Actuator SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1336 of 1556

Downloaded from www.Manualslib.com manuals search engine 9B-17 Lighting Systems:

Terminal Circuit Specification Condition

1 Power source 10 – 14 VIgnition switch is at ON

position.

2———

3 Lighting switchLess than 1.5 VLighting switch is at “HEAD”

position.

10 – 14 VLighting switch is at OFF

position.

4———

5 Diagnosis switch terminal About 5 VIgnition switch is at ON

position.

6Headlight auto leveling

indicatorLess than 1.5 VFor about 3 seconds after

ignition switch is turned on (i.e.,

headlight auto leveling

indicator is lit up).

10 – 14 VMore than about 3 seconds

after ignition switch is turned

on (i.e., headlight auto leveling

indicator is not lit up).

7———

8———

9Ground for headlight auto

leveling control unit0 VIgnition switch is at ON

position.

10Power supply for right

headlight leveling actuator10 – 14 VIgnition switch is at ON

position.

11Power supply for left headlight

leveling actuator10 – 14 VIgnition switch is at ON

position.

12Power supply for rear height

sensorAbout 5 VIgnition switch is at ON

position.

13Power supply for front height

sensorAbout 5 VIgnition switch is at ON

position.

14———

15———

16 Vehicle speed signal Refer to “Reference waveform No.1: ”.

17Signal for right headlight

leveling actuatorLess than 1 VLighting switch is at OFF

position.

1.0 – 12.6 VFor 17 seconds after turning

lighting switch to ON position.

18Signal for left headlight leveling

actuatorLess than 1 VLighting switch is at OFF

position.

1.0 – 12.6 VFor 17 seconds after turning

lighting switch to ON position.

19Input signal for rear height

sensorAbout 2.5 VIgnition switch is at ON

position.

20Input signal for front height

sensorAbout 2.5 VIgnition switch is at ON

position.

21 Ground for rear height sensor 0 VIgnition switch is at ON

position.

22 Ground for front height sensor 0 VIgnition switch is at ON

position.

23Ground for right headlight

leveling actuator0 VIgnition switch is at ON

position.

24

Ground for left headlight

leveling actuator0 VIgnition switch is at ON

position.

Page 1340 of 1556

![SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 9B-21 Lighting Systems:

1

“H”“b”

“a”

2

10

[G] [F] [E]

7

8

9

6

7

5

10

11 8 9

7

6

5

A

A4

3

B B

A

A4

B B

“H”

“H” “H”

“H SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 9B-21 Lighting Systems:

1

“H”“b”

“a”

2

10

[G] [F] [E]

7

8

9

6

7

5

10

11 8 9

7

6

5

A

A4

3

B B

A

A4

B B

“H”

“H” “H”

“H](/img/20/7612/w960_7612-1339.png)

Downloaded from www.Manualslib.com manuals search engine 9B-21 Lighting Systems:

1

“H”“b”

“a”

2

10

[G] [F] [E]

7

8

9

6

7

5

10

11 8 9

7

6

5

A

A4

3

B B

A

A4

B B

“H”

“H” “H”

“H” [C]

[D]

A

A4

B B

[A][B]

“H”“H”

XX XX XX

A

A4

B B

[A][B]

“H” “H” [I] [H]

[I] [H]

3

33

3

333

XX

[A][B]

[A][B]

6

5

8

9

I6RW0C920018-02

2. Headlight bulb 10. Headlight housing [D]: LH steering vehicle shown

3. Cut line (bounding line) 11. Headlight leveling actuator [E]: Without headlight leveling actuator

4. Hot spot X-X: Horizontal center line of headlight bulbs [F]: Headlight manual leveling model

5. Turning (for up adjustment) A-A: Vertical center line of left headlight bulb [G]: Headlight auto leveling model

6. Turning (for down adjustment) B-B: Vertical center line of right headlight bulb [H]: Other than discharge headlight model

7. Aiming gear (for right / left adjustment) [A]: Left headlight [I]: Discharge headlight model

8. Turning (for right adjustment) [B]: Right headlight

9. Turning (for left adjustment) [C]: RH steering vehicle shown

Page 1347 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-28

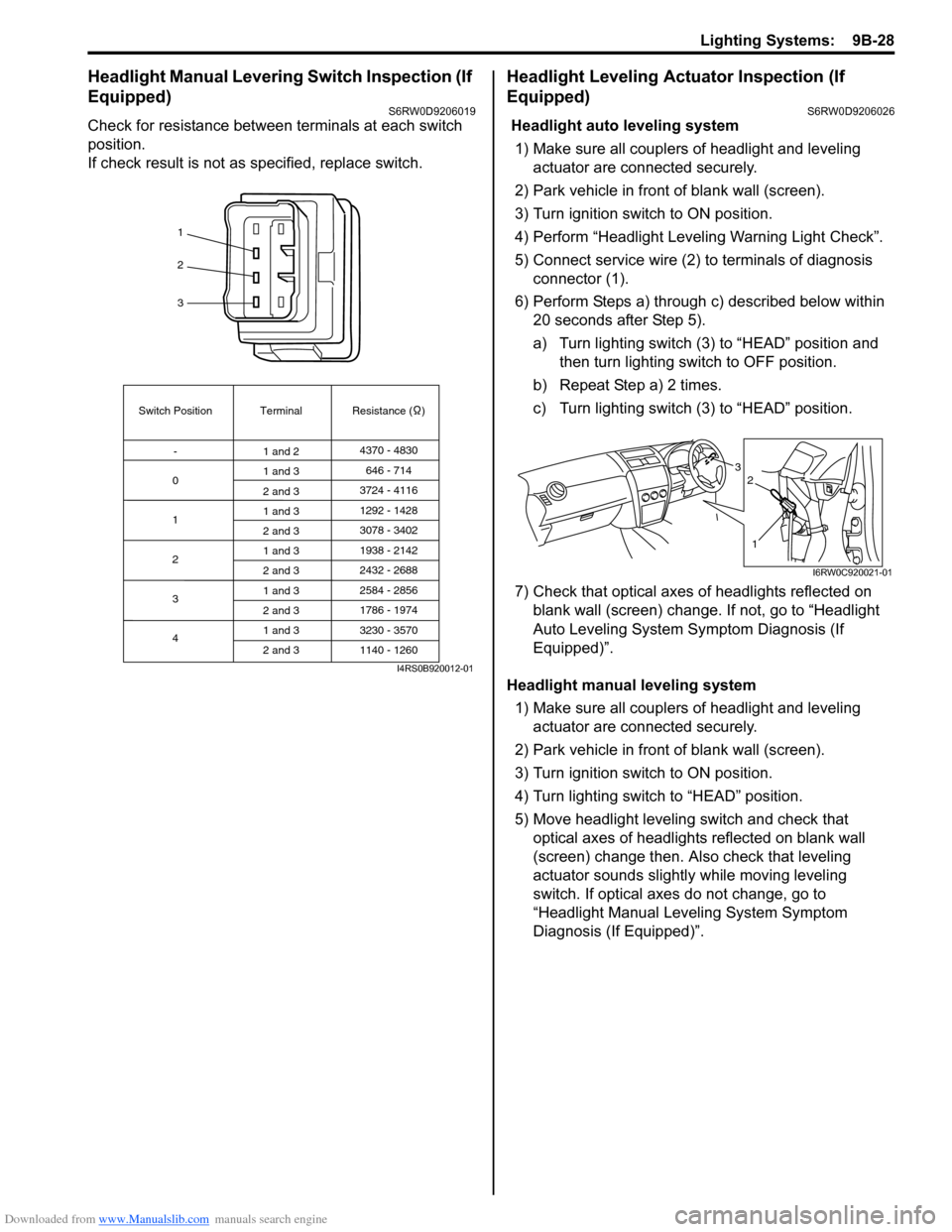

Headlight Manual Levering Switch Inspection (If

Equipped)

S6RW0D9206019

Check for resistance between terminals at each switch

position.

If check result is not as specified, replace switch.

Headlight Leveling Actuator Inspection (If

Equipped)

S6RW0D9206026

Headlight auto leveling system

1) Make sure all couplers of headlight and leveling

actuator are connected securely.

2) Park vehicle in front of blank wall (screen).

3) Turn ignition switch to ON position.

4) Perform “Headlight Leveling Warning Light Check”.

5) Connect service wire (2) to terminals of diagnosis

connector (1).

6) Perform Steps a) through c) described below within

20 seconds after Step 5).

a) Turn lighting switch (3) to “HEAD” position and

then turn lighting switch to OFF position.

b) Repeat Step a) 2 times.

c) Turn lighting switch (3) to “HEAD” position.

7) Check that optical axes of headlights reflected on

blank wall (screen) change. If not, go to “Headlight

Auto Leveling System Symptom Diagnosis (If

Equipped)”.

Headlight manual leveling system

1) Make sure all couplers of headlight and leveling

actuator are connected securely.

2) Park vehicle in front of blank wall (screen).

3) Turn ignition switch to ON position.

4) Turn lighting switch to “HEAD” position.

5) Move headlight leveling switch and check that

optical axes of headlights reflected on blank wall

(screen) change then. Also check that leveling

actuator sounds slightly while moving leveling

switch. If optical axes do not change, go to

“Headlight Manual Leveling System Symptom

Diagnosis (If Equipped)”.

1

2

3

Switch Position

0Terminal Resistance ( )

-

1

2

3

41 and 24370 - 4830

1 and 3

2 and 3

1 and 3

2 and 3

1 and 3

2 and 3

1 and 3

2 and 3

1 and 3

2 and 3646 - 714

3724 - 4116

3078 - 3402 1292 - 1428

1938 - 2142

2584 - 2856

3230 - 3570 2432 - 2688

1786 - 1974

1140 - 1260

I4RS0B920012-01

3

1

2

I6RW0C920021-01

Page 1389 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-4

Inspection of Pinching Prevention Function (Pinching Prevention Function Model)S6RW0D9504032

1) Open driver side door glass fully.

2) Hold a hummer so that its handle (wooden) (1) is placed as shown.

WARNING!

Never attempt to have your hand, arm or any other part of the body punched. Also, use full care not to

have your body caught during inspection.

CAUTION!

If a side visor is installed, be careful so that hammer handle does not contact the visor. A hammer can

be held from inside of the vehicle.

3) Use auto-up function of power window main switch.

4) Check that door glass lowers back automatically to specified position “a” before hammer handle is caught. If there

is any faulty condition, referring to “Power Window Control System Symptom Diagnosis”.

Power Door Mirror Control System Symptom DiagnosisS6RW0D9504003

Driver side door glass

lowers back while using

auto-up function although

nothing is pinched

between door glass and

frame (Pinching

Prevention Function

Model)Foreign matter is attached to door glass,

glass run or sash etc.Remove the foreign matter.

Glass run and/or door sash faultyRepair or replace.

Power window main switch has not been

initializedExecute the initial setting of power window

main switch referring to “Power Window Main

Switch Initialization (Pinching Prevention

Function Model)”.

Power window main switch faultyCheck power window main switch referring to

“Power Window Main Switch Inspection”.

Power window motor faultyCheck power window motor referring to “Pulse

Sensor and Its Circuit Inspection (Pinching

Prevention Function Model)”. Condition Possible cause Correction / Reference Item

“a”. Approx. 220 mm (8.66 in.)

I6RW0D950006-01

Condition Possible cause Correction / Reference Item

All power mirrors do not

operateCircuit fuse blownReplace fuse and check for short circuit.

Power door mirror switch faultyCheck power door mirror switch referring to

“Power Door Mirror Switch Inspection”.

Wiring or grounding faultyRepair circuit.

One power mirror does

not operatePower door mirror switch faultyCheck power door mirror switch referring to

“Power Door Mirror Switch Inspection”.

Power door mirror actuator faultyCheck actuator refraining to “Power Door

Mirror Actuator Inspection”.

Wiring or grounding faultyRepair circuit.

Page 1410 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-25 Glass / Windows / Mirrors:

Door Mirror Removal and InstallationS6RW0D9506024

When removing or installing door mirror, refer to the

figure in “Door Mirror Components”.

Power Door Mirror Switch InspectionS6RW0D9506025

1) Remove driver side door trim referring to step 1) to

3) of “Front Door Glass Removal and Installation”.

2) Remove power window main switch from door trim.

3) Check for continuity between terminals at each

switch position.

If check result is not as specified, replace door mirror

switch.

Power Door Mirror Actuator InspectionS6RW0D9506026

1) Remove door trim referring to step 1) to 3) of “Front

Door Glass Removal and Installation”.

2) Disconnect door mirror coupler (1).

3) Check that door mirror operates properly when

battery voltage is applied to connector terminals.

4) Connect battery positive (+) and negative (–)

terminal to the door mirror terminals as shown.

If it does not follow the table’s operation, replace

door mirror assembly.

*: Vehicle with retractable mirror only

ABC

DEFG

A

BC

DE

FG

Up

Down

Left

Right

L

RH

I

*Set

*Retract

HII5RS0C950004-01

*: Vehicle with retractable mirror only

A

B

C1 Operation

Terminal

Up

Down

Left

Right

*Set

*RetractCDE B A

D

E

I6RW0D950007-01

Page 1413 of 1556

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-2

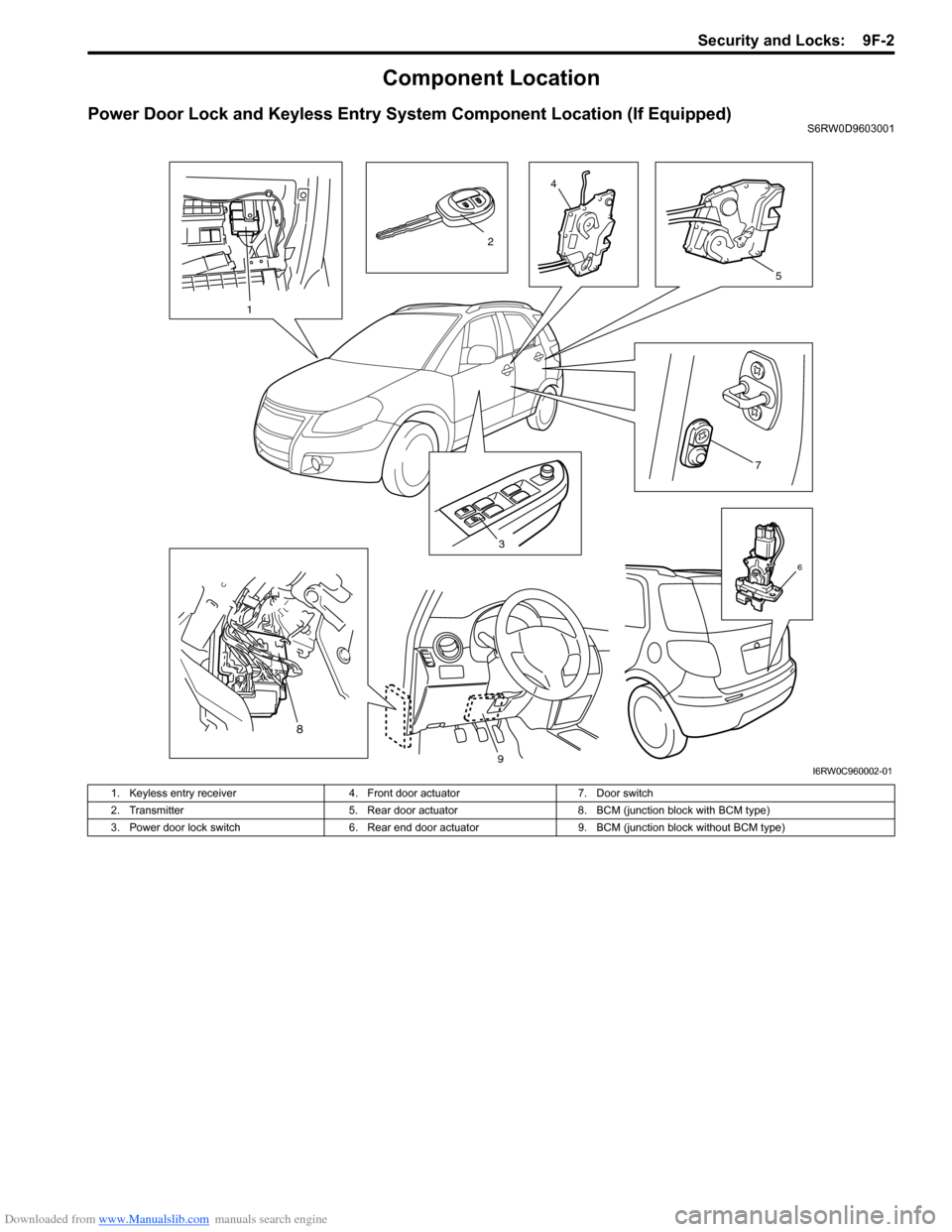

Component Location

Power Door Lock and Keyless Entry System Component Location (If Equipped)S6RW0D9603001

3

7

4

5

6

1

2

8

9I6RW0C960002-01

1. Keyless entry receiver 4. Front door actuator 7. Door switch

2. Transmitter 5. Rear door actuator 8. BCM (junction block with BCM type)

3. Power door lock switch 6. Rear end door actuator 9. BCM (junction block without BCM type)

Page 1414 of 1556

Downloaded from www.Manualslib.com manuals search engine 9F-3 Security and Locks:

Diagnostic Information and Procedures

Power Door Lock System Symptom Diagnosis (If Equipped)S6RW0D9604001

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, refer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Power Door Lock System Operation Inspection (If Equipped)S6RW0D9604002

1) Check the following operation:

a) Turn the driver side key cylinder is turned LOCK once, check all doors lock.

b) Turn the driver side door key cylinder is turned UNLOCK position with door key twice, check all doors unlock.

c) With all doors unlocked, insert key in key cylinder of driver side door and turn it to lock side, turn it again to lock

side within 3 seconds and check that no door can be opened even when door lock knob is moved to unlock

side (dead lock function, if equipped).

If malfunction is found, go to “Power Door Lock System Symptom Diagnosis (If Equipped)”. Condition Possible cause Correction / Reference Item

All door can not be locked

/ unlocked by all of

switchesCircuit fuse blownReplace fuse and check for short circuit.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

All door can not be locked

/ unlocked by only power

door lock switchCircuit fuse blownReplace fuse and check for short circuit.

Power door lock switch faultyCheck power door lock switch referring to

“Power Door Lock Switch Inspection (If

Equipped)”.

Wiring harness connected to power door

lock switch faultyRepair.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

All door can not be locked

/ unlocked by only key

cylinder switchCircuit fuse blownReplace fuse and check for short circuit.

Key cylinder switch faultyCheck key cylinder switch referring to “Door

Key Cylinder Switch Inspection (If Equipped)”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Only one door can not be

locked / unlockedPower door lock actuator faultyCheck actuator referring to “Power Door Lock

Actuator Inspection (If Equipped)”.

Wiring harness connected to applicable

door lock actuator faultyRepair.

BCM faultyReplace after making sure that none of above

parts is faulty.

Page 1416 of 1556

Downloaded from www.Manualslib.com manuals search engine 9F-5 Security and Locks:

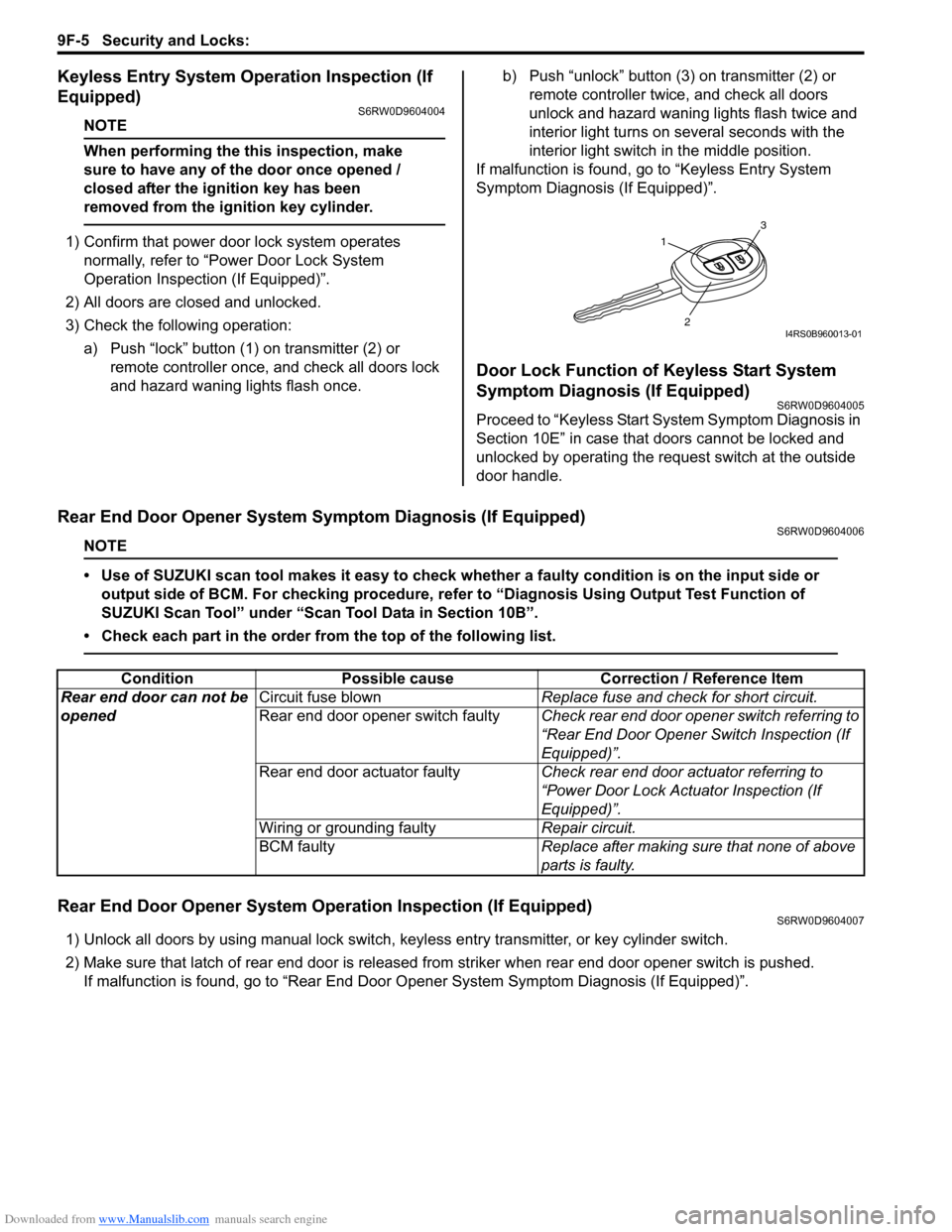

Keyless Entry System Operation Inspection (If

Equipped)

S6RW0D9604004

NOTE

When performing the this inspection, make

sure to have any of the door once opened /

closed after the ignition key has been

removed from the ignition key cylinder.

1) Confirm that power door lock system operates

normally, refer to “Power Door Lock System

Operation Inspection (If Equipped)”.

2) All doors are closed and unlocked.

3) Check the following operation:

a) Push “lock” button (1) on transmitter (2) or

remote controller once, and check all doors lock

and hazard waning lights flash once.b) Push “unlock” button (3) on transmitter (2) or

remote controller twice, and check all doors

unlock and hazard waning lights flash twice and

interior light turns on several seconds with the

interior light switch in the middle position.

If malfunction is found, go to “Keyless Entry System

Symptom Diagnosis (If Equipped)”.

Door Lock Function of Keyless Start System

Symptom Diagnosis (If Equipped)

S6RW0D9604005

Proceed to “Keyless Start System Symptom Diagnosis in

Section 10E” in case that doors cannot be locked and

unlocked by operating the request switch at the outside

door handle.

Rear End Door Opener System Symptom Diagnosis (If Equipped)S6RW0D9604006

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, refer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Rear End Door Opener System Operation Inspection (If Equipped)S6RW0D9604007

1) Unlock all doors by using manual lock switch, keyless entry transmitter, or key cylinder switch.

2) Make sure that latch of rear end door is released from striker when rear end door opener switch is pushed.

If malfunction is found, go to “Rear End Door Opener System Symptom Diagnosis (If Equipped)”.

1

3

2I4RS0B960013-01

Condition Possible cause Correction / Reference Item

Rear end door can not be

openedCircuit fuse blownReplace fuse and check for short circuit.

Rear end door opener switch faultyCheck rear end door opener switch referring to

“Rear End Door Opener Switch Inspection (If

Equipped)”.

Rear end door actuator faultyCheck rear end door actuator referring to

“Power Door Lock Actuator Inspection (If

Equipped)”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Page 1420 of 1556

Downloaded from www.Manualslib.com manuals search engine 9F-9 Security and Locks:

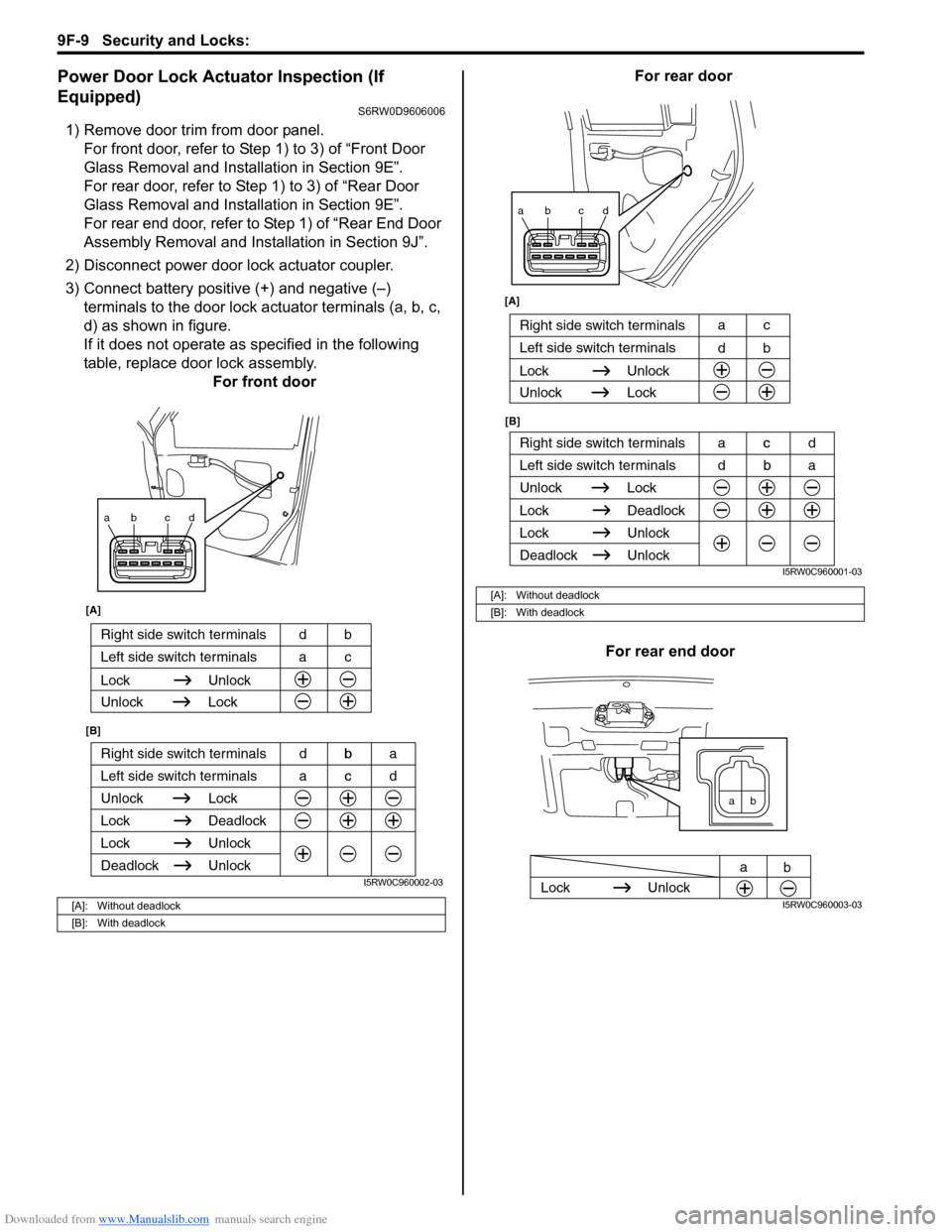

Power Door Lock Actuator Inspection (If

Equipped)

S6RW0D9606006

1) Remove door trim from door panel.

For front door, refer to Step 1) to 3) of “Front Door

Glass Removal and Installation in Section 9E”.

For rear door, refer to Step 1) to 3) of “Rear Door

Glass Removal and Installation in Section 9E”.

For rear end door, refer to Step 1) of “Rear End Door

Assembly Removal and Installation in Section 9J”.

2) Disconnect power door lock actuator coupler.

3) Connect battery positive (+) and negative (–)

terminals to the door lock actuator terminals (a, b, c,

d) as shown in figure.

If it does not operate as specified in the following

table, replace door lock assembly.

For front doorFor rear door

For rear end door

[A]: Without deadlock

[B]: With deadlock

ab cd

Right side switch terminals b

Unlock Lock

Lock Deadlock

Lock Unlock

Left side switch terminals c

Unlock

Deadlock

[A]

[B]

Right side switch terminals bd

Unlock Lock

Lock Unlock

Left side switch terminals ca

acd dba

I5RW0C960002-03

[A]: Without deadlock

[B]: With deadlock

ab cd

Right side switch terminals c

Unlock Lock

Lock Deadlock

Lock Unlock

Left side switch terminals b

Unlock

Deadlock

[B] [A]

Right side switch terminals

b d

Unlock Lock

Lock Unlock

Left side switch terminalsc a

dba acd

I5RW0C960001-03

ab

Lock Unlock

a

b

I5RW0C960003-03

Page 1474 of 1556

Downloaded from www.Manualslib.com manuals search engine 10B-1 Body Electrical Control System:

Control Systems

Body Electrical Control System

Precautions

Precautions in Diagnosing TroubleS6RW0DA200001

• Diagnostic information stored in BCM memory can be cleared as well as checked by using SUZUKI scan tool.

Before using scan tool, read its Operator’s (Instruction) Manual carefully to have good understanding as to what

functions are available and how to use it.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” before inspection and observe what is

written there.

• Communication of ECM, TCM (A/T model), ABS control module, 4WD control module (if equipped), keyless start

control module (if equipped), combination meter and BCM is established by CAN (Controller Area Network). For

detail of CAN communication for BCM, refer to “CAN Communication System Description”. Therefore, handle CAN

communication line with care referring to “Precaution for CAN Communication System in Section 00”.

General Description

BCM General DescriptionS6RW0DA201001

The Body electrical Control Module (BCM) is

incorporated in junction block. Do not attempt removal of

BCM from junction block as it may cause contact failure.

The BCM incorporates relays and controllers which are

used for the following systems and controls them.

• Power door lock (if equipped)

• Keyless entry (if equipped)

• Door lock function of keyless start system (if

equipped)

• Rear wiper

• Combination meter

• Interior light• Warning buzzer

• Rear end door window defogger and door mirror

heater (if equipped)

• Rear end door opener (if equipped)

• Theft deterrent light

Also, the BCM has a function to cause the interior light

and open door warning light in the combination meter to

turn off when any door is left open for longer than 15

minutes to reduce wasteful battery consumption.

In addition, it is possible to check operation of actuator

which is controlled by BCM by using the output test

function of SUZUKI scan tool to operate actuator

simulatively.

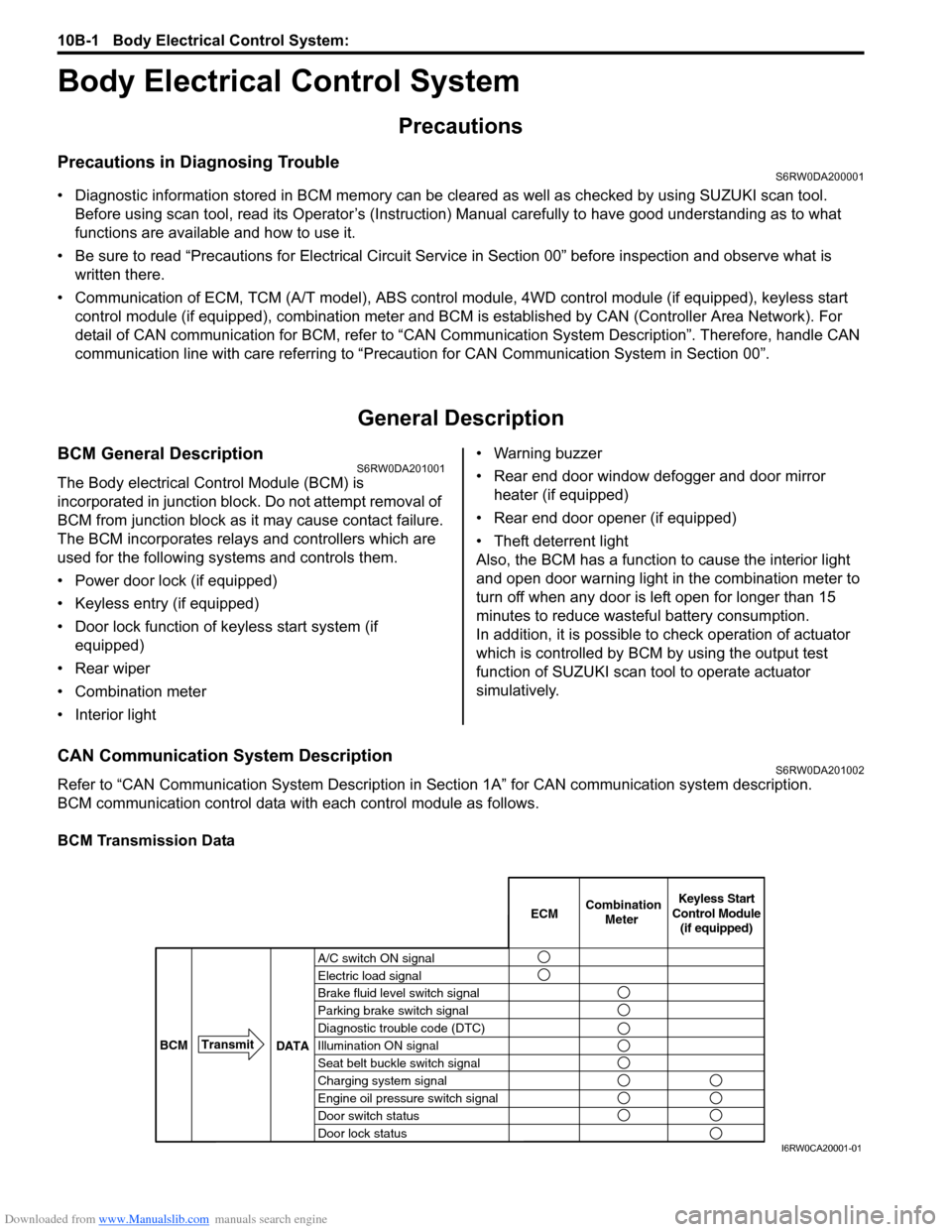

CAN Communication System DescriptionS6RW0DA201002

Refer to “CAN Communication System Description in Section 1A” for CAN communication system description.

BCM communication control data with each control module as follows.

BCM Transmission Data

A/C switch ON signal

Electric load signal

Brake fluid level switch signal

Parking brake switch signal

Diagnostic trouble code (DTC)

Illumination ON signal

Seat belt buckle switch signal

Charging system signal

Engine oil pressure switch signal

Door switch status

Door lock statusECMKeyless Start

Control Module

(if equipped) Combination

Meter

BCMTransmit

DATA

I6RW0CA20001-01