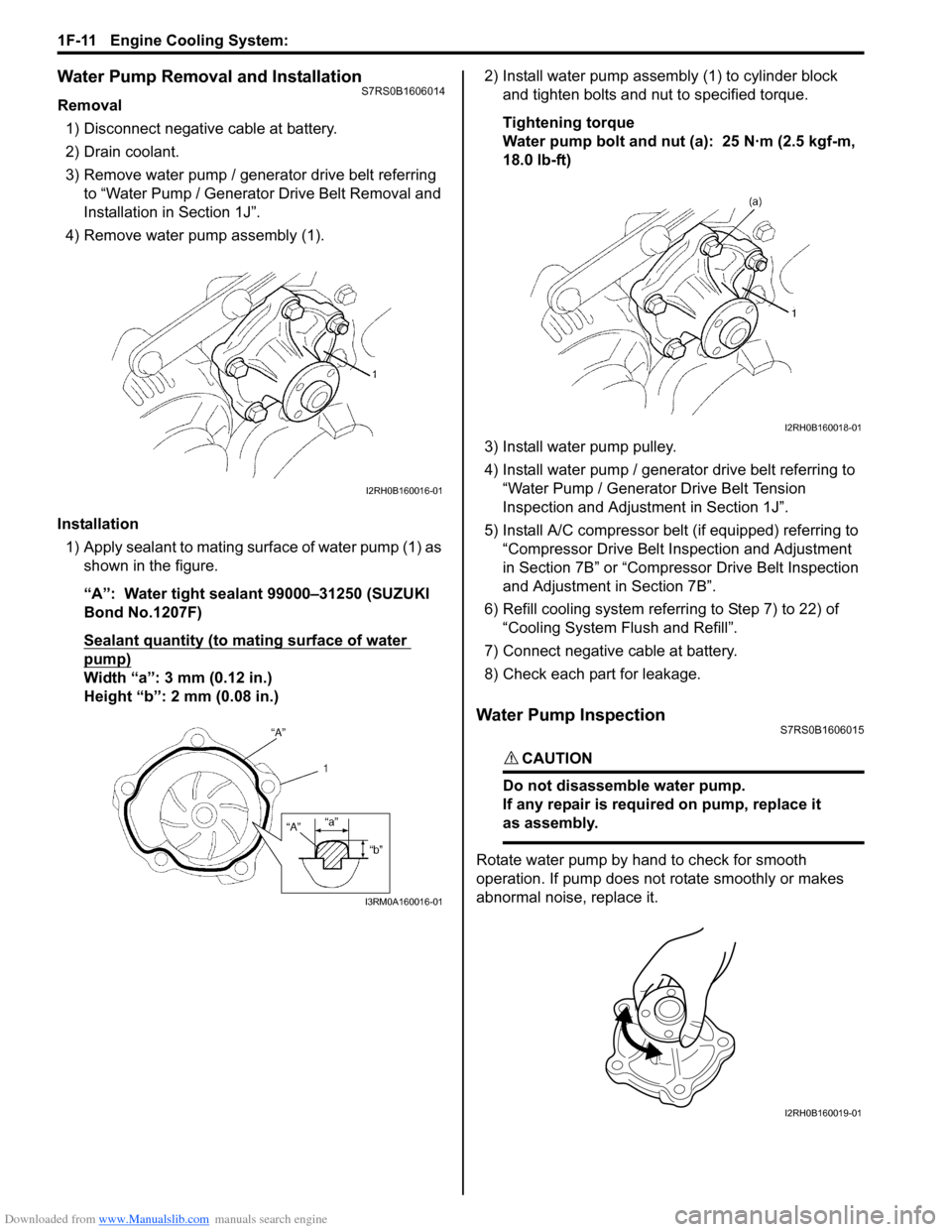

4) Remove water pump assembly (1).

Installation 1) Apply sealant to mating surface of water pump (1) as shown in the figure.

“A”: Water tight sealant 99000–31250 (SUZUKI

Bond No.1207F)

Sealant quantity (to mating surface of water

pump)

Width “a”: 3 mm (0.12 in.)

Height “b”: 2 mm (0.08 in.) 2) Install water pump assemb

ly (1) to cylinder block

and tighten bolts and nut to specified torque.

Tightening torque

Water pump bolt and nut (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

3) Install water pump pulley.

4) Install water pump / generator drive belt referring to “Water Pump / Generator Drive Belt Tension

Inspection and Adjustment in Section 1J”.

5) Install A/C compressor belt (if equipped) referring to “Compressor Drive Belt Inspection and Adjustment

in Section 7B” or “Compressor Drive Belt Inspection

and Adjustment in Section 7B”.

6) Refill cooling system referri ng to Step 7) to 22) of

“Cooling System Flush and Refill”.

7) Connect negative cable at battery.

8) Check each part for leakage.

Water Pump InspectionS7RS0B1606015

CAUTION!

Do not disassemble water pump.

If any repair is requir ed on pump, replace it

as assembly.

Rotate water pump by hand to check for smooth

operation. If pump does not rotate smoothly or makes

abnormal noise, replace it.

I2RH0B160016-01

I3RM0A160016-01

I2RH0B160018-01

I2RH0B160019-01

Page 653 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-9

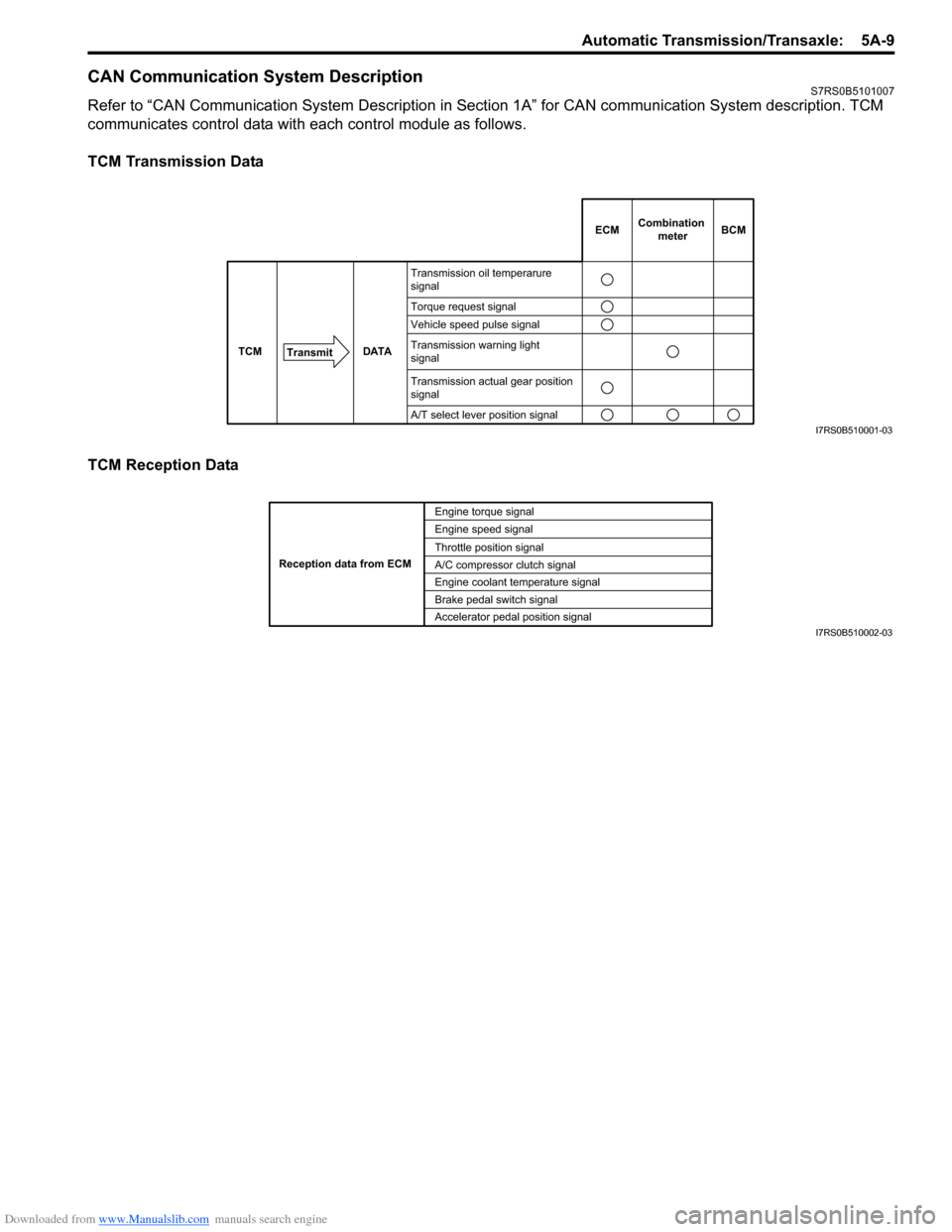

CAN Communication System DescriptionS7RS0B5101007

Refer to “CAN Communication System Description in Section 1A” for CAN communication System description. TCM

communicates control data with each control module as follows.

TCM Transmission Data

TCM Reception Data

DATA

TCM

Transmit

Transmission oil temperarure

signal

Torque request signal

Vehicle speed pulse signal

Transmission warning light

signal

Transmission actual gear position

signal

A/T select lever position signal

ECMCombination

meterBCM

I7RS0B510001-03

Engine torque signal

Engine speed signal

Throttle position signal

A/C compressor clutch signal

Engine coolant temperature signal

Brake pedal switch signal

Reception data from ECM

Accelerator pedal position signalI7RS0B510002-03

Page 662 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-18 Automatic Transmission/Transaxle:

Visual InspectionS7RS0B5104002

Visually check the following parts and systems.

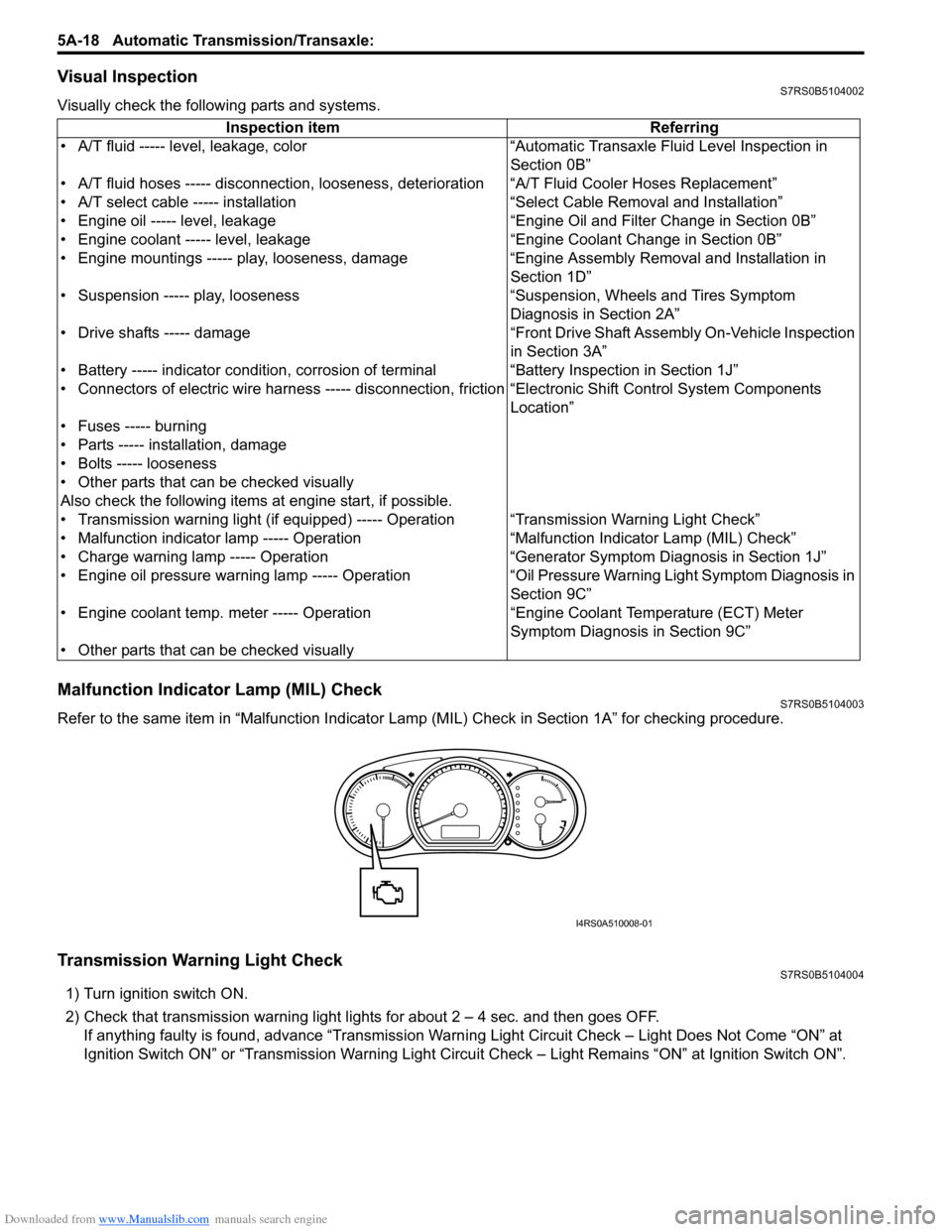

Malfunction Indicator Lamp (MIL) CheckS7RS0B5104003

Refer to the same item in “Malfunction Indicator Lam p (MIL) Check in Section 1A” for checking procedure.

Transmission Warning Light CheckS7RS0B5104004

1) Turn ignition switch ON.

2) Check that transmission warning light lights for about 2 – 4 sec. and then goes OFF.

If anything faulty is found, advance “Transmission Warn ing Light Circuit Check – Light Does Not Come “ON” at

Ignition Switch ON” or “Transmission Warning Light Circu it Check – Light Remains “ON” at Ignition Switch ON”.

Inspection item Referring

• A/T fluid ----- level, leakage, color “Automatic Transaxle Fluid Level Inspection in Section 0B”

• A/T fluid hoses ----- disconnection, looseness, deterioration “A/T Fluid Cooler Hoses Replacement”

• A/T select cable ----- installation “S elect Cable Removal and Installation”

• Engine oil ----- level, leakage “Engine Oil and Filter Change in Section 0B”

• Engine coolant ----- level, leakage “Engine Coolant Change in Section 0B”

• Engine mountings ----- play, looseness, damage “Engine Assembly Removal and Installation in Section 1D”

• Suspension ----- play, looseness “Suspension, Wheels and Tires Symptom Diagnosis in Section 2A”

• Drive shafts ----- damage “Front Drive Shaft Assembly On-Vehicle Inspection in Section 3A”

• Battery ----- indicator condition, corrosion of terminal “Battery Inspection in Section 1J”

• Connectors of electric wire harness ----- disconnection, friction “Electronic Shift Control System Components

Location”

• Fuses ----- burning

• Parts ----- installation, damage

• Bolts ----- looseness

• Other parts that can be checked visually

Also check the following items at engine start, if possible.

• Transmission warning light (if equipped) ----- Operation “Transmission Warning Light Check”

• Malfunction indicator lamp ----- Operation “Malfunction Indicator Lamp (MIL) Check”

• Charge warning lamp ----- Operation “Generator Symptom Diagnosis in Section 1J”

• Engine oil pressure warning lamp ----- Operation “Oil Pressure Warning Ligh t Symptom Diagnosis in

Section 9C”

• Engine coolant temp. meter ----- Operation “Engine Coolant Temperature (ECT) Meter

Symptom Diagnosis in Section 9C”

• Other parts that can be checked visually

I4RS0A510008-01

Page 670 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-26 Automatic Transmission/Transaxle:

TRANSAXLE RANGE

Transaxle range detected by signal fed from

transmission range sensor.

D RANGE SIGNAL

ON: Signal which TCM require ECM to increase idle

speed

OFF: Signal which TCM does not require ECM to

increase idle speed

THROTTLE POSITION (%)

Throttle opening ratio computed by CAN signal from

ECM.

BRAKE SWITCH

Inputted signal from brake light switch on pedal bracket.

ON: Brake pedal depressed

OFF: Brake pedal released

TORQUE REDUCTION SIGNAL

ON: Signal which TCM require ECM to reduce output

torque at shifting gear

OFF: Signal which TCM does not require ECM to reduce

output torque

ENGINE COOLANT TEMPERATURE ( °C, °F)

Engine coolant temperature computed by CAN signal

from ECM. AIR CONDITIONER SIGNAL

ON: Signal which inform that air conditioner compressor

is turned ON.

OFF: Signal which inform that air conditioner

compressor is not turned ON.

ENGINE TORQUE SIGNAL (N

⋅m)

Engine torque computed by duty pulse signal outputted

from ECM.

SLIP RPM (RPM)

This parameter indicates slip ping rotation in the torque

converter (difference between input shaft rotation and

engine rotation)

MIL REQUEST

ON: Signal which TCM requires combination meter to

turn on malfunction indicator lamp.

OFF: Signal which TCM does not require combination

meter to turn on malf unction indicator lamp.

FUEL CUT FLAG

ON: Signal which inform that fuel cut is operating.

OFF: Signal which inform that fuel cut is not operating.

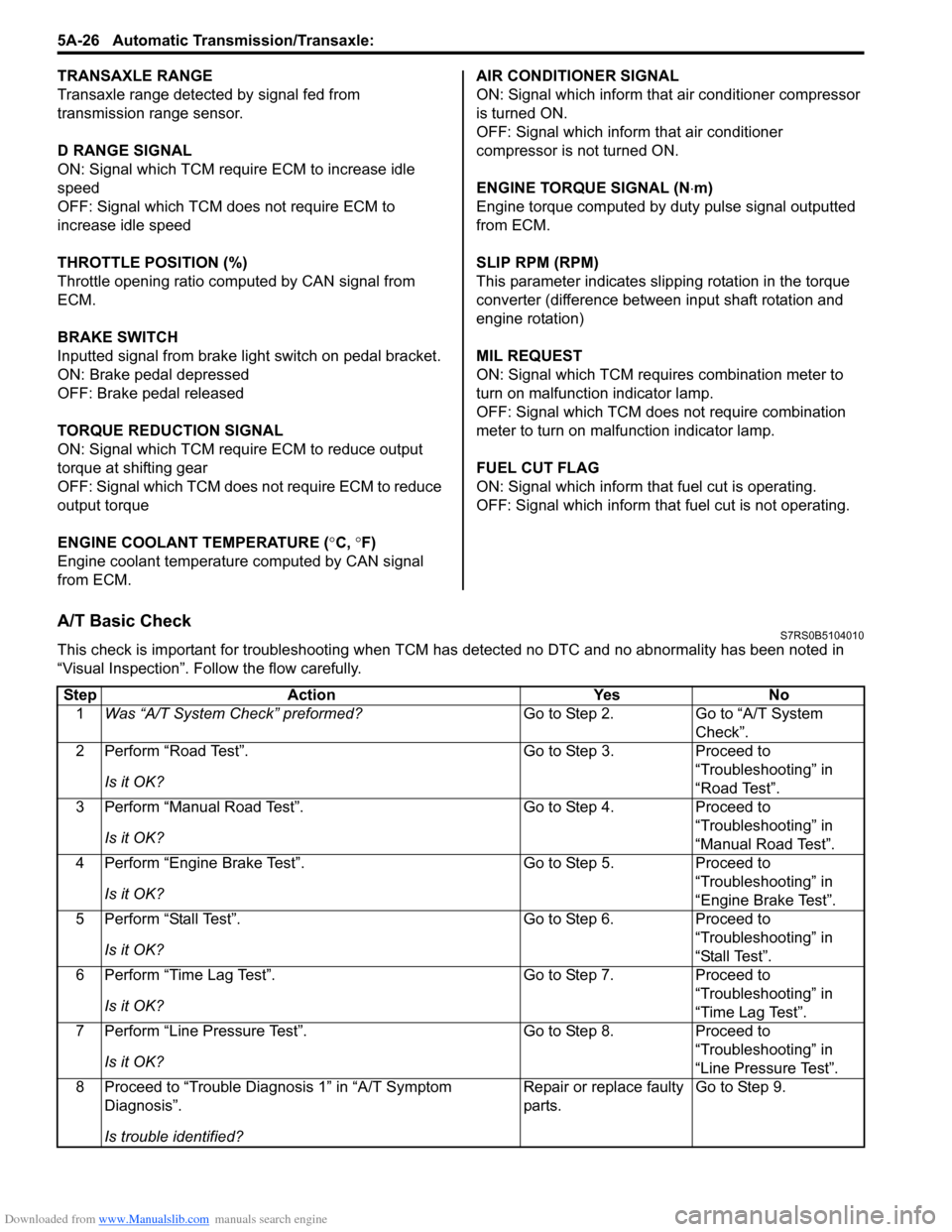

A/T Basic CheckS7RS0B5104010

This check is important for troubleshooting when TCM has detected no DTC and no abnormality has been noted in

“Visual Inspection”. Fo llow the flow carefully.

Step Action YesNo

1 Was “A/T System Check” preformed? Go to Step 2.Go to “A/T System

Check”.

2 Perform “Road Test”.

Is it OK? Go to Step 3.

Proceed to

“Troubleshooting” in

“Road Test”.

3 Perform “Manual Road Test”.

Is it OK? Go to Step 4.

Proceed to

“Troubleshooting” in

“Manual Road Test”.

4 Perform “Engine Brake Test”.

Is it OK? Go to Step 5.

Proceed to

“Troubleshooting” in

“Engine Brake Test”.

5 Perform “Stall Test”.

Is it OK? Go to Step 6.

Proceed to

“Troubleshooting” in

“Stall Test”.

6 Perform “Time Lag Test”.

Is it OK? Go to Step 7.

Proceed to

“Troubleshooting” in

“Time Lag Test”.

7 Perform “Line Pressure Test”.

Is it OK? Go to Step 8.

Proceed to

“Troubleshooting” in

“Line Pressure Test”.

8 Proceed to “Trouble Diag nosis 1” in “A/T Symptom

Diagnosis”.

Is trouble identified? Repair or replace faulty

parts.

Go to Step 9.

Page 681 of 1496

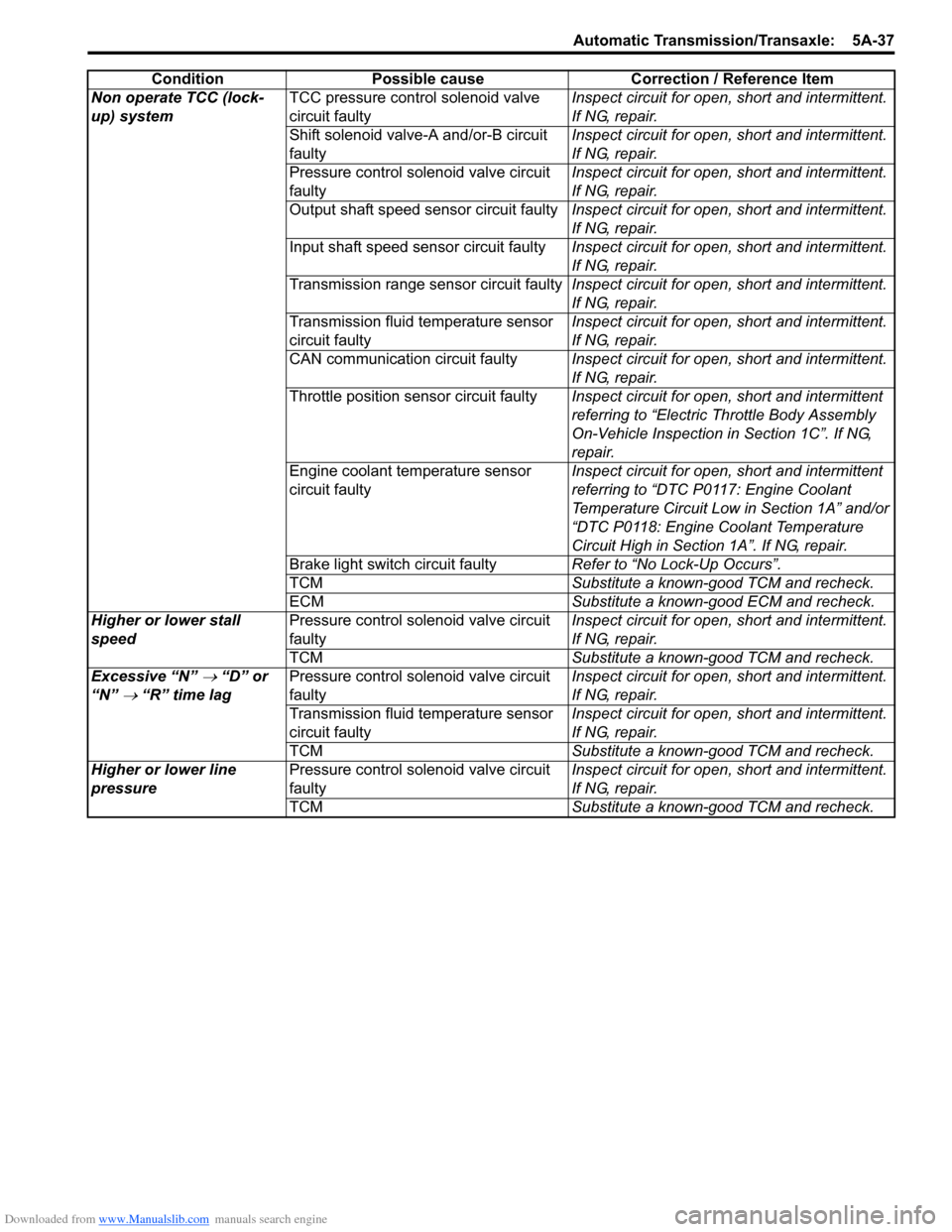

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-37

Non operate TCC (lock-

up) systemTCC pressure control solenoid valve

circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Shift solenoid valve-A and/or-B circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Pressure control solenoid valve circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Input shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission range sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission fluid temperature sensor

circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faulty Inspect circuit for open, short and intermittent

referring to “Electric Throttle Body Assembly

On-Vehicle Inspection in Section 1C”. If NG,

repair.

Engine coolant temperature sensor

circuit faulty Inspect circuit for open, short and intermittent

referring to “DTC P0117: Engine Coolant

Temperature Circuit Low

in Section 1A” and/or

“DTC P0118: Engine Coolant Temperature

Circuit High in Section 1A”. If NG, repair.

Brake light switch circuit faulty Refer to “No Lock-Up Occurs”.

TCM Substitute a known-good TCM and recheck.

ECM Substitute a known-good ECM and recheck.

Higher or lower stall

speed Pressure control solenoid valve circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

TCM Substitute a known-good TCM and recheck.

Excessive “N”

→ “D” or

“N”

→ “R” time lag Pressure control solenoid valve circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission fluid temperature sensor

circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

TCM Substitute a known-good TCM and recheck.

Higher or lower line

pressure Pressure control solenoid valve circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

TCM Substitute a known-good TCM and recheck.

Condition Possible cause Correction / Reference Item

Page 684 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-40 Automatic Transmission/Transaxle:

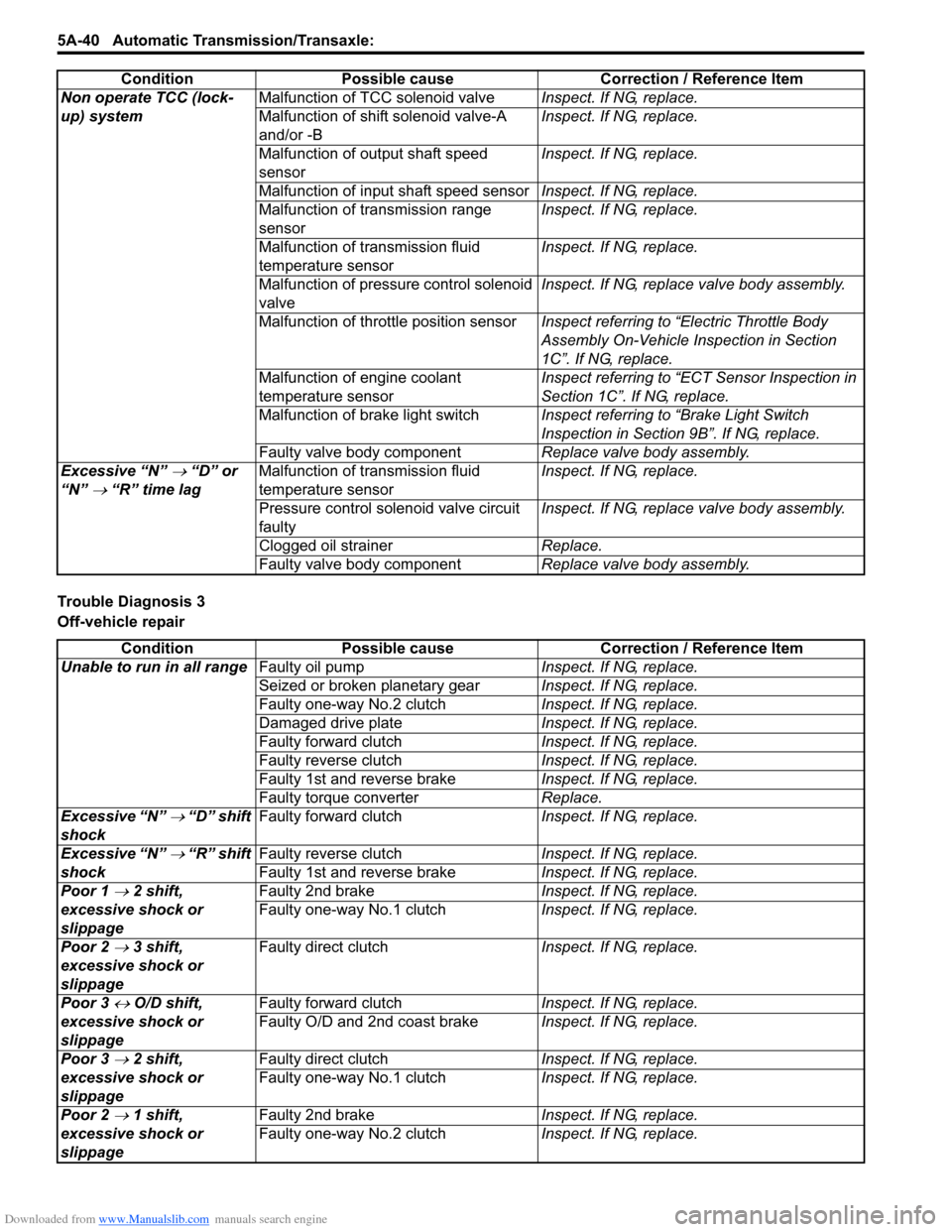

Trouble Diagnosis 3

Off-vehicle repairNon operate TCC (lock-

up) system

Malfunction of TCC solenoid valve

Inspect. If NG, replace.

Malfunction of shift solenoid valve-A

and/or -B Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of input shaft speed sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor Inspect. If NG, replace.

Malfunction of transmission fluid

temperature sensor Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve Inspect. If NG, replace valve body assembly.

Malfunction of throttle position sensor Inspect referring to “Electric Throttle Body

Assembly On-Vehicle Inspection in Section

1C”. If NG, replace.

Malfunction of engine coolant

temperature sensor Inspect referring to “ECT Sensor Inspection in

Section 1C”. If NG, replace.

Malfunction of brake light switch Inspect referring to “Brake Light Switch

Inspection in Section 9B”. If NG, replace.

Faulty valve body component Replace valve body assembly.

Excessive “N”

→ “D” or

“N”

→ “R” time lag Malfunction of transmission fluid

temperature sensor Inspect. If NG, replace.

Pressure control solenoid valve circuit

faulty Inspect. If NG, replace valve body assembly.

Clogged oil strainer Replace.

Faulty valve body component Replace valve body assembly.

Condition Possible cause Correction / Reference Item

Condition

Possible cause Correction / Reference Item

Unable to run in all range Faulty oil pump Inspect. If NG, replace.

Seized or broken planetary gear Inspect. If NG, replace.

Faulty one-way No.2 clutch Inspect. If NG, replace.

Damaged drive plate Inspect. If NG, replace.

Faulty forward clutch Inspect. If NG, replace.

Faulty reverse clutch Inspect. If NG, replace.

Faulty 1st and reverse brake Inspect. If NG, replace.

Faulty torque converter Replace.

Excessive “N”

→ “D” shift

shock Faulty forward clutch

Inspect. If NG, replace.

Excessive “N”

→ “R” shift

shock Faulty reverse clutch

Inspect. If NG, replace.

Faulty 1st and reverse brake Inspect. If NG, replace.

Poor 1

→ 2 shift,

excessive shock or

slippage Faulty 2nd brake

Inspect. If NG, replace.

Faulty one-way No.1 clutch Inspect. If NG, replace.

Poor 2

→ 3 shift,

excessive shock or

slippage Faulty direct clutch

Inspect. If NG, replace.

Poor 3

↔ O/D shift,

excessive shock or

slippage Faulty forward clutch

Inspect. If NG, replace.

Faulty O/D and 2nd coast brake Inspect. If NG, replace.

Poor 3

→ 2 shift,

excessive shock or

slippage Faulty direct clutch

Inspect. If NG, replace.

Faulty one-way No.1 clutch Inspect. If NG, replace.

Poor 2

→ 1 shift,

excessive shock or

slippage Faulty 2nd brake

Inspect. If NG, replace.

Faulty one-way No.2 clutch Inspect. If NG, replace.

Page 685 of 1496

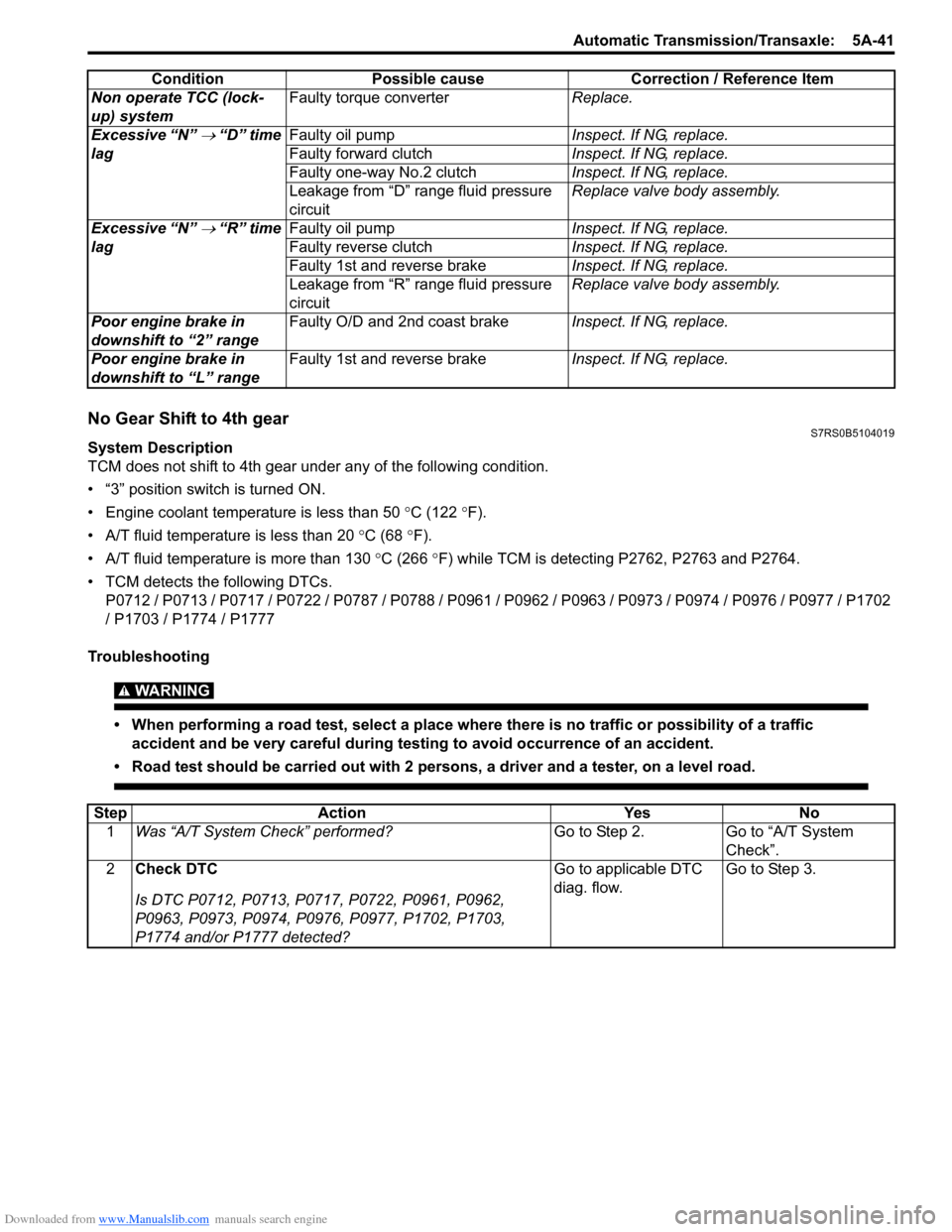

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-41

No Gear Shift to 4th gearS7RS0B5104019

System Description

TCM does not shift to 4th gear under any of the following condition.

• “3” position switch is turned ON.

• Engine coolant temperature is less than 50 °C (122 °F).

• A/T fluid temperature is less than 20 °C (68 °F).

• A/T fluid temperature is more than 130 °C (266 °F) while TCM is detecting P2762, P2763 and P2764.

• TCM detects the following DTCs. P0712 / P0713 / P0717 / P0722 / P0787 / P0788 / P0961 / P0962 / P0963 / P0973 / P0974 / P0976 / P0977 / P1702

/ P1703 / P1774 / P1777

Troubleshooting

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

Non operate TCC (lock-

up) system Faulty torque converter

Replace.

Excessive “N”

→ “D” time

lag Faulty oil pump

Inspect. If NG, replace.

Faulty forward clutch Inspect. If NG, replace.

Faulty one-way No.2 clutch Inspect. If NG, replace.

Leakage from “D” range fluid pressure

circuit Replace valve body assembly.

Excessive “N”

→ “R” time

lag Faulty oil pump

Inspect. If NG, replace.

Faulty reverse clutch Inspect. If NG, replace.

Faulty 1st and reverse brake Inspect. If NG, replace.

Leakage from “R” range fluid pressure

circuit Replace valve body assembly.

Poor engine brake in

downshift to “2” range Faulty O/D and 2nd coast brake

Inspect. If NG, replace.

Poor engine brake in

downshift to “L” range Faulty 1st and reverse brake

Inspect. If NG, replace.

Condition Possible cause Correction / Reference Item

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Check DTC

Is DTC P0712, P0713, P0717, P0722, P0961, P0962,

P0963, P0973, P0974, P0976, P0977, P1702, P1703,

P1774 and/or P1777 detected? Go to applicable DTC

diag. flow.

Go to Step 3.

Page 686 of 1496

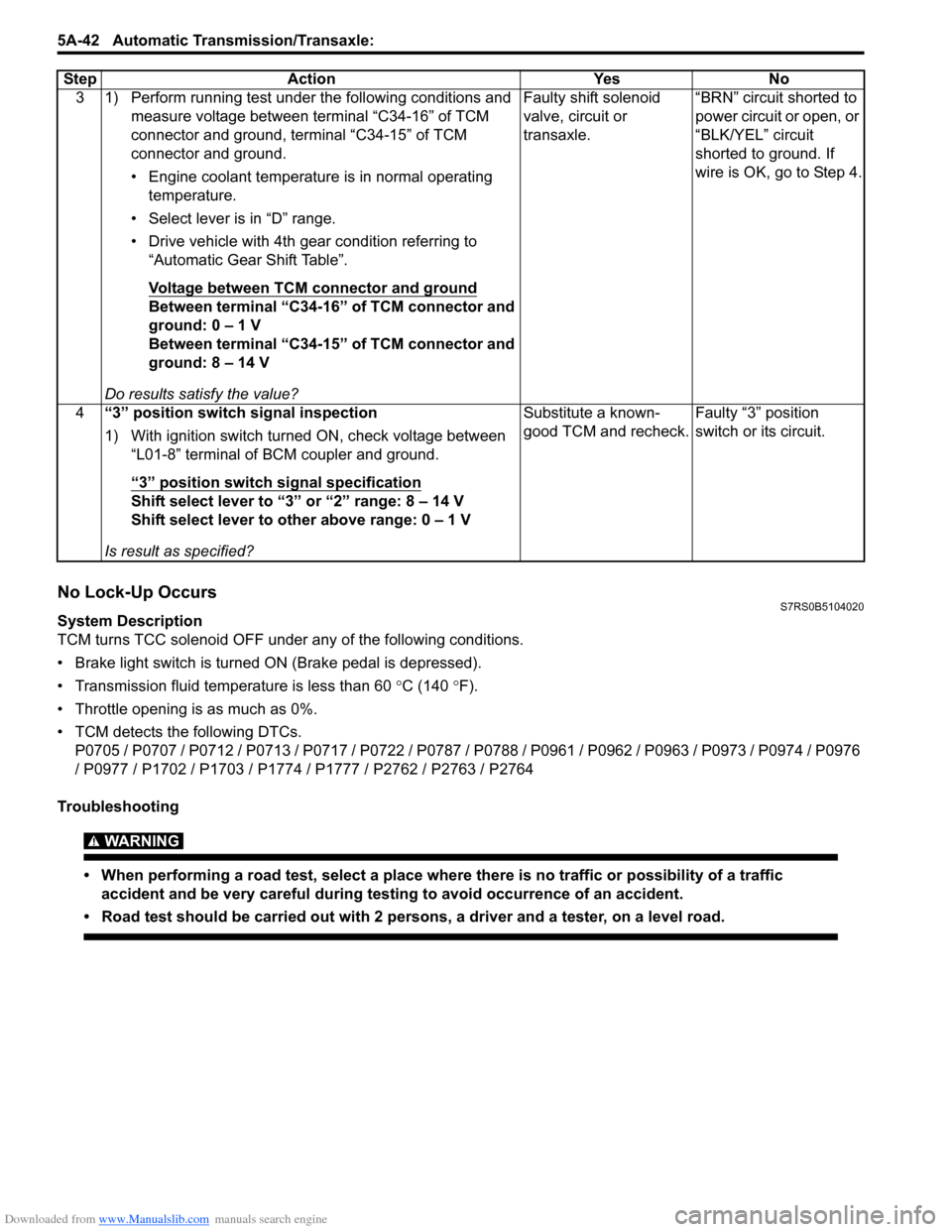

Downloaded from www.Manualslib.com manuals search engine 5A-42 Automatic Transmission/Transaxle:

No Lock-Up OccursS7RS0B5104020

System Description

TCM turns TCC solenoid OFF under any of the following conditions.

• Brake light switch is turned ON (Brake pedal is depressed).

• Transmission fluid temperat ure is less than 60 °C (140 °F).

• Throttle opening is as much as 0%.

• TCM detects the following DTCs. P0705 / P0707 / P0712 / P0713 / P0717 / P0722 / P0787 / P0788 / P0961 / P0962 / P0963 / P0973 / P0974 / P0976

/ P0977 / P1702 / P1703 / P1774 / P1777 / P2762 / P2763 / P2764

Troubleshooting

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

3 1) Perform running test under the following conditions and measure voltage between terminal “C34-16” of TCM

connector and ground, terminal “C34-15” of TCM

connector and ground.

• Engine coolant temperature is in normal operating temperature.

• Select lever is in “D” range.

• Drive vehicle with 4th gear condition referring to “Automatic Gear Shift Table”.

Voltage between TCM connector and ground

Between terminal “C34-16” of TCM connector and

ground: 0 – 1 V

Between terminal “C34-15” of TCM connector and

ground: 8 – 14 V

Do results satisfy the value? Faulty shift solenoid

valve, circuit or

transaxle.

“BRN” circuit shorted to

power circuit or open, or

“BLK/YEL” circuit

shorted to ground. If

wire is OK, go to Step 4.

4 “3” position switch signal inspection

1) With ignition switch turned ON, check voltage between

“L01-8” terminal of BCM coupler and ground.

“3” position switch signal specification

Shift select lever to “3” or “2” range: 8 – 14 V

Shift select lever to other above range: 0 – 1 V

Is result as specified? Substitute a known-

good TCM and recheck.

Faulty “3” position

switch or its circuit.

Step Action Yes No

Page 824 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-10 Manual Transmission/Transaxle:

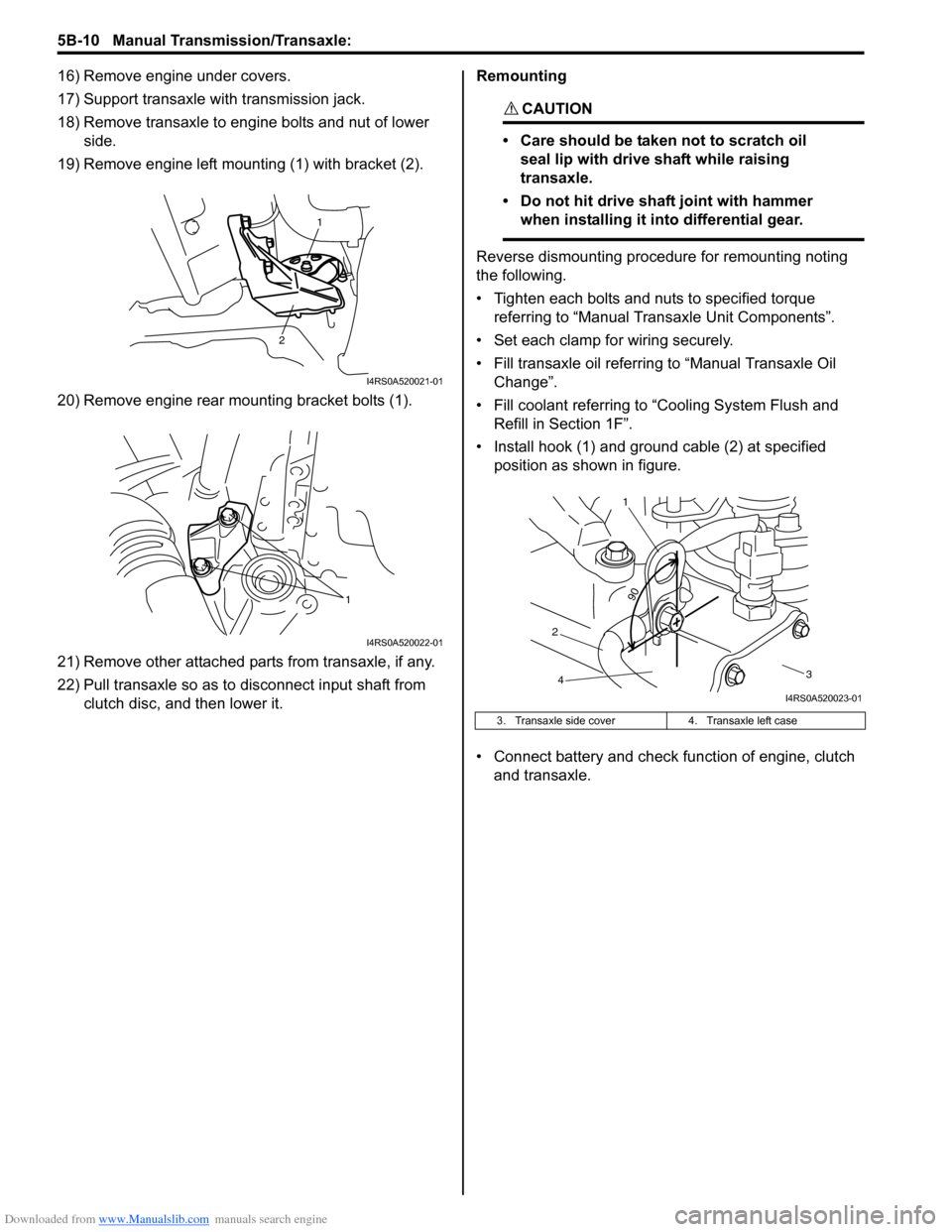

16) Remove engine under covers.

17) Support transaxle with transmission jack.

18) Remove transaxle to engine bolts and nut of lower side.

19) Remove engine left mounting (1) with bracket (2).

20) Remove engine rear mounting bracket bolts (1).

21) Remove other attached parts from transaxle, if any.

22) Pull transaxle so as to disconnect input shaft from clutch disc, and then lower it. Remounting

CAUTION!

• Care should be taken not to scratch oil

seal lip with drive shaft while raising

transaxle.

• Do not hit drive shaft joint with hammer when installing it into differential gear.

Reverse dismounting procedure for remounting noting

the following.

• Tighten each bolts and nuts to specified torque referring to “Manual Transaxle Unit Components”.

• Set each clamp for wiring securely.

• Fill transaxle oil referring to “Manual Transaxle Oil

Change”.

• Fill coolant referring to “Cooling System Flush and

Refill in Section 1F”.

• Install hook (1) and ground cable (2) at specified position as shown in figure.

• Connect battery and check function of engine, clutch

and transaxle.

1

2

I4RS0A520021-01

1

I4RS0A520022-01

3. Transaxle side cover 4. Transaxle left case

90

1

2 3

4

I4RS0A520023-01

Page 934 of 1496

Downloaded from www.Manualslib.com manuals search engine 7-ii Table of Contents

Recommended Service Material ....................... 7B-33

Special Tool ...................................................... 7B-33

Automatic Type .................... .................................7B-34

Precautions.........................................................7B-34 A/C System Caution .......................................... 7B-34

Precautions in Diagnosing Trouble ................... 7B-34

Precautions on Servicing A/C System .............. 7B-34

General Description .......... .................................7B-34

Auto A/C System Descript ion ............................ 7B-34

HVAC Control Module Operation Description ... 7B-36

Refrigerant Type Identifica tion .......................... 7B-36

Sub-Cool A/C System Description .................... 7B-36

A/C Operation Description ................................ 7B-36

On-Board Diagnostic System Description ......... 7B-37

Schematic and Routing Diagram ......................7B-37 Major Components of A/C System .................... 7B-37

A/C System Wiring Diagra m ............................. 7B-38

Diagnostic Information and Procedures ..........7B-39 A/C System Symptom Diagnosis ...................... 7B-39

Abnormal Noise Sympto m Diagnosis of A/C

System ............................................................ 7B-42

DTC Check........................................................ 7B-42

DTC Clearance ................................................. 7B-43

DTC Table ......................................................... 7B-44

Fail-Safe Table ................. ................................. 7B-45

Scan Tool Data ................................................. 7B-46

Air Conditioning System Check......................... 7B-47

Visual Inspection ............................................... 7B-49

DTC B1502: Inside Air Temperature Sensor and/or Its Circuit Malfunction .......................... 7B-49

DTC B1503: A/C Evaporator Air Temperature Sensor and/or Its Circuit Malfunction .............. 7B-50

DTC B1504: Sunload Sensor and/or Its Circuit Malfunction ......... ................................. 7B-52

DTC B1511: Temperature Control Actuator (Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-53

DTC B1512: Air flow Control Actuator (Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-55

DTC B1513: Temperature Control Actuator and/or Its Circuit Malfunction .......................... 7B-57

DTC B1514: Air Flow Co ntrol Actuator and/or

Its Circuit Malfunction ...................................... 7B-60

DTC B1541: HVAC Control Module Back-Up Power Supply Malfunction .............................. 7B-62

DTC B1546: A/C Refrigerant Pressure Malfunction ...................................................... 7B-63

DTC B1551: Serial Communication Circuit Malfunction ...................................................... 7B-63

DTC B1552: Serial Communication Signal Malfunction ...................................................... 7B-64

DTC B1553: CAN Communication Signal Malfunction ...................................................... 7B-65

DTC B1557: Vehicle Speed Sensor Signal Malfunction ...................................................... 7B-65

DTC B1561: Engine Coolant Temperature Sensor Signal Malfunctio n .............................. 7B-66 DTC B1562: Outside Air Temperature Sensor

Signal Malfunction ........................................... 7B-66

DTC B1563: A/C Refr igerant Pressure

Sensor Signal Malfunction .............................. 7B-66

Inspection of HVAC Control Module and Its Circuit .............................................................. 7B-67

A/C System Performance Inspection ................ 7B-70

A/C System Inspection at ECM ......................... 7B-70

Repair Instructions ............ ................................7B-71

Operation Procedure for Refrigerant Charge .... 7B-71

HVAC Unit Components ................................... 7B-72

HVAC Unit Removal and In stallation ................ 7B-73

Temperature Control Actuator Removal and Installation ....................................................... 7B-73

Temperature Control Actuat or Inspection ......... 7B-73

Air Flow Control Actuator Removal and Installation ....................................................... 7B-74

Air Flow Control Actuator Inspection ................. 7B-74

Air Intake Control Actuator Removal and Installation ....................................................... 7B-75

Air Intake Control Actuator Inspection............... 7B-75

Actuator Linkage Inspection .............................. 7B-76

Blower Motor Controller Removal and Installation ....................................................... 7B-76

Blower Motor Controller Inspection ................... 7B-76

HVAC Control Module Removal and Installation ....................................................... 7B-77

Sunload Sensor Removal and Installation ........ 7B-77

Sunload Sensor Inspection ............................... 7B-77

Outside Air Temperature Sensor Removal and Installation ................................................ 7B-77

Outside Air Temperature Sensor Inspection ..... 7B-77

Inside Air Temperature Sensor Removal and Installation ....................................................... 7B-78

Inside Air Temperature Sens or Inspection ........ 7B-78

Condenser Assembly On-Vehicle Inspection .... 7B-78

Condenser Assembly Removal and Installation ....................................................... 7B-78

Receiver/Dryer Removal and Installation .......... 7B-78

Evaporator Inspection ....................................... 7B-78

Evaporator Temperature Sensor Removal and Installation ................................................ 7B-78

Evaporator Temperature Se nsor Inspection ..... 7B-78

Expansion Valve Removal an d Installation ....... 7B-78

Expansion Valve Inspection .............................. 7B-78

A/C Refrigerant Pressure Sensor and Its Circuit Inspection............................................. 7B-78

A/C Refrigerant Pressu re Sensor Removal

and Installation ................................................ 7B-78

Compressor Relay Inspection .

.......................... 7B-78

Compressor Drive Belt Inspection and Adjustment ...................................................... 7B-78

Compressor Drive Belt Removal and Installation ....................................................... 7B-79

Compressor Assembly Removal and Installation ....................................................... 7B-79

Compressor Assembly Components................. 7B-79

Magnet Clutch Removal and Installation........... 7B-79

Magnet Clutch Inspection.................................. 7B-79

Relief Valve Inspection...................................... 7B-79