200 SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 813 of 1556

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-1

Transmission / Transaxle

Manual Transmission/Transaxle

General Description

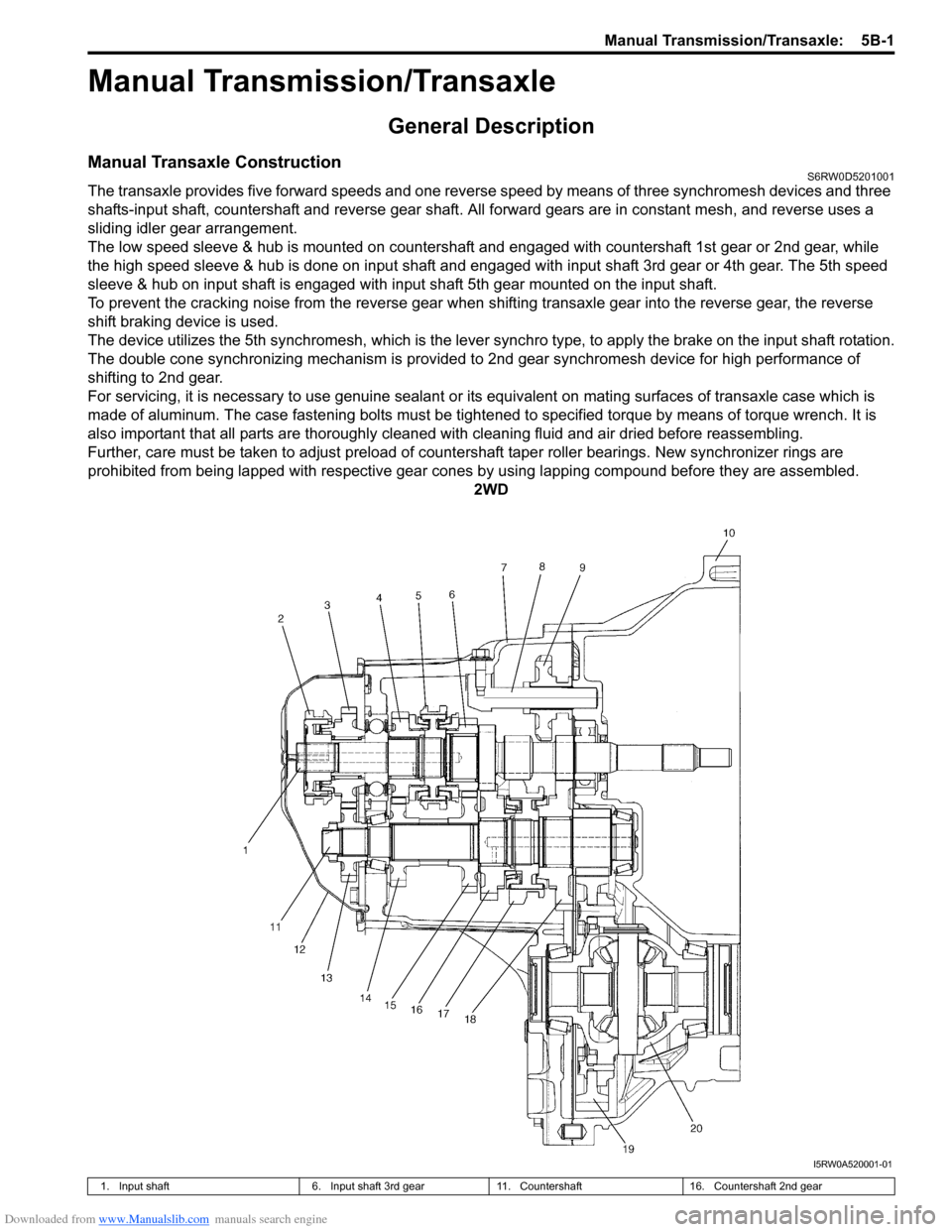

Manual Transaxle ConstructionS6RW0D5201001

The transaxle provides five forward speeds and one reverse speed by means of three synchromesh devices and three

shafts-input shaft, countershaft and reverse gear shaft. All forward gears are in constant mesh, and reverse uses a

sliding idler gear arrangement.

The low speed sleeve & hub is mounted on countershaft and engaged with countershaft 1st gear or 2nd gear, while

the high speed sleeve & hub is done on input shaft and engaged with input shaft 3rd gear or 4th gear. The 5th speed

sleeve & hub on input shaft is engaged with input shaft 5th gear mounted on the input shaft.

To prevent the cracking noise from the reverse gear when shifting transaxle gear into the reverse gear, the reverse

shift braking device is used.

The device utilizes the 5th synchromesh, which is the lever synchro type, to apply the brake on the input shaft rotation.

The double cone synchronizing mechanism is provided to 2nd gear synchromesh device for high performance of

shifting to 2nd gear.

For servicing, it is necessary to use genuine sealant or its equivalent on mating surfaces of transaxle case which is

made of aluminum. The case fastening bolts must be tightened to specified torque by means of torque wrench. It is

also important that all parts are thoroughly cleaned with cleaning fluid and air dried before reassembling.

Further, care must be taken to adjust preload of countershaft taper roller bearings. New synchronizer rings are

prohibited from being lapped with respective gear cones by using lapping compound before they are assembled.

2WD

I5RW0A520001-01

1. Input shaft 6. Input shaft 3rd gear 11. Countershaft 16. Countershaft 2nd gear

Page 814 of 1556

Downloaded from www.Manualslib.com manuals search engine 5B-2 Manual Transmission/Transaxle:

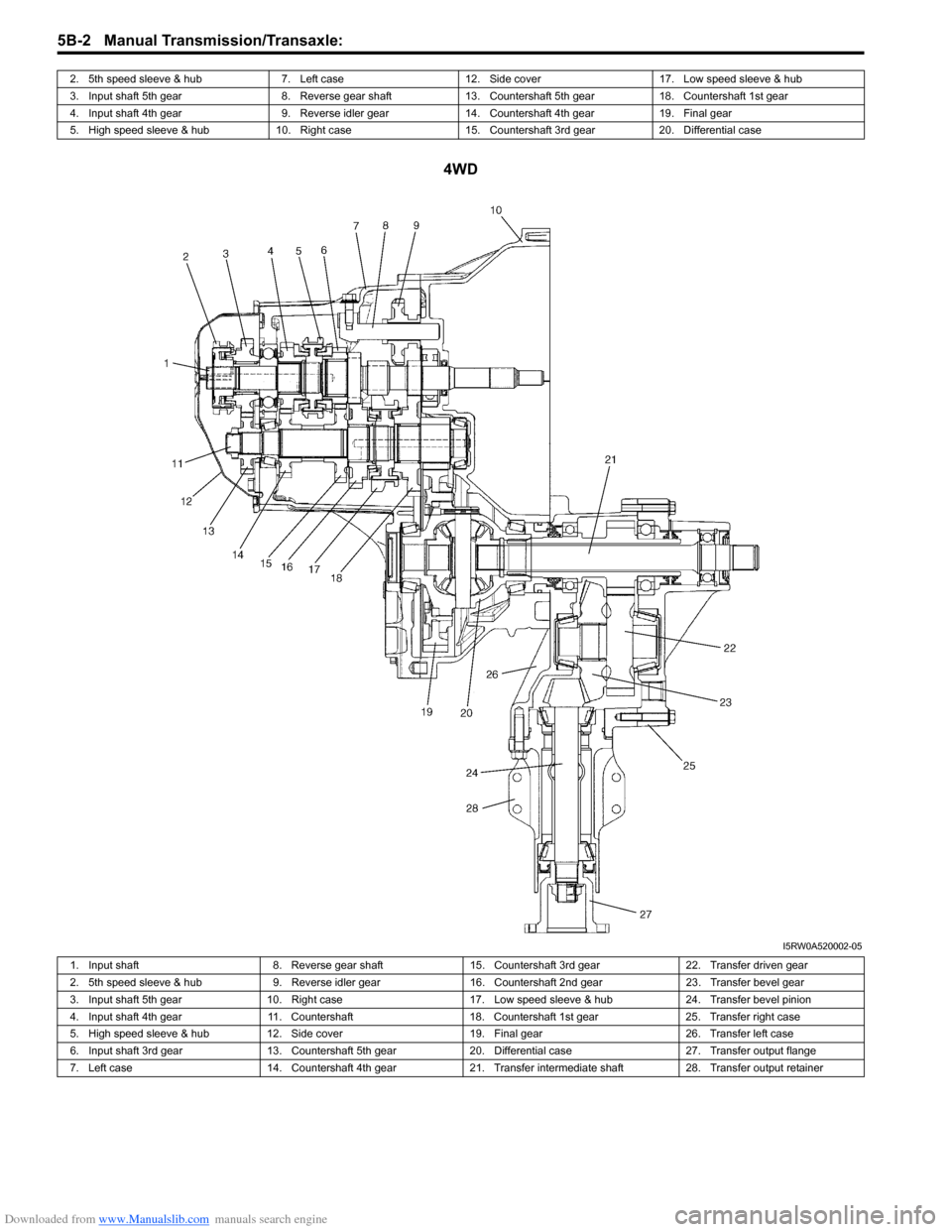

4WD

2. 5th speed sleeve & hub 7. Left case 12. Side cover 17. Low speed sleeve & hub

3. Input shaft 5th gear 8. Reverse gear shaft 13. Countershaft 5th gear 18. Countershaft 1st gear

4. Input shaft 4th gear 9. Reverse idler gear 14. Countershaft 4th gear 19. Final gear

5. High speed sleeve & hub 10. Right case 15. Countershaft 3rd gear 20. Differential case

I5RW0A520002-05

1. Input shaft 8. Reverse gear shaft 15. Countershaft 3rd gear 22. Transfer driven gear

2. 5th speed sleeve & hub 9. Reverse idler gear 16. Countershaft 2nd gear 23. Transfer bevel gear

3. Input shaft 5th gear 10. Right case 17. Low speed sleeve & hub 24. Transfer bevel pinion

4. Input shaft 4th gear 11. Countershaft 18. Countershaft 1st gear 25. Transfer right case

5. High speed sleeve & hub 12. Side cover 19. Final gear 26. Transfer left case

6. Input shaft 3rd gear 13. Countershaft 5th gear 20. Differential case 27. Transfer output flange

7. Left case 14. Countershaft 4th gear 21. Transfer intermediate shaft 28. Transfer output retainer

Page 815 of 1556

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-3

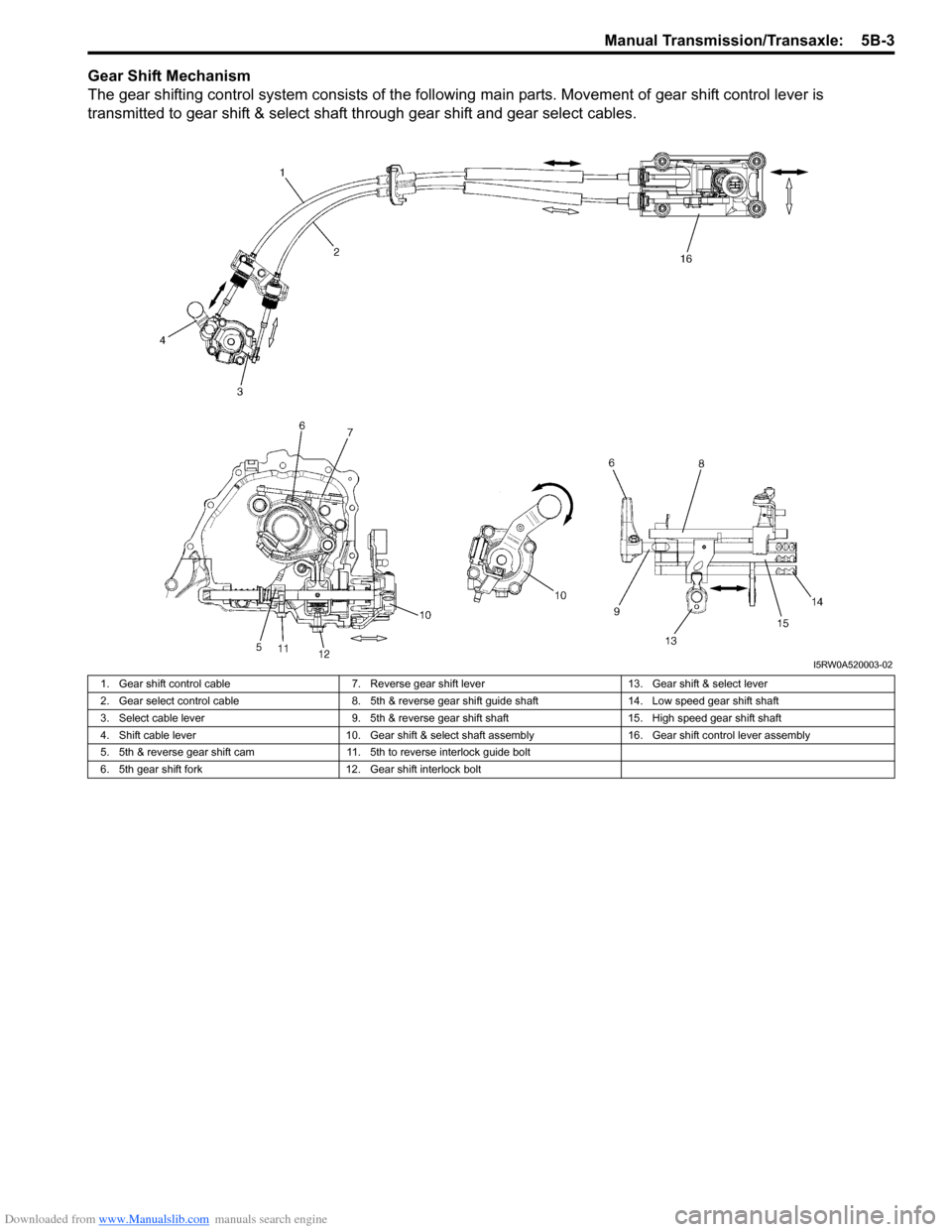

Gear Shift Mechanism

The gear shifting control system consists of the following main parts. Movement of gear shift control lever is

transmitted to gear shift & select shaft through gear shift and gear select cables.

I5RW0A520003-02

1. Gear shift control cable 7. Reverse gear shift lever 13. Gear shift & select lever

2. Gear select control cable 8. 5th & reverse gear shift guide shaft 14. Low speed gear shift shaft

3. Select cable lever 9. 5th & reverse gear shift shaft 15. High speed gear shift shaft

4. Shift cable lever 10. Gear shift & select shaft assembly 16. Gear shift control lever assembly

5. 5th & reverse gear shift cam 11. 5th to reverse interlock guide bolt

6. 5th gear shift fork 12. Gear shift interlock bolt

Page 816 of 1556

Downloaded from www.Manualslib.com manuals search engine 5B-4 Manual Transmission/Transaxle:

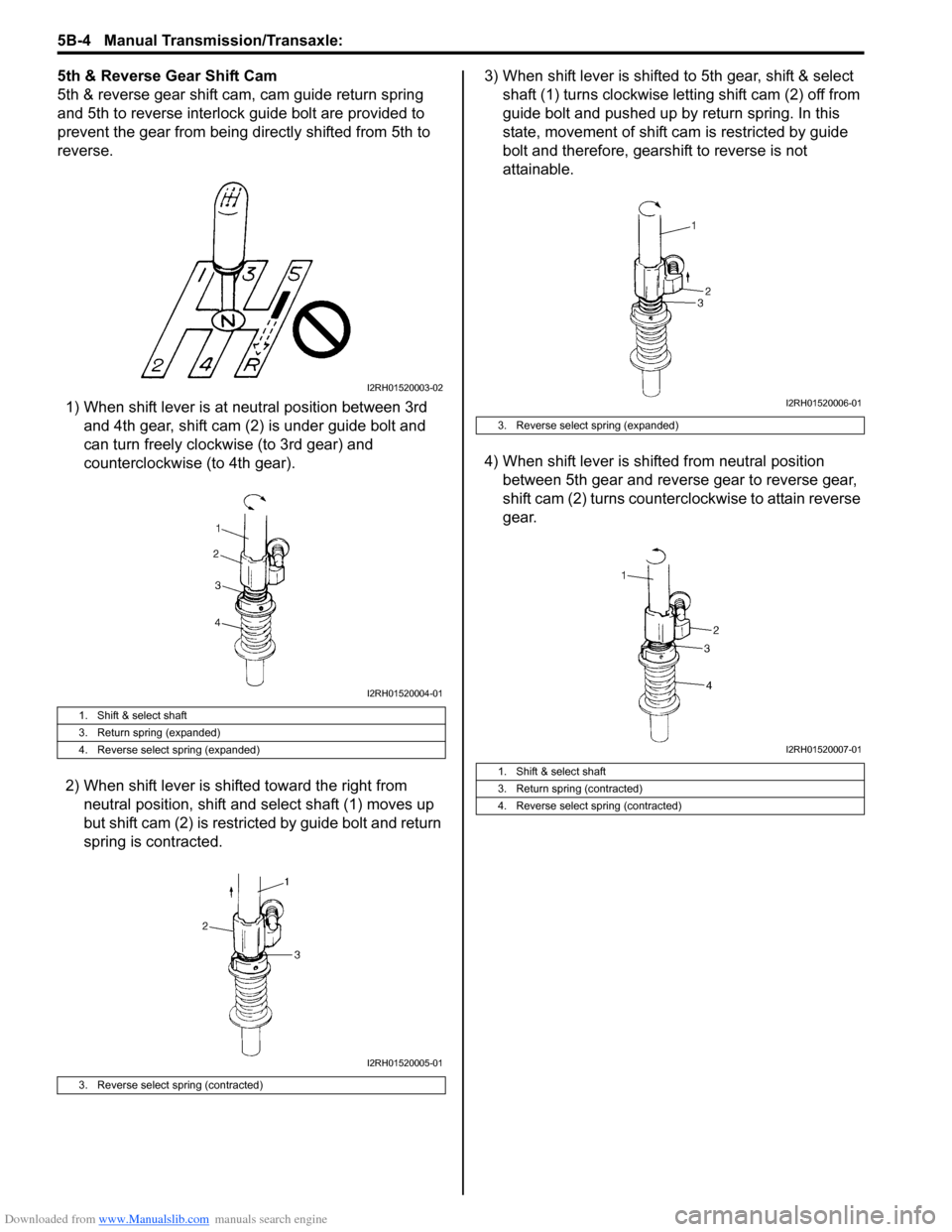

5th & Reverse Gear Shift Cam

5th & reverse gear shift cam, cam guide return spring

and 5th to reverse interlock guide bolt are provided to

prevent the gear from being directly shifted from 5th to

reverse.

1) When shift lever is at neutral position between 3rd

and 4th gear, shift cam (2) is under guide bolt and

can turn freely clockwise (to 3rd gear) and

counterclockwise (to 4th gear).

2) When shift lever is shifted toward the right from

neutral position, shift and select shaft (1) moves up

but shift cam (2) is restricted by guide bolt and return

spring is contracted.3) When shift lever is shifted to 5th gear, shift & select

shaft (1) turns clockwise letting shift cam (2) off from

guide bolt and pushed up by return spring. In this

state, movement of shift cam is restricted by guide

bolt and therefore, gearshift to reverse is not

attainable.

4) When shift lever is shifted from neutral position

between 5th gear and reverse gear to reverse gear,

shift cam (2) turns counterclockwise to attain reverse

gear.

1. Shift & select shaft

3. Return spring (expanded)

4. Reverse select spring (expanded)

3. Reverse select spring (contracted)

I2RH01520003-02

I2RH01520004-01

I2RH01520005-01

3. Reverse select spring (expanded)

1. Shift & select shaft

3. Return spring (contracted)

4. Reverse select spring (contracted)

I2RH01520006-01

I2RH01520007-01

Page 817 of 1556

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-5

Diagnostic Information and Procedures

Manual Transaxle Symptom DiagnosisS6RW0D5204001

Repair Instructions

Manual Transaxle Oil Level CheckS6RW0D5206001

1) Lift up vehicle and check oil leakage. Repair leaky

point, if any.

2) Remove oil level / filler plug (1) and check oil

contamination and oil level is lower end of oil level /

filler plug hole (2).

If oil is excessive dirty or insufficient, replace oil or

pour specified oil up to plug hole.

3) Apply sealant to thread of level / filler plug, and then

tighten it to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Transaxle oil level / filler plug (a): 21 N·m (2.1

kgf-m, 15.5 lb-ft)Condition Possible cause Correction / Reference Item

Gears slipping out of

meshWorn shift fork shaftReplace

Worn shift fork or synchronizer sleeveReplace

Weak or damaged locating springsReplace

Worn bearings on input shaft or

countershaftReplace

Worn chamfered tooth on sleeve and

gearReplace sleeve and gear

Hard shiftingInadequate lubricantReplenish

Improper clutch pedal free travelReplace clutch arm or master cylinder

Distorted or broken clutch discReplace

Damaged clutch pressure plateReplace clutch cover

Worn synchronizer ringReplace

Worn chamfered tooth on sleeve or gearReplace sleeve or gear

Worn gear shift control shaft joint bushReplace

Distorted shift shaftReplace

Broken gear shift / select control cablesReplace

NoiseInadequate or insufficient lubricantReplenish

Damaged or worn bearing(s)Replace

Damaged or worn gear(s)Replace

Damaged or worn synchronizer partsReplace

I5RW0A520004-01

Page 818 of 1556

Downloaded from www.Manualslib.com manuals search engine 5B-6 Manual Transmission/Transaxle:

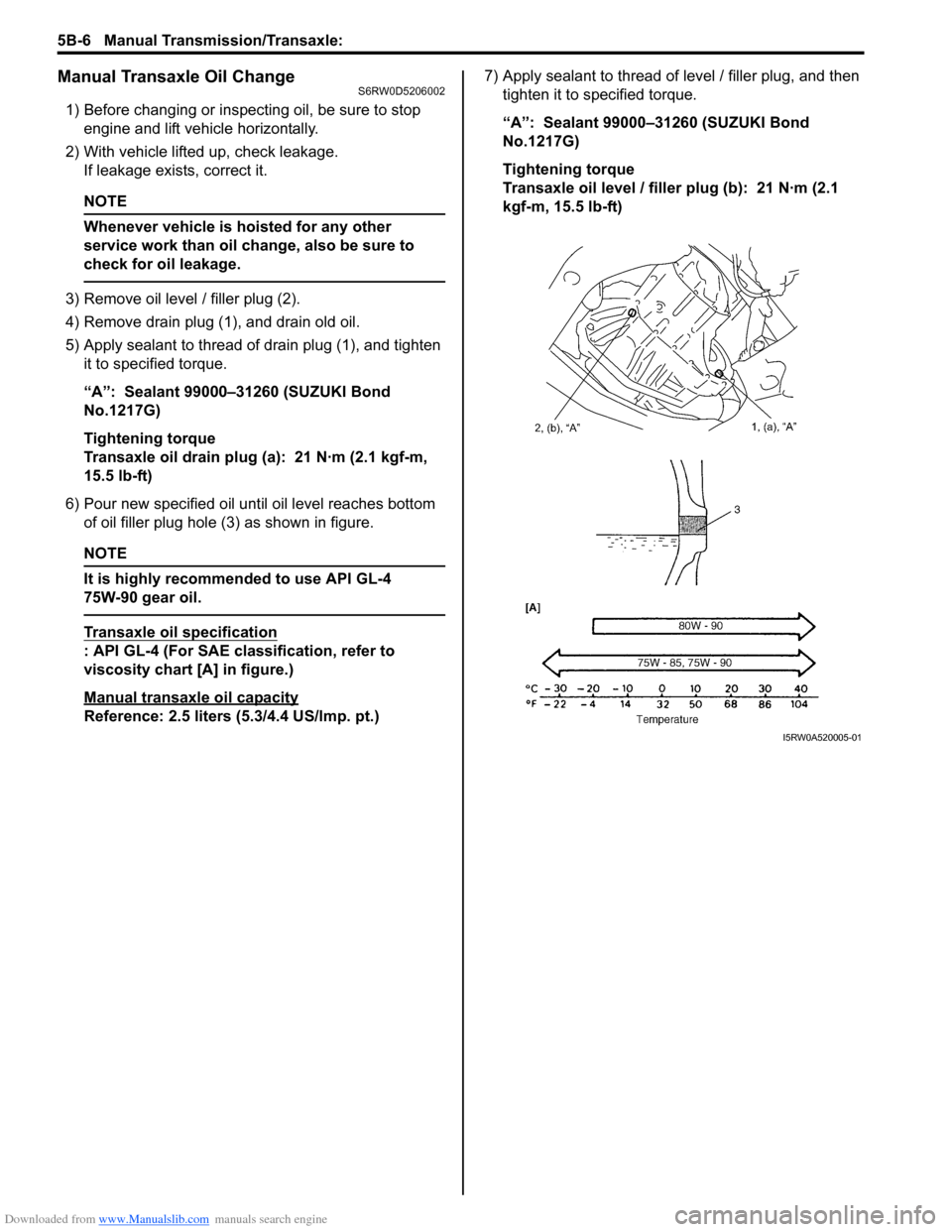

Manual Transaxle Oil ChangeS6RW0D5206002

1) Before changing or inspecting oil, be sure to stop

engine and lift vehicle horizontally.

2) With vehicle lifted up, check leakage.

If leakage exists, correct it.

NOTE

Whenever vehicle is hoisted for any other

service work than oil change, also be sure to

check for oil leakage.

3) Remove oil level / filler plug (2).

4) Remove drain plug (1), and drain old oil.

5) Apply sealant to thread of drain plug (1), and tighten

it to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Transaxle oil drain plug (a): 21 N·m (2.1 kgf-m,

15.5 lb-ft)

6) Pour new specified oil until oil level reaches bottom

of oil filler plug hole (3) as shown in figure.

NOTE

It is highly recommended to use API GL-4

75W-90 gear oil.

Transaxle oil specification

: API GL-4 (For SAE classification, refer to

viscosity chart [A] in figure.)

Manual transaxle oil capacity

Reference: 2.5 liters (5.3/4.4 US/lmp. pt.)7) Apply sealant to thread of level / filler plug, and then

tighten it to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Transaxle oil level / filler plug (b): 21 N·m (2.1

kgf-m, 15.5 lb-ft)

I5RW0A520005-01

Page 819 of 1556

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-7

Differential Side Oil Seal ReplacementS6RW0D5206003

1) Lift up vehicle and drain transaxle oil.

2) Remove drive shaft assembly and center shaft

referring to “Front Drive Shaft Assembly Removal

and Installation in Section 3A”.

3) Remove oil seal (1) by using special tool.

Special tool

(A): 09913–50121

4) Install a new oil seal (1) by using special tool.

NOTE

• When installing oil seal, face its spring

side inward.

• Install oil seal horizontally to surface of

case.

Special tool

(A): 09913–75810

(B): 09913–75510

Distance between case and right oil seal for 2WD

“a”: 9.5 – 10.5 mm (0.37 – 0.41 in.)

Distance between case and left oil seal

“b”: 0 – 1.0 mm (0 – 0.04 in.)5) Apply grease to oil seal lip and at the same time

check drive shaft where oil seal contacts and make

sure of its smoothness.

“A”: Grease 99000–25011 (SUZUKI Super

Grease A)

6) Insert drive shaft assembly and center shaft referring

to “Front Drive Shaft Assembly Removal and

Installation in Section 3A”.

7) Pour transaxle oil referring to “Manual Transaxle Oil

Change”.

(A)

1I5RW0A520006-02

“b”

“a”

1, “A”

(A)(B)

I5RW0A520051-01

Page 820 of 1556

Downloaded from www.Manualslib.com manuals search engine 5B-8 Manual Transmission/Transaxle:

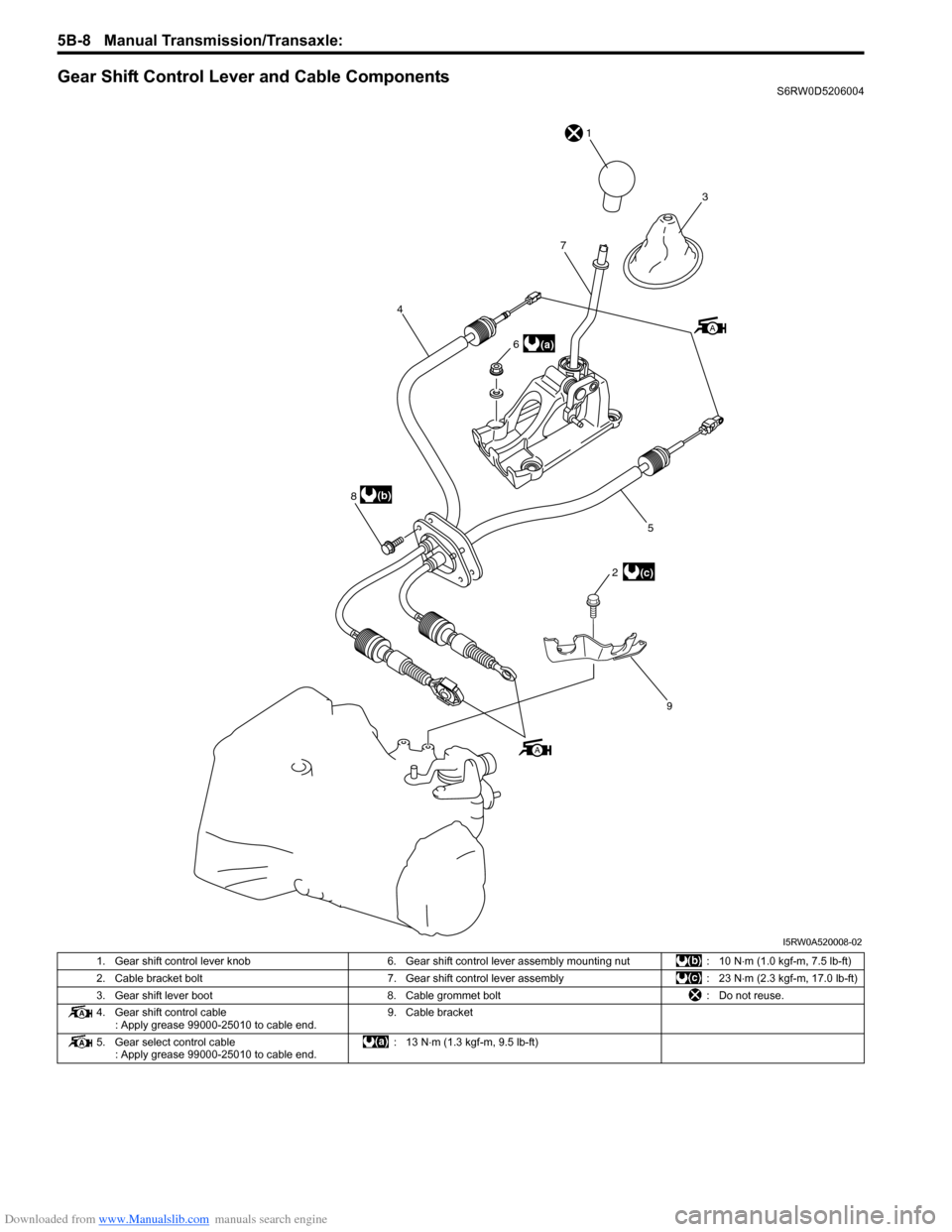

Gear Shift Control Lever and Cable ComponentsS6RW0D5206004

1

7

3

4

(a) 6

A

8(b)

2

(c)

5

9

A

I5RW0A520008-02

1. Gear shift control lever knob 6. Gear shift control lever assembly mounting nut : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

2. Cable bracket bolt 7. Gear shift control lever assembly : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

3. Gear shift lever boot 8. Cable grommet bolt : Do not reuse.

4. Gear shift control cable

: Apply grease 99000-25010 to cable end.9. Cable bracket

5. Gear select control cable

: Apply grease 99000-25010 to cable end.:13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

Page 821 of 1556

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-9

Gear Shift Control Lever and Cable Removal

and Installation

S6RW0D5206005

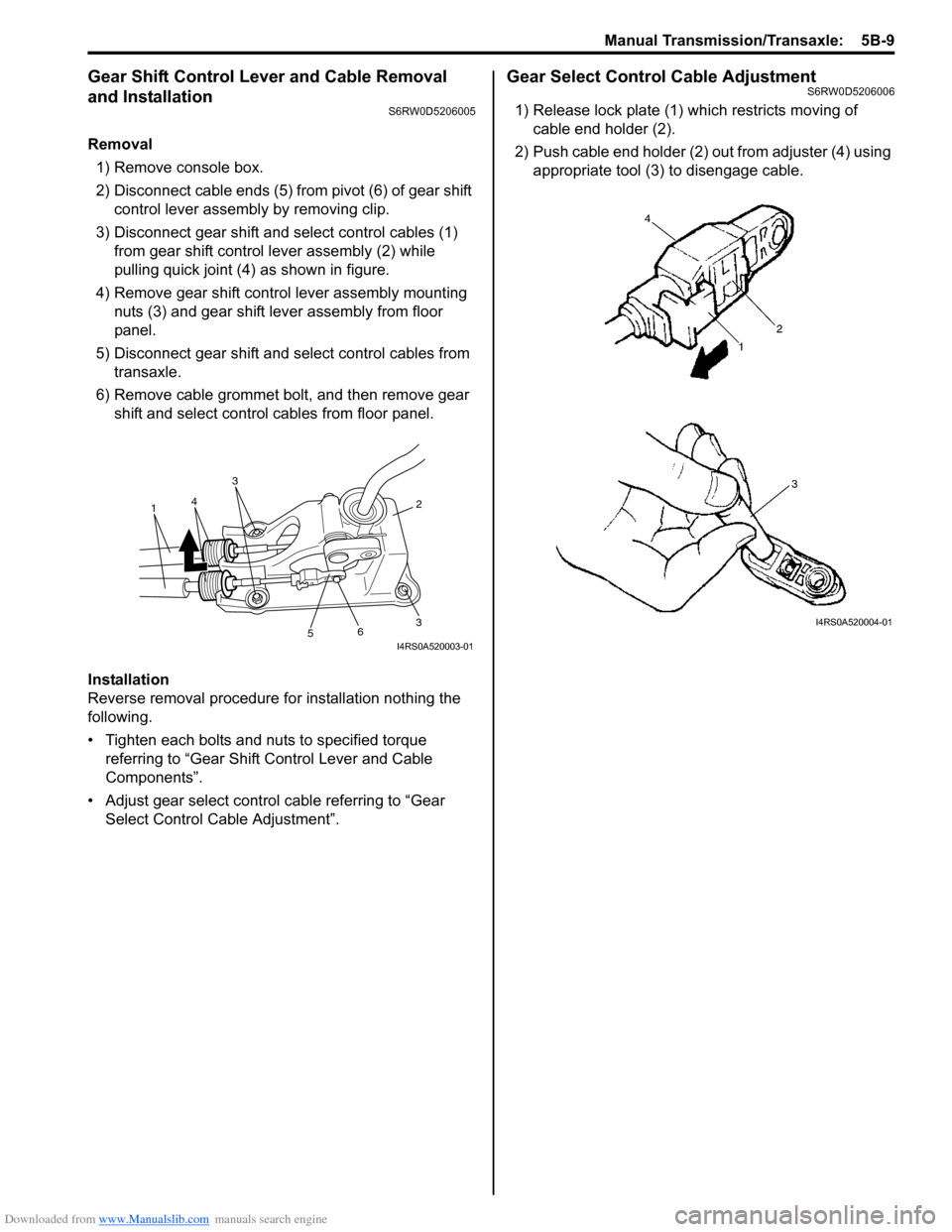

Removal

1) Remove console box.

2) Disconnect cable ends (5) from pivot (6) of gear shift

control lever assembly by removing clip.

3) Disconnect gear shift and select control cables (1)

from gear shift control lever assembly (2) while

pulling quick joint (4) as shown in figure.

4) Remove gear shift control lever assembly mounting

nuts (3) and gear shift lever assembly from floor

panel.

5) Disconnect gear shift and select control cables from

transaxle.

6) Remove cable grommet bolt, and then remove gear

shift and select control cables from floor panel.

Installation

Reverse removal procedure for installation nothing the

following.

• Tighten each bolts and nuts to specified torque

referring to “Gear Shift Control Lever and Cable

Components”.

• Adjust gear select control cable referring to “Gear

Select Control Cable Adjustment”.

Gear Select Control Cable AdjustmentS6RW0D5206006

1) Release lock plate (1) which restricts moving of

cable end holder (2).

2) Push cable end holder (2) out from adjuster (4) using

appropriate tool (3) to disengage cable.

36

5

2

3

41

I4RS0A520003-01

I4RS0A520004-01

Page 822 of 1556

Downloaded from www.Manualslib.com manuals search engine 5B-10 Manual Transmission/Transaxle:

3) Apply grease to pin (5) of gear shift control lever, and

then install adjuster (1) into pin of gear shift control

lever securely.

“A”: Grease 99000–25011 (SUZUKI Super

Grease A)

4) Push cable end holder (2) in the direction of A.

NOTE

At this time, do not apply force in the cable

operation direction B to adjuster.

5) Slide lock plate (3) in the direction of C, until it gets

over the claw (4) of cable end holder.

Back Up Light Switch Removal and InstallationS6RW0D5206007

Removal

1) Remove battery and tray with ECM.

2) Disconnect back up light switch coupler (1).

3) Remove back up light switch.

Installation

1) Apply oil to new O-ring (1) and tighten back up light

switch (2) to specified torque.

Tightening torque

Back up light switch (a): 23 N·m (2.3 kgf-m, 17.0

lb-ft)

2) Connect back up light switch coupler.

3) Install battery and tray with ECM.

Back Up Light Switch InspectionS6RW0D5206008

Check back up light switch for function using ohmmeter.

Switch ON (Push): Continuity

Switch OFF (Release): No continuity

3

3

41

2

A C

1

B

5, “A”

I4RS0A520005-01

2. Gear shift and select shaft assembly

2

1I5RW0A520009-01

1 2, (a)

I3RH0A520006-01

I5RW0A520050-01