SUZUKI SWIFT 2017 5.G Owners Manual

Manufacturer: SUZUKI, Model Year: 2017, Model line: SWIFT, Model: SUZUKI SWIFT 2017 5.GPages: 336, PDF Size: 6.24 MB

Page 221 of 336

7-30

INSPECTION AND MAINTENANCE

74LH0-74E

NOTE:

Do not flex the wiper blade frame end more

than necessary. If you do, it can break off.

54G135

(1) Retainer

4) If the new blade is provided without the

two metal retainers, move them from

the old blade to the new one.

5) Install the new blade in the reverse

order of removal.

Make sure the blade is properly

retained by all the hooks.

6) Reinstall wiper frame to arm in the

reverse order of removal.Windshield Washer Fluid

80JM078

Check that there is washer fluid in the tank.

Refill it if necessary. Use a good quality

windshield washer fluid, diluted with water

as necessary.Air Conditioning SystemIf you do not use the air conditioner for a

long period, such as during winter, it may

not give the best performance when you

start using it again. To help maintain opti-

mum performance and durability of your air

conditioner, it needs to be run periodically.

Operate the air conditioner at least once a

month for one minute with the engine

idling. This circulates the refrigerant and oil

and helps protect the internal components.

Replacement of the Air Conditioner

Filter (if equipped)Since special procedures are required, we

recommend you take your vehicle to your

MARUTI SUZUKI dealer for the air condi-

tioner filter replacement.

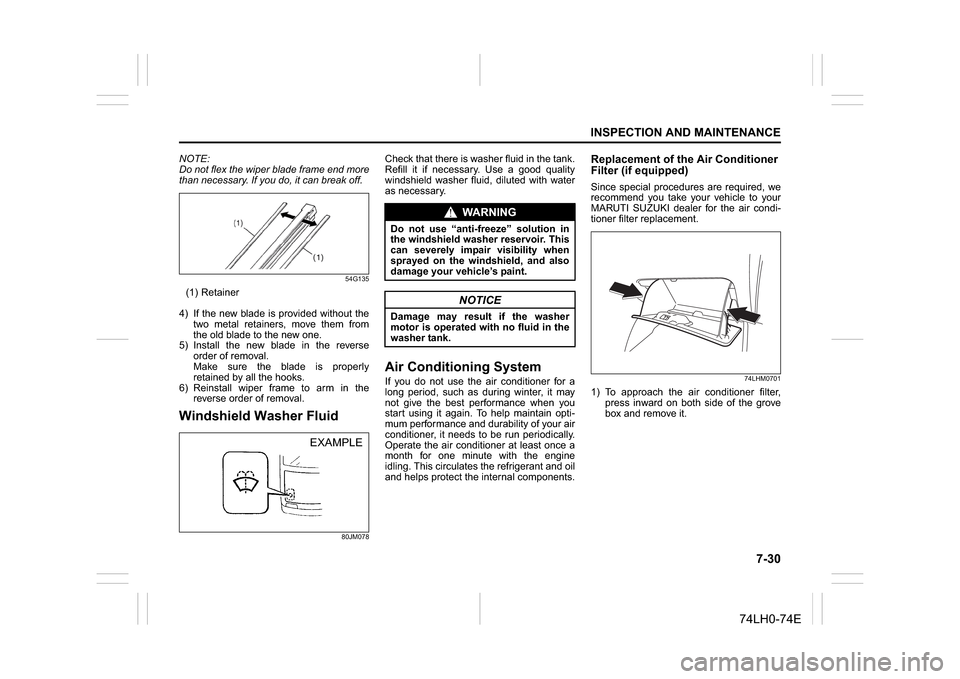

74LHM0701

1) To approach the air conditioner filter,

press inward on both side of the grove

box and remove it.

EXAMPLE

WA R N I N G

Do not use “anti-freeze” solution in

the windshield washer reservoir. This

can severely impair visibility when

sprayed on the windshield, and also

damage your vehicle’s paint.

NOTICE

Damage may result if the washer

motor is operated with no fluid in the

washer tank.

Page 222 of 336

7-31INSPECTION AND MAINTENANCE

74LH0-74E

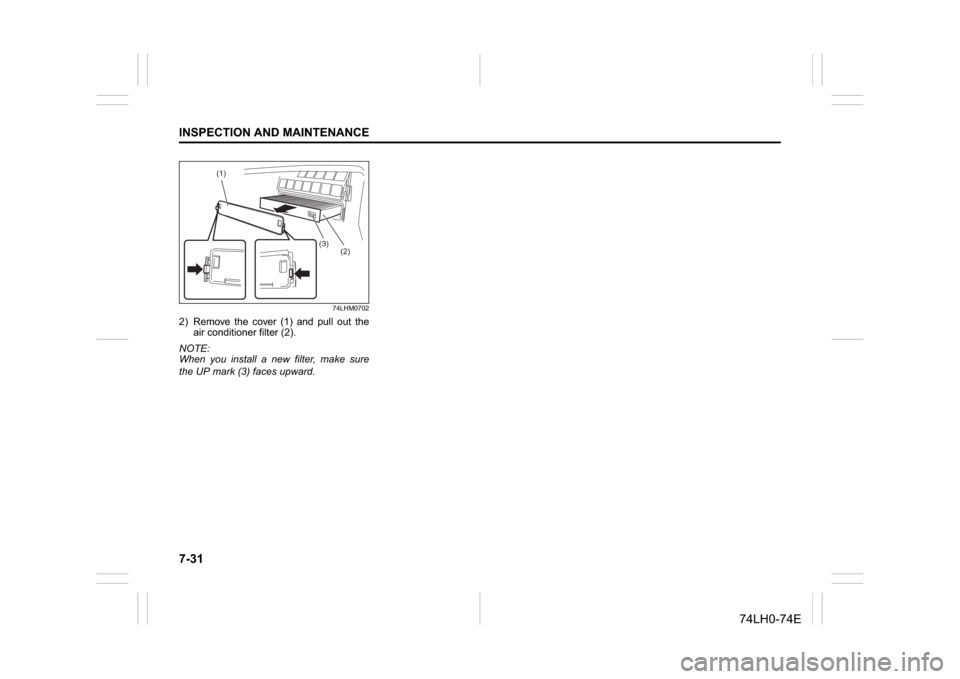

74LHM0702

2) Remove the cover (1) and pull out the

air conditioner filter (2).

NOTE:

When you install a new filter, make sure

the UP mark (3) faces upward.

(1)

(2)

(3)

Page 223 of 336

EMERGENCY SERVICE

EMERGENCY SERVICE

Tire Changing Tool ............................................................. 8-1

Jacking Instructions ........................................................... 8-2

Jump Starting Instructions ................................................ 8-5

If the Starter Does Not Operate .......................................... 8-6

If the Engine is Flooded ...................................................... 8-6

If the Engine Overheats ...................................................... 8-7

Warning Triangle ................................................................. 8-8

8

74LH0-74E

Page 224 of 336

8-1EMERGENCY SERVICE

74LH0-74E

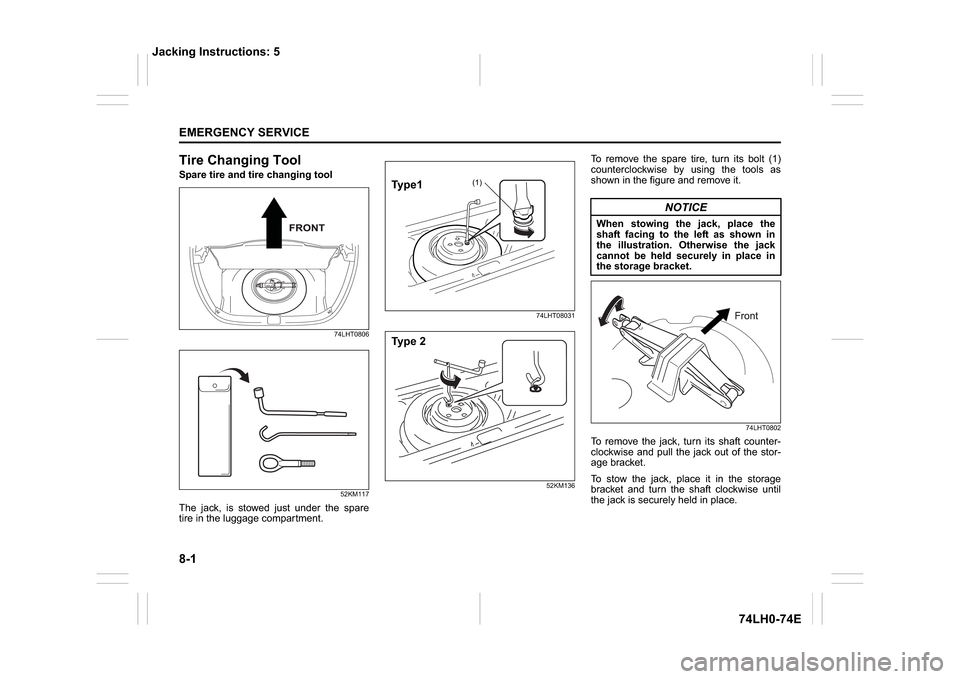

Tire Changing ToolSpare tire and tire changing tool

74LHT0806

52KM117

The jack, is stowed just under the spare

tire in the luggage compartment.

74LHT08031

52KM136

To remove the spare tire, turn its bolt (1)

counterclockwise by using the tools as

shown in the figure and remove it.

74LHT0802

To remove the jack, turn its shaft counter-

clockwise and pull the jack out of the stor-

age bracket.

To stow the jack, place it in the storage

bracket and turn the shaft clockwise until

the jack is securely held in place.

(1)

Ty p e 1Ty p e 2

NOTICE

When stowing the jack, place the

shaft facing to the left as shown in

the illustration. Otherwise the jack

cannot be held securely in place in

the storage bracket.

Jacking Instructions: 5

Page 225 of 336

8-2

EMERGENCY SERVICE

74LH0-74E

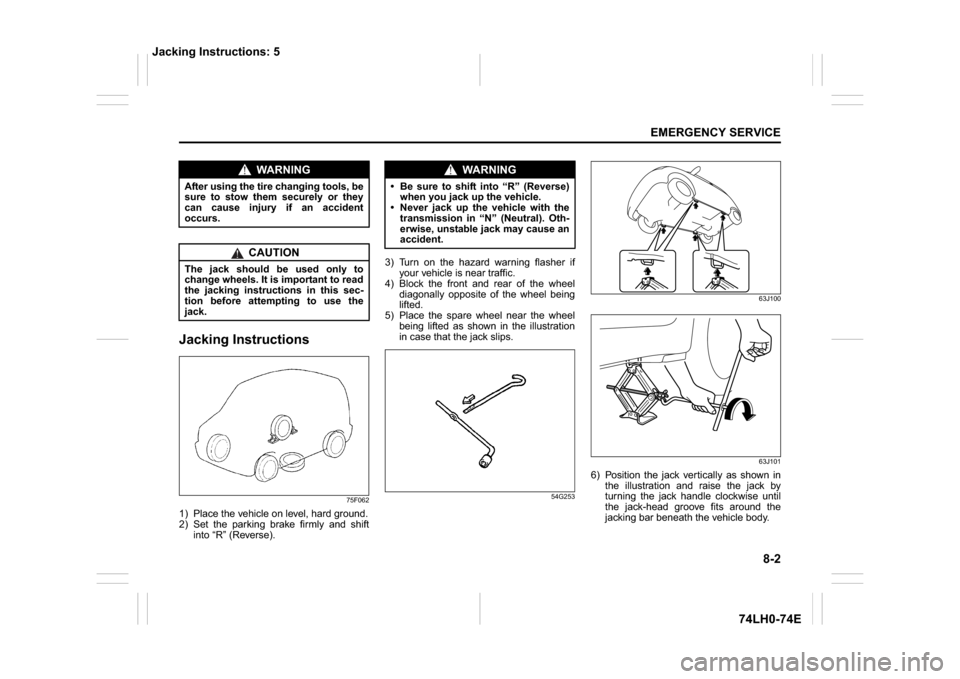

Jacking Instructions

75F062

1) Place the vehicle on level, hard ground.

2) Set the parking brake firmly and shift

into “R” (Reverse).3) Turn on the hazard warning flasher if

your vehicle is near traffic.

4) Block the front and rear of the wheel

diagonally opposite of the wheel being

lifted.

5) Place the spare wheel near the wheel

being lifted as shown in the illustration

in case that the jack slips.

54G25363J100

63J101

6) Position the jack vertically as shown in

the illustration and raise the jack by

turning the jack handle clockwise until

the jack-head groove fits around the

jacking bar beneath the vehicle body.

WA R N I N G

After using the tire changing tools, be

sure to stow them securely or they

can cause injury if an accident

occurs.

CAUTION

The jack should be used only to

change wheels. It is important to read

the jacking instructions in this sec-

tion before attempting to use the

jack.

WA R N I N G

Be sure to shift into “R” (Reverse)

when you jack up the vehicle.

Never jack up the vehicle with the

transmission in “N” (Neutral). Oth-

erwise, unstable jack may cause an

accident.

Jacking Instructions: 5

Page 226 of 336

8-3EMERGENCY SERVICE

74LH0-74E

7) Continue to raise the jack slowly and

smoothly until the tire clears the

ground. Do not raise the vehicle more

than necessary.

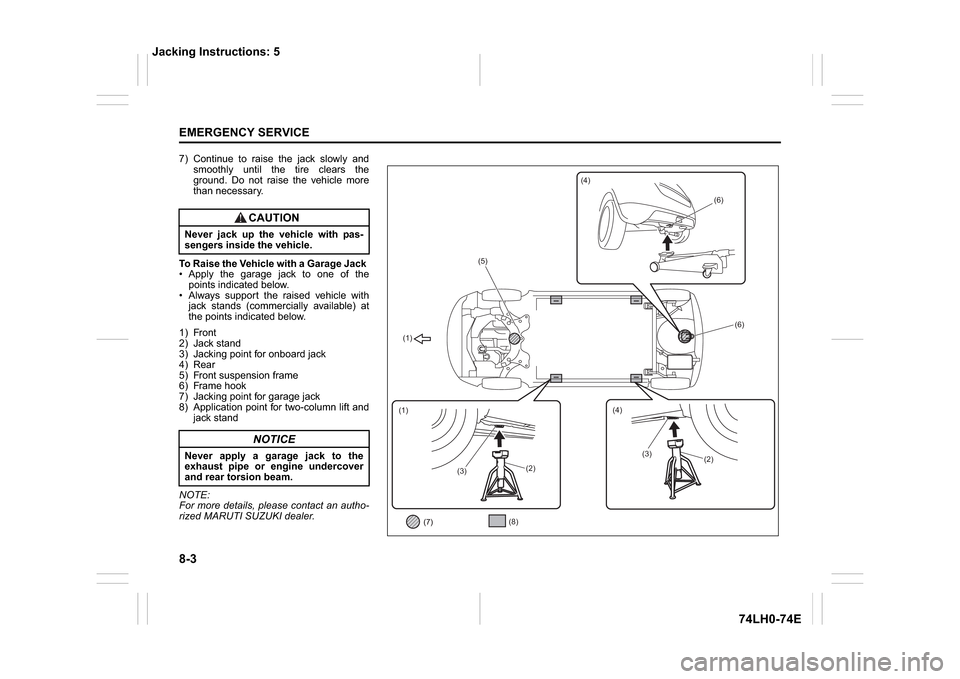

To Raise the Vehicle with a Garage Jack

Apply the garage jack to one of the

points indicated below.

Always support the raised vehicle with

jack stands (commercially available) at

the points indicated below.

1) Front

2) Jack stand

3) Jacking point for onboard jack

4) Rear

5) Front suspension frame

6) Frame hook

7) Jacking point for garage jack

8) Application point for two-column lift and

jack stand

NOTE:

For more details, please contact an autho-

rized MARUTI SUZUKI dealer.

CAUTION

Never jack up the vehicle with pas-

sengers inside the vehicle.

NOTICE

Never apply a garage jack to the

exhaust pipe or engine undercover

and rear torsion beam.

(1)

(1)

(2)(2)

(3)(4)

(5)

(7) (7)(8)

(6)

(6)

(4)

(3)

Jacking Instructions: 5

Page 227 of 336

8-4

EMERGENCY SERVICE

74LH0-74E

Changing WheelsTo change a wheel, use the following pro-

cedure:

1) Clear all passengers and luggage from

the vehicle.

NOTE:

The Jack and tools are located under the

spare wheel.

2) Remove the jack, tools and spare wheel

from the vehicle.

3) Loosen, but do not remove the wheel

nuts.

4) Jack up the vehicle (follow the jacking

instructions in this section).

5) Remove the wheel nuts and wheel.

6) Before installing the new wheel, clean

any mud or dirt off from the surface of

the wheel and hub with a clean cloth.

Clean the hub carefully; it may be hot

from driving.

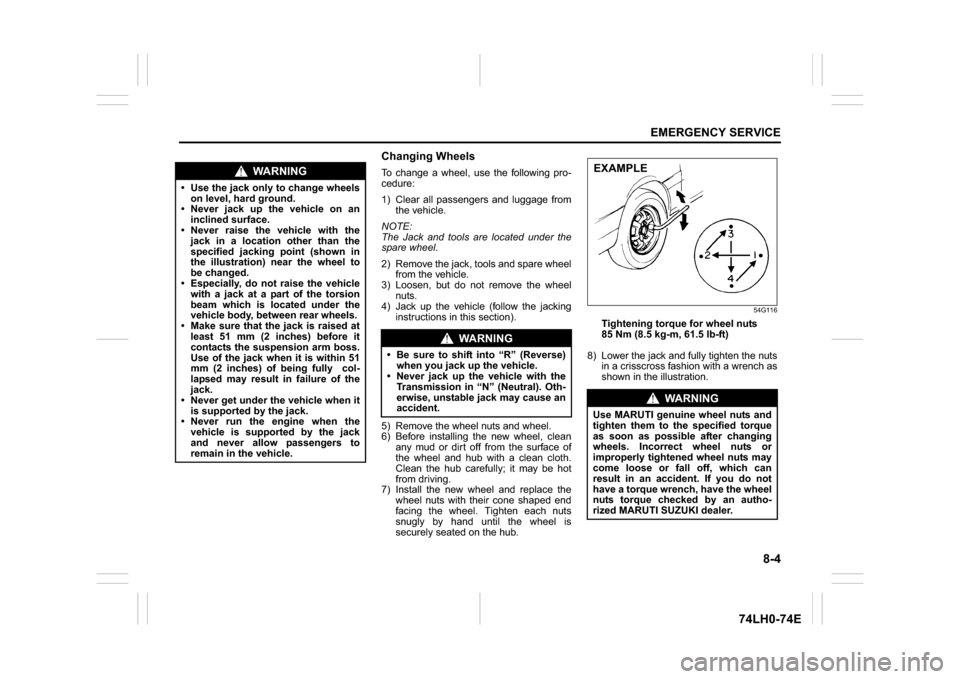

7) Install the new wheel and replace the

wheel nuts with their cone shaped end

facing the wheel. Tighten each nuts

snugly by hand until the wheel is

securely seated on the hub.

54G116

Tightening torque for wheel nuts

85 Nm (8.5 kg-m, 61.5 lb-ft)

8) Lower the jack and fully tighten the nuts

in a crisscross fashion with a wrench as

shown in the illustration.

WARNING

Use the jack only to change wheels

on level, hard ground.

Never jack up the vehicle on an

inclined surface.

Never raise the vehicle with the

jack in a location other than the

specified jacking point (shown in

the illustration) near the wheel to

be changed.

Especially, do not raise the vehicle

with a jack at a part of the torsion

beam which is located under the

vehicle body, between rear wheels.

Make sure that the jack is raised at

least 51 mm (2 inches) before it

contacts the suspension arm boss.

Use of the jack when it is within 51

mm (2 inches) of being fully col-

lapsed may result in failure of the

jack.

Never get under the vehicle when it

is supported by the jack.

Never run the engine when the

vehicle is supported by the jack

and never allow passengers to

remain in the vehicle.

WARNING

Be sure to shift into “R” (Reverse)

when you jack up the vehicle.

Never jack up the vehicle with the

Transmission in “N” (Neutral). Oth-

erwise, unstable jack may cause an

accident.

WARNING

Use MARUTI genuine wheel nuts and

tighten them to the specified torque

as soon as possible after changing

wheels. Incorrect wheel nuts or

improperly tightened wheel nuts may

come loose or fall off, which can

result in an accident. If you do not

have a torque wrench, have the wheel

nuts torque checked by an autho-

rized MARUTI SUZUKI dealer.EXAMPLE

Page 228 of 336

8-5EMERGENCY SERVICE

74LH0-74E

Full Wheel Cover (if equipped)

60G309

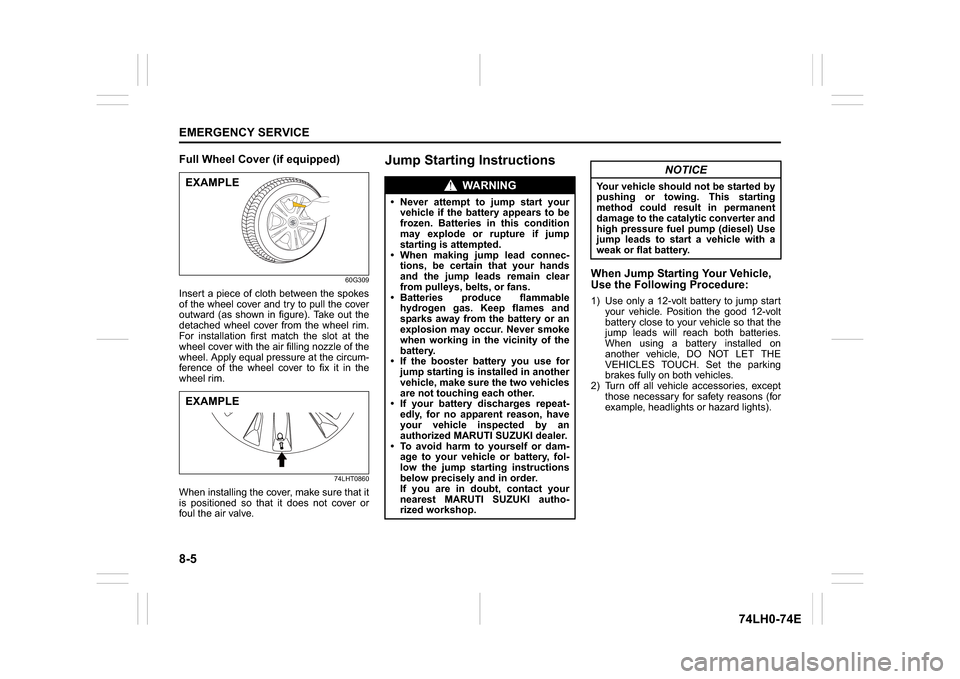

Insert a piece of cloth between the spokes

of the wheel cover and try to pull the cover

outward (as shown in figure). Take out the

detached wheel cover from the wheel rim.

For installation first match the slot at the

wheel cover with the air filling nozzle of the

wheel. Apply equal pressure at the circum-

ference of the wheel cover to fix it in the

wheel rim.

74LHT0860

When installing the cover, make sure that it

is positioned so that it does not cover or

foul the air valve.

Jump Starting Instructions

When Jump Starting Your Vehicle,

Use the Following Procedure:1) Use only a 12-volt battery to jump start

your vehicle. Position the good 12-volt

battery close to your vehicle so that the

jump leads will reach both batteries.

When using a battery installed on

another vehicle, DO NOT LET THE

VEHICLES TOUCH. Set the parking

brakes fully on both vehicles.

2) Turn off all vehicle accessories, except

those necessary for safety reasons (for

example, headlights or hazard lights).

EXAMPLEEXAMPLE

WA R N I N G

Never attempt to jump start your

vehicle if the battery appears to be

frozen. Batteries in this condition

may explode or rupture if jump

starting is attempted.

When making jump lead connec-

tions, be certain that your hands

and the jump leads remain clear

from pulleys, belts, or fans.

Batteries produce flammable

hydrogen gas. Keep flames and

sparks away from the battery or an

explosion may occur. Never smoke

when working in the vicinity of the

battery.

If the booster battery you use for

jump starting is installed in another

vehicle, make sure the two vehicles

are not touching each other.

If your battery discharges repeat-

edly, for no apparent reason, have

your vehicle inspected by an

authorized MARUTI SUZUKI dealer.

To avoid harm to yourself or dam-

age to your vehicle or battery, fol-

low the jump starting instructions

below precisely and in order.

If you are in doubt, contact your

nearest MARUTI SUZUKI autho-

rized workshop.

NOTICE

Your vehicle should not be started by

pushing or towing. This starting

method could result in permanent

damage to the catalytic converter and

high pressure fuel pump (diesel) Use

jump leads to start a vehicle with a

weak or flat battery.

Page 229 of 336

8-6

EMERGENCY SERVICE

74LH0-74E

71LST0802

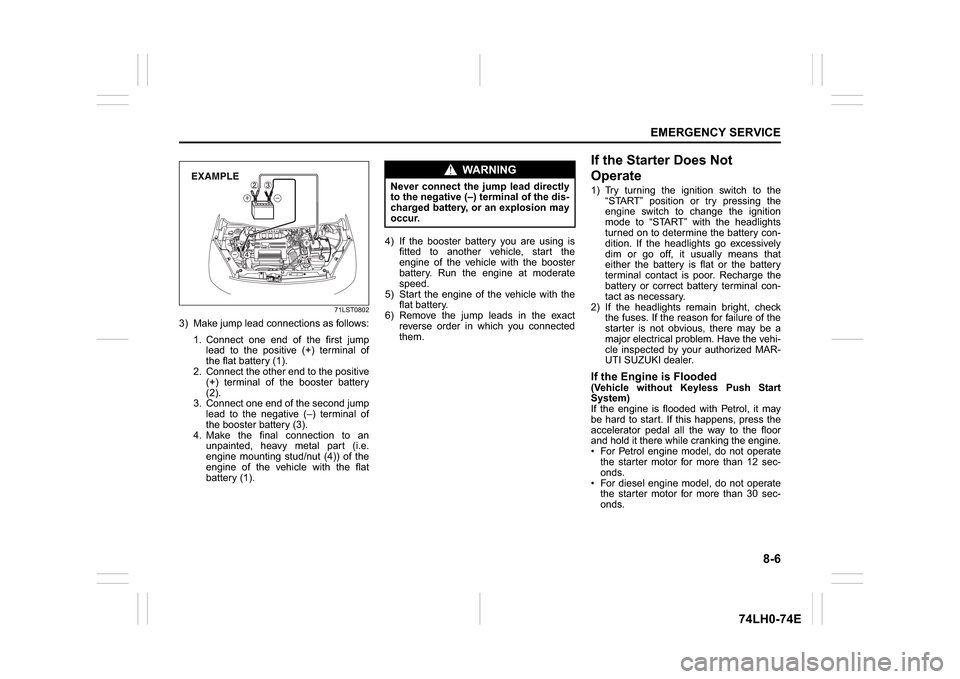

3) Make jump lead connections as follows:

1. Connect one end of the first jump

lead to the positive (+) terminal of

the flat battery (1).

2. Connect the other end to the positive

(+) terminal of the booster battery

(2).

3. Connect one end of the second jump

lead to the negative (–) terminal of

the booster battery (3).

4. Make the final connection to an

unpainted, heavy metal part (i.e.

engine mounting stud/nut (4)) of the

engine of the vehicle with the flat

battery (1).4) If the booster battery you are using is

fitted to another vehicle, start the

engine of the vehicle with the booster

battery. Run the engine at moderate

speed.

5) Start the engine of the vehicle with the

flat battery.

6) Remove the jump leads in the exact

reverse order in which you connected

them.

If the Starter Does Not

Operate1) Try turning the ignition switch to the

“START” position or try pressing the

engine switch to change the ignition

mode to “START” with the headlights

turned on to determine the battery con-

dition. If the headlights go excessively

dim or go off, it usually means that

either the battery is flat or the battery

terminal contact is poor. Recharge the

battery or correct battery terminal con-

tact as necessary.

2) If the headlights remain bright, check

the fuses. If the reason for failure of the

starter is not obvious, there may be a

major electrical problem. Have the vehi-

cle inspected by your authorized MAR-

UTI SUZUKI dealer.If the Engine is Flooded(Vehicle without Keyless Push Start

System)

If the engine is flooded with Petrol, it may

be hard to start. If this happens, press the

accelerator pedal all the way to the floor

and hold it there while cranking the engine.

For Petrol engine model, do not operate

the starter motor for more than 12 sec-

onds.

For diesel engine model, do not operate

the starter motor for more than 30 sec-

onds.

EXAMPLE

WA R N I N G

Never connect the jump lead directly

to the negative (–) terminal of the dis-

charged battery, or an explosion may

occur.

Page 230 of 336

8-7EMERGENCY SERVICE

74LH0-74E

(Vehicle with Keyless Push Start Sys-

tem)

If the engine is flooded with Petrol, it may

be hard to start. If this happens, press the

accelerator pedal all the way to the floor

and hold it there while cranking the engine.

For Petrol engine model, do not operate

the starter motor for more than 12 sec-

onds.

For diesel engine model, do not operate

the starter motor for more than 30 sec-

onds.

NOTE:

If the engine refuses to start, the starter

motor automatically stops after a certain

period of time. After the starter motor has

automatically stopped or there is anything

abnormal in the engine starting system,

the starter motor runs only while the

engine switch is held pressed.

If the Engine OverheatsThe engine could overheat temporarily

under severe driving conditions. If the

engine coolant temperature gauge indi-

cates overheating during driving:

1) Turn off the air conditioner, if equipped.

2) Take the vehicle to a safe place and

park.

3) Let the engine run at the normal idle

speed for a few minutes until the indica-

tor is within the normal, acceptable

temperature range between “H” and

“C”.

If the temperature indication does not

come down to within the normal, accept-

able range:

1) Turn off the engine and check that the

water pump belt and pulleys are not

damaged or slipping. If any abnormality

is found, correct it.

2) Check the coolant level in the reservoir.

If it is found to be lower than the “LOW”line, look for leaks at the radiator, water

pump, and radiator and heater hoses. If

you locate any leaks that may have

caused the overheating, do not run the

engine until these problems have been

corrected.

3) If you do not find a leak, carefully add

coolant to the reservoir and then the

radiator, if necessary. (Refer to “Engine

Coolant” in the “INSPECTION AND

MAINTENANCE” section.)

NOTE:

If your engine overheats and you are

unsure what to do, contact your MARUTI

SUZUKI dealer.

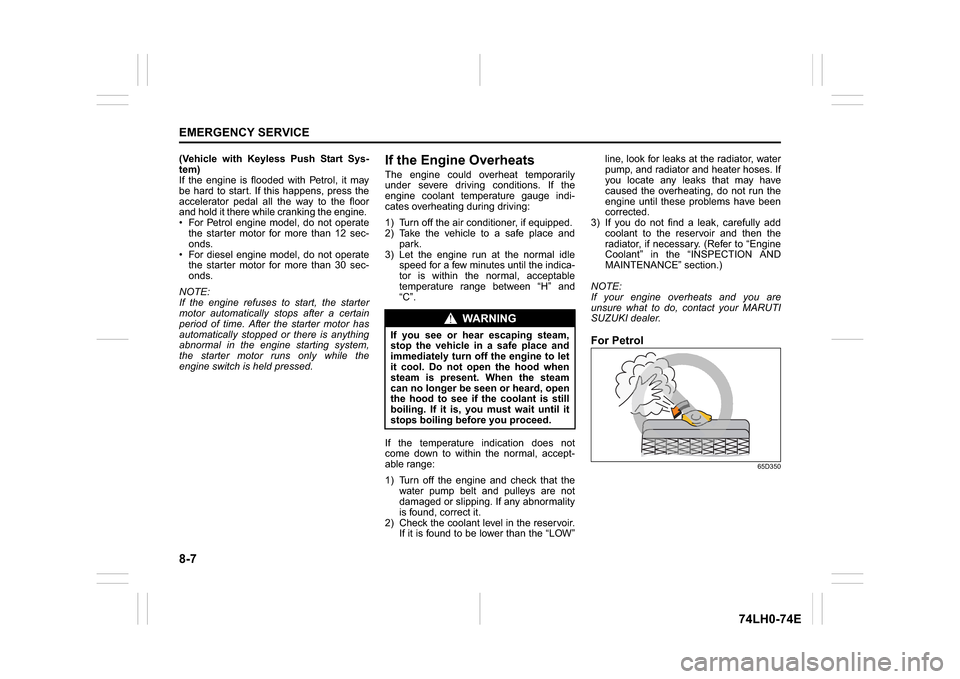

For Petrol

65D350

WA R N I N G

If you see or hear escaping steam,

stop the vehicle in a safe place and

immediately turn off the engine to let

it cool. Do not open the hood when

steam is present. When the steam

can no longer be seen or heard, open

the hood to see if the coolant is still

boiling. If it is, you must wait until it

stops boiling before you proceed.