battery type SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 10 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-5 Precautions:

• When performing service to electrical parts that does not require use of battery power, disconnect the

negative cable of the battery.

• When disconnecting the negative cable from the battery, be careful to the following.

– Check and record DTCs in ECM and HVAC control module if necessary before disconnecting.

– Record displayed contents of the clock and/or audio system, etc. before disconnecting and reset it

as before after connecting.

– For vehicle equipped with electric throttle body system, perform electric throttle body system

calibration referring to “Electric Throttle Body

System Calibration in Section 1C” after

reconnecting the negative cable to the battery.

– For vehicle equipped with ESP ®, calibrate steering

angle sensor referring to “Sensor Calibration in

Section 4F” after reconnecting the negative cable

to the battery.

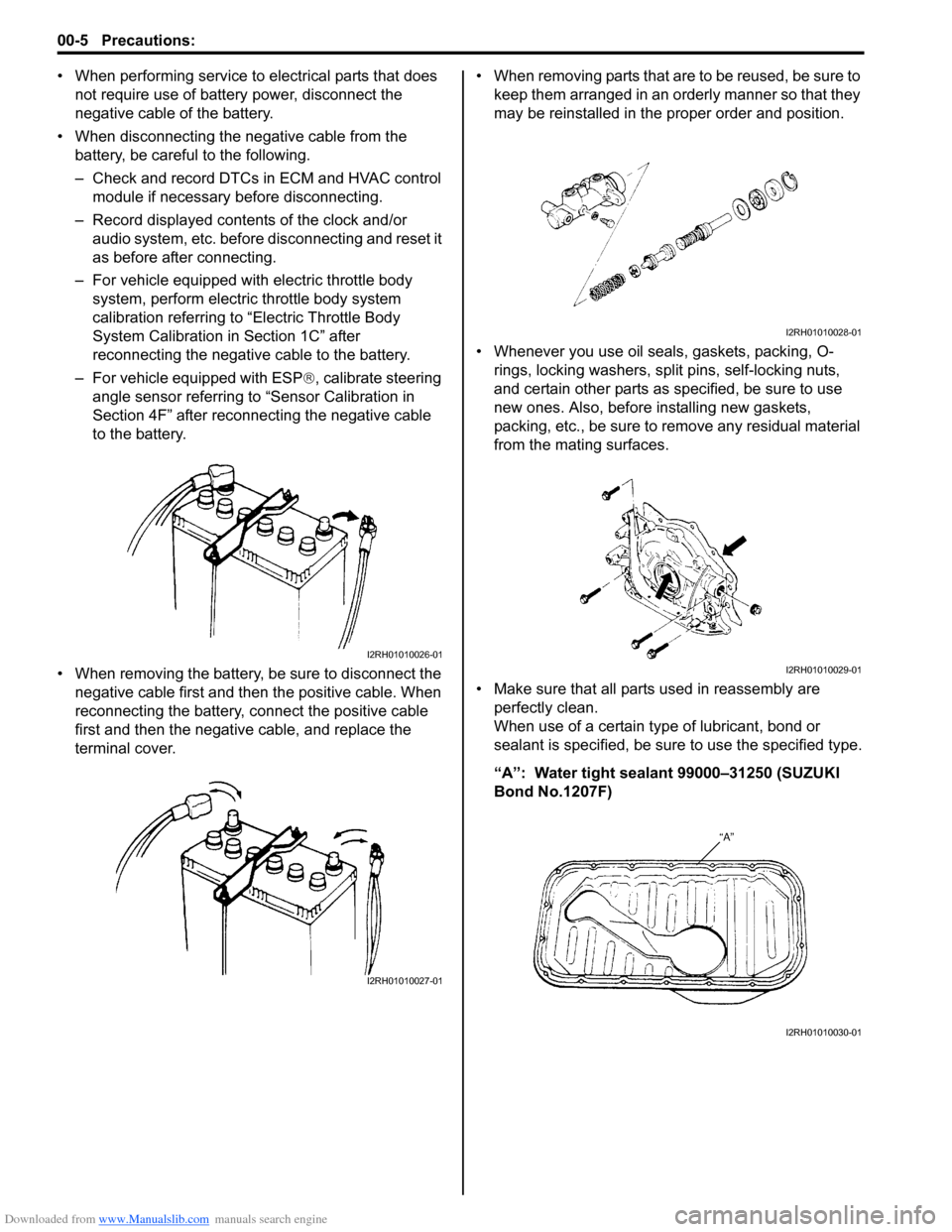

• When removing the battery, be sure to disconnect the negative cable first and then the positive cable. When

reconnecting the battery, connect the positive cable

first and then the negative cable, and replace the

terminal cover. • When removing parts that are to be reused, be sure to

keep them arranged in an orderly manner so that they

may be reinstalled in the proper order and position.

• Whenever you use oil seals, gaskets, packing, O- rings, locking washers, split pins, self-locking nuts,

and certain other parts as specified, be sure to use

new ones. Also, before installing new gaskets,

packing, etc., be sure to remove any residual material

from the mating surfaces.

• Make sure that all parts used in reassembly are perfectly clean.

When use of a certain type of lubricant, bond or

sealant is specified, be sure to use the specified type.

“A”: Water tight sealant 99000–31250 (SUZUKI

Bond No.1207F)

I2RH01010026-01

I2RH01010027-01

I2RH01010028-01

I2RH01010029-01

I2RH01010030-01

Page 14 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-9 Precautions:

• Be careful not to touch the electrical terminals of parts which use microcomputers (e.g. electronic control unit

like as ECM, PCM, P/S controller, etc.). The static

electricity from your body can damage these parts.

• Never connect any tester (voltmeter, ohmmeter, or whatever) to electronic control unit when its coupler is

disconnected. Attempt to do it may cause damage to

it.

• Never connect an ohmmeter to electronic control unit with its coupler connected to it. Attempt to do it may

cause damage to electronic control unit and sensors.

• Be sure to use a specified voltmeter / ohmmeter. Otherwise, accurate measurements may not be

obtained or personal injury ma y result. If not specified,

use a voltmeter with high impedance (M Ω/V

minimum) or a digital type voltmeter.

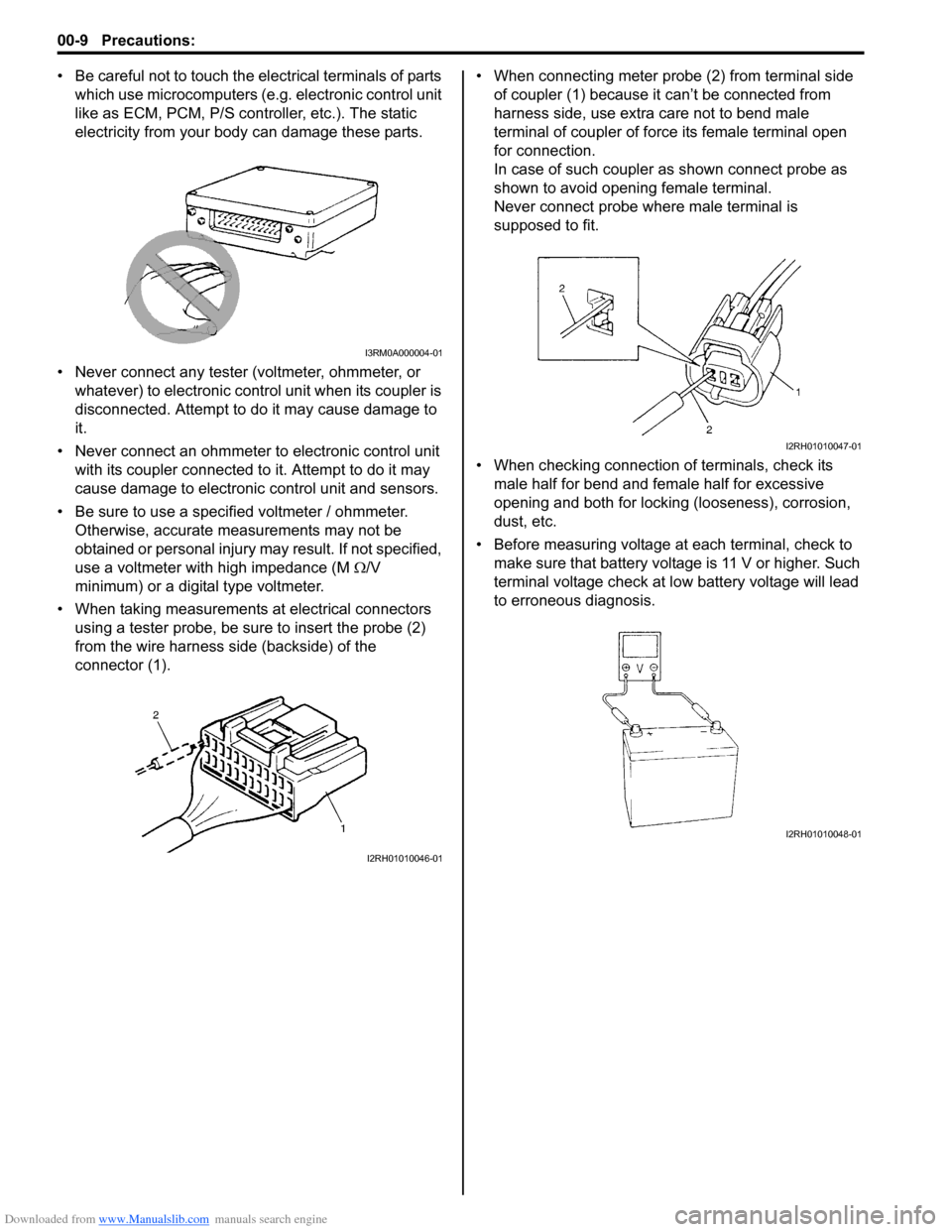

• When taking measurements at electrical connectors using a tester probe, be sure to insert the probe (2)

from the wire harness side (backside) of the

connector (1). • When connecting meter probe (2) from terminal side

of coupler (1) because it can’t be connected from

harness side, use extra care not to bend male

terminal of coupler of force its female terminal open

for connection.

In case of such coupler as shown connect probe as

shown to avoid opening female terminal.

Never connect probe where male terminal is

supposed to fit.

• When checking connection of terminals, check its

male half for bend and female half for excessive

opening and both for locking (looseness), corrosion,

dust, etc.

• Before measuring voltage at each terminal, check to make sure that battery voltage is 11 V or higher. Such

terminal voltage check at lo w battery voltage will lead

to erroneous diagnosis.

I3RM0A000004-01

I2RH01010046-01

I2RH01010047-01

I2RH01010048-01

Page 51 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-1

Engine

Engine General Information and Diagnosis

Precautions

Precautions on Engine ServiceS7RS0B1100001

CAUTION!

The following information on engine service

should be noted carefully, as it is important in

preventing damage, and in contributing to

reliable engine performance.

• When raising or supporting engine for any reason, do

not use a jack under oil pan. Due to small clearance

between oil pan and oil pump strainer, jacking against

oil pan may cause it to be bent against strainer,

resulting in damaged oil pick-up unit.

• It should be kept in mind , while working on engine,

that 12-volt electrical syste m is capable of violent and

damaging short circuits.

When performing any work where electrical terminals

can be grounded, ground cable of the battery should

be disconnected at battery.

• Any time the air cleaner, throttle body or intake manifold is removed, the intake opening should be

covered. This will protect against accidental entrance

of foreign material which could follow intake passage

into cylinder and cause extensive damage when

engine is started.

Precaution on On-Board Diagnostic (OBD)

System

S7RS0B1100005

There are two types of On -Board Diagnostic (OBD)

system, Euro OBD system and non-Euro-OBD system,

depending on the vehicle specification.

As the diagnosis function is different between these two

types, be sure to fully understand the OBD system

referring to “On-Board Diagnostic System Description”.

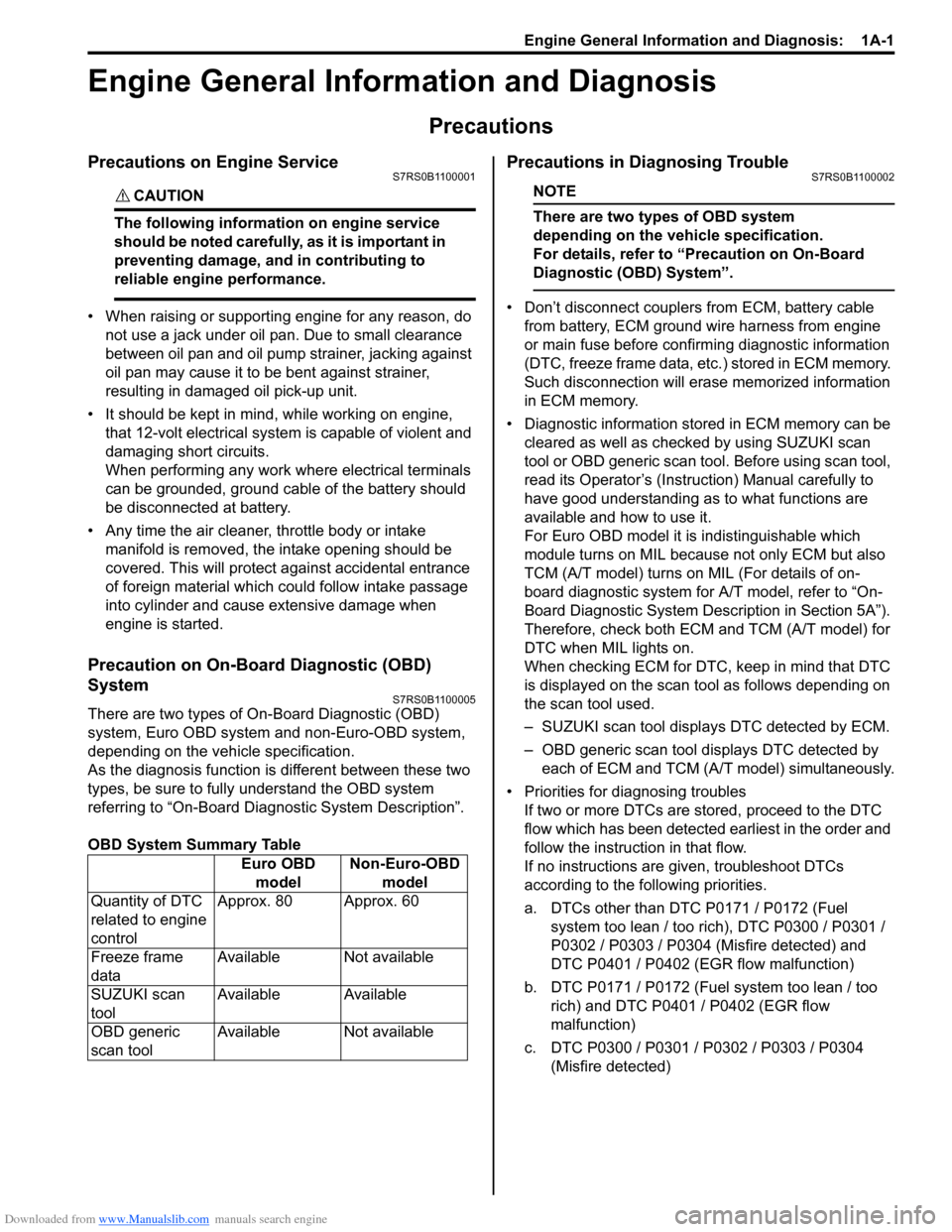

OBD System Summary Table

Precautions in Diagnosing TroubleS7RS0B1100002

NOTE

There are two types of OBD system

depending on the vehicle specification.

For details, refer to “Precaution on On-Board

Diagnostic (OBD) System”.

• Don’t disconnect couplers from ECM, battery cable

from battery, ECM ground wire harness from engine

or main fuse before confirming diagnostic information

(DTC, freeze frame data, etc.) stored in ECM memory.

Such disconnection will erase memorized information

in ECM memory.

• Diagnostic information stored in ECM memory can be cleared as well as checke d by using SUZUKI scan

tool or OBD generic scan tool. Before using scan tool,

read its Operator’s (Instruction) Manual carefully to

have good understanding as to what functions are

available and how to use it.

For Euro OBD model it is indistinguishable which

module turns on MIL because not only ECM but also

TCM (A/T model) turns on MIL (For details of on-

board diagnostic system for A/T model, refer to “On-

Board Diagnostic System Description in Section 5A”).

Therefore, check both ECM and TCM (A/T model) for

DTC when MIL lights on.

When checking ECM for DTC, keep in mind that DTC

is displayed on the scan tool as follows depending on

the scan tool used.

– SUZUKI scan tool displays DTC detected by ECM.

– OBD generic scan tool displays DTC detected by each of ECM and TCM (A/T model) simultaneously.

• Priorities for diagnosing troubles If two or more DTCs are stored, proceed to the DTC

flow which has been detected earliest in the order and

follow the instructi on in that flow.

If no instructions are given, troubleshoot DTCs

according to the following priorities.

a. DTCs other than DTC P0171 / P0172 (Fuel system too lean / too rich), DTC P0300 / P0301 /

P0302 / P0303 / P0304 (Misfire detected) and

DTC P0401 / P0402 (EGR flow malfunction)

b. DTC P0171 / P0172 (Fuel system too lean / too rich) and DTC P0401 / P0402 (EGR flow

malfunction)

c. DTC P0300 / P0301 / P0302 / P0303 / P0304 (Misfire detected)

Euro OBD

model Non-Euro-OBD

model

Quantity of DTC

related to engine

control Approx. 80 Approx. 60

Freeze frame

data Available Not available

SUZUKI scan

tool Available Available

OBD generic

scan tool Available Not available

Page 77 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-27

DTC ClearanceS7RS0B1104004

NOTE

There are two types of OBD system

depending on the vehicle specification.

For details, refer to “Precaution on On-Board

Diagnostic (OBD) System”.

Using Scan Tool1) Connect OBD generic scan to ol or SUZUKI scan tool

to data link connector in the same manner as when

making this connection for DTC check.

2) Turn ignition switch OFF and then ON.

3) Erase DTC and pending DTC according to instructions displayed on scan tool. Refer to scan

tool operator’s manual for further details.

4) After completing the clear ance, turn ignition switch

OFF and disconnect scan tool from data link

connector.

NOTE

DTC and freeze frame data stored in ECM

memory are also cleared in the following

cases. Be careful not to clear them before

keeping their record.

• When power to ECM is cut off (by disconnecting battery cable, removing

fuse or disconnecting ECM connectors).

• When the same malfunction (DTC) is not detected again during 40 engine warm-up

cycles. (See “Warm-Up Cycle” of “On-

Board Diagnostic System Description”.)

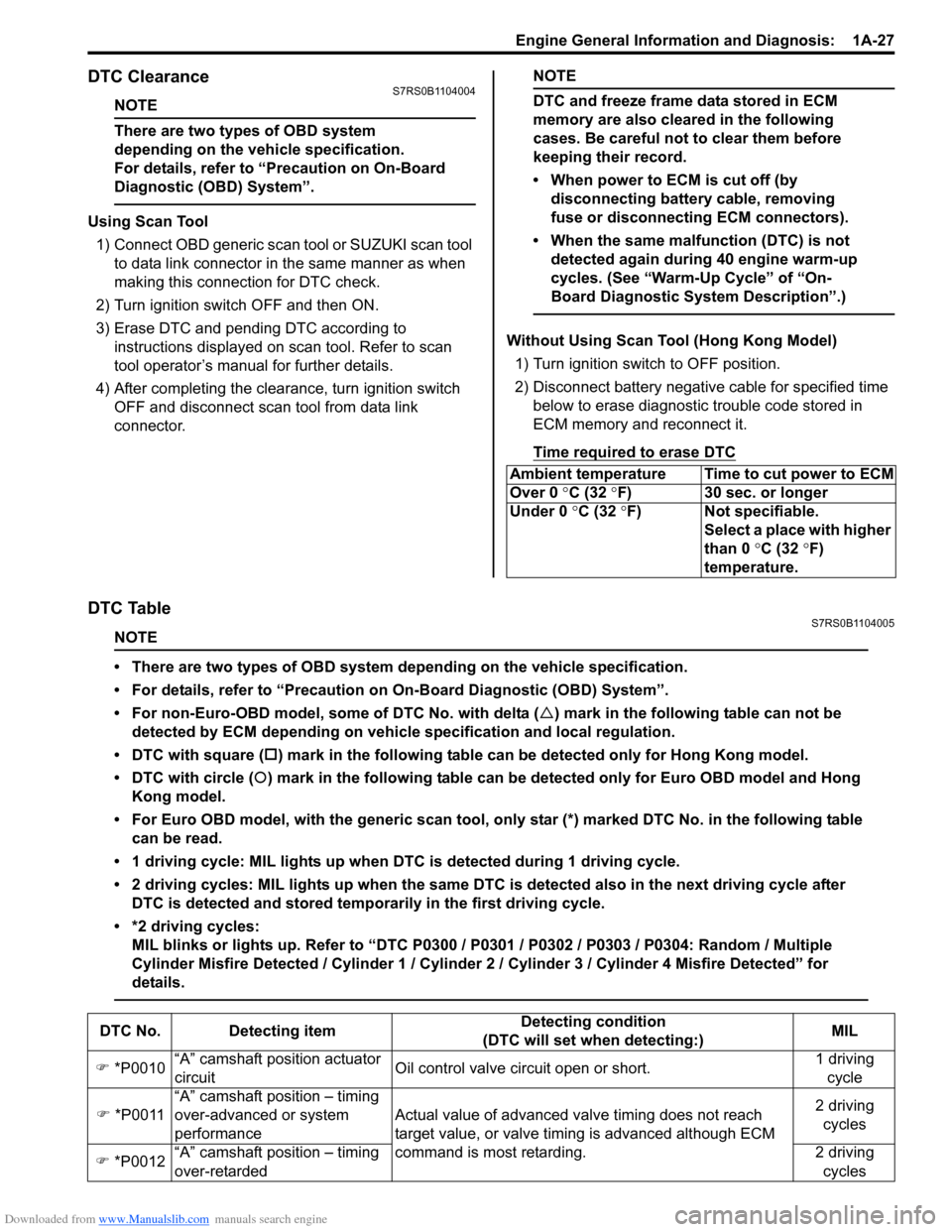

Without Using Scan Tool (Hong Kong Model)

1) Turn ignition switch to OFF position.

2) Disconnect battery negative cable for specified time below to erase diagnostic trouble code stored in

ECM memory and reconnect it.

Time required to erase DTC

DTC TableS7RS0B1104005

NOTE

• There are two types of OBD system depending on the vehicle specification.

• For details, refer to “Precaution on On-Board Diagnostic (OBD) System”.

• For non-Euro-OBD model, some of DTC No. with delta ( �U) mark in the following table can not be

detected by ECM depending on vehicl e specification and local regulation.

• DTC with square ( �†) mark in the following table can be detected only for Hong Kong model.

• DTC with circle ( �{) mark in the following table can be detected only for Euro OBD model and Hong

Kong model.

• For Euro OBD model, with the generic scan tool, onl y star (*) marked DTC No. in the following table

can be read.

• 1 driving cycle: MIL lights up when DTC is detected during 1 driving cycle.

• 2 driving cycles: MIL lights up when the same DTC is detected also in the next driving cycle after DTC is detected and stored temporarily in the first driving cycle.

• *2 driving cycles: MIL blinks or lights up. Refer to “DTC P0300 / P0301 / P0302 / P0303 / P0304: Random / Multiple

Cylinder Misfire Detected / Cylinder 1 / Cylinder 2 / Cylinder 3 / Cylinder 4 Misfire Detected” for

details.

Ambient temperature Time to cut power to ECM

Over 0 °C (32 ° F) 30 sec. or longer

Under 0 °C (32 °F) Not specifiable.

Select a place with higher

than 0 °C (32 °F)

temperature.

DTC No. Detecting item Detecting condition

(DTC will set when detecting:) MIL

�) *P0010 “A” camshaft position actuator

circuit Oil control valve circuit open or short. 1 driving

cycle

�) *P0011 “A” camshaft position – timing

over-advanced or system

performance Actual value of advanced va

lve timing does not reach

target value, or valve timi ng is advanced although ECM

command is most retarding. 2 driving

cycles

�) *P0012 “A” camshaft position – timing

over-retarded 2 driving

cycles

Page 267 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-217

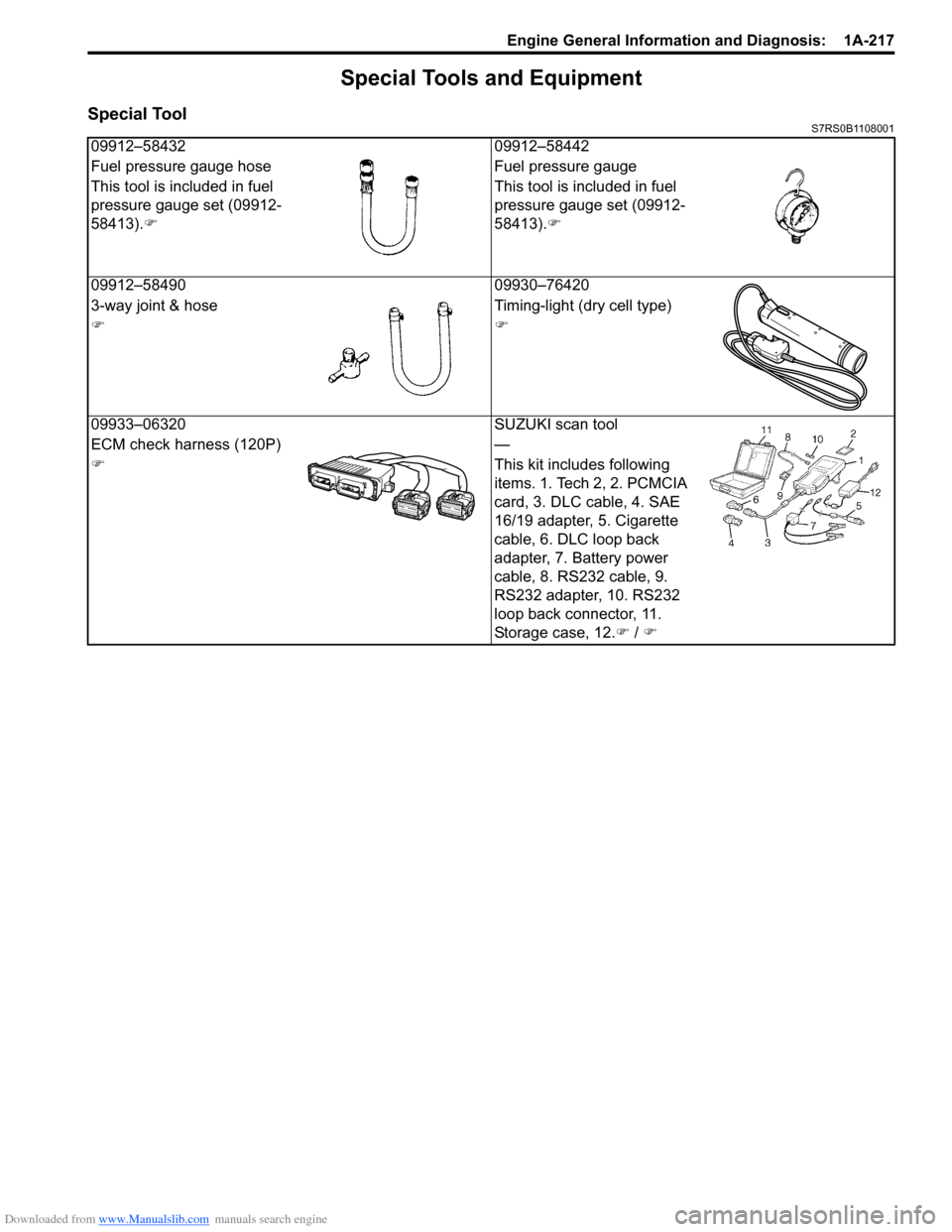

Special Tools and Equipment

Special ToolS7RS0B1108001

09912–5843209912–58442

Fuel pressure gauge hose Fuel pressure gauge

This tool is included in fuel

pressure gauge set (09912-

58413). �) This tool is included in fuel

pressure gauge set (09912-

58413).

�)

09912–58490 09930–76420

3-way joint & hose Timing-light (dry cell type)

�)�)

09933–06320 SUZUKI scan tool

ECM check harness (120P) —

�) This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12.�) / �)

Page 364 of 1496

Downloaded from www.Manualslib.com manuals search engine 1F-1 Engine Cooling System:

Engine

Engine Cooling System

General Description

Cooling System DescriptionS7RS0B1601001

The cooling system consists of the radiator cap, radiator, coolant reservoir, hoses, water pump, cooling fan and

thermostat. The radiator is of tube-and-fin type.

Coolant DescriptionS7RS0B1601002

WARNING!

• Do not remove radiator cap to check engine coolant level; check coolant visually at the see-through coolant reservoir. Coolant should be added only to reservoir as necessary.

• As long as there is pressure in the cooling system, the temperature can be considerably higher than the boiling temperature of the solution in the radiator without causing the solution to boil. Removal

of the radiator cap while engine is hot and pressure is high will cause the solution to boil

instantaneously and possibly with explosive force, spewing the solution over engine, fenders and

person removing cap. If the solution contains flammable anti-freeze such as alcohol (not

recommended for use at any time), there is also the possibility of causing a serious fire.

• Check to make sure that engine coolant temperature is cold before removing any part of cooling system.

• Also be sure to disconnect negative cable from battery terminal before removing any part.

The coolant recovery system is standard. The coolant in the radiator expands with heat, and the coolant is overflowed

to the reservoir.

When the system cools down, the coolant is drawn back into the radiator.

The cooling system has be en filled with a quality coolant that is a 50/50 mixture of water and ethylene glycol

antifreeze.

This 50/50 mixture coolant solution provides freezing protection to –36 °C (–33 °F).

• Maintain cooling system freeze protection at –36 °C (–33 °F) to ensure protection against corrosion and loss of

coolant from boiling. This should be done even if freezing temperatures are not expected.

• Add ethylene glycol base coolant when coolant has to be added because of coolant loss or to provide added protection against freezing at temperature lower than –36 °C (–33 °F).

NOTE

• Alcohol or methanol base coolant or plain water alone should not be used in cooling system at any

time as damage to cooling system could occur.

• Coolant must be mixed with deminerated water or distilled water.

Anti-freeze proportioning table

For M/T model For A/T model

Freezing temperature °

C –36 –36

° F –33 –33

Anti-freeze / Anti-corrosion coolant concentration % 50 50

Ratio of compound to cooling water ltr. 3.10/3.10 3.05/3.05

US pt. 6.55/6.55 6.44/6.44

Imp pt. 5.46/5.46 5.37/5.37

Page 376 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-1 Fuel System:

Engine

Fuel System

Precautions

Precautions on Fuel System ServiceS7RS0B1700001

WARNING!

Before attempting service of any type on fuel system, the following should be always observed in

order to reduce the risk of fire and personal injury.

• Disconnect negative cable at battery.

• Do not smoke, and place no smoking signs near work area.

• Be sure to have CO

2 fire extinguisher handy.

• Be sure to perform work in a well-ventilated area and away from any open flames (such as gas hot heater).

• Wear safety glasses.

• To relieve fuel vapor pressure in fuel tank, remove fuel filler cap from fuel filler neck and then

reinstall it.

• As fuel feed line is still under high fuel pr essure even after stopping engine, loosening or

disconnecting fuel feed line directly may cause dangerous spout of fuel. Before loosening or

disconnecting fuel feed line, make sure to relieve fuel pressure referring to “Fuel Pressure Relief

Procedure”.

• A small amount of fuel may be released when the fuel line is disconnected. In order to reduce the risk of personal injury, cover a shop cloth to the fitting to be disconnected. Be sure to put that cloth

in an approved container after disconnecting.

• Never run engine with fuel pump relay disconnected when engine and exhaust system are hot.

• Note that fuel hose connection varies with each type of pipe. Be sure to connect and clamp each hose correctly referring to “Fuel Hose Disconnecting and Reconnecting”.

After connecting, make sure that it has no twist or kink.

• When installing inje ctor or fuel feed pipe, lubr icate its O-ring with gasoline.

General Description

Fuel System DescriptionS7RS0B1701001

CAUTION!

This engine requires the unleaded fuel only.

The leaded and/or low lead fuel can result in

engine damage and reduce the effectiveness

of the emission control system.

The main components of the fuel system are fuel tank,

fuel pump assembly (with fuel filter, fuel level gauge, fuel

pressure regulator, fuel feed line and fuel vapor line.

For the details of fuel flow, refer to “Fuel Delivery System

Diagram”.

Fuel Delivery System DescriptionS7RS0B1701002

The fuel delivery system consists of the fuel tank, fuel

pump assembly (with built-in f uel filter and fuel pressure

regulator), delivery pipe, injectors and fuel feed line.

The fuel in the fuel tank is pumped up by the fuel pump,

sent into delivery pipe and injected by the injectors.

As the fuel pump assembly is equipped with built-in fuel

filter and fuel pressure regulator, the fuel is filtered and

its pressure is regulated before being sent to the feed

pipe.

The excess fuel at fuel pressure regulation process is

returned back into the fuel tank.

Also, fuel vapor generated in fuel tank is led through the

fuel vapor line into the EVAP canister.

For system diagram, refer to “Fuel Delivery System

Diagram”.

Page 401 of 1496

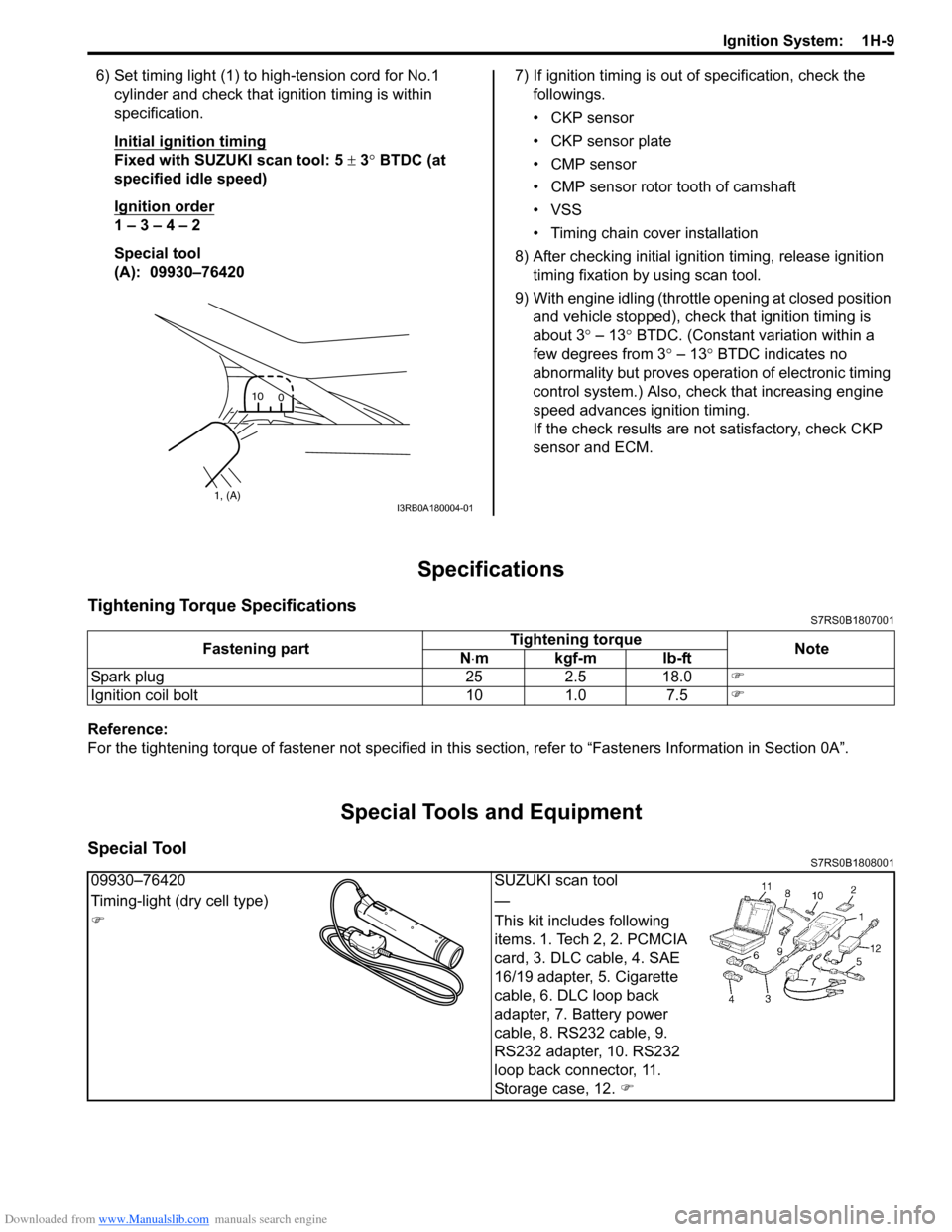

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-9

6) Set timing light (1) to high-tension cord for No.1 cylinder and check that ignition timing is within

specification.

Initial ignition timing

Fixed with SUZUKI scan tool: 5 ± 3° BTDC (at

specified idle speed)

Ignition order

1 – 3 – 4 – 2

Special tool

(A): 09930–76420 7) If ignition timing is out

of specification, check the

followings.

• CKP sensor

• CKP sensor plate

• CMP sensor

• CMP sensor rotor tooth of camshaft

• VSS

• Timing chain cover installation

8) After checking initial igniti on timing, release ignition

timing fixation by using scan tool.

9) With engine idling (throttl e opening at closed position

and vehicle stopped), check that ignition timing is

about 3 ° – 13° BTDC. (Constant variation within a

few degrees from 3 ° – 13° BTDC indicates no

abnormality but proves operation of electronic timing

control system.) Also, check that increasing engine

speed advances ignition timing.

If the check results are not satisfactory, check CKP

sensor and ECM.

Specifications

Tightening Torque SpecificationsS7RS0B1807001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS7RS0B1808001

1, (A)10

0I3RB0A180004-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Spark plug 25 2.5 18.0 �)

Ignition coil bolt 10 1.0 7.5 �)

09930–76420SUZUKI scan tool

Timing-light (dry cell type) —

�) This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. �)

Page 411 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-1

Engine

Charging System

General Description

Battery DescriptionS7RS0B1A01001

The battery has three major functions in the electrical

system.

• It is a source of electrical energy for cranking the engine.

• It acts as a voltage stabilizer for the electrical system.

• It can, for a limited time, provide energy when the electrical load exceeds the output of the generator.

Carrier and Hold-Down

The battery carrier should be in good condition so that it

will support the battery securely and keep it level. Before

installing the battery, the ba ttery carrier and hold-down

clamp should be clean and free from corrosion and

make certain there are no parts in carrier.

To prevent the battery from shaking in its carrier, the

hold-down bolts should be tight enough but not over-

tightened.

Electrolyte Freezing

The freezing point of electrolyte depends on its specific

gravity. Since freezing may ruin a battery, it should be

protected against freezing by keeping it in a fully

charged condition. If a battery is frozen accidentally, it

should not be charged until it is warmed.

Sulfation

If the battery is allowed to stand for a long period in

discharged condition, the lead sulfate becomes

converted into a hard, cryst alline substance, which will

not easily turn back to the active material again during

the subsequent recharging. “Sulfation” means the result

as well as the process of that reaction. Such a battery

can be revived by very slow charging and may be

restored to usable condition but its capacity is lower than

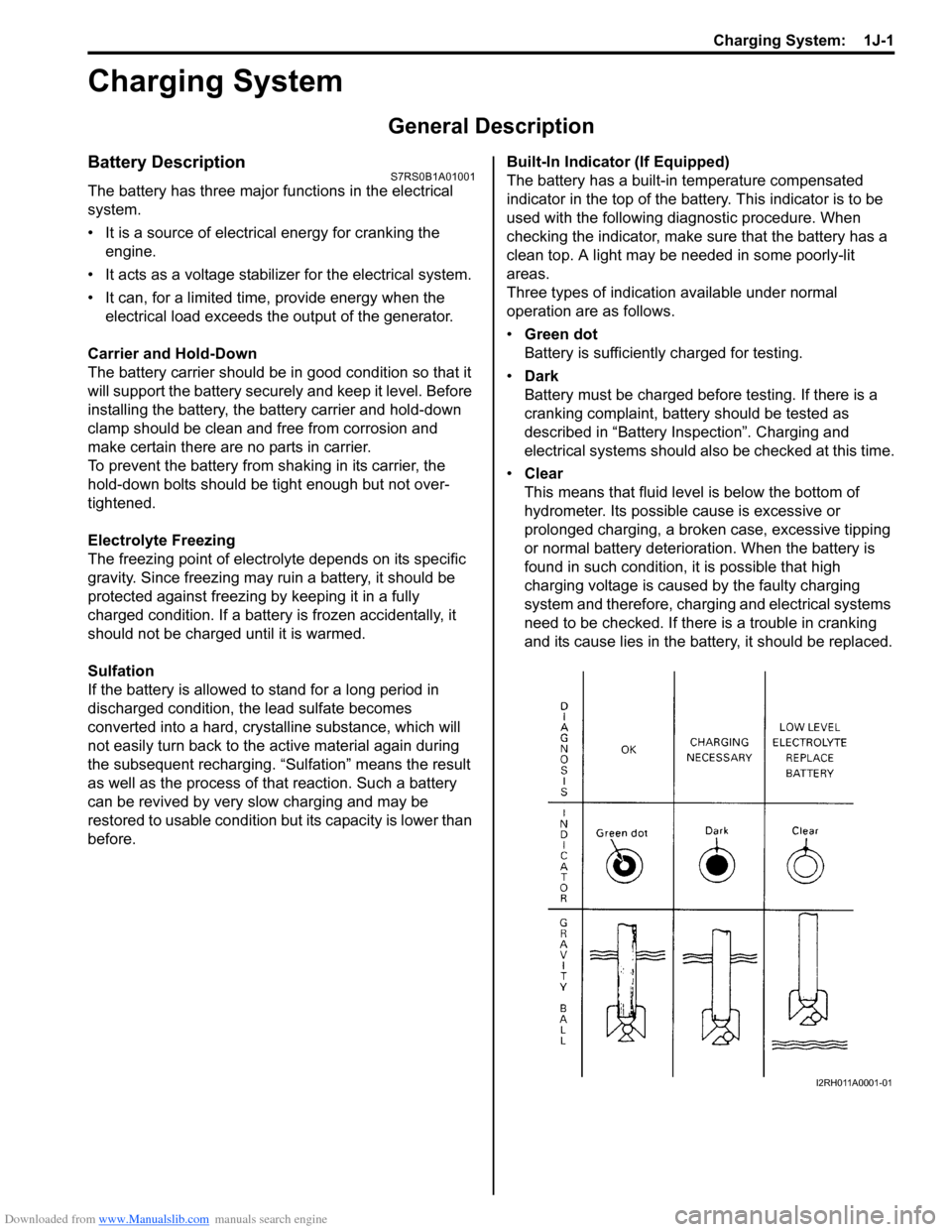

before. Built-In Indicator (If Equipped)

The battery has a built-in temperature compensated

indicator in the top of the battery. This indicator is to be

used with the following diagnostic procedure. When

checking the indicator, make sure that the battery has a

clean top. A light may be needed in some poorly-lit

areas.

Three types of indication available under normal

operation are as follows.

•

Green dot

Battery is sufficiently charged for testing.

• Dark

Battery must be charged before testing. If there is a

cranking complaint, battery should be tested as

described in “Battery Inspection”. Charging and

electrical systems should also be checked at this time.

• Clear

This means that fluid level is below the bottom of

hydrometer. Its possible cause is excessive or

prolonged charging, a broken case, excessive tipping

or normal battery deteriorat ion. When the battery is

found in such condition, it is possible that high

charging voltage is caused by the faulty charging

system and therefore, charging and electrical systems

need to be checked. If there is a trouble in cranking

and its cause lies in the battery, it should be replaced.

I2RH011A0001-01

Page 423 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-13

Specifications

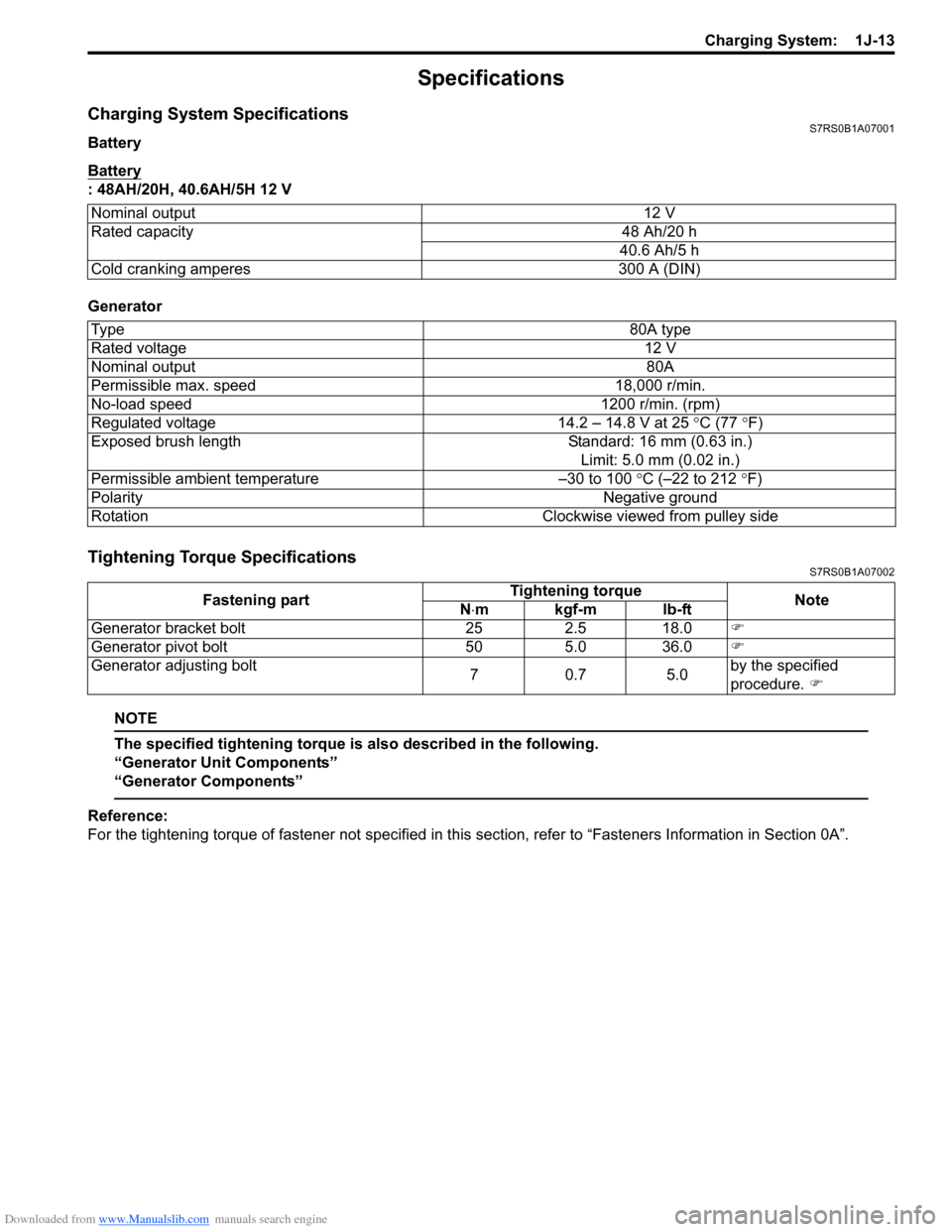

Charging System SpecificationsS7RS0B1A07001

Battery

Battery

: 48AH/20H, 40.6AH/5H 12 V

Generator

Tightening Torque SpecificationsS7RS0B1A07002

NOTE

The specified tightening torque is also described in the following.

“Generator Unit Components”

“Generator Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Nominal output

12 V

Rated capacity 48 Ah/20 h

40.6 Ah/5 h

Cold cranking amperes 300 A (DIN)

Ty p e 80A type

Rated voltage 12 V

Nominal output 80A

Permissible max. speed 18,000 r/min.

No-load speed 1200 r/min. (rpm)

Regulated voltage 14.2 – 14.8 V at 25 ° C (77 °F)

Exposed brush length Standard: 16 mm (0.63 in.)

Limit: 5.0 mm (0.02 in.)

Permissible ambient temperature –30 to 100 °C (–22 to 212 °F)

Polarity Negative ground

Rotation Clockwise viewed from pulley side

Fastening partTightening torque

Note

N ⋅mkgf-mlb-ft

Generator bracket bolt 25 2.5 18.0 �)

Generator pivot bolt 50 5.0 36.0 �)

Generator adjusting bolt 70.7 5.0by the specified

procedure.

�)