Switch SUZUKI SX4 2006 1.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 61 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-11

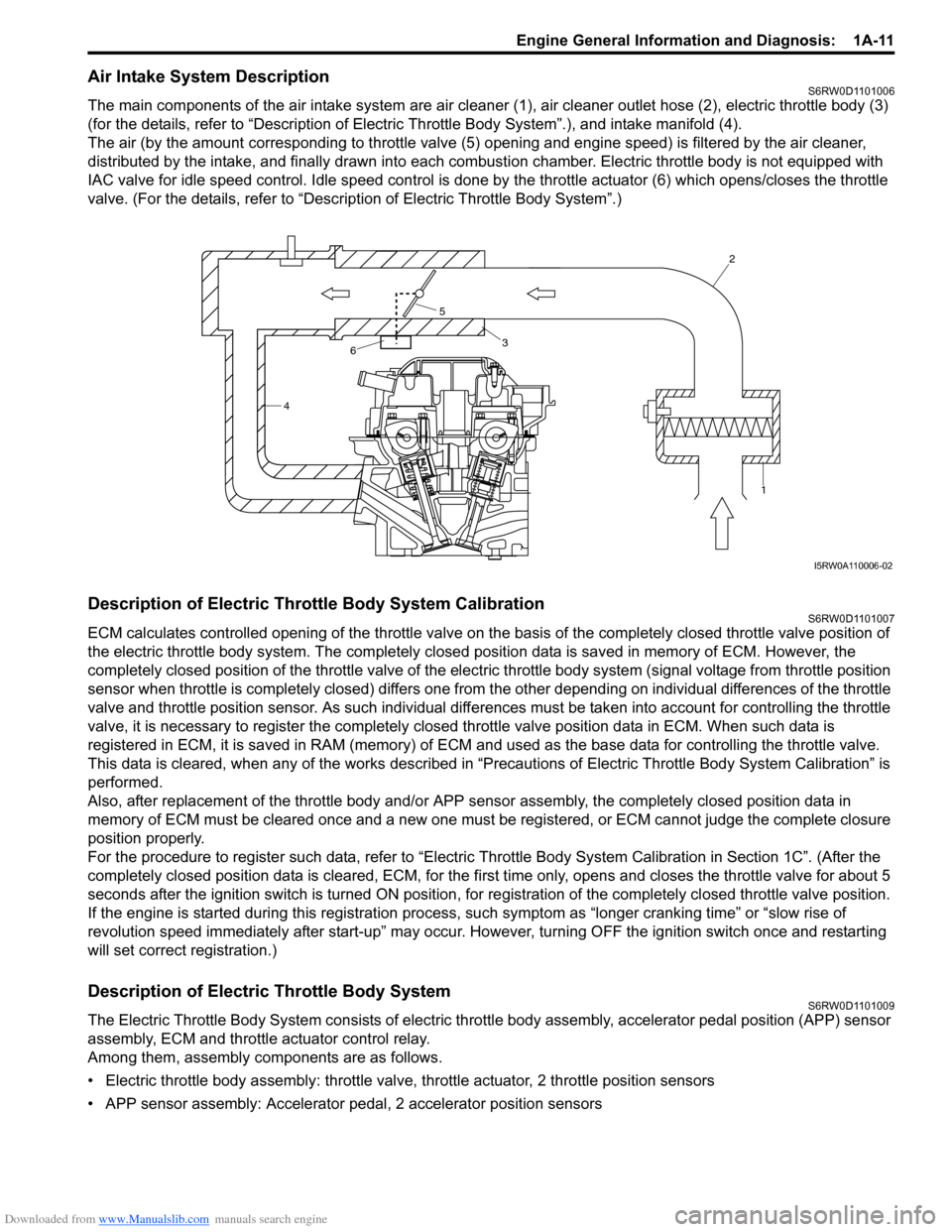

Air Intake System DescriptionS6RW0D1101006

The main components of the air intake system are air cleaner (1), air cleaner outlet hose (2), electric throttle body (3)

(for the details, refer to “Description of Electric Throttle Body System”.), and intake manifold (4).

The air (by the amount corresponding to throttle valve (5) opening and engine speed) is filtered by the air cleaner,

distributed by the intake, and finally drawn into each combustion chamber. Electric throttle body is not equipped with

IAC valve for idle speed control. Idle speed control is done by the throttle actuator (6) which opens/closes the throttle

valve. (For the details, refer to “Description of Electric Throttle Body System”.)

Description of Electric Throttle Body System CalibrationS6RW0D1101007

ECM calculates controlled opening of the throttle valve on the basis of the completely closed throttle valve position of

the electric throttle body system. The completely closed position data is saved in memory of ECM. However, the

completely closed position of the throttle valve of the electric throttle body system (signal voltage from throttle position

sensor when throttle is completely closed) differs one from the other depending on individual differences of the throttle

valve and throttle position sensor. As such individual differences must be taken into account for controlling the throttle

valve, it is necessary to register the completely closed throttle valve position data in ECM. When such data is

registered in ECM, it is saved in RAM (memory) of ECM and used as the base data for controlling the throttle valve.

This data is cleared, when any of the works described in “Precautions of Electric Throttle Body System Calibration” is

performed.

Also, after replacement of the throttle body and/or APP sensor assembly, the completely closed position data in

memory of ECM must be cleared once and a new one must be registered, or ECM cannot judge the complete closure

position properly.

For the procedure to register such data, refer to “Electric Throttle Body System Calibration in Section 1C”. (After the

completely closed position data is cleared, ECM, for the first time only, opens and closes the throttle valve for about 5

seconds after the ignition switch is turned ON position, for registration of the completely closed throttle valve position.

If the engine is started during this registration process, such symptom as “longer cranking time” or “slow rise of

revolution speed immediately after start-up” may occur. However, turning OFF the ignition switch once and restarting

will set correct registration.)

Description of Electric Throttle Body SystemS6RW0D1101009

The Electric Throttle Body System consists of electric throttle body assembly, accelerator pedal position (APP) sensor

assembly, ECM and throttle actuator control relay.

Among them, assembly components are as follows.

• Electric throttle body assembly: throttle valve, throttle actuator, 2 throttle position sensors

• APP sensor assembly: Accelerator pedal, 2 accelerator position sensors

42

1

3

5

6

I5RW0A110006-02

Page 63 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-13

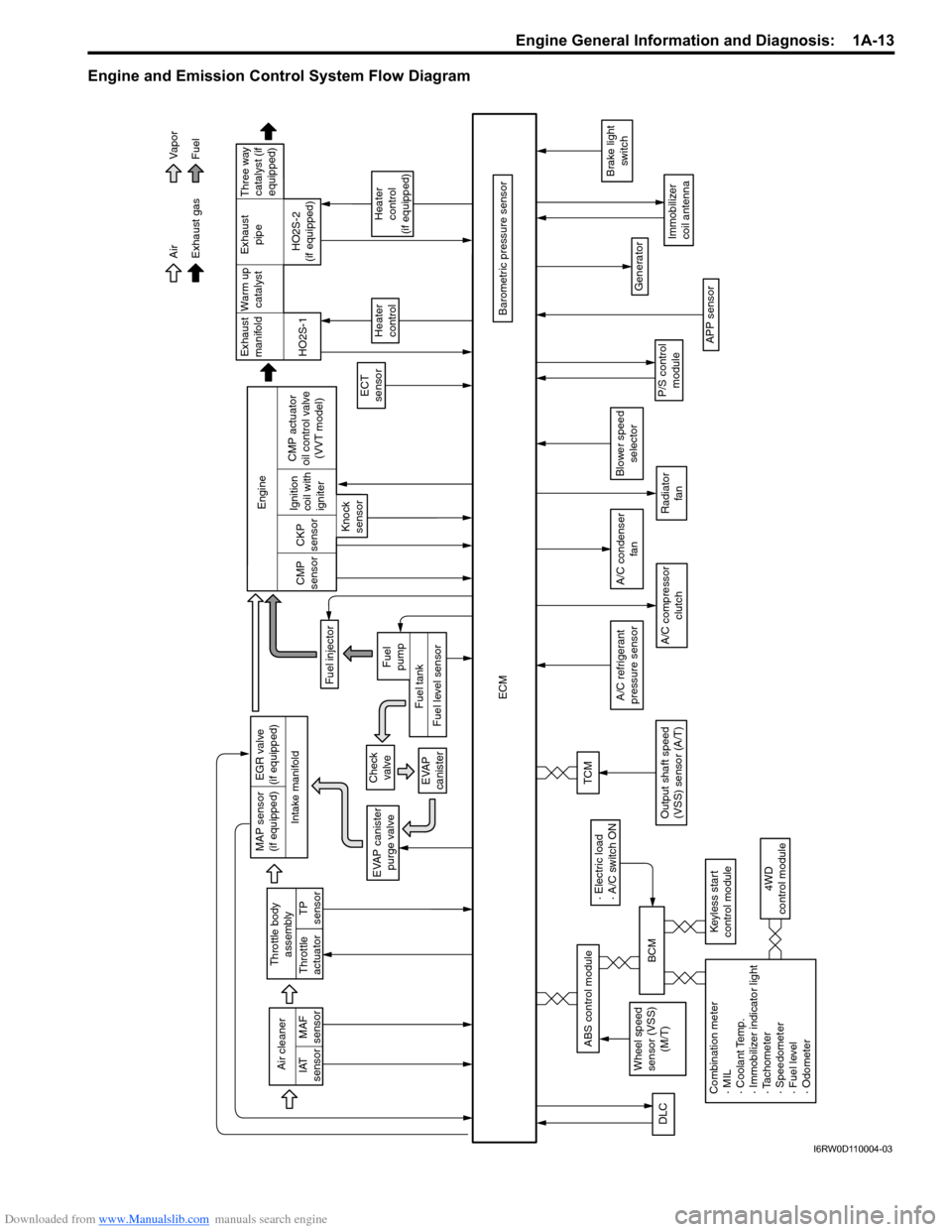

Engine and Emission Control System Flow Diagram

Intake manifoldExhaust

manifold

Exhaust gas Air

Fuel Vapor

War m up

catalystExhaust

pipe

EVAP canister

purge valve

Fuel injector

ECT

sensor

ECM

Heater

control

Heater

control

(if equipped)

Barometric pressure sensor HO2S-1HO2S-2

(if equipped) Engine

CMP

sensorCKP

sensor

Knock

sensorIgnition

coil with

igniter

APP sensor

A/C compressor

clutch

Generator

Immobilizer

coil antenna

P/S control

module

Brake light

switch

Air cleaner

IAT

sensorMAF

sensor

A/C refrigerant

pressure sensor

TP

sensor Throttle body

assembly

Throttle

actuator

A/C condenser

fan

DLC

Radiator

fan

Combination meter

· MIL

· Coolant Temp.

· Immobilizer indicator light

· Tachometer

· Speedometer

· Fuel level

· Odometer4WD

control module

Wheel speed

sensor (VSS)

(M/T)

· Electric load

· A/C switch ON

BCM

Keyless start

control module

ABS control module

Blower speed

selector

MAP sensor

(if equipped)EGR valve

(if equipped)

Check

valve

EVAP

canister

Fuel level sensorFuel tankFuel

pump

CMP actuator

oil control valve

(VVT model)

TCM

Output shaft speed

(VSS) sensor (A/T)

Three way

catalyst (if

equipped)

I6RW0D110004-03

Page 64 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-14 Engine General Information and Diagnosis:

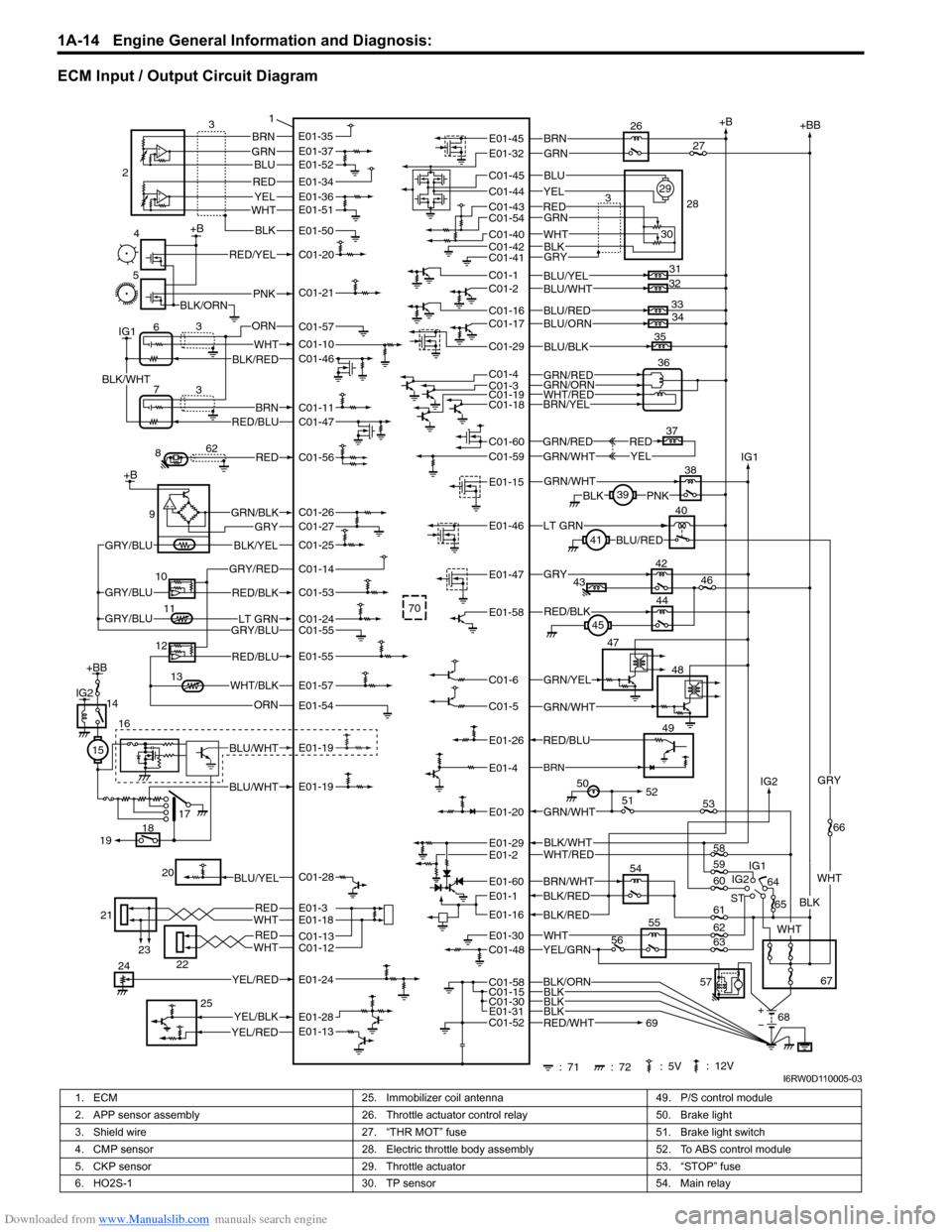

ECM Input / Output Circuit Diagram

51 50

+B

54

IG1+BB

ST64

65

67

BLK/WHTWHT/RED

BRN/WHTBLK/RED

BLK/RED

57

: 71

: 72 : 5V : 12V68 IG1

BLK

WHT

GRY

YEL/GRNWHT

66

58

61

62

63 55

70

60 59

53

WHT

4+B

5

PNK

RED/YEL

BLK/ORN

C01-20

C01-21

8RED62C01-56

13WHT/BLKE01-57

ORNE01-54

21

23WHTRED

WHTRED

22

E01-3E01-18

C01-13C01-12

YEL/RED 24E01-24

YEL/BLK

YEL/RED 25E01-28E01-13

E01-30

E01-16

E01-60E01-1

E01-29

GRN/WHTE01-20

C01-48

E01-2

GRN/YEL47

48

GRN/WHTC01-5

C01-6

44

45RED/BLKE01-58

42

43GRY46E01-47

40LT GRN41BLU/REDE01-46

38

39

PNKBLKGRN/WHTE01-15

GRN/REDGRN/WHT37YELREDC01-59C01-60

35BLU/BLKC01-29

31

32

33

34BLU/YELBLU/WHT

BLU/REDBLU/ORNC01-17C01-16

C01-1C01-2

BLK/ORNBLKC01-30

C01-58C01-15

E01-31BLKBLK

49RED/BLU

BRNE01-4

E01-26 9

GRY

BLK/YELGRY/BLU

GRN/BLKC01-26C01-27

C01-25 +B

IG16

7WHT

BRNRED/BLU

BLK/WHT

3 3

ORN

BLK/RED

C01-57

C01-10

C01-11

C01-46

C01-47

GRY/REDC01-14

11LT GRNGRY/BLUGRY/BLU12RED/BLU

C01-55

E01-55

C01-24

10

RED/BLKGRY/BLUC01-53

IG2

IG2

69RED/WHTC01-52

26

RED

BRNGRN

BLU

GRN

WHTBLK

28

30 2927

3YEL

GRYC01-41C01-42C01-40

C01-43C01-44

C01-45

E01-45E01-32

C01-54

BRN/YELWHT/RED

GRN/REDGRN/ORN

C01-18C01-1936C01-3C01-4

56

1

52

IG2+BB

BLU/WHT

BLU/WHT

14

15

17

16

E01-19

E01-19

18

19

BRNGRNBLU

REDYELWHT

E01-353

BLK

E01-37E01-52

E01-34E01-36E01-51

E01-50

2

20BLU/YELC01-28

I6RW0D110005-03

1. ECM 25. Immobilizer coil antenna 49. P/S control module

2. APP sensor assembly 26. Throttle actuator control relay 50. Brake light

3. Shield wire 27. “THR MOT” fuse 51. Brake light switch

4. CMP sensor 28. Electric throttle body assembly 52. To ABS control module

5. CKP sensor 29. Throttle actuator 53. “STOP” fuse

6. HO2S-1 30. TP sensor 54. Main relay

Page 65 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-15

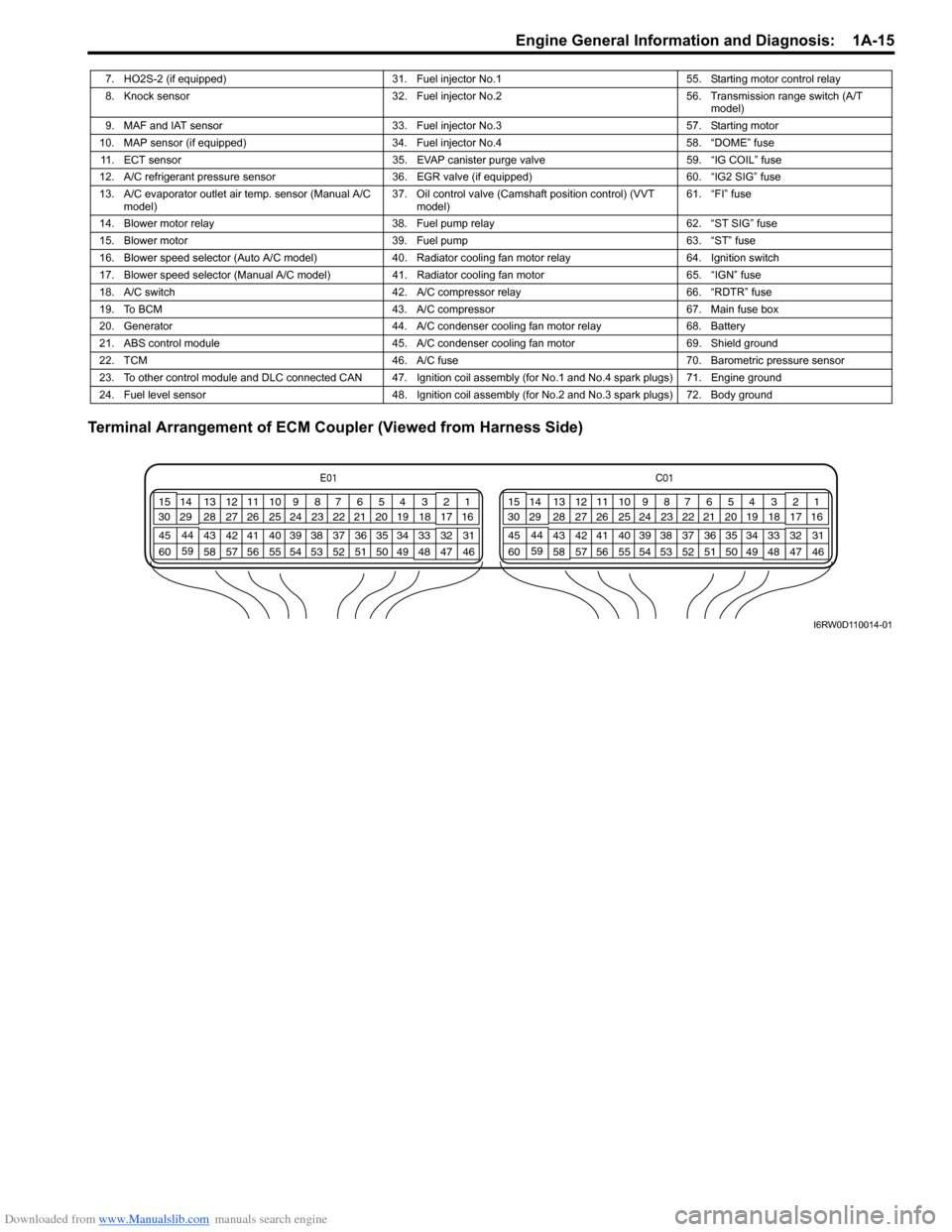

Terminal Arrangement of ECM Coupler (Viewed from Harness Side)

7. HO2S-2 (if equipped) 31. Fuel injector No.1 55. Starting motor control relay

8. Knock sensor 32. Fuel injector No.2 56. Transmission range switch (A/T

model)

9. MAF and IAT sensor 33. Fuel injector No.3 57. Starting motor

10. MAP sensor (if equipped) 34. Fuel injector No.4 58. “DOME” fuse

11. ECT sensor 35. EVAP canister purge valve 59. “IG COIL” fuse

12. A/C refrigerant pressure sensor 36. EGR valve (if equipped) 60. “IG2 SIG” fuse

13. A/C evaporator outlet air temp. sensor (Manual A/C

model)37. Oil control valve (Camshaft position control) (VVT

model)61. “FI” fuse

14. Blower motor relay 38. Fuel pump relay 62. “ST SIG” fuse

15. Blower motor 39. Fuel pump 63. “ST” fuse

16. Blower speed selector (Auto A/C model) 40. Radiator cooling fan motor relay 64. Ignition switch

17. Blower speed selector (Manual A/C model) 41. Radiator cooling fan motor 65. “IGN” fuse

18. A/C switch 42. A/C compressor relay 66. “RDTR” fuse

19. To BCM 43. A/C compressor 67. Main fuse box

20. Generator 44. A/C condenser cooling fan motor relay 68. Battery

21. ABS control module 45. A/C condenser cooling fan motor 69. Shield ground

22. TCM 46. A/C fuse 70. Barometric pressure sensor

23. To other control module and DLC connected CAN 47. Ignition coil assembly (for No.1 and No.4 spark plugs) 71. Engine ground

24. Fuel level sensor 48. Ignition coil assembly (for No.2 and No.3 spark plugs) 72. Body ground

E01C01

3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238 3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238

I6RW0D110014-01

Page 67 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-17

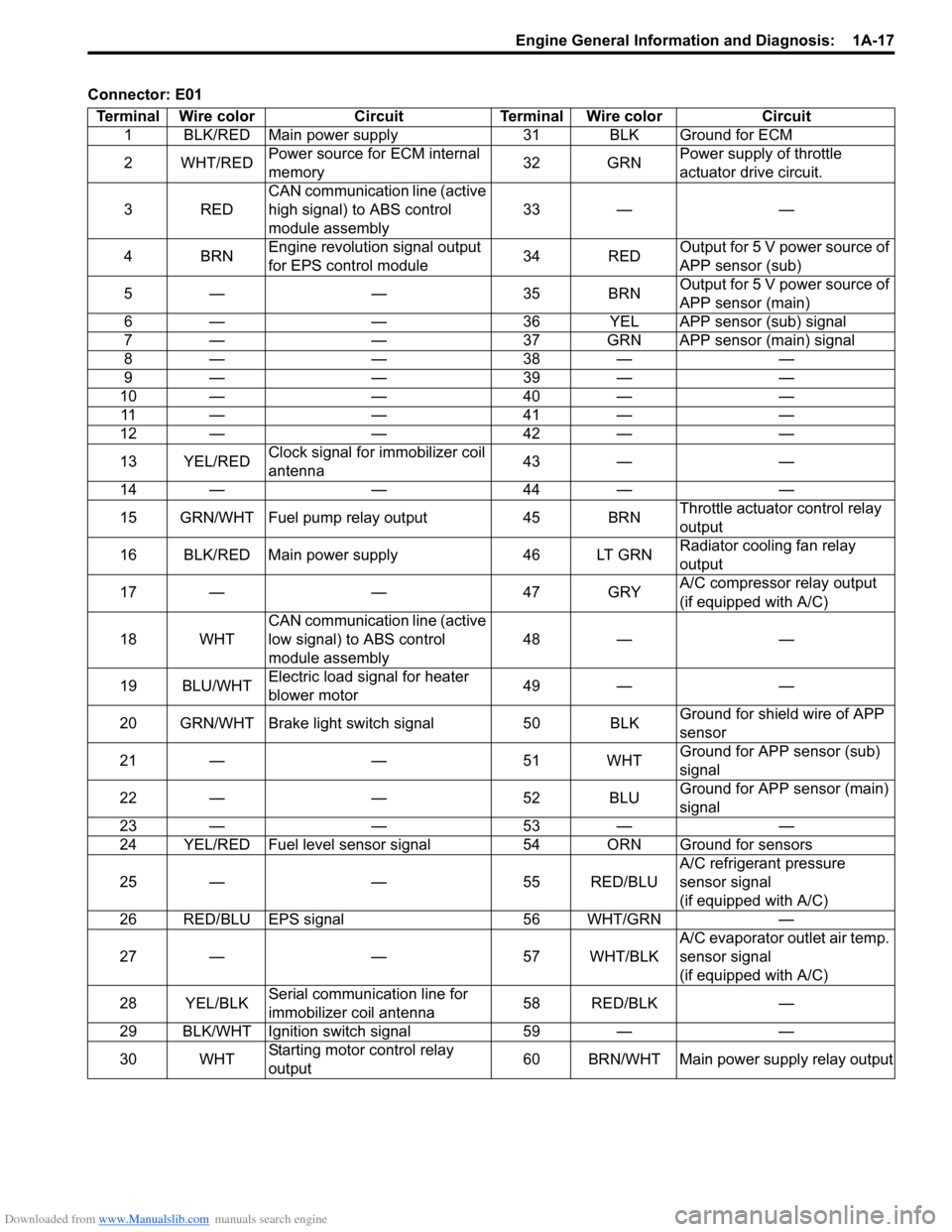

Connector: E01

Terminal Wire color Circuit Terminal Wire color Circuit

1 BLK/RED Main power supply 31 BLK Ground for ECM

2WHT/REDPower source for ECM internal

memory32 GRNPower supply of throttle

actuator drive circuit.

3REDCAN communication line (active

high signal) to ABS control

module assembly33 — —

4BRNEngine revolution signal output

for EPS control module34 REDOutput for 5 V power source of

APP sensor (sub)

5— — 35BRNOutput for 5 V power source of

APP sensor (main)

6 — — 36 YEL APP sensor (sub) signal

7 — — 37 GRN APP sensor (main) signal

8— — 38— —

9— — 39— —

10 — — 40 — —

11 — — 4 1 — —

12 — — 42 — —

13 YEL/REDClock signal for immobilizer coil

antenna43 — —

14 — — 44 — —

15 GRN/WHT Fuel pump relay output 45 BRNThrottle actuator control relay

output

16 BLK/RED Main power supply 46 LT GRNRadiator cooling fan relay

output

17 — — 47 GRYA/C compressor relay output

(if equipped with A/C)

18 WHTCAN communication line (active

low signal) to ABS control

module assembly48 — —

19 BLU/WHTElectric load signal for heater

blower motor49 — —

20 GRN/WHT Brake light switch signal 50 BLKGround for shield wire of APP

sensor

21 — — 51 WHTGround for APP sensor (sub)

signal

22 — — 52 BLUGround for APP sensor (main)

signal

23 — — 53 — —

24 YEL/RED Fuel level sensor signal 54 ORN Ground for sensors

25 — — 55 RED/BLUA/C refrigerant pressure

sensor signal

(if equipped with A/C)

26 RED/BLU EPS signal 56 WHT/GRN —

27 — — 57 WHT/BLKA/C evaporator outlet air temp.

sensor signal

(if equipped with A/C)

28 YEL/BLKSerial communication line for

immobilizer coil antenna58 RED/BLK —

29 BLK/WHT Ignition switch signal 59 — —

30 WHTStarting motor control relay

output60 BRN/WHT Main power supply relay output

Page 68 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-18 Engine General Information and Diagnosis:

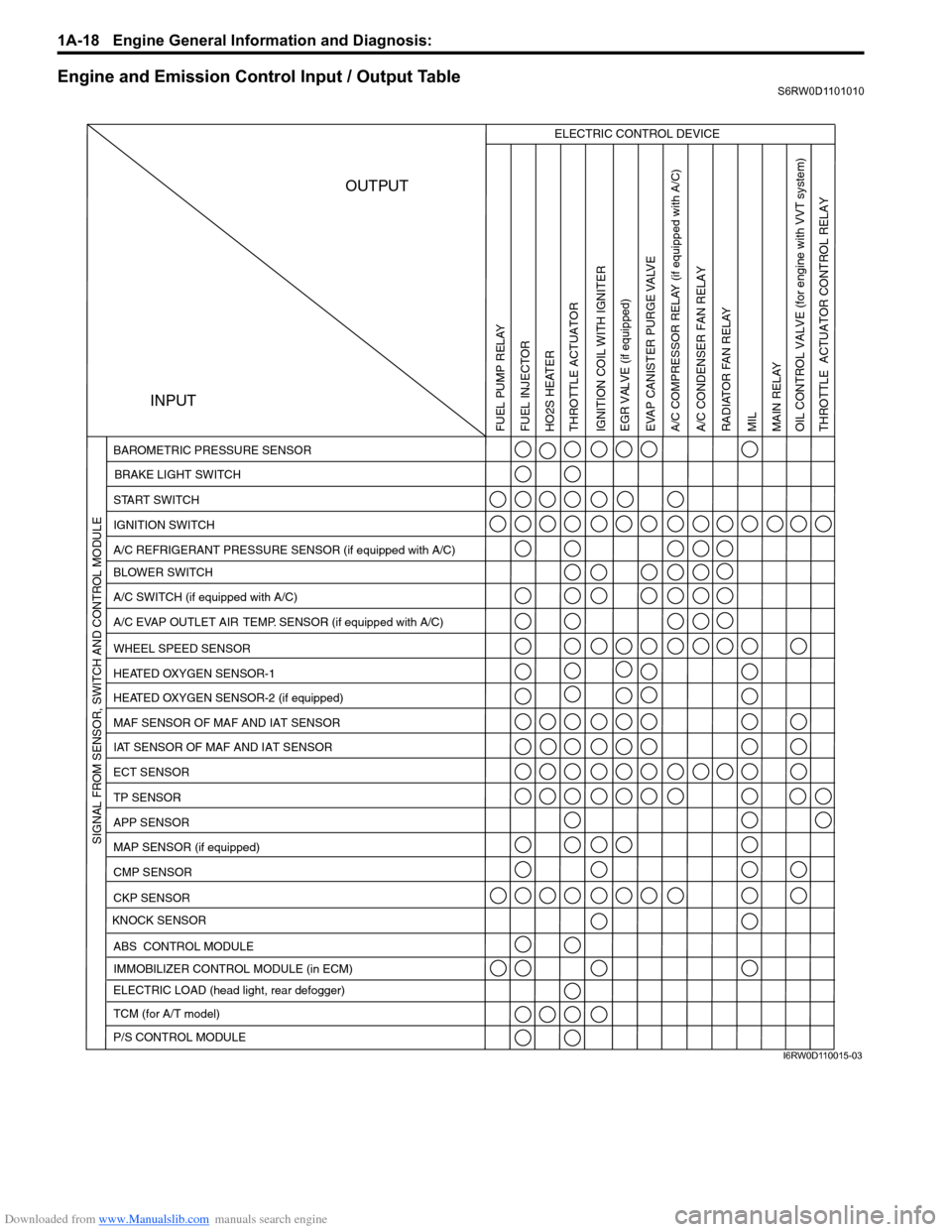

Engine and Emission Control Input / Output TableS6RW0D1101010

INPUTOUTPUT

ELECTRIC CONTROL DEVICE

BAROMETRIC PRESSURE SENSOR

BRAKE LIGHT SWITCH

START SWITCH

IGNITION SWITCH

A/C REFRIGERANT PRESSURE SENSOR (if equipped with A/C)

BLOWER SWITCH

A/C SWITCH (if equipped with A/C)

A/C EVAP OUTLET AIR TEMP. SENSOR (if equipped with A/C)

WHEEL SPEED SENSOR

HEATED OXYGEN SENSOR-1

HEATED OXYGEN SENSOR-2 (if equipped)

IAT SENSOR OF MAF AND IAT SENSOR MAF SENSOR OF MAF AND IAT SENSOR

ECT SENSOR

TP SENSOR

THROTTLE ACTUATOR

A/C CONDENSER FAN RELAY FUEL PUMP RELAY

FUEL INJECT

THROTTLE ACTUATOR CONTROL RELAYOR

HO2S HEATER

IGNITION COIL WITH IGNITER

EGR VALVE (if equipped)

EVAP CANISTER PURGE VALVEA/C COMPRESSOR RELAY (if equipped with A/C)RADIATOR FAN RELAY

MIL

MAIN RELAY

OIL CONTROL VALVE (for engine with VVT system) SIGNAL FROM SENSOR, SWITCH AND CONTROL MODULE

ABS CONTROL MODULE

KNOCK SENSOR

MAP SENSOR (if equipped)

CMP SENSOR

CKP SENSOR

IMMOBILIZER CONTROL MODULE (in ECM)

ELECTRIC LOAD (head light, rear defogger

TCM (for A/T model

P/S CONTROL MODULE))

APP SENSOR

I6RW0D110015-03

Page 70 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-20 Engine General Information and Diagnosis:

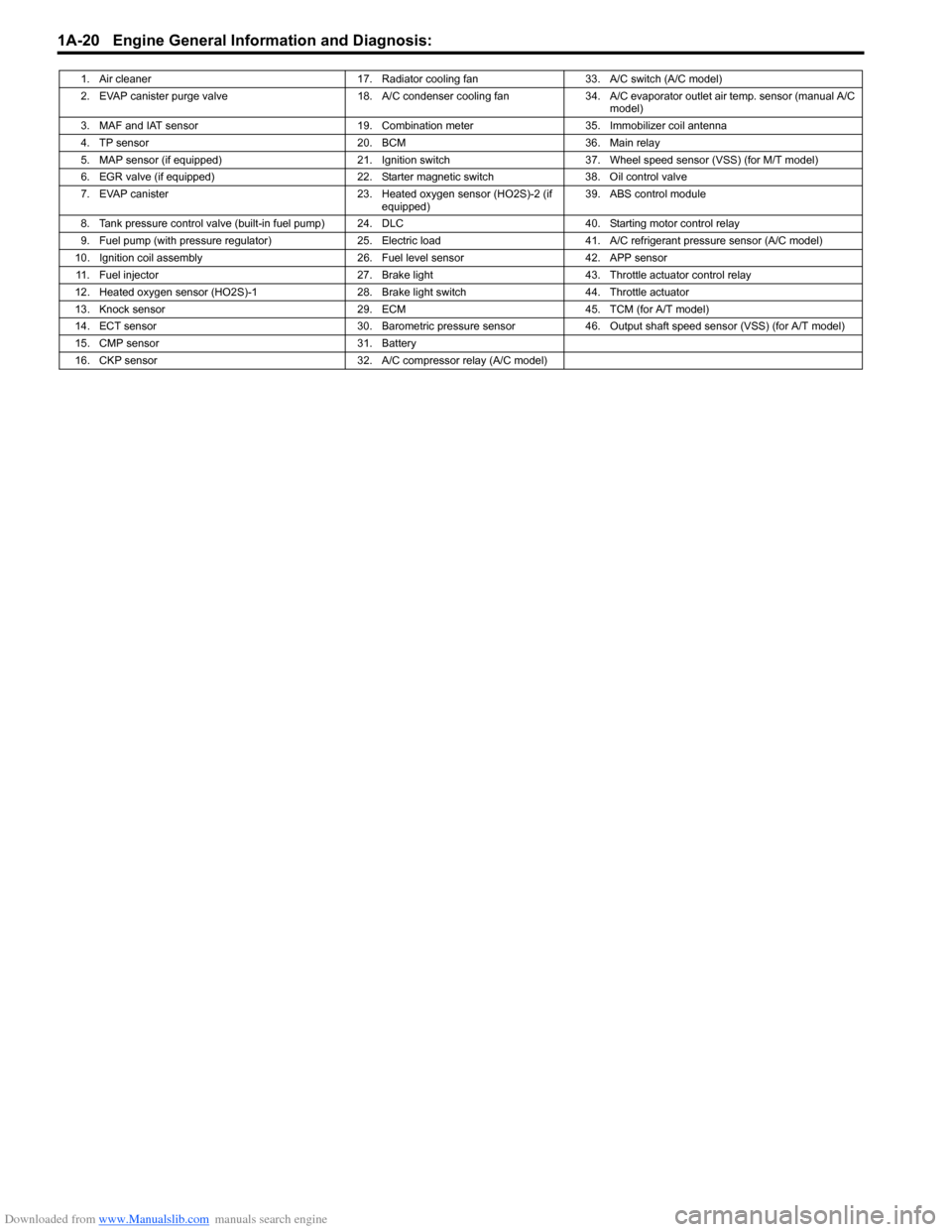

1. Air cleaner 17. Radiator cooling fan 33. A/C switch (A/C model)

2. EVAP canister purge valve 18. A/C condenser cooling fan 34. A/C evaporator outlet air temp. sensor (manual A/C

model)

3. MAF and IAT sensor 19. Combination meter 35. Immobilizer coil antenna

4. TP sensor 20. BCM 36. Main relay

5. MAP sensor (if equipped) 21. Ignition switch37. Wheel speed sensor (VSS) (for M/T model)

6. EGR valve (if equipped) 22. Starter magnetic switch 38. Oil control valve

7. EVAP canister 23. Heated oxygen sensor (HO2S)-2 (if

equipped)39. ABS control module

8. Tank pressure control valve (built-in fuel pump) 24. DLC 40. Starting motor control relay

9. Fuel pump (with pressure regulator) 25. Electric load 41. A/C refrigerant pressure sensor (A/C model)

10. Ignition coil assembly 26. Fuel level sensor 42. APP sensor

11. Fuel injector 27. Brake light 43. Throttle actuator control relay

12. Heated oxygen sensor (HO2S)-1 28. Brake light switch 44. Throttle actuator

13. Knock sensor 29. ECM 45. TCM (for A/T model)

14. ECT sensor 30. Barometric pressure sensor 46. Output shaft speed sensor (VSS) (for A/T model)

15. CMP sensor 31. Battery

16. CKP sensor 32. A/C compressor relay (A/C model)

Page 71 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-21

Component Location

Electronic Control System Components LocationS6RW0D1103001

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

H*E*

10

D

G* C

6A

B*

e

3*

12*

a8 13

b

1

5-1

d

2

11

g

4

7

9

i

j

Fh k f

n

c J

5

K*

14

I6RW0D110016-03

Information sensors Control devices Others

1. MAF and IAT sensor a: Fuel injector A: ECM

2. Electric throttle body assembly

(built-in throttle position sensor and throttle

actuator)b: EVAP canister purge valve B: Combination meter

3. Brake light switch c: Fuel pump relay C: EVAP canister

4. ECT sensor d: EGR valve (if equipped) D: A/C evaporator outlet air temp. sensor

(if equipped with A/C)

5. Heated oxygen sensor-1 e: Malfunction indicator lamp E: Data link connector

5-1. Heated oxygen sensor-2 (if equipped) f: Radiator cooling fan relay F: A/C compressor relay (if equipped with A/C)

6. Battery g: Ignition coil assembly (with ignitor) G: BCM (included in junction block assembly)

7. CMP sensor (for engine with VVT system) h: Main relay H: Immobilizer coil antenna

8. MAP sensor (if equipped) i: Oil control valve (for engine with VVT system) J: A/C refrigerant pressure sensor

(if equipped with A/C)

9. CKP sensor j: A/C condenser cooling fan relay K: TCM (for A/T model)

10. Fuel level sensor k: Starting motor control relay

11. Knock sensor m: Immobilizer indicator lamp

12. APP sensor n: Throttle actuator control relay

13. Front wheel speed sensor (RH, LH) (VSS)

14. CMP sensor (for engine without VVT system)

Page 75 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-25

Step 2: DTC / Freeze Frame Data Check, Record and

Clearance

First, check DTC (including pending DTC), referring to

“DTC Check”. If DTC is indicated, print it and freeze

frame data or write them down and then clear them by

referring to “DTC Clearance”. DTC indicates malfunction

that occurred in the system but does not indicate

whether it exists now or it occurred in the past and the

normal condition has been restored now. To check which

case applies, check the symptom in question according

to Step 5 and recheck DTC according to Step 6 and 7.

Attempt to diagnose a trouble based on DTC in this step

only or failure to clear the DTC in this step will lead to

incorrect diagnosis, trouble diagnosis of a normal circuit

or difficulty in troubleshooting.

Step 3 and 4: Visual Inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the engine

referring to “Visual Inspection”.

Step 5: Trouble Symptom Confirmation

Based on information obtained in “Step 1: Customer

Complaint Analysis: ” and “Step 2: DTC / Freeze Frame

Data Check, Record and Clearance: ”, confirm trouble

symptoms. Also, reconfirm DTC according to “DTC

Confirmation Procedure” described in each DTC diag.

flow.

Step 6 and 7: Rechecking and Record of DTC /

Freeze Frame Data

Refer to “DTC Check” for checking procedure.

Step 8: Engine Basic Inspection and Engine

Symptom Diagnosis

Perform basic engine check according to “Engine Basic

Inspection” first. When the end of the flow has been

reached, check the parts of the system suspected as a

possible cause referring to “Engine Symptom Diagnosis”

and based on symptoms appearing on the vehicle

(symptoms obtained through steps of customer

complaint analysis, trouble symptom confirmation and/or

basic engine check) and repair or replace faulty parts, if

any.

Step 9: Troubleshooting for DTC (See each DTC

Diag. Flow)

Based on the DTC indicated in Step 6 or 7 and referring

to the applicable DTC diag. flow, locate the cause of the

trouble, namely in a sensor, switch, wire harness,

connector, actuator, ECM or other part and repair or

replace faulty parts.Step 10: Intermittent Problems Check

Check parts where an intermittent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of DTC recorded in Step 2.

Step 11: Final Confirmation Test

Confirm that the problem symptom has gone and the

engine is free from any abnormal conditions. If what has

been repaired is related to the DTC, clear the DTC once,

perform DTC confirmation procedure and confirm that no

DTC is indicated.

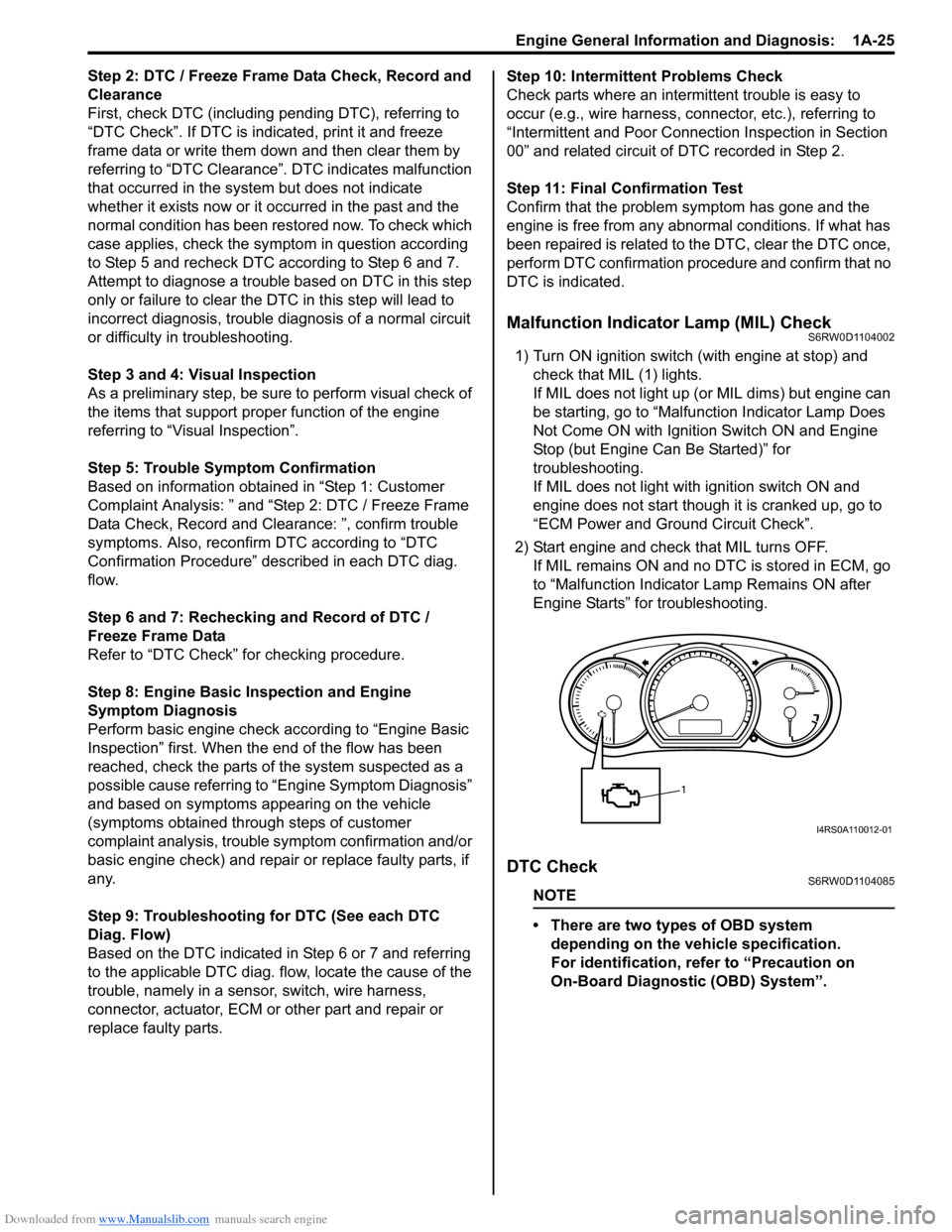

Malfunction Indicator Lamp (MIL) CheckS6RW0D1104002

1) Turn ON ignition switch (with engine at stop) and

check that MIL (1) lights.

If MIL does not light up (or MIL dims) but engine can

be starting, go to “Malfunction Indicator Lamp Does

Not Come ON with Ignition Switch ON and Engine

Stop (but Engine Can Be Started)” for

troubleshooting.

If MIL does not light with ignition switch ON and

engine does not start though it is cranked up, go to

“ECM Power and Ground Circuit Check”.

2) Start engine and check that MIL turns OFF.

If MIL remains ON and no DTC is stored in ECM, go

to “Malfunction Indicator Lamp Remains ON after

Engine Starts” for troubleshooting.

DTC CheckS6RW0D1104085

NOTE

• There are two types of OBD system

depending on the vehicle specification.

For identification, refer to “Precaution on

On-Board Diagnostic (OBD) System”.

1

I4RS0A110012-01

Page 76 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-26 Engine General Information and Diagnosis:

• The MIL is turned on when the ECM and/or

TCM detect malfunction(s). Each ECM and

TCM stores diagnostic information as the

diagnostic trouble code (DTC) in its

memory and outputs the DTC to the scan

tool.

Therefore, check both of the ECM and TCM

for any DTC with the scan tool because the

DTC stored in ECM and TCM is not read

and displayed at a time. However, each of

the ECM and TCM needs not to be checked

with the generic scan tool because the

DTC stored in ECM and TCM is read and

displayed at a time.

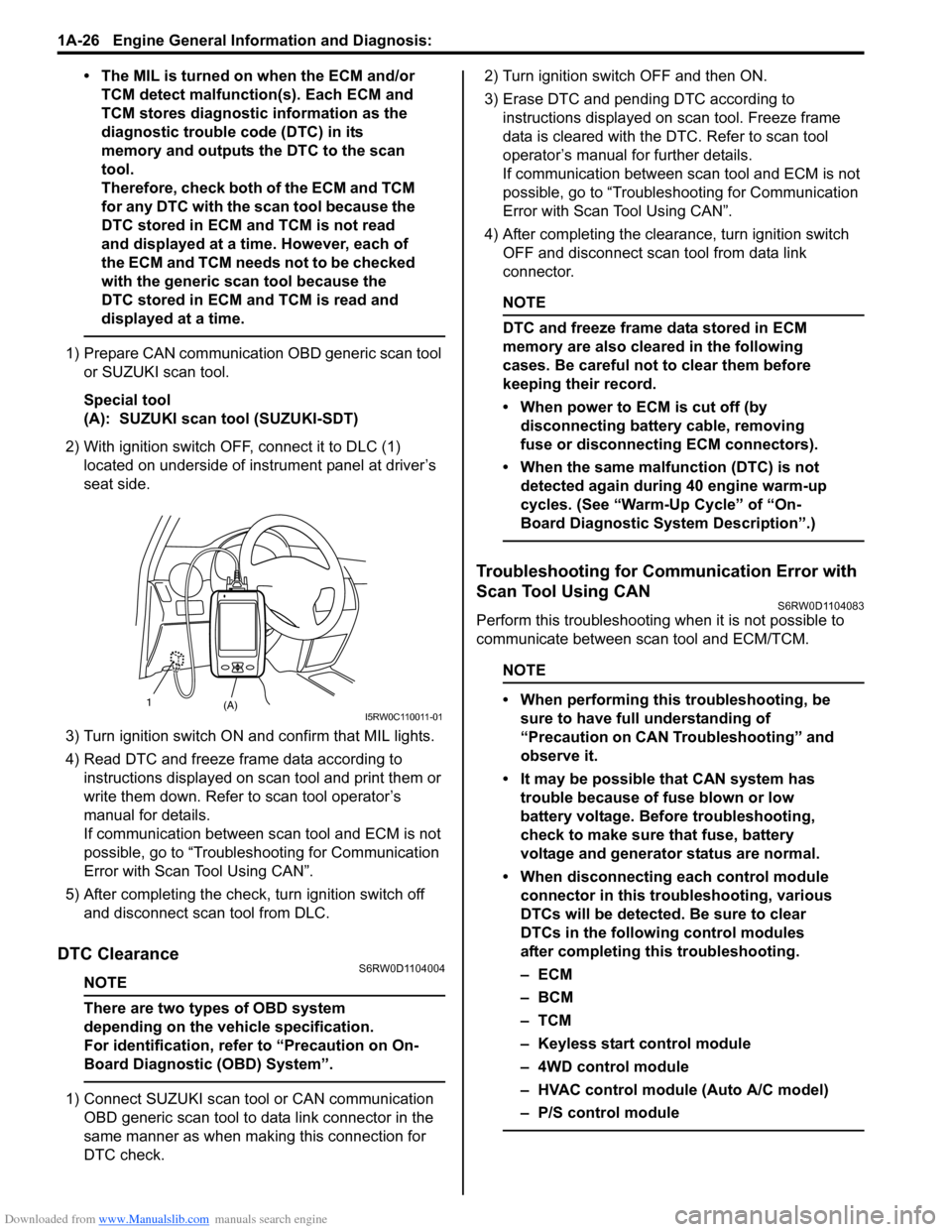

1) Prepare CAN communication OBD generic scan tool

or SUZUKI scan tool.

Special tool

(A): SUZUKI scan tool (SUZUKI-SDT)

2) With ignition switch OFF, connect it to DLC (1)

located on underside of instrument panel at driver’s

seat side.

3) Turn ignition switch ON and confirm that MIL lights.

4) Read DTC and freeze frame data according to

instructions displayed on scan tool and print them or

write them down. Refer to scan tool operator’s

manual for details.

If communication between scan tool and ECM is not

possible, go to “Troubleshooting for Communication

Error with Scan Tool Using CAN”.

5) After completing the check, turn ignition switch off

and disconnect scan tool from DLC.

DTC ClearanceS6RW0D1104004

NOTE

There are two types of OBD system

depending on the vehicle specification.

For identification, refer to “Precaution on On-

Board Diagnostic (OBD) System”.

1) Connect SUZUKI scan tool or CAN communication

OBD generic scan tool to data link connector in the

same manner as when making this connection for

DTC check.2) Turn ignition switch OFF and then ON.

3) Erase DTC and pending DTC according to

instructions displayed on scan tool. Freeze frame

data is cleared with the DTC. Refer to scan tool

operator’s manual for further details.

If communication between scan tool and ECM is not

possible, go to “Troubleshooting for Communication

Error with Scan Tool Using CAN”.

4) After completing the clearance, turn ignition switch

OFF and disconnect scan tool from data link

connector.

NOTE

DTC and freeze frame data stored in ECM

memory are also cleared in the following

cases. Be careful not to clear them before

keeping their record.

• When power to ECM is cut off (by

disconnecting battery cable, removing

fuse or disconnecting ECM connectors).

• When the same malfunction (DTC) is not

detected again during 40 engine warm-up

cycles. (See “Warm-Up Cycle” of “On-

Board Diagnostic System Description”.)

Troubleshooting for Communication Error with

Scan Tool Using CAN

S6RW0D1104083

Perform this troubleshooting when it is not possible to

communicate between scan tool and ECM/TCM.

NOTE

• When performing this troubleshooting, be

sure to have full understanding of

“Precaution on CAN Troubleshooting” and

observe it.

• It may be possible that CAN system has

trouble because of fuse blown or low

battery voltage. Before troubleshooting,

check to make sure that fuse, battery

voltage and generator status are normal.

• When disconnecting each control module

connector in this troubleshooting, various

DTCs will be detected. Be sure to clear

DTCs in the following control modules

after completing this troubleshooting.

–ECM

–BCM

–TCM

– Keyless start control module

– 4WD control module

– HVAC control module (Auto A/C model)

– P/S control module

(A) 1I5RW0C110011-01