check SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1013 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-65

DTC Troubleshooting

DTC B1553: CAN Communication Signal MalfunctionS7RS0B7224021

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1557: Vehicle Speed Sensor Signal MalfunctionS7RS0B7224022

DTC Detecting Condition and Trouble Area

DTC TroubleshootingStep Action Yes No

1 Serial communication signal data check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Check “Refrigerant Pressure”, “Vehicle Speed”, “Coolant Temp” and “Outside Air Temp” varies displayed on scan

tool.

Is displayed each va ries described varies in “Scan Tool

Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 2.

2 Serial communication signal check

1) Connect connectors to BCM and HVAC control module.

2) Using oscilloscope, check that serial communication

signal is outputted referring to “Reference waveform

No.8” of “Inspection of BCM and its Circuits in Section

10B”.

Is serial communication signal outputted at “G37-11”

terminal of BCM connector? HVAC control module

faulty.

BCM (included in

junction block

assembly) faulty.

DTC detecting condition

Trouble area

HVAC control module receives error code fr om BCM continuously.• CAN communication circuit

• BCM (included in junction block assembly)

•ECM

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM and BCM for DTC.

Is there DTC(s)? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition

Trouble area

HVAC control module receives error code from BCM continuously. • VSS circuit

• VSS

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM for DTC.

Is there DTC P0500? Go to “DTC P0480: Fan

1 (Radiator Cooling

Fan) Control Circuit in

Section 1A”.

Substitute a known-

good HVAC control

module and recheck.

Page 1014 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-66 Air Conditioning System: Automatic Type

DTC B1561: Engine Coolant Temperature Sensor Signal MalfunctionS7RS0B7224023

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1562: Outside Air Temperature Sensor Signal MalfunctionS7RS0B7224024

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1563: A/C Refrigerant Pressure Sensor Signal MalfunctionS7RS0B7224025

DTC Detecting Condition and Trouble Area

DTC TroubleshootingDTC detecting condition Trouble area

HVAC control module receives error code from BCM continuously. • ECT sensor circuit

• ECT sensor

• HVAC control module

StepAction YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM for DTC.

Are there DTC P0116, P0117 or P0118? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition

Trouble area

HVAC control module receives er ror code from BCM continuously. • Outside air temperature sensor

circuit

• Outside air temperature sensor

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check BCM for DTC.

Are there DTC B1141, B1142 or B1143? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition

Trouble area

HVAC control module receives er ror code from BCM continuously. • A/C refrigerant pressure sensor

circuit

• A/C refrigerant pressure sensor

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM for DTC.

Are there DTC P0532 or P0533? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

Page 1015 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-67

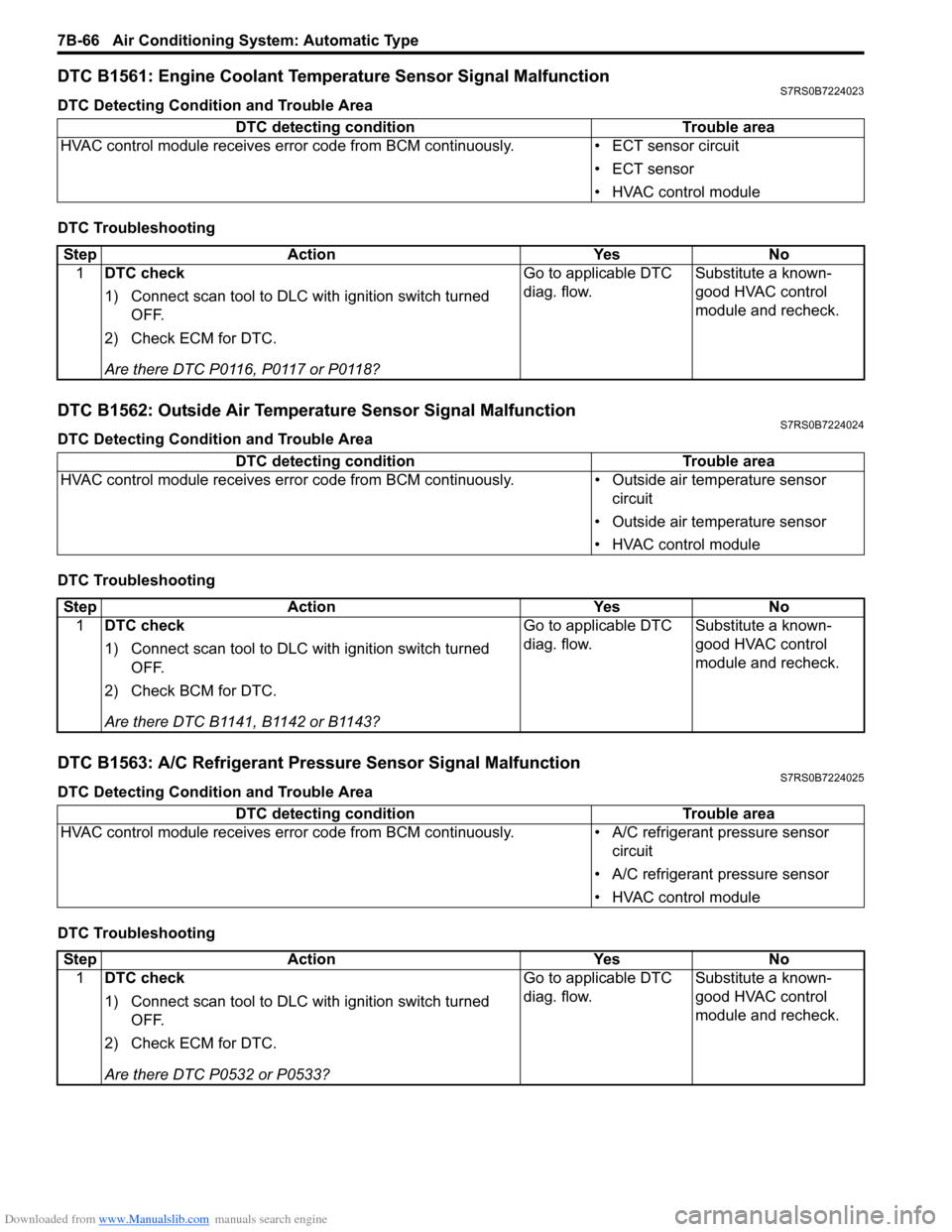

Inspection of HVAC Control Module and Its CircuitS7RS0B7224026

HVAC control module and its circuits can be checked at HVAC control module wiring couplers by measuring voltage.

CAUTION!

HVAC control module can not be checked by itself. It is strictly prohibited to connect voltmeter to

HVAC control module with couplers disconnected from it.

Voltage Check

1) Remove HVAC control module referring to “HVAC Control Module Removal and Installation”.

2) Check voltage at each terminal.

NOTE

As each terminal voltage is affected by the battery voltage, confirm that it is 11 V or more when ignition

switch is ON.

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

1

2

I5RS0A722017-02

1. HVAC control module2. HVAC control module connector (viewed from harness side)

Terminal Wire Color CircuitNormal

Vo l ta g e Condition

G51-1 BRN/WHT Air flow control actuator

(DEF) 10 – 14 V

Ignition switch turned ON, ai

r flow control actuator is

working in operation fr om VENT to DEF position

0 – 1 V Ignition switch turned ON, except the above condition

G51-2 BRN/YEL Air flow control actuator

(FACE) 10 – 14 V

Ignition switch turned ON, ai

r flow control actuator is

working in operation fr om DEF to VENT position

0 – 1 V Ignition switch turned ON, except the above condition

G51-3 GRY/BLU Temperature control

actuator (COOL) 10 – 14 VIgnition switch turned ON, temperature control

actuator is working in ope

ration from HOT to COOL

position

0 – 1 V Ignition switch turned ON, except the above condition

G51-4 GRY/RED Temperature control

actuator (HOT) 10 – 14 VIgnition switch turned ON, temperature control

actuator is working in operation from COOL to HOT

position

0 – 1 V Ignition switch turned ON, except the above condition

G51-5 PPL/WHT Serial communication line

of data link connector 10 – 14 V Ignition switch turned ON

G51-6 — — — —

G51-7 YEL Serial communication line

of BCM Refer to “Inspection of BCM a

nd its Circuits in Section 10B”

Page 1018 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-70 Air Conditioning System: Automatic Type

A/C System Performance InspectionS7RS0B7224027

Refer to “A/C System Performance Inspection”.

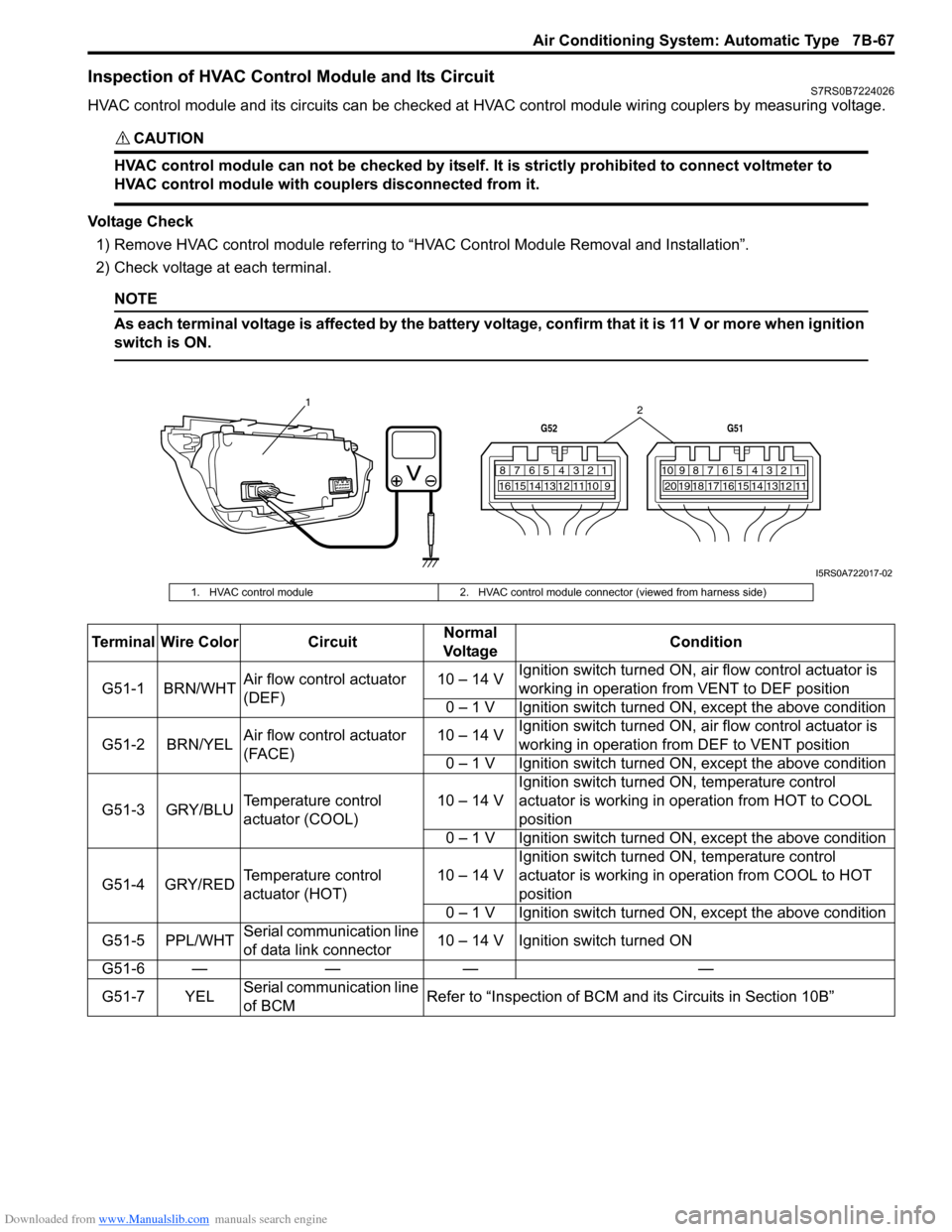

A/C System Inspection at ECMS7RS0B7224028

Voltage Check

ECM and its circuits can be checked by measuring voltage with special tool connected.

CAUTION!

• ECM connectors are waterproofed. Each terminal of the ECM connectors is sealed up with the

grommet. Therefore, do not measure circuit voltage and resistance by inserting the tester’s probe

into the sealed terminal at the harness side. Or, ECM and its circuits may be damaged by water.

• ECM cannot be checked by itself. It is strictly prohibited to connect voltmeter or ohmmeter to ECM with couplers disconnected from ECM.

1) Remove ECM (1) from its bracket by referring to “Electric Throttle Body System Calibration in Section 1C”.

2) Connect special tool (2) between ECM and ECM connectors securely.

3) Check voltage at each terminal.

NOTE

As each terminal voltage is affected by the battery voltage, confirm that the battery voltage is 11 V or

more when ignition sw itch is ON position.

Terminal arrangement of ECM coupler (Viewed from harness side)

1

2

I5RS0A722018-01

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

I4RS0A720010-01

Page 1021 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-73

HVAC Unit Removal and InstallationS7RS0B7226003

Refer to “HVAC Unit Removal and Installation”.

Temperature Control Actuator Removal and

Installation

S7RS0B7226004

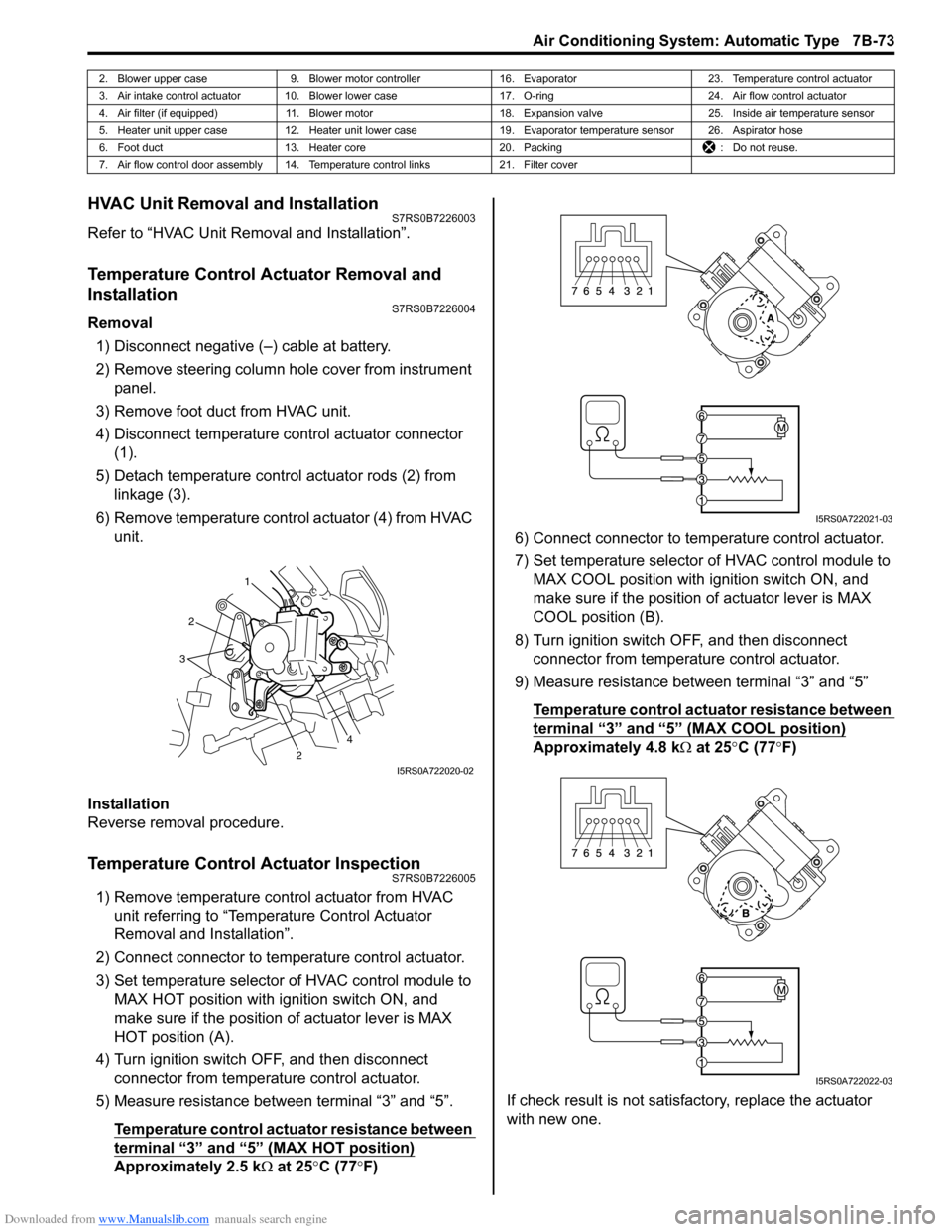

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hol e cover from instrument

panel.

3) Remove foot duct from HVAC unit.

4) Disconnect temperature control actuator connector (1).

5) Detach temperature control actuator rods (2) from linkage (3).

6) Remove temperature control actuator (4) from HVAC unit.

Installation

Reverse removal procedure.

Temperature Control Actuator InspectionS7RS0B7226005

1) Remove temperature control actuator from HVAC unit referring to “Temperature Control Actuator

Removal and Installation”.

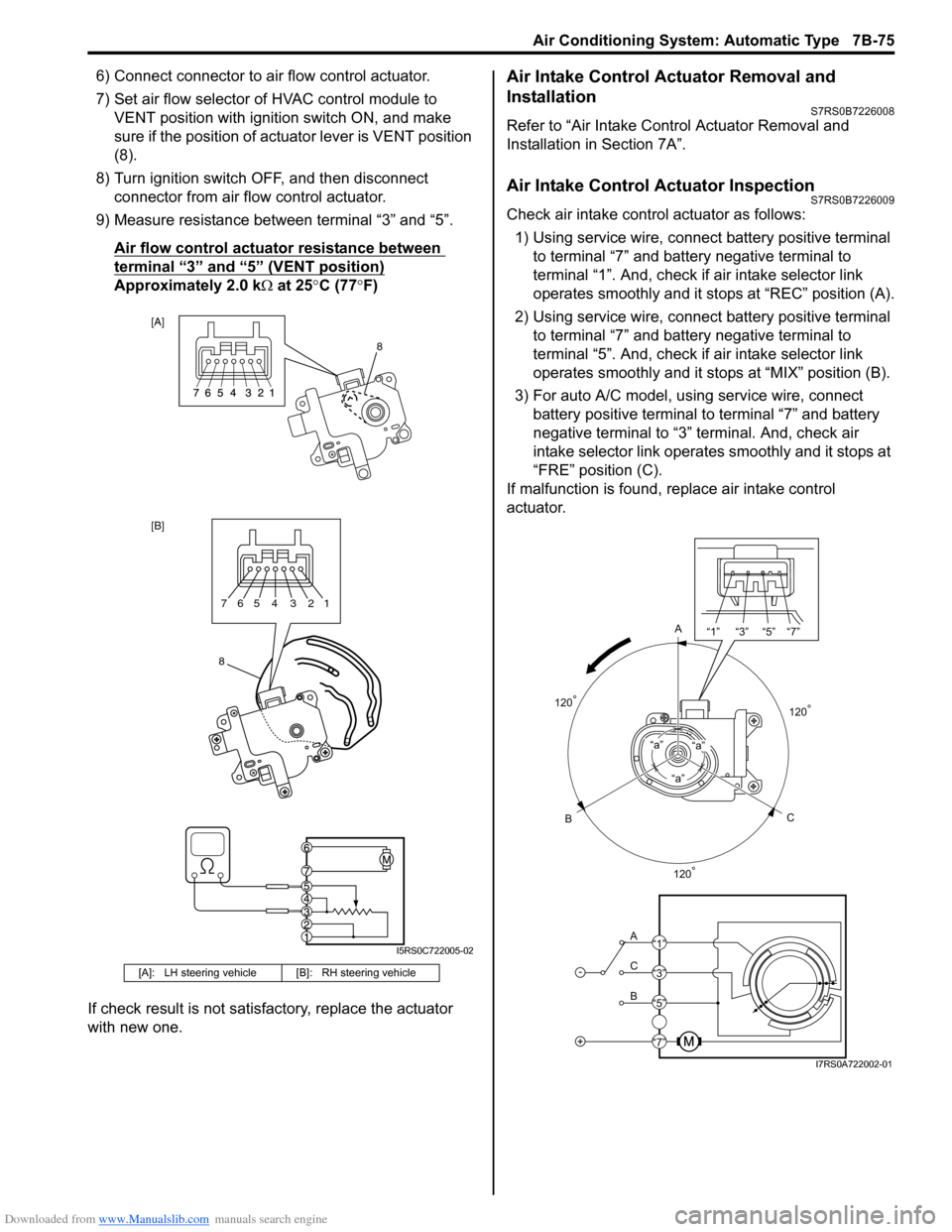

2) Connect connector to temperature control actuator.

3) Set temperature selector of HVAC control module to MAX HOT position with ignition switch ON, and

make sure if the position of actuator lever is MAX

HOT position (A).

4) Turn ignition switch OFF, and then disconnect connector from temperature control actuator.

5) Measure resistance between terminal “3” and “5”.

Temperature control actuator resistance between

terminal “3” and “5” (MAX HOT position)

Approximately 2.5 k Ω at 25 °C (77 °F) 6) Connect connector to tem

perature control actuator.

7) Set temperature selector of HVAC control module to MAX COOL position with ignition switch ON, and

make sure if the position of actuator lever is MAX

COOL position (B).

8) Turn ignition switch OFF, and then disconnect connector from temperature control actuator.

9) Measure resistance between terminal “3” and “5”

Temperature control actuator resistance between

terminal “3” and “5” (MAX COOL position)

Approximately 4.8 k Ω at 25 °C (77 °F)

If check result is not satisfactory, replace the actuator

with new one.

2. Blower upper case 9. Blower motor controller 16. Evaporator 23. Temperature control actuator

3. Air intake control actuator 10. Blower lower case 17. O-ring24. Air flow control actuator

4. Air filter (if equipped) 11. Blower motor 18. Expansion valve25. Inside air temperature sensor

5. Heater unit upper case 12. Heater unit lower case 19. Evaporator temperature sensor 26. Aspirator hose

6. Foot duct 13. Heater core 20. Packing : Do not reuse.

7. Air flow control door assembly 14. Temperature control links 21. Filter cover

1

2

2

3

4

I5RS0A722020-02

I5RS0A722021-03

I5RS0A722022-03

Page 1023 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-75

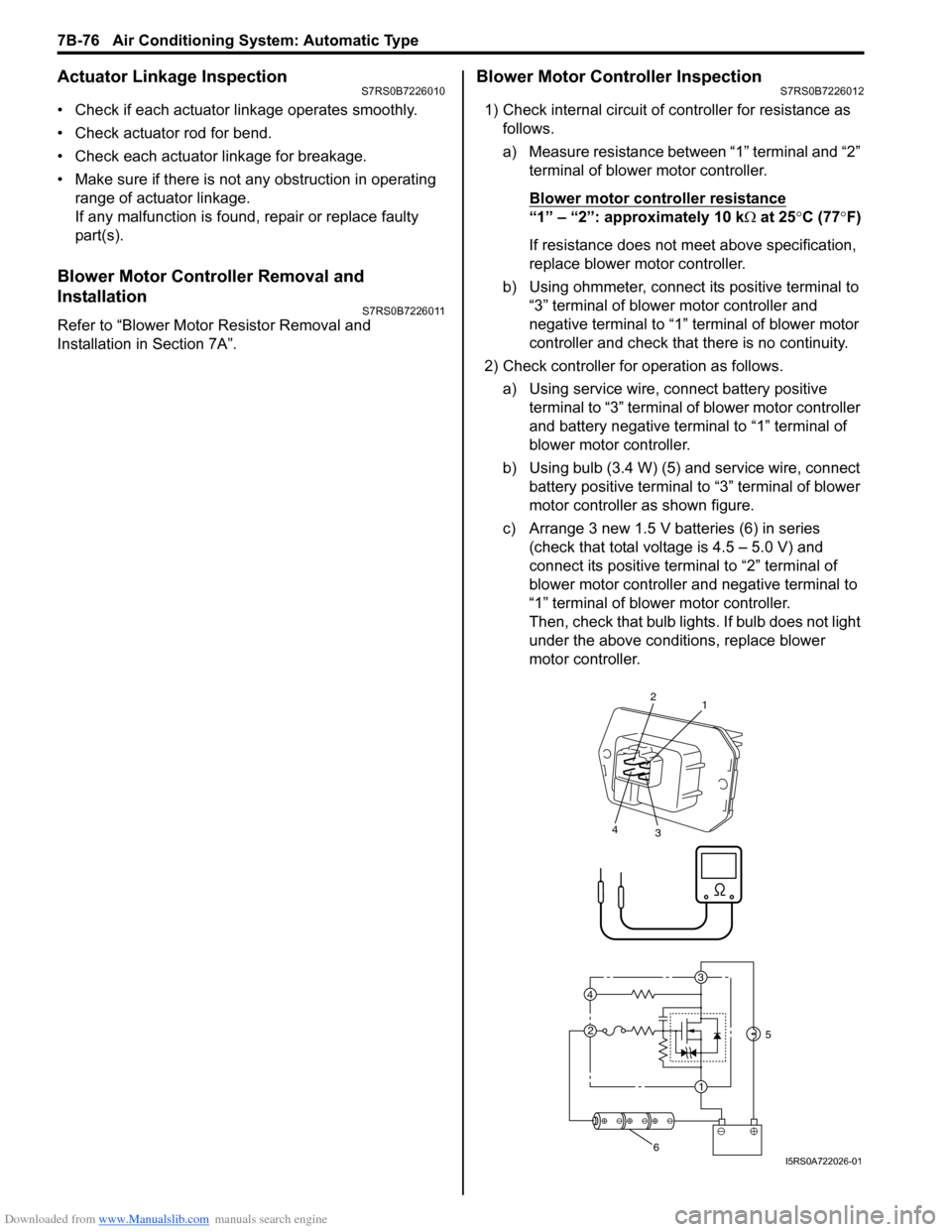

6) Connect connector to air flow control actuator.

7) Set air flow selector of HVAC control module to VENT position with ignition switch ON, and make

sure if the position of act uator lever is VENT position

(8).

8) Turn ignition switch OFF, and then disconnect connector from air flow control actuator.

9) Measure resistance between terminal “3” and “5”.

Air flow control actuator resistance between

terminal “3” and “5” (VENT position)

Approximately 2.0 k Ω at 25 °C (77 °F)

If check result is not satisfactory, replace the actuator

with new one.

Air Intake Control Actuator Removal and

Installation

S7RS0B7226008

Refer to “Air Intake Control Actuator Removal and

Installation in Section 7A”.

Air Intake Control Actuator InspectionS7RS0B7226009

Check air intake contro l actuator as follows:

1) Using service wire, connect battery positive terminal

to terminal “7” and battery negative terminal to

terminal “1”. And, check if air intake selector link

operates smoothly and it stops at “REC” position (A).

2) Using service wire, connect battery positive terminal

to terminal “7” and battery negative terminal to

terminal “5”. And, check if air intake selector link

operates smoothly and it stops at “MIX” position (B).

3) For auto A/C model, using service wire, connect battery positive terminal to terminal “7” and battery

negative terminal to “3” terminal. And, check air

intake selector link operates smoothly and it stops at

“FRE” position (C).

If malfunction is found, replace air intake control

actuator.

[A]: LH steering vehicl e [B]: RH steering vehicle

[A]

[B]

8

8765 4 3 21

I5RS0C722005-02

A

C

B“a”

“a”“a”

-

+

A

C

B “1” “3” “5” “7”

“1”

“3”

“5”

“7”

120

°

120° 120

°

I7RS0A722002-01

Page 1024 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-76 Air Conditioning System: Automatic Type

Actuator Linkage InspectionS7RS0B7226010

• Check if each actuator linkage operates smoothly.

• Check actuator rod for bend.

• Check each actuator linkage for breakage.

• Make sure if there is not any obstruction in operating range of actuator linkage.

If any malfunction is found, repair or replace faulty

part(s).

Blower Motor Controller Removal and

Installation

S7RS0B7226011

Refer to “Blower Motor Resistor Removal and

Installation in Section 7A”.

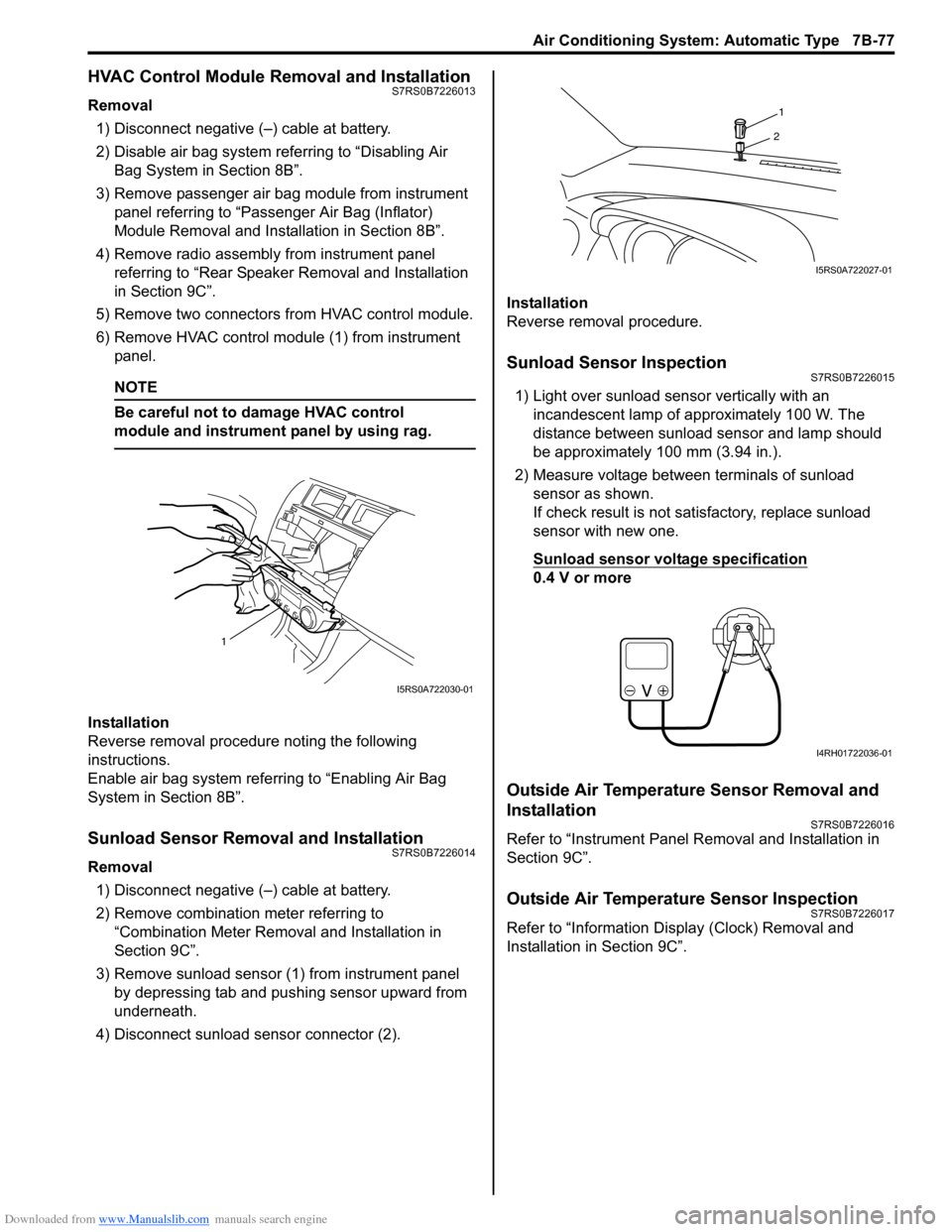

Blower Motor Controller InspectionS7RS0B7226012

1) Check internal circuit of controller for resistance as follows.

a) Measure resistance between “1” terminal and “2” terminal of blower motor controller.

Blower motor cont roller resistance

“1” – “2”: approximately 10 k Ω at 25 °C (77 °F)

If resistance does not meet above specification,

replace blower motor controller.

b) Using ohmmeter, connect its positive terminal to “3” terminal of blower motor controller and

negative terminal to “1” terminal of blower motor

controller and check that there is no continuity.

2) Check controller for operation as follows. a) Using service wire, connect battery positive terminal to “3” terminal of blower motor controller

and battery negative terminal to “1” terminal of

blower motor controller.

b) Using bulb (3.4 W) (5) and service wire, connect battery positive terminal to “3” terminal of blower

motor controller as shown figure.

c) Arrange 3 new 1.5 V batteries (6) in series (check that total voltage is 4.5 – 5.0 V) and

connect its positive term inal to “2” terminal of

blower motor controller and negative terminal to

“1” terminal of blower motor controller.

Then, check that bulb lights. If bulb does not light

under the above conditions, replace blower

motor controller.

3

1

2

4

2

1

3

4

5

6I5RS0A722026-01

Page 1025 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-77

HVAC Control Module Removal and InstallationS7RS0B7226013

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Rear Speaker Removal and Installation

in Section 9C”.

5) Remove two connectors fr om HVAC control module.

6) Remove HVAC control modu le (1) from instrument

panel.

NOTE

Be careful not to damage HVAC control

module and instrument panel by using rag.

Installation

Reverse removal procedure noting the following

instructions.

Enable air bag system referring to “Enabling Air Bag

System in Section 8B”.

Sunload Sensor Removal and InstallationS7RS0B7226014

Removal

1) Disconnect negative (–) cable at battery.

2) Remove combination meter referring to “Combination Meter Removal and Installation in

Section 9C”.

3) Remove sunload sensor (1) from instrument panel by depressing tab and pushing sensor upward from

underneath.

4) Disconnect sunload sensor connector (2). Installation

Reverse removal procedure.

Sunload Sensor InspectionS7RS0B7226015

1) Light over sunload sensor vertically with an

incandescent lamp of approximately 100 W. The

distance between sunload sensor and lamp should

be approximately 100 mm (3.94 in.).

2) Measure voltage between terminals of sunload sensor as shown.

If check result is not satisfactory, replace sunload

sensor with new one.

Sunload sensor voltage specification

0.4 V or more

Outside Air Temperature Sensor Removal and

Installation

S7RS0B7226016

Refer to “Instrument Panel Re moval and Installation in

Section 9C”.

Outside Air Temperature Sensor InspectionS7RS0B7226017

Refer to “Information Display (Clock) Removal and

Installation in Section 9C”.

1

I5RS0A722030-01

1

2

I5RS0A722027-01

I4RH01722036-01

Page 1029 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 8- i

8

Section 8

CONTENTS

Restraint

Precautions ................................................. 8-1

Precautions............................................................. 8-1

Precautions on Restraint ....................................... 8-1

Seat Belts .......... ............................... ........ 8A-1

Precautions........................................................... 8A-1

Precautions on Service a nd Diagnosis of Seat

Belt .................................................................... 8A-1

General Description ............................................. 8A-1 Seat Belt Construction ........................................ 8A-1

Diagnostic Information and Procedures ............ 8A-2 Repair and Inspection Required after Accident ............................................................ 8A-2

Repair Instructions .............................................. 8A-3 Front Seat Belt Components ............................... 8A-3

Front Seat Belt Removal and Installation ............ 8A-4

Front Seat Belt Inspection ................................... 8A-4

Rear Seat Belt Components ............................... 8A-6

Rear Seat Belt Removal and Installation ............ 8A-7

Rear Seat Belt Inspection ................................... 8A-7

Specifications ....................................................... 8A-7

Tightening Torque Specifications ........................ 8A-7

Air Bag System ............... ......................... 8B-1

Precautions........................................................... 8B-1

Precautions on Service and Diagnosis of Air Bag System....................................................... 8B-1

Precautions on Handling and Storage of Air Bag System Components . ................................ 8B-2

Precautions on Disposal of Air Bag and Seat

Belt Pretensioner .............................................. 8B-5

General Description ............................................. 8B-5 Air Bag System Construction .............................. 8B-5

Air Bag System Input / Output Table .................. 8B-6

Schematic and Routing Diagram ........................ 8B-7 Air Bag System Wiring Circuit Diagram .............. 8B-7

Component Locatio n ........................................... 8B-9

Air Bag System Components, Wiring and Connectors Location ......................................... 8B-9

Diagnostic Information and Procedures .......... 8B-10 Air Bag Diagnostic System Check .................... 8B-10

Air Bag Diagnostic System Check Flow ............ 8B-10

DTC Table ......................................................... 8B-11

DTC Check ....................................................... 8B-12 DTC Clearance ................................................. 8B-12

Scan Tool Data ................................................. 8B-13

“AIR BAG” Warning Right Comes ON Steady .. 8B-13

“AIR BAG” Warning Right Does Not Come

ON ................................................................... 8B-15

“AIR BAG” Warning Right Flashes .................... 8B-16

DTC B1013: SDM fault...................................... 8B-17

DTC B1014: “AIR BAG” Warning Right Circuit Failure ............................................................. 8B-17

DTC B1016: Power Source Voltage High ......... 8B-18

DTC B1017: Power Source Voltage Low .......... 8B-20

DTC B1021: Front Air Bag Module Deployed ... 8B-22

DTC B1024 / B1025: Side-Air Bag (Driver / Passenger) Deployed...................................... 8B-22

DTC B1026: Pretensioner Activated ................. 8B-23

DTC B1027: Reusable Number Exceeded ....... 8B-24

DTC B1031: Driver Air Bag Initiator Circuit

Resistance High .............................................. 8B-24

DTC B1032: Driver Air Bag Initiator Circuit

Resistance Low ............................................... 8B-29

DTC B1033: Driver Air Bag Initiator Circuit

Short to Ground............................................... 8B-34

DTC B1034: Driver Air Bag Initiator Circuit

Short to Power Circuit .... ................................. 8B-39

DTC B1041: Passenger Air Bag Initiator Circuit Resistance High ................................... 8B-44

DTC B1042: Passenger Air Bag Initiator Circuit Resistance Low.................................... 8B-47

DTC B1043: Passenger Air Bag Initiator Circuit Short to Ground ................................... 8B-50

DTC B1044: Passenger Air Bag Initiator Circuit Short to Power Circ uit .......................... 8B-53

DTC B1051 / B1055: Driver / Passenger Pretensioner Initiator Circuit Resistance

High ................................................................. 8B-56

DTC B1052 / B1056: Driver / Passenger Pretensioner Initiator Circu it Resistance Low .. 8B-58

DTC B1053 / B1057: Driver / Passenger Pretensioner Initiator Circuit Short to Ground .. 8B-60

DTC B1054 / B1058: Driver / Passenger Pretensioner Initiator Circuit Short to Power

Circuit .............................................................. 8B-62

DTC B1061 / B1065: Driver / Passenger Side- Air Bag Initiator Circuit Resistance High ......... 8B-64

Page 1030 of 1496

Downloaded from www.Manualslib.com manuals search engine 8-ii Table of Contents

DTC B1062 / B1066: Driver / Passenger Side-Air Bag Initiator Circuit Resistance Low .......... 8B-67

DTC B1063 / B1067: Driver / Passenger Side- Air Bag Initiator Circuit S hort to Ground .......... 8B-70

DTC B1064 / B1068: Driver / Passenger Side- Air Bag Initiator Circu it Short to Power

Circuit .............................................................. 8B-73

DTC B1071: Forward-Sensor Performance Problem ........................................................... 8B-76

DTC B1072: Forward-Sensor Communication Error ................................................................ 8B-76

DTC B1073: Forward-Sensor Circuit Short to Ground ............................................................ 8B-76

DTC B1074: Forward-Sensor Circuit Short to Power Circuit or Open ..................................... 8B-78

DTC B1081 / B1091: Driver / Passenger Side- Sensor Performance Probl em ......................... 8B-80

DTC B1082 / B1092: Driver / Passenger Side- Sensor Communication Erro r .......................... 8B-80

DTC B1083 / B1093: Driver / Passenger Side- Sensor Circuit Short to Ground ....................... 8B-80

DTC B1084 / B1094: Driver / Passenger Side- Sensor Circuit Short to Power Circuit or

Open ............................................................... 8B-81

DTC B1085 / B1095: Wrong Side-Sensor (Driver Side / Passenger) ID ........................... 8B-83

DTC B1361 / B1365: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Resistance

High ................................................................. 8B-84

DTC B1362 / B1366: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Resistance

Low ................................................................. 8B-86

DTC B1363 / B1367: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Short to

Ground ............................................................ 8B-88

DTC B1364 / B1368: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Short to

Power Circuit ................................................... 8B-90

Contact Coil Cable and Its Circuit Check .......... 8B-93 Inspection of Intermittent and Poor

Connections .................................................... 8B-95

Repair and Inspection Required after Accident .......................................................... 8B-96

Repair Instructions ............ ................................8B-98

Disabling Air Bag System.................................. 8B-98

Enabling Air Bag System .................................. 8B-99

SDM Removal and Installation ........................ 8B-100

SDM Inspection ............................................... 8B-101

Driver Air Bag (Inflato r) Module Removal and

Installation ..................................................... 8B-101

Driver Air Bag (Inflator) Module Inspection ..... 8B-103

Passenger Air Bag (Inflator) Module Removal and Installation .............................................. 8B-103

Passenger Air Bag (I nflator) Module

Inspection ...................................................... 8B-105

Side-Air Bag (Inflator) Module Removal and

Installation ..................................................... 8B-105

Side-Air Bag (Inflator) Inspection .................... 8B-107

Side Curtain-Air Bag (Inflator) Module Removal and Installation ............................... 8B-107

Side Curtain-Air Bag (Inflator) Module Inspection ...................................................... 8B-109

Forward-Sensor Removal and Installation ...... 8B-109

Forward-Sensor In spection ............................. 8B-110

Side-Sensor Removal and Installation ............ 8B-110

Side-Sensor Inspection ................................... 8B-111

Passenger Air Bag (Inflator) Module Repair

Harness Installation....................................... 8B-112

Air Bag (Inflator) Module and Seat Belt Pretensioner Disposal ................................... 8B-113

Deployed Air Bag (Inflator) Module and Activated Seat Belt Pretensioner Disposal.... 8B-124

Specifications .................. .................................8B-125

Tightening Torque Specifications .................... 8B-125

Special Tools and Equipmen t .........................8B-125

Use of Special Tools ....................................... 8B-125

Recommended Service Material ..................... 8B-127

Special Tool .................................................... 8B-127