Automatic transaxle components SUZUKI SX4 2006 1.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 750 of 1556

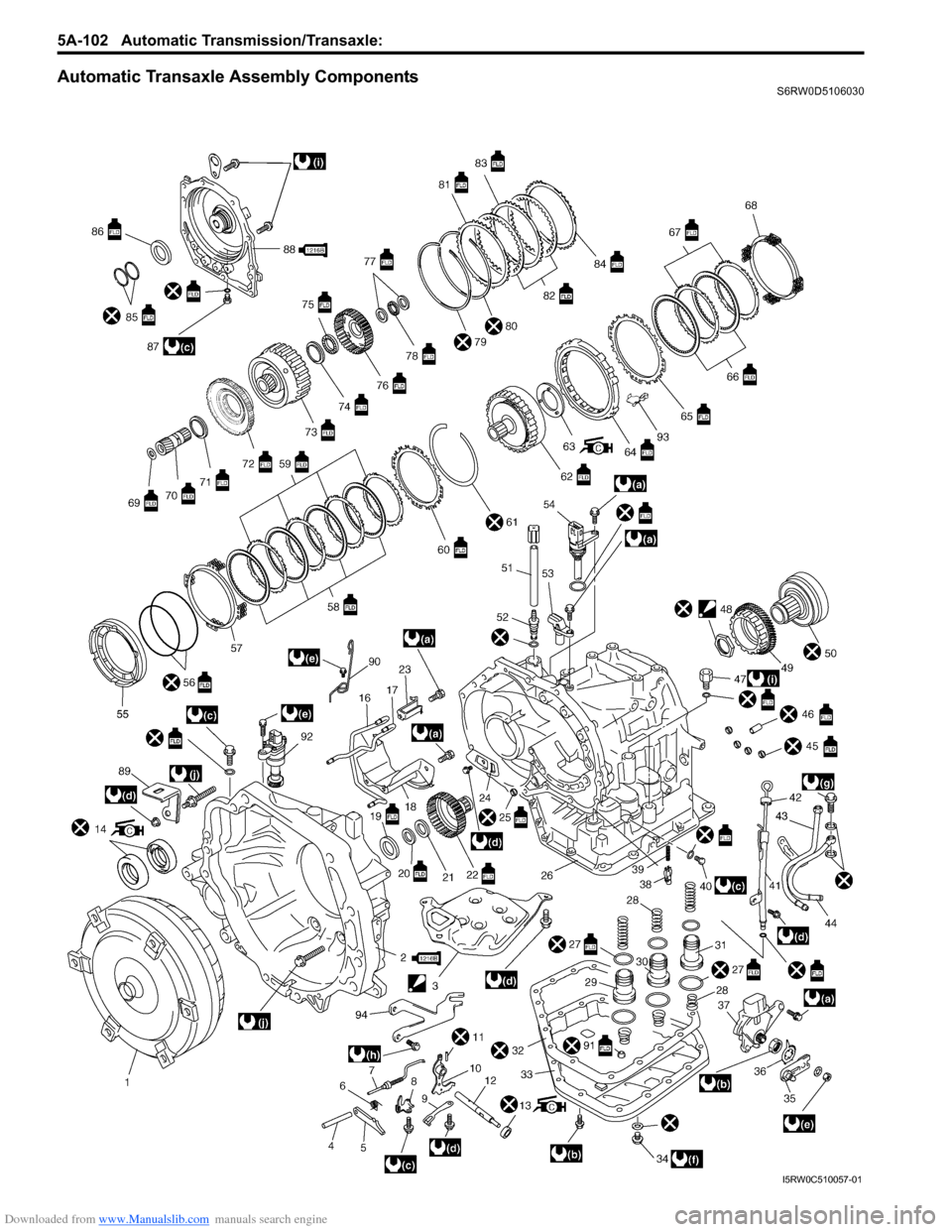

Downloaded from www.Manualslib.com manuals search engine 5A-102 Automatic Transmission/Transaxle:

Automatic Transaxle Assembly ComponentsS6RW0D5106030

I5RW0C510057-01

Page 764 of 1556

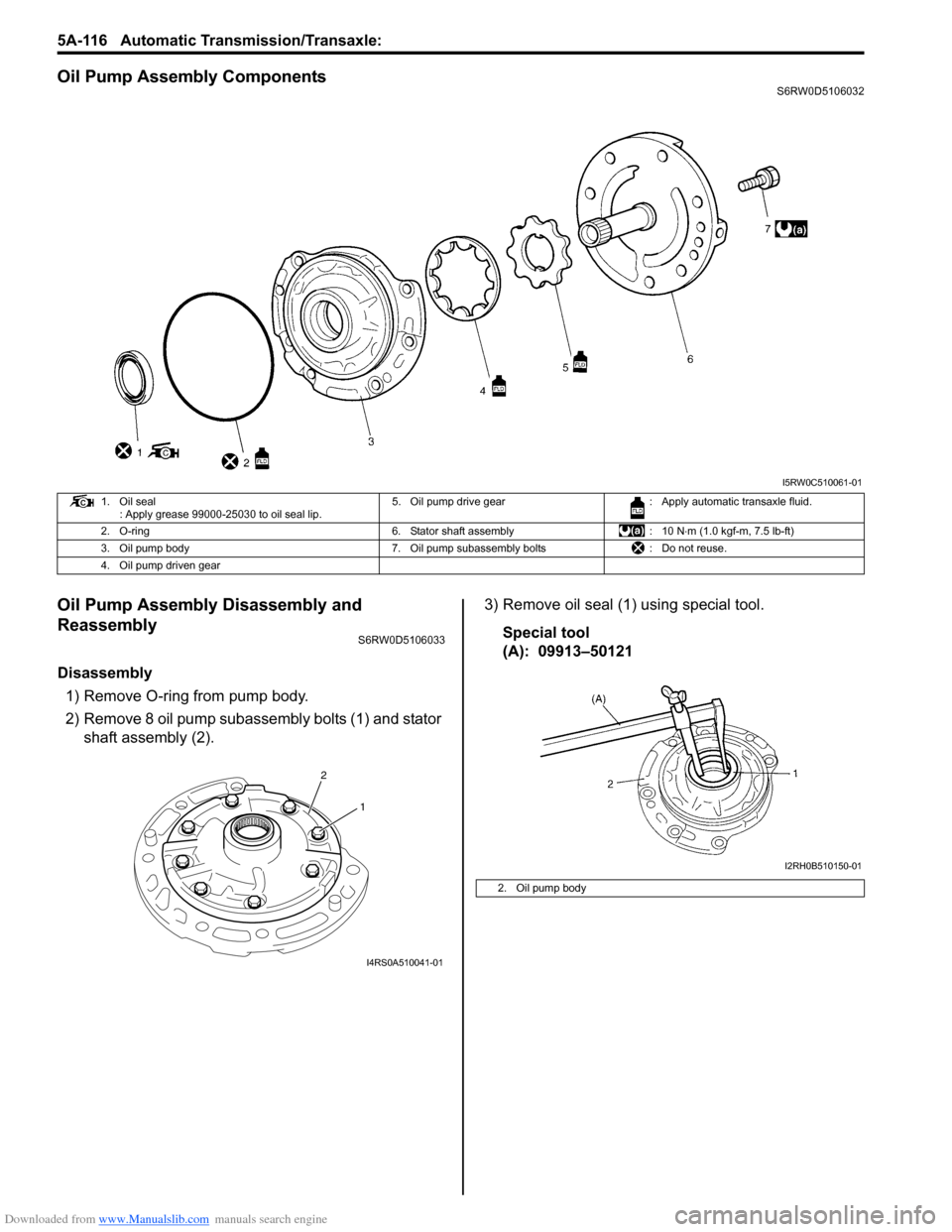

Downloaded from www.Manualslib.com manuals search engine 5A-116 Automatic Transmission/Transaxle:

Oil Pump Assembly ComponentsS6RW0D5106032

Oil Pump Assembly Disassembly and

Reassembly

S6RW0D5106033

Disassembly

1) Remove O-ring from pump body.

2) Remove 8 oil pump subassembly bolts (1) and stator

shaft assembly (2).3) Remove oil seal (1) using special tool.

Special tool

(A): 09913–50121

I5RW0C510061-01

1. Oil seal

: Apply grease 99000-25030 to oil seal lip.5. Oil pump drive gear : Apply automatic transaxle fluid.

2. O-ring 6. Stator shaft assembly : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

3. Oil pump body 7. Oil pump subassembly bolts : Do not reuse.

4. Oil pump driven gear

2

1

I4RS0A510041-01

2. Oil pump body

I2RH0B510150-01

Page 767 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-119

Direct Clutch Assembly ComponentsS6RW0D5106035

Direct Clutch Assembly Preliminary CheckS6RW0D5106036

Install direct clutch assembly (1) to oil pump assembly

(2) blow in air (400 – 800 kPa, 4 – 8 kg/cm2, 57 – 113

psi) through oil hole (3) of oil pump assembly with

special tool attached on upper surface of direct clutch

piston, and measure piston stroke of direct clutch.

If piston stroke exceeds specified value, disassemble,

inspect and replace inner parts.

Special tool

(A): 09900–20607

(B): 09900–20701

Direct clutch piston stroke

0.4 – 0.7 mm (0.016 – 0.027 in.)

I2RH0B510160-01

1. Input shaft front thrust bearing 6. Outer O-ring 11. Direct clutch retaining plate

2. Input shaft seal ring 7. Direct clutch return spring subassembly 12. Plate snap ring

3. Input shaft subassembly 8. Shaft snap ring : Apply automatic transaxle fluid.

4. Inner O-ring 9. Direct clutch separator plate : Do not reuse.

5. Direct clutch piston 10. Direct clutch disc

I2RH0B510161-01

Page 771 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-123

Forward and Reverse Clutch Assembly ComponentsS6RW0D5106039

Forward and Reverse Clutch Assembly

Preliminary Check

S6RW0D5106040

1) Install forward and reverse clutch assembly (1) to

transaxle rear cover (2), blow in compressed air (400

– 800 kPa, 4 – 8 kg/cm

2, 57 – 113 psi) through oil

hole (4) of transaxle rear cover with the special tool

attached on the upper surface of reverse clutch

retaining plate (3), and measure reverse clutch

piston stroke.

If piston stroke exceeds specified value,

disassemble, inspect and replace inner parts.

Special tool

(A): 09900–20607

(B): 09900–20701Reverse clutch piston stroke

1.20 – 1.60 mm (0.047 – 0.063 in.)

I3RM0B510061-01

1. Forward clutch balancer 8. Intermediate shaft seal ring 15. Forward clutch retaining plate

2. Forward clutch return spring subassembly 9. Reverse clutch plate snap ring 16. Forward clutch disc

3. Forward clutch piston 10. Reverse clutch retaining plate 17. Forward clutch separator plate

4. Forward clutch piston O-ring 11. Reverse clutch separator plate 18. Balancer snap ring

5. Forward clutch drum 12. Reverse clutch disc : Apply automatic transaxle fluid.

6. Forward clutch drum O-ring 13. Reverse clutch cushion plate : Do not reuse.

7. Intermediate shaft subassembly 14. Forward clutch plate snap ring

I2RH0B510176-01

Page 776 of 1556

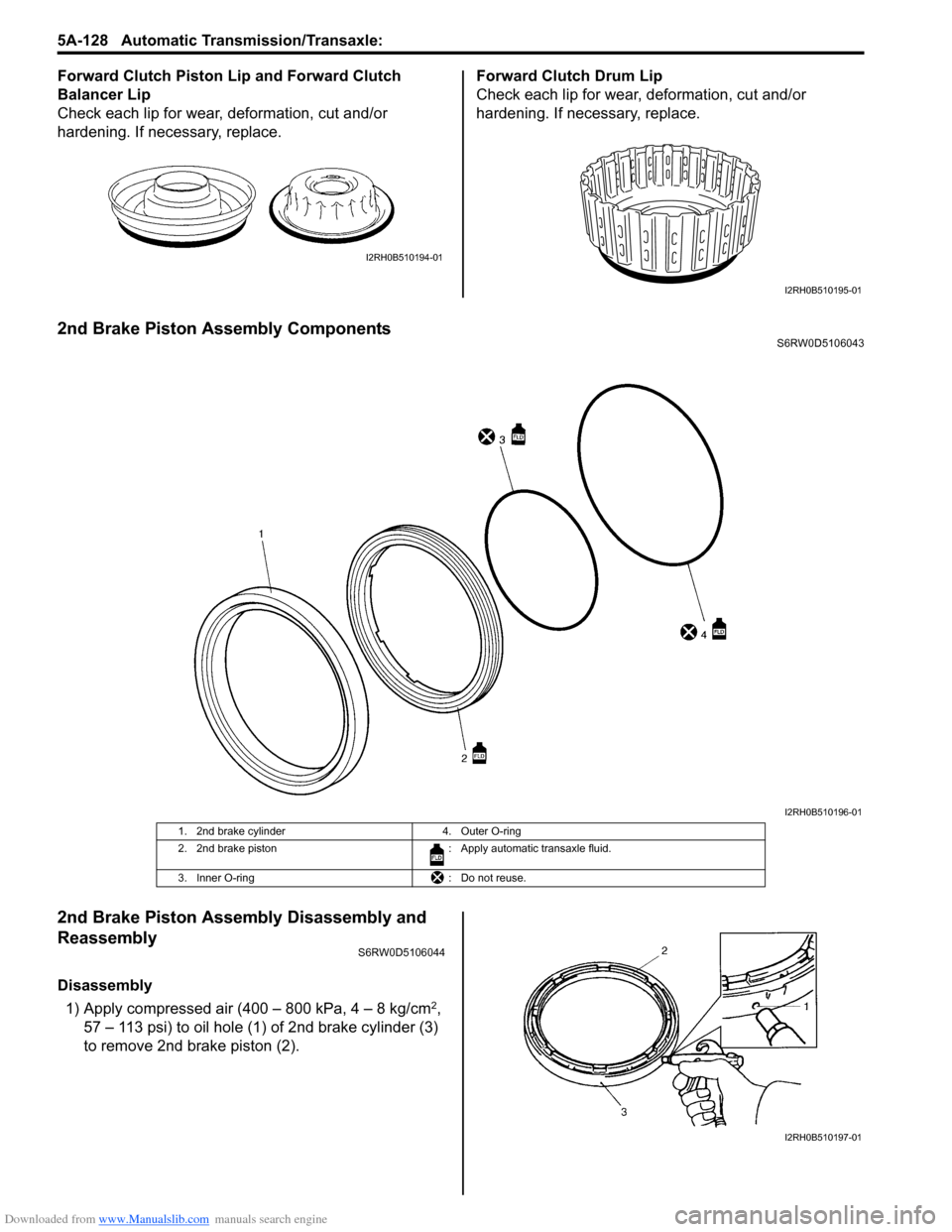

Downloaded from www.Manualslib.com manuals search engine 5A-128 Automatic Transmission/Transaxle:

Forward Clutch Piston Lip and Forward Clutch

Balancer Lip

Check each lip for wear, deformation, cut and/or

hardening. If necessary, replace.Forward Clutch Drum Lip

Check each lip for wear, deformation, cut and/or

hardening. If necessary, replace.

2nd Brake Piston Assembly ComponentsS6RW0D5106043

2nd Brake Piston Assembly Disassembly and

Reassembly

S6RW0D5106044

Disassembly

1) Apply compressed air (400 – 800 kPa, 4 – 8 kg/cm

2,

57 – 113 psi) to oil hole (1) of 2nd brake cylinder (3)

to remove 2nd brake piston (2).

I2RH0B510194-01

I2RH0B510195-01

I2RH0B510196-01

1. 2nd brake cylinder 4. Outer O-ring

2. 2nd brake piston : Apply automatic transaxle fluid.

3. Inner O-ring : Do not reuse.

I2RH0B510197-01

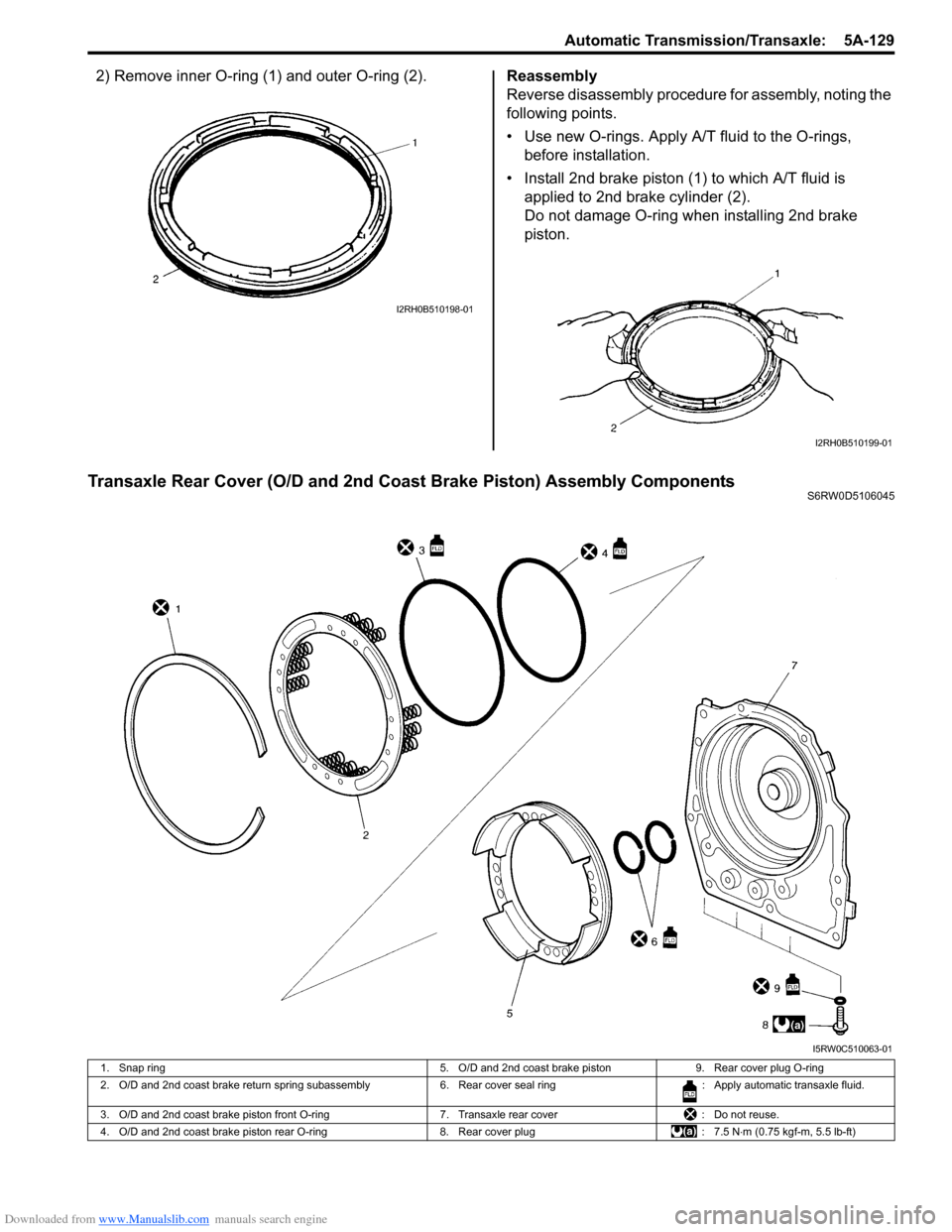

Page 777 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-129

2) Remove inner O-ring (1) and outer O-ring (2).Reassembly

Reverse disassembly procedure for assembly, noting the

following points.

• Use new O-rings. Apply A/T fluid to the O-rings,

before installation.

• Install 2nd brake piston (1) to which A/T fluid is

applied to 2nd brake cylinder (2).

Do not damage O-ring when installing 2nd brake

piston.

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly ComponentsS6RW0D5106045

I2RH0B510198-01

I2RH0B510199-01

I5RW0C510063-01

1. Snap ring 5. O/D and 2nd coast brake piston 9. Rear cover plug O-ring

2. O/D and 2nd coast brake return spring subassembly 6. Rear cover seal ring : Apply automatic transaxle fluid.

3. O/D and 2nd coast brake piston front O-ring 7. Transaxle rear cover : Do not reuse.

4. O/D and 2nd coast brake piston rear O-ring 8. Rear cover plug : 7.5 N⋅m (0.75 kgf-m, 5.5 lb-ft)

Page 780 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-132 Automatic Transmission/Transaxle:

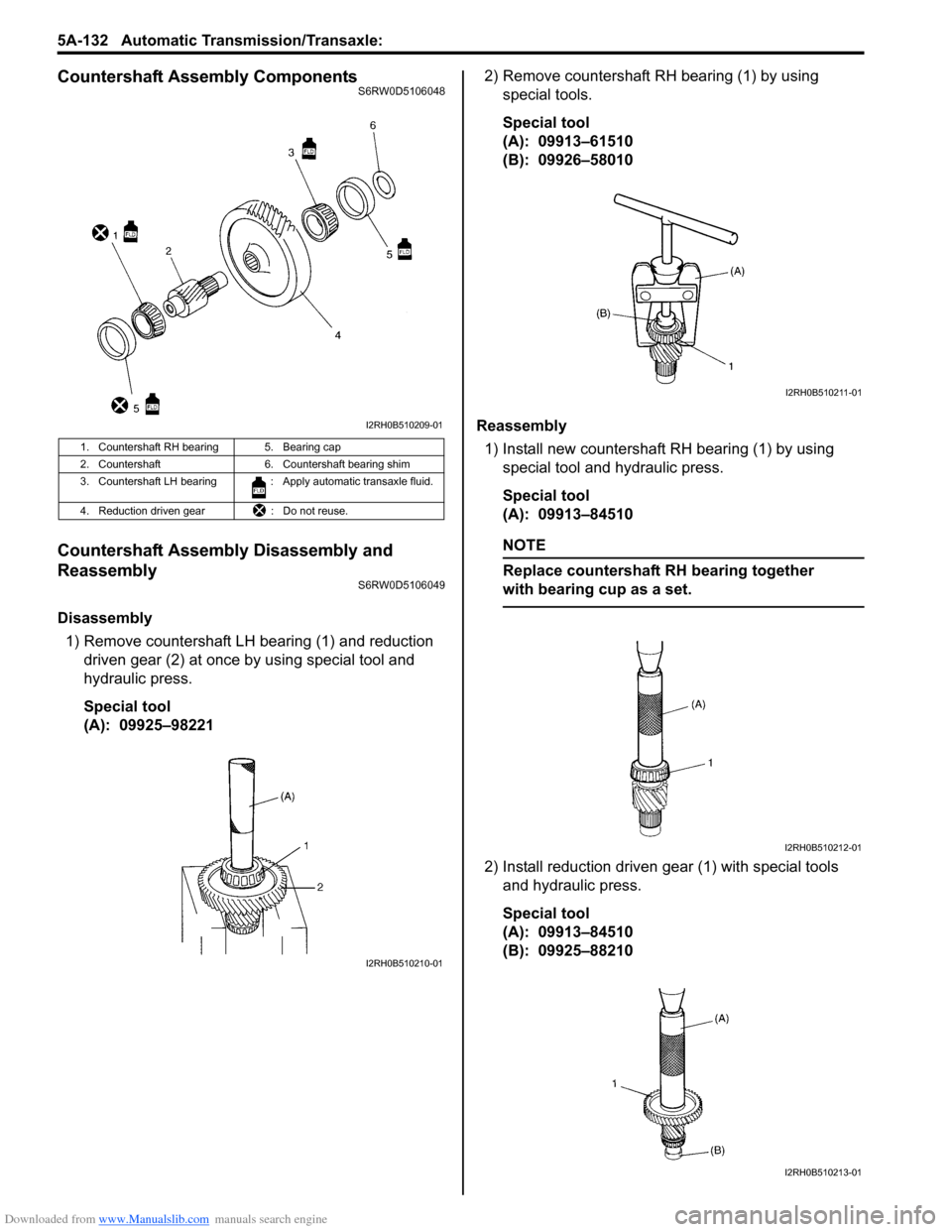

Countershaft Assembly ComponentsS6RW0D5106048

Countershaft Assembly Disassembly and

Reassembly

S6RW0D5106049

Disassembly

1) Remove countershaft LH bearing (1) and reduction

driven gear (2) at once by using special tool and

hydraulic press.

Special tool

(A): 09925–982212) Remove countershaft RH bearing (1) by using

special tools.

Special tool

(A): 09913–61510

(B): 09926–58010

Reassembly

1) Install new countershaft RH bearing (1) by using

special tool and hydraulic press.

Special tool

(A): 09913–84510

NOTE

Replace countershaft RH bearing together

with bearing cup as a set.

2) Install reduction driven gear (1) with special tools

and hydraulic press.

Special tool

(A): 09913–84510

(B): 09925–88210

1. Countershaft RH bearing 5. Bearing cap

2. Countershaft 6. Countershaft bearing shim

3. Countershaft LH bearing : Apply automatic transaxle fluid.

4. Reduction driven gear : Do not reuse.

I2RH0B510209-01

I2RH0B510210-01

I2RH0B510211-01

I2RH0B510212-01

I2RH0B510213-01

Page 781 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-133

3) Install countershaft LH bearing (1) with special tools

and hydraulic press.

Special tool

(A): 09913–84510

(B): 09925–88210

Valve Body Assembly ComponentsS6RW0D5106050

I2RH0B510214-01

I4RS0A510044-01

1. Pressure control solenoid valve 6. Temperature sensor clamp : Apply automatic transaxle fluid.

2. Shift solenoid valve-A (No.1) 7. Valve body assembly : 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

3. Shift solenoid valve-B (No.2) 8. Manual valve : Do not reuse.

4. TCC pressure control solenoid valve 9. Solenoid lock plate

5. Timing solenoid valve 10. O-ring

Page 783 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-135

Reassembly

Reverse disassembly procedure for assembly, noting the

following points.

• Shift solenoid valve-A and -B are identical

• After applying A/T fluid to new O-rings, fit them to

solenoid valves, then install solenoid valves to valve

body.

• Tighten solenoid valve bolts to specified torque

Tightening torque

Solenoid valve bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

Solenoid valve bolt specification

Differential Assembly ComponentsS6RW0D5106052

Bolt Length “a” Pieces

A (1) 49 mm (1.93 in.) 5

B (2) 20 mm (0.79 in.) 1

C (3) 60 mm (2.36 in.) 1

1

1 1

3

2

"a"

I4RS0A510046-01

I5RW0C510064-01

1. Differential side RH bearing 5. Side bearing shim : Apply automatic transaxle fluid.

2. Output shaft speed sensor (VSS) drive gear 6. Final gear bolt : 78 N⋅m (7.8 kgf-m, 56.5 lb-ft)

3. Differential case subassembly 7. Side bearing cup : Do not reuse.

4. Final gear 8. Differential side LH bearing

Page 808 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-160 Automatic Transmission/Transaxle:

94) Install manual select lever (1).

Tightening torque

Manual select lever nut (a): 13 N·m (1.3 kgf-m,

9.5 lb-ft)

95) Install engine mounting LH bracket (1). Tighten

engine mounting LH bracket bolts and nut to

specified torque referring to “Engine Mountings

Components in Section 1D”.

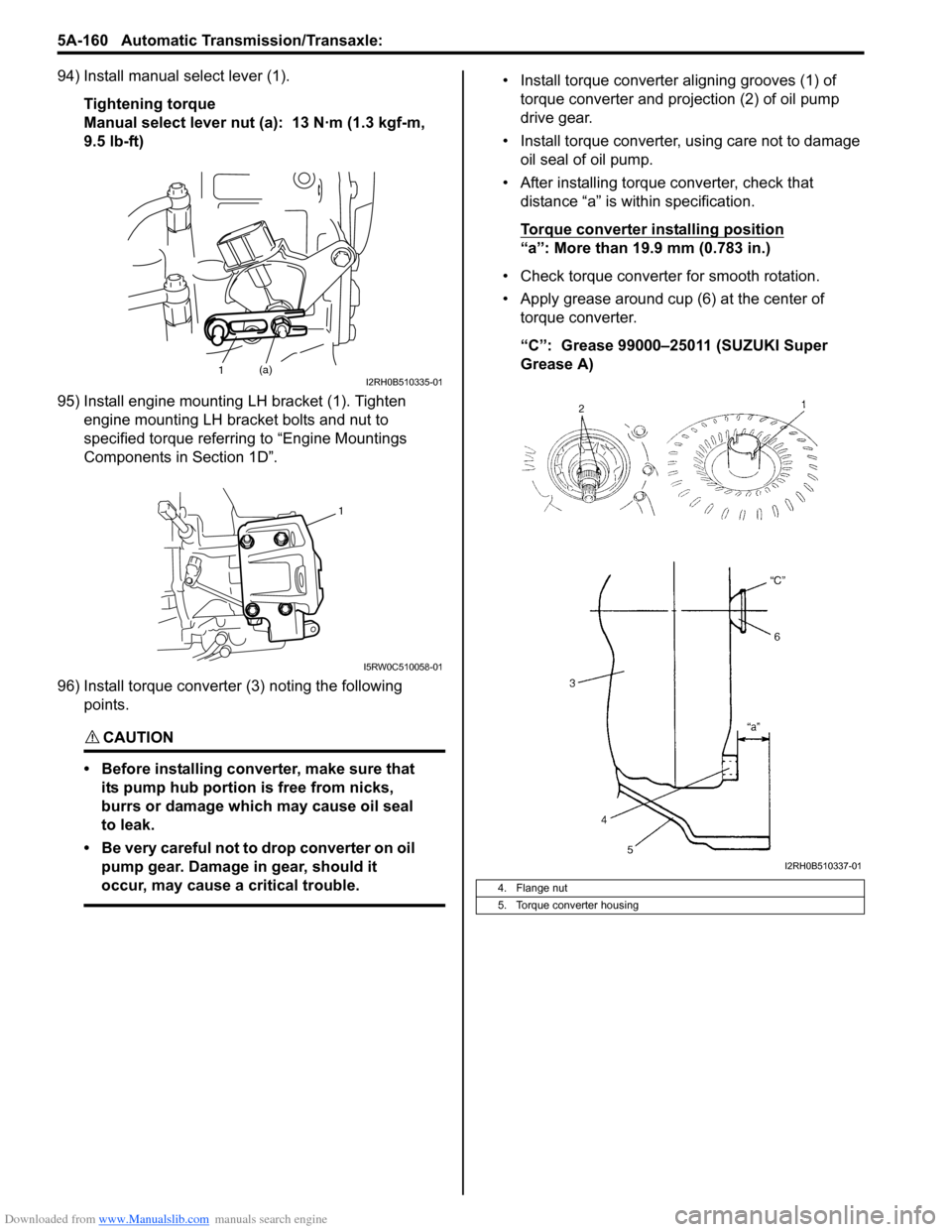

96) Install torque converter (3) noting the following

points.

CAUTION!

• Before installing converter, make sure that

its pump hub portion is free from nicks,

burrs or damage which may cause oil seal

to leak.

• Be very careful not to drop converter on oil

pump gear. Damage in gear, should it

occur, may cause a critical trouble.

• Install torque converter aligning grooves (1) of

torque converter and projection (2) of oil pump

drive gear.

• Install torque converter, using care not to damage

oil seal of oil pump.

• After installing torque converter, check that

distance “a” is within specification.

Torque converter installing position

“a”: More than 19.9 mm (0.783 in.)

• Check torque converter for smooth rotation.

• Apply grease around cup (6) at the center of

torque converter.

“C”: Grease 99000–25011 (SUZUKI Super

Grease A)

1(a)I2RH0B510335-01

1

I5RW0C510058-01

4. Flange nut

5. Torque converter housing

I2RH0B510337-01