Cylinder Head Removal and SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 47 of 1496

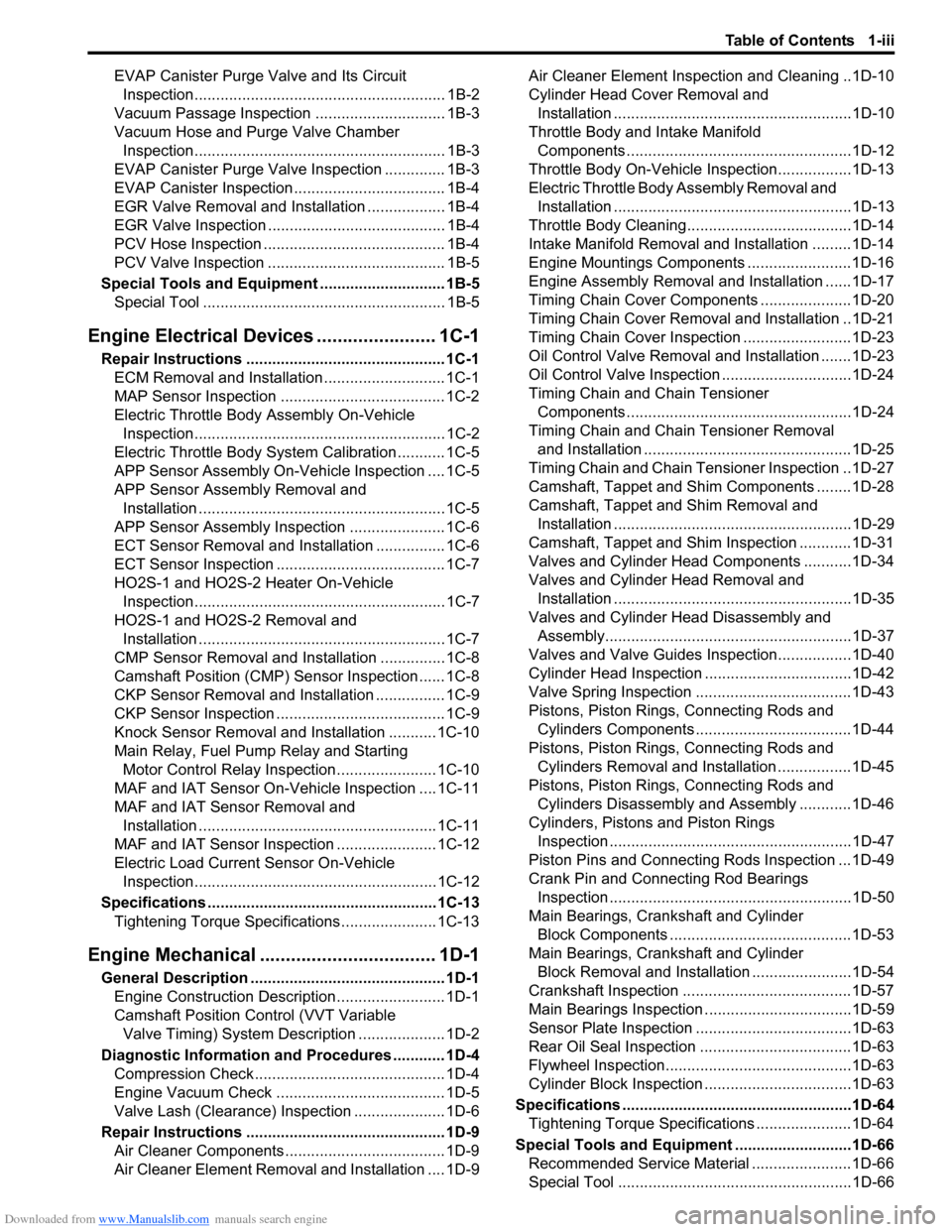

Downloaded from www.Manualslib.com manuals search engine Table of Contents 1-iii

EVAP Canister Purge Valve and Its Circuit

Inspection.......................................................... 1B-2

Vacuum Passage Inspection .............................. 1B-3

Vacuum Hose and Purge Valve Chamber Inspection.......................................................... 1B-3

EVAP Canister Purge Valve Inspection .............. 1B-3

EVAP Canister Inspection ... ................................ 1B-4

EGR Valve Removal and Installation .................. 1B-4

EGR Valve Inspection ......................................... 1B-4

PCV Hose Inspection .......................................... 1B-4

PCV Valve Inspection ......................................... 1B-5

Special Tools and Equipmen t ............................. 1B-5

Special Tool ........................................................ 1B-5

Engine Electrical Devices .. ..................... 1C-1

Repair Instructions .............................................. 1C-1

ECM Removal and Installation ............................ 1C-1

MAP Sensor Inspection ...................................... 1C-2

Electric Throttle Body Assembly On-Vehicle

Inspection.......................................................... 1C-2

Electric Throttle Body System Calibration ........... 1C-5

APP Sensor Assembly On-V ehicle Inspection .... 1C-5

APP Sensor Assembly Removal and Installation ......................................................... 1C-5

APP Sensor Assembly Inspection ...................... 1C-6

ECT Sensor Removal and In stallation ................ 1C-6

ECT Sensor Inspection ....................................... 1C-7

HO2S-1 and HO2S-2 Heater On-Vehicle Inspection.......................................................... 1C-7

HO2S-1 and HO2S-2 Removal and Installation ......................................................... 1C-7

CMP Sensor Removal and In stallation ............... 1C-8

Camshaft Position (CMP) Se nsor Inspection ...... 1C-8

CKP Sensor Removal and Installation ................ 1C-9

CKP Sensor Inspection ....................................... 1C-9

Knock Sensor Removal and Installation ........... 1C-10

Main Relay, Fuel Pump Relay and Starting

Motor Control Relay Inspection....................... 1C-10

MAF and IAT Sensor On-Vehicle Inspection .... 1C-11

MAF and IAT Sensor Removal and Installation ....................................................... 1C-11

MAF and IAT Sensor Inspection ....................... 1C-12

Electric Load Current Sensor On-Vehicle Inspection........................................................ 1C-12

Specifications ..................................................... 1C-13

Tightening Torque Specifications ...................... 1C-13

Engine Mechanical ......... ......................... 1D-1

General Description ............................................. 1D-1

Engine Construction Description ......................... 1D-1

Camshaft Position Control (VVT Variable Valve Timing) System Description .................... 1D-2

Diagnostic Information and Procedures ............ 1D-4 Compression Check ............................................ 1D-4

Engine Vacuum Check ....................................... 1D-5

Valve Lash (Clearance) Inspection ..................... 1D-6

Repair Instructions .............................................. 1D-9 Air Cleaner Components ..................................... 1D-9

Air Cleaner Element Removal and Installation .... 1D-9 Air Cleaner Element Ins

pection and Cleaning ..1D-10

Cylinder Head Co ver Removal and

Installation .......................................................1D-10

Throttle Body and Intake Manifold

Components ....................................................1D-12

Throttle Body On-Vehicle Inspection.................1D-13

Electric Throttle Body Assembly Removal and Installation .......................................................1D-13

Throttle Body Cleaning......................................1D-14

Intake Manifold Removal and Installation .........1D-14

Engine Mountings Components ........................1D-16

Engine Assembly Removal and Installation ......1D-17

Timing Chain Cover Components .....................1D-20

Timing Chain Cover Removal and Installation ..1D-21

Timing Chain Cover Inspection .........................1D-23

Oil Control Valve Removal and Installation .......1D-23

Oil Control Valve Inspection ..............................1D-24

Timing Chain and Chain Tensioner Components ....................................................1D-24

Timing Chain and Chain Tensioner Removal and Installation ................................................1D-25

Timing Chain and Chain Tensioner Inspection ..1D-27

Camshaft, Tappet and Shim Components ........1D-28

Camshaft, Tappet and Shim Removal and Installation .......................................................1D-29

Camshaft, Tappet and Shim Inspection ............1D-31

Valves and Cylinder Head Components ...........1D-34

Valves and Cylinder Head Removal and

Installation .......................................................1D-35

Valves and Cylinder Head Disassembly and Assembly.........................................................1D-37

Valves and Valve Guides Inspection.................1D-40

Cylinder Head Inspection . .................................1D-42

Valve Spring Inspection ....................................1D-43

Pistons, Piston Rings , Connecting Rods and

Cylinders Components ....................................1D-44

Pistons, Piston Rings , Connecting Rods and

Cylinders Removal and Installation .................1D-45

Pistons, Piston Rings , Connecting Rods and

Cylinders Disassembly and Assembly ............1D-46

Cylinders, Pistons and Piston Rings Inspection ........................................................1D-47

Piston Pins and Connecting Rods Inspection ...1D-49

Crank Pin and Connecting Rod Bearings Inspection ........................................................1D-50

Main Bearings, Cran kshaft and Cylinder

Block Components ..........................................1D-53

Main Bearings, Cran kshaft and Cylinder

Block Removal and Installa tion .......................1D-54

Crankshaft Inspection .......................................1D-57

Main Bearings Inspection . .................................1D-59

Sensor Plate Inspection ....................................1D-63

Rear Oil Seal Inspection ...................................1D-63

Flywheel Inspection...........................................1D-63

Cylinder Block Inspection ..................................1D-63

Specifications .................... .................................1D-64

Tightening Torque Specifications ......................1D-64

Special Tools and Equipmen t ...........................1D-66

Recommended Service Material .......................1D-66

Special Tool ......................................................1D-66

Page 91 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-41

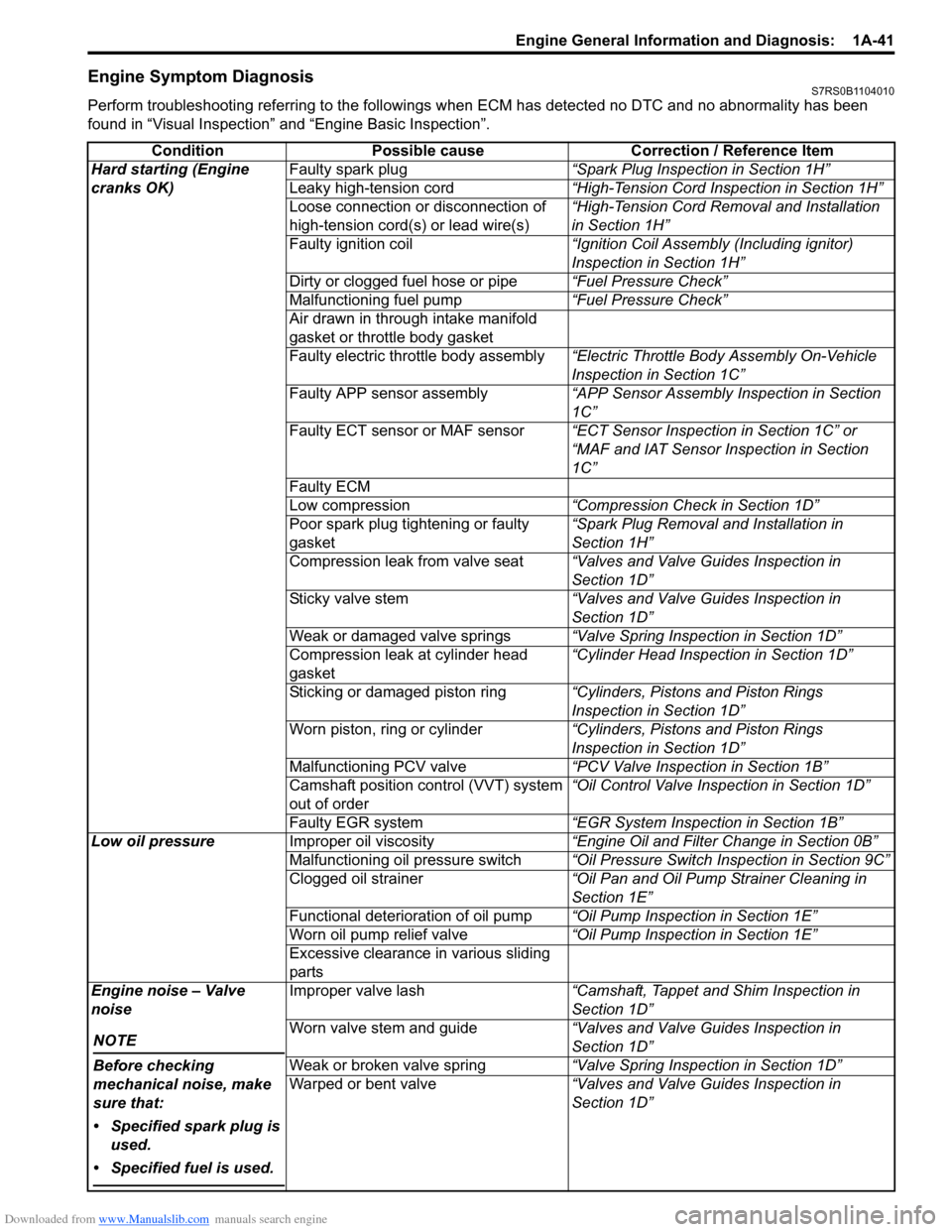

Engine Symptom DiagnosisS7RS0B1104010

Perform troubleshooting referring to the followings when ECM has detected no DTC and no abnormality has been

found in “Visual Inspection” and “Engine Basic Inspection”.

Condition Possible cause Correction / Reference Item

Hard starting (Engine

cranks OK) Faulty spark plug

“Spark Plug Inspection in Section 1H”

Leaky high-tension cord “High-Tension Cord Inspection in Section 1H”

Loose connection or disconnection of

high-tension cord(s) or lead wire(s) “High-Tension Cord Removal and Installation

in Section 1H”

Faulty ignition coil “Ignition Coil Assembly (Including ignitor)

Inspection in Section 1H”

Dirty or clogged fuel hose or pipe “Fuel Pressure Check”

Malfunctioning fuel pump “Fuel Pressure Check”

Air drawn in through intake manifold

gasket or throttle body gasket

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty ECT sensor or MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty ECM

Low compression “Compression Check in Section 1D”

Poor spark plug tightening or faulty

gasket “Spark Plug Removal and Installation in

Section 1H”

Compression leak from valve seat “Valves and Valve Guides Inspection in

Section 1D”

Sticky valve stem “Valves and Valve Guides Inspection in

Section 1D”

Weak or damaged valve springs “Valve Spring Inspection in Section 1D”

Compression leak at cylinder head

gasket “Cylinder Head Inspection in Section 1D”

Sticking or damaged piston ring “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn piston, ring or cylinder “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Malfunctioning PCV valve “PCV Valve Inspection in Section 1B”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Faulty EGR system “EGR System Inspection in Section 1B”

Low oil pressure Improper oil viscosity “Engine Oil and Filter Change in Section 0B”

Malfunctioning oil pressure switch “Oil Pressure Switch Inspection in Section 9C”

Clogged oil strainer “Oil Pan and Oil Pump Strainer Cleaning in

Section 1E”

Functional deterioration of oil pump “Oil Pump Inspection in Section 1E”

Worn oil pump relief valve “Oil Pump Inspection in Section 1E”

Excessive clearance in various sliding

parts

Engine noise – Valve

noise

NOTE

Before checking

mechanical noise, make

sure that:

• Specified spark plug is used.

• Specified fuel is used.

Improper valve lash “Camshaft, Tappet and Shim Inspection in

Section 1D”

Worn valve stem and guide “Valves and Valve Guides Inspection in

Section 1D”

Weak or broken valve spring “Valve Spring Inspection in Section 1D”

Warped or bent valve “Valves and Valve Guides Inspection in

Section 1D”

Page 92 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-42 Engine General Information and Diagnosis:

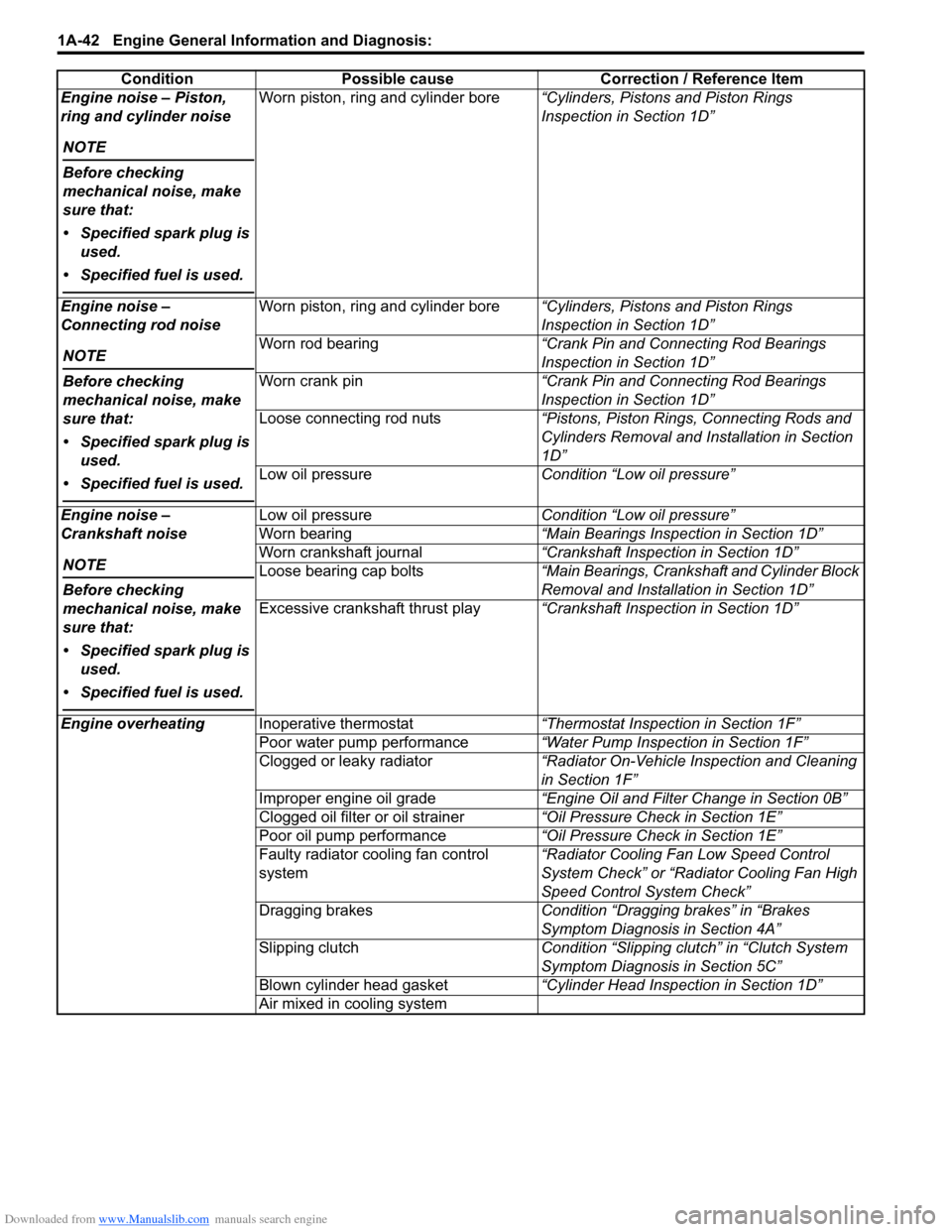

Engine noise – Piston,

ring and cylinder noise

NOTE

Before checking

mechanical noise, make

sure that:

• Specified spark plug is used.

• Specified fuel is used.

Worn piston, ring and cylinder bore “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Engine noise –

Connecting rod noise

NOTE

Before checking

mechanical noise, make

sure that:

• Specified spark plug is used.

• Specified fuel is used.

Worn piston, ring and cylinder bore “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn rod bearing “Crank Pin and Connecting Rod Bearings

Inspection in Section 1D”

Worn crank pin “Crank Pin and Connecting Rod Bearings

Inspection in Section 1D”

Loose connecting rod nuts “Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation in Section

1D”

Low oil pressure Condition “Low oil pressure”

Engine noise –

Crankshaft noise

NOTE

Before checking

mechanical noise, make

sure that:

• Specified spark plug is used.

• Specified fuel is used.

Low oil pressure Condition “Low oil pressure”

Worn bearing “Main Bearings Inspection in Section 1D”

Worn crankshaft journal “Crankshaft Inspection in Section 1D”

Loose bearing cap bolts “Main Bearings, Crankshaft and Cylinder Block

Removal and Installation in Section 1D”

Excessive crankshaft thrust play “Crankshaft Inspection in Section 1D”

Engine overheating Inoperative thermostat “Thermostat Inspection in Section 1F”

Poor water pump performance “Water Pump Inspection in Section 1F”

Clogged or leaky radiator “Radiator On-Vehicle Inspection and Cleaning

in Section 1F”

Improper engine oil grade “Engine Oil and Filter Change in Section 0B”

Clogged oil filter or oil strainer “Oil Pressure Check in Section 1E”

Poor oil pump performance “Oil Pressure Check in Section 1E”

Faulty radiator cooling fan control

system “Radiator Cooling Fan Low Speed Control

System Check” or “Rad

iator Cooling Fan High

Speed Control System Check”

Dragging brakes Condition “Dragging brakes” in “Brakes

Symptom Diagnosis in Section 4A”

Slipping clutch Condition “Slipping clutch” in “Clutch System

Symptom Diagnosis in Section 5C”

Blown cylinder head gasket “Cylinder Head Inspection in Section 1D”

Air mixed in cooling system

Condition Possible cause Correction / Reference Item

Page 93 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-43

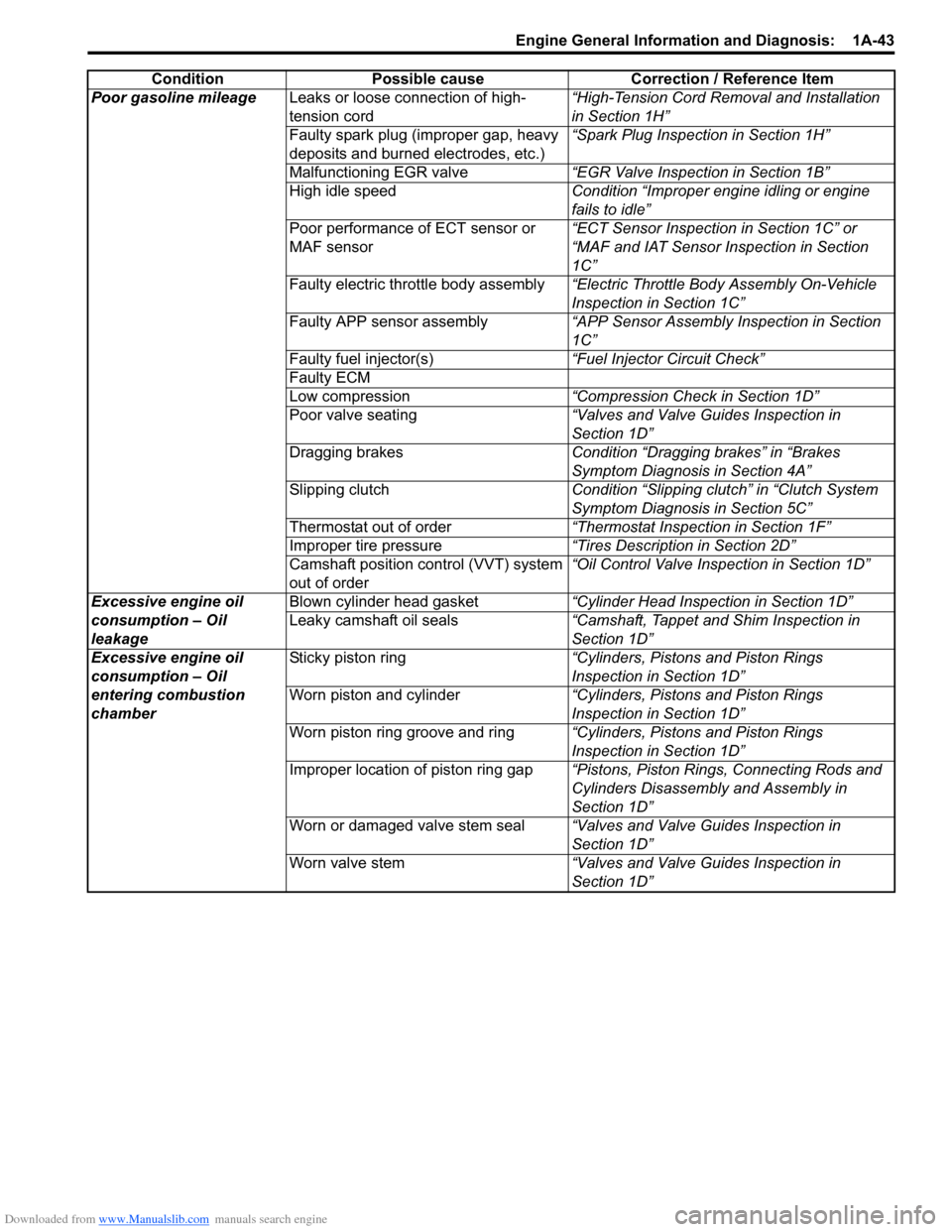

Poor gasoline mileageLeaks or loose connection of high-

tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Faulty spark plug (improper gap, heavy

deposits and burned electrodes, etc.) “Spark Plug Inspection in Section 1H”

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

High idle speed Condition “Improper engine idling or engine

fails to idle”

Poor performance of ECT sensor or

MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty fuel injector(s) “Fuel Injector Circuit Check”

Faulty ECM

Low compression “Compression Check in Section 1D”

Poor valve seating “Valves and Valve Guides Inspection in

Section 1D”

Dragging brakes Condition “Dragging brakes” in “Brakes

Symptom Diagnosis in Section 4A”

Slipping clutch Condition “Slipping clutch” in “Clutch System

Symptom Diagnosis in Section 5C”

Thermostat out of order “Thermostat Inspection in Section 1F”

Improper tire pressure “Tires Description in Section 2D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Excessive engine oil

consumption – Oil

leakage Blown cylinder head gasket

“Cylinder Head Inspection in Section 1D”

Leaky camshaft oil seals “Camshaft, Tappet and Shim Inspection in

Section 1D”

Excessive engine oil

consumption – Oil

entering combustion

chamber Sticky piston ring

“Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn piston and cylinder “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn piston ring groove and ring “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Improper location of piston ring gap “Pistons, Piston Rings, Connecting Rods and

Cylinders Disassembly and Assembly in

Section 1D”

Worn or damaged valve stem seal “Valves and Valve Guides Inspection in

Section 1D”

Worn valve stem “Valves and Valve Guides Inspection in

Section 1D”

Condition Possible cause Correction / Reference Item

Page 95 of 1496

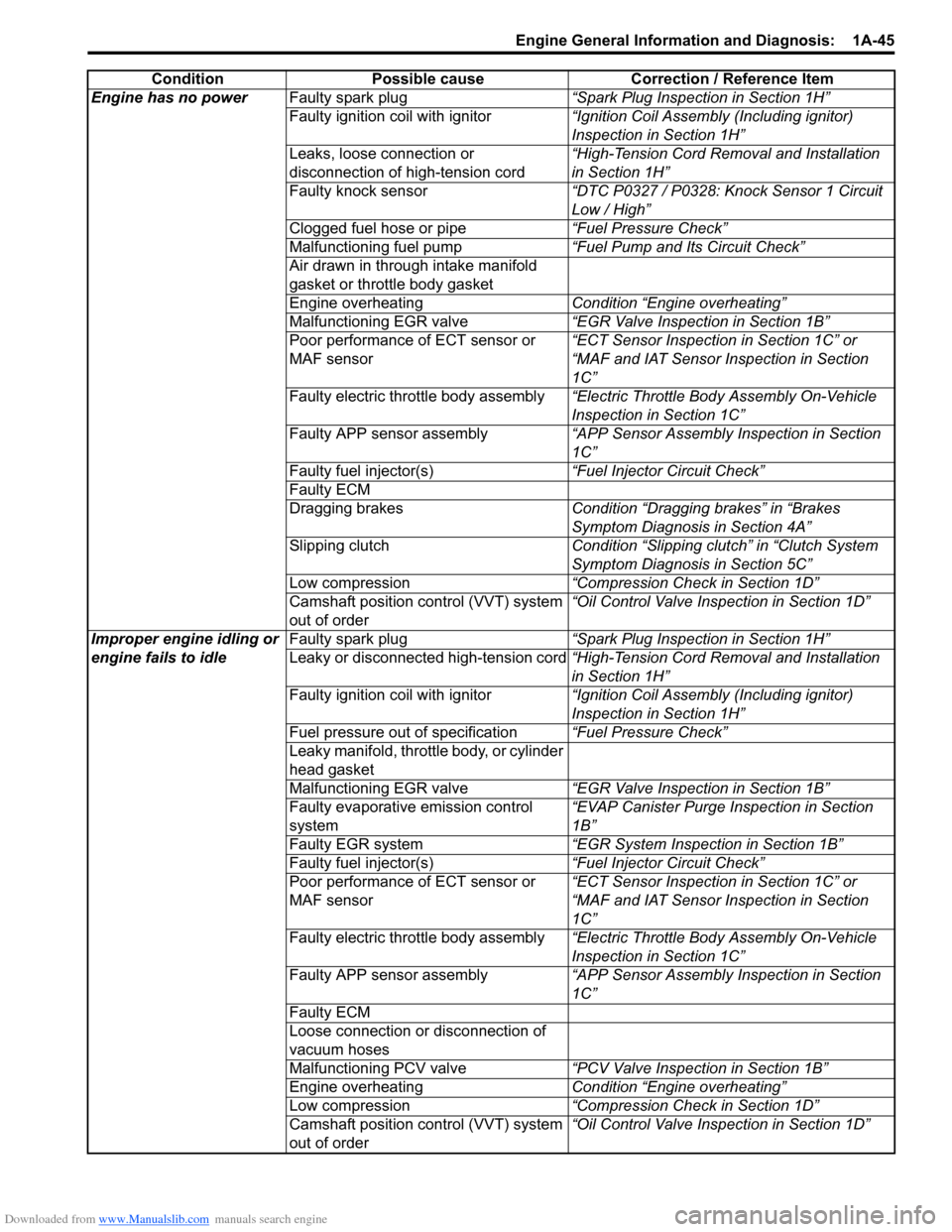

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-45

Engine has no powerFaulty spark plug “Spark Plug Inspection in Section 1H”

Faulty ignition coil with ignitor “Ignition Coil Assembly (Including ignitor)

Inspection in Section 1H”

Leaks, loose connection or

disconnection of high-tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Faulty knock sensor “DTC P0327 / P0328: Knock Sensor 1 Circuit

Low / High”

Clogged fuel hose or pipe “Fuel Pressure Check”

Malfunctioning fuel pump “Fuel Pump and Its Circuit Check”

Air drawn in through intake manifold

gasket or throttle body gasket

Engine overheating Condition “Engine overheating”

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Poor performance of ECT sensor or

MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty fuel injector(s) “Fuel Injector Circuit Check”

Faulty ECM

Dragging brakes Condition “Dragging brakes” in “Brakes

Symptom Diagnosis in Section 4A”

Slipping clutch Condition “Slipping clutch” in “Clutch System

Symptom Diagnosis in Section 5C”

Low compression “Compression Check in Section 1D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Improper engine idling or

engine fails to idle Faulty spark plug

“Spark Plug Inspection in Section 1H”

Leaky or disconnected high-tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Faulty ignition coil with ignitor “Ignition Coil Assembly (Including ignitor)

Inspection in Section 1H”

Fuel pressure out of specification “Fuel Pressure Check”

Leaky manifold, throttle body, or cylinder

head gasket

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Faulty evaporative emission control

system “EVAP Canister Purge Inspection in Section

1B”

Faulty EGR system “EGR System Inspection in Section 1B”

Faulty fuel injector(s) “Fuel Injector Circuit Check”

Poor performance of ECT sensor or

MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty ECM

Loose connection or disconnection of

vacuum hoses

Malfunctioning PCV valve “PCV Valve Inspection in Section 1B”

Engine overheating Condition “Engine overheating”

Low compression “Compression Check in Section 1D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Condition Possible cause Correction / Reference Item

Page 103 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-53

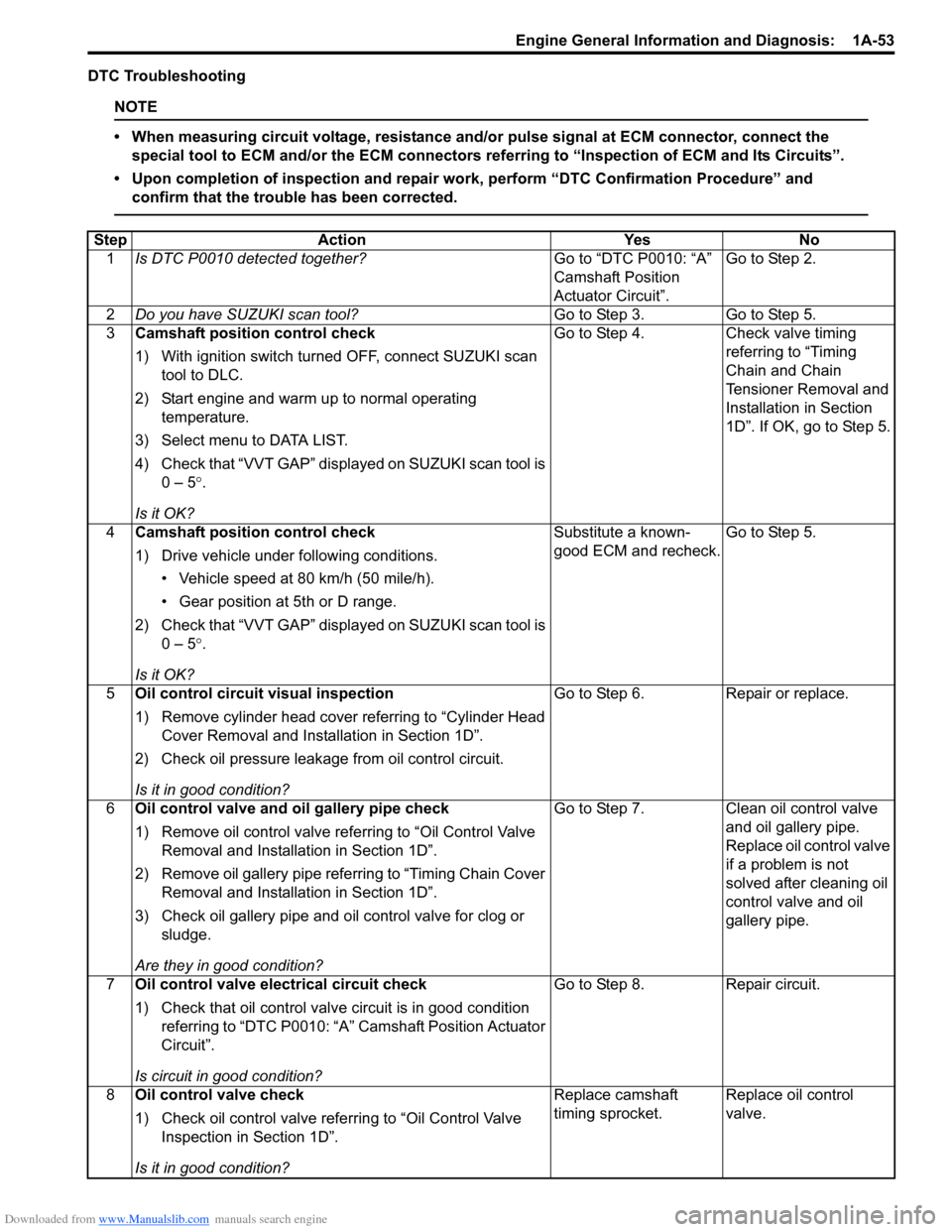

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Is DTC P0010 detected together? Go to “DTC P0010: “A”

Camshaft Position

Actuator Circuit”.Go to Step 2.

2 Do you have SUZUKI scan tool? Go to Step 3.Go to Step 5.

3 Camshaft position control check

1) With ignition switch turned OFF, connect SUZUKI scan

tool to DLC.

2) Start engine and warm up to normal operating temperature.

3) Select menu to DATA LIST.

4) Check that “VVT GAP” displayed on SUZUKI scan tool is 0 – 5 °.

Is it OK? Go to Step 4.

Check valve timing

referring to “Timing

Chain and Chain

Tensioner Removal and

Installation in Section

1D”. If OK, go to Step 5.

4 Camshaft position control check

1) Drive vehicle under following conditions.

• Vehicle speed at 80 km/h (50 mile/h).

• Gear position at 5th or D range.

2) Check that “VVT GAP” displayed on SUZUKI scan tool is 0 – 5 °.

Is it OK? Substitute a known-

good ECM and recheck.

Go to Step 5.

5 Oil control circuit visual inspection

1) Remove cylinder head cover referring to “Cylinder Head

Cover Removal and Insta llation in Section 1D”.

2) Check oil pressure leakage from oil control circuit.

Is it in good condition? Go to Step 6.

Repair or replace.

6 Oil control valve and oil gallery pipe check

1) Remove oil control valve re ferring to “Oil Control Valve

Removal and Installation in Section 1D”.

2) Remove oil gallery pipe refe rring to “Timing Chain Cover

Removal and Installation in Section 1D”.

3) Check oil gallery pipe and o il control valve for clog or

sludge.

Are they in good condition? Go to Step 7.

Clean oil control valve

and oil gallery pipe.

Replace oil control valve

if a problem is not

solved after cleaning oil

control valve and oil

gallery pipe.

7 Oil control valve electrical circuit check

1) Check that oil control valve circuit is in good condition

referring to “DTC P0010: “A” Camshaft Position Actuator

Circuit”.

Is circuit in good condition? Go to Step 8.

Repair circuit.

8 Oil control valve check

1) Check oil control valve refe rring to “Oil Control Valve

Inspection in Section 1D”.

Is it in good condition? Replace camshaft

timing sprocket.

Replace oil control

valve.

Page 271 of 1496

Downloaded from www.Manualslib.com manuals search engine Aux. Emission Control Devices: 1B-4

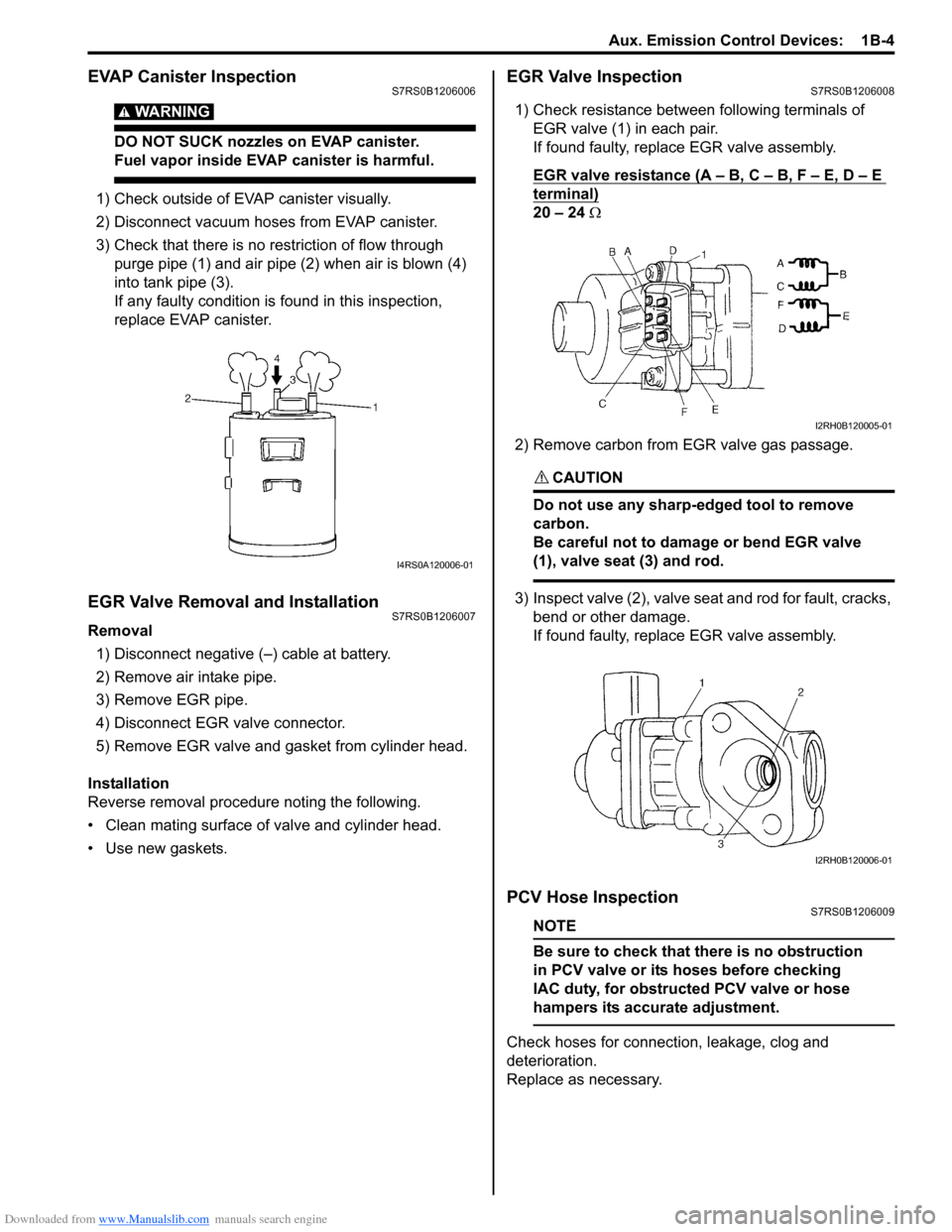

EVAP Canister InspectionS7RS0B1206006

WARNING!

DO NOT SUCK nozzles on EVAP canister.

Fuel vapor inside EVAP canister is harmful.

1) Check outside of EVAP canister visually.

2) Disconnect vacuum hoses from EVAP canister.

3) Check that there is no restriction of flow through purge pipe (1) and air pipe (2) when air is blown (4)

into tank pipe (3).

If any faulty condition is found in this inspection,

replace EVAP canister.

EGR Valve Removal and InstallationS7RS0B1206007

Removal

1) Disconnect negative (–) cable at battery.

2) Remove air intake pipe.

3) Remove EGR pipe.

4) Disconnect EGR valve connector.

5) Remove EGR valve and gasket from cylinder head.

Installation

Reverse removal procedure noting the following.

• Clean mating surface of valve and cylinder head.

• Use new gaskets.

EGR Valve InspectionS7RS0B1206008

1) Check resistance between following terminals of EGR valve (1) in each pair.

If found faulty, replace EGR valve assembly.

EGR valve resistance (A – B, C – B, F – E, D – E

terminal)

20 – 24 Ω

2) Remove carbon from EGR valve gas passage.

CAUTION!

Do not use any sharp-edged tool to remove

carbon.

Be careful not to damage or bend EGR valve

(1), valve seat (3) and rod.

3) Inspect valve (2), valve seat and rod for fault, cracks, bend or other damage.

If found faulty, replace EGR valve assembly.

PCV Hose InspectionS7RS0B1206009

NOTE

Be sure to check that there is no obstruction

in PCV valve or its hoses before checking

IAC duty, for obstructed PCV valve or hose

hampers its accurate adjustment.

Check hoses for connection, leakage, clog and

deterioration.

Replace as necessary.

I4RS0A120006-01

I2RH0B120005-01

I2RH0B120006-01

Page 280 of 1496

Downloaded from www.Manualslib.com manuals search engine 1C-8 Engine Electrical Devices:

Installation

Reverse removal procedure noting the following.

• Tighten heated oxygen sensor to specified torque.Tightening torque

Heated oxygen sensor (a): 45 N·m (4.5 kgf-m,

32.5 lb-ft)

• Install exhaust manifold referring to “Exhaust Manifold Removal and Installation in Section 1K”, if removed.

• Connect connector of heated oxygen sensor and clamp wire harness securely.

• After installing heated oxygen sensor, start engine and check that no exhaust gas leakage exists.

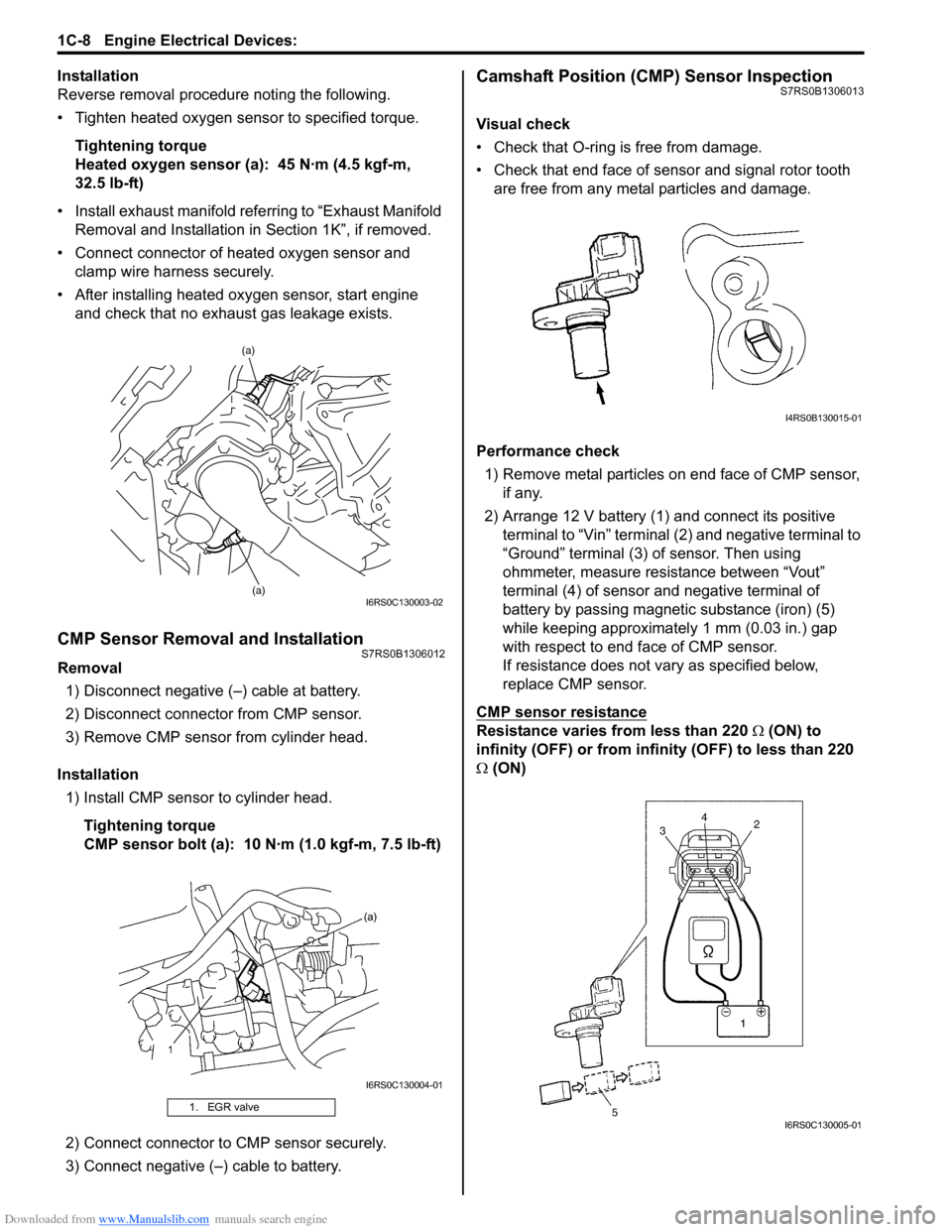

CMP Sensor Removal and InstallationS7RS0B1306012

Removal

1) Disconnect negative (–) cable at battery.

2) Disconnect connector from CMP sensor.

3) Remove CMP sensor from cylinder head.

Installation 1) Install CMP sensor to cylinder head.

Tightening torque

CMP sensor bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

2) Connect connector to CMP sensor securely.

3) Connect negative (–) cable to battery.

Camshaft Position (CMP) Sensor InspectionS7RS0B1306013

Visual check

• Check that O-ring is free from damage.

• Check that end face of sensor and signal rotor tooth are free from any metal particles and damage.

Performance check 1) Remove metal particles on end face of CMP sensor, if any.

2) Arrange 12 V battery (1) and connect its positive terminal to “Vin” terminal (2) and negative terminal to

“Ground” terminal (3) of sensor. Then using

ohmmeter, measure resistance between “Vout”

terminal (4) of sensor and negative terminal of

battery by passing magnetic substance (iron) (5)

while keeping approximately 1 mm (0.03 in.) gap

with respect to end face of CMP sensor.

If resistance does not vary as specified below,

replace CMP sensor.

CMP sensor resistance

Resistance varies from less than 220 Ω (ON) to

infinity (OFF) or from infinity (OFF) to less than 220

Ω (ON)

1. EGR valve

(a)

(a)

I6RS0C130003-02

I6RS0C130004-01

I4RS0B130015-01

I6RS0C130005-01

Page 291 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-6

6) Connect special tool (Vacuum gauge) to PCV hose (1).

Special tool

(A): 09915–67311

7) Blind PCV valve (2) using tape (3) or the like.

8) Install air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

9) Run engine at specified idle speed and read vacuum gauge. Vacuum should be within specification.

Vacuum specification (at sea level)

59 – 73 kPa (45 – 55 cmHg, 17.7 – 21.6 in.Hg) at

specified idle speed

10) Remove air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

11) Disconnect special tool (vacuum gage) from PCV valve.

12) Detach blind cap from PCV valve, and connect PCV hose to PCV valve.

13) Install air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

14) Install engine cover.

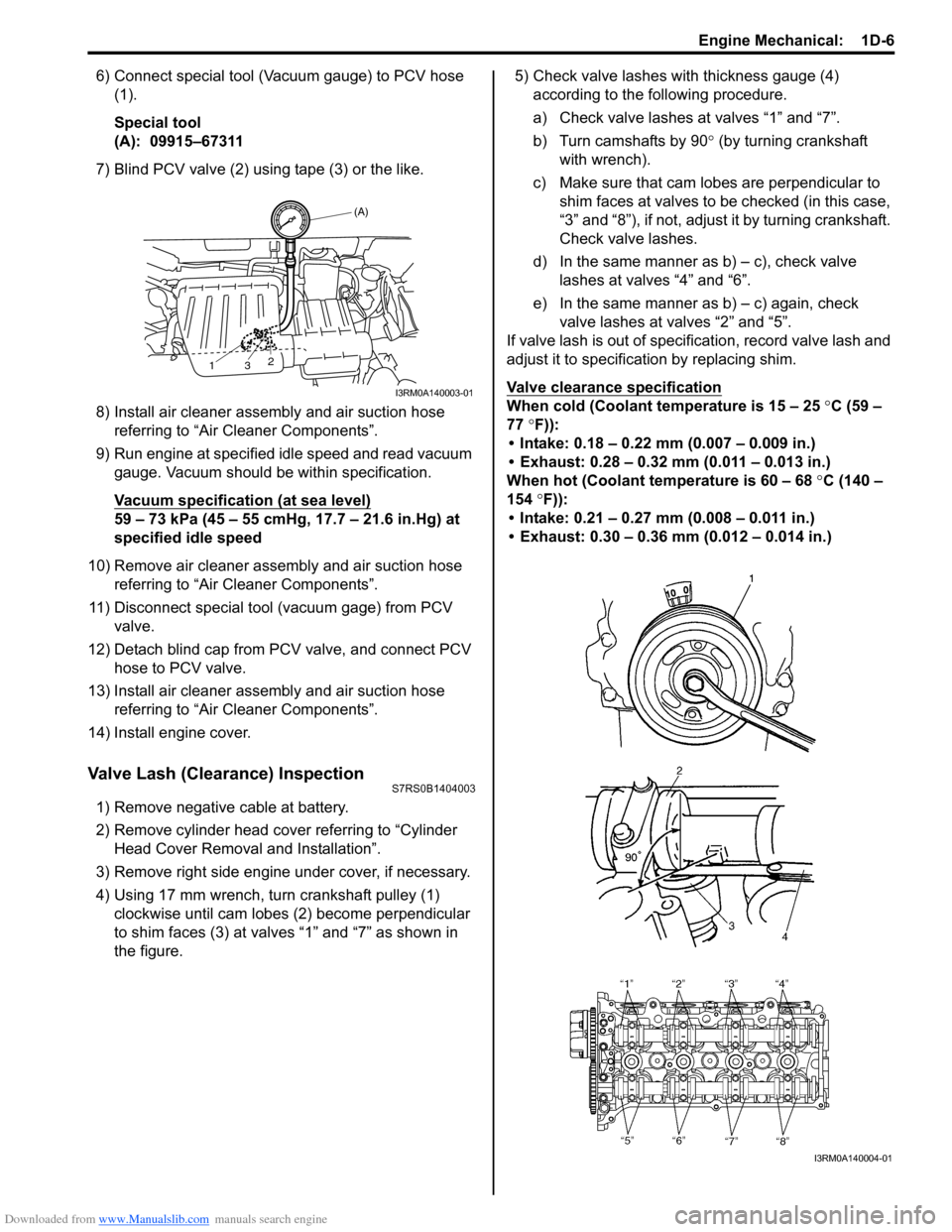

Valve Lash (Clearance) InspectionS7RS0B1404003

1) Remove negative cable at battery.

2) Remove cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

3) Remove right side engine under cover, if necessary.

4) Using 17 mm wrench, turn crankshaft pulley (1) clockwise until cam lobes (2) become perpendicular

to shim faces (3) at valves “1” and “7” as shown in

the figure. 5) Check valve lashes with thickness gauge (4)

according to the following procedure.

a) Check valve lashes at valves “1” and “7”.

b) Turn camshafts by 90 ° (by turning crankshaft

with wrench).

c) Make sure that cam lobes are perpendicular to shim faces at valves to be checked (in this case,

“3” and “8”), if not, adjust it by turning crankshaft.

Check valve lashes.

d) In the same manner as b) – c), check valve

lashes at valves “4” and “6”.

e) In the same manner as b) – c) again, check valve lashes at valves “2” and “5”.

If valve lash is out of specification, record valve lash and

adjust it to specification by replacing shim.

Valve clearance specification

When cold (Coolant te mperature is 15 – 25 °C (59 –

77 °F)):

• Intake: 0.18 – 0.22 mm (0.007 – 0.009 in.)

• Exhaust: 0.28 – 0.32 mm (0.011 – 0.013 in.)

When hot (Coolant temperature is 60 – 68 °C (140 –

154 °F)):

• Intake: 0.21 – 0.27 mm (0.008 – 0.011 in.)

• Exhaust: 0.30 – 0.36 mm (0.012 – 0.014 in.)

(A)

13 2

I3RM0A140003-01

I3RM0A140004-01

Page 293 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-8

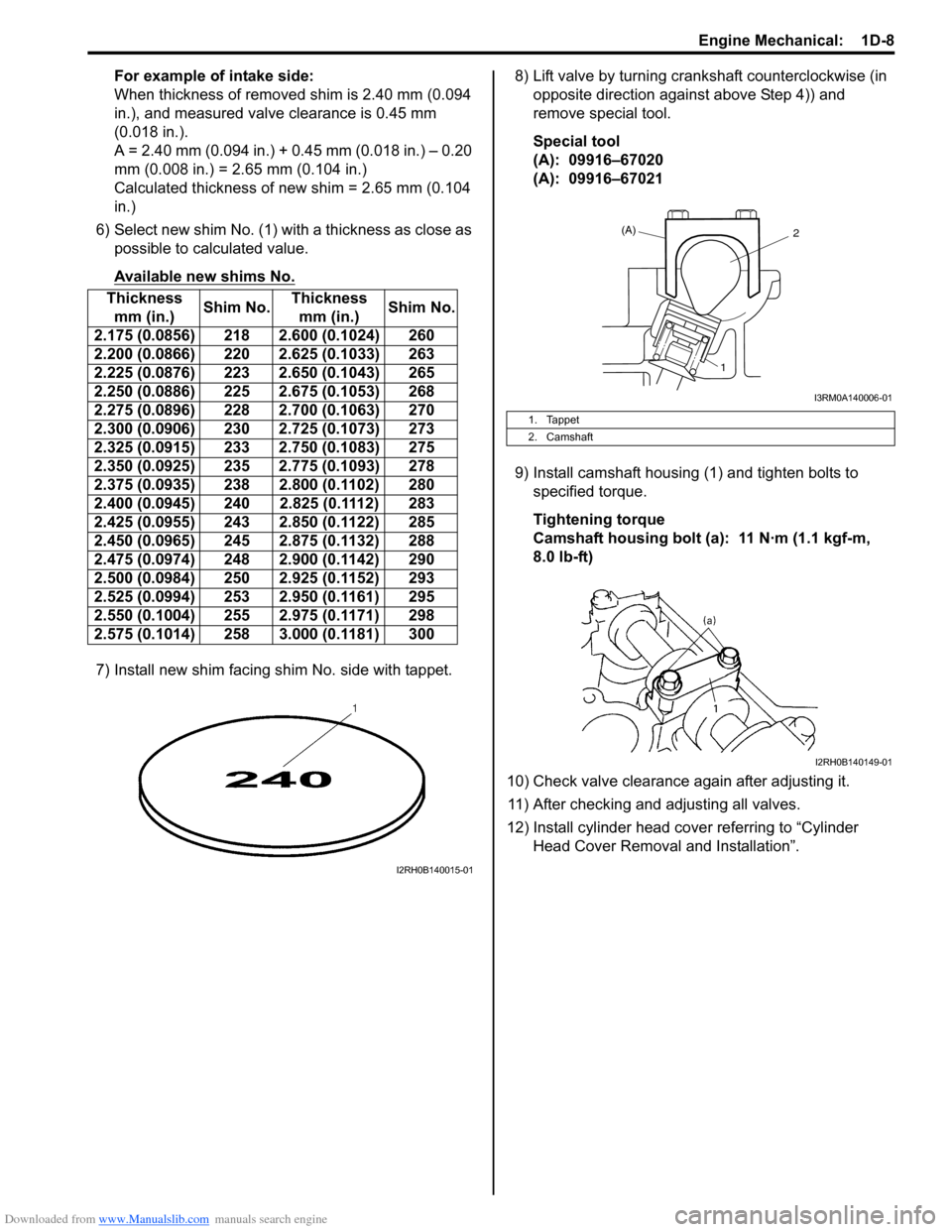

For example of intake side:

When thickness of removed shim is 2.40 mm (0.094

in.), and measured valve clearance is 0.45 mm

(0.018 in.).

A = 2.40 mm (0.094 in.) + 0.45 mm (0.018 in.) – 0.20

mm (0.008 in.) = 2.65 mm (0.104 in.)

Calculated thickness of new shim = 2.65 mm (0.104

in.)

6) Select new shim No. (1) with a thickness as close as possible to calculated value.

Available new shims No.

7) Install new shim facing shim No. side with tappet. 8) Lift valve by turning crankshaft counterclockwise (in

opposite direction against above Step 4)) and

remove special tool.

Special tool

(A): 09916–67020

(A): 09916–67021

9) Install camshaft housing (1) and tighten bolts to specified torque.

Tightening torque

Camshaft housing bolt (a ): 11 N·m (1.1 kgf-m,

8.0 lb-ft)

10) Check valve clearance again after adjusting it. 11) After checking and adjusting all valves.

12) Install cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

Thickness

mm (in.) Shim No.Thickness

mm (in.) Shim No.

2.175 (0.0856) 218 2.600 (0.1024) 260

2.200 (0.0866) 220 2.625 (0.1033) 263

2.225 (0.0876) 223 2.650 (0.1043) 265

2.250 (0.0886) 225 2.675 (0.1053) 268

2.275 (0.0896) 228 2.700 (0.1063) 270

2.300 (0.0906) 230 2.725 (0.1073) 273

2.325 (0.0915) 233 2.750 (0.1083) 275

2.350 (0.0925) 235 2.775 (0.1093) 278

2.375 (0.0935) 238 2.800 (0.1102) 280

2.400 (0.0945) 240 2.825 (0.1112) 283

2.425 (0.0955) 243 2.850 (0.1122) 285

2.450 (0.0965) 245 2.875 (0.1132) 288

2.475 (0.0974) 248 2.900 (0.1142) 290

2.500 (0.0984) 250 2.925 (0.1152) 293

2.525 (0.0994) 253 2.950 (0.1161) 295

2.550 (0.1004) 255 2.975 (0.1171) 298

2.575 (0.1014) 258 3.000 (0.1181) 300

I2RH0B140015-01

1. Tappet

2. Camshaft

(A)2

1

I3RM0A140006-01

I2RH0B140149-01