Can line SUZUKI SX4 2006 1.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1496 of 1556

Downloaded from www.Manualslib.com manuals search engine 10B-23 Body Electrical Control System:

BCM connector “G04”E04-13 — — —

E04-14 — — —

Terminal Circuit Normal voltage Condition

G04-1CAN communication line (low)

for DLC*1.6 – 2.5 V

Refer to “Reference waveform No. 3: ” G04-2CAN communication line (low)

for each control module*1.6 – 2.5 V

G04-3CAN communication line

(high) for DLC*2.5 – 3.6 V

G04-4CAN communication line

(high) for each control module*2.5 – 3.6 V

G04-5Serial communication line of

data link connector 7 – 12 V Ignition switch is at ON position

G04-6 — — —

G04-7 — — —

G04-8 Theft deterrent light10 – 14 V Theft deterrent light is not lit up

0 V Theft deterrent light is lit up

G04-9 — — —

G04-10 — — —

G04-11Serial communication line for

information display and HVAC

control module (if equipped)*0 – 1 V

↑↓

10 – 14 VRefer to “Reference waveform No. 5: ”

G04-12Ground for keyless entry

receiver (if equipped)0 V —

G04-13Power supply for keyless

entry receiver (if equipped)4 – 6 V Ignition switch is at all positions

G04-14Signal for keyless entry

receiver (if equipped)*0 – 1 V

↑↓

4 – 6 VRefer to “Reference waveform No. 6: ”

G04-15 Vehicle speed signal output*0 – 1 V

↑↓

4 – 6VRefer to “Reference waveform No. 7: ”

G04-16 Key reminder switch10 – 14 V Ignition key is inserted to ignition key cylinder

0 VIgnition key is pulled out from ignition key

cylinder

G04-17Rear end door window

defogger switch*3 – 14 V Refer to “Reference waveform No. 8: ”

0 VIgnition switch is at ON position and rear end

door window defogger switch is pushed

G04-18 A/C switch (if equipped)*3 – 14 V Refer to “Reference waveform No. 8: ”

0 VIgnition switch is at ON position, blower speed

selector is at any position other than OFF

position and A/C switch is at ON position

G04-19 — — —

G04-20 — — —

G04-21 Rear wiper INT switch*0 – 1 V

↑↓

10 – 14 VRefer to “Reference waveform No. 9: ”

0 VIgnition switch is at ON position and rear

wiper switch is at INT position

G04-22 Rear wiper low switch*0 – 1 V

↑↓

10 – 14 VRefer to “Reference waveform No. 9: ”

0 VIgnition switch is at ON position and rear

wiper switch is at LOW position Terminal Circuit Normal voltage Condition

Page 1499 of 1556

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-26

Reference waveform No. 1

Parking brake or brake fluid level switch signal (1)

Reference waveform No. 2

Driver seat belt switch signal (1)Reference waveform No. 3

CAN communication signal

Reference waveform No. 4

Oil pressure switch signal (1) Measurement terminal Parking brake switch

CH2: “L01-6” to “G271-3”

Brake fluid level switch

CH2: “E04-5” to “G271-3”

Oscilloscope setting CH1: 5 V / DIV

TIME: 10 ms / DIV

Measurement

conditionParking brake switch:

• Ignition switch is at ON

position, parking brake lever

is released

Brake fluid level switch

• Ignition switch is at ON

position, brake fluid level is in

normal

Measurement terminal CH2: “L01-14” to “G271-3”

Oscilloscope setting CH2: 5 V/DIV

TIME: 4 ms/DIV

Measurement

conditionIgnition switch is at ON position

and driver side seat belt is

fastened

I4RS0AA20018-02

I4RS0AA20016-02

Measurement terminal CAN communication signal for

ABS control module

CH2: “E04-1” to “G271-3”

CH3: “E04-2” to “G271-3”

CAN communication signal for

DLC

CH2: “G04-3” to “G271-3”

CH3: “G04-1” to “G271-3”

CAN communication signal for

each control module

CH2: “G04-4” to “G271-3”

CH3: “G04-2” to “G271-3”

Oscilloscope setting CH2: 1 V/DIV

CH3: 1 V/DIV

TIME: 40 µs/ DIV

Measurement

conditionIgnition switch is at ON position

1. CAN communication line signal (High)

2. CAN communication line signal (Low)

Measurement terminal CH2: “E04-11” to “G271-3”

Oscilloscope setting CH2: 5 V / DIV

TIME: 10 ms / DIV

Measurement

conditionEngine is running and oil

pressure is in normal condition

I4RS0AA20017-02

I4RS0AA20018-02

Page 1503 of 1556

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-1

Control Systems

Immobilizer Control System

Precautions

Precautions in Diagnosing TroublesS6RW0DA300001

• Before confirming the diagnostic trouble code (DTC),

do not disconnect connector from ECM, battery cable

from battery, ground wire harness, or main fuse. Such

disconnection will erase DTC stored in ECM.

• DTC stored in ECM memory can be checked as well

as cleared by using SUZUKI scan tool. Before using

SUZUKI scan tool, read its operator’s manual

carefully to know how to use it and what functions are

available.

• Be sure to read “Precautions for Electrical Circuit

Service in Section 00” before inspection.

• Communication of ECM, BCM, ABS control module,

TCM (if equipped), 4WD control module (if equipped),

keyless start control module (if equipped),

combination meter and DLC is established by CAN

(Controller Area Network). Therefore, handle CAN

communication lines with care referring to “Precaution

for CAN Communication System in Section 00”.

For CAN communication system, refer to description

on “CAN Communication System Description in

Section 1A”.

Precaution in Replacing ECMS6RW0DA300002

• If ECM is replaced with new or used one without

Immobilizer control function, the engine will not be

started. In case of the above, check if the newly

installed ECM has Immobilizer control function.

• After ECM is replaced with new one or used one, the

transponder code in the transponder built in the

ignition key has to be registered with ECM. Or, the

engine cannot be started up. For the registration

procedure, refer to “Procedure after ECM

Replacement”.

Precaution in Replacing Ignition KeyS6RW0DA300003

To register ignition key in case of replacing key(s) and/or

making spare key(s), the transponder code in the ignition

key is registered with ECM. Or the engine can not be

started up. For the registration procedure, refer to

“Registration of the Ignition Key”.

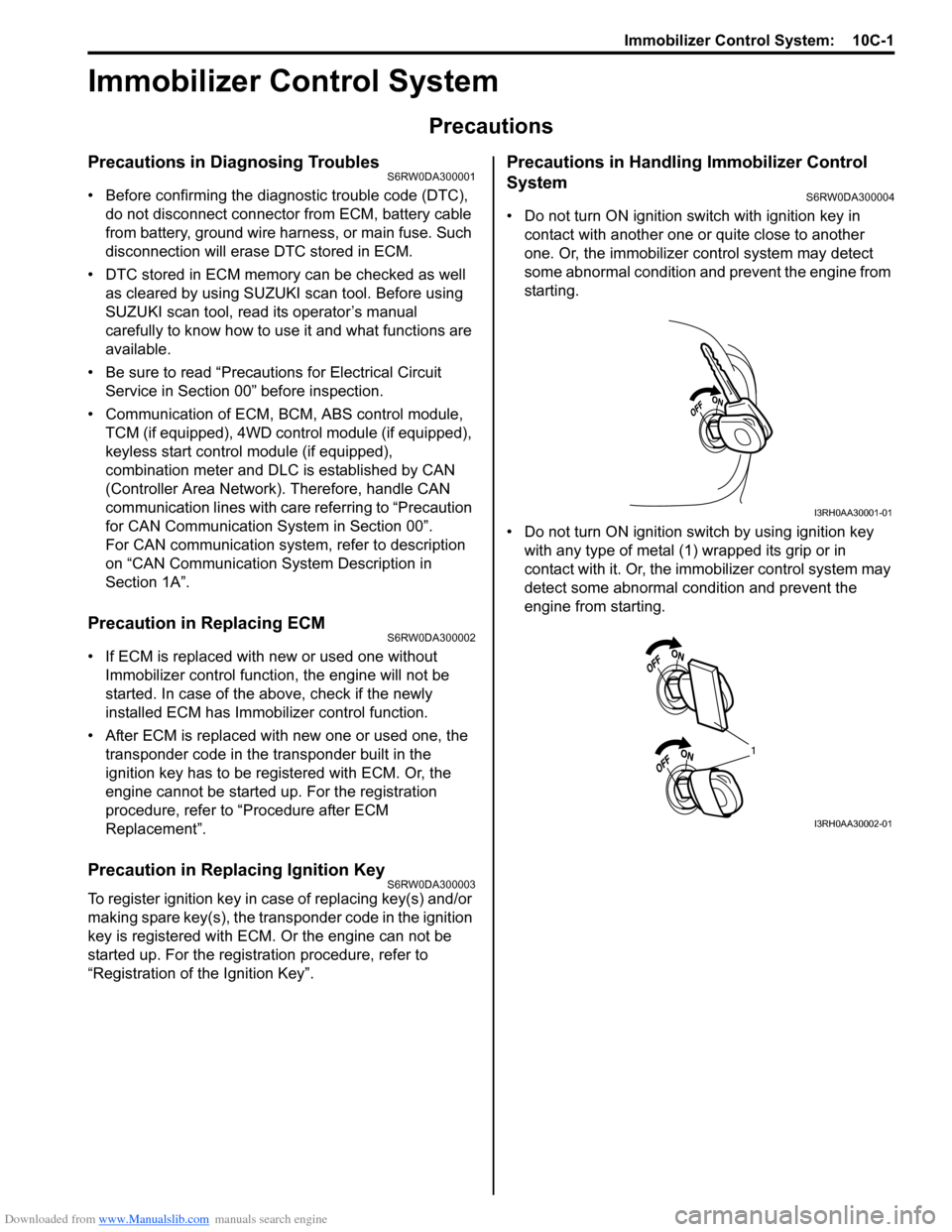

Precautions in Handling Immobilizer Control

System

S6RW0DA300004

• Do not turn ON ignition switch with ignition key in

contact with another one or quite close to another

one. Or, the immobilizer control system may detect

some abnormal condition and prevent the engine from

starting.

• Do not turn ON ignition switch by using ignition key

with any type of metal (1) wrapped its grip or in

contact with it. Or, the immobilizer control system may

detect some abnormal condition and prevent the

engine from starting.

I3RH0AA30001-01

1

I3RH0AA30002-01

Page 1504 of 1556

Downloaded from www.Manualslib.com manuals search engine 10C-2 Immobilizer Control System:

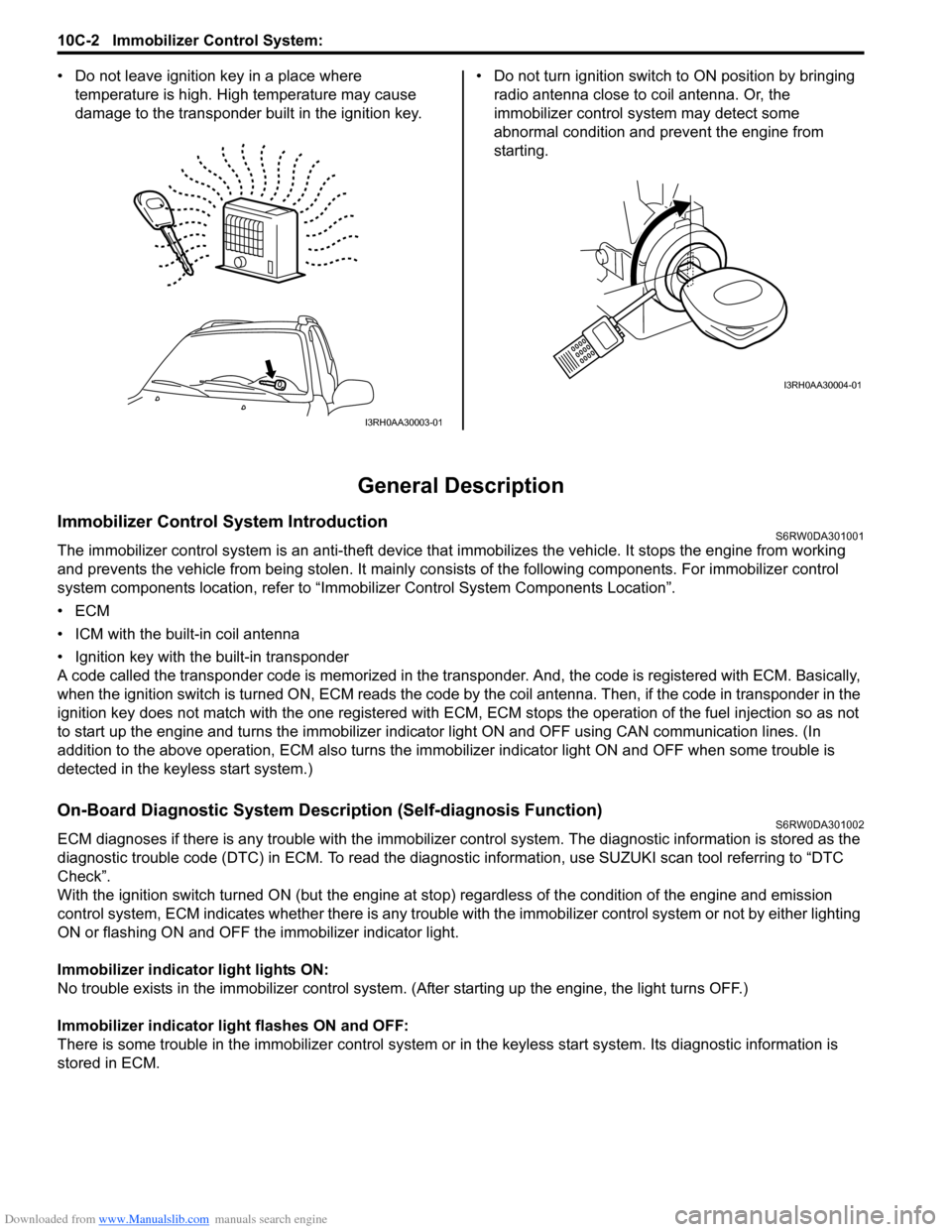

• Do not leave ignition key in a place where

temperature is high. High temperature may cause

damage to the transponder built in the ignition key.• Do not turn ignition switch to ON position by bringing

radio antenna close to coil antenna. Or, the

immobilizer control system may detect some

abnormal condition and prevent the engine from

starting.

General Description

Immobilizer Control System IntroductionS6RW0DA301001

The immobilizer control system is an anti-theft device that immobilizes the vehicle. It stops the engine from working

and prevents the vehicle from being stolen. It mainly consists of the following components. For immobilizer control

system components location, refer to “Immobilizer Control System Components Location”.

•ECM

• ICM with the built-in coil antenna

• Ignition key with the built-in transponder

A code called the transponder code is memorized in the transponder. And, the code is registered with ECM. Basically,

when the ignition switch is turned ON, ECM reads the code by the coil antenna. Then, if the code in transponder in the

ignition key does not match with the one registered with ECM, ECM stops the operation of the fuel injection so as not

to start up the engine and turns the immobilizer indicator light ON and OFF using CAN communication lines. (In

addition to the above operation, ECM also turns the immobilizer indicator light ON and OFF when some trouble is

detected in the keyless start system.)

On-Board Diagnostic System Description (Self-diagnosis Function)S6RW0DA301002

ECM diagnoses if there is any trouble with the immobilizer control system. The diagnostic information is stored as the

diagnostic trouble code (DTC) in ECM. To read the diagnostic information, use SUZUKI scan tool referring to “DTC

Check”.

With the ignition switch turned ON (but the engine at stop) regardless of the condition of the engine and emission

control system, ECM indicates whether there is any trouble with the immobilizer control system or not by either lighting

ON or flashing ON and OFF the immobilizer indicator light.

Immobilizer indicator light lights ON:

No trouble exists in the immobilizer control system. (After starting up the engine, the light turns OFF.)

Immobilizer indicator light flashes ON and OFF:

There is some trouble in the immobilizer control system or in the keyless start system. Its diagnostic information is

stored in ECM.

I3RH0AA30003-01

I3RH0AA30004-01

Page 1509 of 1556

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-7

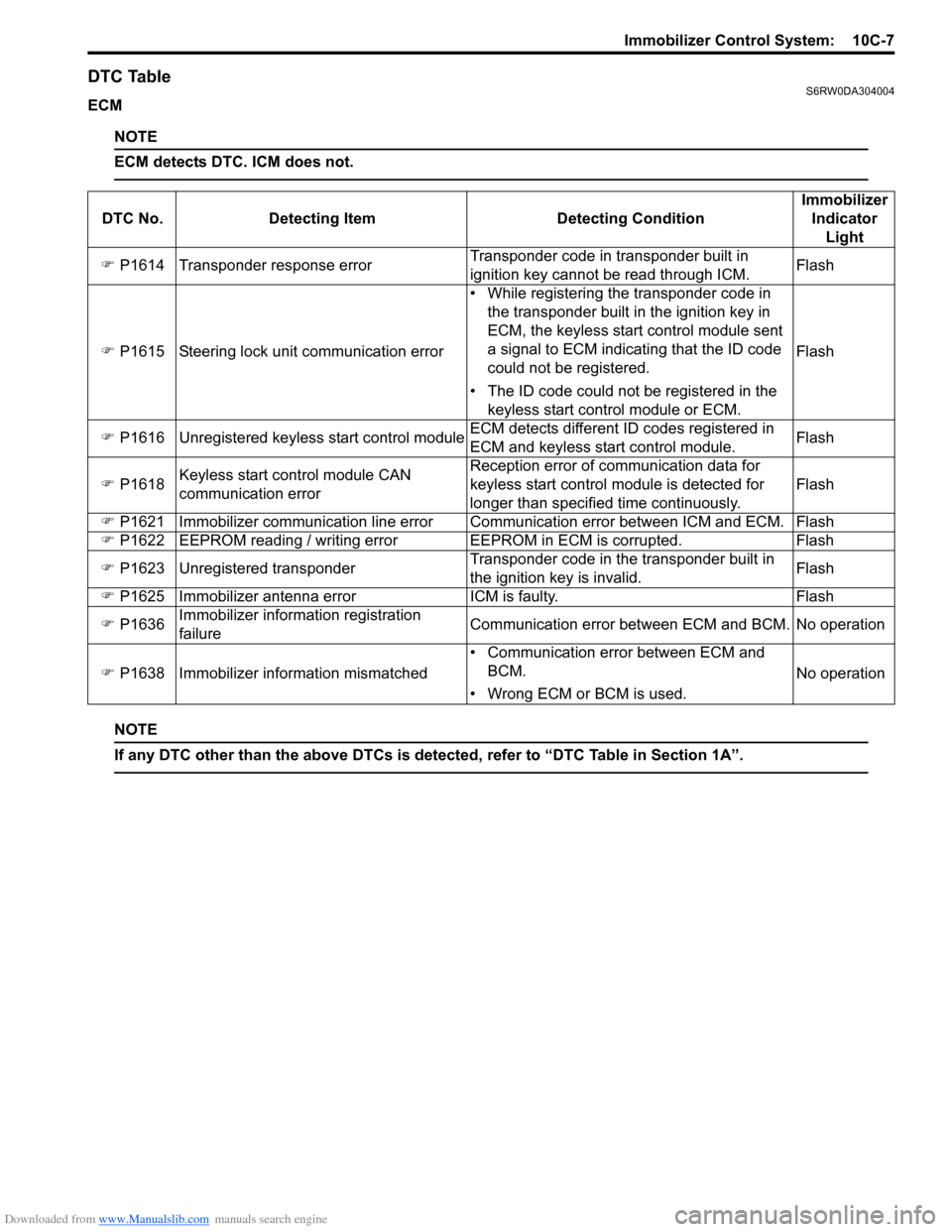

DTC TableS6RW0DA304004

ECM

NOTE

ECM detects DTC. ICM does not.

NOTE

If any DTC other than the above DTCs is detected, refer to “DTC Table in Section 1A”.

DTC No. Detecting Item Detecting ConditionImmobilizer

Indicator

Light

�) P1614 Transponder response errorTransponder code in transponder built in

ignition key cannot be read through ICM.Flash

�) P1615 Steering lock unit communication error• While registering the transponder code in

the transponder built in the ignition key in

ECM, the keyless start control module sent

a signal to ECM indicating that the ID code

could not be registered.

• The ID code could not be registered in the

keyless start control module or ECM.Flash

�) P1616 Unregistered keyless start control moduleECM detects different ID codes registered in

ECM and keyless start control module.Flash

�) P1618Keyless start control module CAN

communication errorReception error of communication data for

keyless start control module is detected for

longer than specified time continuously.Flash

�) P1621 Immobilizer communication line error Communication error between ICM and ECM. Flash

�) P1622 EEPROM reading / writing error EEPROM in ECM is corrupted. Flash

�) P1623 Unregistered transponderTransponder code in the transponder built in

the ignition key is invalid.Flash

�) P1625 Immobilizer antenna error ICM is faulty. Flash

�) P1636Immobilizer information registration

failureCommunication error between ECM and BCM. No operation

�) P1638 Immobilizer information mismatched• Communication error between ECM and

BCM.

• Wrong ECM or BCM is used.No operation

Page 1515 of 1556

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-13

DTC P1618: Keyless Start Control Module CAN Communication ErrorS6RW0DA304011

Refer to “Troubleshooting for CAN-DTC in Section 1A”.

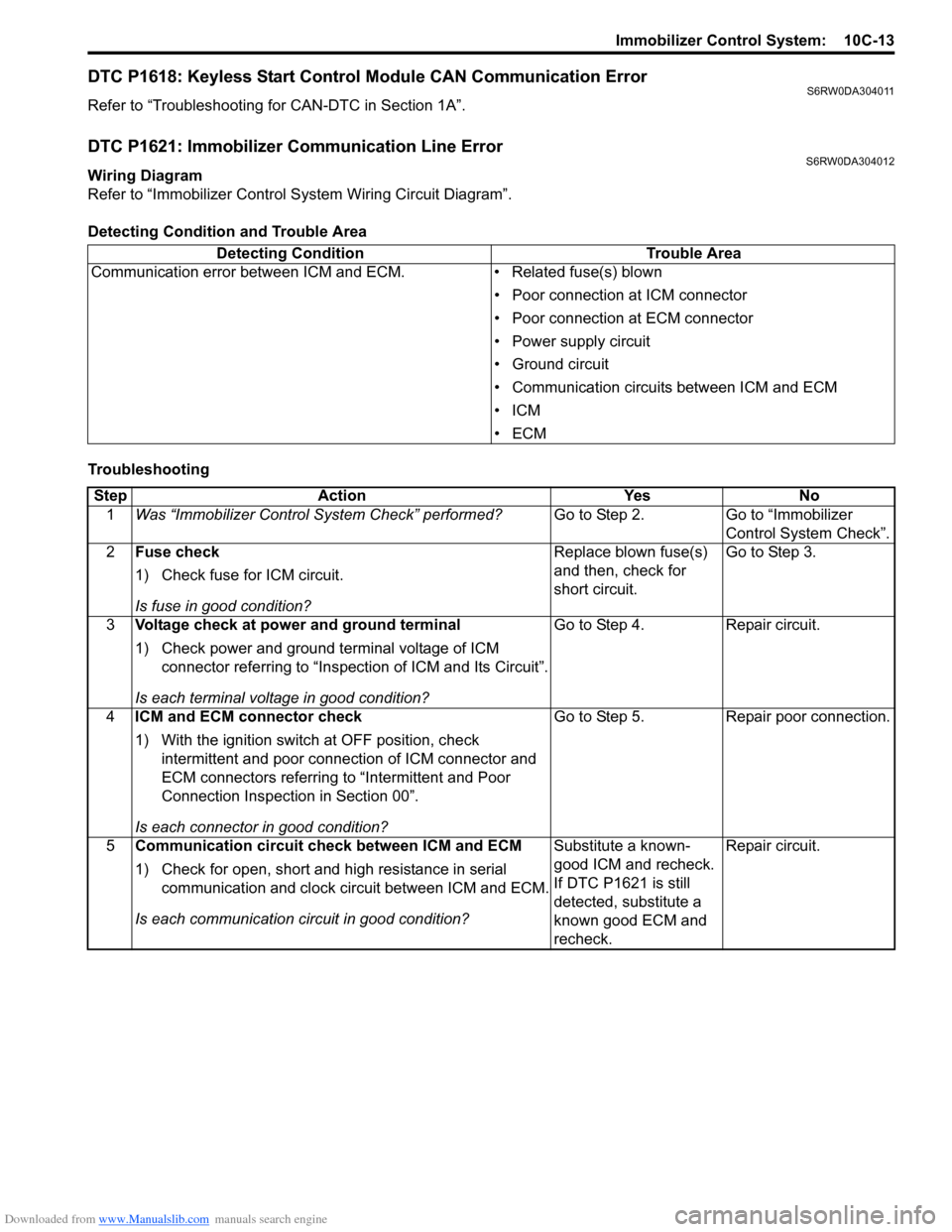

DTC P1621: Immobilizer Communication Line ErrorS6RW0DA304012

Wiring Diagram

Refer to “Immobilizer Control System Wiring Circuit Diagram”.

Detecting Condition and Trouble Area

TroubleshootingDetecting Condition Trouble Area

Communication error between ICM and ECM. • Related fuse(s) blown

• Poor connection at ICM connector

• Poor connection at ECM connector

• Power supply circuit

• Ground circuit

• Communication circuits between ICM and ECM

•ICM

•ECM

Step Action Yes No

1Was “Immobilizer Control System Check” performed?Go to Step 2. Go to “Immobilizer

Control System Check”.

2Fuse check

1) Check fuse for ICM circuit.

Is fuse in good condition?Replace blown fuse(s)

and then, check for

short circuit.Go to Step 3.

3Voltage check at power and ground terminal

1) Check power and ground terminal voltage of ICM

connector referring to “Inspection of ICM and Its Circuit”.

Is each terminal voltage in good condition?Go to Step 4. Repair circuit.

4ICM and ECM connector check

1) With the ignition switch at OFF position, check

intermittent and poor connection of ICM connector and

ECM connectors referring to “Intermittent and Poor

Connection Inspection in Section 00”.

Is each connector in good condition?Go to Step 5. Repair poor connection.

5Communication circuit check between ICM and ECM

1) Check for open, short and high resistance in serial

communication and clock circuit between ICM and ECM.

Is each communication circuit in good condition?Substitute a known-

good ICM and recheck.

If DTC P1621 is still

detected, substitute a

known good ECM and

recheck.Repair circuit.

Page 1520 of 1556

Downloaded from www.Manualslib.com manuals search engine 10C-18 Immobilizer Control System:

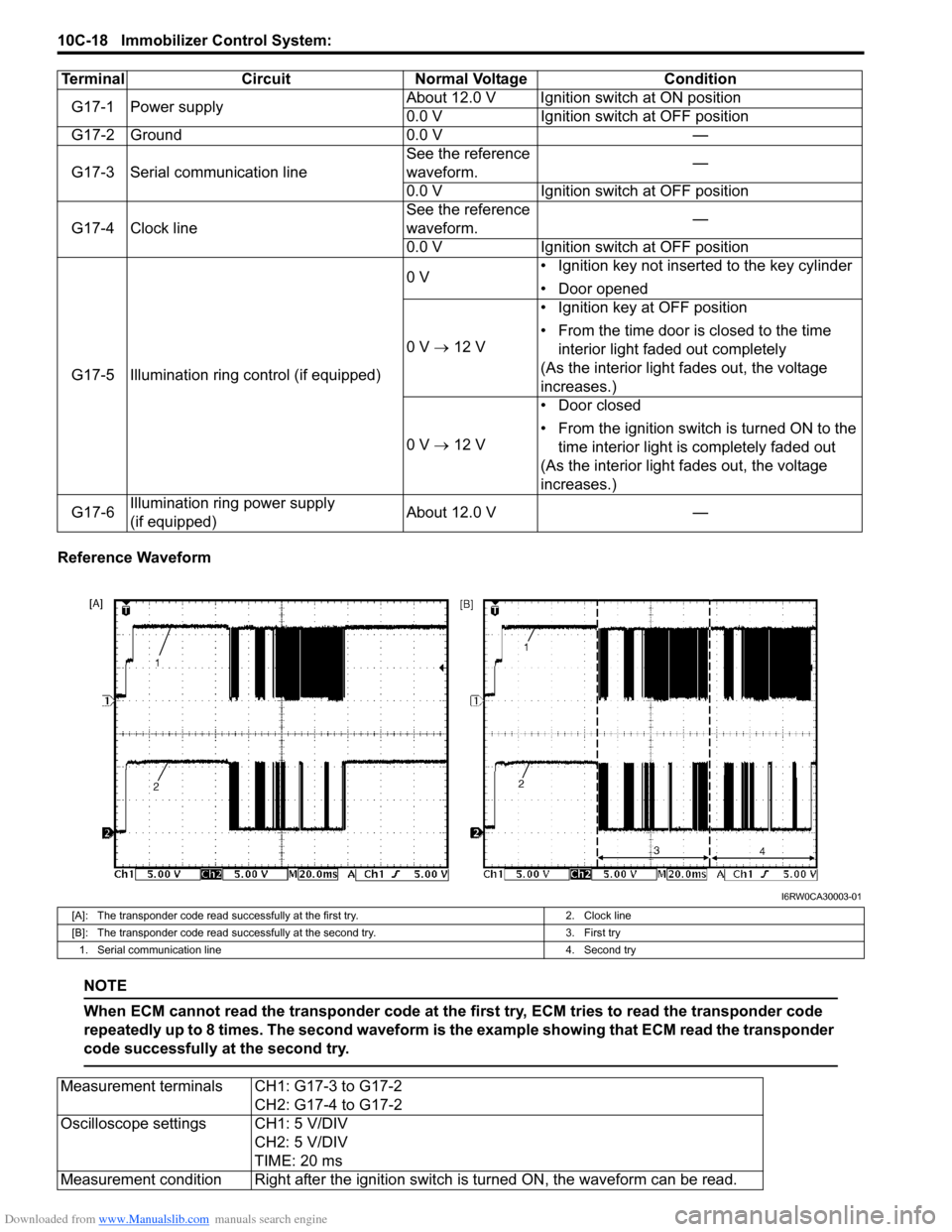

Reference Waveform

NOTE

When ECM cannot read the transponder code at the first try, ECM tries to read the transponder code

repeatedly up to 8 times. The second waveform is the example showing that ECM read the transponder

code successfully at the second try.

Terminal Circuit Normal Voltage Condition

G17-1 Power supplyAbout 12.0 V Ignition switch at ON position

0.0 V Ignition switch at OFF position

G17-2 Ground 0.0 V —

G17-3 Serial communication lineSee the reference

waveform.—

0.0 V Ignition switch at OFF position

G17-4 Clock lineSee the reference

waveform.—

0.0 V Ignition switch at OFF position

G17-5 Illumination ring control (if equipped)0 V• Ignition key not inserted to the key cylinder

• Door opened

0 V → 12 V• Ignition key at OFF position

• From the time door is closed to the time

interior light faded out completely

(As the interior light fades out, the voltage

increases.)

0 V → 12 V• Door closed

• From the ignition switch is turned ON to the

time interior light is completely faded out

(As the interior light fades out, the voltage

increases.)

G17-6Illumination ring power supply

(if equipped)About 12.0 V —

I6RW0CA30003-01

[A]: The transponder code read successfully at the first try. 2. Clock line

[B]: The transponder code read successfully at the second try. 3. First try

1. Serial communication line 4. Second try

Measurement terminals CH1: G17-3 to G17-2

CH2: G17-4 to G17-2

Oscilloscope settings CH1: 5 V/DIV

CH2: 5 V/DIV

TIME: 20 ms

Measurement condition Right after the ignition switch is turned ON, the waveform can be read.

Page 1530 of 1556

Downloaded from www.Manualslib.com manuals search engine 10E-8 Keyless Start System:

Diagnostic Information and Procedures

Precautions in Diagnosing TroublesS6RW0DA504001

• The keyless start system executes data transmission/

reception by means of the radio wave. Therefore,

proper operation may not be obtained if use of the

door lock function and engine start function of the

keyless start system is attempted near the place

where strong radio wave is emitted (TV and radio

broadcasting stations, etc.).

• Diagnostic information stored in keyless start control

module memory can be checked only by key indicator

light.

• Be sure to use the trouble diagnosis procedure as

described in “Keyless Start System Check”. Failure to

follow it may result in incorrect diagnosis. (Some other

DTC may be stored by mistake in the memory of

keyless start control module during inspection.)

• Be sure to read“Precautions for Electrical Circuit

Service in Section 00” before inspection and observe

what is written there.

• Communication of ECM, TCM (A/T model), BCM,

ABS control module, 4WD control module (if

equipped), keyless start control module and

combination meter is established by CAN (Controller

Area Network). (For detail of CAN communication for

keyless start control module, refer to “CAN

Communication System Description”). Therefore,

handle CAN communication line with care referring to

“Precaution for CAN Communication System in

Section 00”.

• Replacement of the keyless start control module

When keyless start control module is replaced with

new one, make sure that register remote controller ID

code to keyless start control module correctly

according to “Registration Procedure for Remote

Controller ID Code”.• Keyless start control module substitution

When the keyless start control module used in

another vehicle was installed in the vehicle being

serviced, register the ID code of the remote controller

to the keyless start control module first and then the

following code.

– With immobilizer control system, register the

ignition key transponder code for the immobilizer

control system in ECM. For registration procedure

of that, refer to “Registration of the Ignition Key in

Section 10C”.

– Without immobilizer control system, register the

steering lock unit ID code in keyless start control

module. For registration procedure of that, refer to

“Keyless Start Registration”.

Self-Diagnosis FunctionS6RW0DA504002

The keyless start control module has self-diagnosis

function to monitor the system components and circuits

while the keyless start system is at work. When the

keyless start control module detects an abnormality in

the system, it saves the area where such abnormality

has occurred as a DTC in its memory. The DTC stored in

memory of the keyless start control module is indicated

by the key indicator light in the combination meter

flashing in a specific pattern. For DTC indication, refer to

“DTC Check” and for the clearing procedure, to “DTC

Clearance”.

Keyless Start System Diagnosis IntroductionS6RW0DA504003

To ensure that the trouble diagnosis is done accurately

and smoothly, observe “Precautions in Diagnosing

Troubles” and follow “Keyless Start System Check”.

4. Ignition knob switch 13. Rear end door request switch 22. Ignition Switch

5. Key reminder switch 14. Driver side door lock switch

6. Driver side door antenna 15. Passenger side door lock switch

Page 1538 of 1556

Downloaded from www.Manualslib.com manuals search engine 10E-16 Keyless Start System:

G16-18 CAN communication line (low) *1.6 – 2.5 V

Refer to “Reference waveform No. 4: ”

G16-19 CAN communication line (high) *2.5 – 3.6 V

G16-20 Power supply for steering lock unit 4 – 6 V Full time

G16-21 — — —

G16-22 — — —

G16-23 Passenger side door antenna (–)

*0 – 5 V Refer to “Reference waveform No. 1: ”

G16-24 Passenger side door antenna (+)

G16-25 — — —

G16-26 — — —

G16-27 — — —

G16-28 — — —

G16-29 Signal for steering lock unit4 – 6 VIgnition knob switch is at any position other

than ON and OFF position

*0 – 5 V Refer to “Reference waveform No. 5: ”

G16-30 Ground for steering lock unit 0 – 1 V Full time

G16-31 — — —

G16-32 Rear end door request switch10 – 12 V Request switch of rear end door is released

0 – 1 V Request switch of rear end door is pushed

G16-33 Driver side door lock switch0 – 1 VDriver side door is at unlock position and

passenger side door is at lock position

4 – 6 VDriver and passenger side door is at lock

position

*3 – 5 V Refer to “Reference waveform No. 6: ”

G16-34 Ignition knob switch10 – 12 VWhen pushing ignition knob switch of steering

lock unit

0 – 1 VWhen releasing ignition knob switch of

steering lock unit

G16-35 — — —

G16-36 Passenger side door request switch10 – 12 VRequest switch of passenger side door is

released

0 – 1 VRequest switch of passenger side door is

pushed

G16-37 Passenger side door lock switch0 – 1 VPassenger side door is at unlock position and

driver side door is at lock position

4 – 6 VDriver and passenger side door is at lock

position

*3 – 5 V Refer to “Reference waveform No. 6: ”

G16-38 — — —

G16-39 — — —

G16-40 — — — Terminal

NumberCircuitNormal

Vo l ta g eCondition

Page 1540 of 1556

Downloaded from www.Manualslib.com manuals search engine 10E-18 Keyless Start System:

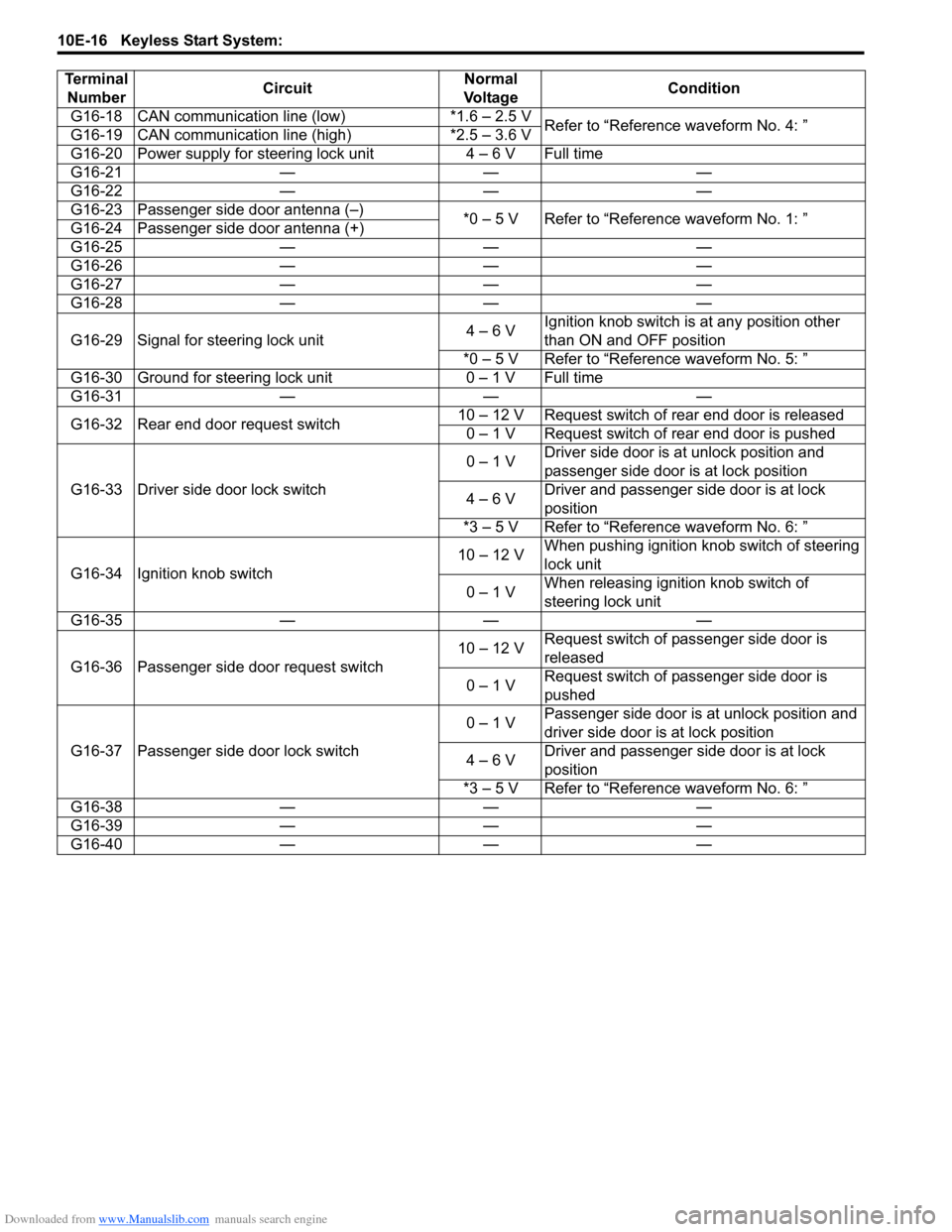

Reference waveform No. 4

CAN communication signals

(CAN signal communicated to each control module

when ignition switch is turned ON)

Reference waveform No. 5

Steering lock unit signal

(Signal (1) communicated between keyless start control

module and steering lock unit when measurement

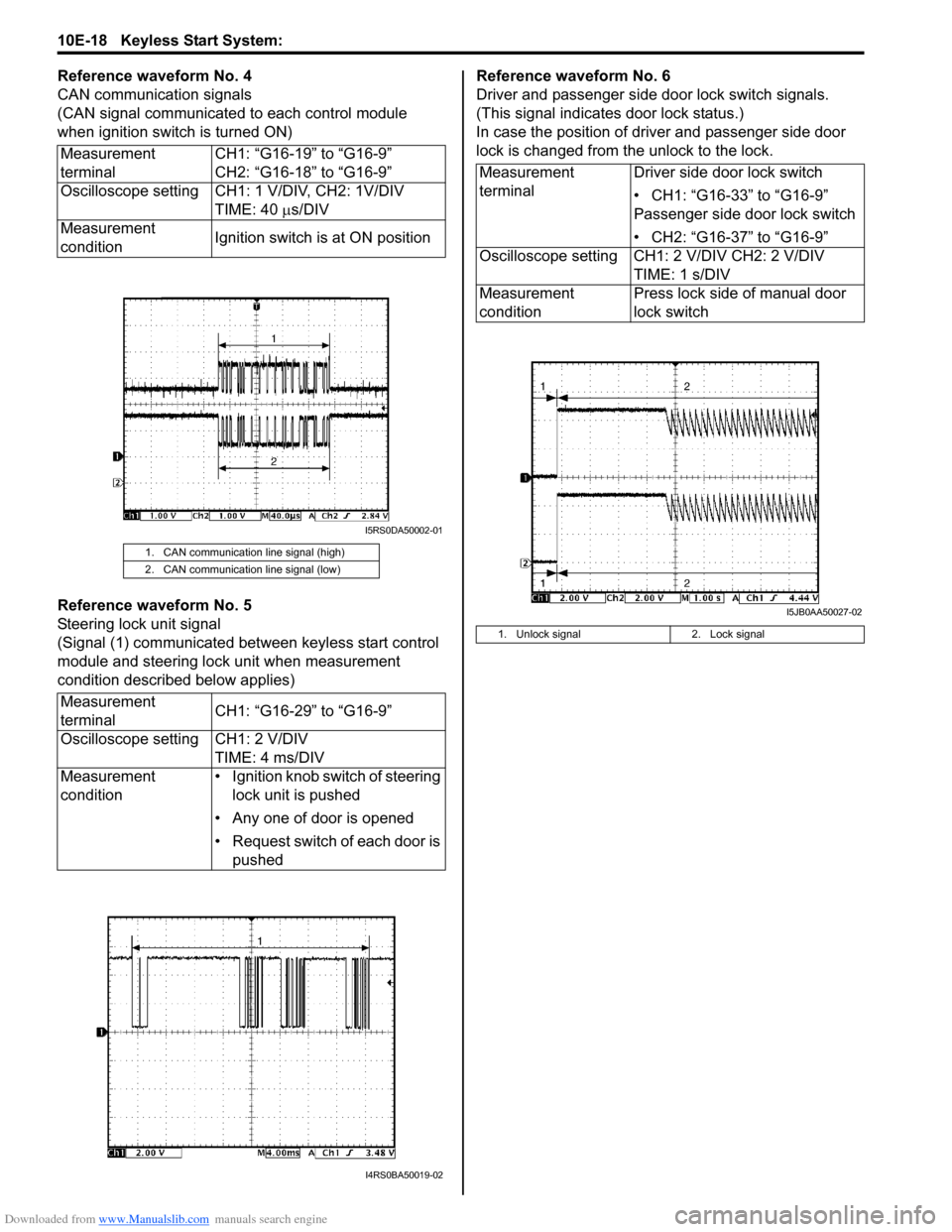

condition described below applies)Reference waveform No. 6

Driver and passenger side door lock switch signals.

(This signal indicates door lock status.)

In case the position of driver and passenger side door

lock is changed from the unlock to the lock.

Measurement

terminalCH1: “G16-19” to “G16-9”

CH2: “G16-18” to “G16-9”

Oscilloscope setting CH1: 1 V/DIV, CH2: 1V/DIV

TIME: 40 µs/DIV

Measurement

conditionIgnition switch is at ON position

1. CAN communication line signal (high)

2. CAN communication line signal (low)

Measurement

terminalCH1: “G16-29” to “G16-9”

Oscilloscope setting CH1: 2 V/DIV

TIME: 4 ms/DIV

Measurement

condition• Ignition knob switch of steering

lock unit is pushed

• Any one of door is opened

• Request switch of each door is

pushed

I5RS0DA50002-01

I4RS0BA50019-02

Measurement

terminalDriver side door lock switch

• CH1: “G16-33” to “G16-9”

Passenger side door lock switch

• CH2: “G16-37” to “G16-9”

Oscilloscope setting CH1: 2 V/DIV CH2: 2 V/DIV

TIME: 1 s/DIV

Measurement

conditionPress lock side of manual door

lock switch

1. Unlock signal 2. Lock signal

I5JB0AA50027-02