bearing SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 877 of 1556

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-8

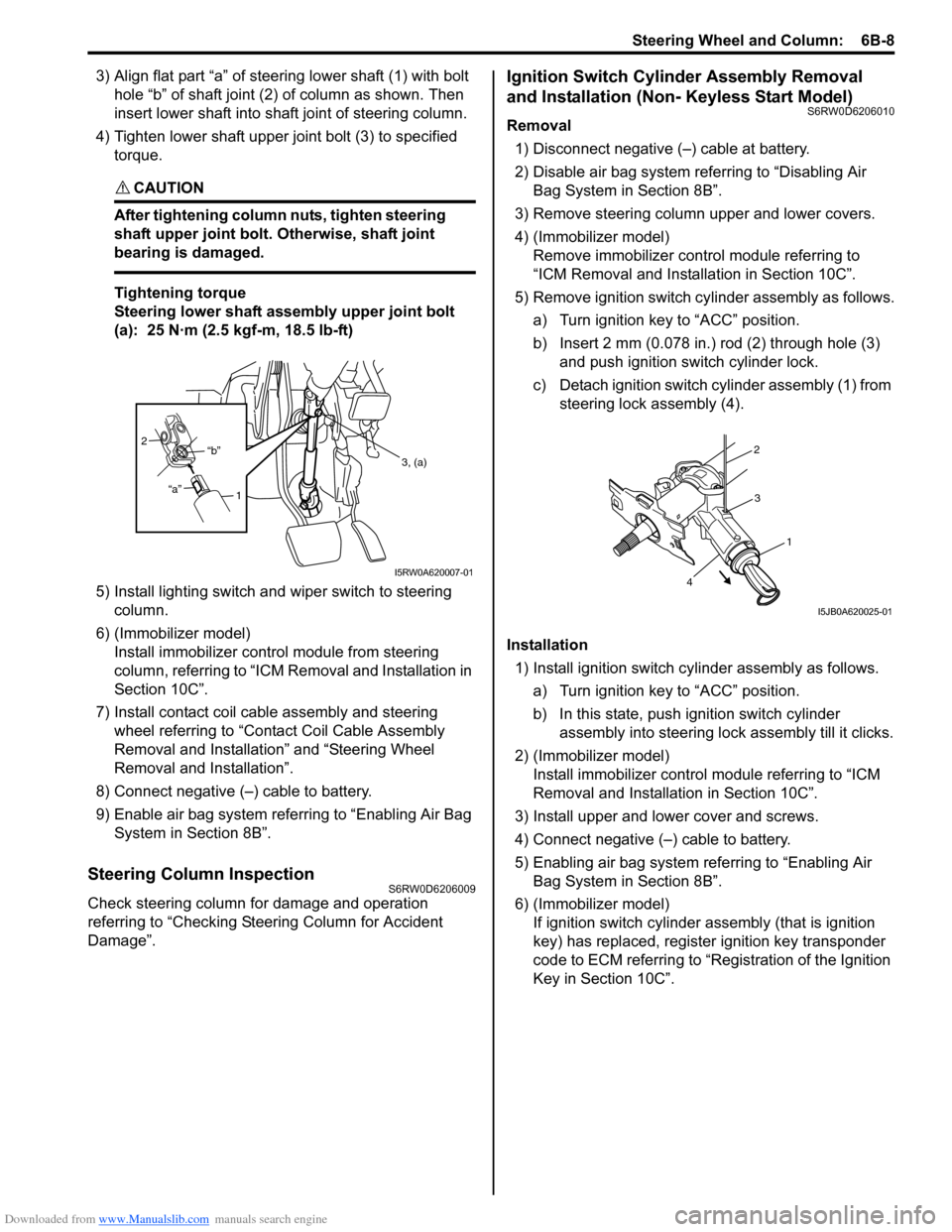

3) Align flat part “a” of steering lower shaft (1) with bolt

hole “b” of shaft joint (2) of column as shown. Then

insert lower shaft into shaft joint of steering column.

4) Tighten lower shaft upper joint bolt (3) to specified

torque.

CAUTION!

After tightening column nuts, tighten steering

shaft upper joint bolt. Otherwise, shaft joint

bearing is damaged.

Tightening torque

Steering lower shaft assembly upper joint bolt

(a): 25 N·m (2.5 kgf-m, 18.5 lb-ft)

5) Install lighting switch and wiper switch to steering

column.

6) (Immobilizer model)

Install immobilizer control module from steering

column, referring to “ICM Removal and Installation in

Section 10C”.

7) Install contact coil cable assembly and steering

wheel referring to “Contact Coil Cable Assembly

Removal and Installation” and “Steering Wheel

Removal and Installation”.

8) Connect negative (–) cable to battery.

9) Enable air bag system referring to “Enabling Air Bag

System in Section 8B”.

Steering Column InspectionS6RW0D6206009

Check steering column for damage and operation

referring to “Checking Steering Column for Accident

Damage”.

Ignition Switch Cylinder Assembly Removal

and Installation (Non- Keyless Start Model)

S6RW0D6206010

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air

Bag System in Section 8B”.

3) Remove steering column upper and lower covers.

4) (Immobilizer model)

Remove immobilizer control module referring to

“ICM Removal and Installation in Section 10C”.

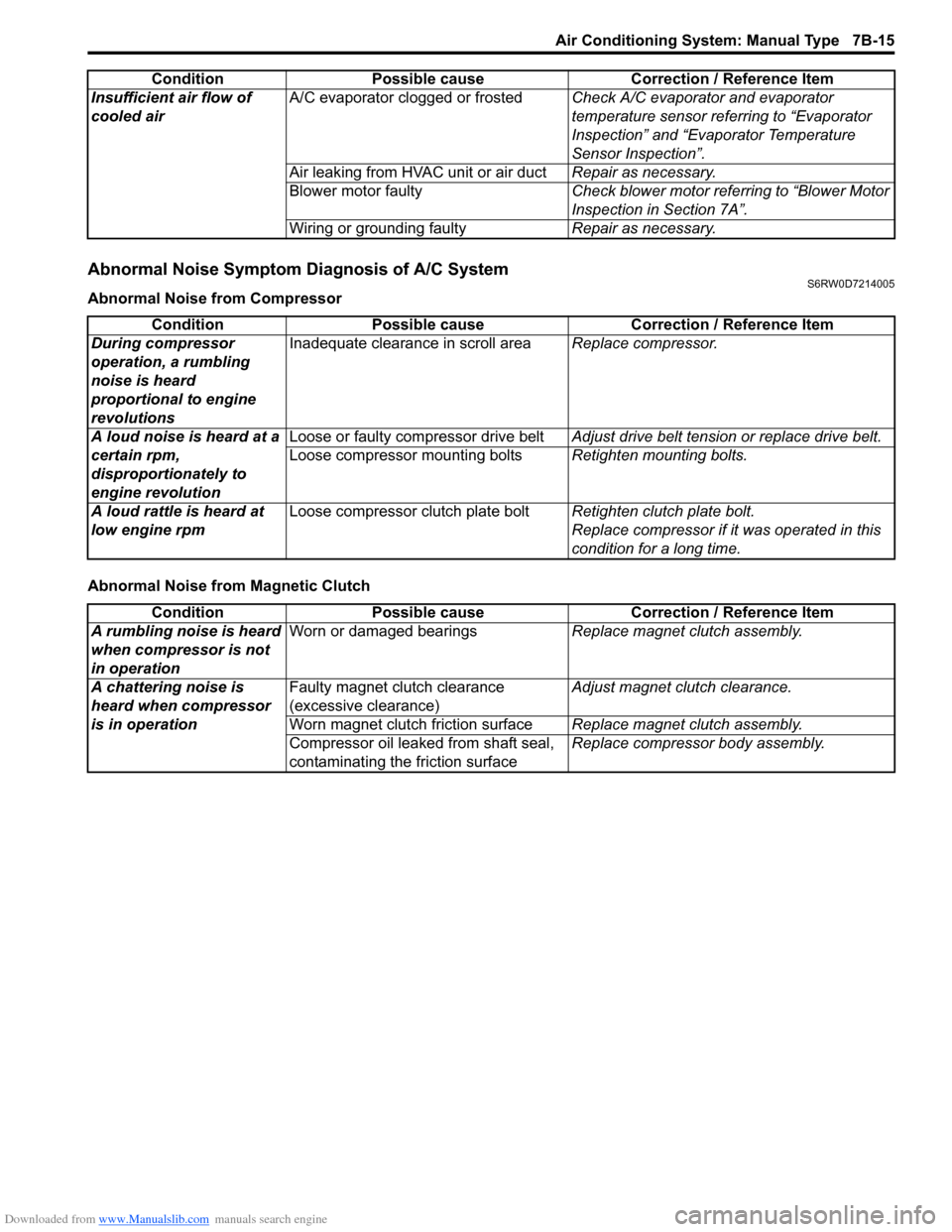

5) Remove ignition switch cylinder assembly as follows.

a) Turn ignition key to “ACC” position.

b) Insert 2 mm (0.078 in.) rod (2) through hole (3)

and push ignition switch cylinder lock.

c) Detach ignition switch cylinder assembly (1) from

steering lock assembly (4).

Installation

1) Install ignition switch cylinder assembly as follows.

a) Turn ignition key to “ACC” position.

b) In this state, push ignition switch cylinder

assembly into steering lock assembly till it clicks.

2) (Immobilizer model)

Install immobilizer control module referring to “ICM

Removal and Installation in Section 10C”.

3) Install upper and lower cover and screws.

4) Connect negative (–) cable to battery.

5) Enabling air bag system referring to “Enabling Air

Bag System in Section 8B”.

6) (Immobilizer model)

If ignition switch cylinder assembly (that is ignition

key) has replaced, register ignition key transponder

code to ECM referring to “Registration of the Ignition

Key in Section 10C”.

1 2

“a”“b”

3, (a)

I5RW0A620007-01

2

3

1

4

I5JB0A620025-01

Page 955 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-15

Abnormal Noise Symptom Diagnosis of A/C SystemS6RW0D7214005

Abnormal Noise from Compressor

Abnormal Noise from Magnetic ClutchInsufficient air flow of

cooled airA/C evaporator clogged or frostedCheck A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Temperature

Sensor Inspection”.

Air leaking from HVAC unit or air ductRepair as necessary.

Blower motor faultyCheck blower motor referring to “Blower Motor

Inspection in Section 7A”.

Wiring or grounding faultyRepair as necessary. Condition Possible cause Correction / Reference Item

Condition Possible cause Correction / Reference Item

During compressor

operation, a rumbling

noise is heard

proportional to engine

revolutionsInadequate clearance in scroll areaReplace compressor.

A loud noise is heard at a

certain rpm,

disproportionately to

engine revolutionLoose or faulty compressor drive beltAdjust drive belt tension or replace drive belt.

Loose compressor mounting boltsRetighten mounting bolts.

A loud rattle is heard at

low engine rpmLoose compressor clutch plate boltRetighten clutch plate bolt.

Replace compressor if it was operated in this

condition for a long time.

Condition Possible cause Correction / Reference Item

A rumbling noise is heard

when compressor is not

in operationWorn or damaged bearingsReplace magnet clutch assembly.

A chattering noise is

heard when compressor

is in operationFaulty magnet clutch clearance

(excessive clearance)Adjust magnet clutch clearance.

Worn magnet clutch friction surfaceReplace magnet clutch assembly.

Compressor oil leaked from shaft seal,

contaminating the friction surfaceReplace compressor body assembly.

Page 956 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-16 Air Conditioning System: Manual Type

Abnormal Noise from Tubing

Abnormal Noise from Condenser Assembly

Abnormal Noise from Crankshaft Pulley

Abnormal Noise from Tension Pulley

Abnormal Noise from A/C Evaporator

Abnormal Noise from Blower MotorCondition Possible cause Correction / Reference Item

A droning noise is heard

from inside of the vehicle,

but not particularly

noticeable in engine

compartmentFaulty tubing clampsReposition clamps or increase the number of

clamps.

Resonance caused by pulsation from

variations in refrigerant pressureAttach a silencer to tubing, or modify its

position and length.

Condition Possible cause Correction / Reference Item

Considerable vibration in

condenser assemblyResonance from condenser assembly

bracket and bodyFirmly insert a silencer between condenser

assembly bracket and body.

Condition Possible cause Correction / Reference Item

A large rattling noise is

heard at idle or sudden

accelerationLoosen crankshaft pulley boltRetighten bolt.

Condition Possible cause Correction / Reference Item

Clattering noise is heard

from pulleyWorn or damaged bearingReplace tension pulley.

Pulley cranks upon

contactCracked or loose bracketReplace or retighten bracket.

Condition Possible cause Correction / Reference Item

Whistling sound is heard

from A/C evaporatorDepending on the combination of the

interior / exterior temperatures, engine

rpm and refrigerant pressure, the

refrigerant flowing out of the expansion

valve may, under certain conditions,

make a whistling soundAt times, slightly decreasing refrigerant volume

may stop this noise.

Inspect expansion valve and replace if faulty.

Condition Possible cause Correction / Reference Item

Blower motor emits a

chirping sound in

proportion to its speed of

rotationWorn or damaged motor brushes or

commutatorReplace blower motor.

Fluttering noise or large

droning noise is heard

from blower motorLeaves or other debris introduced from

fresh air inlet to blower motorRemove debris and make sure that the screen

at fresh air inlet is intact.

Page 972 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-32 Air Conditioning System: Manual Type

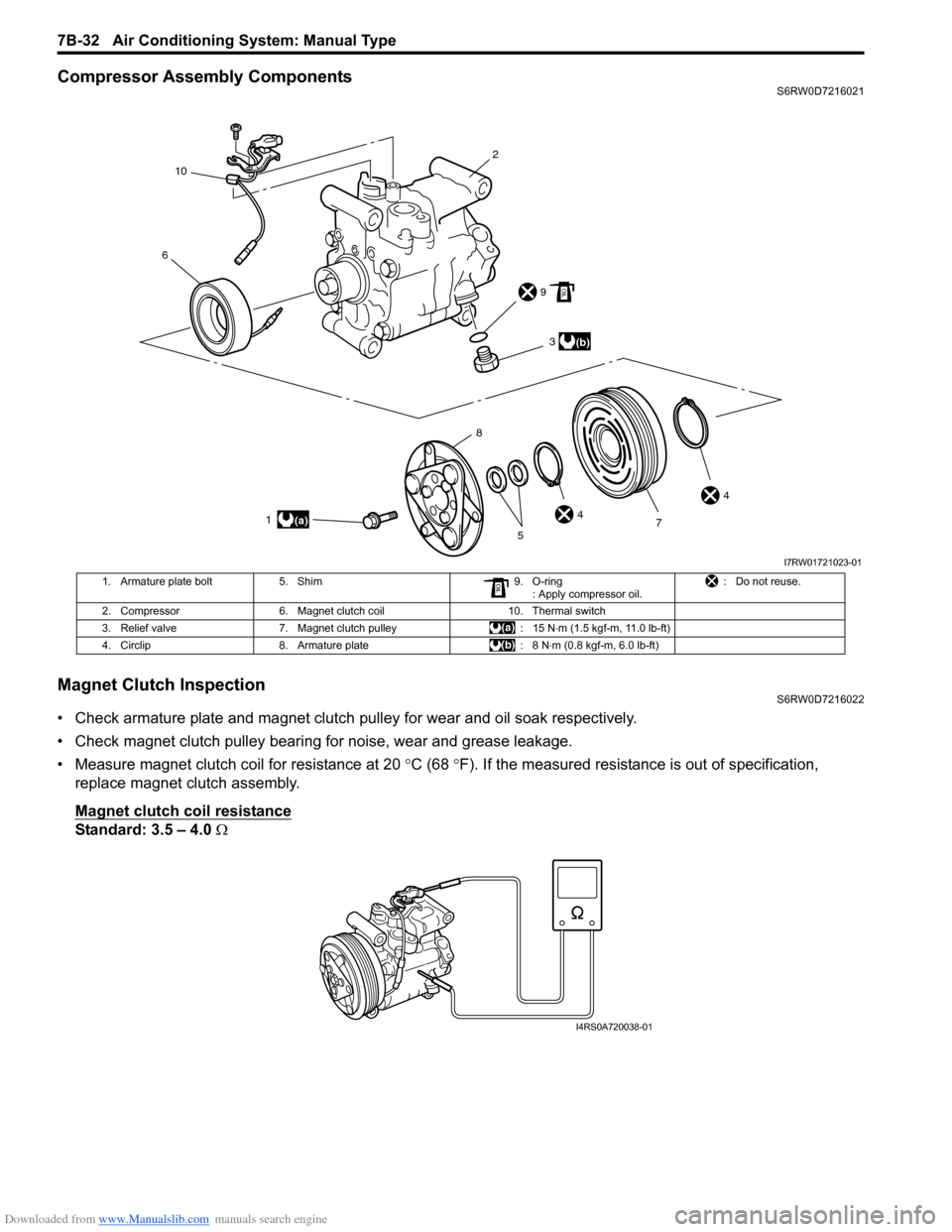

Compressor Assembly ComponentsS6RW0D7216021

Magnet Clutch InspectionS6RW0D7216022

• Check armature plate and magnet clutch pulley for wear and oil soak respectively.

• Check magnet clutch pulley bearing for noise, wear and grease leakage.

• Measure magnet clutch coil for resistance at 20 °C (68 °F). If the measured resistance is out of specification,

replace magnet clutch assembly.

Magnet clutch coil resistance

Standard: 3.5 – 4.0 Ω

6

2

9

4

4 3

1

7

5 8(a)

(b)

10

I7RW01721023-01

1. Armature plate bolt 5. Shim 9. O-ring

: Apply compressor oil.: Do not reuse.

2. Compressor 6. Magnet clutch coil 10. Thermal switch

3. Relief valve 7. Magnet clutch pulley : 15 N⋅m (1.5 kgf-m, 11.0 lb-ft)

4. Circlip 8. Armature plate : 8 N⋅m (0.8 kgf-m, 6.0 lb-ft)

I4RS0A720038-01