ECU SUZUKI SX4 2006 1.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1036 of 1556

Downloaded from www.Manualslib.com manuals search engine 8A-5 Seat Belts:

Front Seat Belt Removal and InstallationS6RW0D8106002

WARNING!

• Never attempt to disassemble or repair the

retractor (seat belt pretensioner). If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service

and Diagnosis of Seat Belt” before starting

to work and observe every precaution

during work. Neglecting them may result in

personal injury or unactivation of the seat

belt pretensioner when necessary.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Refer to “Disabling Air Bag

System in Section 8B”.

3) Remove center pillar lower trim.

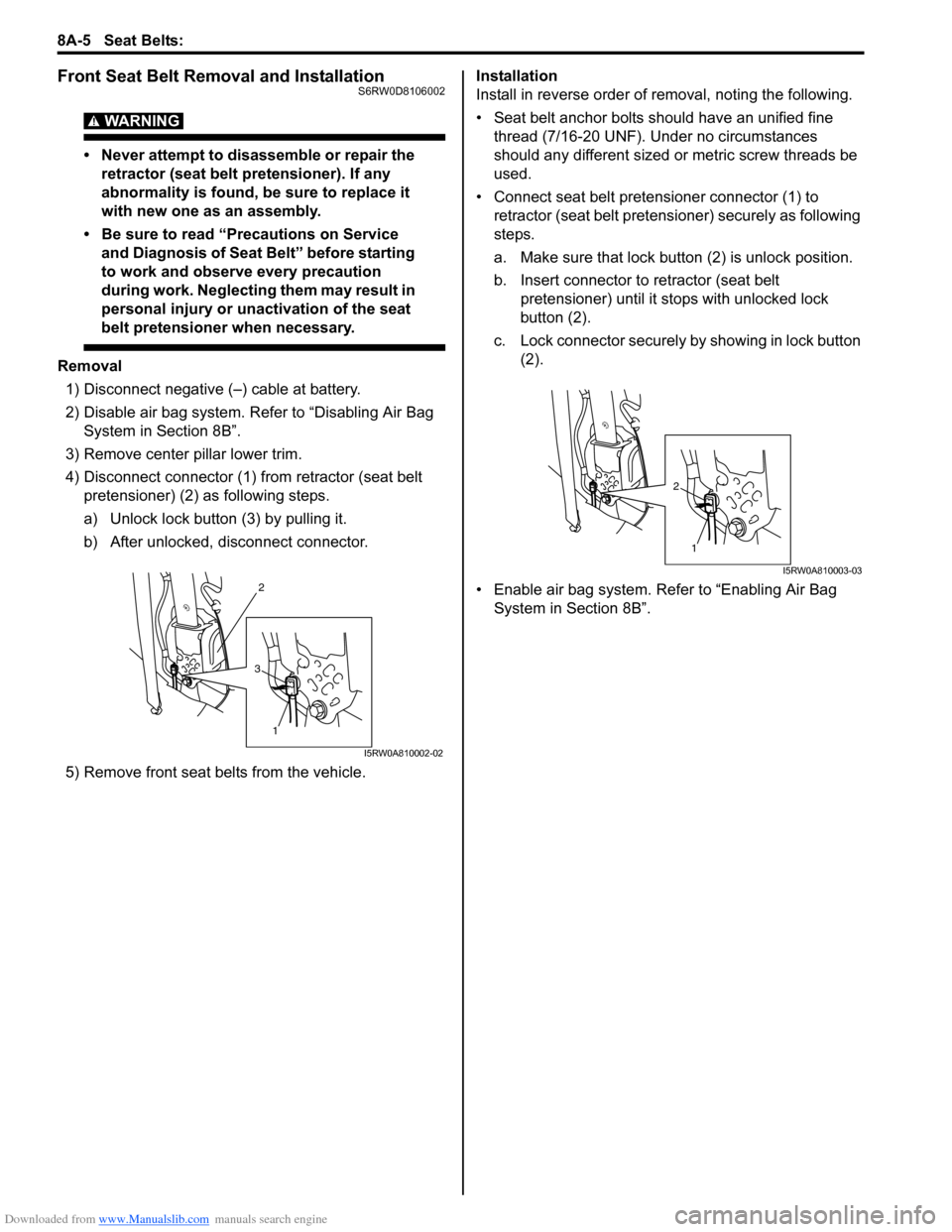

4) Disconnect connector (1) from retractor (seat belt

pretensioner) (2) as following steps.

a) Unlock lock button (3) by pulling it.

b) After unlocked, disconnect connector.

5) Remove front seat belts from the vehicle.Installation

Install in reverse order of removal, noting the following.

• Seat belt anchor bolts should have an unified fine

thread (7/16-20 UNF). Under no circumstances

should any different sized or metric screw threads be

used.

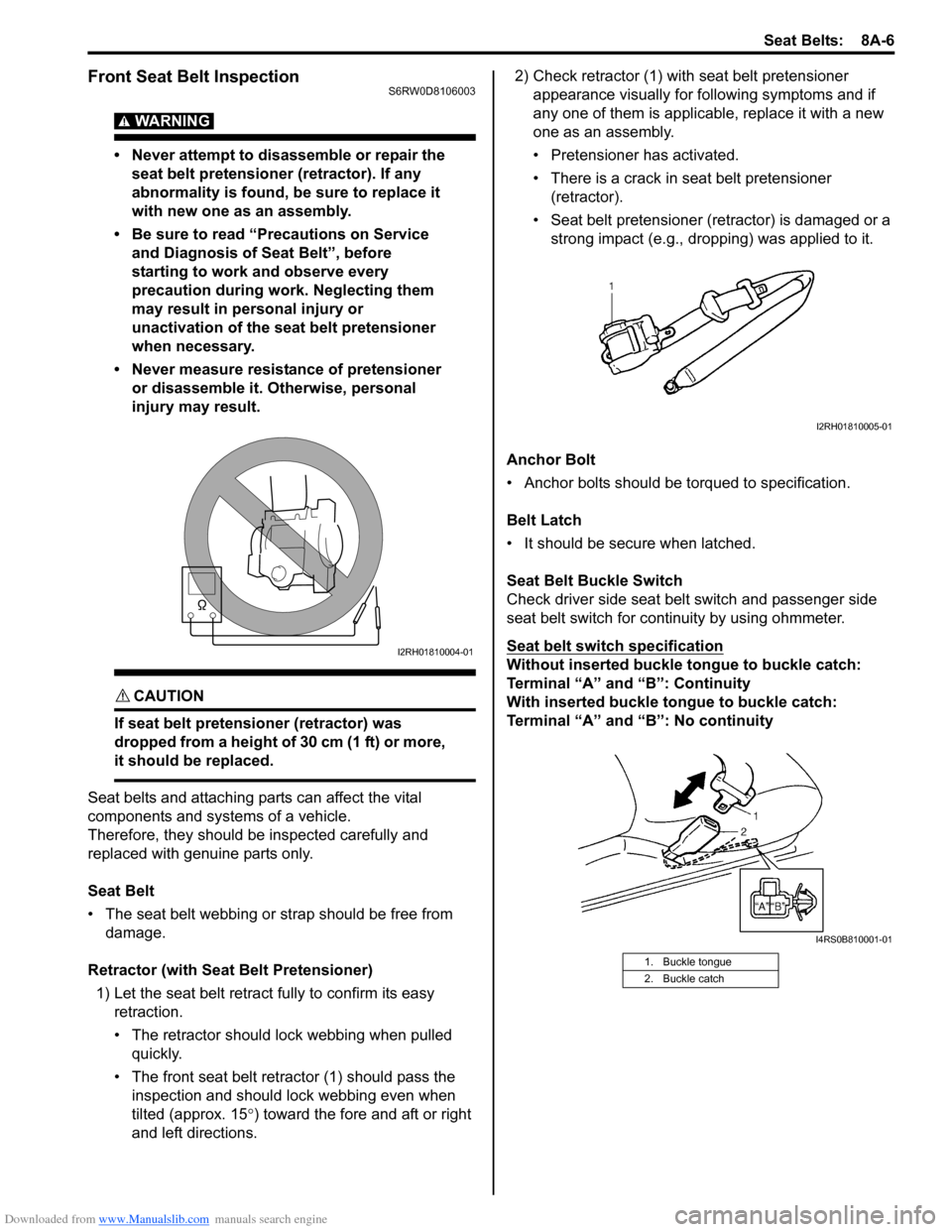

• Connect seat belt pretensioner connector (1) to

retractor (seat belt pretensioner) securely as following

steps.

a. Make sure that lock button (2) is unlock position.

b. Insert connector to retractor (seat belt

pretensioner) until it stops with unlocked lock

button (2).

c. Lock connector securely by showing in lock button

(2).

• Enable air bag system. Refer to “Enabling Air Bag

System in Section 8B”.

2

1

3

I5RW0A810002-02

1

2

I5RW0A810003-03

Page 1037 of 1556

Downloaded from www.Manualslib.com manuals search engine Seat Belts: 8A-6

Front Seat Belt InspectionS6RW0D8106003

WARNING!

• Never attempt to disassemble or repair the

seat belt pretensioner (retractor). If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service

and Diagnosis of Seat Belt”, before

starting to work and observe every

precaution during work. Neglecting them

may result in personal injury or

unactivation of the seat belt pretensioner

when necessary.

• Never measure resistance of pretensioner

or disassemble it. Otherwise, personal

injury may result.

CAUTION!

If seat belt pretensioner (retractor) was

dropped from a height of 30 cm (1 ft) or more,

it should be replaced.

Seat belts and attaching parts can affect the vital

components and systems of a vehicle.

Therefore, they should be inspected carefully and

replaced with genuine parts only.

Seat Belt

• The seat belt webbing or strap should be free from

damage.

Retractor (with Seat Belt Pretensioner)

1) Let the seat belt retract fully to confirm its easy

retraction.

• The retractor should lock webbing when pulled

quickly.

• The front seat belt retractor (1) should pass the

inspection and should lock webbing even when

tilted (approx. 15°) toward the fore and aft or right

and left directions.2) Check retractor (1) with seat belt pretensioner

appearance visually for following symptoms and if

any one of them is applicable, replace it with a new

one as an assembly.

• Pretensioner has activated.

• There is a crack in seat belt pretensioner

(retractor).

• Seat belt pretensioner (retractor) is damaged or a

strong impact (e.g., dropping) was applied to it.

Anchor Bolt

• Anchor bolts should be torqued to specification.

Belt Latch

• It should be secure when latched.

Seat Belt Buckle Switch

Check driver side seat belt switch and passenger side

seat belt switch for continuity by using ohmmeter.

Seat belt switch specification

Without inserted buckle tongue to buckle catch:

Terminal “A” and “B”: Continuity

With inserted buckle tongue to buckle catch:

Terminal “A” and “B”: No continuityI2RH01810004-01

1. Buckle tongue

2. Buckle catch

I2RH01810005-01

I4RS0B810001-01

Page 1043 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-4

• Never attempt to disassemble the seat belt

pretensioners (retractor assembly).

• If any abnormality is found, be sure to replace it with

new one as an assembly.

• When an abnormality is noted as existing in the live

(inactivated) seat belt pretensioner, be sure to activate

it before discarding it.

• When grease, cleaning agent oil, water, etc., got on

the seat belt pretensioners (retractor assembly), wipe

it off immediately with a dry cloth.

• If seat belt pretensioner was dropped from a height of

30 cm (1 ft) or more, it should be replaced with a new

one as an assembly.

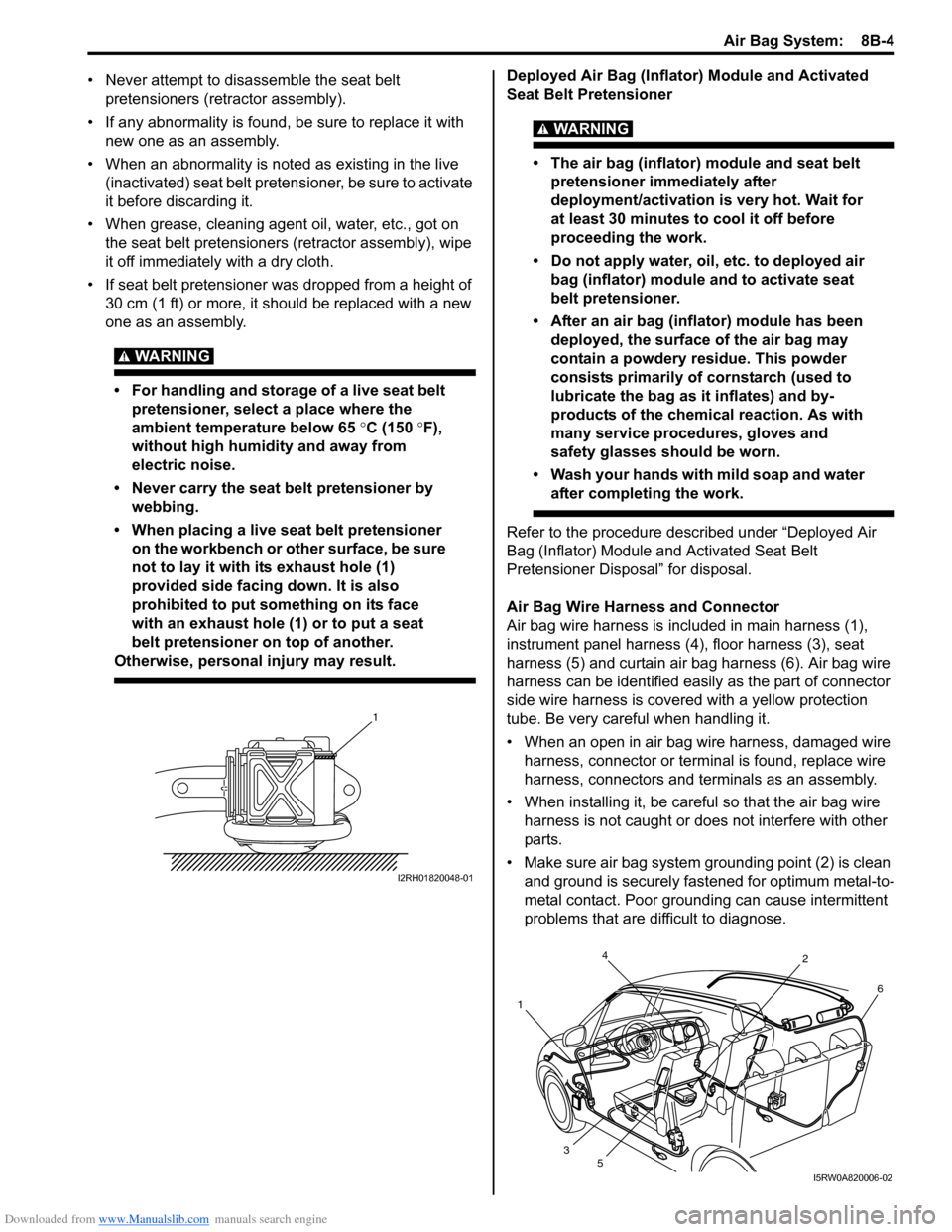

WARNING!

• For handling and storage of a live seat belt

pretensioner, select a place where the

ambient temperature below 65 °C (150 °F),

without high humidity and away from

electric noise.

• Never carry the seat belt pretensioner by

webbing.

• When placing a live seat belt pretensioner

on the workbench or other surface, be sure

not to lay it with its exhaust hole (1)

provided side facing down. It is also

prohibited to put something on its face

with an exhaust hole (1) or to put a seat

belt pretensioner on top of another.

Otherwise, personal injury may result.

Deployed Air Bag (Inflator) Module and Activated

Seat Belt Pretensioner

WARNING!

• The air bag (inflator) module and seat belt

pretensioner immediately after

deployment/activation is very hot. Wait for

at least 30 minutes to cool it off before

proceeding the work.

• Do not apply water, oil, etc. to deployed air

bag (inflator) module and to activate seat

belt pretensioner.

• After an air bag (inflator) module has been

deployed, the surface of the air bag may

contain a powdery residue. This powder

consists primarily of cornstarch (used to

lubricate the bag as it inflates) and by-

products of the chemical reaction. As with

many service procedures, gloves and

safety glasses should be worn.

• Wash your hands with mild soap and water

after completing the work.

Refer to the procedure described under “Deployed Air

Bag (Inflator) Module and Activated Seat Belt

Pretensioner Disposal” for disposal.

Air Bag Wire Harness and Connector

Air bag wire harness is included in main harness (1),

instrument panel harness (4), floor harness (3), seat

harness (5) and curtain air bag harness (6). Air bag wire

harness can be identified easily as the part of connector

side wire harness is covered with a yellow protection

tube. Be very careful when handling it.

• When an open in air bag wire harness, damaged wire

harness, connector or terminal is found, replace wire

harness, connectors and terminals as an assembly.

• When installing it, be careful so that the air bag wire

harness is not caught or does not interfere with other

parts.

• Make sure air bag system grounding point (2) is clean

and ground is securely fastened for optimum metal-to-

metal contact. Poor grounding can cause intermittent

problems that are difficult to diagnose.

1

I2RH01820048-01

4

12

6

3

5

I5RW0A820006-02

Page 1053 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-14

DTC TableS6RW0D8204003

NOTE

The DTCs (B1022 and B1023) shown with asterisk (*) below have been established only for the M15A

engine model with 4A/T equipped with slip-control (i.e., Hong Kong model). These codes are meant to

be recorded when External Scrapping Deployment Controller is operated by a Japanese authorized

special scrapping trader. Therefore, normally these codes will not appear outside Japan. However,

should these codes be detected, SDM must be replaced because the cause is due to SDM detection

failure.

SDM DTC

DTC No. Detecting itemDetecting condition

(DTC will set when detecting)Trouble area

—Normal — —

�) B1013 SDM internal failureMalfunctioned SDM internal

circuit, G sensor, memory or

CPU.•SDM

�) B1014 “AIR BAG” warning light circuit“AIR BAG” warning light circuit

has been shorted to ground,

shorted to power or opened for

more than 4 sec.• “AIR BAG” warning light circuit

• Combination meter

•SDM

�) B1016 Power supply voltage too highPower supply voltage is more

than 21.4 V for, more than 16

sec.• Charging system

•SDM

�) B1017 Power supply voltage too lowPower supply voltage is less

than 7.2 V for more than 16 sec.• Charging system

•SDM

�) B1021Front air bag deployment

recordDeployment of front air bag has

been recorded in SDM.If this DTC has been recorded

even though air bag has not

been deployed

•SDM

• Driver and/or Passenger air

bag module

• Those initiator circuit.

*B1022Scrapping deployment

controller activatedScrapping deployment command

has been input to SDM from

external scrapping deployment

controller•SDM

*B1023 Scraping deployment recordScrapping deployment execution

has been recorded in SDM•SDM

�) B1024Driver side-air bag deployment

recordDeployment of driver side-air

bag has been recorded in SDM.If this DTC has been recorded

even though side-air bag has not

been deployed

•SDM

• Driver side-air bag module

• Its initiator circuit

�) B1025Passenger side-air bag

deployment recordDeployment of passenger side-

air bag has been recorded in

SDM.If this DTC has been recorded

even though side-air bag has not

been deployed

•SDM

• Passenger side-air bag

module

• Its initiator circuit

Page 1124 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-85 Air Bag System:

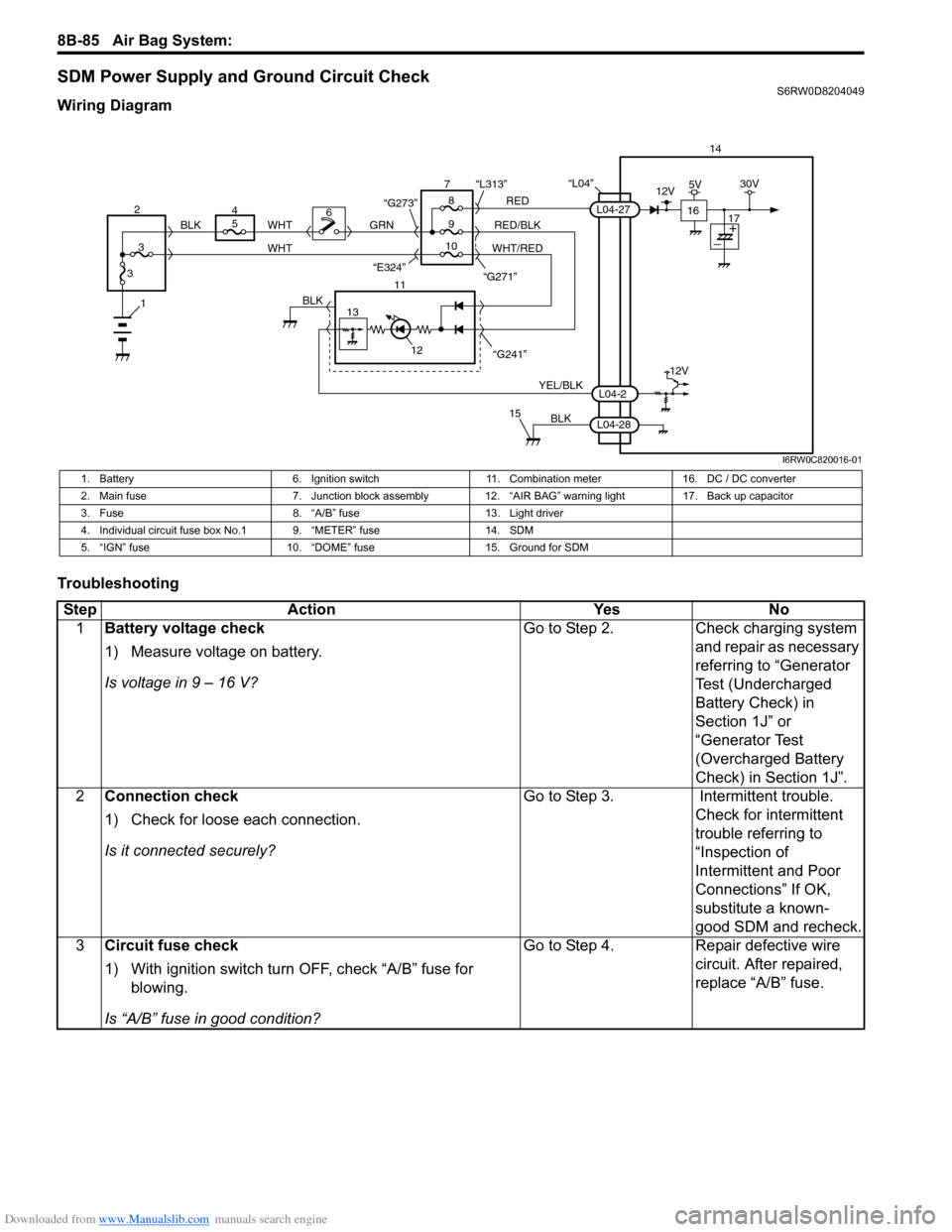

SDM Power Supply and Ground Circuit CheckS6RW0D8204049

Wiring Diagram

Troubleshooting

“L04”14

5

9RED

RED/BLK GRN

YEL/BLK

BLK

8 7

11

12

15

L04-2

L04-28

L04-27

“G241” “G271” “L313”

13

12V

6

1BLK

WHT WHT

WHT/RED 2

34

310 BLK

“G273”

“E324”16

12V5V30V

17

I6RW0C820016-01

1. Battery 6. Ignition switch 11. Combination meter 16. DC / DC converter

2. Main fuse 7. Junction block assembly 12. “AIR BAG” warning light 17. Back up capacitor

3. Fuse 8. “A/B” fuse 13. Light driver

4. Individual circuit fuse box No.1 9. “METER” fuse 14. SDM

5. “IGN” fuse 10. “DOME” fuse 15. Ground for SDM

Step Action Yes No

1Battery voltage check

1) Measure voltage on battery.

Is voltage in 9 – 16 V?Go to Step 2. Check charging system

and repair as necessary

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J” or

“Generator Test

(Overcharged Battery

Check) in Section 1J”.

2Connection check

1) Check for loose each connection.

Is it connected securely?Go to Step 3. Intermittent trouble.

Check for intermittent

trouble referring to

“Inspection of

Intermittent and Poor

Connections” If OK,

substitute a known-

good SDM and recheck.

3Circuit fuse check

1) With ignition switch turn OFF, check “A/B” fuse for

blowing.

Is “A/B” fuse in good condition?Go to Step 4. Repair defective wire

circuit. After repaired,

replace “A/B” fuse.

Page 1130 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-91 Air Bag System:

CAUTION!

After detecting one time of such collision as

to meet deployment conditions, the SDM

must not be used.

Refer to “Air Bag Diagnostic System Check”

when checking the SDM.

Accident with Deployment / Activation – Component

Replacement

When driver and passenger air bags are deployed, the

following components must be replaced.

• Driver and passenger air bag (inflator) modules

• Driver and passenger seat belt pretensioners

• SDM after detecting such collision as to meet

deployment conditions

• Forward impact-sensor

• Instrument panel

When side-air bag and side curtain-air bag are deployed,

the following components must be replaced.

• Deployed side-air bag (inflator) module

• Deployed side curtain-air bag (inflator) module

• Side impact-sensor

•SDM

Accident with or without Deployment / Activation –

Component Inspections

Certain air bag and restraint system components must

be inspected after any crash, whether the air bag system

activated or not. If any faulty condition is found in the

following checks, replace faulty part.

Those components are:

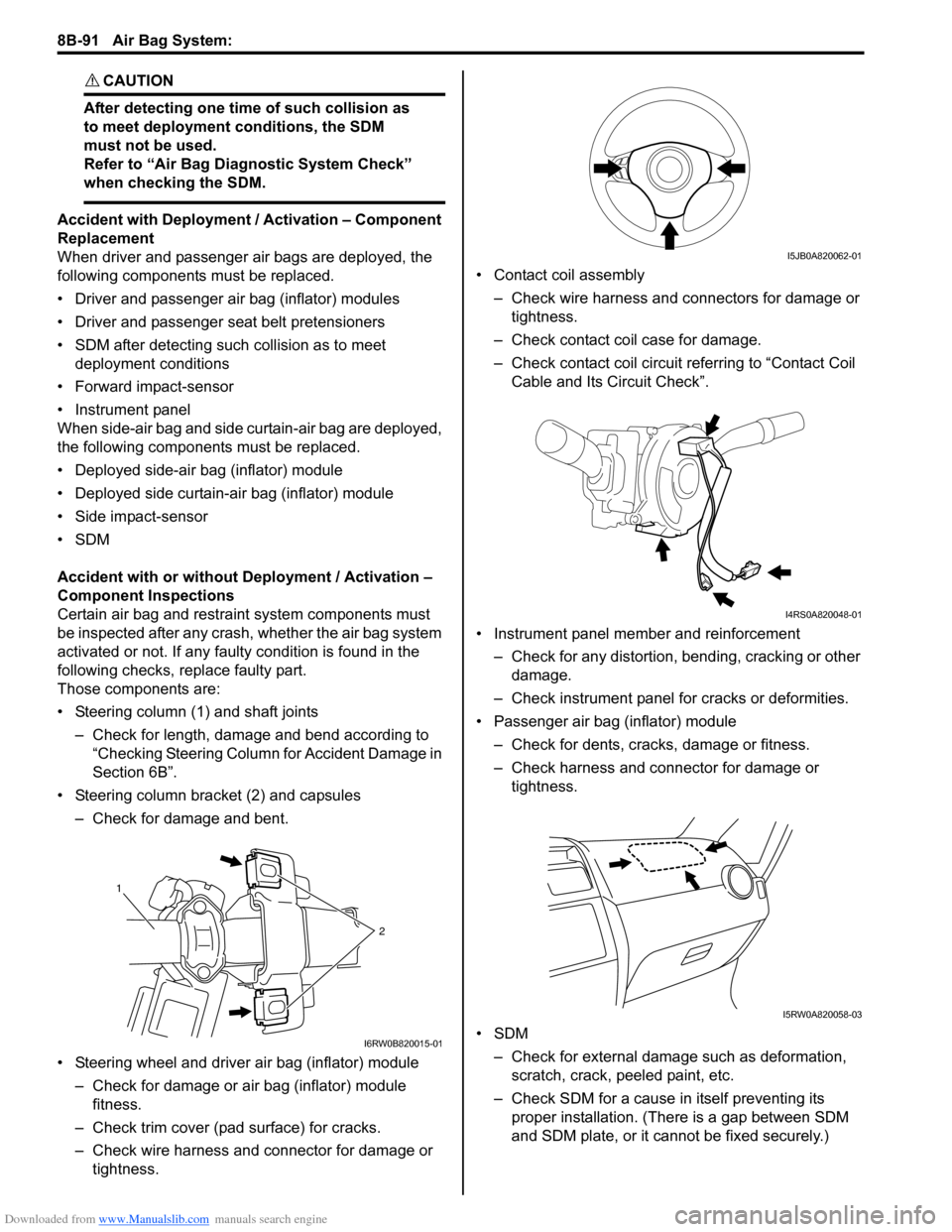

• Steering column (1) and shaft joints

– Check for length, damage and bend according to

“Checking Steering Column for Accident Damage in

Section 6B”.

• Steering column bracket (2) and capsules

– Check for damage and bent.

• Steering wheel and driver air bag (inflator) module

– Check for damage or air bag (inflator) module

fitness.

– Check trim cover (pad surface) for cracks.

– Check wire harness and connector for damage or

tightness.• Contact coil assembly

– Check wire harness and connectors for damage or

tightness.

– Check contact coil case for damage.

– Check contact coil circuit referring to “Contact Coil

Cable and Its Circuit Check”.

• Instrument panel member and reinforcement

– Check for any distortion, bending, cracking or other

damage.

– Check instrument panel for cracks or deformities.

• Passenger air bag (inflator) module

– Check for dents, cracks, damage or fitness.

– Check harness and connector for damage or

tightness.

•SDM

– Check for external damage such as deformation,

scratch, crack, peeled paint, etc.

– Check SDM for a cause in itself preventing its

proper installation. (There is a gap between SDM

and SDM plate, or it cannot be fixed securely.)

1

2

I6RW0B820015-01

I5JB0A820062-01

I4RS0A820048-01

I5RW0A820058-03

Page 1134 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-95 Air Bag System:

Installation

1) Check that none of the following faulty conditions

exists.

• Bend, scratch, deformity in vehicle body where

SDM is mounted.

• Foreign matter or rust on mating surface of vehicle

body where SDM is mounted.

2) Install SDM (2) to vehicle.

CAUTION!

Ensure that arrow on the SDM is pointing

toward the front of the vehicle.

3) Tighten SDM bolts (1) to specified torque.

Tightening torque

SDM bolt (a): 9 N·m (0.9 kgf-m, 6.5 lb-ft)

4) Connect SDM connector (2) to SDM (3) securely.

5) Install G sensor bracket (1) to floor panel.6) Install G sensor referring to “G Sensor Removal and

Installation (4WD Model) in Section 4E”.

7) Install console box upper cover.

8) Enable air bag system referring to “Enabling Air Bag

System”.

9) Connect negative (–) cable at battery.

SDM InspectionS6RW0D8206004

WARNING!

During service procedures, be very careful

when handling a Sensing and Diagnostic

Module (SDM).

Be sure to read “Precautions on Service and

Diagnosis of Air Bag System” before starting

to work and observe every precaution during

work. Neglecting them may result in personal

injury or inactivation of the air bag system

when necessary.

CAUTION!

• Do not connect a tester whatever type it

may be.

• Never repair or disassemble SDM.

• If SDM has been dropped, it should be

replaced.

If any faulty condition is found in the following checks,

replace.

• Check SDM and SDM plate for dents, cracks or

deformation.

• Check SDM connector for damage, cracks or lock

mechanism.

• Check SDM terminal for bend, corrosion or rust.

Driver Air Bag (Inflator) Module Removal and

Installation

S6RW0D8206005

WARNING!

When handling an air bag (inflator) module,

be sure to read “Precautions on Handling

and Storage of Air Bag System Components”

and observe each instruction. Failure to

follow them could cause a damage to the air

bag (inflator) module or result in personal

injury.

A: Forward

2. SDM

23 A1, (a)

I4RS0A820107-01

1

2

I5RW0A820064-01

Page 1135 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-96

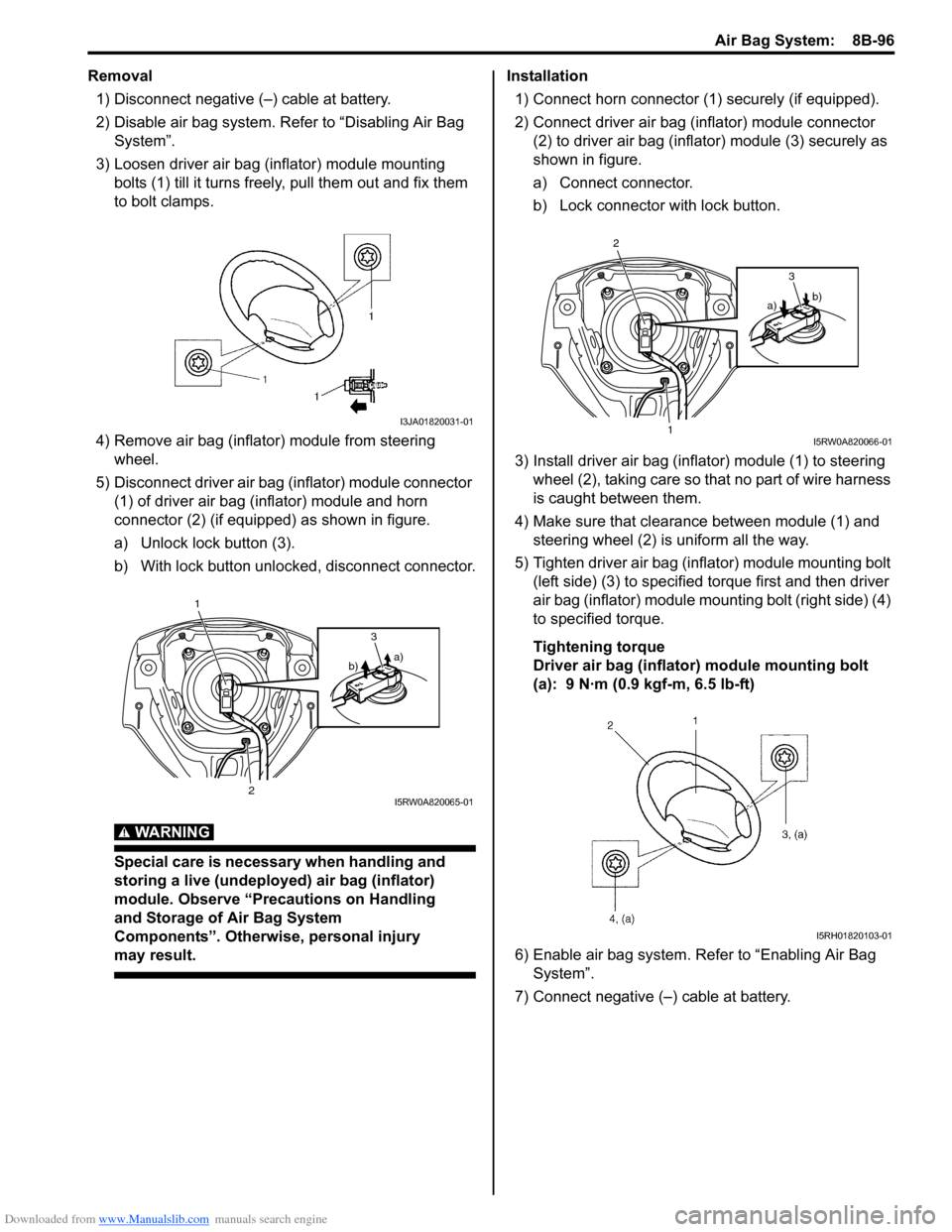

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Refer to “Disabling Air Bag

System”.

3) Loosen driver air bag (inflator) module mounting

bolts (1) till it turns freely, pull them out and fix them

to bolt clamps.

4) Remove air bag (inflator) module from steering

wheel.

5) Disconnect driver air bag (inflator) module connector

(1) of driver air bag (inflator) module and horn

connector (2) (if equipped) as shown in figure.

a) Unlock lock button (3).

b) With lock button unlocked, disconnect connector.

WARNING!

Special care is necessary when handling and

storing a live (undeployed) air bag (inflator)

module. Observe “Precautions on Handling

and Storage of Air Bag System

Components”. Otherwise, personal injury

may result.

Installation

1) Connect horn connector (1) securely (if equipped).

2) Connect driver air bag (inflator) module connector

(2) to driver air bag (inflator) module (3) securely as

shown in figure.

a) Connect connector.

b) Lock connector with lock button.

3) Install driver air bag (inflator) module (1) to steering

wheel (2), taking care so that no part of wire harness

is caught between them.

4) Make sure that clearance between module (1) and

steering wheel (2) is uniform all the way.

5) Tighten driver air bag (inflator) module mounting bolt

(left side) (3) to specified torque first and then driver

air bag (inflator) module mounting bolt (right side) (4)

to specified torque.

Tightening torque

Driver air bag (inflator) module mounting bolt

(a): 9 N·m (0.9 kgf-m, 6.5 lb-ft)

6) Enable air bag system. Refer to “Enabling Air Bag

System”.

7) Connect negative (–) cable at battery.

I3JA01820031-01

1

2

a)

b)3

I5RW0A820065-01

2

1

b)

a)3

I5RW0A820066-01

I5RH01820103-01

Page 1137 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-98

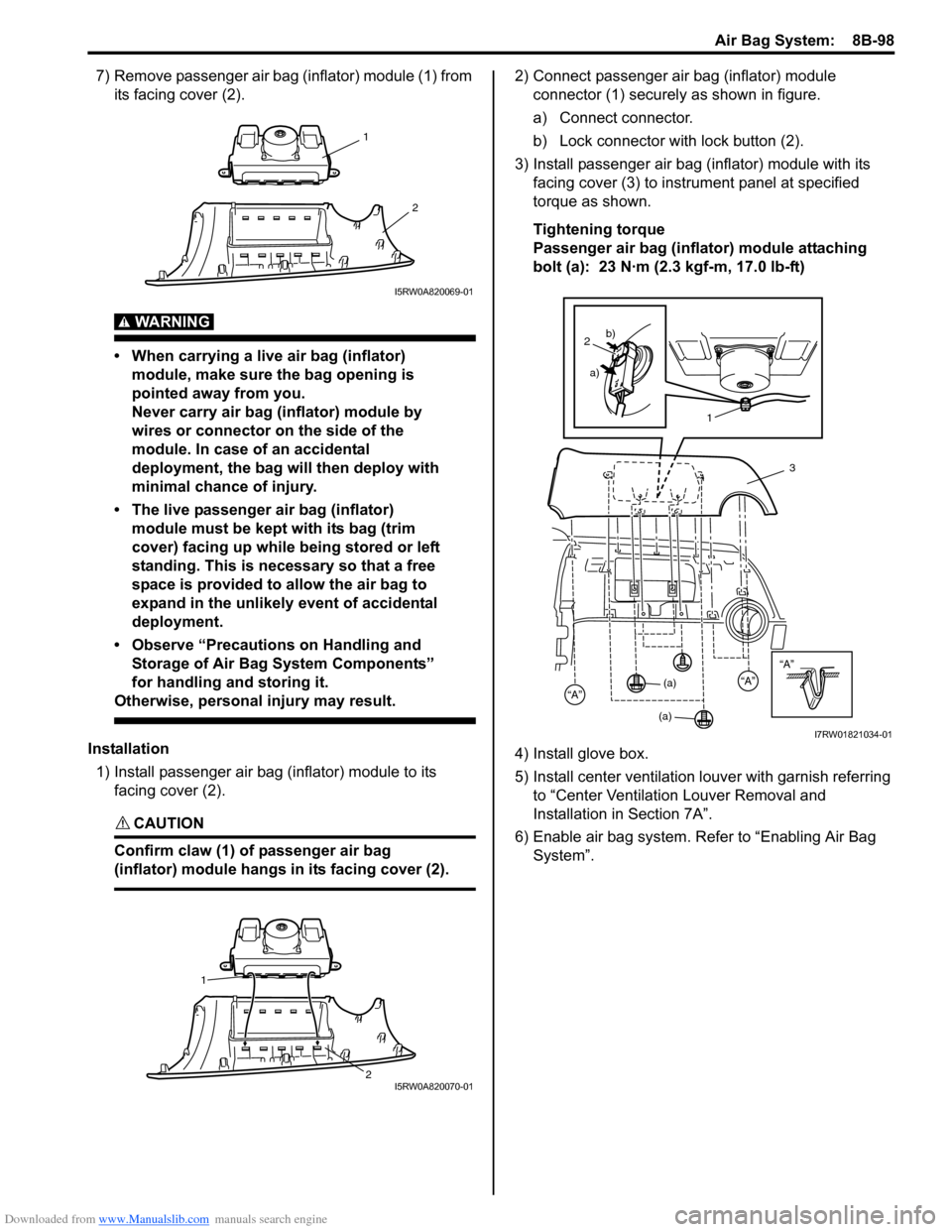

7) Remove passenger air bag (inflator) module (1) from

its facing cover (2).

WARNING!

• When carrying a live air bag (inflator)

module, make sure the bag opening is

pointed away from you.

Never carry air bag (inflator) module by

wires or connector on the side of the

module. In case of an accidental

deployment, the bag will then deploy with

minimal chance of injury.

• The live passenger air bag (inflator)

module must be kept with its bag (trim

cover) facing up while being stored or left

standing. This is necessary so that a free

space is provided to allow the air bag to

expand in the unlikely event of accidental

deployment.

• Observe “Precautions on Handling and

Storage of Air Bag System Components”

for handling and storing it.

Otherwise, personal injury may result.

Installation

1) Install passenger air bag (inflator) module to its

facing cover (2).

CAUTION!

Confirm claw (1) of passenger air bag

(inflator) module hangs in its facing cover (2).

2) Connect passenger air bag (inflator) module

connector (1) securely as shown in figure.

a) Connect connector.

b) Lock connector with lock button (2).

3) Install passenger air bag (inflator) module with its

facing cover (3) to instrument panel at specified

torque as shown.

Tightening torque

Passenger air bag (inflator) module attaching

bolt (a): 23 N·m (2.3 kgf-m, 17.0 lb-ft)

4) Install glove box.

5) Install center ventilation louver with garnish referring

to “Center Ventilation Louver Removal and

Installation in Section 7A”.

6) Enable air bag system. Refer to “Enabling Air Bag

System”.

1

2

I5RW0A820069-01

1

2

I5RW0A820070-01

“A”

3

“A”“A”

2

a)b)

1

(a)

(a)

I7RW01821034-01

Page 1140 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-101 Air Bag System:

2) Install new sleeve (1) and sleeve lock nut (2) to side-

air bag (inflator) module, then tighten nut to specified

torque.

Tightening torque

Sleeve lock nut (a): 2.5 N·m (0.25 kgf-m, 2.0 lb-

ft)

3) Connect side-air bag (inflator) module connector (1)

securely as shown in the figure.

a) Connect connector.

b) Lock connector with lock button (2).

4) Insert claw (1) of side-air bag (inflator) module on

installation hole (2).

5) Install side-air bag (inflator) module by pushing it into

fastener (3) securely.

6) Roll down backside seat back surface and fix seat

back surface fastener securely.Side-Air Bag (Inflator) InspectionS6RW0D8206021

WARNING!

• Never attempt to disassemble or repair the

side-air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service

and Diagnosis of Air Bag System” before

starting to work and observe every

precaution during work. Neglecting them

may result in personal injury or

undeployment of the air bag when

necessary.

CAUTION!

If air bag (inflator) module was dropped from

a height of 90 cm (3 ft) or more, it should be

replaced.

Check air bag (inflator) module appearance visually for

the following symptoms and if any one of them is found,

replace with a new one.

• Air bag has deployed.

• There is a crack in trim cover (pad surface).

• Wire harness or connector is damaged.

• Air bag (inflator) module is damaged or a strong

impact was applied to it.

• Bend or deformity of air bag (inflator) module bracket.

12, (a)

I4RS0A820073-02

1

2

a) b)

I4RS0A820070-01

1

2

3

I4RS0A820074-02

I4RS0A820075-02